service CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1416 of 1938

The speed sensor generates 8 pulses per sensor

revolution. These signals, in conjunction with a

closed throttle signal from the throttle position sen-

sor, indicate a closed throttle deceleration to the

PCM. When the vehicle is stopped at idle, a closed

throttle signal is received by the PCM (but a speed

sensor signal is not received).

In addition to determining distance and vehicle

speed, the output from the sensor is used to control

speed control operation.

SPEED CONTROLÐPCM INPUTS

The speed control system provides five separate

inputs to the PCM; On/Off, Set, Resume/Accel, Cancel,

and Decel.. The On/Off input informs the PCM that

the speed control system has been activated. The Set

input informs the PCM that a fixed vehicle speed has

been selected. The Resume input indicates to the PCM

that the previous fixed speed is requested.

Speed control operation will start at 50 km/h±142

km/h (35±85 mph). The upper range of operation is

not restricted by vehicle speed. Inputs that affect

speed control operation are vehicle speed sensor and

throttle position sensor.

Refer to Group 8H for further speed control infor-

mation.

DIESEL PCM RELAYÐPCM INPUT

A 12 volt signal at this input indicates to the PCM

that the Diesel relay has been activated. The Diesel

relay is located in the PDC. The PDC is located next

to the battery in the engine compartment. For the

location of the relay within the PDC, refer to label on

PDC cover.

This input is used only to sense that the Diesel

relay is energized. If the PCM does not see 12 volts +

at this input when the Diesel relay should be acti-

vated, it will set a Diagnostic Trouble Code (DTC).

FIVE VOLT POWERÐPCM OUTPUT

This circuit supplies approximately 5 volts to

power the Accelerator Pedal Postion Sensor, Mass Air

Flow Sensor, and A/C Pressure Sensor.

ENGINE COOLANT GAUGEÐPCM OUTPUT

Refer to the Instrument Panel and Gauges group

for additional information.

ENGINE OIL PRESSURE GAUGEÐPCM OUTPUT

Refer to the Instrument Panel and Gauges group

for additional information.

GLOW PLUG LAMPÐPCM OUTPUT

The Glow Plug lamp (malfunction indicator lamp)

illuminates on the message center each time the igni-

tion (key) switch is turned on. It will stay on for

about two seconds as a bulb test.If the PCM receives an incorrect signal, or no sig-

nal from certain sensors or components, the lamp

BLINKS. This is a warning that the PCM has

recorded a system or sensor malfunction. It signals

an immediate need for service. There are only 5

HARD faults that can turn on this lamp to make it

blink.

SPEED CONTROLÐPCM OUTPUTS

These two circuits control the fuel quantity actua-

tor to regulate vehicle speed. Refer to Group 8H for

Speed Control information.

AIR CONDITIONING RELAYÐPCM OUTPUT

This circuit controls a ground signal for operation

of the A/C clutch relay. Also refer to Air Conditioning

(A/C) ControlsÐPCM Input for additional informa-

tion.

The A/C relay is located in the Power Distribution

Center (PDC). The PDC is located next to the battery

in the engine compartment. For the location of the

relay within the PDC, refer to label on PDC cover.

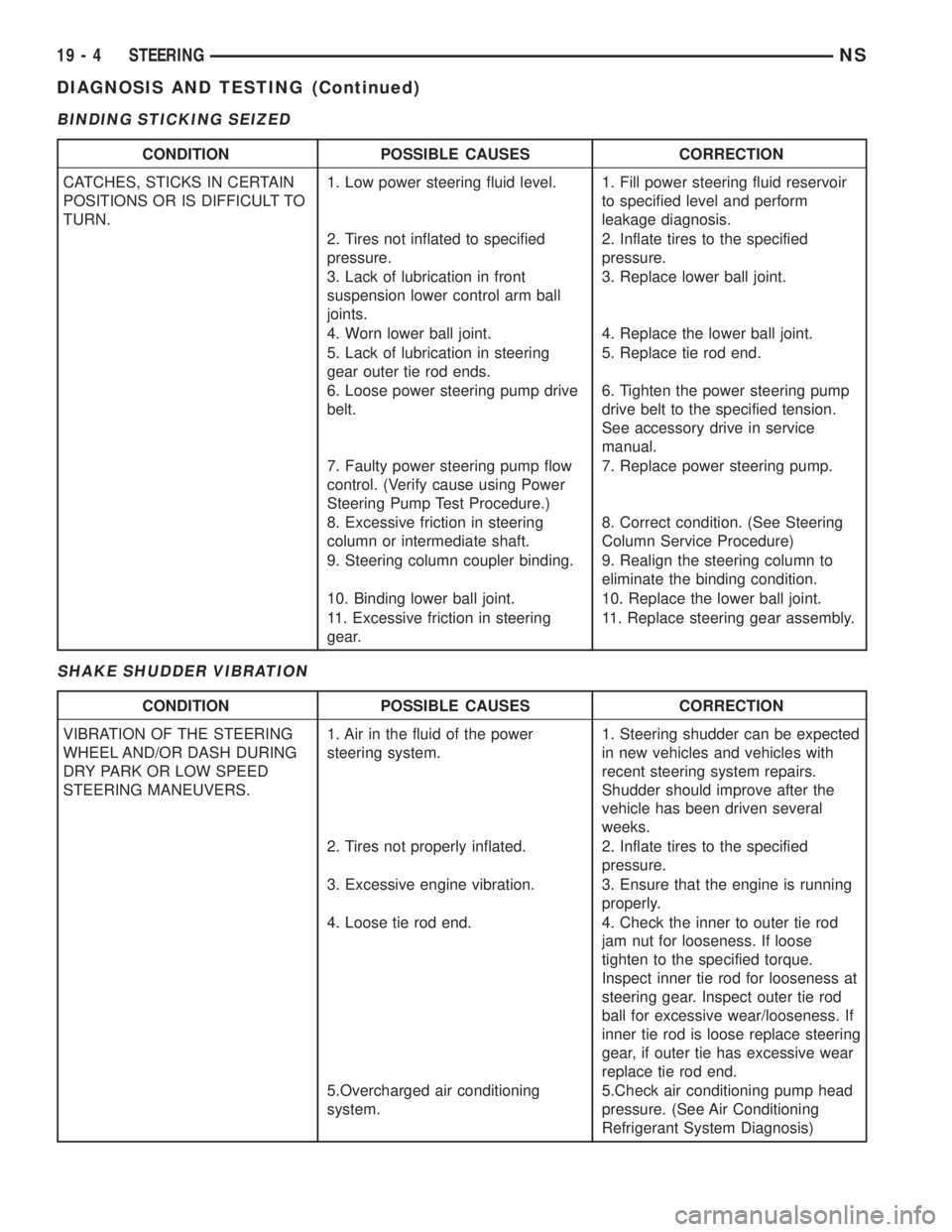

FUEL TIMING SOLENOIDÐPCM OUTPUT

The fuel timing solenoid is located on the bottom of

the fuel injection pump (Fig. 10).

