sensor CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1667 of 1938

REMOVAL

(1) Remove electrical connector at crankshaft posi-

tion sensor (Fig. 25).

(2) Remove screw retaining the crankshaft position

sensor to the bellhousing.

(3) Remove the crankshaft position sensor.

INSTALLATION

(1) For installation, reverse removal procedure.

CROSSOVER LEVER

REMOVAL

(1) Remove crossover cable. Refer to Gearshift

Cable removal.

(2) Using a pin punch, remove the crossover roll

pin from lever.

(3) Pull up and remove the crossover lever from

the transaxle crossover shaft.

INSTALLATION

(1) For installation, reverse removal procedure.

Replace the roll pin that was removed with a new

one.

SELECTOR LEVER

REMOVAL

(1) Remove the selector cable. Refer to Gearshift

Cable removal.

(2) Using a pin punch, remove the roll pin from

the lever.

(3) Remove the selector lever from the transaxle

selector shaft

INSTALLATION

(1) For installation, reverse removal procedure.

Replace the roll pin with a new one.

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

EXTENSION HOUSING AXLE SEAL

REMOVAL

(1) Remove axle shaft. Refer to Group 2, Suspen-

sion and Driveshafts for service procedures.

(2) Insert a flat±blade pry tool into the axle seal

bore (Fig. 26).

(3) Using the pry tool, carefully pop out the seal

taking care not to nick the seal bore.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Position axle seal at extension housing.

(4) Using Tool L-4520 and Tool C-4171, tap seal

into position (Fig. 27).

Fig. 25 Crankshaft Position Sensor

Fig. 26 Extension Housing Axle Seal

Fig. 27 Install Seal

NS/GSA±598 MANUAL TRANSAXLE 21 - 11

REMOVAL AND INSTALLATION (Continued)

Page 1668 of 1938

DIFFERENTIAL BEARING RETAINER AXLE

SEAL

REMOVAL

(1) Remove axle shaft. Refer to Group 2, Suspen-

sion and Driveshafts for service procedures.

(2) Insert a flat±blade pry tool into the axle seal

bore.

(3) Using the pry tool, carefully pop out the seal

taking care not to nick the seal bore.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Position axle seal at extension housing.

(4) Using Tool L-4520 and Tool C-4171, tap seal

into position.

SHIFT SHAFT SEALS

It isnotnecessary to remove the shift shaft cover

from the transaxle to service the shift shaft seals.

REMOVAL

(1) Remove the shift lever from the seal that is to

be serviced. Refer to shift lever removal for service

procedure.

(2) Using a pick tool, pry up on the shift shaft seal

and remove seal from bore.

INSTALLATION

(1) Position new shift shaft seal in bore.

(2) Install shift shaft seal into bore using an

appropriate size deep±well socket.

TRANSAXLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

²Gearshift housing

²5th speed synchronizer

²5th speed gear

²Roller detents and springs

²Speedometer pinion

²Vehicle speed sensor

²Bearing retainer plate.

²All external covers

²Shift shaft seals

²Axle shaft seals

To service any other component of the A-598 tran-

saxle you must remove it from the vehicle.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove air intake hose. Disconnect air mass

meter connector.

(3) Remove intercooler hose.(4) Remove connectors for back-up lamp (Fig. 28)

and crank position sensor (Fig. 29).

(5) Remove crank position sensor (2.5L VM Diesel

only).

(6) Remove wiring harness bracket at transaxle

(Fig. 30).

(7) Remove crossover and shift selector cables (Fig.

31).

(8) Remove the two top bolts at the rear engine

mount bracket.

(9) Remove bolts securing the coolant reservoir to

the top of the engine. Move the coolant reservoir out

of the way.

(10) Install an engine support chain to the cylinder

head assembly (Fig. 32).

Fig. 28 Back-up Lamp Connector

Fig. 29 Crankshaft Position Sensor

21 - 12 A±598 MANUAL TRANSAXLENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1669 of 1938

(11) Remove three upper bellhousing bolts (Fig.

