sensor CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1548 of 1938

TORQUE MANAGEMENT

Most 41TE transaxles utilize torque management.

Torque management is a unique function of the Pow-

ertrain Control Module (PCM). The PCM receives

output signals from the Transmission Control Module

(TCM) and many various engine sensors. The PCM

evaluates these signals and decides if it is necessary

to decrease the output of the engine's torque. This

reduction in torque does not interfere with the nor-

mal operation of the vehicle. This reduction in torque

will prolong the life of the drivetrain components.

Torque reduction is not noticeable in normal driving

functions. The torque reduction function shuts off

above 16 MPH.

ON-BOARD DIAGNOSTICS

This vehicle utilizes a diagnostic system called

OBDII. The powertrain control module communicates

with the Transmission Control Module. Whenever

the transaxle sets a fault in the Transmission Con-

trol Module (dependent on which fault is set), the

powertrain control module will turn on a MIL (Mal-

function Indicator Lamp) on the instrument cluster.

By reading the code in the powertrain control module

it will tell you where the fault occurred. If the fault

occurred in the transaxle, the controller will read a

CODE 45.For further information regarding OBDII,

refer to Group 25, Emission Systems.

These controls provide comprehensive, on-board

transaxle diagnostics. The information available can

aid in transaxle diagnosis. For example, apply ele-

ment buildup rate indicates solenoid performance.

Also included are self diagnostic functions. Self diag-

nostics allow the technician to test the condition of

the electronic controls. The Transmission Control

Module continuously monitors its critical functions. It

also records any malfunctions, and the number of

engine starts since the last malfunction. This allows

the technician to use the information in the event of

a customer complaint.

TRANSMISSION CONTROL MODULE

Do not interchange Transmission Control Modules

with previous year transmission control modules. If a

same year TCM is being used from a different vehi-

cle, the following procedures must be performed:

²Quick Learn Procedure

²Electronic Pinion Factor Procedure

The Transmission Control Module is located on the

right inner fender panel, in the engine compartment.

It is held in place by four mounting screws.NOTE: If the Transmission Control Module has

been replaced, the following procedures must be

performed:

²Quick Learn Procedure: This procedure will

allow the transmission control module to learn the

characteristics of the vehicle.

²Electronic Pinion Factor Procedure: This proce-

dure will reprogram the TCM to compensate for dif-

ferent tire sizes and final drive ratios.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by a lever type gear-

shift incorporated within the steering column. The

control has six selector lever positions: P (park), R

(reverse), N (neutral), and D (drive), 2 (second), and

1 (first). The parking lock is applied by moving the

selector lever past a gate to the P position.Do not

apply the parking lock until the vehicle has

stopped; otherwise, a severe ratchet noise will

occur.

TRANSMISSION RANGE SENSOR

The 41TE transaxle is equipped with a transmis-

sion range sensor that is located on top of the valve

body. This sensor will allow for accurate transmission

gear position measurement.

To service the transmission range sensor (TRS),

you must remove the valve body. For repair proce-

dures, refer to the Removal and Installation section

within this group.

Also located within the TRS is a transmission tem-

perature sensor. This sensor is used to measure the

transmission fluid sump temperature. The transmis-

sion temperature sensor is serviced with the TRS as

a unit.

SHIFT POSITION INDICATOR

The shifter position indicator is located in the

instrument cluster. The shifter position indicator out-

lines with a box the gear position the transaxle man-

ual valve lever is in.

The transmission range sensor (located on the

valvebody) sends a signal to the TCM on the position

of the transaxle manual valve lever. The TCM

receives the switch signal and processes the data.

The TCM sends the Shift Lever Position (SLP) infor-

mation to the BCM via the CCD bus. The BCM then

outlines with a box the appropriate shifter position

indicator in the instrument cluster.

To replace the shifter position indicator, refer to

Group 8E, Instrument Panel And Gauges.

21 - 74 TRANSAXLE AND POWER TRANSFER UNITNS

DESCRIPTION AND OPERATION (Continued)

Page 1552 of 1938

REVERSE CLUTCH

Apply air pressure to the reverse clutch apply pas-

sage and watch for the push/pull piston to move rear-

ward. The piston should return to its starting

position when the air pressure is removed.

2/4 CLUTCH

Apply air pressure to the feed hole located on the

2/4 clutch retainer. Look in the area where the 2/4

piston contacts the first separator plate and watch

carefully for the 2/4 piston to move rearward. The

piston should return to its original position after the

air pressure is removed.

LOW/REVERSE CLUTCH

Apply air pressure to the low/reverse clutch feed

hole (rear of case, between 2 bolt holes). Then, look

in the area where the low/reverse piston contacts thefirst separator plate. Watch carefully for the piston to

move forward. The piston should return to its origi-

nal position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks the

output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not

rotate with hand torque. Release the air pressure

and confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

(2) Fluid leakage at or around the torque converter

area may originate from an engine oil leak. The area

should be examined closely. Factory fill fluid is red

and, therefore, can be distinguished from engine oil.

(3) Prior to removing the transaxle, perform the

following checks:

(4) When leakage is determined to originate from

the transaxle, check fluid level prior to removal of

the transaxle and torque converter.

(5) High oil level can result in oil leakage out the

vent in the manual shaft. If the fluid level is high,

adjust to proper level.

(6) After performing this operation, inspect for

leakage. If a leak persists, perform the following

operation on the vehicle. This will determine if the

torque converter or transaxle is leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside

(peripheral) weld.

²Torque converter hub weld.

NOTE: Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

SHIFT POSITION INDICATOR

The transmission range sensor (on the valve body)

sends a signal to the TCM on the position of the

transaxle manual valve lever. The TCM receives the

switch signal and processes the data. The TCM sends

the Shift Lever Position (SLP) information to the

BCM via the CCD bus. The BCM then outlines with

a box the appropriate shifter position indicator in the

instrument cluster.

Fig. 3 Air Pressure Test Plate

Fig. 4 Testing Reverse Clutch

21 - 78 TRANSAXLE AND POWER TRANSFER UNITNS

DIAGNOSIS AND TESTING (Continued)

Page 1553 of 1938

If a problem arises with the shifter position indica-

tor, consult the following chart for diagnostic infor-

mation. If the malfunction cannot be corrected using

the chart, consult the proper diagnostic manual.

To replace the shifter position indicator, refer to

Group 8E, Instrument Panel And Gauges.SERVICE PROCEDURES

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only fluids

labeled MOPARtATF PLUS 3 (Automatic Transmis-

sion fluid) Type 7176 should be used.