This 12+ volt, pulse width modulated (duty±cycle)

output controls the amount of fuel timing (advance)

in the fuel injection pump. The higher the duty-

Fig. 9 Glow Plug Lamp Symbol

Fig. 10 Fuel Timing Solenoid

14 - 48 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1430 of 1938

BINDING STICKING SEIZED

SHAKE SHUDDER VIBRATION

CONDITION POSSIBLE CAUSES CORRECTION

CATCHES, STICKS IN CERTAIN

POSITIONS OR IS DIFFICULT TO

TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir

to specified level and perform

leakage diagnosis.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified

pressure.

3. Lack of lubrication in front

suspension lower control arm ball

joints.3. Replace lower ball joint.

4. Worn lower ball joint. 4. Replace the lower ball joint.

5. Lack of lubrication in steering

gear outer tie rod ends.5. Replace tie rod end.

6. Loose power steering pump drive

belt.6. Tighten the power steering pump

drive belt to the specified tension.

See accessory drive in service

manual.

7. Faulty power steering pump flow

control. (Verify cause using Power

Steering Pump Test Procedure.)7. Replace power steering pump.

8. Excessive friction in steering

column or intermediate shaft.8. Correct condition. (See Steering

Column Service Procedure)

9. Steering column coupler binding. 9. Realign the steering column to

eliminate the binding condition.

10. Binding lower ball joint. 10. Replace the lower ball joint.

11. Excessive friction in steering

gear.11. Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

VIBRATION OF THE STEERING

WHEEL AND/OR DASH DURING

DRY PARK OR LOW SPEED

STEERING MANEUVERS.1. Air in the fluid of the power

steering system.1. Steering shudder can be expected

in new vehicles and vehicles with

recent steering system repairs.

Shudder should improve after the

vehicle has been driven several

weeks.

2. Tires not properly inflated. 2. Inflate tires to the specified

pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end. 4. Check the inner to outer tie rod

jam nut for looseness. If loose

tighten to the specified torque.

Inspect inner tie rod for looseness at

steering gear. Inspect outer tie rod

ball for excessive wear/looseness. If

inner tie rod is loose replace steering

gear, if outer tie has excessive wear

replace tie rod end.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure. (See Air Conditioning

Refrigerant System Diagnosis)

19 - 4 STEERINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1433 of 1938

VEHICLE LEADS TO THE SIDE

POWER STEERING FLUID LEAK

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES NOT

WANT RETURN TO CENTER

POSITION.1. Radial tire lead. 1.Rotate tires as recommended in

the Tire And Wheel Group of this

service manual.

2. Front suspension misaligned. 2. Align the front suspension as

required. Refer to the Wheel

Alignment Procedure in the

Suspension Group of this service

manual for the required wheel

alignment procedure.

3. Wheel braking. 3. Check for dragging brakes. Refer

to the procedures in the Brake

Group of this service manual.

4. Unbalanced steering gear valve.

(If this is the cause, the steering

efforts will be very light in direction

of lead and heavier in the opposite

direction.4. Replace steering gear.

STEERING WHEEL HAS FORE

AND AFT LOOSENESS.1. Steering wheel to steering column

shaft retaining nut not properly

tightened and torqued.1. Tighten the retaining nut to its

specified torque specification.

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

3. Loose steering column to

instrument panel mounting nuts.3. Verify that the 4 mounting nuts for

the steering column are tightened to

the specified torque.

4. Binding intermediate steering

shaft coupler.4. Disconnect intermediate steering

coupler and see if looseness no

longer exists. If yes replace

intermendiate steering coupler.

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH: NO

VISIBLE SIGNS OF A LEAK ON

THE STEERING GEAR, POWER

STEERING PUMP, FLOOR OR

ANYWHERE ELSE.1. Overfilled power steering pump

fluid reservoir.1. Adjust the power steering fluid fill

to the correct level.

LOW FLUID LEVEL WITH:

VISIBLE LEAK ON STEERING

GEAR, POWER STEERING

PUMP, FLOOR OR ANYWHERE

ELSE.2. Power steering hose connections

at the power steering pump or

steering gear.2. Check for loose fittings and if

found, tighten the fitting to its

specified torque. If fittings are tight

examine the fittings for damaged or

missing O-ring seals and replace as

required.

3. Power steering pump or power

steering gear leaking.3. Identify the location of the leak

and repair or replace the component

as required. Refer to Power Steering

Pump and/or Power Steering Gear in

this group of the service manual for

required procedures.

