sensor CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1566 of 1938

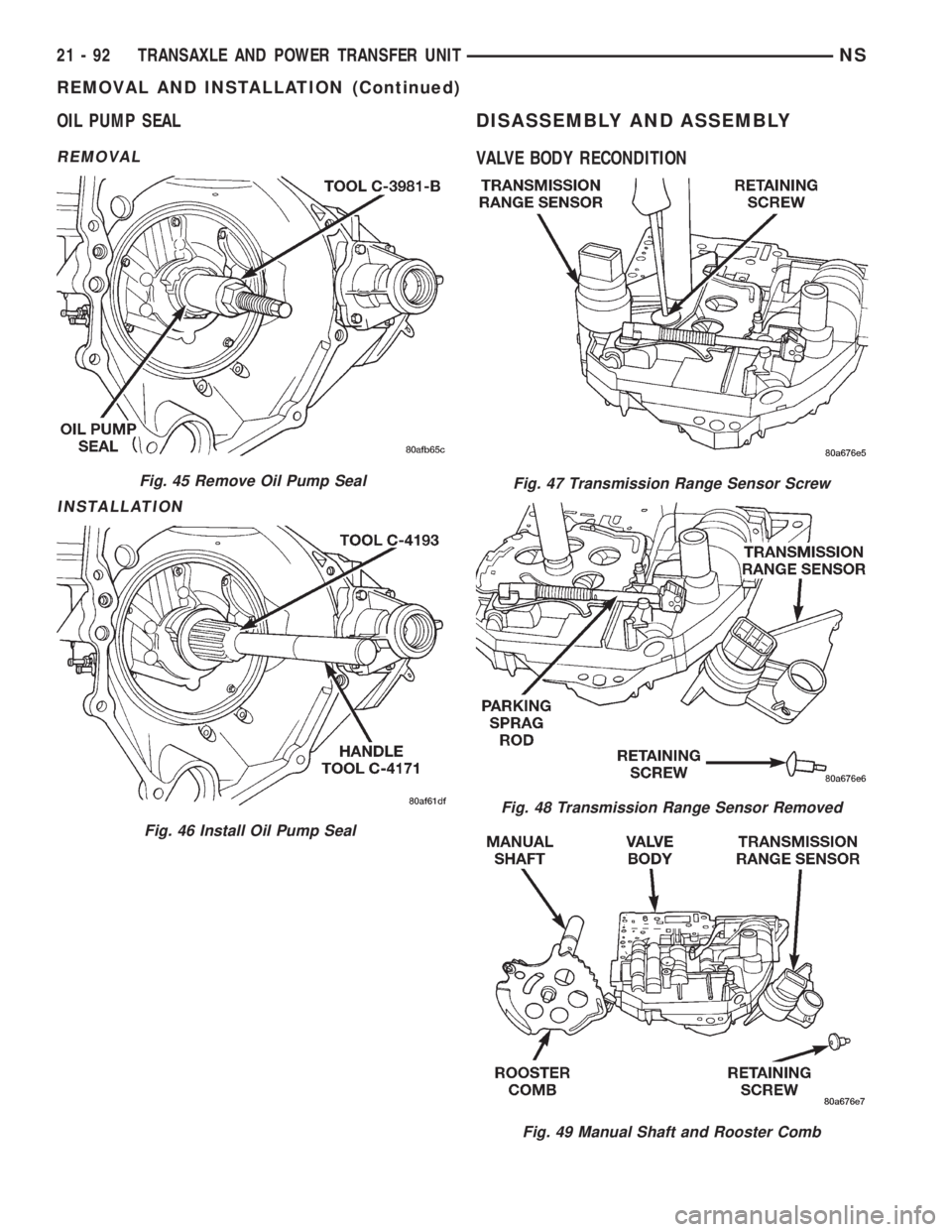

OIL PUMP SEAL

REMOVAL

INSTALLATION

DISASSEMBLY AND ASSEMBLY

VALVE BODY RECONDITION

Fig. 45 Remove Oil Pump Seal

Fig. 46 Install Oil Pump Seal

Fig. 47 Transmission Range Sensor Screw

Fig. 48 Transmission Range Sensor Removed

Fig. 49 Manual Shaft and Rooster Comb

21 - 92 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1569 of 1938

TRANSAXLE DISASSEMBLE

NOTE: Tag all clutch pack assemblies, as they are

removed, for reassembly identification.

CAUTION: Do not intermix clutch discs or plates as

the unit might then fail.

(1) Remove input and output speed sensors.

(2) Remove transaxle solenoid pack (Fig. 59).

