service CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1375 of 1938

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube or a

quick┬▒connect fitting. Replace complete line/tube as

necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the fuel lines/tubes are prop-

erly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses are of a special construction.

If it is necessary to replace these lines/tubes/hoses,

use only original equipment type.

The hose clamps used to secure the rubber hoses

are of a special rolled edge construction. This con-

struction is used to prevent the edge of the clamp

from cutting into the hose. Only these rolled edge

type clamps may be used in this system. All other

types of clamps may cut into the hoses and cause

fuel leaks.

Where a rubber hose is joined to a metal tube

(staked), do not attempt to repair. Replace entire

line/tube assembly.

Use new original equipment type hose clamps.

Tighten hose clamps to 2 N┬┤m (20 in. lbs.) torque.

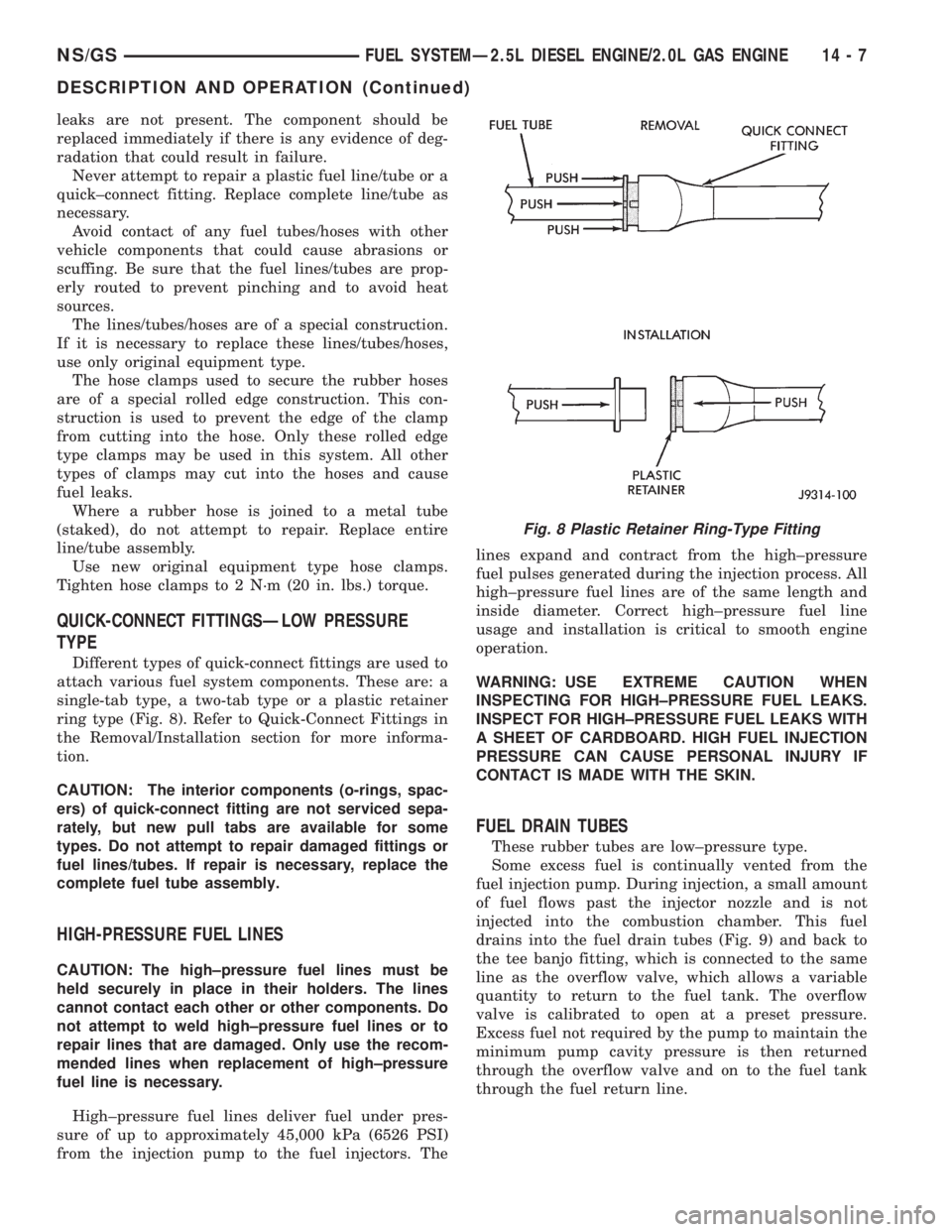

QUICK-CONNECT FITTINGSÐLOW PRESSURE

TYPE

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type (Fig. 8). Refer to Quick-Connect Fittings in

the Removal/Installation section for more informa-

tion.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately, but new pull tabs are available for some

types. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

HIGH-PRESSURE FUEL LINES

CAUTION: The high┬▒pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high┬▒pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high┬▒pressure

fuel line is necessary.

High┬▒pressure fuel lines deliver fuel under pres-

sure of up to approximately 45,000 kPa (6526 PSI)

from the injection pump to the fuel injectors. Thelines expand and contract from the high┬▒pressure

fuel pulses generated during the injection process. All

high┬▒pressure fuel lines are of the same length and

inside diameter. Correct high┬▒pressure fuel line

usage and installation is critical to smooth engine

operation.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH┬▒PRESSURE FUEL LEAKS.

