maintenance CHRYSLER VOYAGER 1996 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 190 of 1938

INSTALL

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as shown in this

section may result in contact with moving parts

and/or over extension of cables, resulting in an

open circuit.

(1) Install wheel speed sensor head. Note, the plas-

tic anti rotation pin must be fully seated prior to

installing the attaching bolt.

CAUTION: Prior to installing the speed sensor

head attaching bolt, the plastic anti-rotation pin

must be fully seated into the bearing flange.

(2) Install the wheel speed sensor head to bearing

flange attaching bolt (Fig. 42). Tighten the attaching

bolt to a torque 12 N´m (105 in. lbs.)

(3) Check the air gap between the face of the

wheel speed sensor and the top surface of the tone-

wheel. Air gap must be less then the maximum

allowable tolerance of 1.2 mm (.047 in.).

(4) Install the 2 routing brackets attaching the

speed sensor cable and brake tube to the rear axle

(Fig. 41).The rear wheel speed sensor cable

should be routed under the rear brake tube

(Fig. 41).

CAUTION: When installing rear wheel speed sen-

sor cable in the routing clips on rear brake flex

hose, be sure not to damage the routing clips.

Routing clips are molded onto the hose and will

require replacement of the brake flex hose if dam-

aged during installation of the wheel speed sensor

cable.(5) Install speed sensor cable into routing clips on

rear brake flex hose (Fig. 41).

(6) If installing a right rear speed sensor cable,

install the speed sensor cable grommet on the axle

brake flex hose bracket (Fig. 40).

CAUTION: The wheel speed sensor cable connec-

tors for the left and right rear wheel speed sensors

are keyed differently. Therefore, when connecting a

wheel speed sensor cable to the vehicle wiring har-

ness, do not force the connectors together. If the

connectors are forced together, damage to the con-

nectors will occur.

(7) Plug speed sensor cable connector into vehicle

wiring harness (Fig. 38).Be sure speed sensor

cable connector is fully seated and locked into

vehicle wiring harness connector.

(8) Install the speed sensor cable grommet into the

body, being sure the grommet is fully seated into the

body hole.

(9) Install the tire and wheel assembly on vehicle.

(10) Road test vehicle to ensure proper operation

of the base and ABS braking systems.

WHEEL SPEED SENSOR (REAR AWD)

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the tire and wheel assembly from the

vehicle.

CAUTION: When unplugging speed sensor cable

from vehicle wiring harness be careful not to dam-

age pins on the electrical connectors. Also inspect

connectors for any signs of previous damage.

(3) Remove grommet from floor pan of vehicle and

unplug speed sensor cable connector from vehicle

wiring harness (Fig. 43).

CAUTION: When removing rear wheel speed sen-

sor cable from routing clips on rear brake flex hose,

be sure not to damage the routing clips. Routing

clips are molded onto the hose and will require

replacement of the brake flex hose if damaged dur-

ing removal of the speed sensor cable.

Fig. 42 Rear Wheel Speed Sensor Attaching Bolt

5 - 108 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 192 of 1938

(2) Install the wheel speed sensor head attaching

bolt (Fig. 46). Tighten the attaching bolt to a torque

12 N´m (105 in. lbs.)

(3) Check the air gap between the face of the

wheel speed sensor and the top surface of the tone-

wheel. Air gap must be less then the maximum

allowable tolerance of 1.2 mm (.047 in.).

(4) Install the routing brackets attaching the speed

sensor cable and brake tube to the rear axle (Fig.

45).The rear wheel speed sensor cable should

be routed under the rear brake tube (Fig. 45).

CAUTION: When installing rear wheel speed sen-

sor cable in the routing clips on rear brake flex

hose, be sure not to damage the routing clips.

Routing clips are molded onto the hose and will

require replacement of the brake flex hose if dam-

aged during installation of the wheel speed sensor

cable.

(5) Install speed sensor cable into routing clips on

rear brake flex hose (Fig. 44).

CAUTION: The wheel speed sensor cable connec-

tors for the left and right rear wheel speed sensors

are keyed differently. Therefore, when connecting a

wheel speed sensor cable to the vehicle wiring har-

ness, do not force the connectors together. If the

connectors are forced together, damage to the con-

nectors will occur.

(6) Plug speed sensor cable connector into vehicle

wiring harness (Fig. 43).Be sure speed sensor

cable connector is fully seated and locked into

vehicle wiring harness connector.

(7) Install the speed sensor cable grommet into the

body, being sure the grommet is fully seated into the

body hole.

(8) Install the tire and wheel assembly on vehicle.

(9) Road test vehicle to ensure proper operation of

the base and ABS braking systems.

TONE WHEEL (REAR FWD)

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this service man-

ual for required lifting procedure.

(2) Remove the wheel and tire assembly.