33).

(12) Install engine bridge fixture to chain and sup-

port engine (Fig. 34).(13) Hoist the vehicle.

(14) Remove front wheels.

(15) Remove axle shaft hub nuts.

(16) Remove steering knuckle steering stop studs.

(17) Remove lower control arm pinch bolts (Fig.

35).

(18) Using a pry bar, unseat lower control arm

from steering knuckle (Fig. 36).

(19) Remove drain plug and drain transaxle fluid

(Fig. 37).

(20) Remove right and left axle shaft assemblies

(21) Remove vehicle speed sensor wiring connector

(Fig. 38).

(22) Remove clutch cable retaining clip (Fig. 39).

Remove clutch cable from transaxle housing.

(23) Remove adapter plate and front engine mount

bolts (Fig. 40) (Fig. 41).

(24) Remove two remaining rear engine mount

bolts.

CAUTION: Always use a safety chain when remov-

ing or installing transaxle assembly.

Fig. 30 Wiring Harness Bracket

Fig. 31 Shift Cables

Fig. 32 Engine Support Chain

Fig. 33 Upper Bellhousing Bolts

Fig. 34 Engine Bridge Fixture

NS/GSA±598 MANUAL TRANSAXLE 21 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1670 of 1938

(25) Install transmission jack under transaxle

assembly.

(26) Remove left fender splash shield.

(27) Remove (4) left mount bolts (Fig. 42).(28) Remove lower bellhousing bolts.

(29) Lower transaxle and remove.

INSTALLATION

(1) For installation, reverse removal procedure.

NOTE: Lower control arm pinch bolts must be

installed with the bolt heads to the rear of the ball

joints.

(2) Fill transaxle to the proper level with the spec-

ified lubricant.

(3) While the vehicle is elevated slightly, run the

transaxle through all the forward gears. Apply

brakes and shift into reverse. Run the transaxle

through reverse gear.

Fig. 35 Lower Control Arm Pinch Bolt

Fig. 36 Unseat Control Arm

Fig. 37 Transaxle Drain Plug

Fig. 38 Vehicle Speed Sensor

Fig. 39 Clutch Cable Clip

21 - 14 A±598 MANUAL TRANSAXLENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1674 of 1938

(12) Remove the front wheels.(13) Remove the two (2) axle shaft hub nuts.

(14) Remove three upper bellhousing bolts.

(15) Remove steering stop studs at steering knuck-

les.