INSPECT FOR HIGH┬▒PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

FUEL DRAIN TUBES

These rubber tubes are low┬▒pressure type.

Some excess fuel is continually vented from the

fuel injection pump. During injection, a small amount

of fuel flows past the injector nozzle and is not

injected into the combustion chamber. This fuel

drains into the fuel drain tubes (Fig. 9) and back to

the tee banjo fitting, which is connected to the same

line as the overflow valve, which allows a variable

quantity to return to the fuel tank. The overflow

valve is calibrated to open at a preset pressure.

Excess fuel not required by the pump to maintain the

minimum pump cavity pressure is then returned

through the overflow valve and on to the fuel tank

through the fuel return line.

Fig. 8 Plastic Retainer Ring-Type Fitting

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1377 of 1938

DIAGNOSIS AND TESTING

GENERAL INFORMATION

This section of the group will cover a general diag-

nosis of diesel engine fuel system components.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

The PCM must be tested with the DRBIII scan

tool. The DRBIII should be the first step in any diag-

nosis of engine performance complaints. Refer to the

1997 GS 2.5L Diesel Powertrain Diagnostic Proce-

dures manual for diagnosis and testing of the diesel

engine control system.

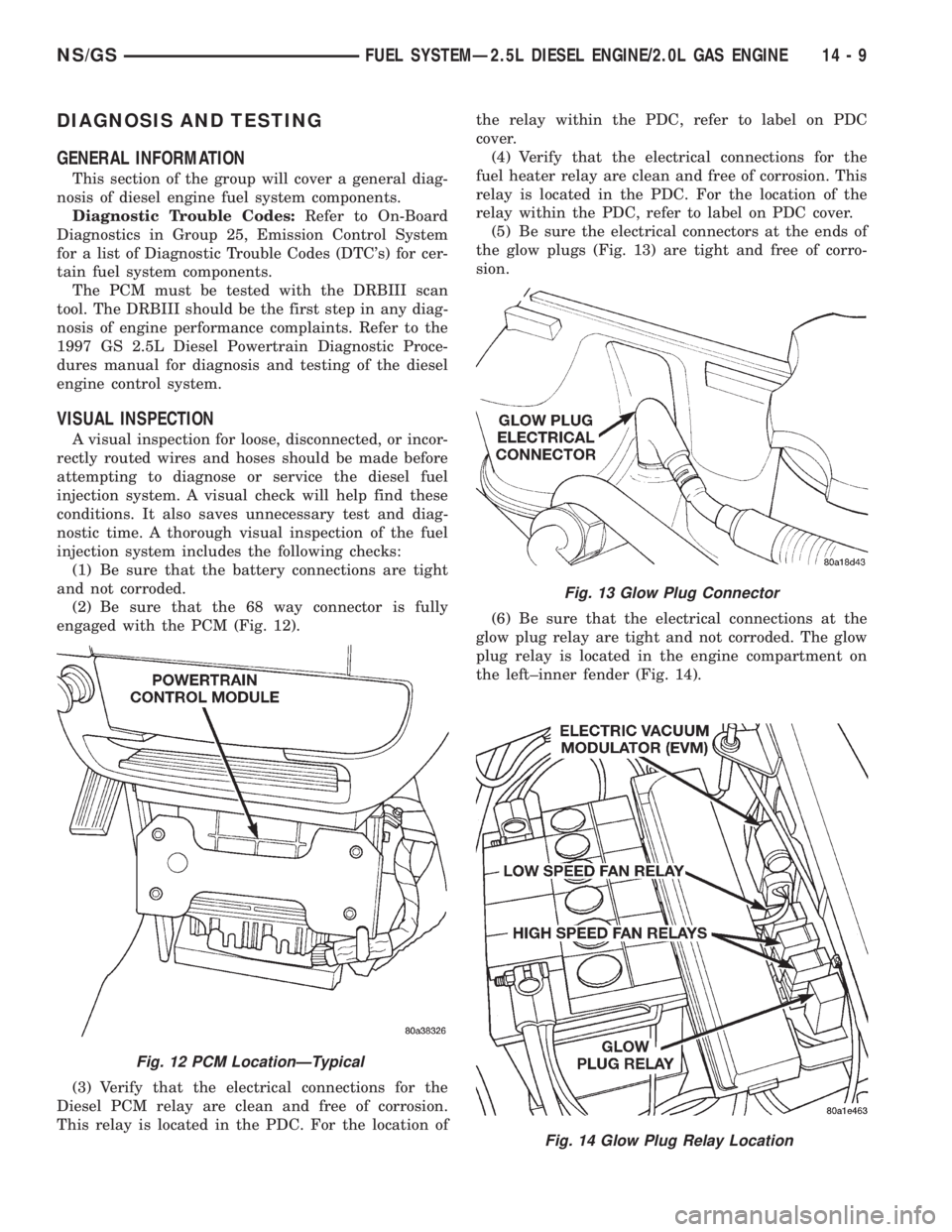

VISUAL INSPECTION

A visual inspection for loose, disconnected, or incor-

rectly routed wires and hoses should be made before

attempting to diagnose or service the diesel fuel

injection system. A visual check will help find these

conditions. It also saves unnecessary test and diag-

nostic time. A thorough visual inspection of the fuel

injection system includes the following checks:

(1) Be sure that the battery connections are tight

and not corroded.

(2) Be sure that the 68 way connector is fully

engaged with the PCM (Fig. 12).