(3) Remove rear brake drum from the hub/bearing

assembly.

(4) Remove the rear wheel speed sensor from the

rear hub/bearing flange (Fig. 47). This will prevent

damage to the speed sensor during removal and

installation of the hub/bearing assembly.(5) Remove the 4 bolts (Fig. 48) attaching the hub/

bearing assembly to the flange of the rear axle.

(6) Remove the hub/bearing assembly from the

rear axle and brake support plate (Fig. 49).

Fig. 47 Rear Wheel Speed Sensor

Fig. 48 Rear Hub/Bearing Mounting Bolts

Fig. 49 Removing Rear Hub/Bearing From Axle

5 - 110 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 199 of 1938

CLUTCH

CONTENTS

page page

GENERAL INFORMATION

CLUTCH COMPONENTS.................. 1

CLUTCH DISC AND COVER APPLICATION . . . 3

CLUTCH REPLACEMENT................. 3

DESCRIPTION AND OPERATION

CLUTCH PEDAL POSITION SWITCH........ 4

CLUTCH RELEASE SYSTEM.............. 4

DIAGNOSIS AND TESTING

CLASH±INTO±REVERSE

COMPLAINTS........................ 8

CLUTCH CHATTER COMPLAINTS.......... 8

CLUTCH COVER AND DISC RUNOUT....... 8

CLUTCH DIAGNOSIS.................... 6

CLUTCH PEDAL POSITION SWITCH........ 4

DRIVE PLATE MISALIGNMENT............ 7

REMOVAL AND INSTALLATION

CLUTCH ASSEMBLY (2.5L DIESEL)....... 13

CLUTCH CABLE SYSTEM Ð LHD.......... 8

CLUTCH PEDAL POSITION SWITCH....... 10CLUTCH RELEASE BEARING AND FORK . . . 14

HYDRAULIC CLUTCH LINKAGE SYSTEM Ð

RHD ............................... 11

MASTER CYLINDER SYSTEM

Ð RHD ............................ 12

MODULAR CLUTCH ASSEMBLY (2.0L AND

2.4L GASOLINE)..................... 13

QUICK CONNECT COUPLING

Ð RHD ............................ 12

SLAVE CYLINDER ASSEMBLY

Ð RHD ............................ 12

CLEANING AND INSPECTION

CLEANING PRECAUTIONS............... 15

CLUTCH CONTAMINATION.............. 15

ADJUSTMENTS

CLUTCH CABLE Ð LHD................ 16

CLUTCH PEDAL POSITION SWITCH....... 16

SPECIFICATIONS

CLUTCH TIGHTENING REFERENCE........ 16

GENERAL INFORMATION

CLUTCH COMPONENTS

The clutch used in the 2.0 liter and 2.4 liter gaso-

line engine is a single, dry-disc modular clutch

assembly. The modular clutch assembly combines the

pressure plate cover, pressure plate, disc, and fly-

wheel into one unit. The unit rides on the input shaft

of the transmission and is bolted to the drive plate

mounted on the rear of the crankshaft. The clutch

used in the 2.5 liter diesel engine is a conventional

clutch and pressure plate arrangement.