Fig. 58 Low/Reverse Switch Valve And T/C Limit

Valve

Fig. 59 Remove Solenoid Pack

Fig. 60 Remove Oil Pan Bolts

Fig. 61 Remove Oil Pan

Fig. 62 Remove Oil Filter

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 95

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1572 of 1938

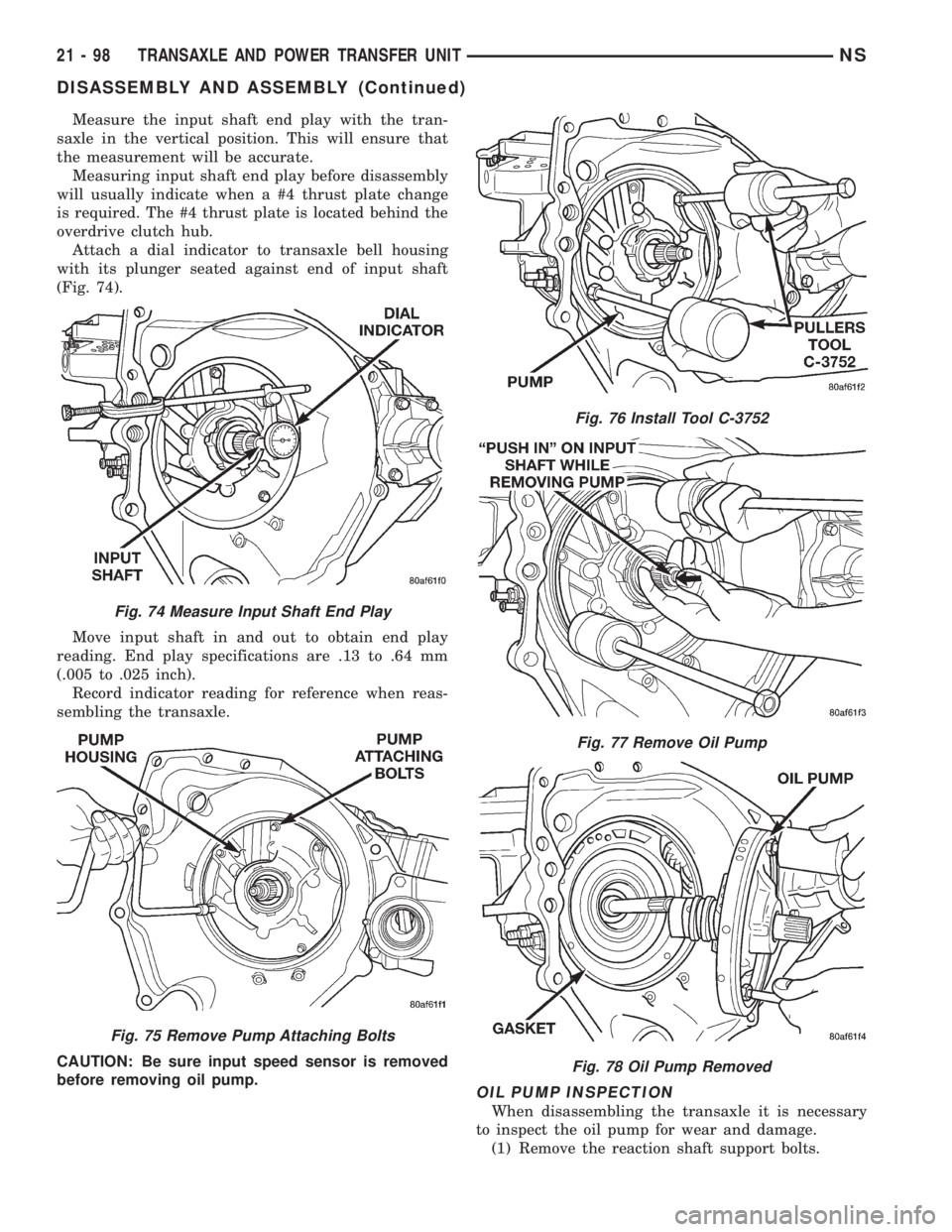

Measure the input shaft end play with the tran-

saxle in the vertical position. This will ensure that

the measurement will be accurate.

Measuring input shaft end play before disassembly

will usually indicate when a #4 thrust plate change

is required. The #4 thrust plate is located behind the

overdrive clutch hub.

Attach a dial indicator to transaxle bell housing

with its plunger seated against end of input shaft

(Fig. 74).

Move input shaft in and out to obtain end play

reading. End play specifications are .13 to .64 mm

(.005 to .025 inch).

Record indicator reading for reference when reas-

sembling the transaxle.

CAUTION: Be sure input speed sensor is removed

before removing oil pump.

OIL PUMP INSPECTION

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage.

(1) Remove the reaction shaft support bolts.