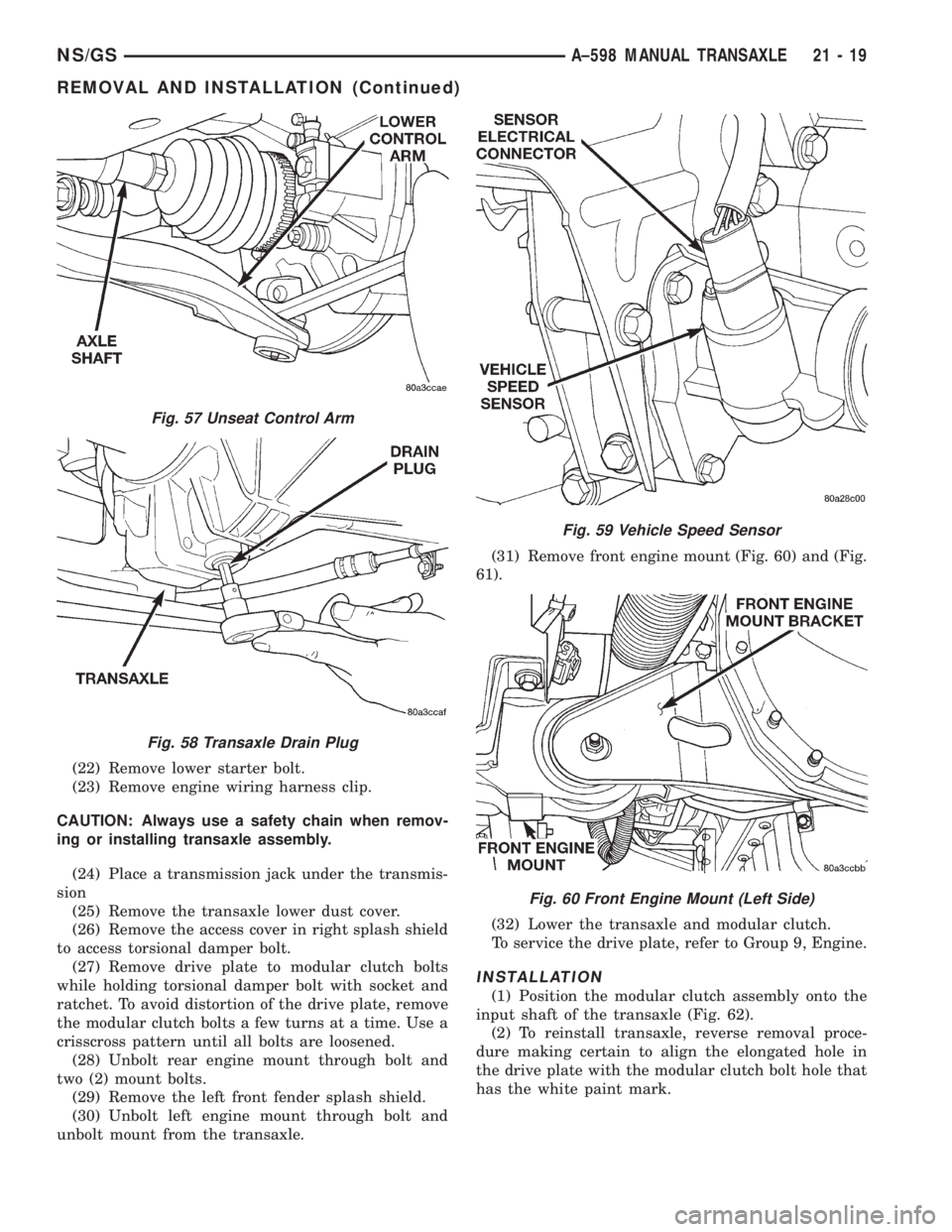

(16) Remove lower control arm pinch bolts (Fig.

56).

(17) Using a pry bar, unseat lower control arm

from steering knuckle (Fig. 57).

(18) Remove drain plug and drain transaxle fluid

(Fig. 58).

(19) Remove right and left axle shaft assemblies

(20) Remove vehicle speed sensor wiring connector

(Fig. 59).

(21) Remove structural brace from engine and

transaxle.

Fig. 52 Engine Support Chain Ð Typical

Fig. 53 Throttle Control Shield

Fig. 54 Throttle Control Support Bracket

Fig. 55 Shift Cables

Fig. 56 Lower Control Arm Pinch Bolt

21 - 18 A±598 MANUAL TRANSAXLENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1675 of 1938

(22) Remove lower starter bolt.

(23) Remove engine wiring harness clip.

CAUTION: Always use a safety chain when remov-

ing or installing transaxle assembly.

(24) Place a transmission jack under the transmis-

sion

(25) Remove the transaxle lower dust cover.

(26) Remove the access cover in right splash shield

to access torsional damper bolt.

(27) Remove drive plate to modular clutch bolts

while holding torsional damper bolt with socket and

ratchet. To avoid distortion of the drive plate, remove

the modular clutch bolts a few turns at a time. Use a

crisscross pattern until all bolts are loosened.

(28) Unbolt rear engine mount through bolt and

two (2) mount bolts.

(29) Remove the left front fender splash shield.

(30) Unbolt left engine mount through bolt and

unbolt mount from the transaxle.(31) Remove front engine mount (Fig. 60) and (Fig.

61).

(32) Lower the transaxle and modular clutch.

To service the drive plate, refer to Group 9, Engine.

INSTALLATION

(1) Position the modular clutch assembly onto the

input shaft of the transaxle (Fig. 62).