(3) Verify that the electrical connections for the

Diesel PCM relay are clean and free of corrosion.

This relay is located in the PDC. For the location ofthe relay within the PDC, refer to label on PDC

cover.

(4) Verify that the electrical connections for the

fuel heater relay are clean and free of corrosion. This

relay is located in the PDC. For the location of the

relay within the PDC, refer to label on PDC cover.

(5) Be sure the electrical connectors at the ends of

the glow plugs (Fig. 13) are tight and free of corro-

sion.

(6) Be sure that the electrical connections at the

glow plug relay are tight and not corroded. The glow

plug relay is located in the engine compartment on

the left┬▒inner fender (Fig. 14).

Fig. 12 PCM LocationÐTypical

Fig. 13 Glow Plug Connector

Fig. 14 Glow Plug Relay Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 9

Page 1379 of 1938

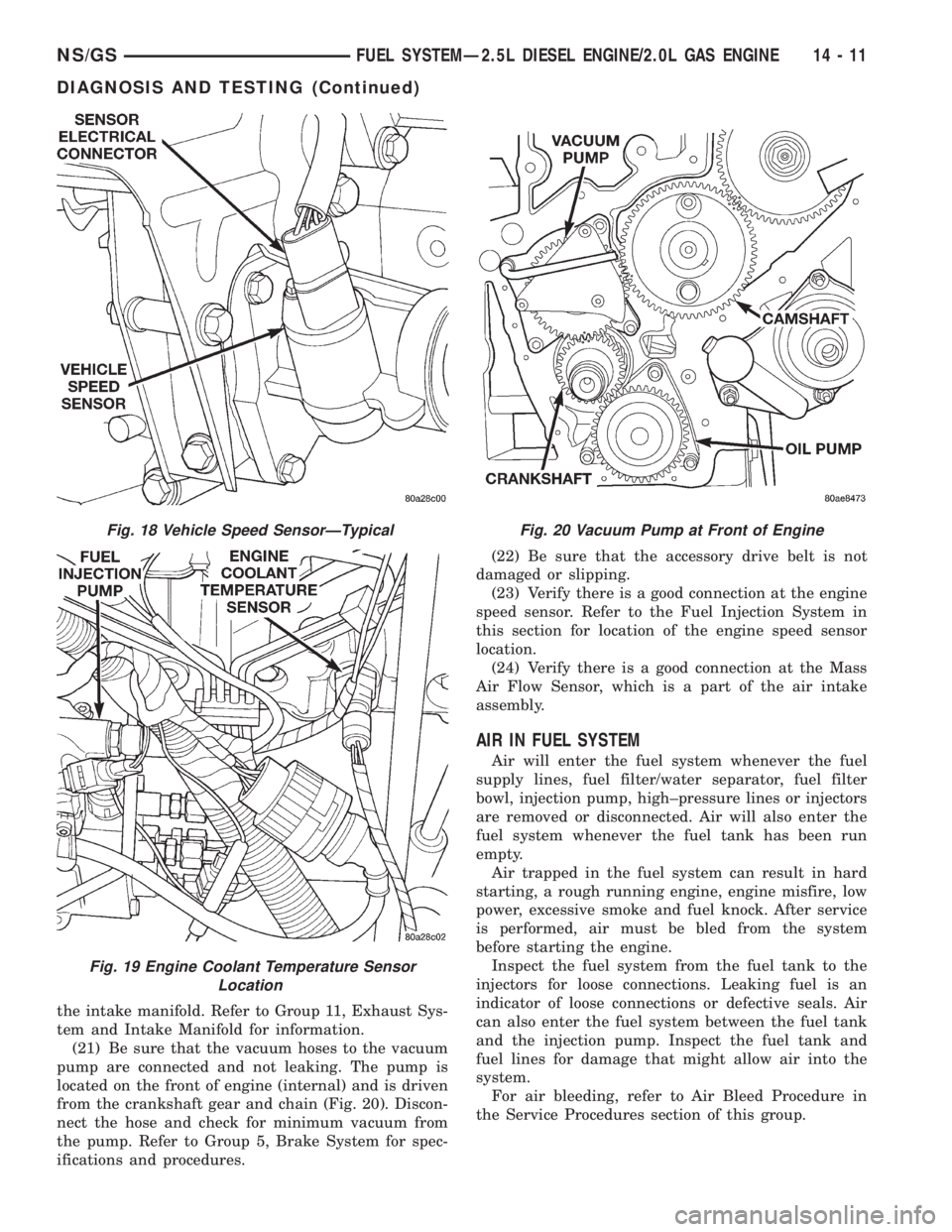

the intake manifold. Refer to Group 11, Exhaust Sys-

tem and Intake Manifold for information.

(21) Be sure that the vacuum hoses to the vacuum

pump are connected and not leaking. The pump is

located on the front of engine (internal) and is driven

from the crankshaft gear and chain (Fig. 20). Discon-

nect the hose and check for minimum vacuum from

the pump. Refer to Group 5, Brake System for spec-

ifications and procedures.(22) Be sure that the accessory drive belt is not

damaged or slipping.

(23) Verify there is a good connection at the engine

speed sensor. Refer to the Fuel Injection System in

this section for location of the engine speed sensor

location.

(24) Verify there is a good connection at the Mass

Air Flow Sensor, which is a part of the air intake

assembly.