Fig. 74 Measure Input Shaft End Play

Fig. 75 Remove Pump Attaching Bolts

Fig. 76 Install Tool C-3752

Fig. 77 Remove Oil Pump

Fig. 78 Oil Pump Removed

21 - 98 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1608 of 1938

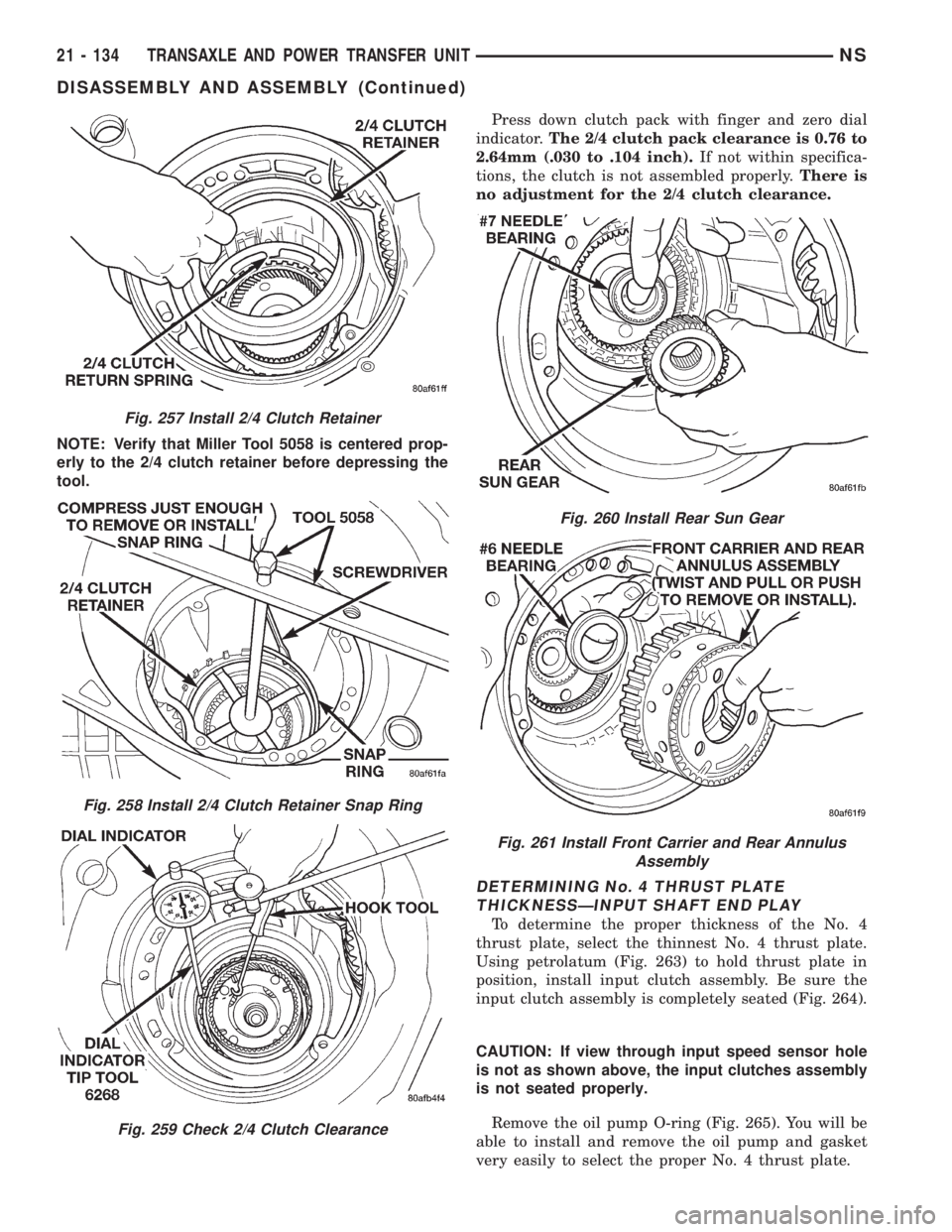

NOTE: Verify that Miller Tool 5058 is centered prop-

erly to the 2/4 clutch retainer before depressing the

tool.Press down clutch pack with finger and zero dial

indicator.The 2/4 clutch pack clearance is 0.76 to

2.64mm (.030 to .104 inch).If not within specifica-

tions, the clutch is not assembled properly.There is

no adjustment for the 2/4 clutch clearance.

DETERMINING No. 4 THRUST PLATE

THICKNESSÐINPUT SHAFT END PLAY

To determine the proper thickness of the No. 4

thrust plate, select the thinnest No. 4 thrust plate.

Using petrolatum (Fig. 263) to hold thrust plate in

position, install input clutch assembly. Be sure the

input clutch assembly is completely seated (Fig. 264).

CAUTION: If view through input speed sensor hole

is not as shown above, the input clutches assembly

is not seated properly.

Remove the oil pump O-ring (Fig. 265). You will be

able to install and remove the oil pump and gasket

very easily to select the proper No. 4 thrust plate.

