height CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 163 of 1938

group of the service manual for the installation pro-

cedure.

(13) Install wheel and tire.

(14) Tighten the wheel mounting nuts in the

proper sequence until all nuts are torqued to half the

specified torque. Then repeat the tightening sequence

to the full specified torque of 129 N´m (95 ft. lbs.).

(15) Lower vehicle.

(16) Apply and release the park brake pedal one

time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump brake

pedal several times to ensure the vehicle has a firm

enough pedal to stop the vehicle.

(17) Road test the vehicle to ensure proper func-

tion of the vehicle's brake system.

PARK BRAKE CABLE ADJUSTMENT

The park brake cables on this vehicle have an

automatic self adjuster built into the park brake

pedal mechanism. When the foot operated park brake

pedal is in its released (upward most) position, a

clock spring automatically adjusts the park brake

cables. The park brake cables are adjusted (ten-

sioned) just enough to remove all the slack from the

cables. The automatic adjuster system will not over

adjust the cables causing rear brake drag.

Due to the automatic adjust feature of the park

brake pedal, adjustment of the parking brake cables

on these vehicles relies on proper drum brake and

park brake shoe adjustment. See Rear Brake Adjust-

ment and Park Brake Shoe Adjustment in the Ser-

vice Adjustments Section in this group of the service

manual.

When the park brake pedal is applied the self

adjuster is by-passed and the pedal operates nor-

mally to engage the park brakes.

When a service procedure needs to be performed on

the park brake pedal or the park brake cables, the

automatic self adjuster can be manually locked out

by the service technician.

PROPORTIONING VALVE (HEIGHT SENSING)

Proportioning valve actuator adjustment will be

required if there is a complaint of premature rear

wheel lockup and the front and rear brake shoe lin-

ings checked OK during inspection, the height sens-

ing proportioning valve required replacement, or

there is a complaint of excessive pedal effort and the

vacuum booster and brake pedal checked OK. Make

sure the proportioning valve and the mounting

bracket are firmly attached to the vehicle. Then, pro-

ceed with the following procedure to perform the

adjustment of the actuator.(1) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or with a frame contact type

hoist so the rear suspension of the vehicle is hanging

free. See hoisting in the Lubrication And Mainte-

nance section of this service manual.

(2) Remove rear wheels/tires.

(3) Using an appropriate jack, support the rear

axle prior to the removal of the track bar and shock

absorber bolts from the rear axle.

(4) Unbolt the track bar from the rear axle.

(5) Unbolt both shock absorbers from the rear

axle.

(6) Loosen (do not remove) both of the leaf spring

to front spring hanger pivot bolts.

NOTE: When lowering the rear axle be sure that the

leaf springs do not come in contact with the hoist

limiting the downward movement of the axle. If this

occurs an improper adjustment of the actuator may

result.

(7) Lower the rear axle so it is at its farthest point

of downward movement.

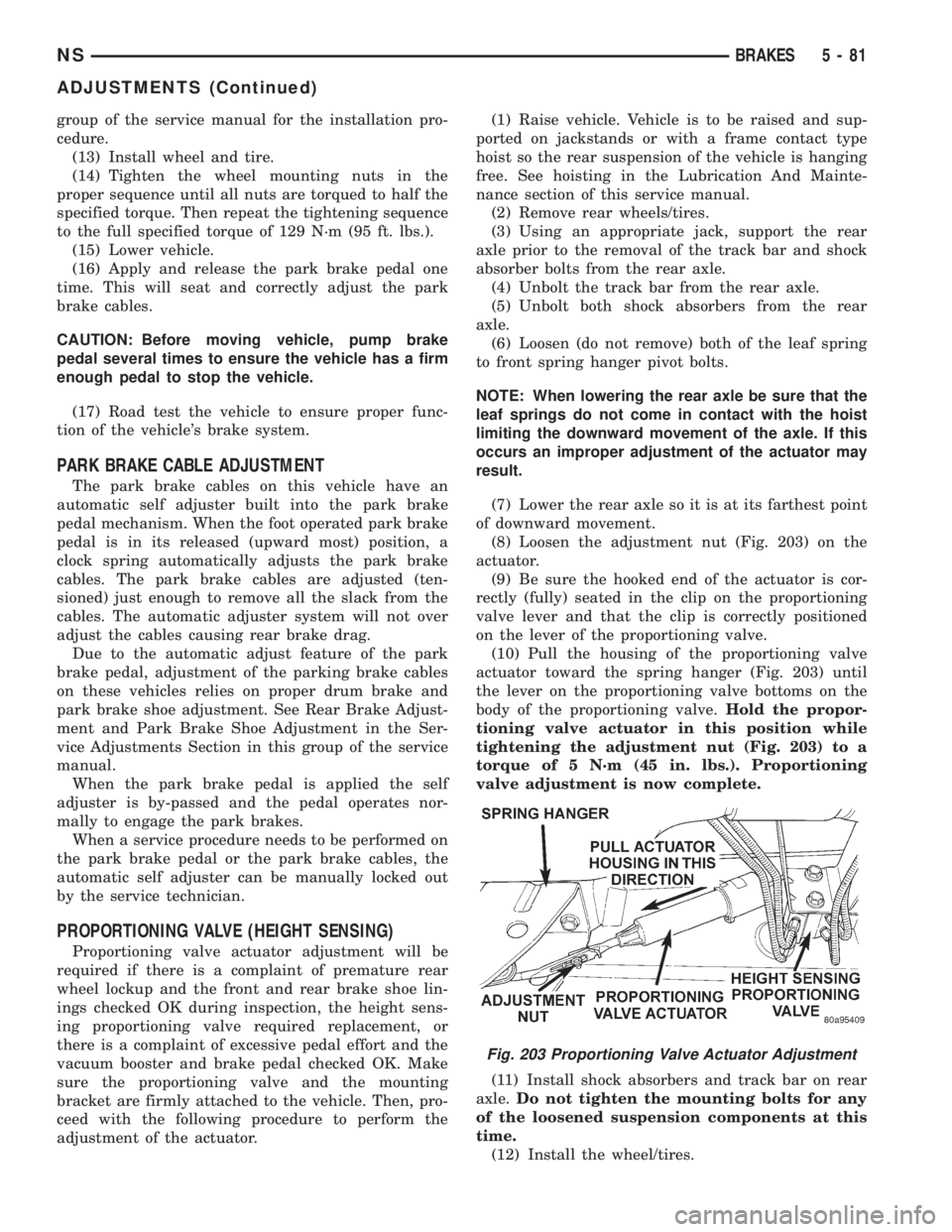

(8) Loosen the adjustment nut (Fig. 203) on the

actuator.