AIR IN FUEL SYSTEM

Air will enter the fuel system whenever the fuel

supply lines, fuel filter/water separator, fuel filter

bowl, injection pump, high┬▒pressure lines or injectors

are removed or disconnected. Air will also enter the

fuel system whenever the fuel tank has been run

empty.

Air trapped in the fuel system can result in hard

starting, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

is performed, air must be bled from the system

before starting the engine.

Inspect the fuel system from the fuel tank to the

injectors for loose connections. Leaking fuel is an

indicator of loose connections or defective seals. Air

can also enter the fuel system between the fuel tank

and the injection pump. Inspect the fuel tank and

fuel lines for damage that might allow air into the

system.

For air bleeding, refer to Air Bleed Procedure in

the Service Procedures section of this group.

Fig. 18 Vehicle Speed SensorÐTypical

Fig. 19 Engine Coolant Temperature Sensor

Location

Fig. 20 Vacuum Pump at Front of Engine

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1380 of 1938

FUEL HEATER RELAY TEST

The fuel heater relay is located in the Power Dis-

tribution Center (PDC). Refer to RelaysÐOperation/

Testing in Fuel Ingection System section of this

group for test procedures.

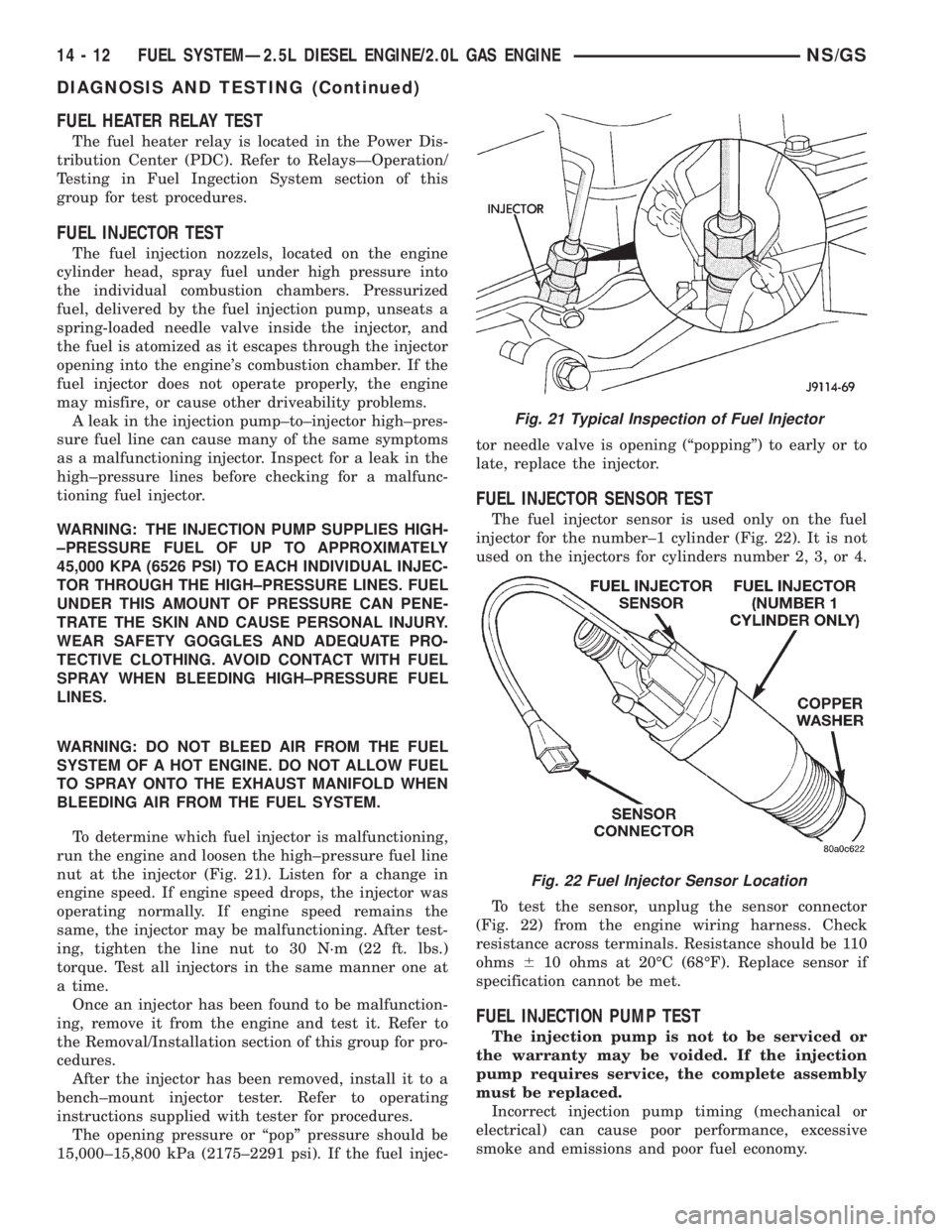

FUEL INJECTOR TEST

The fuel injection nozzels, located on the engine

cylinder head, spray fuel under high pressure into

the individual combustion chambers. Pressurized

fuel, delivered by the fuel injection pump, unseats a

spring-loaded needle valve inside the injector, and

the fuel is atomized as it escapes through the injector

opening into the engine's combustion chamber. If the

fuel injector does not operate properly, the engine

may misfire, or cause other driveability problems.