(2) To reinstall transaxle, reverse removal proce-

dure making certain to align the elongated hole in

the drive plate with the modular clutch bolt hole that

has the white paint mark.

Fig. 57 Unseat Control Arm

Fig. 58 Transaxle Drain Plug

Fig. 59 Vehicle Speed Sensor

Fig. 60 Front Engine Mount (Left Side)

NS/GSA±598 MANUAL TRANSAXLE 21 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1715 of 1938

(14) Apply a bead of MopartGasket Maker or

equivalent onto bearing support plate. Install bearing

support plate.

(15) Install necessary shim calculated from Step

12

(16) Install bearing retainer plate. Tighten bearing

retainer plate to 17 N´m (250 in. lbs.).

(17) Install 5th drive gear onto the input shaft.

(18) Install 5th gear, synchro, fork, and plate.

(19) Install 5th gear synchro snap ring.

(20) Install 5th gear shift fork roll pin.

(21) Use Special Tool 6252 to hold 5th gear and

install new 5th gear nut at input shaft. Tighten the

retaining nut to 176 N´m (130 ft. lbs.).

(22) Use Special Tool 6930 to stake the 5th gear

retaining nut onto the input shaft (Fig. 234).

(23) Apply a bead of MopartGasket Maker or

equivalent onto end cover. Install 5th gear/synchro

end cover. Tighten bolts to 28 N´m (250 in. lbs.).

SPECIFICATIONS

A-598 (T-750) MANUAL TRANSAXLE

DESCRIPTION TORQUE

Back-up Lamp Switch..........27N´m(20ft.lbs.)

Bearing Retainer Plate........28N´m(250 in. lbs.)

Crossover Cable Adj. Screw......8N´m(70in.lbs.)

Drain Plug..................23N´m(17ft.lbs.)

Differential Housing...........54N´m(40ft.lbs.)

Diff. Bearing Retainer.........61N´m(45ft.lbs.)

Diff. Ring Gear Bolts..........94N´m(70ft.lbs.)

End Cover Bolts..............28N´m(21ft.lbs.)

Extension Housing...........28N´m(250 in. lbs.)

Gearshift Housing...........28N´m(250 in. lbs.)

*Input Gear Nut............176 N´m (130 ft. lbs.)

Input Retainer..............28N´m(250 in. lbs.)

Reverse Blocker.............12N´m(105 in. lbs.)

Transaxle Case Bolts..........29N´m(21ft.lbs.)

Vehicle Speed Sensor...........7N´m(60in.lbs.)

Vent........................6N´m(60in.lbs.)

NOTE: *The 5th/input gear is torqued to specifica-

tion and then staked in two places using Special

Tool 6930.

NOTE: Bolts that have thread sealer or torque lock

patches should not be reused. Always install new

bolts in these applications.

A-558 MANUAL TRANSAXLEÐRHD VEHICLES

DESCRIPTION TORQUE

Back-up Lamp Switch..........27N´m(20ft.lbs.)

Bearing Retainer Plate........28N´m(250 in. lbs.)

Crossover Cable Adj. Screw......8N´m(70in.lbs.)

Drain Plug..................23N´m(17ft.lbs.)

Modular Clutch to Drive

Plate Bolts................74N´m(55ft.lbs.)

Transaxle Case Bolts..........29N´m(21ft.lbs.)

Vehicle Speed Sensor...........7N´m(60in.lbs.)

Vent........................6N´m(60in.lbs.)

Fig. 233 Measure Depth Of Cup

Fig. 234 Staking 5th Gear Retaining Nut

NV T750 (A-598) MANUAL TRANSAXLE FLUID

FILL

TRANSAXLEMETRIC MEA-

SUREU.S. MEASURE

NV T750 1.9-2.2 Liters 2.0-2.3 Quarts

NS/GSA±598 MANUAL TRANSAXLE 21 - 59

ADJUSTMENTS (Continued)

Page 1823 of 1938

DIAGNOSTICS

During the Actuator calibration, diagnostics are

performed on the actuators and evaporator tempera-

ture Fin Sensor. Once diagnostics are completed the

REAR WIPER and INTERMITTENT LED's will flash

to indicate either a successful calibration or the

appropriate fail code(s). At this time manual testing

of the Blend, Mode and Driver (if equipped) potenti-

ometers can be performed. If a failure is detected

during Diagnostics a fault will be set in the control.