(9) Be sure the hooked end of the actuator is cor-

rectly (fully) seated in the clip on the proportioning

valve lever and that the clip is correctly positioned

on the lever of the proportioning valve.

(10) Pull the housing of the proportioning valve

actuator toward the spring hanger (Fig. 203) until

the lever on the proportioning valve bottoms on the

body of the proportioning valve.Hold the propor-

tioning valve actuator in this position while

tightening the adjustment nut (Fig. 203) to a

torque of 5 N´m (45 in. lbs.). Proportioning

valve adjustment is now complete.

(11) Install shock absorbers and track bar on rear

axle.Do not tighten the mounting bolts for any

of the loosened suspension components at this

time.

(12) Install the wheel/tires.

Fig. 203 Proportioning Valve Actuator Adjustment

NSBRAKES 5 - 81

ADJUSTMENTS (Continued)

Page 165 of 1938

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.........Standard

Hydraulic System...........Dual-Diagonally Split

Antilock Brake Sytem (Teves Mark-20)...........

MASTER CYLINDER ASSEMBLY:

Supplier..............................Bosch

Type For Non-ABSAnd

ABS Brakes. . . .Conventional Compensating Port

Type For ABS Brakes

With Traction Control . . .Dual Center Port Design

Body Material...............Anodized Aluminum

Reservoir Material................Polypropelene

MASTER CYLINDER BORE /

STROKE AND SPLIT:

ABS W/Disc/Drum Brakes......23.8 mm x 36 mm

(.937 in. x 1.47 in.)

AWD W/Disc/Disc Brakes........25.4 mm x 39 mm

(1.00 in. x 1.50 in.)

Displacement Split.....................50/50

MASTER CYLINDER FLUID OUTLET PORTS:

Non-ABS And ABS . . .Primary 7/16±24 Secondary 7/

16±24

ABS With Traction Control.......Primary M12 x 1

Secondary M12 x 1

Outlet Fitting Type Non-ABS

AndABS...........Double Wall Inverted Flare

Outlet Fitting Type ABS With

Traction Control...................ISO Flare

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting Type............ISO Flare

BOOSTER:

Make/Type.................Bosch Vacuum Assist

Mounting Studs.....................M8x1.25

Type .........................270 ZLT RSMV

Boost At 20 inches Of

Manifold Vacuum...........3800 N´m (850 lbs.)

PROPORTIONING VALVE:

Material...........................Aluminum

Function....................Hydraulic Pressure

Proportioning To Rear Brakes

BRAKE PEDAL

Pedal Ratio.............................3.36

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components..............17N´m(145 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

MASTER CYLINDER:

To Vacuum Booster

Mounting Nut............25N´m(225 in. lbs.)

FIXED PROPORTIONING VALVE:

To Frame Rail Attaching

Bolts....................14N´m(125 in. lbs.)

HEIGHT SENSING PROPORTIONING VALVE:

To Mounting Bracket

Attaching Bolts...........23N´m(200 in. lbs.)

Actuator Assembly

Adjustment Nut.............5N´m(45in.lbs.)

Mounting Bracket To Frame

Rail Bolts................17N´m(150 in. lbs.)

JUNCTION BLOCK (NON-ABS BRAKES)

To Suspension Cradle

Mounting Bolt............28N´m(250 in. lbs.)

VACUUM BOOSTER:

To Dash Panel Mounting

Nuts....................28N´m(250 in. lbs.)

REAR WHEEL CYLINDER:

To Support Plate Mounting

Bolts.....................8N´m(75in.lbs.)

Bleeder Screw...............10N´m(80in.lbs.)

BRAKE SUPPORT PLATE:

To Rear Axle Mounting Bolts . . .130 N´m (95 ft. lbs.)

DISC BRAKE CALIPER:

Guide Pin Bolts..............41N´m(30ft.lbs.)

Bleeder Screw..............15N´m(125 in. lbs.)

ABS HYDRAULIC CONTROL UNIT:

Mounting Bracket To

Suspension Cradle Bolts.....28N´m(250 in. lbs.)

To Mounting Bracket Isolator

Attaching Bolts............11N´m(97in.lbs.)

CAB To HCU Mounting Screws . . .2 N´m (17 in. lbs.)

WHEEL SPEED SENSOR:

To Axle Or Steering Knuckle

Mounting Bolt............12N´m(105 in. lbs.)

PARKING BRAKE:

Pedal Assembly Mounting

Bolts....................28N´m(250 in. lbs.)

REAR HUB AND BEARING:

To Axle Mounting Bolts........129 N´m (95 ft. lbs.)

WHEEL:

Stud Lug Nut........115±156 N´m (84-115 ft. lbs.)

NSBRAKES 5 - 83

SPECIFICATIONS (Continued)

Page 194 of 1938

SPECIFICATIONS

SPEED SENSOR TONE WHEEL RUNOUT

The total indicator runout allowed for both the

front and rear tone wheel measured using a dial indi-

cator is 0.15 mm (.006 in.).