If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

30,000 MILE TRANSAXLE OIL CHANGE

When a vehicle attains 30,000 miles on its odome-

ter it is recommended that the transaxle oil be

changed. To change the oil, use the procedure that

follows:

It is recommended that a transaxle fluid exchanger

(ATF 2000+ or equivalent) be used to replace the

used fluid in the transaxle. If a fluid exchanger is not

available use a fluid suction pump (Vaculayor equiv-

alent) to draw the fluid out of the dipstick tube. If a

fluid suction pump is not available remove the oil

pan and drain the fluid.

CAUTION: Chrysler Corporation does not recom-

mend using any fluid exchanger that introduces

additives into the transaxle.

TRANSAXLE FLUID EXCHANGER METHOD

(1) To perform the transaxle fluid exchange, the

transaxle must be at operating temperature. Drive

the vehicle till it reaches full operating temperature.

(2) Verify that the fill tank on the transaxle fluid

exchanger (ATF 2000+ or equivalent) is clean and

dry.

(3) Fill the tank to the recommended fill capacity

with Mopar ATF Plus 3 Type 7176.

(4) Hookup the vehicle to the machine following

the manufacturers instructions. Perform the

exchange procedure following the instructions pro-

vided with the machine.

(5) Once machine has completed the fluid

exchange. Check the fluid level and condition and fill

to proper level with Mopar ATF Plus 3 Type 7176.

NOTE: Verify that the transaxle cooler lines are

tightened to proper specifications. Cooler line

torque specification is 2 N´m (18 in. lbs.).

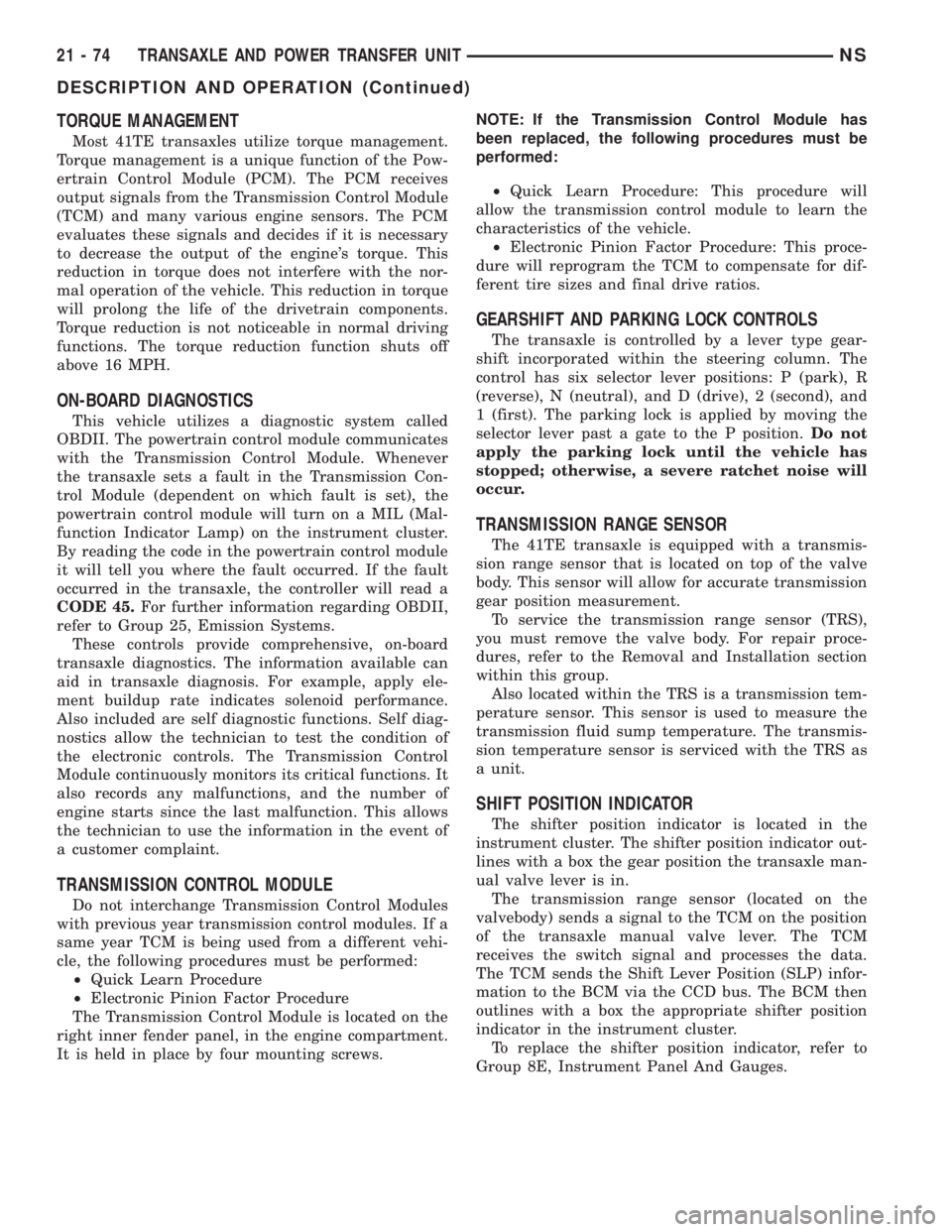

CONDITION POSSIBLE CAUSE

ALL PRND3L DISPLAY

LIGHTS9ON9IN P&N

GEAR POSITIONS1.Check wiring and

connectors

2. Faulty trans. range

sensor

3. Faulty manual lever

ALL DISPLAY LIGHTS

9ON9IN ALL GEAR

POSITIONS1. Check wiring &

connectors

2. Faulty trans. range

sensor

3. Faulty manual lever

4. CCD communication

malfunction

5. Check oil level

ALL DISPLAY LIGHTS

9OFF91. Normal transient

condition between P&R

and R&N gear positions

2. Check shift lever

linkage

3. Body controller

malfunction

4. Check wiring and

connectors

5. Faulty cluster

ALL DISPLAY LIGHTS

9OFF9ACCOMPANIED

BY A9NO BUS9

MESSAGE1. CCD communication

malfunction

DISPLAY LIGHTS OUT

OF SEQUENCE WITH

SHIFT LEVER1. Check wiring and

connectors

2. Faulty trans. range

sensor

3. Faulty manual lever

4. CCD communication

malfunction

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 79

DIAGNOSIS AND TESTING (Continued)

Page 1557 of 1938

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRBIII

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

(1) Plug the DRBIII scan tool into the data link

connector. The connector is located under the instru-

ment panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRBIII to perform the Quick

Learn Procedure.