NSSTEERING 19 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1435 of 1938

POWER STEERING PUMP

INDEX

page page

DESCRIPTION AND OPERATION

POWER STEERING PUMP OPERATION....... 9

DIAGNOSIS AND TESTING

POWER STEERING PUMP FLOW RATE AND

PRESSURE TEST....................... 9

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL

OPERATION.......................... 10

POWER STEERING SYSTEM FLUID LEVEL

CHECK.............................. 10

REMOVAL AND INSTALLATION

2.4 LITER POWER STEERING PUMP......... 11

3.0 LITER POWER STEERING PUMP........ 13

3.3/3.8 LITER POWER STEERING PUMP...... 16

POWER STEERING FLUID PRESSURE HOSE . . 19POWER STEERING FLUID RESERVOIR TO

PUMP SUPPLY HOSE................... 18

POWER STEERING FLUID RETURN HOSE.... 21

REMOTE POWER STEERING FLUID

RESERVOIR.......................... 22

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP FLOW CONTROL

VALVE SEAL.......................... 23

POWER STEERING PUMP PULLEY.......... 23

SPECIFICATIONS

POWER STEERING PUMP FASTENER

TORQUE SPECIFICATIONS.............. 24

POWER STEERING SYSTEM

SPECIFICATIONS...................... 24

SPECIAL TOOLS

POWER STEERING PUMP................. 25

DESCRIPTION AND OPERATION

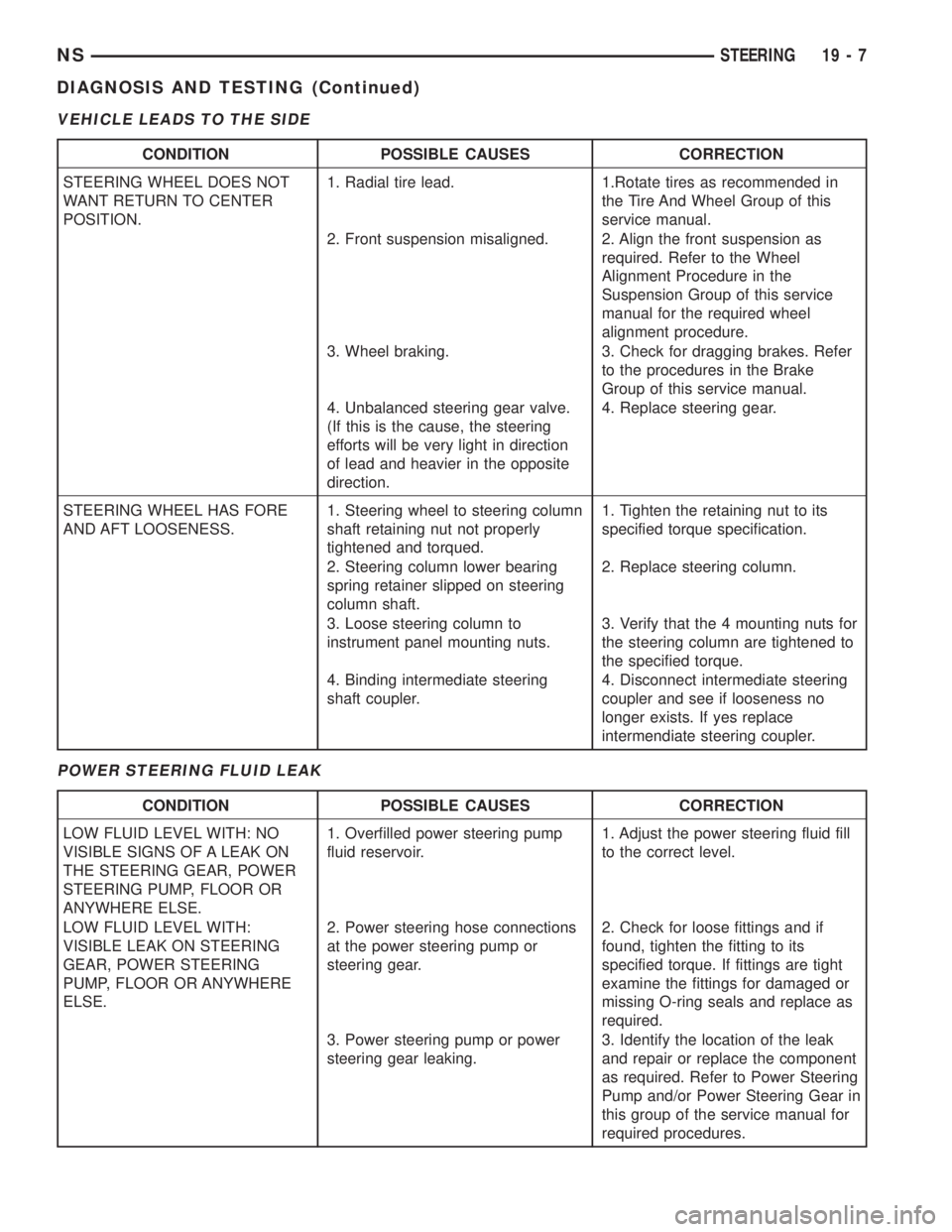

POWER STEERING PUMP OPERATION

Hydraulic pressure for the operation of the power

steering gear is provided by a belt driven power

steering pump (Fig. 1). The power steering pump is a

constant flow rate and displacement vane type pump.

The power steering pump used on all applications is

the Vane-Submerged remote reservoir style power

steering pump.

The remote reservoir type pump (Fig. 1) has the

pump housing and internal components combined

with the fluid housing. But it has a remote reservoir

for the power steering fluid supply.

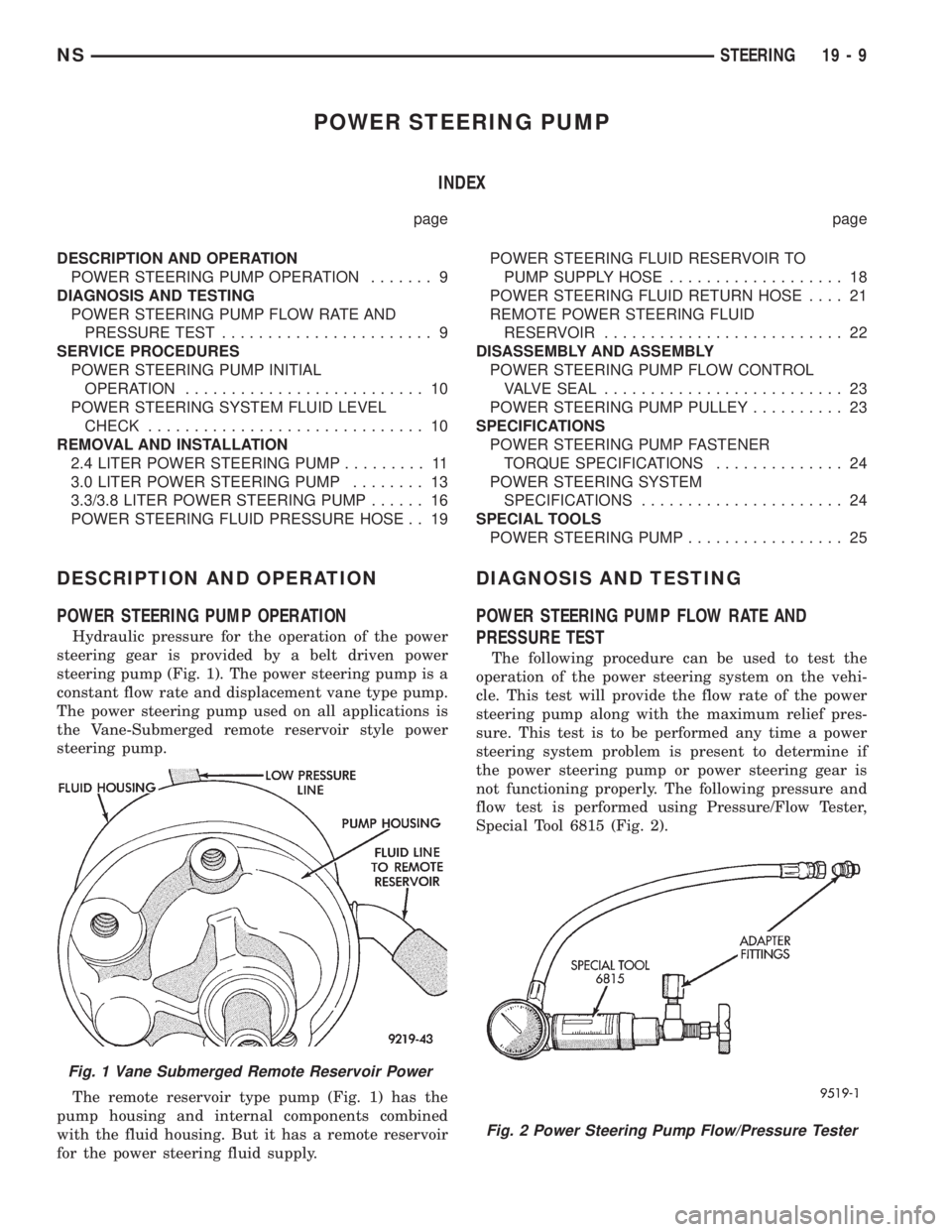

DIAGNOSIS AND TESTING

POWER STEERING PUMP FLOW RATE AND

PRESSURE TEST

The following procedure can be used to test the

operation of the power steering system on the vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed any time a power

steering system problem is present to determine if

the power steering pump or power steering gear is

not functioning properly. The following pressure and

flow test is performed using Pressure/Flow Tester,

Special Tool 6815 (Fig. 2).