WHEEL SPEED SENSOR TO TONE WHEEL

CLEARANCE

FRONT WHEEL

Minimum Clearance .35mm (.014 in.)

Maxamum Clearance 1.2 mm (.047 in.)

REAR WHEEL

Minimum Clearance .40mm (.016 in.)

Maxamum Clearance 1.2 mm (.047 in.)

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components..............17N´m(145 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

MASTER CYLINDER:

To Vacuum Booster

Mounting Nut............25N´m(225 in. lbs.)

FIXED PROPORTIONING VALVE:

To Frame Rail Attaching

Bolts....................14N´m(125 in. lbs.)

HEIGHT SENSING PROPORTIONING VALVE:

To Mounting Bracket

Attaching Bolts...........23N´m(200 in. lbs.)

Actuator Assembly

Adjustment Nut.............5N´m(45in.lbs.)

Mounting Bracket To

Frame Rail Bolts..........17N´m(150 in. lbs.)

JUNCTION BLOCK (NON-ABS BRAKES)

To Suspension Cradle

Mounting Bolt............28N´m(250 in. lbs.)

VACUUM BOOSTER:

To Dash Panel Mounting

Nuts....................28N´m(250 in. lbs.)DESCRIPTION TORQUE

REAR WHEEL CYLINDER:

To Support Plate Mounting

Bolts.....................8N´m(75in.lbs.)

Bleeder Screw...............10N´m(80in.lbs.)

BRAKE SUPPORT PLATE:

To Rear Axle Mounting Bolts . . .130 N´m (95 ft. lbs.)

DISC BRAKE CALIPER:

Guide Pin Bolts..............41N´m(30ft.lbs.)

Bleeder Screw..............15N´m(125 in. lbs.)

ABS HYDRAULIC CONTROL UNIT:

Mounting Bracket To

Suspension Cradle Bolts.....28N´m(250 in. lbs.)

To Mounting Bracket Isolator

Attaching Bolts............11N´m(97in.lbs.)

CAB To HCU Mounting Screws . . .2 N´m (17 in. lbs.)

WHEEL SPEED SENSOR:

To Axle Or Steering Knuckle

Mounting Bolt............12N´m(105 in. lbs.)

PARKING BRAKE:

Pedal Assembly Mounting

Bolts....................28N´m(250 in. lbs.)

REAR HUB AND BEARING:

To Axle Mounting Bolts........129 N´m (95 ft. lbs.)

WHEEL:

Stud Lug Nut........115±156 N´m (84-115 ft. lbs.)

5 - 112 BRAKESNS

Page 457 of 1938

HEADLAMP ALIGNMENT

INDEX

page page

GENERAL INFORMATION

HEADLAMP ALIGNMENT................... 5

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION....... 5ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN.................... 5