CLUTCH CABLE AND PEDAL Ð LHD

The clutch cable has a unique self-adjuster mecha-

nism built into the cable which compensates for

clutch disc wear. The cable requires no maintenance

or lubrication. There are no serviceable components

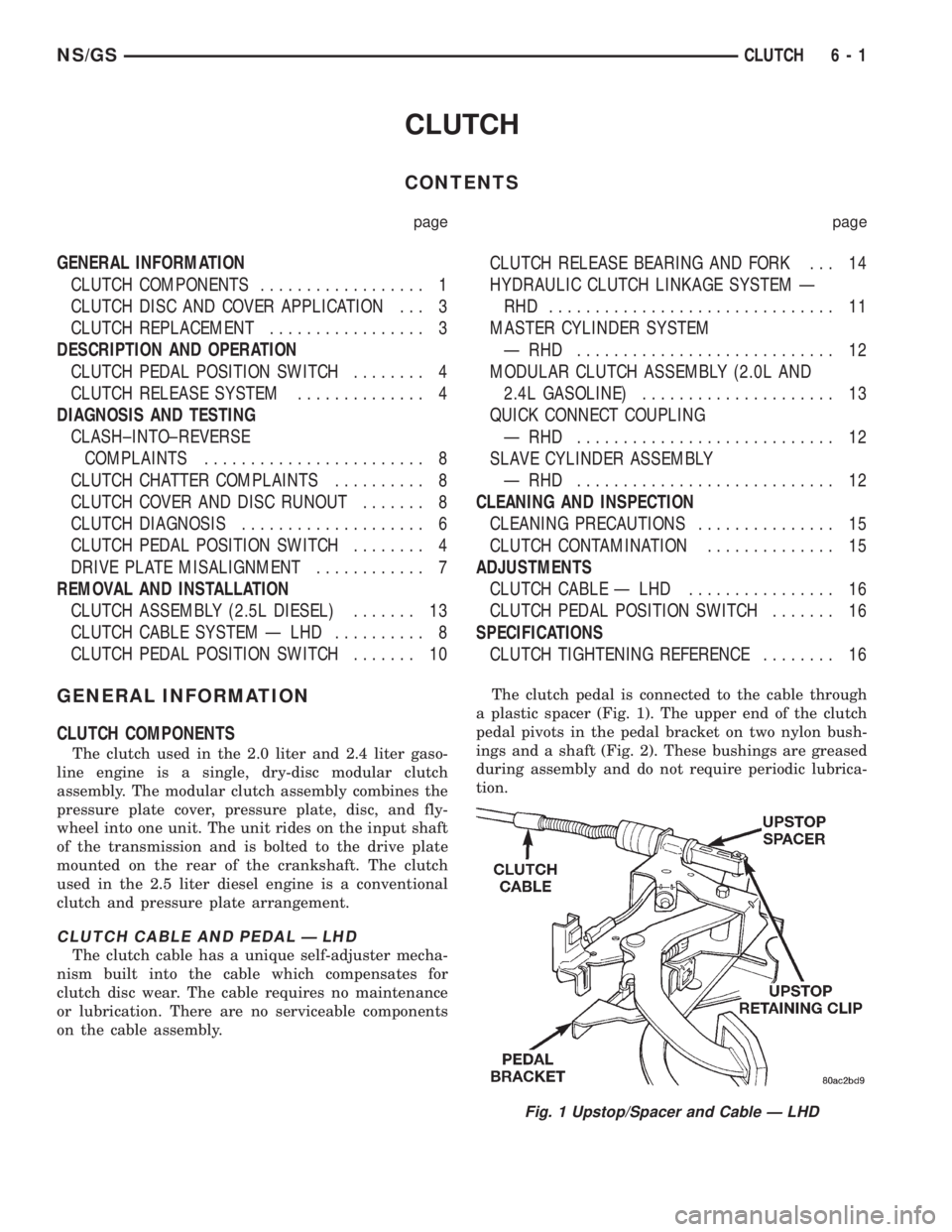

on the cable assembly.The clutch pedal is connected to the cable through

a plastic spacer (Fig. 1). The upper end of the clutch

pedal pivots in the pedal bracket on two nylon bush-

ings and a shaft (Fig. 2). These bushings are greased

during assembly and do not require periodic lubrica-

tion.