Fig. 1 Vane Submerged Remote Reservoir Power

Fig. 2 Power Steering Pump Flow/Pressure Tester

NSSTEERING 19 - 9

Page 1436 of 1938

POWER STEERING PUMP FLOW AND

PRESSURE TEST PROCEDURE

(1) Check power steering pump drive belt tension

and adjust as necessary.

(2) Disconnect power steering fluid pressure hose,

at power steering pump. Use a container for dripping

fluid.

(3) Connect Pressure Gauge, Special Tool from kit

6815 to both hoses using adapter fittings. Connect

spare pressure hose, to power steering pump pres-

sure hose fitting.

(4) Completely open valve on Special Tool 6815.

(5) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

and get air out of fluid. Then shut off engine.

(6) Check power steering fluid level, and add fluid

as necessary. Start engine again and let idle.

(7) Pressure gauge should read below 862 kPa

(125 psi), if above, inspect the hoses for restrictions

and repair as necessary. The initial pressure reading

should be in the range of 345-552 kPa (50-80 psi).

The flow meter should read between 1.3 and 1.9

GPM

CAUTION: The following test procedure involves

testing power steering pump maximum pressure

output and flow control valve operation. Do not

leave valve closed for more than 5 seconds as the

pump could be damaged.

(8) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be within specifications and within

345 kPa (50 psi) of each other.

NOTE: Power steering pump maximum relief pres-

sure is 9653 to 10342 kPa (1400 to 1500 psi.).

²If power steering pump pressures are within the

specifications but not within 345 kPa (50 psi) of each

other, then replace power steering pump.

²If pressures are within 345 kPa (50 psi) of each

other but below specifications, then replace power

steering pump.

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

because, pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the

stops, recording the highest indicated pressure at

each position. Compare pressure gauge readings to

power steering pump specifications. If highest output

pressures are not the same against either stop, the

steering gear is leaking internally and must be

replaced.

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL CHECK

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt. Then check

fluid level. The dipstick should indicate COLD when

fluid is at normal ambient temperature, approxi-

mately 21ÉC to 27ÉC (70ÉF to 80ÉF). In all pumps add

fluid as necessary, use onlyMopar Power Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateFULL COLDwhen the

fluid is at normal temperature of approximately 21ÉC

to 27ÉC (70ÉF to 80ÉF).

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(2) Start the engine and let run for a few seconds.

Then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

19 - 10 STEERINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1437 of 1938

REMOVAL AND INSTALLATION

2.4 LITER POWER STEERING PUMP

REMOVE

WARNING: POWER STEERING OIL, ENGINE COM-

PONENTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Remove the (-) negative battery cable from the

battery and isolate cable.

(4) Remove the drive belt from the power steering

pump pulley. See Cooling, Group 7 for detailed

removal procedure.

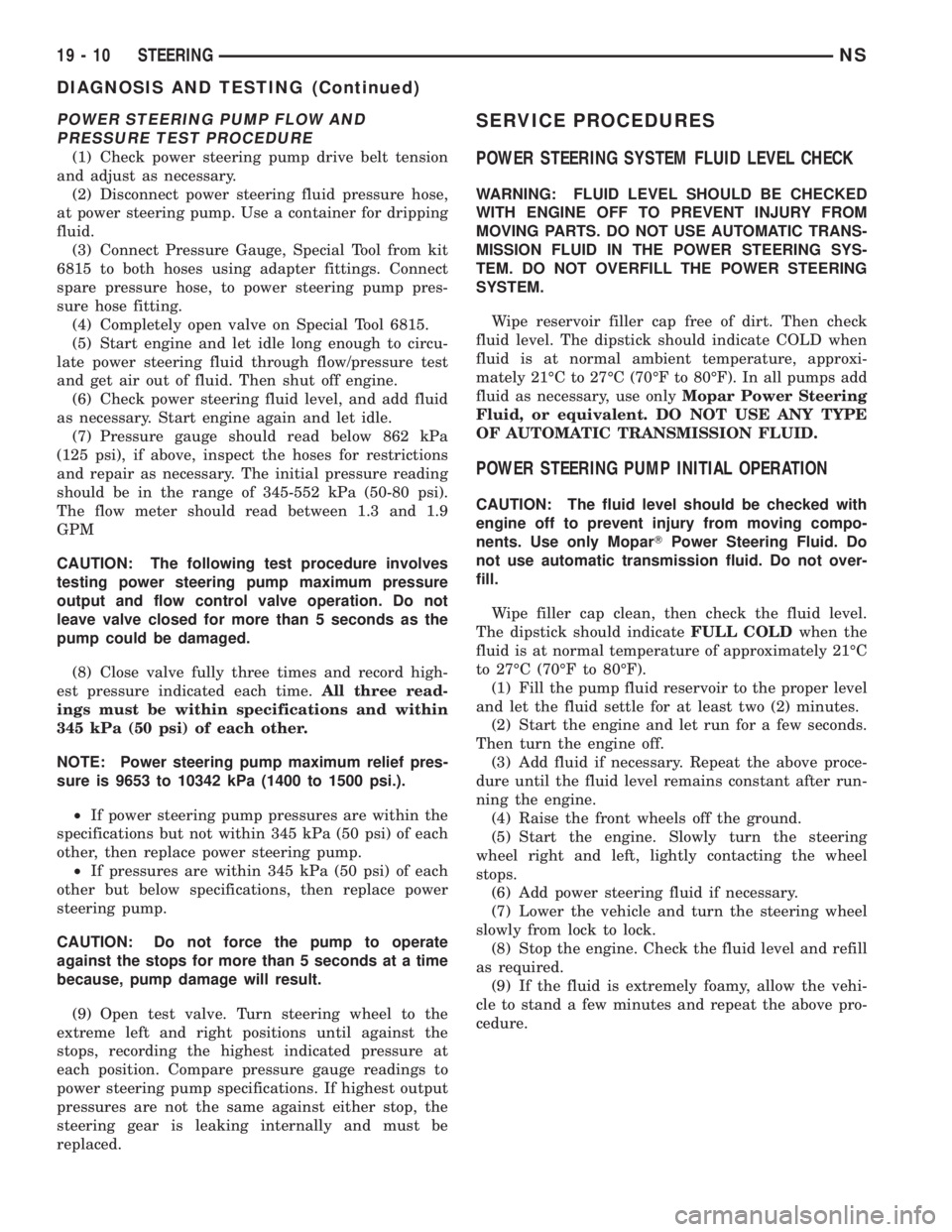

(5) Loosenbut do not removethe nut attaching

the front bracket for the power steering pump (Fig.

3) to the aluminum mounting bracket.

(6) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting, in the Lubri-

cation and Maintenance section of this service man-

ual for the required lifting procedure.

(7) Disconnect the oxygen sensor wiring harness

from the vehicle wiring harness. Access to connection

at vehicle wiring harness is through the oxygen sen-

sor wiring harness grommet in the floor pan of the

vehicle.