PINION FACTOR PROCEDURE

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The TCM must

be calibrated to the different combinations of equip-

ment available. A procedure has been developed

called Pinion Factor. It allows the technician to set

the Transmission Control Module initial setting so

that the speedometer readings will be correct.

Failure to perform this procedure will cause a No

Speedometer Operation condition.

This procedure must be performed if the Transmis-

sion Control Module has been replaced.

To properly read or reset the Pinion Factor, it is

necessary to use a DRBIII scan tool. Perform the fol-

lowing steps with the DRBIII scan tool to read or

reset the Pinion Factor:

(1) Plug the DRBIII scan tool into the data link

connector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRBIII scan tool screen.

REMOVAL AND INSTALLATION

GEARSHIFT CABLE

REMOVAL

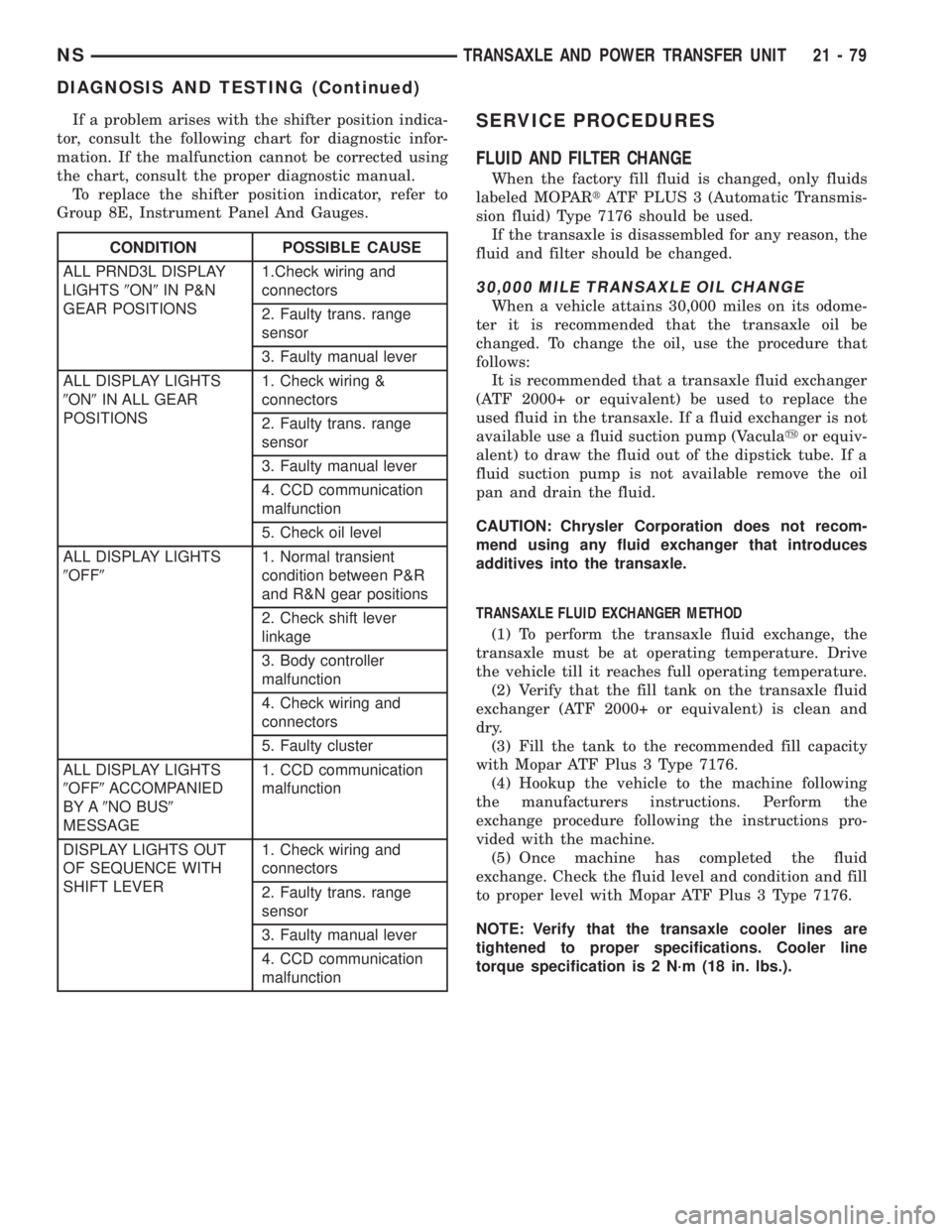

(1) Remove cable eyelet attachment from transaxle

operating lever pin (Fig. 6).

(2) Using pliers, squeeze ears of cable conduit

attachment at mounting bracket (Fig. 7) and push

through hole to remove (Fig. 8).

(3) Remove the under instrument panel silencer

(Fig. 9). Refer to Group 8E, Instrument Panel And

Gauges for more information.

(4) At the steering column attachment, remove the

cable eyelet attachment from the shift lever pin.(5) Using pliers, squeeze ears of cable attachment

at mounting bracket then push through hole to

remove.

(6) Unseat the dash grommet and remove the

cable from the vehicle.

INSTALLATION

(1) Install cable into steering column attachment

bracket. Verify conduit ears are fully engaged. Verify

cable does not interfere with brake pedal actuation.

(2) Attach cable eyelet fitting onto shift lever pin.

(3) Insert transaxle end of cable through dash

panel hole and fully seat grommet.

(4) Install instrument panel silencer. Verify gear-

shift cable is routed through the slot in the silencer.

CAUTION: Failure to route the cable properly at the

silencer may cause brake pedal interference.

(5) Attach transaxle end of cable to the mounting

bracket on the transaxle. Assure the conduit attach-

ment ears are fully seated.

Fig. 6 Gearshift Cable

Fig. 7 Grommet Clips

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 83

SERVICE PROCEDURES (Continued)

Page 1559 of 1938

SOLENOID ASSEMBLY-REPLACE

To install solenoid assembly, reverse removal pro-

cedure. Tighten screws to 12 N´m (105 in. lbs.).