Fig. 257 Install 2/4 Clutch Retainer

Fig. 258 Install 2/4 Clutch Retainer Snap Ring

Fig. 259 Check 2/4 Clutch Clearance

Fig. 260 Install Rear Sun Gear

Fig. 261 Install Front Carrier and Rear Annulus

Assembly

21 - 134 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1609 of 1938

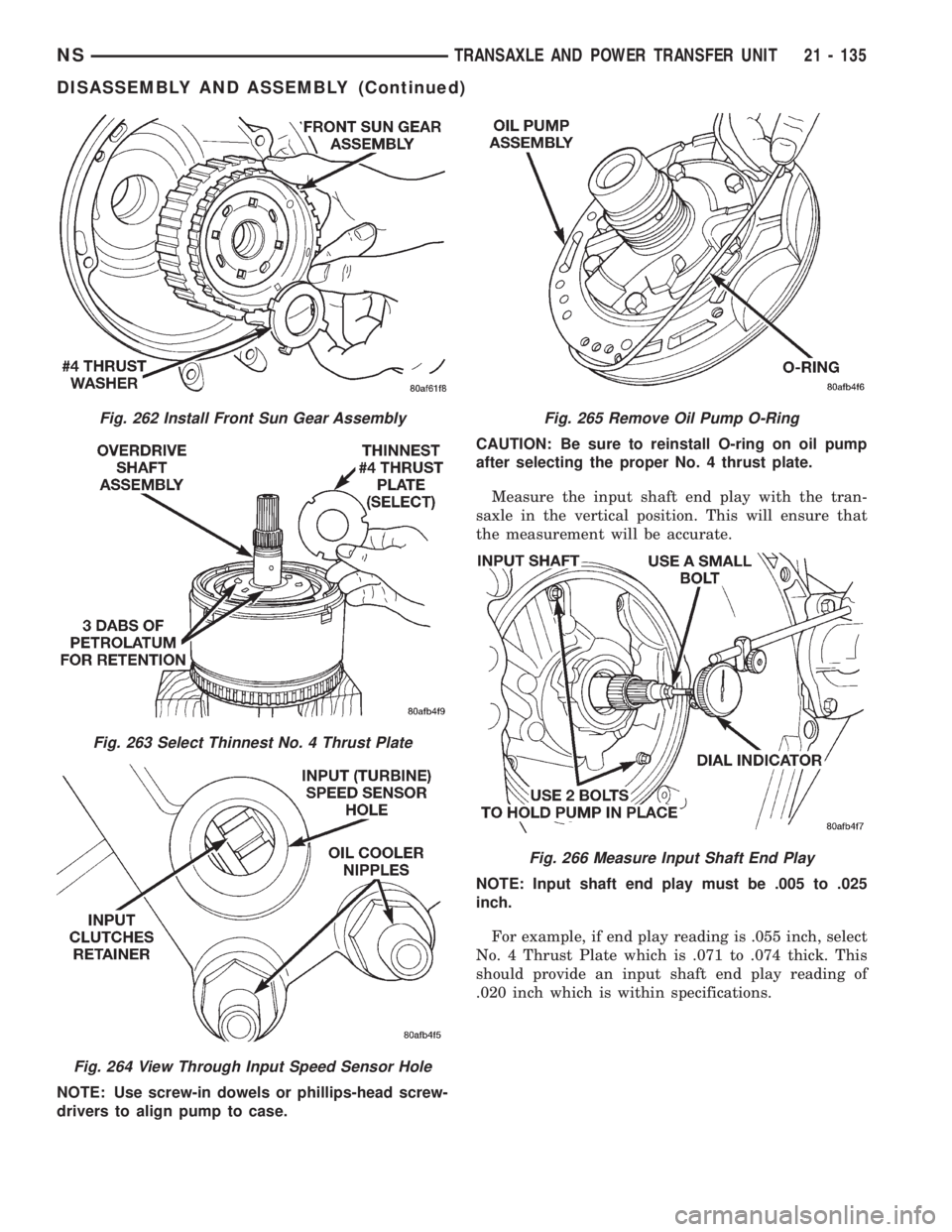

NOTE: Use screw-in dowels or phillips-head screw-

drivers to align pump to case.CAUTION: Be sure to reinstall O-ring on oil pump

after selecting the proper No. 4 thrust plate.

Measure the input shaft end play with the tran-

saxle in the vertical position. This will ensure that

the measurement will be accurate.

NOTE: Input shaft end play must be .005 to .025

inch.

For example, if end play reading is .055 inch, select

No. 4 Thrust Plate which is .071 to .074 thick. This

should provide an input shaft end play reading of

.020 inch which is within specifications.

Fig. 262 Install Front Sun Gear Assembly

Fig. 263 Select Thinnest No. 4 Thrust Plate

Fig. 264 View Through Input Speed Sensor Hole

Fig. 265 Remove Oil Pump O-Ring

Fig. 266 Measure Input Shaft End Play

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 135

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1613 of 1938

(1) Install transaxle solenoid pack (Fig. 284).

(2) Install input and output speed sensors.

This concludes the assembly of the transaxle cen-

terline.

DIFFERENTIAL REPAIR

NOTE: The differential is serviced as an assembly.

The only parts that are serviceable within the differ-

ential are the differential bearing cups and cones. If

any other part fails within the differential, you must

replace the differential assembly along with the

transfer shaft.

DISASSEMBLE

The transfer shaft should be removed for differen-

tial repair and bearing turning torque checking.

(1) Remove the differential cover and bolts (Fig.

285) (Fig. 286).

(2) Remove the differential bearing retainer and

bolts (Fig. 287) (Fig. 288).(3) Using a plastic hammer, remove extension

housing/adapter plate on the right side of the tran-

saxle.