GENERAL INFORMATION

HEADLAMP ALIGNMENT

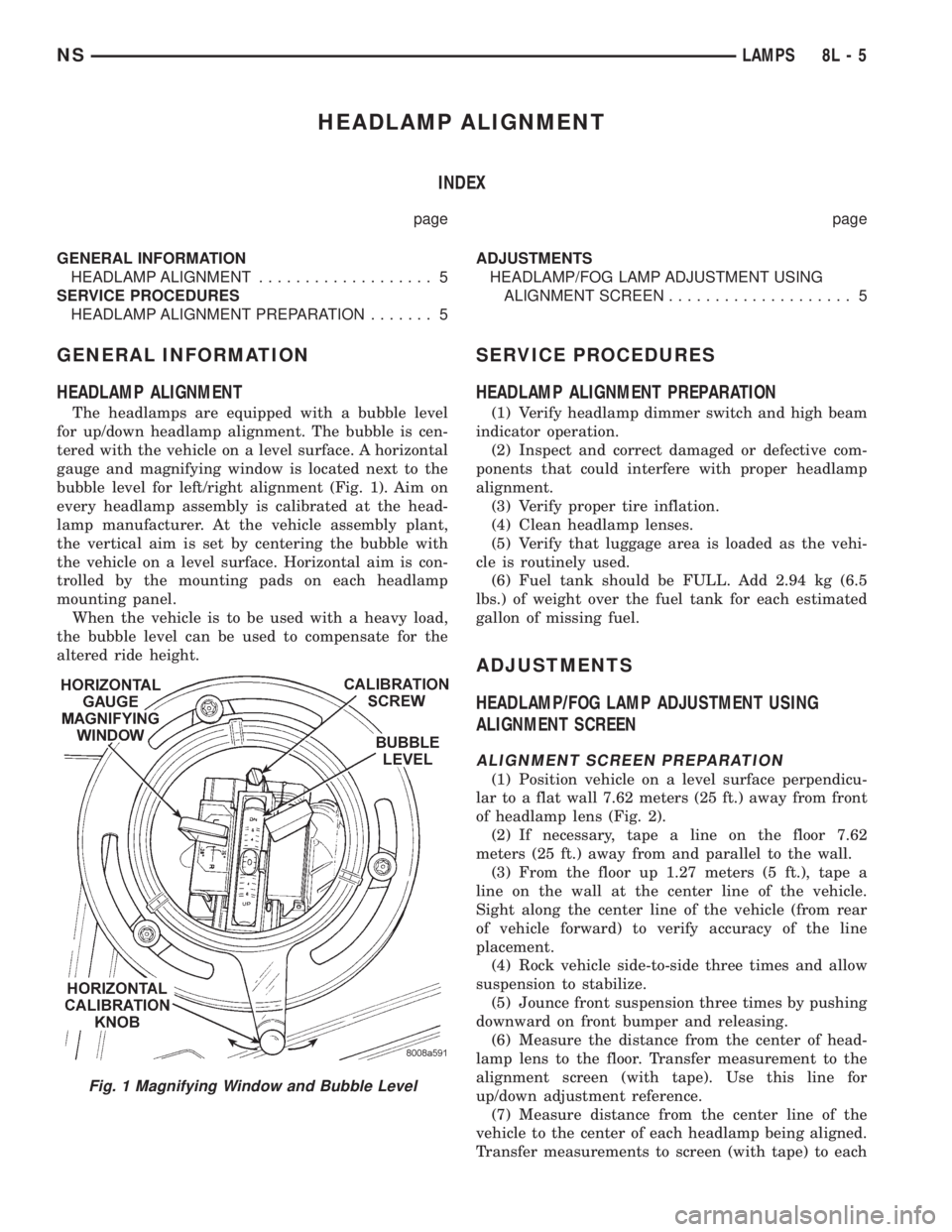

The headlamps are equipped with a bubble level

for up/down headlamp alignment. The bubble is cen-

tered with the vehicle on a level surface. A horizontal

gauge and magnifying window is located next to the

bubble level for left/right alignment (Fig. 1). Aim on

every headlamp assembly is calibrated at the head-

lamp manufacturer. At the vehicle assembly plant,

the vertical aim is set by centering the bubble with

the vehicle on a level surface. Horizontal aim is con-

trolled by the mounting pads on each headlamp

mounting panel.

When the vehicle is to be used with a heavy load,

the bubble level can be used to compensate for the

altered ride height.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is loaded as the vehi-

cle is routinely used.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens (Fig. 2).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall.

(3) From the floor up 1.27 meters (5 ft.), tape a

line on the wall at the center line of the vehicle.

Sight along the center line of the vehicle (from rear

of vehicle forward) to verify accuracy of the line

placement.

(4) Rock vehicle side-to-side three times and allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the center line of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

Fig. 1 Magnifying Window and Bubble Level

NSLAMPS 8L - 5

Page 483 of 1938

HEADLAMP ALIGNMENT

INDEX

page page

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION...... 5ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN.................. 5

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Verify that the headlamp leveling switch is in

the ª0º position.

(3) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(4) Verify proper tire inflation.

(5) Clean headlamp lenses.

(6) Verify that luggage area is loaded as the vehi-

cle is routinely used.

(7) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 10 meters (32.8 ft.) away from front

of headlamp lens (Fig. 1).

(2) Place 75 kg in the driver's seat to simulate the

ride height of the vehicle when driven.

(3) If necessary, tape a line on the floor 10 meters

(32.8 ft) away from and parallel to the wall.

(4) From the floor up 1.27 meters (5 ft), tape a line

on the wall at the centerline of the vehicle. Sight

along the centerline of the vehicle (from rear of vehi-

cle forward) to verify accuracy of the line placement.

NS/GSLAMPS 8L - 5

Page 1065 of 1938

BALANCE SHAFTS

Balance shaft lubrication is provided through an

oil passage from the number 1 main bearing cap

through the balance shaft carrier support leg. This

passage directly supplies oil to the front bearings and

internal machined passages in the shafts that routes

oil from front to rear shaft bearing journals

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

BALANCE SHAFTS:2.4L engines are equipped

with two balance shafts installed in a carrier

attached to the lower crankcase. The shafts intercon-

nect through gears to rotate in opposite directions.These gears are driven by a short chain from the

crankshaft, to rotate at two times crankshaft speed.

This counterbalances certain engine reciprocating

masses.

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A closed deck design is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4.5 mm. The bed-

plate incorporates main bearing caps. Rear seal

retainer is integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 60 mm diameter

main and 50 mm diameter crank pin journals (all)

have undercut fillets that are deep rolled for added

strength. To evenly distribute bearing loads and min-

imize internal stress, 8 counterweights are used.

Hydrodynamic seals provide end sealing, where the

crankshaft exits the block. Anaerobic gasket material

is used for parting line sealing in the block. A sin-

tered powder metal timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides

motive power; via timing belt to the camshaft sprock-

ets (providing timed valve actuation) and to the

water pump.

PISTONS:There is provisions for free wheeling

valve train. Piston has a unique height. All engines

use pressed in piston pins to attach forged powder

metal connecting rods. Incorporate hex head cap

screw threaded into the connecting rod. Piston and

Rods are serviced as a assembly.