NOTE: The exhaust system needs to be removed

from the engine to allow for an area to remove the

power steering pump from the vehicle.(8) Remove the catalytic converter from the

exhaust manifold. Then remove all the exhaust sys-

tem hangers/isolators from the brackets on the

exhaust system.

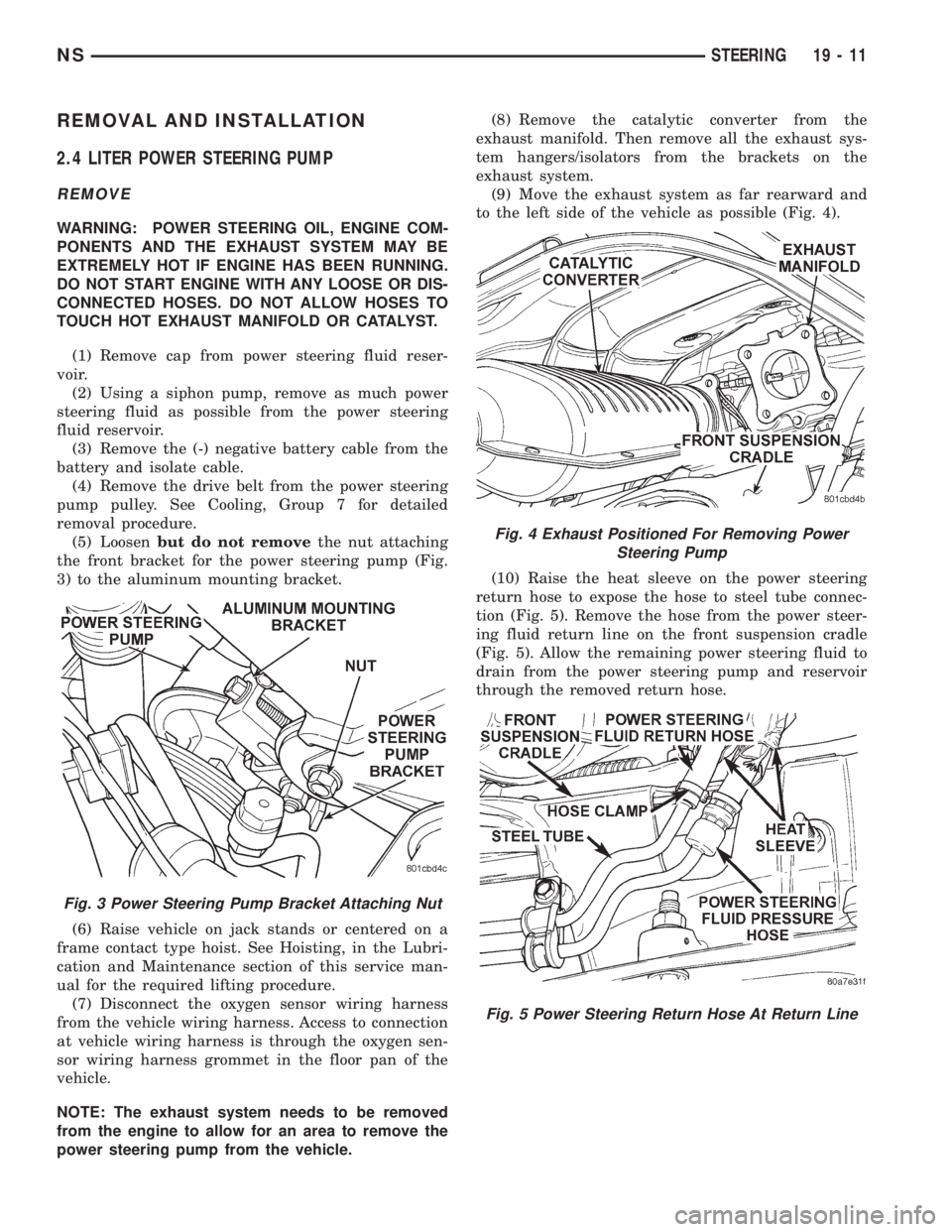

(9) Move the exhaust system as far rearward and

to the left side of the vehicle as possible (Fig. 4).

(10) Raise the heat sleeve on the power steering

return hose to expose the hose to steel tube connec-

tion (Fig. 5). Remove the hose from the power steer-

ing fluid return line on the front suspension cradle

(Fig. 5). Allow the remaining power steering fluid to

drain from the power steering pump and reservoir

through the removed return hose.