A leak in the injection pump┬▒to┬▒injector high┬▒pres-

sure fuel line can cause many of the same symptoms

as a malfunctioning injector. Inspect for a leak in the

high┬▒pressure lines before checking for a malfunc-

tioning fuel injector.

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

┬▒PRESSURE FUEL OF UP TO APPROXIMATELY

45,000 KPA (6526 PSI) TO EACH INDIVIDUAL INJEC-

TOR THROUGH THE HIGH┬▒PRESSURE LINES. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE THE SKIN AND CAUSE PERSONAL INJURY.

WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING. AVOID CONTACT WITH FUEL

SPRAY WHEN BLEEDING HIGH┬▒PRESSURE FUEL

LINES.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

To determine which fuel injector is malfunctioning,

run the engine and loosen the high┬▒pressure fuel line

nut at the injector (Fig. 21). Listen for a change in

engine speed. If engine speed drops, the injector was

operating normally. If engine speed remains the

same, the injector may be malfunctioning. After test-

ing, tighten the line nut to 30 N┬┤m (22 ft. lbs.)

torque. Test all injectors in the same manner one at

a time.

Once an injector has been found to be malfunction-

ing, remove it from the engine and test it. Refer to

the Removal/Installation section of this group for pro-

cedures.

After the injector has been removed, install it to a

bench┬▒mount injector tester. Refer to operating

instructions supplied with tester for procedures.

The opening pressure or ªpopº pressure should be

15,000±15,800 kPa (2175±2291 psi). If the fuel injec-tor needle valve is opening (ªpoppingº) to early or to

late, replace the injector.

FUEL INJECTOR SENSOR TEST

The fuel injector sensor is used only on the fuel

injector for the number┬▒1 cylinder (Fig. 22). It is not

used on the injectors for cylinders number 2, 3, or 4.

To test the sensor, unplug the sensor connector

(Fig. 22) from the engine wiring harness. Check

resistance across terminals. Resistance should be 110

ohms610 ohms at 20ÉC (68ÉF). Replace sensor if

specification cannot be met.

FUEL INJECTION PUMP TEST

The injection pump is not to be serviced or

the warranty may be voided. If the injection

pump requires service, the complete assembly

must be replaced.

Incorrect injection pump timing (mechanical or

electrical) can cause poor performance, excessive

smoke and emissions and poor fuel economy.

Fig. 21 Typical Inspection of Fuel Injector

Fig. 22 Fuel Injector Sensor Location

14 - 12 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1382 of 1938

START positions, fuel supply is allowed at the injec-

tion pump.

(1) Disconnect the electrical pigtail connector (test

connector) (Fig. 23) from the main engine wiring har-

ness. Do not disconnect wiring directly at solenoid.

(2) Connect the leads of a voltmeter between a

good ground and the disconnected engine wiring har-

ness.

(3) Turn the key to the ON position. Do not

attempt to start engine.

(4) 12V+ should be observed at wiring harness. If

not, refer to Group 8, Wiring for wiring schematics

and repair as necessary.

(5) T

urn the key to the START position. 12V+ should

be observed at wiring harness. If not, refer to Group 8,

Wiring for wiring schematics and repair as necessary.

The fault may be in the ignition (key) switch.

12V+ must be observed in both the ON and START

positions. If 12V+ was observed, proceed to the next

step.

(6) With key still in the ON position, connect and

disconnect the wiring harness to the solenoid. As this

is done, a clicking noise should be heard coming from

the solenoid. If not, replace solenoid. Refer to Fuel

Shutdown Solenoid in the Removal/Installation sec-

tion of this group for procedures.

HIGH-PRESSURE FUEL LINE LEAK TEST

High┬▒pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES

OF UP TO 45,000 KPA (6526 PSI), USE EXTREME

CAUTION WHEN INSPECTING FOR HIGH┬▒PRESSURE

FUEL LEAKS. DO NOT GET YOUR HAND, OR ANY

PART OF YOUR BODY NEAR A SUSPECTED LEAK.

INSPECT FOR HIGH┬▒PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

Start the engine. Move the cardboard over the

high┬▒pressure fuel lines and check for fuel spray onto

the cardboard (Fig. 24). If a high┬▒pressure line con-

nection is leaking, bleed the system and tighten the

connection. Refer to the Air Bleed Procedure in this

group for procedures. Replace damaged, restricted or

leaking high┬▒pressure fuel lines with the correct

replacement line.

CAUTION: The high┬▒pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high┬▒pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high┬▒pressure

fuel line is necessary.

WASTEGATE (TURBOCHARGER)

Refer to Group 11, Exhaust System and Intake

Manifold for information.

SERVICE PROCEDURES

AIR BLEED PROCEDURES

AIR BLEEDING AT FUEL FILTER

A certain amount of air may become trapped in the

fuel system when fuel system components are ser-

viced or replaced. Bleed the system as needed after

fuel system service according to the following proce-

dures.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

Some air enters the fuel system when the fuel fil-

ter or injection pump supply line is changed. This

small amount of air is vented automatically from the

injection pump through the fuel drain manifold tubes

if the filter was changed according to instructions.

Ensure the bowl of the fuel filter/water separator is

full of fuel

It may be necessary to manually bleed the system

if:

┬▓The bowl of the fuel filter/water separator is not

partially filled before installation of a new filter

┬▓The injection pump is replaced

Fig. 24 Typical Test for Leaks with Cardboard

14 - 14 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1383 of 1938

┬▓High┬▒pressure fuel line connections are loosened

or lines replaced

┬▓Initial engine start┬▒up or start┬▒up after an

extended period of no engine operation

┬▓Running fuel tank empty

FUEL INJECTION PUMP BLEEDING

(1) If the fuel injection pump has been replaced,

air should be bled at the overflow valve before

attempting to start engine.