Fig. 283 Install Pan Bolts

Fig. 284 Install Solenoid Pack

Fig. 285 Differential Cover Bolts

Fig. 286 Remove Differential Cover

Fig. 287 Differential Retainer Bolts

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 139

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1632 of 1938

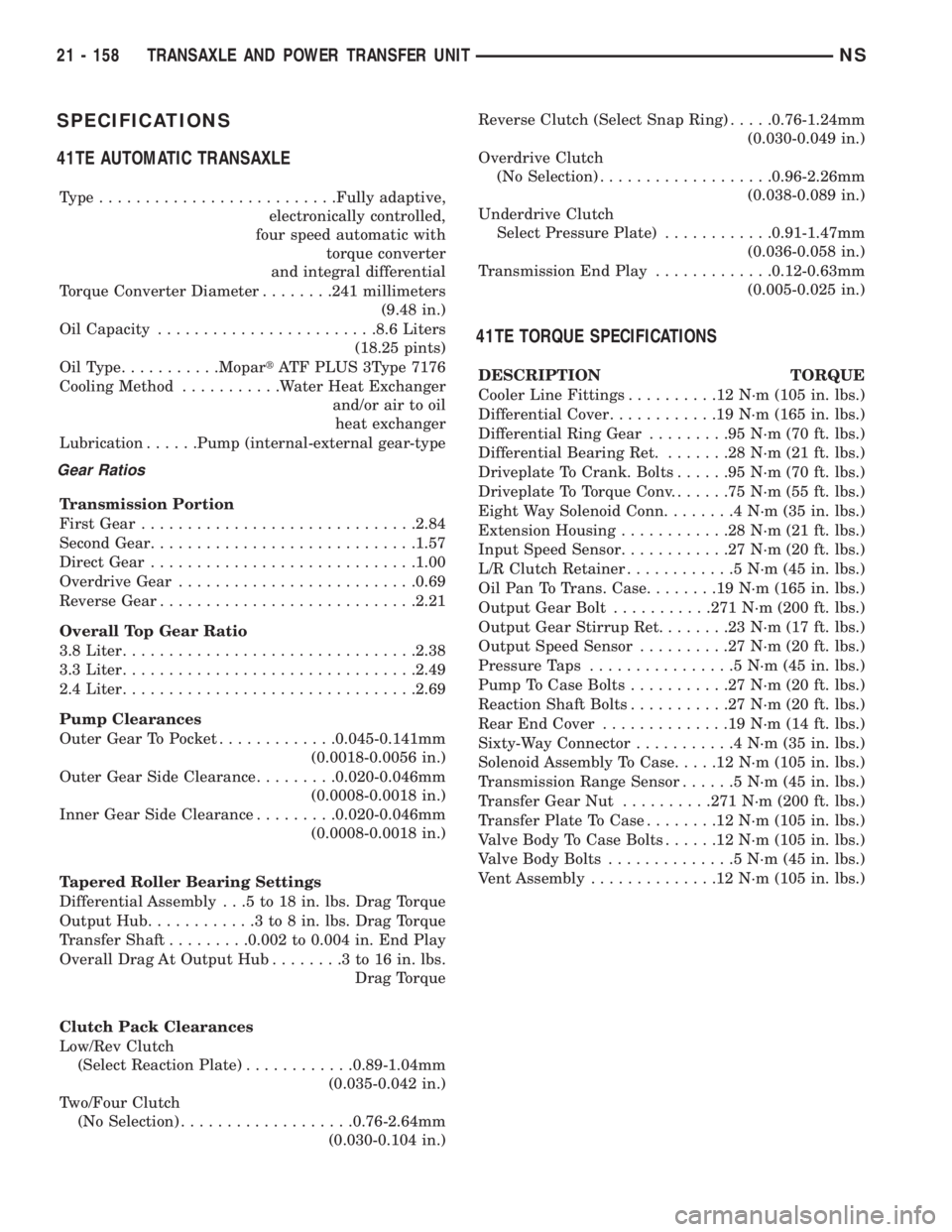

SPECIFICATIONS

41TE AUTOMATIC TRANSAXLE

Type..........................Fully adaptive,

electronically controlled,

four speed automatic with

torque converter

and integral differential

Torque Converter Diameter........241 millimeters

(9.48 in.)

Oil Capacity........................8.6 Liters

(18.25 pints)

OilType...........MopartATF PLUS 3Type 7176

Cooling Method...........Water Heat Exchanger

and/or air to oil

heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.84

Second Gear.............................1.57

Direct Gear.............................1.00

Overdrive Gear..........................0.69

Reverse Gear............................2.21

Overall Top Gear Ratio

3.8 Liter................................2.38

3.3 Liter................................2.49

2.4 Liter................................2.69

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . .5 to 18 in. lbs. Drag Torque

Output Hub............3to8in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.004 in. End Play

Overall Drag At Output Hub........3to16in.lbs.

Drag Torque

Clutch Pack Clearances

Low/Rev Clutch

(Select Reaction Plate)............0.89-1.04mm

(0.035-0.042 in.)

Two/Four Clutch

(No Selection)...................0.76-2.64mm

(0.030-0.104 in.)Reverse Clutch (Select Snap Ring).....0.76-1.24mm

(0.030-0.049 in.)

Overdrive Clutch

(No Selection)...................0.96-2.26mm

(0.038-0.089 in.)

Underdrive Clutch

Select Pressure Plate)............0.91-1.47mm

(0.036-0.058 in.)

Transmission End Play.............0.12-0.63mm

(0.005-0.025 in.)

41TE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Cooler Line Fittings..........12N´m(105 in. lbs.)

Differential Cover............19N´m(165 in. lbs.)

Differential Ring Gear.........95N´m(70ft.lbs.)

Differential Bearing Ret........28N´m(21ft.lbs.)

Driveplate To Crank. Bolts......95N´m(70ft.lbs.)

Driveplate To Torque Conv.......75N´m(55ft.lbs.)

Eight Way Solenoid Conn........4N´m(35in.lbs.)

Extension Housing............28N´m(21ft.lbs.)

Input Speed Sensor............27N´m(20ft.lbs.)

L/R Clutch Retainer............5N´m(45in.lbs.)

Oil Pan To Trans. Case........19N´m(165 in. lbs.)

Output Gear Bolt...........271 N´m (200 ft. lbs.)

Output Gear Stirrup Ret........23N´m(17ft.lbs.)

Output Speed Sensor..........27N´m(20ft.lbs.)

Pressure Taps................5N´m(45in.lbs.)

Pump To Case Bolts...........27N´m(20ft.lbs.)

Reaction Shaft Bolts...........27N´m(20ft.lbs.)

Rear End Cover..............19N´m(14ft.lbs.)

Sixty-Way Connector...........4N´m(35in.lbs.)

Solenoid Assembly To Case.....12N´m(105 in. lbs.)

Transmission Range Sensor......5N´m(45in.lbs.)

Transfer Gear Nut..........271 N´m (200 ft. lbs.)

Transfer Plate To Case........12N´m(105 in. lbs.)

Valve Body To Case Bolts......12N´m(105 in. lbs.)

Valve Body Bolts..............5N´m(45in.lbs.)

Vent Assembly..............12N´m(105 in. lbs.)