Fig. 3 Power Steering Pump Bracket Attaching Nut

Fig. 4 Exhaust Positioned For Removing Power

Steering Pump

Fig. 5 Power Steering Return Hose At Return Line

NSSTEERING 19 - 11

Page 1440 of 1938

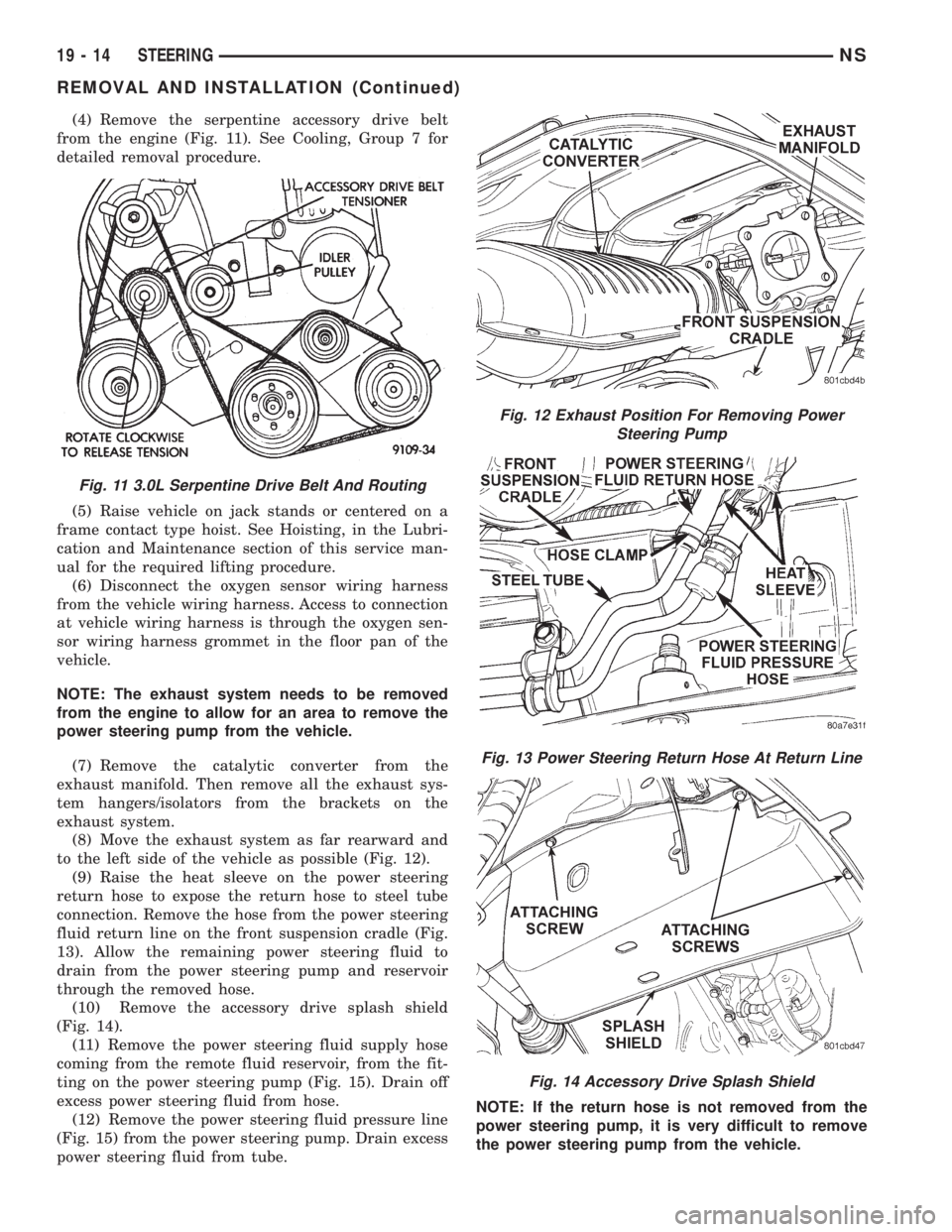

(4) Remove the serpentine accessory drive belt

from the engine (Fig. 11). See Cooling, Group 7 for

detailed removal procedure.

(5) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting, in the Lubri-

cation and Maintenance section of this service man-

ual for the required lifting procedure.

(6) Disconnect the oxygen sensor wiring harness

from the vehicle wiring harness. Access to connection

at vehicle wiring harness is through the oxygen sen-

sor wiring harness grommet in the floor pan of the

vehicle.

NOTE: The exhaust system needs to be removed

from the engine to allow for an area to remove the

power steering pump from the vehicle.

(7) Remove the catalytic converter from the

exhaust manifold. Then remove all the exhaust sys-

tem hangers/isolators from the brackets on the

exhaust system.

(8) Move the exhaust system as far rearward and

to the left side of the vehicle as possible (Fig. 12).

(9) Raise the heat sleeve on the power steering

return hose to expose the return hose to steel tube

connection. Remove the hose from the power steering

fluid return line on the front suspension cradle (Fig.

13). Allow the remaining power steering fluid to

drain from the power steering pump and reservoir

through the removed hose.

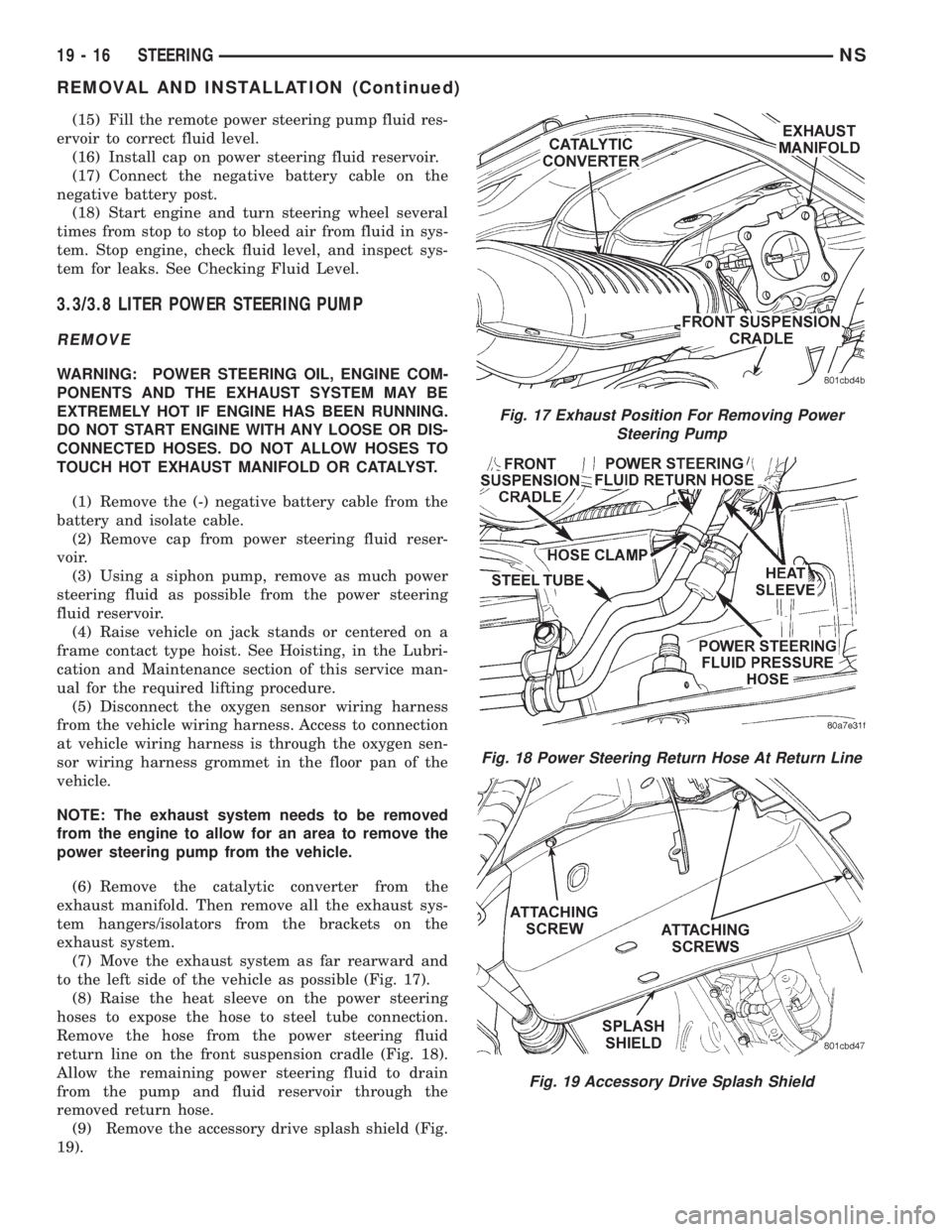

(10) Remove the accessory drive splash shield

(Fig. 14).

(11) Remove the power steering fluid supply hose

coming from the remote fluid reservoir, from the fit-

ting on the power steering pump (Fig. 15). Drain off

excess power steering fluid from hose.

(12) Remove the power steering fluid pressure line

(Fig. 15) from the power steering pump. Drain excess

power steering fluid from tube.NOTE: If the return hose is not removed from the

power steering pump, it is very difficult to remove

the power steering pump from the vehicle.

Fig. 11 3.0L Serpentine Drive Belt And Routing

Fig. 12 Exhaust Position For Removing Power

Steering Pump

Fig. 13 Power Steering Return Hose At Return Line

Fig. 14 Accessory Drive Splash Shield

19 - 14 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1442 of 1938

(15) Fill the remote power steering pump fluid res-

ervoir to correct fluid level.