Fig. 1 Upstop/Spacer and Cable Ð LHD

NS/GSCLUTCH 6 - 1

Page 200 of 1938

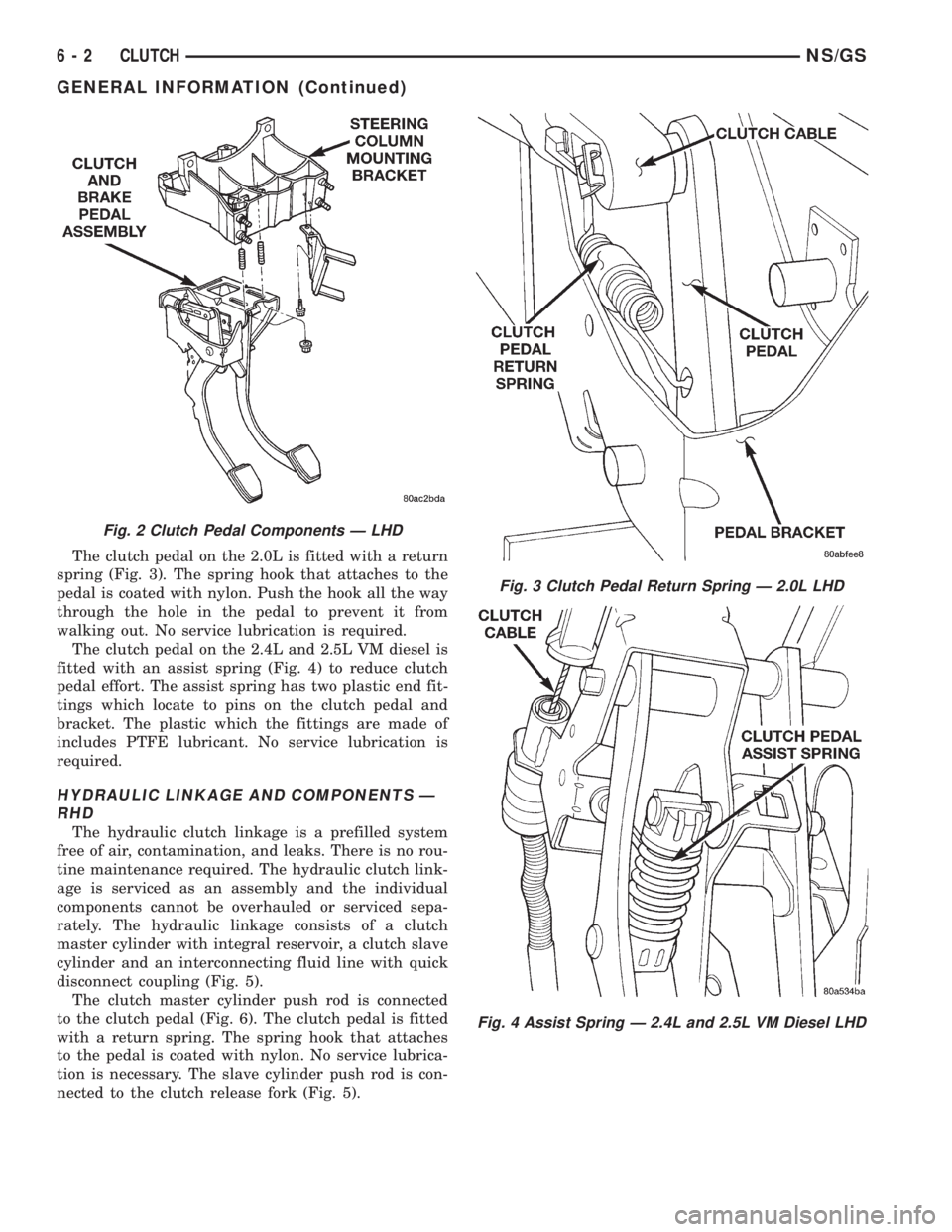

The clutch pedal on the 2.0L is fitted with a return

spring (Fig. 3). The spring hook that attaches to the

pedal is coated with nylon. Push the hook all the way

through the hole in the pedal to prevent it from

walking out. No service lubrication is required.

The clutch pedal on the 2.4L and 2.5L VM diesel is

fitted with an assist spring (Fig. 4) to reduce clutch

pedal effort. The assist spring has two plastic end fit-

tings which locate to pins on the clutch pedal and

bracket. The plastic which the fittings are made of

includes PTFE lubricant. No service lubrication is

required.

HYDRAULIC LINKAGE AND COMPONENTS Ð

RHD

The hydraulic clutch linkage is a prefilled system

free of air, contamination, and leaks. There is no rou-

tine maintenance required. The hydraulic clutch link-

age is serviced as an assembly and the individual

components cannot be overhauled or serviced sepa-

rately. The hydraulic linkage consists of a clutch

master cylinder with integral reservoir, a clutch slave

cylinder and an interconnecting fluid line with quick

disconnect coupling (Fig. 5).

The clutch master cylinder push rod is connected

to the clutch pedal (Fig. 6). The clutch pedal is fitted

with a return spring. The spring hook that attaches

to the pedal is coated with nylon. No service lubrica-

tion is necessary. The slave cylinder push rod is con-

nected to the clutch release fork (Fig. 5).

Fig. 2 Clutch Pedal Components Ð LHD

Fig. 3 Clutch Pedal Return Spring Ð 2.0L LHD

Fig. 4 Assist Spring Ð 2.4L and 2.5L VM Diesel LHD

6 - 2 CLUTCHNS/GS

GENERAL INFORMATION (Continued)