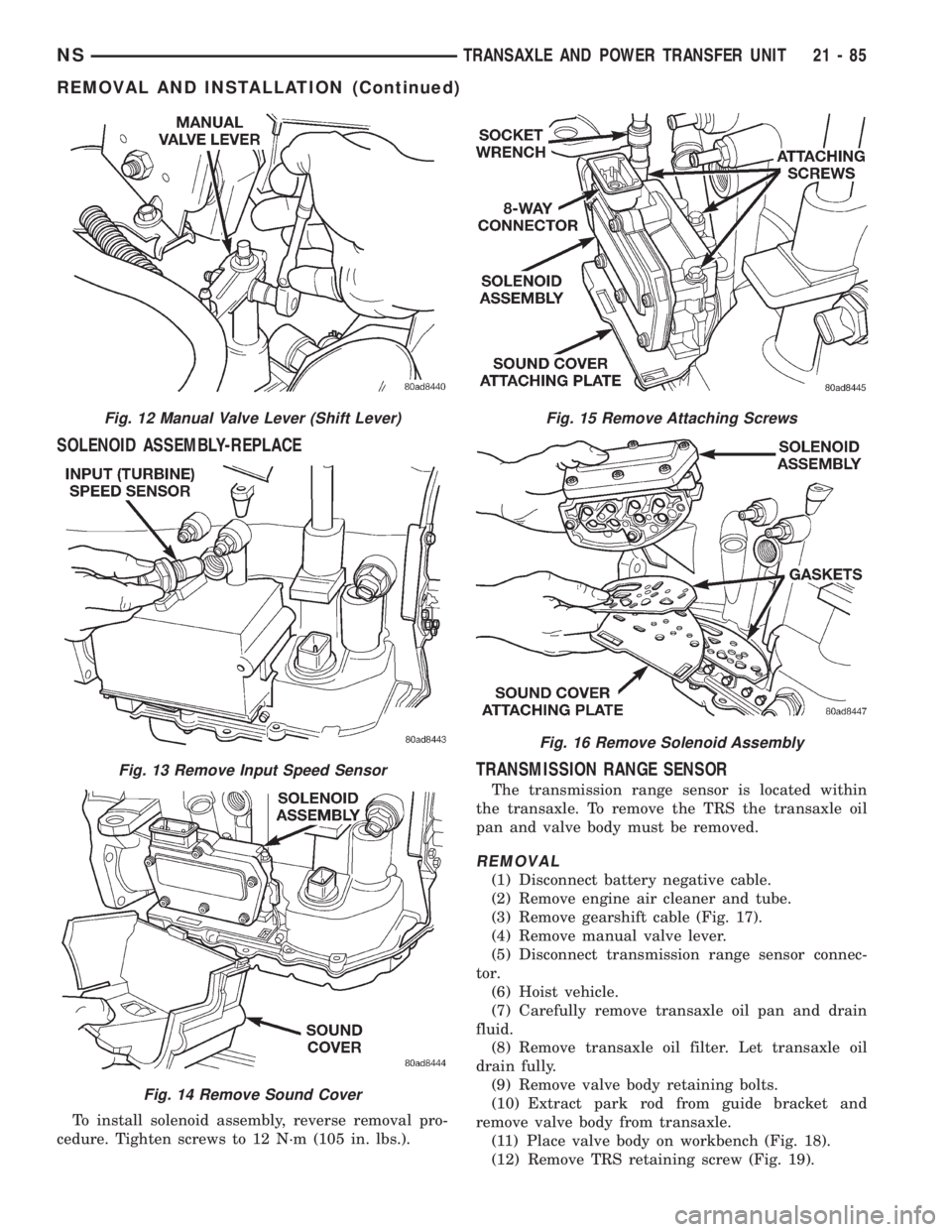

TRANSMISSION RANGE SENSOR

The transmission range sensor is located within

the transaxle. To remove the TRS the transaxle oil

pan and valve body must be removed.

REMOVAL

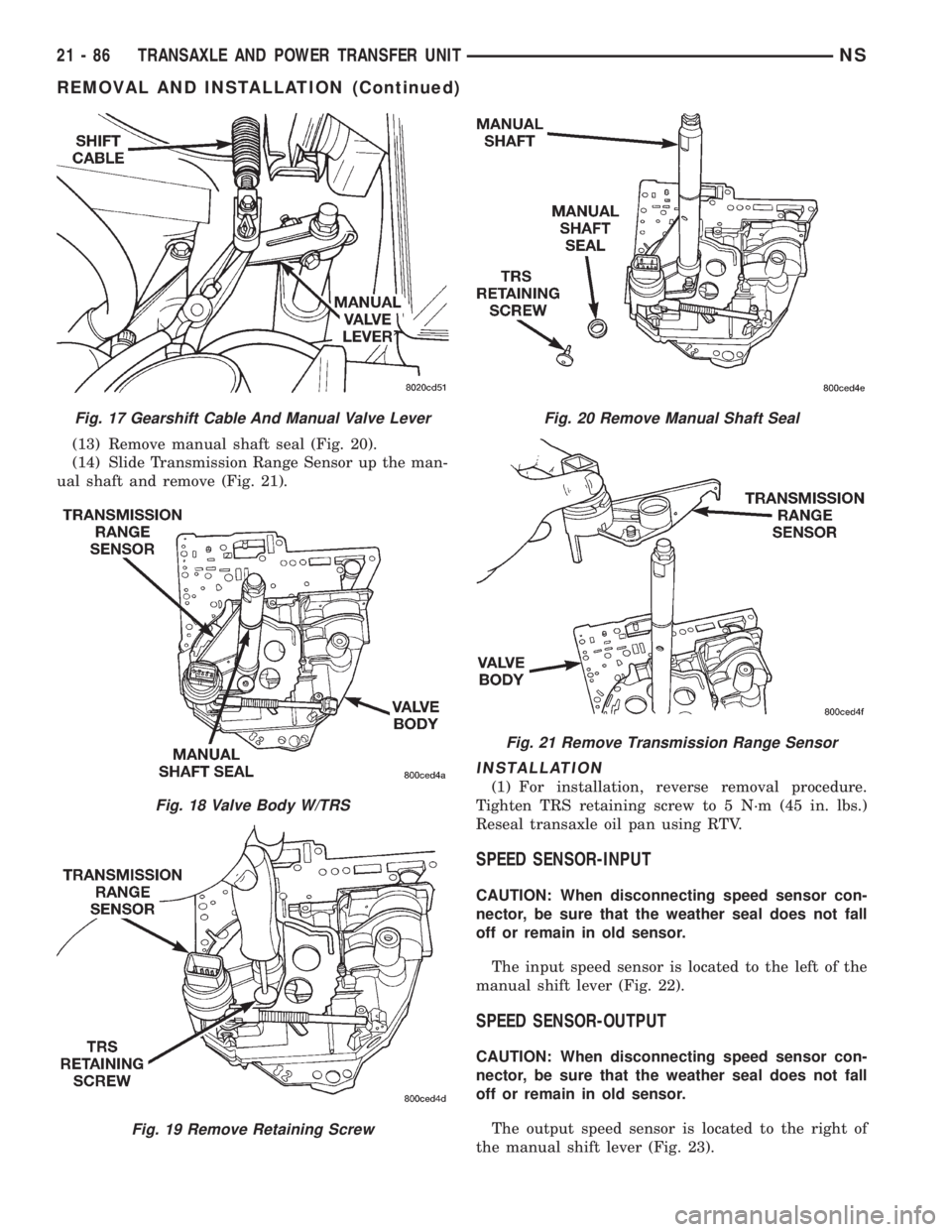

(1) Disconnect battery negative cable.