(16) Install cap on power steering fluid reservoir.

(17) Connect the negative battery cable on the

negative battery post.

(18) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.3/3.8 LITER POWER STEERING PUMP

REMOVE

WARNING: POWER STEERING OIL, ENGINE COM-

PONENTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove cap from power steering fluid reser-

voir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(4) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting, in the Lubri-

cation and Maintenance section of this service man-

ual for the required lifting procedure.

(5) Disconnect the oxygen sensor wiring harness

from the vehicle wiring harness. Access to connection

at vehicle wiring harness is through the oxygen sen-

sor wiring harness grommet in the floor pan of the

vehicle.

NOTE: The exhaust system needs to be removed

from the engine to allow for an area to remove the

power steering pump from the vehicle.

(6) Remove the catalytic converter from the

exhaust manifold. Then remove all the exhaust sys-

tem hangers/isolators from the brackets on the

exhaust system.

(7) Move the exhaust system as far rearward and

to the left side of the vehicle as possible (Fig. 17).

(8) Raise the heat sleeve on the power steering

hoses to expose the hose to steel tube connection.

Remove the hose from the power steering fluid

return line on the front suspension cradle (Fig. 18).

Allow the remaining power steering fluid to drain

from the pump and fluid reservoir through the

removed return hose.

(9) Remove the accessory drive splash shield (Fig.

19).

Fig. 17 Exhaust Position For Removing Power

Steering Pump

Fig. 18 Power Steering Return Hose At Return Line

Fig. 19 Accessory Drive Splash Shield

19 - 16 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1445 of 1938

cation and Maintenance section of this service man-

ual, for the required lifting procedure to be used for

this vehicle.

(5) Remove at power steering pump, the power

steering fluid hose coming from the power steering

fluid reservoir. Let the power steering fluid drain out

of the reservoir and hose.

(6) Lower vehicle.

(7) Remove hose clamp attaching the power steer-

ing fluid supply hose to the power steering fluid res-

ervoir (Fig. 24).

(8) Remove the power steering fluid supply hose

from the vehicle. Hose is removed from the top of the

engine compartment.

INSTALL

CAUTION: On V-6 engine applications, the power

steering fluid reservoir to power steering hose must

be routed tightly against the strut tower and parallel

to the dash panel. It must also be routed under the

wiring harness and below the drip tube. This rout-

ing will prevent the power steering fluid supply

hose from coming in contact with the accessory

drive belt.

(1) Install and correctly route the power steering

fluid supply hose from remote fluid reservoir down to

power steering pump.

(2) Install the fluid supply hose onto the power

steering fluid reservoir (Fig. 24). Install the hose

clamp on the fluid supply hose.Be sure hose clamp

is installed past bead on fluid reservoir fitting.

(3) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this service man-

ual, for the required lifting procedure to be used for

this vehicle.

(4) Install power steering fluid supply hose on

power steering pump. Install the hose clamp on the

fluid supply hose.Be sure hose clamp is installed

past bead on pump fitting.

(5) Lower vehicle.

(6) Install routing clip on power steering fluid sup-

ply hose. Be sure routing clip is installed in a posi-

tion to correctly align with stud in strut tower.

(7) Install routing clip for power steering fluid sup-

ply hose on stud in strut tower (Fig. 25).

(8) Fill the remote fluid reservoir to the proper

level and let the fluid settle for at least two (2) min-

utes.

(9) Start the engine and let run for a few seconds.

Then turn the engine off.

(10) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(11) Raise the front wheels off the ground.(12) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(13) Add power steering fluid if necessary.

(14) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(15) Stop the engine. Check the fluid level and

refill as required.

(16) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

POWER STEERING FLUID PRESSURE HOSE

Service all power steering hoses with vehicle raised

on hoist. Cap all open ends of hoses, power steering

pump fittings and steering gear ports to prevent

entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE

PARTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

For part reference and part location for the vehicle

that is being serviced, refer to the following figure

numbers. These show the hose bracket locations,

hose routings and fitting locations by the engine

application of the vehicle. Use these figure numbers

when referring to the removal or installation proce-

dures for the power steering hoses listed below.

REMOVE

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering fluid.

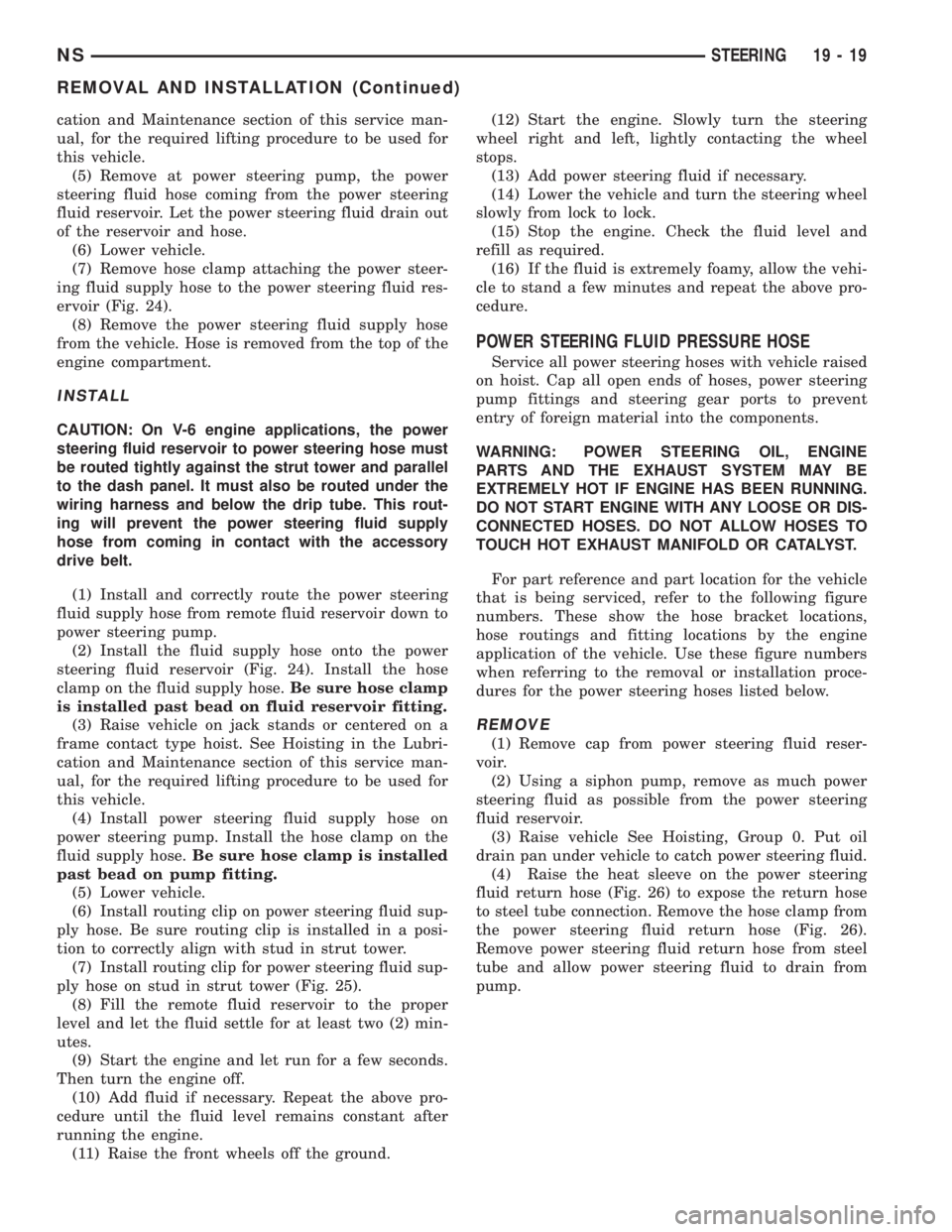

(4) Raise the heat sleeve on the power steering

fluid return hose (Fig. 26) to expose the return hose

to steel tube connection. Remove the hose clamp from

the power steering fluid return hose (Fig. 26).