When Ignition is cycled OFF and then ON or Diag-

nostics is aborted, the REAR WIPER and INTER-

MITTENT LED's will flash simultaneously showing

that a failure has occurred. The control will not indi-

cate the fail code, but only that a failure had

occurred during the last diagnostics test. The only

way to clear the failure codes is repeat the Calibra-

tion Diagnostic and Cooldown test, after all repairs

are completed.

COOLDOWN TEST

This test has been designed for performance test-

ing of the A/C system at the manufacturing facility. If

the HVAC control module is replaced, the Cooldown

test will occur during Calibration test. Cooldown will

not occur on Heater Only units. During the Cooldown

test the control will monitor the temperature of the

Fin Sensor. The A/C system must be able to bring the

evaporator temperature down a predetermined mini-

mum amount in less than 2 minutes.

CALIBRATION/COOLDOWN LED DISPLAY

CODES

See table for definition of flashing LED's. If no

problems are found, the control functions normally.

CALIBRATION/DIAGNOSTICS TEST ENTRY

TO INITIATE TESTS:

²Set Blower motor ON HIGH

²Set Mode position to Panel

²Open all A/C outlets

²Set Temperature to Cold (Both slide pots if

equipped)

²Depress WASH and REAR WIPER button simul-

taneously for 5 Seconds (Until all LED's light)

RESULTS:

²All LED's will turn on for 5 Seconds

²Calibration Test is running when REAR WIPER

and INTERMITTENT are alternately flashing.

Cooldown test is running if A/C and RECIRC are

alternately flashing.

²Acceptable results is REAR WIPER LED is the

only LED flashing. Push Rear Wiper to exit.

²After all tests have passed, Calibration Diagnos-

tics and Cooldown can be run separately.

Fig. 7 Radio Bezel and HVAC Control, Rear Blower

Motor Switch and Zone Control

CALIBRATION/COOLDOWN LED DISPLAY

CODES

LED'S PASS/FAILCORREC-

TIVE

ACTION

NO LED'S

FLASHING-

NORMAL

OPERATIONPASSED

CALIBRATION,

DIAGNOSTICS

AND

COOLDOWNNONE

REAR WIPER AND

INTERMITTENT

LED'S FLASH

SIMULTANEOUSLYFAILED

CALIBRATION

DIAGNOSTICSRUN

CALIBRATION

TEST

A/C AND RECIRC

LED'S FLASH

SIMULTANEOUSLYFAILED

COOLDOWNRUN

COOLDOWN

TEST

REAR WIPER AND

INTERMITTENT

LED'S ARE

FLASHING

SIMULTANEOUSLY

A/C AND RECIRC

LED'S ARE

FLASHING

SIMULTANEOUSLYFAILED

CALIBRATION,

DIAGNOSTICS

AND FAILED

COOLDOWN

TESTRUN

CALIBRATION

TEST

NSHEATING AND AIR CONDITIONING 24 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1824 of 1938

COOLDOWN TEST ENTRY

TO INITIATE TESTS:

²Set Blower motor ON HIGH

²Set Mode position to Panel

²Open all A/C outlets

²Set Temperature to Cold (Both slide pots if

equipped)

²Depress WASH and A/C simultaneously for 5

Seconds

NOTE: Prior to start of test, If the evaporator is

already cold, the system will fail test. To correct,

operate system with A/C OFF and the blower motor

ON high for three minutes prior to starting test.

RESULTS:

²All LED's will turn on for 5 Seconds

²Cooldown Test is running when A/C and

RECIRC. are alternately flashing. If A/C and

RECIRC. are flashing simultaneously, Cooldown has

failed.