PISTONS RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

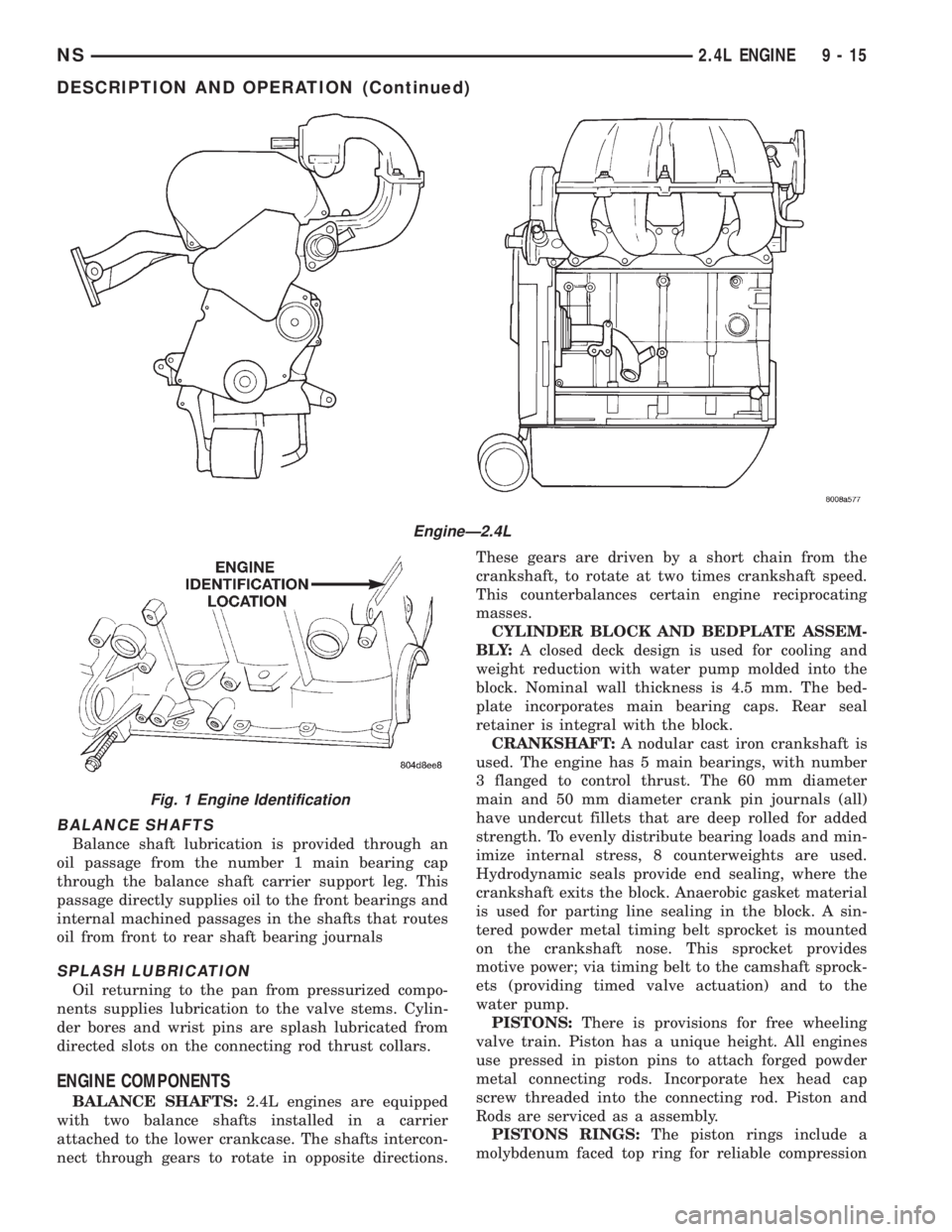

EngineÐ2.4L

Fig. 1 Engine Identification

NS2.4L ENGINE 9 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1071 of 1938

OPTIONAL CRANKSHAFT END PLAY CHECK

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek, using care not to dam-

age any bearing surface.DO NOTloosen main bear-

ing cap.

(2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

VALVE SERVICE RECONDITION

VALVE REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool C-3422-B or equivalent.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

(3) If valve stems are worn more than 0.05 mm

(0.002 in.), replace valve.

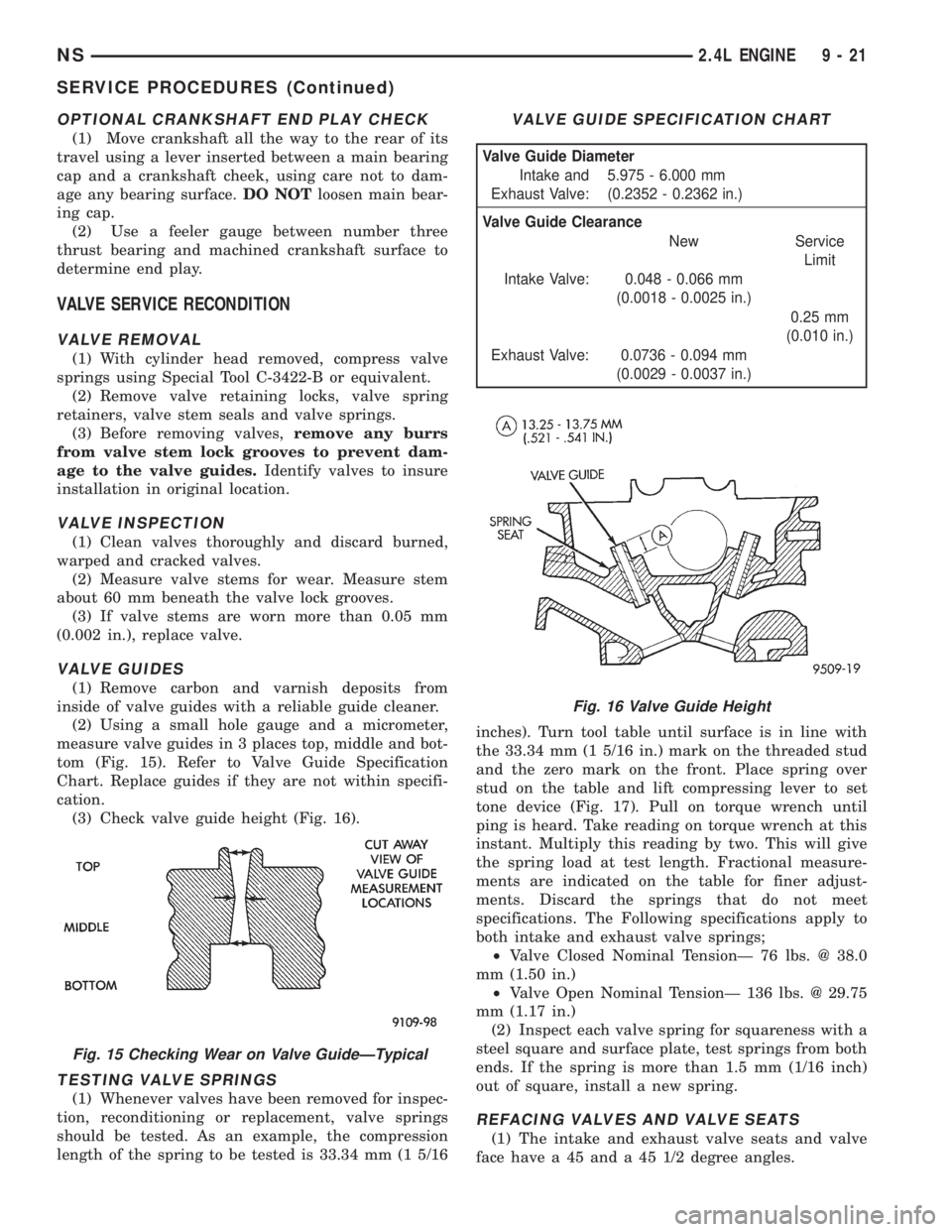

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 15). Refer to Valve Guide Specification

Chart. Replace guides if they are not within specifi-

cation.