Page 209 of 1938

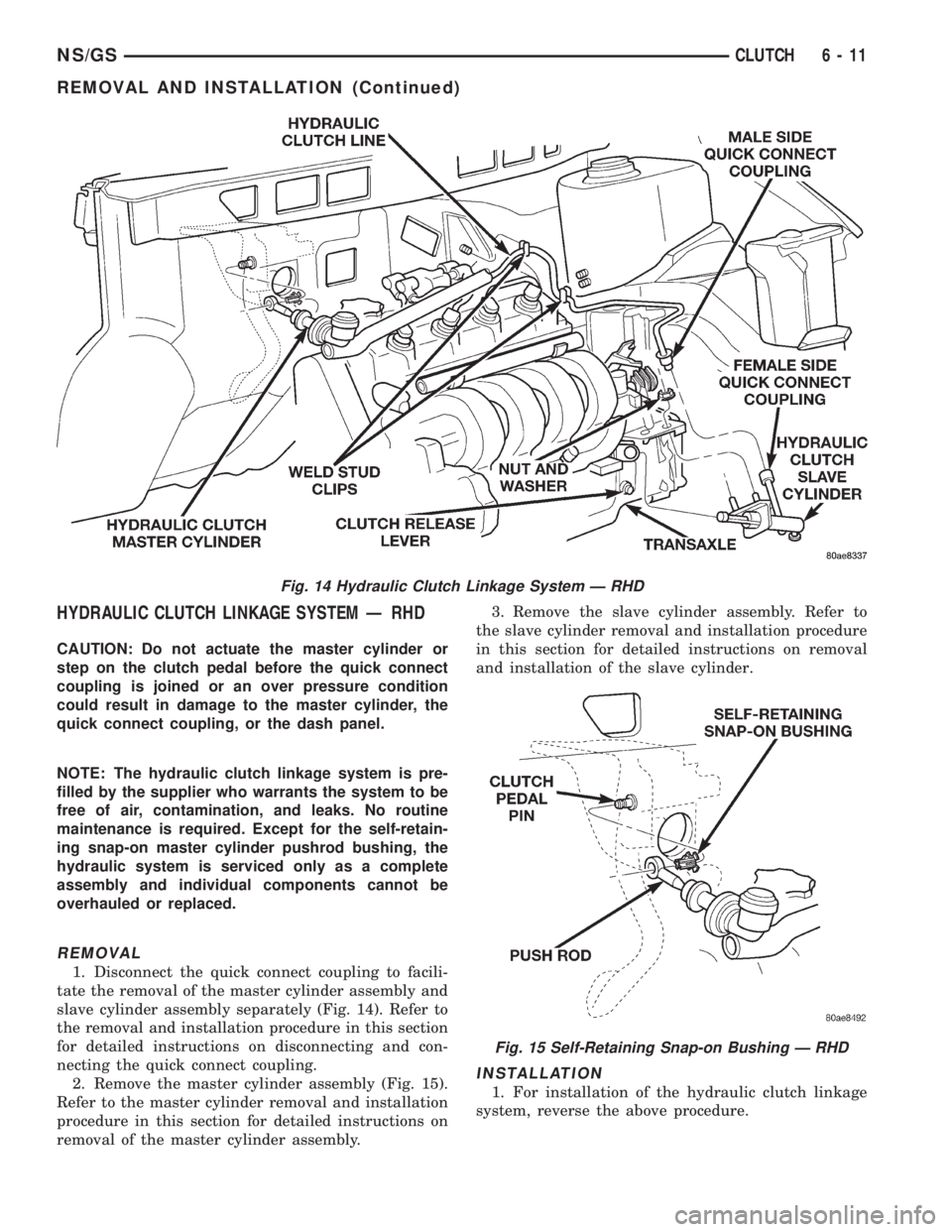

HYDRAULIC CLUTCH LINKAGE SYSTEM Ð RHD

CAUTION: Do not actuate the master cylinder or

step on the clutch pedal before the quick connect

coupling is joined or an over pressure condition

could result in damage to the master cylinder, the

quick connect coupling, or the dash panel.

NOTE: The hydraulic clutch linkage system is pre-

filled by the supplier who warrants the system to be

free of air, contamination, and leaks. No routine

maintenance is required. Except for the self-retain-

ing snap-on master cylinder pushrod bushing, the

hydraulic system is serviced only as a complete

assembly and individual components cannot be

overhauled or replaced.

REMOVAL

1. Disconnect the quick connect coupling to facili-

tate the removal of the master cylinder assembly and

slave cylinder assembly separately (Fig. 14). Refer to

the removal and installation procedure in this section

for detailed instructions on disconnecting and con-

necting the quick connect coupling.

2. Remove the master cylinder assembly (Fig. 15).

Refer to the master cylinder removal and installation

procedure in this section for detailed instructions on

removal of the master cylinder assembly.3. Remove the slave cylinder assembly. Refer to

the slave cylinder removal and installation procedure

in this section for detailed instructions on removal

and installation of the slave cylinder.

INSTALLATION

1. For installation of the hydraulic clutch linkage

system, reverse the above procedure.

Fig. 14 Hydraulic Clutch Linkage System Ð RHD

Fig. 15 Self-Retaining Snap-on Bushing Ð RHD

NS/GSCLUTCH 6 - 11

REMOVAL AND INSTALLATION (Continued)

Page 253 of 1938

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

SAFETY PRECAUTIONS AND WARNINGS..... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)........ 1

CHARGING TIME REQUIRED............... 2

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR........ 2

BATTERY IGNITION OFF DRAW (IOD)........ 3

BATTERY LOAD TEST..................... 4

BATTERY OPEN CIRCUIT VOLTAGE TEST..... 6SERVICE PROCEDURES

BATTERY CHARGING..................... 6

CHARGING COMPLETELY DISCHARGED

BATTERY............................. 7

VISUAL INSPECTION..................... 7

REMOVAL AND INSTALLATION

BATTERY TRAY.......................... 9

BATTERY............................... 8

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 10

TORQUE.............................. 10

GENERAL INFORMATION

INTRODUCTION

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle. The determination of whether a battery

is good or bad is made by its ability to accept a

charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE)

battery is equipped with a hydrometer (test indica-

tor) built into the battery cover. The specific gravity

indicates the battery's state-of-charge. The OE bat-

tery is sealed and water cannot be added.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged. The battery top, posts, and terminals should

be cleaned when other under hood maintenance is

performed.