(2) Remove engine air cleaner and tube.

(3) Remove gearshift cable (Fig. 17).

(4) Remove manual valve lever.

(5) Disconnect transmission range sensor connec-

tor.

(6) Hoist vehicle.

(7) Carefully remove transaxle oil pan and drain

fluid.

(8) Remove transaxle oil filter. Let transaxle oil

drain fully.

(9) Remove valve body retaining bolts.

(10) Extract park rod from guide bracket and

remove valve body from transaxle.

(11) Place valve body on workbench (Fig. 18).

(12) Remove TRS retaining screw (Fig. 19).

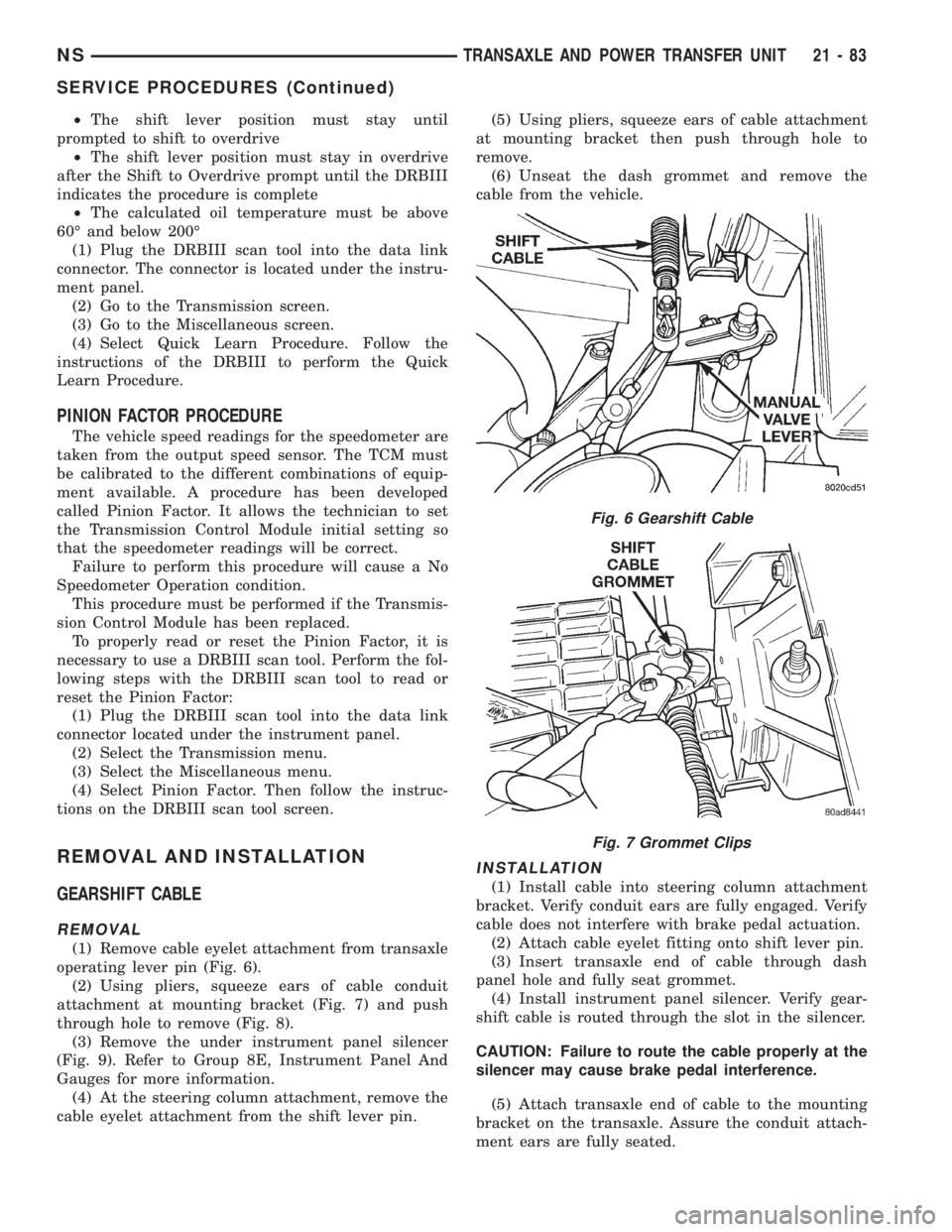

Fig. 12 Manual Valve Lever (Shift Lever)

Fig. 13 Remove Input Speed Sensor

Fig. 14 Remove Sound Cover

Fig. 15 Remove Attaching Screws

Fig. 16 Remove Solenoid Assembly

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 85

REMOVAL AND INSTALLATION (Continued)

Page 1560 of 1938

(13) Remove manual shaft seal (Fig. 20).

(14) Slide Transmission Range Sensor up the man-

ual shaft and remove (Fig. 21).

INSTALLATION

(1) For installation, reverse removal procedure.

Tighten TRS retaining screw to 5 N´m (45 in. lbs.)

Reseal transaxle oil pan using RTV.

SPEED SENSOR-INPUT

CAUTION: When disconnecting speed sensor con-

nector, be sure that the weather seal does not fall

off or remain in old sensor.

The input speed sensor is located to the left of the

manual shift lever (Fig. 22).

SPEED SENSOR-OUTPUT

CAUTION: When disconnecting speed sensor con-

nector, be sure that the weather seal does not fall

off or remain in old sensor.

The output speed sensor is located to the right of

the manual shift lever (Fig. 23).