(3) Check valve guide height (Fig. 16).

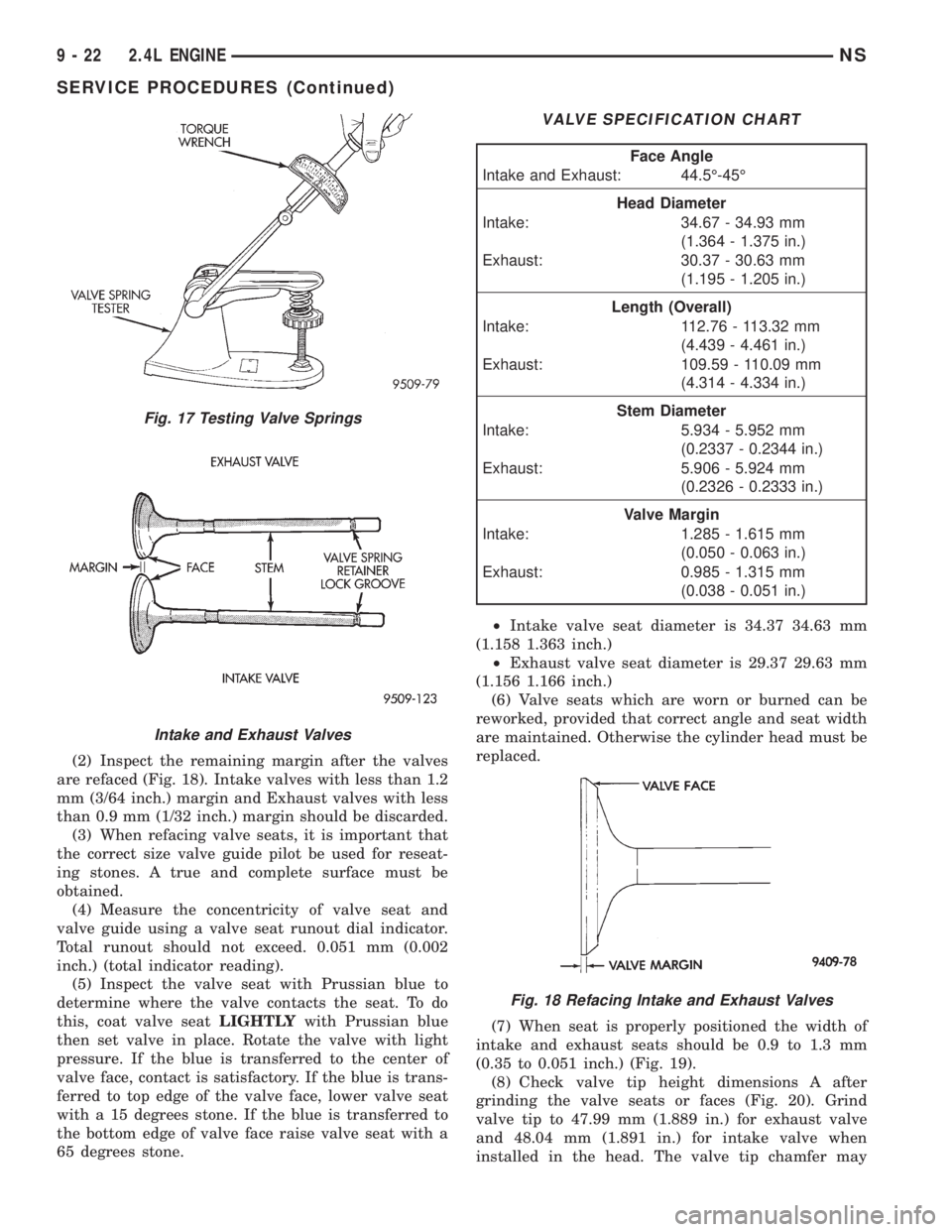

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested. As an example, the compression

length of the spring to be tested is 33.34 mm (1 5/16inches). Turn tool table until surface is in line with

the 33.34 mm (1 5/16 in.) mark on the threaded stud

and the zero mark on the front. Place spring over

stud on the table and lift compressing lever to set

tone device (Fig. 17). Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Discard the springs that do not meet

specifications. The Following specifications apply to

both intake and exhaust valve springs;

²Valve Closed Nominal TensionÐ 76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ 136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 and a 45 1/2 degree angles.

Fig. 15 Checking Wear on Valve GuideÐTypical

VALVE GUIDE SPECIFICATION CHART

Valve Guide Diameter

Intake and

Exhaust Valve:5.975 - 6.000 mm

(0.2352 - 0.2362 in.)

Valve Guide Clearance

New Service

Limit

Intake Valve: 0.048 - 0.066 mm

(0.0018 - 0.0025 in.)

0.25 mm

(0.010 in.)

Exhaust Valve: 0.0736 - 0.094 mm

(0.0029 - 0.0037 in.)

Fig. 16 Valve Guide Height

NS2.4L ENGINE 9 - 21

SERVICE PROCEDURES (Continued)

Page 1072 of 1938

(2) Inspect the remaining margin after the valves

are refaced (Fig. 18). Intake valves with less than 1.2

mm (3/64 inch.) margin and Exhaust valves with less

than 0.9 mm (1/32 inch.) margin should be discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.²Intake valve seat diameter is 34.37 34.63 mm

(1.158 1.363 inch.)