(a) Loosen the overflow valve (Fig. 25) at the

rear of the injection pump.

(b) Place a towel below the valve.

WARNING: WHEN CRANKING THE ENGINE TO

BLEED AIR FROM THE INJECTION PUMP, THE

ENGINE MAY START. PLACE THE TRANSMISSION

IN NEUTRAL OR PARK AND SET PARKING BRAKE

BEFORE ENGAGING THE STARTER MOTOR.

CAUTION: Do not engage the starter motor for

more than 30 seconds at a time. Allow 2 minutes

between cranking intervals.

(2) Crank the engine for 30 seconds at a time to

allow air trapped in the injection pump to vent out

the fuel injector drain tubes. Continue this procedure

until the engine starts. Observe the previous WARN-

ING and CAUTION.

(3) Tighten overflow valve.

HIGH┬▒PRESSURE FUEL LINE BLEEDING

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

┬▒PRESSURE FUEL OF APPROXIMATELY 59,000 KPA

(8,557 PSI) TO EACH INDIVIDUAL INJECTOR

THROUGH THE HIGH┬▒PRESSURE LINES. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE THE SKIN AND CAUSE PERSONAL INJURY.

WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING AND AVOID CONTACT WITH

FUEL SPRAY WHEN BLEEDING HIGH┬▒PRESSURE

FUEL LINES.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

Bleed air from one injector at time.

(1) Loosen the high┬▒pressure fuel line fitting at

the injector (Fig. 26).

(2) Crank the engine until all air has been bled

from the line.Do not operate the starter motor

for longer than 30 seconds. Wait 2 minutes

between cranking intervals.

(3) Start the engine and bleed one injector at a

time until the engine runs smoothly.

FUEL INJECTION PUMP TIMING

Refer to Removal/Installation and Adjusting Fuel

Pump Timing in this Group.

Fig. 25 Overflow Valve

Fig. 26 Bleeding High±Pressure Fuel LineÐTypical

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 15

SERVICE PROCEDURES (Continued)