When the electrolyte level is below the top of the

plates, Clear in the test Indicator, the battery must

be replaced. The battery must be completely charged,

and the battery top, posts, and cable clamps must be

cleaned before diagnostic procedures are performed.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE. DO NOT USE

OPEN FLAME NEAR BATTERY. REMOVE METALLIC

JEWELRY WORN ON HANDS OR WRISTS TO AVOID

INJURY BY ACCIDENTAL ARCING OF BATTERY

CURRENT.

WHEN USING A HIGH OUTPUT BOOSTING DEVICE,

DO NOT ALLOW THE DISABLED VEHICLE'S BAT-

TERY TO EXCEED 16 VOLTS. PERSONAL INJURY

OR DAMAGE TO ELECTRICAL SYSTEM CAN

RESULT.

TO PROTECT THE HANDS FROM BATTERY ACID, A

SUITABLE PAIR OF HEAVY DUTY RUBBER

GLOVES, NOT THE HOUSEHOLD TYPE, SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY. SAFETY GLASSES ALSO SHOULD BE

WORN.

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)

A completely normal vehicle will have a small

amount of current drain on the battery with the key

out of the ignition. It can range from 5 to 25 milli-

amperes after all the modules time out. If a vehicle

will not be operated for approximately a 20 days, the

IOD fuse should be pulled to eliminate the vehicle

electrical drain on the battery. The IOD fuse is

NSBATTERY 8A - 1

Page 255 of 1938

use. Refer to Causes of Battery Discharging in this

Group for more information.

NOTE: CLEAR COLOR = Replace Battery

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN CLEAR COLOR DOT IS VISIBLE. PERSONAL

INJURY MAY OCCUR.

A clear color dot shows electrolyte level in battery

is below the test indicator (Fig. 1). Water cannot be

added to a maintenance free battery. The battery

must be replaced. A low electrolyte level may be

caused by an over charging condition. Refer to Gen-

erator Test Procedures on Vehicle.

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 25 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF

position, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The con-

tinuous draw is due to various electronic features or

accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period of approximately 20

days the IOD fuse should be pulled. The fuse is

located in the power distribution center. Disconnec-

tion of this fuse will reduce the level of battery dis-

charge. Refer to Battery Diagnosis and Testing table

and to the proper procedures.

ABNORMAL BATTERY DISCHARGING

²Corroded battery posts, cables or terminals.

²Loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system due to equipment or accessories

installed after delivery.

²Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use.²Defective electrical circuit or component causing

excess Ignition Off Draw (IOD). Refer to Battery

Ignition Off Draw (IOD).

²Defective charging system.

²Defective battery.

BATTERY IGNITION OFF DRAW (IOD)

High current draw on the battery with the ignition

OFF will discharge a battery. After a dead battery is

serviced the vehicle Ignition Off Draw (IOD) should

be checked. Determine if a high current draw condi-

tion exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Liftgate and glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the Illuminated Entry System to time out

in approximately 30 seconds, if equipped.

²During Transmission Control Module (TCM)

power down there will be 500 milliamperes present

for 20 minutes. Afterwards less than 1.0 milliampere.

(2) Disconnect battery negative cable (Fig. 4).

CAUTION: Always disconnect the meter before

opening a door.

(3) Using an multimeter, that has least a milliam-

pere range of 200 mA. Set meter to the highest mA

range. Install meter between the battery negative

cable and battery negative post (Fig. 5). Carefully

remove the test lamp without disconnecting the

meter. After all modules time-out the total vehicle

IOD should be less than 25 milliamperes. If ignition

off draw is more than 25 milliamperes go to Step 4.

(4) Each time the test lamp or milliampere meter

is disconnected and connected, all electronic timer

functions will be activated for approximately one

minute. The Body Control Module (BCM) ignition off

draw can reach 90 milliamperes.

(5) Remove the PDC fuses:

²Interior lamps

²Brake lamp

²IOD

(6) If there is any reading, with fuses removed

there is a short circuit in the wiring. Refer to Group

8W, wiring diagrams. If reading is less than 25 mA

go to Step 8.