21 - 158 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1657 of 1938

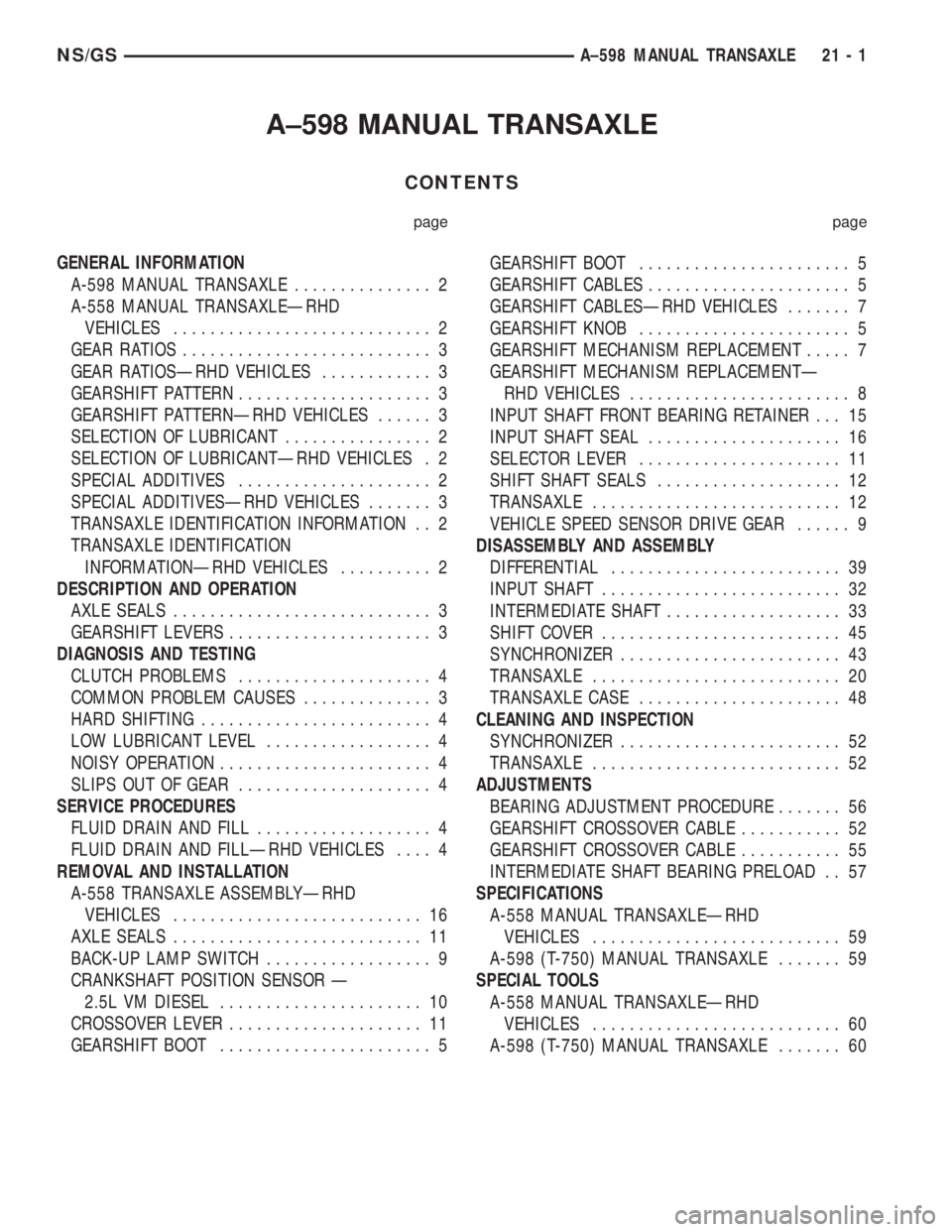

A±598 MANUAL TRANSAXLE

CONTENTS

page page

GENERAL INFORMATION

A-598 MANUAL TRANSAXLE............... 2

A-558 MANUAL TRANSAXLEÐRHD

VEHICLES............................ 2

GEAR RATIOS........................... 3

GEAR RATIOSÐRHD VEHICLES............ 3

GEARSHIFT PATTERN..................... 3

GEARSHIFT PATTERNÐRHD VEHICLES...... 3

SELECTION OF LUBRICANT................ 2

SELECTION OF LUBRICANTÐRHD VEHICLES . 2

SPECIAL ADDITIVES..................... 2

SPECIAL ADDITIVESÐRHD VEHICLES....... 3

TRANSAXLE IDENTIFICATION INFORMATION . . 2

TRANSAXLE IDENTIFICATION

INFORMATIONÐRHD VEHICLES.......... 2

DESCRIPTION AND OPERATION

AXLE SEALS............................ 3

GEARSHIFT LEVERS...................... 3

DIAGNOSIS AND TESTING

CLUTCH PROBLEMS..................... 4

COMMON PROBLEM CAUSES.............. 3

HARD SHIFTING......................... 4

LOW LUBRICANT LEVEL.................. 4

NOISY OPERATION....................... 4

SLIPS OUT OF GEAR..................... 4

SERVICE PROCEDURES

FLUID DRAIN AND FILL................... 4

FLUID DRAIN AND FILLÐRHD VEHICLES.... 4

REMOVAL AND INSTALLATION

A-558 TRANSAXLE ASSEMBLYÐRHD

VEHICLES........................... 16

AXLE SEALS........................... 11

BACK-UP LAMP SWITCH.................. 9

CRANKSHAFT POSITION SENSOR Ð

2.5L VM DIESEL...................... 10

CROSSOVER LEVER..................... 11

GEARSHIFT BOOT....................... 5GEARSHIFT BOOT....................... 5

GEARSHIFT CABLES...................... 5

GEARSHIFT CABLESÐRHD VEHICLES....... 7

GEARSHIFT KNOB....................... 5

GEARSHIFT MECHANISM REPLACEMENT..... 7

GEARSHIFT MECHANISM REPLACEMENTÐ

RHD VEHICLES........................ 8

INPUT SHAFT FRONT BEARING RETAINER . . . 15

INPUT SHAFT SEAL..................... 16

SELECTOR LEVER...................... 11

SHIFT SHAFT SEALS.................... 12

TRANSAXLE........................... 12

VEHICLE SPEED SENSOR DRIVE GEAR...... 9

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL......................... 39