Page 1386 of 1938

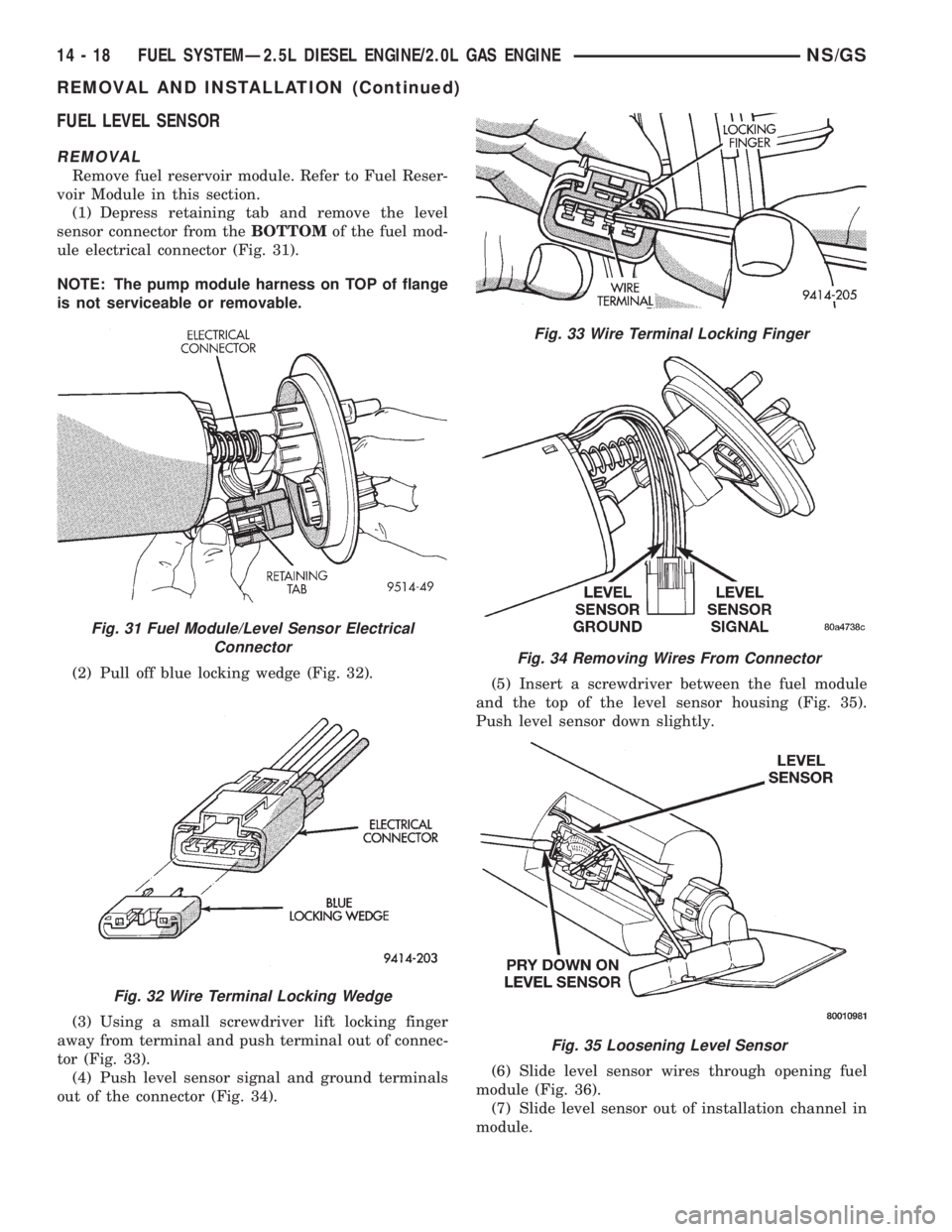

FUEL LEVEL SENSOR

REMOVAL

Remove fuel reservoir module. Refer to Fuel Reser-

voir Module in this section.

(1) Depress retaining tab and remove the level

sensor connector from theBOTTOMof the fuel mod-

ule electrical connector (Fig. 31).

NOTE: The pump module harness on TOP of flange

is not serviceable or removable.

(2) Pull off blue locking wedge (Fig. 32).

(3) Using a small screwdriver lift locking finger

away from terminal and push terminal out of connec-

tor (Fig. 33).

(4) Push level sensor signal and ground terminals

out of the connector (Fig. 34).(5) Insert a screwdriver between the fuel module

and the top of the level sensor housing (Fig. 35).

Push level sensor down slightly.

(6) Slide level sensor wires through opening fuel

module (Fig. 36).

(7) Slide level sensor out of installation channel in

module.

Fig. 31 Fuel Module/Level Sensor Electrical

Connector

Fig. 32 Wire Terminal Locking Wedge

Fig. 33 Wire Terminal Locking Finger

Fig. 34 Removing Wires From Connector

Fig. 35 Loosening Level Sensor

14 - 18 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1390 of 1938

(14) Gauge reading should be at 0.60 mm. If not,

the pump must be rotated for adjustment:

(a) Loosen the three injection pump mounting

nuts at the mounting flanges. These flanges are

equipped with slotted holes. The slotted holes are

used to rotate and position the injection pump for

fuel timing. Loosen the three nuts just enough to

rotate the pump.

(b) Rotate the pumpclockwise(as viewed from

front) until .60 mm is indicated on the dial indica-

tor gauge.

(c) Tighten the three pump mounting nuts to 30

N┬┤m (22 ft. lbs.) torque.

(d) Recheck the dial indicator after tightening

the pump mounting nuts. Gauge should still be

reading 0.60 mm. Loosen pump mounting nuts and

readjust if necessary.

(15) Remove dial indicator and adapter tools.

(16) Install access plug and washer to rear of

injection pump.

(17) Install plug at timing gear cover.

(18) Remove dial indicator from valve stem.

(19) Install valve spring and keepers.

(20) Install rocker arm assembly and tighten nuts.

(21) Install and connect the four high┬▒pressure

fuel lines to the fuel injection pump. Also connect

fuel lines at the fuel injectors. For procedures, refer

to High┬▒Pressure Fuel Lines in this group.

(22) Install electrical connector at engine coolant

temperature sensor.

(23) Connect electrical connector at fuel shutdown

solenoid.(24) Connect the main engine wiring harness to

the glow plugs.

(25) Connect the fuel timing solenoid pigtail har-

ness to the engine wiring harness.

(26) Connect the overflow valve/banjo fitting (fuel

return line assembly). Replace copper gaskets before

installing.

(27) Connect the rubber fuel return and supply

hoses to metal lines at pump. Tighten hose clamps to

2 N┬┤m (20 in. lbs.) torque.

(28) Install generator assembly.

(29) Install engine accessory drive belt. Refer to

Group 7, Cooling System for procedures.

(30) Install negative battery cable to battery.

(31) Start the engine and bring to normal operat-

ing temperature.

(32) Check for fuel leaks.

FUEL INJECTORS

Four fuel injectors are used on each engine. Of these

four, two different types are used. The fuel injector used

on cylinder number one is equipped with a fuel injector

sensor (Fig. 47). The other three fuel injectors are iden-

tical.

Do not place the fuel injector equipped with

the fuel injector sensor into any other location

except the cylinder number one position.

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Thoroughly clean the area around the injector

with compressed air.

(3) Remove the fuel drain hoses (tubes) at each

injector (Fig. 48) being serviced. Each of these hoses

is slip┬▒fit to the fitting on injector.

(4) Remove the high┬▒pressure fuel line at injector

being removed. Refer to High┬▒Pressure Fuel Lines in

this group for procedures.