CALIBRATION DIAGNOSTICS AND

COOLDOWN ABORT

Test can be aborted by doing one of the following:

²Depressing Rear Window Defogger, RECIRC and

Rear Wiper buttons.

²Cycling Ignition OFF and then ON.

²Control will automatically abort after 15 min-

utes from the time Calibration Diagnostics and

Cooldown was entered.

The HVAC control module will return to normal

operation or may indicate unsuccessful Calibration

Diagnostics or Cooldown test by LED's flashing

simultaneously.

EEPROM DATA

Calibration Diagnostics, Cooldown Status and

evaporator temperature Fin Sensor values are stored

in an EEPROM memory internal to the control. The

microcomputer within the HVAC control module uses

this information:

²To determine if Cooldown needs to run

²For proper position of the Heater-A/C unit

assembly doors

ACTUATOR CALIBRATION AND

DIAGNOSTICS.

NOTE: Do not run actuators unless they are prop-

erly mounted on the HVAC control module.

Actuator end point calibration takes approximately

60 seconds. The REAR WIPER and INTERMITTENT

LED's will flash alternately during the test. The con-

trol will cycle the Blend actuator(s) to the Heat stopfirst then back to Cold. After the Blend actuator(s)

have been calibrated the Mode actuator will be cycled

to Defrost and then to Panel. Successful calibration

is defined as actuator travel falling within their min-

imum and maximum limits.

BLEND/PASSENGER ACTUATOR BACKGROUND

The Blend/Passenger Actuator can move the tem-

perature door in two directions. When the voltage at

Pin 12 of the control module is high, about 11.5 volts,

and the voltage at Pin 17 is low, about 1.5 volts, the

door will move towards the Heat position. When Pin

17 is High and Pin 12 is Low the door will move

towards the Cold position. When both Pins are high

or both Pins are low, the actuator will not move. The

Blend/Passenger feedback signal is a voltage signal

that is supplied by the actuator to the control. The

signal will be about 4.0 volts in the Heat position

and 1.0 volt in the Cold position. As the position of

the Blend/Passenger actuator changes, so will the

feedback signal. The feedback signal is necessary for

the correct positioning of the temperature door.

DRIVER ACTUATOR BACKGROUND

The Driver Actuator can move the temperature

door in two directions. When the voltage at Pin 15 of

the control module is high, about 11.5 volts, and the

voltage at Pin 13 is low, about 1.5 volts the door will

move towards the Cold position. When Pin 13 is High

and Pin 15 is Low the door will move towards the

Heat position. When both Pins are high or when both

Pins are low, the actuator will not move. The Driver

feedback signal is a voltage signal that is supplied by

the actuator to the control. The signal will be about

4.0 volts in the Heat position and 1.0 volt in the Cold

position. As the position of the Driver Actuator

changes, so will the feedback signal. The feedback

signal is necessary for the correct positioning of the

temperature door.

MODE ACTUATOR BACKGROUND

The Mode actuator can move the mode door in two

directions. When the voltage at Pin 18 of the control

module is high, about 11.5 volts, and the voltage at

Pin 12 is low, about 1.5 volts the door will move

towards the Panel position. When Pin 12 is High and

Pin 18 is Low the door will move towards the Defrost

position. When both Pin are high or when both Pins

are low, the actuator will not move. The Mode door

feedback signal is a voltage signal that is supplied by

the actuator to the control. The signal will be about

4.5 volts in the Panel position and 0.5 volts in the

Defrost position. As the position of the Mode actuator

changes, so will the feedback signal. The feedback

signal is necessary for the correct positioning of the

mode door.

24 - 8 HEATING AND AIR CONDITIONINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1825 of 1938

FAIL CODES/LEVEL DISPLAY

Fail Codes/Level are displayed using the REAR

WIPER and INTERMITTENT LED's flashing in the

sequence indicated below. The REAR WIPER LED

represents the Level and the INTERMITTENT LED

represents the Value. After Calibration/Diagnostics is

completed, the control will begin flashing Level 1

codes. Depressing the WASH button will cycle to

Level 2, depressing WASH again will cycle to Level 3.