Remove power steering fluid return hose from steel

tube and allow power steering fluid to drain from

pump.

NSSTEERING 19 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1447 of 1938

(6) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

26).

(7) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat sleeves must cover

the entire rubber hose and hose to tube connection

portion of both the power steering fluid pressure

and return hoses (Fig. 26).

(8) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(9) After hoses are installed and power steering

system is filled with fluid and cap is installed on res-

ervoir. Start the engine and check for leaks. (See

Pump Installation).

POWER STEERING FLUID RETURN HOSE

Service all power steering hoses with vehicle raised

on hoist. Cap all open ends of hoses, power steering

pump fittings and steering gear ports to prevent

entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE

PARTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

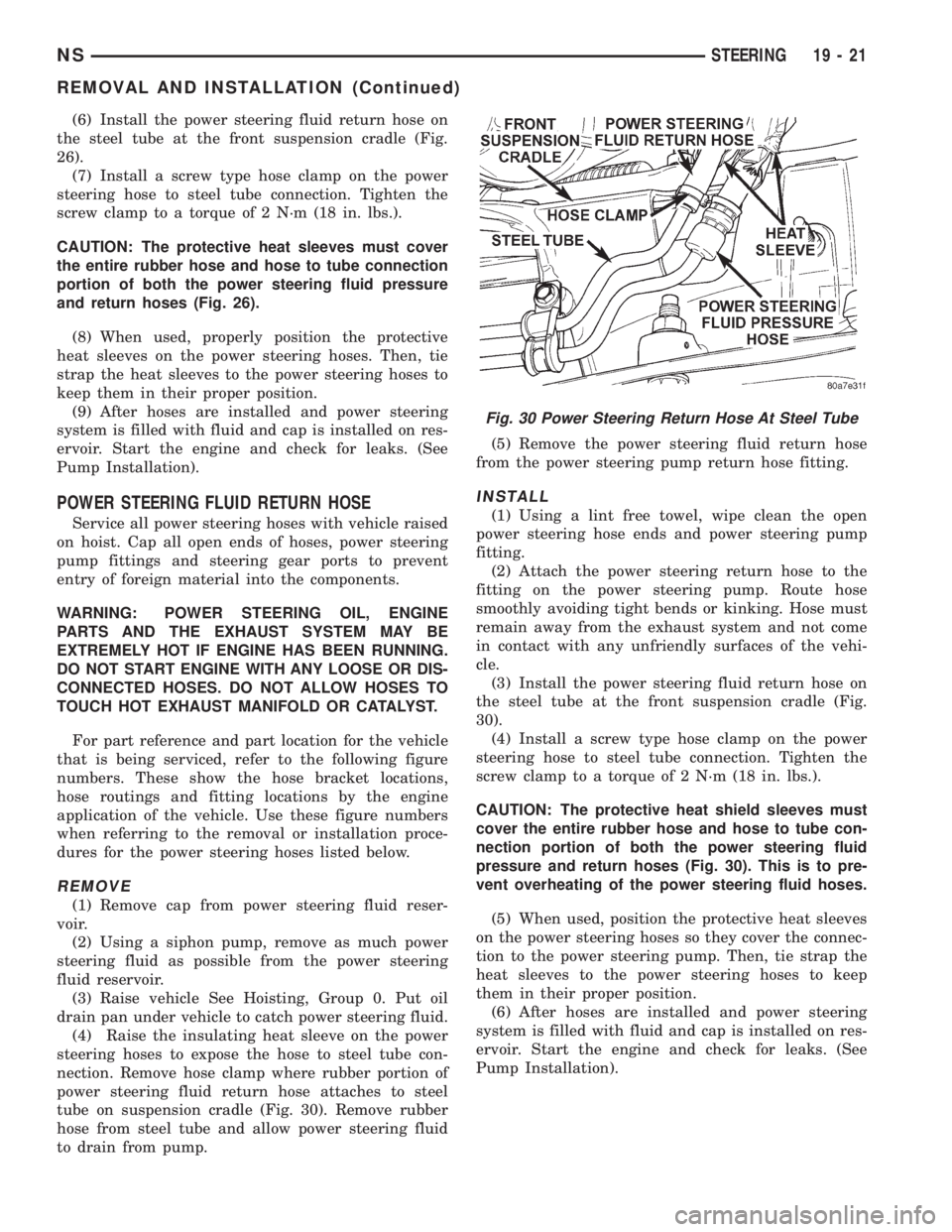

For part reference and part location for the vehicle

that is being serviced, refer to the following figure

numbers. These show the hose bracket locations,

hose routings and fitting locations by the engine

application of the vehicle. Use these figure numbers

when referring to the removal or installation proce-

dures for the power steering hoses listed below.

REMOVE

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering fluid.

(4) Raise the insulating heat sleeve on the power

steering hoses to expose the hose to steel tube con-

nection. Remove hose clamp where rubber portion of

power steering fluid return hose attaches to steel

tube on suspension cradle (Fig. 30). Remove rubber

hose from steel tube and allow power steering fluid

to drain from pump.(5) Remove the power steering fluid return hose

from the power steering pump return hose fitting.

INSTALL

(1) Using a lint free towel, wipe clean the open

power steering hose ends and power steering pump

fitting.

(2) Attach the power steering return hose to the

fitting on the power steering pump. Route hose

smoothly avoiding tight bends or kinking. Hose must

remain away from the exhaust system and not come

in contact with any unfriendly surfaces of the vehi-

cle.

(3) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

30).

(4) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 30). This is to pre-

vent overheating of the power steering fluid hoses.

(5) When used, position the protective heat sleeves

on the power steering hoses so they cover the connec-

tion to the power steering pump. Then, tie strap the

heat sleeves to the power steering hoses to keep

them in their proper position.

(6) After hoses are installed and power steering

system is filled with fluid and cap is installed on res-

ervoir. Start the engine and check for leaks. (See

Pump Installation).

Fig. 30 Power Steering Return Hose At Steel Tube

NSSTEERING 19 - 21

REMOVAL AND INSTALLATION (Continued)