(7) Install all fuses. After installing fuse, the cur-

rent can reach 90 mA. After time-out the reading

should not exceed 25 mA. If OK go to. If not, discon-

nect:

²Radio

²Body Control Module

²Remote Keyless Entry Module

Fig. 3 Test Indicator

NSBATTERY 8A - 3

DIAGNOSIS AND TESTING (Continued)

Page 263 of 1938

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

SAFETY PRECAUTIONS AND WARNINGS.... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)....... 2

CHARGING TIME REQUIRED.............. 2

DIAGNOSIS AND TESTING

BATTERY DISCHARGING................. 3

BATTERY IGNITION OFF DRAW............ 3

BATTERY LOAD TEST................... 5

BATTERY OPEN CIRCUIT VOLTAGE TEST.... 6SERVICE PROCEDURES

BATTERY CHARGING.................... 6

CHARGING COMPLETELY DISCHARGED

BATTERY............................ 7

VISUAL INSPECTION.................... 7

REMOVAL AND INSTALLATION

BATTERY............................. 8

BATTERY TRAY........................ 9

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 9

TORQUE............................. 10

GENERAL INFORMATION

INTRODUCTION

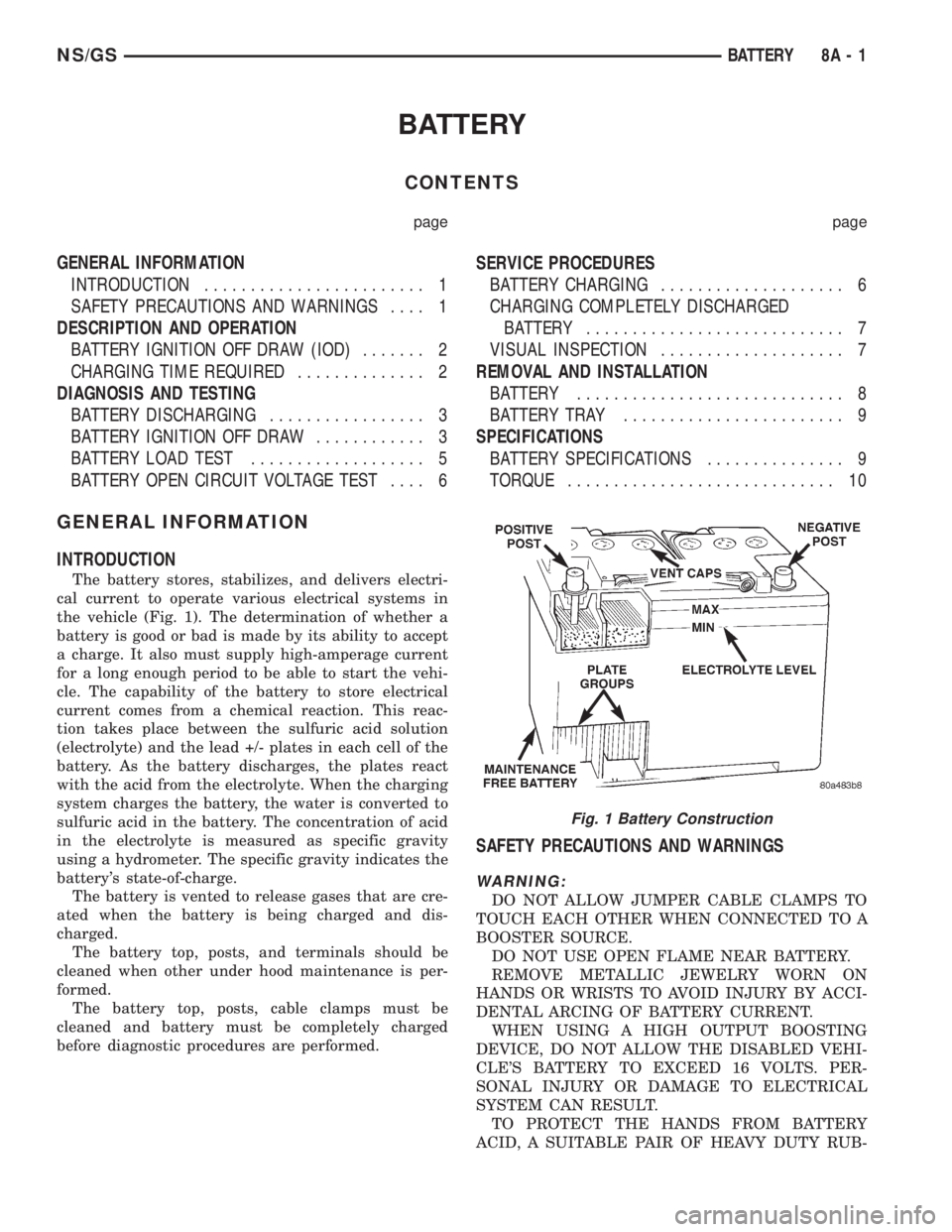

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle (Fig. 1). The determination of whether a

battery is good or bad is made by its ability to accept

a charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The specific gravity indicates the

battery's state-of-charge.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged.