INPUT SHAFT.......................... 32

INTERMEDIATE SHAFT................... 33

SHIFT COVER.......................... 45

SYNCHRONIZER........................ 43

TRANSAXLE........................... 20

TRANSAXLE CASE...................... 48

CLEANING AND INSPECTION

SYNCHRONIZER........................ 52

TRANSAXLE........................... 52

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURE....... 56

GEARSHIFT CROSSOVER CABLE........... 52

GEARSHIFT CROSSOVER CABLE........... 55

INTERMEDIATE SHAFT BEARING PRELOAD . . 57

SPECIFICATIONS

A-558 MANUAL TRANSAXLEÐRHD

VEHICLES........................... 59

A-598 (T-750) MANUAL TRANSAXLE....... 59

SPECIAL TOOLS

A-558 MANUAL TRANSAXLEÐRHD

VEHICLES........................... 60

A-598 (T-750) MANUAL TRANSAXLE....... 60

NS/GSA±598 MANUAL TRANSAXLE 21 - 1

Page 1665 of 1938

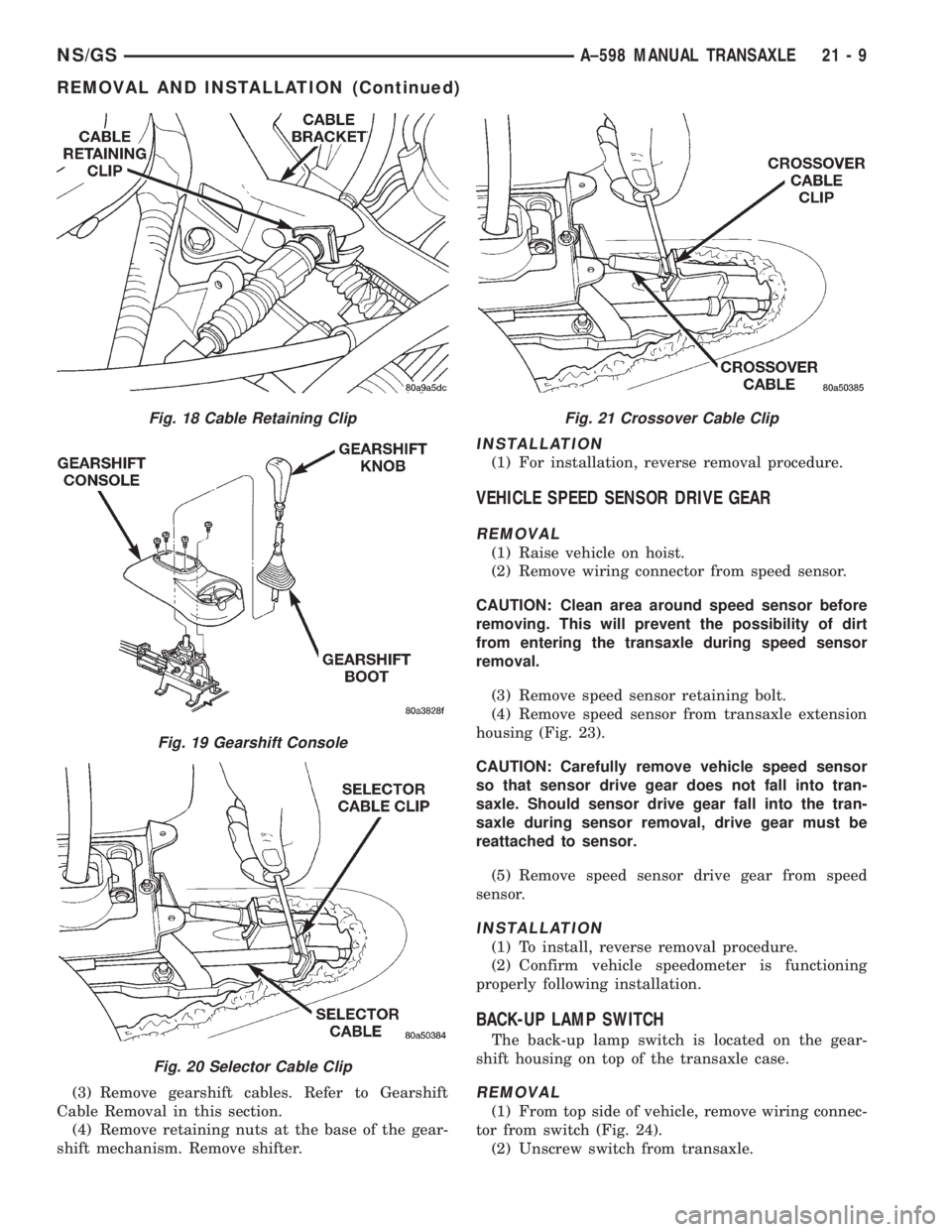

(3) Remove gearshift cables. Refer to Gearshift

Cable Removal in this section.

(4) Remove retaining nuts at the base of the gear-

shift mechanism. Remove shifter.

INSTALLATION

(1) For installation, reverse removal procedure.