(5) Remove the injector using special socket tool

number VM.1012A. When removing cylinder number

Fig. 46 Installing Dial Indicator and Special Adapter

Tools

Fig. 47 Fuel Injector SensorÐNumber±1 Cylinder

14 - 22 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1396 of 1938

FUEL DELIVERY SYSTEMÐ2.0L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ELECTRIC FUEL PUMP.................. 28

FUEL DELIVERY SYSTEM................ 28

FUEL INJECTORS...................... 28

FUEL LEVEL SENSOR................... 28

FUEL PRESSURE REGULATOR........... 28

FUEL PUMP MODULE................... 28

FUEL TANK........................... 28

PRESSURE-VACUUM FILLER CAPÐ

2.0L ENGINE......................... 28

QUICK-CONNNECT FITTINGSÐ

2.0L ENGINE......................... 28

DIAGNOSIS AND TESTING

FUEL INJECTORSÐ2.0L ENGINE.......... 29

FUEL LEVEL SENSORÐ2.0L ENGINE....... 28

FUEL PUMP PRESSURE TESTÐ

2.0L ENGINE......................... 28SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.0L ENGINE............ 29

HOSES AND CLAMPSÐ2.0L ENGINE....... 29

QUICK-CONNNECT FITTINGSÐ2.0L ENGINE . 29

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL.................. 31

FUEL FILTERÐ2.0L ENGINE.............. 29

FUEL INJECTORS...................... 30

FUEL LEVEL SENSORÐ2.0L ENGINE....... 30

FUEL PRESSURE REGULATORÐ

2.0L ENGINE......................... 29

FUEL PRESSURE REGULATORÐ

2.0L ENGINE......................... 29

FUEL PUMP MODULEÐ2.0L ENGINE....... 29

FUEL TANKÐ2.0L ENGINE............... 30

TORQUE SPECIFICATION................ 31

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM

Refer to the Fuel Delivery Sytem in the Fuel Deliv-

ery Section of group 14 for the 2.4/3.0/3.3/3.8L

engines for more information.

FUEL PUMP MODULE

Refer to the Fuel Pump Module for the 2.4/3.0/3.3/

3.8L engines in the Fuel Delivery System section of

group 14.

ELECTRIC FUEL PUMP

Refer to the Electric Fuel Pump for the 2.4/3.0/3.3/

3.8L engines in the Fuel Delivery System Section of

group 14 for more information.

FUEL LEVEL SENSOR

Refer to the Fuel Level Sensor for the 2.4/3.0/3.3/

3.8L engines in the Fuel Delivery System section of

group 14 for more information.

FUEL PRESSURE REGULATOR

Refer to the Fuel Pressure Regulator for the 2.4/

3.0/3.3/3.8L engines in the Fuel Delivery System sec-

tion of group 14 for more information.

FUEL INJECTORS

Refer to the Fuel Injectors for the 2.4/3.0/3.3/3.8L

engines in the Fuel Delivery System section of group

14 for more information.

FUEL TANK

Refer to the Fuel Tank for the 2.4/3.0/3.3/3.8L

engines in the Fuel Delivery System section of group

14 for more information.

PRESSURE-VACUUM FILLER CAPÐ2.0L ENGINE

Refer to the Pressure-Vacuum Filler Cap for the

2.4/3.0/3.3/3.8L engines in the Fuel Delivery System

section of group 14 for more information.

QUICK-CONNNECT FITTINGSÐ2.0L ENGINE

Refer to the Quick Connect Fittings for the 2.4/3.0/

3.3/3.8L engines in the Fuel Delivery System section

of group 14 for more information.

DIAGNOSIS AND TESTING

FUEL PUMP PRESSURE TESTÐ2.0L ENGINE

Refer to the Fuel Pressure Test for the 2.4/3.0/3.3/

3.8L engines in the Fuel Delivery System section of

group 14 for more information.

FUEL LEVEL SENSORÐ2.0L ENGINE

Refer to the Fuel Level Sensor for the 2.4/3.0/3.3/

3.8L engines in the Fuel Delivery System section of

group 14 for more information.

14 - 28 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

Page 1397 of 1938

FUEL INJECTORSÐ2.0L ENGINE

Refer to the Fuel Injectors for the 2.4/3.0/3.3/3.8L

engines in the Fuel Delivery System section of group

14 for more information.

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.0L ENGINE

Refer to the Fuel System Pressure Release Proce-

dure for the 2.4/3.0/3.3/3.8L engines in the Fuel

Delivery System section of group 14 for more infor-

mation.

HOSES AND CLAMPSÐ2.0L ENGINE

Refer to Hoses and Clamps for the 2.4/3.0/3.3/3.8L

engines in the Fuel Delivery System section of group

14 for more information.

QUICK-CONNNECT FITTINGSÐ2.0L ENGINE

Refer to the Quick Connect Fittings for the 2.4/3.0/

3.3/3.8L engines under Service Procedures in the

Fuel Delivery System section of group 14 for more

information.

REMOVAL AND INSTALLATION

FUEL FILTERÐ2.0L ENGINE

Refer to the Fuel Filter for the 2.4/3.0/3.3/3.8L

engines under Removal and Installation in the Fuel

Delivery System section of group 14 for more infor-

mation.

FUEL PUMP MODULEÐ2.0L ENGINE

Refer to the Fuel Pump Module for the 2.4/3.0/3.3/

3.8L engines under Removal and Installation in theFuel Delivery System section of group 14 for more

information.

FUEL PRESSURE REGULATORÐ2.0L ENGINE

Refer to the Fuel Pressure Rgulator for the 2.4/3.0/

3.3/3.8L engines under Removal and Installation in

the Fuel Delivery System section of group 14 for

more information.

FUEL PRESSURE REGULATORÐ2.0L ENGINE

Refer to the Fuel Pressure Regulator for the 2.4/

3.0/3.3/3.8L engines under Removal and Installation

in the Fuel Delivery System section of group 14 for

more information.

Fig. 1 Fuel Pressure Test PortÐ2.0L

Fig. 2 FUEL LEVEL SENSOR DIAGNOSIS

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 29

DIAGNOSIS AND TESTING (Continued)