²Exhaust valve seat diameter is 29.37 29.63 mm

(1.156 1.166 inch.)

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. Otherwise the cylinder head must be

replaced.

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.9 to 1.3 mm

(0.35 to 0.051 inch.) (Fig. 19).

(8) Check valve tip height dimensions A after

grinding the valve seats or faces (Fig. 20). Grind

valve tip to 47.99 mm (1.889 in.) for exhaust valve

and 48.04 mm (1.891 in.) for intake valve when

installed in the head. The valve tip chamfer may

Fig. 17 Testing Valve Springs

Intake and Exhaust Valves

VALVE SPECIFICATION CHART

Face Angle

Intake and Exhaust: 44.5É-45É

Head Diameter

Intake: 34.67 - 34.93 mm

(1.364 - 1.375 in.)

Exhaust: 30.37 - 30.63 mm

(1.195 - 1.205 in.)

Length (Overall)

Intake: 112.76 - 113.32 mm

(4.439 - 4.461 in.)

Exhaust: 109.59 - 110.09 mm

(4.314 - 4.334 in.)

Stem Diameter

Intake: 5.934 - 5.952 mm

(0.2337 - 0.2344 in.)

Exhaust: 5.906 - 5.924 mm

(0.2326 - 0.2333 in.)

Valve Margin

Intake: 1.285 - 1.615 mm

(0.050 - 0.063 in.)

Exhaust: 0.985 - 1.315 mm

(0.038 - 0.051 in.)

Fig. 18 Refacing Intake and Exhaust Valves

9 - 22 2.4L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1073 of 1938

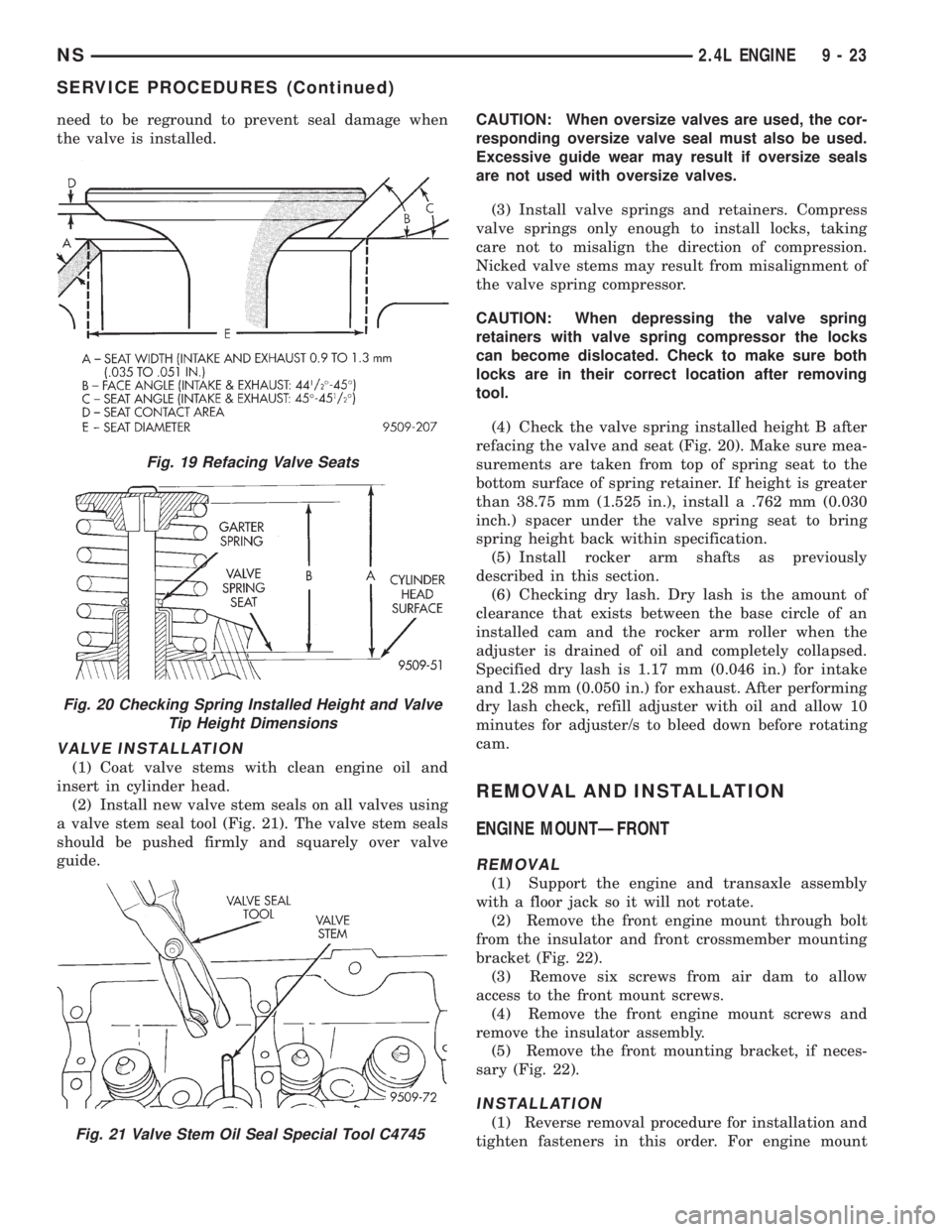

need to be reground to prevent seal damage when

the valve is installed.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 21). The valve stem seals

should be pushed firmly and squarely over valve

guide.CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 20). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a .762 mm (0.030

inch.) spacer under the valve spring seat to bring

spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster/s to bleed down before rotating

cam.