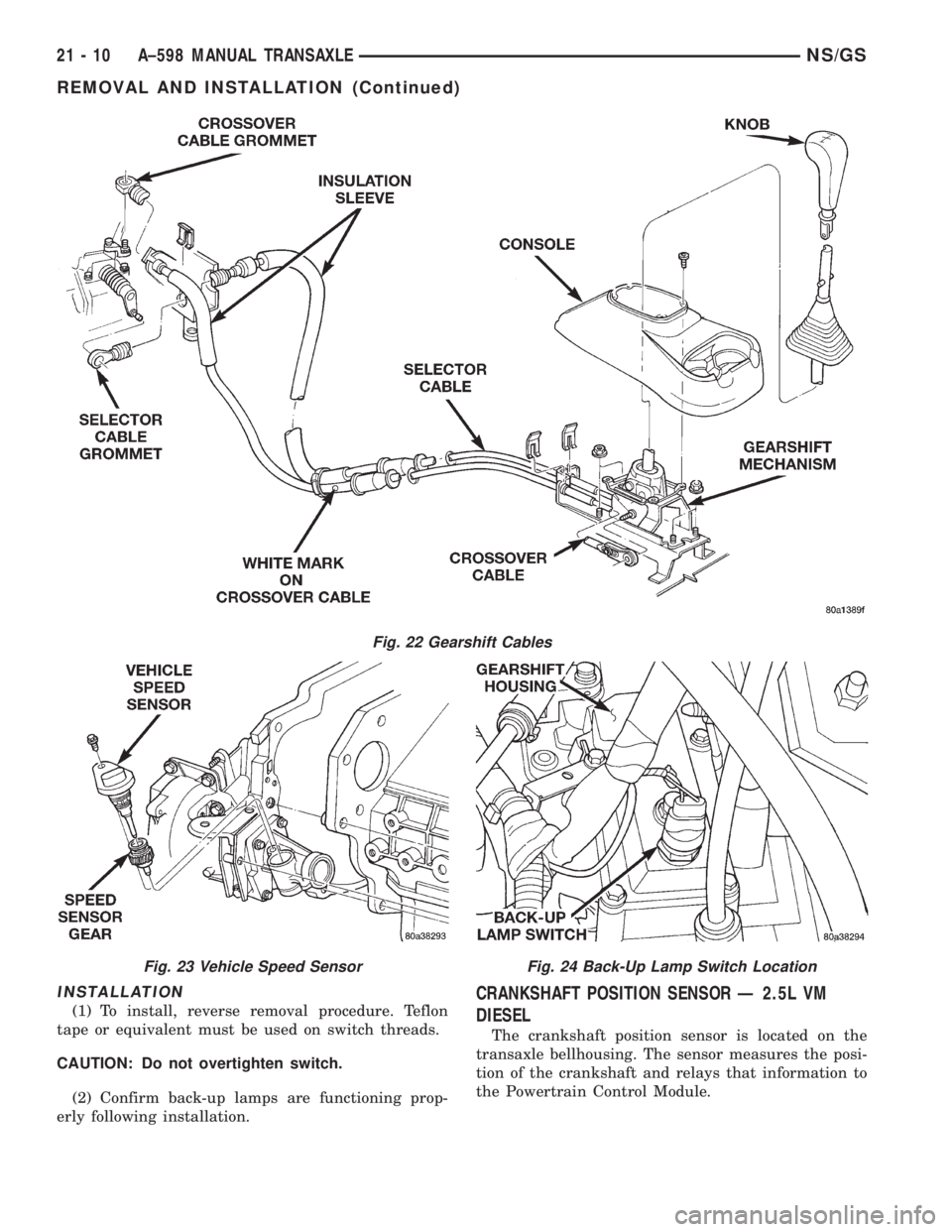

VEHICLE SPEED SENSOR DRIVE GEAR

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove wiring connector from speed sensor.

CAUTION: Clean area around speed sensor before

removing. This will prevent the possibility of dirt

from entering the transaxle during speed sensor

removal.

(3) Remove speed sensor retaining bolt.

(4) Remove speed sensor from transaxle extension

housing (Fig. 23).

CAUTION: Carefully remove vehicle speed sensor

so that sensor drive gear does not fall into tran-

saxle. Should sensor drive gear fall into the tran-

saxle during sensor removal, drive gear must be

reattached to sensor.

(5) Remove speed sensor drive gear from speed

sensor.

INSTALLATION

(1) To install, reverse removal procedure.

(2) Confirm vehicle speedometer is functioning

properly following installation.

BACK-UP LAMP SWITCH

The back-up lamp switch is located on the gear-

shift housing on top of the transaxle case.

REMOVAL

(1) From top side of vehicle, remove wiring connec-

tor from switch (Fig. 24).

(2) Unscrew switch from transaxle.

Fig. 18 Cable Retaining Clip

Fig. 19 Gearshift Console

Fig. 20 Selector Cable Clip

Fig. 21 Crossover Cable Clip

NS/GSA±598 MANUAL TRANSAXLE 21 - 9

REMOVAL AND INSTALLATION (Continued)

Page 1666 of 1938

INSTALLATION

(1) To install, reverse removal procedure. Teflon

tape or equivalent must be used on switch threads.

CAUTION: Do not overtighten switch.

(2) Confirm back-up lamps are functioning prop-

erly following installation.

CRANKSHAFT POSITION SENSOR Ð 2.5L VM

DIESEL

The crankshaft position sensor is located on the

transaxle bellhousing. The sensor measures the posi-

tion of the crankshaft and relays that information to

the Powertrain Control Module.

Fig. 22 Gearshift Cables

Fig. 23 Vehicle Speed SensorFig. 24 Back-Up Lamp Switch Location

21 - 10 A±598 MANUAL TRANSAXLENS/GS

REMOVAL AND INSTALLATION (Continued)