Fig. 17 Gearshift Cable And Manual Valve Lever

Fig. 18 Valve Body W/TRS

Fig. 19 Remove Retaining Screw

Fig. 20 Remove Manual Shaft Seal

Fig. 21 Remove Transmission Range Sensor

21 - 86 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1561 of 1938

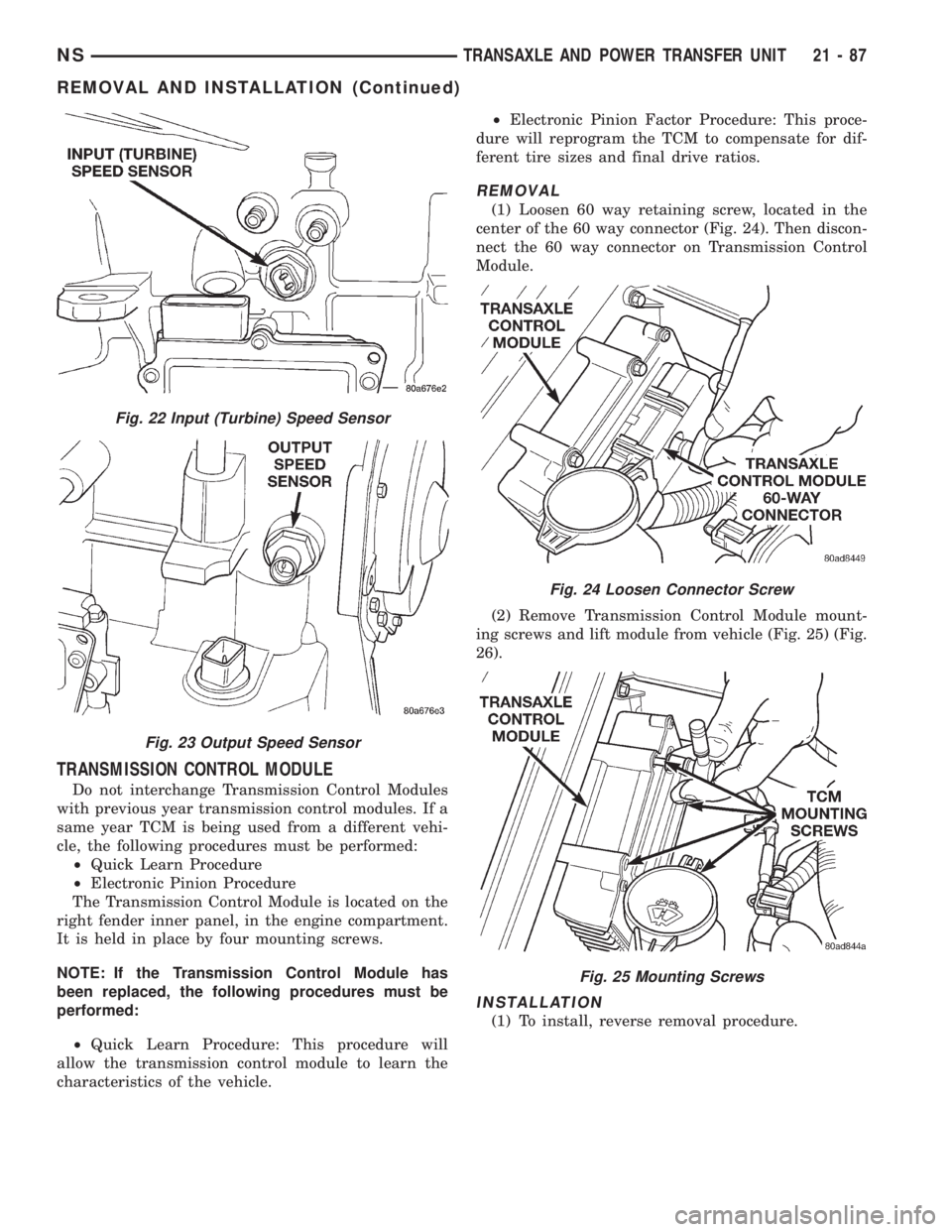

TRANSMISSION CONTROL MODULE

Do not interchange Transmission Control Modules

with previous year transmission control modules. If a

same year TCM is being used from a different vehi-

cle, the following procedures must be performed:

²Quick Learn Procedure

²Electronic Pinion Procedure

The Transmission Control Module is located on the

right fender inner panel, in the engine compartment.

It is held in place by four mounting screws.

NOTE: If the Transmission Control Module has

been replaced, the following procedures must be

performed:

²Quick Learn Procedure: This procedure will

allow the transmission control module to learn the

characteristics of the vehicle.²Electronic Pinion Factor Procedure: This proce-

dure will reprogram the TCM to compensate for dif-

ferent tire sizes and final drive ratios.

REMOVAL

(1) Loosen 60 way retaining screw, located in the

center of the 60 way connector (Fig. 24). Then discon-

nect the 60 way connector on Transmission Control

Module.

(2) Remove Transmission Control Module mount-

ing screws and lift module from vehicle (Fig. 25) (Fig.

26).

INSTALLATION

(1) To install, reverse removal procedure.

Fig. 22 Input (Turbine) Speed Sensor

Fig. 23 Output Speed Sensor

Fig. 24 Loosen Connector Screw

Fig. 25 Mounting Screws

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 87

REMOVAL AND INSTALLATION (Continued)