REMOVAL AND INSTALLATION

ENGINE MOUNTÐFRONT

REMOVAL

(1) Support the engine and transaxle assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 22).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 22).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order. For engine mount

Fig. 19 Refacing Valve Seats

Fig. 20 Checking Spring Installed Height and Valve

Tip Height Dimensions

Fig. 21 Valve Stem Oil Seal Special Tool C4745

NS2.4L ENGINE 9 - 23

SERVICE PROCEDURES (Continued)

Page 1085 of 1938

(4) Install cylinder head cover using procedure out-

lined in this section.

(5) Install rear timing belt cover and timing belt

idler pulley.

(6) Install timing belt and camshaft sprocket.

Refer to procedure outlined in this section.

(7) Install cam sensor and fuel injectors wiring

connectors.

(8) Install coil pack and plug wires onto the

engine. Connect coil pack wiring connector.

(9) Install power steering pump assembly.

(10) Raise vehicle and install the exhaust pipe to

the manifold.

(11) Install power brake vacuum hose to the intake

manifold.

(12) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(13) Install throttle linkage. Refer to Group 14,

Fuel System for procedures.

(14) Install air cleaner and connect all vacuum

lines, electrical wiring and fuel lines to the throttle

body.

(15) Fill cooling system. Refer to Group 7, Cooling

System for procedure. Connect negative battery

cable.

VALVES AND VALVE SPRINGS

REMOVAL

(1) With cylinder head removed, compress valve

springs using a universal valve spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

(4) Inspect and clean the valves. Refer to Cleaning

and Inspection outlined in this section for procedure.

INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

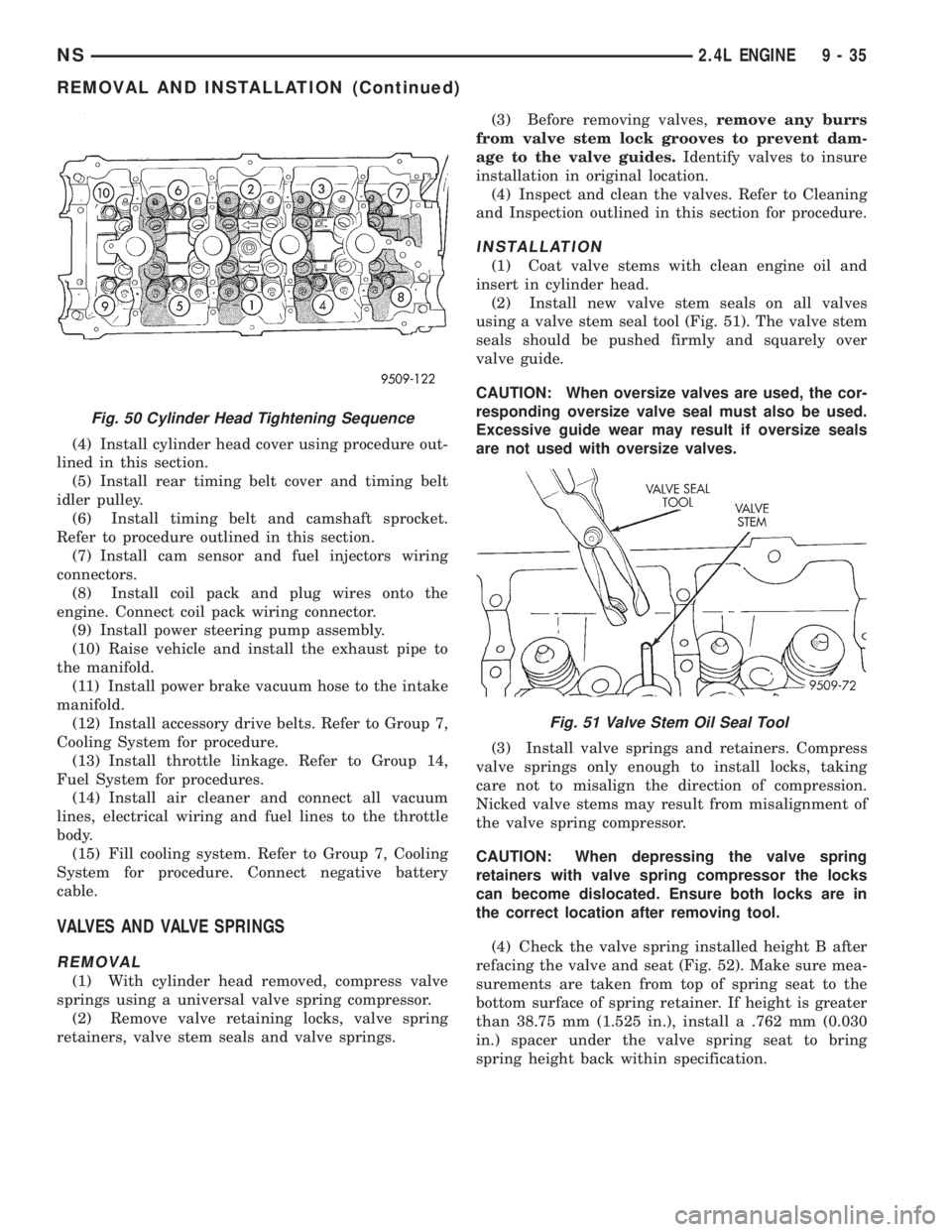

(2) Install new valve stem seals on all valves

using a valve stem seal tool (Fig. 51). The valve stem

seals should be pushed firmly and squarely over

valve guide.

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Ensure both locks are in

the correct location after removing tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 52). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a .762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.

Fig. 50 Cylinder Head Tightening Sequence

Fig. 51 Valve Stem Oil Seal Tool

NS2.4L ENGINE 9 - 35

REMOVAL AND INSTALLATION (Continued)