Each time the WASH button is depressed will cycle

to the next level. After Level 5 is reached, you will

cycle back to Level 1. If the Control is a Heater Only

you will only cycle from Levels 1 to 3.

TEMPERATURE AND MODE POTENTIOMETER

DIAGNOSTICS

The Temperature and Mode Potentiometer can be

tested after calibration is complete by pressing the

WASH button and cycling to Levels 2, 3 or 5 as dis-

played by the REAR WIPER LED. On Heater Only

units you can only cycle to Levels 2 and 3. In eachindividual test the INTERMITTENT LED flash rate

will change as the Temperature or Mode potentiome-

ter is moved from one end to the other, see Potenti-

ometer vs. Position and Flash Rate table.

EVAPORATOR PROBE TEMPERATURE

DIAGNOSTICS

The evaporator probe can be tested by using the

INTERMITTENT LED to display the actual temper-

ature the sensor is reading. The HVAC control mod-

ule can only display temperatures from 1 to 99

degrees. To read the temperature, perform the follow-

ing:

²Set Blower motor to any speed other than OFF

²Set A/C to ON, if A/C Clutch does not engage

make sure Fail Codes 5 and 6 are cleared.To clear

the error code 5 and 6 the evaporator probe and/or

the wiring repair needs to be completed. Then, press

and hold the intermittent wipe button for 5 seconds.

²Run Diagnostics (Depress REAR WIPER and

REAR WASH)

²When Diagnostics is complete, Cycle to Level 4.

Display Sequence is as follows:

²REAR WIPER LED will display the Level

²INTERMITTENT LED will display ten's digit

²Short Pause

²INTERMITTENT LED will display the one's

digit.

The HVAC control module will continue to cycle

the Level and then Temperature until the level is

changed or Calibration Diagnostics and Cooldown

test is exited.

HVAC CONTROL DIAGNOSTIC CONDITIONS

For wiring circuits, wiring connectors, and Pin

numbers, refer to Group 8W, Wiring Diagrams.

After calibration, Rear Wiper LED flashing

once, Intermittent LED not flashing.

The system has passed calibration. Press the Rear

Wiper button to exit calibration.

WIPE BUTTON LED

LEVEL DISPLAY

1 FAIL CODES

2 MODE POTENTIOMETER TEST

3 BLEND/PASS. POTENTIOMETER TEST

4 EVAPORATOR PROBE (A/C AND ZONE

UNITS ONLY)

5 DRIVER POTENTIOMETER (ZONE UNITS

ONLY)

LEVEL 1±FAILURE CODE VALUES

(INTERMITTENT WIPE BUTTON LED)

CODE DEFINITION

0 PASSED ALL TESTS

1 MODE ACTUATOR DID NOT REACH

DEFROST POSITION

2 MODE ACTUATOR DID NOT REACH

PANEL POSITION

3 BLEND/PASS. ACTUATOR DID NOT

REACH COLD STOP

4 BLEND PASS. ACTUATOR DID NOT

REACH HEAT STOP

5 EVAPORATOR PROBE OPEN

6 EVAPORATOR PROBE SHORTED

7 DRIVER ACTUATOR DID NOT REACH

COLD STOP

8 ZONE/DRIVER ACTUATOR DID NOT

REACH HEAT STOP

9 CONTROL HEAD INTERNAL FAILURE

POTENTIOMETER VS. POSITION AND FLASH

RATE

POTENTIOM-

ETERINTERMIT-

TENT LED

FASTER

FLASH RATEINTERMITTENT

LED SLOWER

FLASH RATE

MODE PANEL DEFROST

BLEND/PASS. HOT COLD

DRIVER HOT COLD

NSHEATING AND AIR CONDITIONING 24 - 9

DIAGNOSIS AND TESTING (Continued)