Page 1563 of 1938

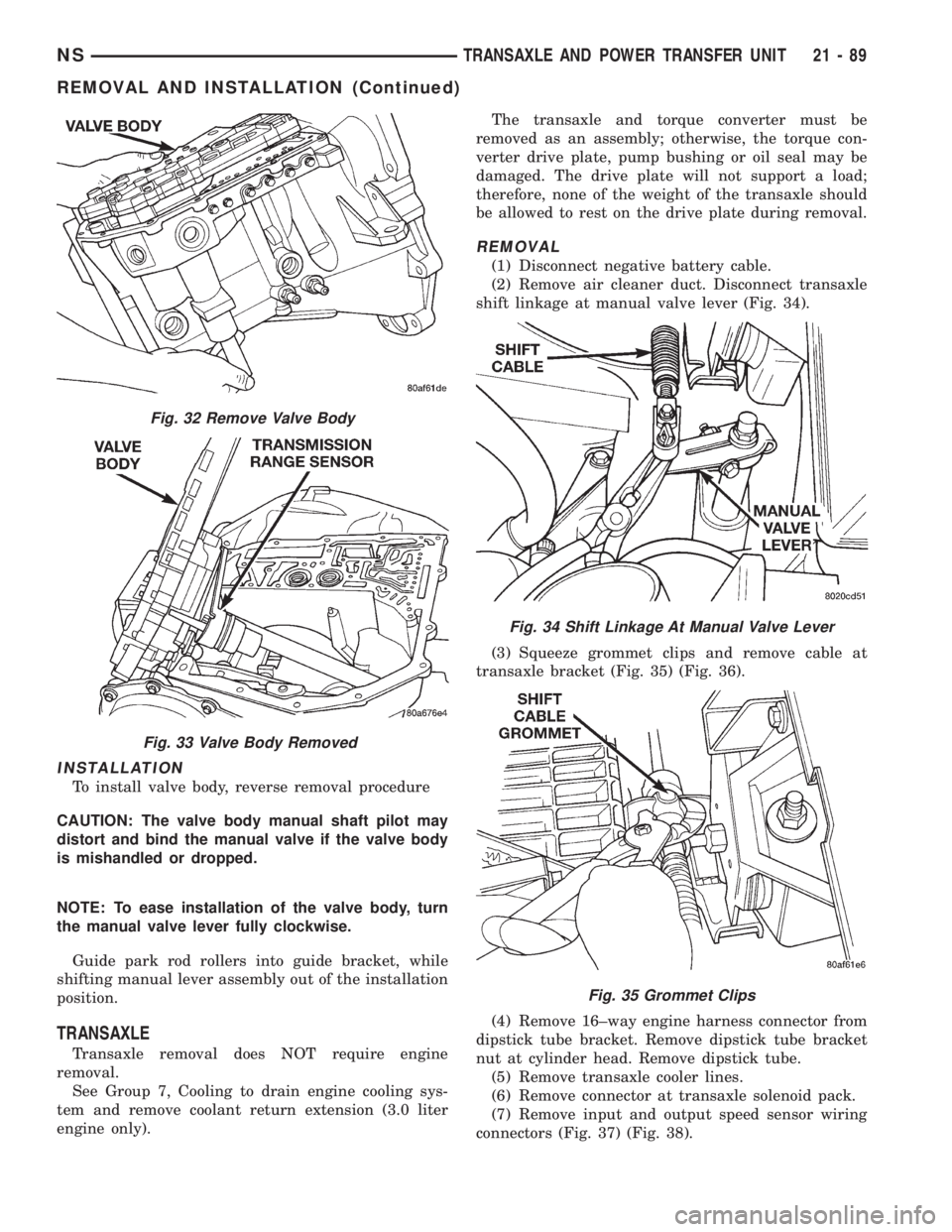

INSTALLATION

To install valve body, reverse removal procedure

CAUTION: The valve body manual shaft pilot may

distort and bind the manual valve if the valve body

is mishandled or dropped.

NOTE: To ease installation of the valve body, turn

the manual valve lever fully clockwise.

Guide park rod rollers into guide bracket, while

shifting manual lever assembly out of the installation

position.

TRANSAXLE

Transaxle removal does NOT require engine

removal.

See Group 7, Cooling to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only).The transaxle and torque converter must be

removed as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner duct. Disconnect transaxle

shift linkage at manual valve lever (Fig. 34).

(3) Squeeze grommet clips and remove cable at

transaxle bracket (Fig. 35) (Fig. 36).

(4) Remove 16±way engine harness connector from

dipstick tube bracket. Remove dipstick tube bracket

nut at cylinder head. Remove dipstick tube.

(5) Remove transaxle cooler lines.

(6) Remove connector at transaxle solenoid pack.

(7) Remove input and output speed sensor wiring

connectors (Fig. 37) (Fig. 38).

Fig. 32 Remove Valve Body

Fig. 33 Valve Body Removed

Fig. 34 Shift Linkage At Manual Valve Lever

Fig. 35 Grommet Clips

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 89

REMOVAL AND INSTALLATION (Continued)

Page 1564 of 1938

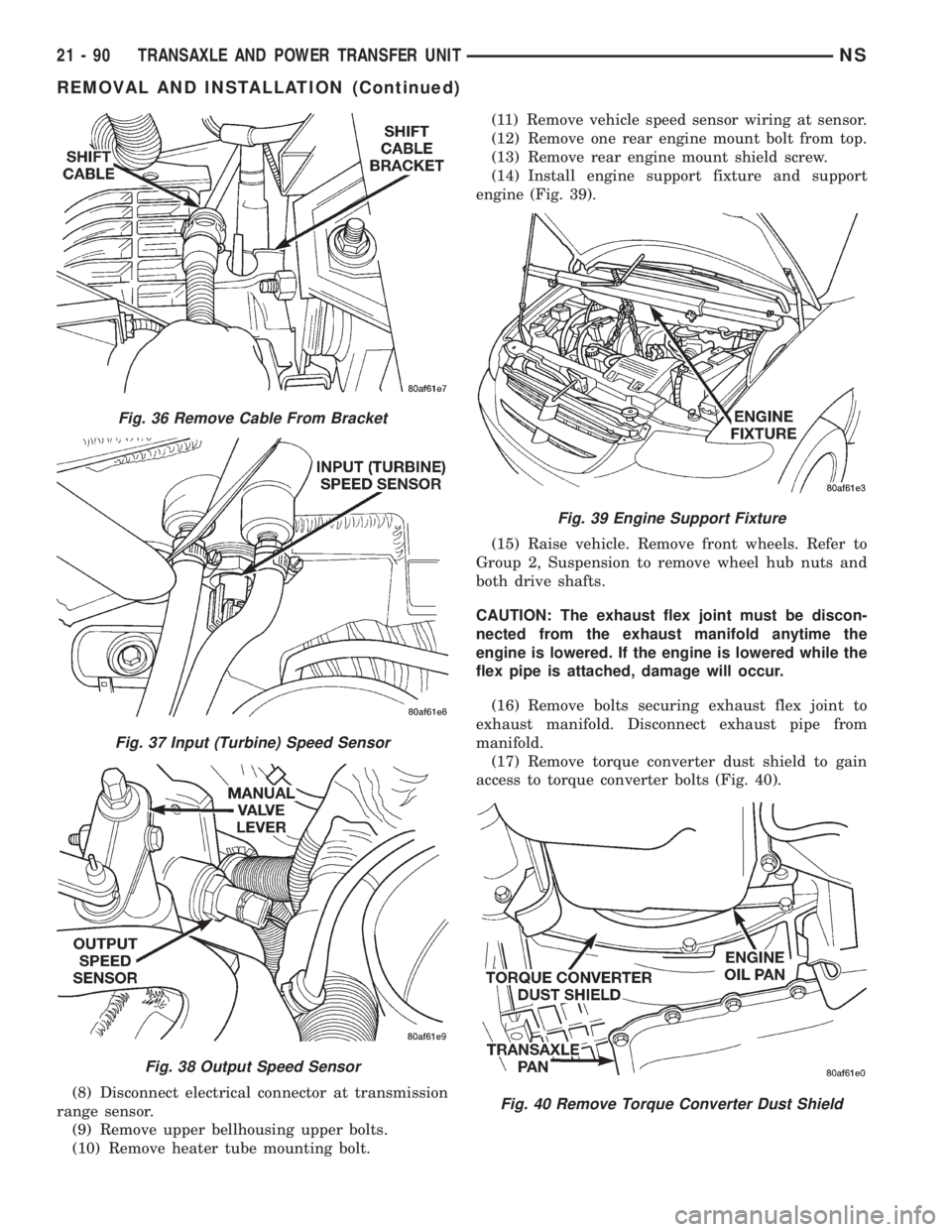

(8) Disconnect electrical connector at transmission

range sensor.

(9) Remove upper bellhousing upper bolts.

(10) Remove heater tube mounting bolt.(11) Remove vehicle speed sensor wiring at sensor.

(12) Remove one rear engine mount bolt from top.

(13) Remove rear engine mount shield screw.

(14) Install engine support fixture and support

engine (Fig. 39).

(15) Raise vehicle. Remove front wheels. Refer to

Group 2, Suspension to remove wheel hub nuts and

both drive shafts.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.

(16) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(17) Remove torque converter dust shield to gain

access to torque converter bolts (Fig. 40).

Fig. 36 Remove Cable From Bracket

Fig. 37 Input (Turbine) Speed Sensor

Fig. 38 Output Speed Sensor

Fig. 39 Engine Support Fixture

Fig. 40 Remove Torque Converter Dust Shield

21 - 90 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1565 of 1938

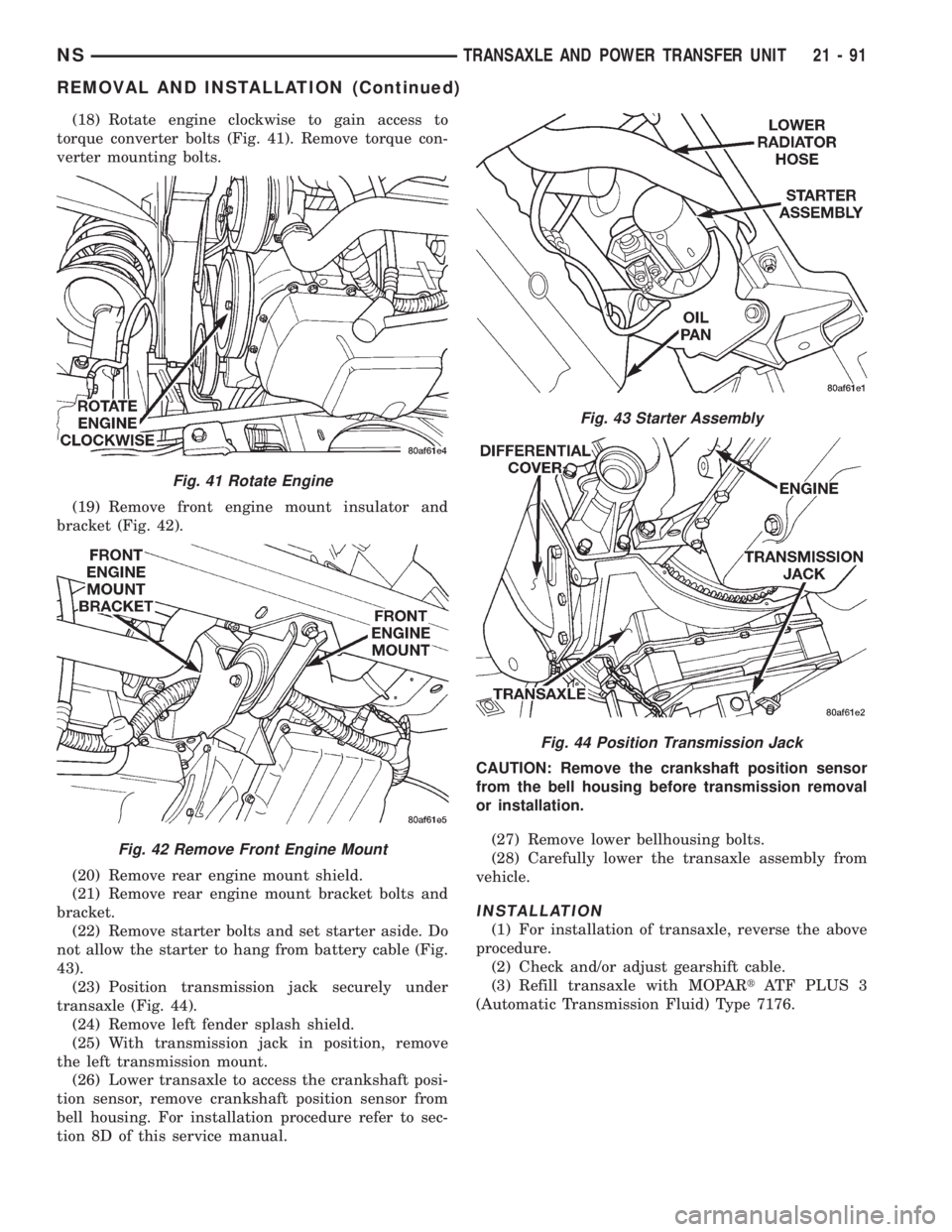

(18) Rotate engine clockwise to gain access to

torque converter bolts (Fig. 41). Remove torque con-

verter mounting bolts.

(19) Remove front engine mount insulator and

bracket (Fig. 42).

(20) Remove rear engine mount shield.

(21) Remove rear engine mount bracket bolts and

bracket.

(22) Remove starter bolts and set starter aside. Do

not allow the starter to hang from battery cable (Fig.

43).

(23) Position transmission jack securely under

transaxle (Fig. 44).

(24) Remove left fender splash shield.

(25) With transmission jack in position, remove

the left transmission mount.

(26) Lower transaxle to access the crankshaft posi-

tion sensor, remove crankshaft position sensor from

bell housing. For installation procedure refer to sec-

tion 8D of this service manual.CAUTION: Remove the crankshaft position sensor

from the bell housing before transmission removal

or installation.

(27) Remove lower bellhousing bolts.

(28) Carefully lower the transaxle assembly from

vehicle.

INSTALLATION

(1) For installation of transaxle, reverse the above

procedure.

(2) Check and/or adjust gearshift cable.

(3) Refill transaxle with MOPARtATF PLUS 3

(Automatic Transmission Fluid) Type 7176.

Fig. 41 Rotate Engine

Fig. 42 Remove Front Engine Mount

Fig. 43 Starter Assembly

Fig. 44 Position Transmission Jack

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 91

REMOVAL AND INSTALLATION (Continued)