The battery top, posts, and terminals should be

cleaned when other under hood maintenance is per-

formed.

The battery top, posts, cable clamps must be

cleaned and battery must be completely charged

before diagnostic procedures are performed.

SAFETY PRECAUTIONS AND WARNINGS

WARNING:

DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

DO NOT USE OPEN FLAME NEAR BATTERY.

REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW THE DISABLED VEHI-

CLE'S BATTERY TO EXCEED 16 VOLTS. PER-

SONAL INJURY OR DAMAGE TO ELECTRICAL

SYSTEM CAN RESULT.

TO PROTECT THE HANDS FROM BATTERY

ACID, A SUITABLE PAIR OF HEAVY DUTY RUB-

Fig. 1 Battery Construction

NS/GSBATTERY 8A - 1

Page 299 of 1938

IGNITION SYSTEM

CONTENTS

page page

GENERAL INFORMATION................... 1

2.4L ENGINE............................ 16

3.0L ENGINE............................ 233.3/3.8L ENGINE........................ 28

IGNITION SWITCH AND LOCK CYLINDER..... 35

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

AUTOMATIC SHUTDOWN (ASD) RELAY....... 4

CAMSHAFT POSITION SENSOR............. 5

CRANKSHAFT POSITION SENSOR........... 5

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR.............................. 6

IGNITION COIL.......................... 4

IGNITION SYSTEM....................... 2

INTRODUCTION......................... 1

KNOCK SENSOR......................... 7

LOCK KEY CYLINDER..................... 7

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR.............................. 6

POWERTRAIN CONTROL MODULE........... 1

SPARK PLUG CABLE...................... 3

SPARK PLUGSÐ2.4/3.0L................... 2

SPARK PLUGSÐ3.3/3.8L................... 2

THROTTLE POSITION SENSOR (TPS)........ 7DIAGNOSIS AND TESTING

CAMSHAFT POSITION SENSOR AND

CRANKSHAFT POSITION SENSOR......... 11

CHECK COIL TESTÐ2.4L.................. 9

CHECK COIL TESTÐ3.3/3.8L................ 9

ENGINE COOLANT TEMPERATURE SENSOR . . 11

FAILURE TO START TEST................. 10

IGNITION TIMING PROCEDURE............ 11

INTAKE AIR TEMPERATURE SENSOR........ 11

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST........................ 11

SPARK PLUG CONDITION................. 11

TESTING FOR SPARK AT COILÐ2.4/3.3/3.8L

ENGINES............................. 8

TESTING FOR SPARK AT COILÐ3.0L......... 8

THROTTLE POSITION SENSOR............ 13

SERVICE PROCEDURES

IGNITION TIMING PROCEDURE............ 15

POWERTRAIN CONTROL MODULE.......... 13

SPARK PLUG GAP ADJUSTMENT........... 13

GENERAL INFORMATION

INTRODUCTION

This group describes the ignition systems for the

2.4, 3.0, and 3.3/3.8L engines.

On Board Diagnostics is described in Group 25 -

Emission Control Systems.

Group 0 - Lubrication and Maintenance, contains

general maintenance information for ignition related

items. The Owner's Manual also contains mainte-

nance information.

POWERTRAIN CONTROL MODULE

The ignition system is regulated by the Powertrain

Control Module (PCM) (Fig. 1). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls

ground circuit for the ignition coil. By switching the

ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

During the crank-start period the PCM advances

ignition timing a set amount. During engine opera-

tion, the amount of spark advance provided by the

PCM is determined by the following input factors:

NSIGNITION SYSTEM 8D - 1

Page 300 of 1938

²available manifold vacuum

²barometric pressure

²engine coolant temperature

²engine RPM

²intake air temperature (2.4L only)

²throttle position

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

IGNITION SYSTEM

NOTE: The 2.4, 3.0 and 3.3/3.8L engines use a fixed

ignition timing system. Basic ignition timing is not

adjustable. All spark advance is determined by the

Powertrain Control Module (PCM).

The distributorless ignition system used on 2.4 and

3.3/3.8L engines is refered to as the Direct Ignition

System (DIS). The system's three main components

are the coil pack, crankshaft position sensor, and

camshaft position sensor. The crankshaft position

sensor and camshaft position sensor are hall effect

devices.

The 3.0L engine uses a distributor, crankshaft sen-

sor and ignition coil. The system's main components

are the distributor, distributor pickup, camshaft sig-

nal, crankshaft signal and ignition coil.

SPARK PLUGSÐ2.4/3.0L

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O - Lubrication and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Refer to the Spark Plug Condition section of

this group. After cleaning, file the center electrode

flat with a small flat point file or jewelers file. Adjust

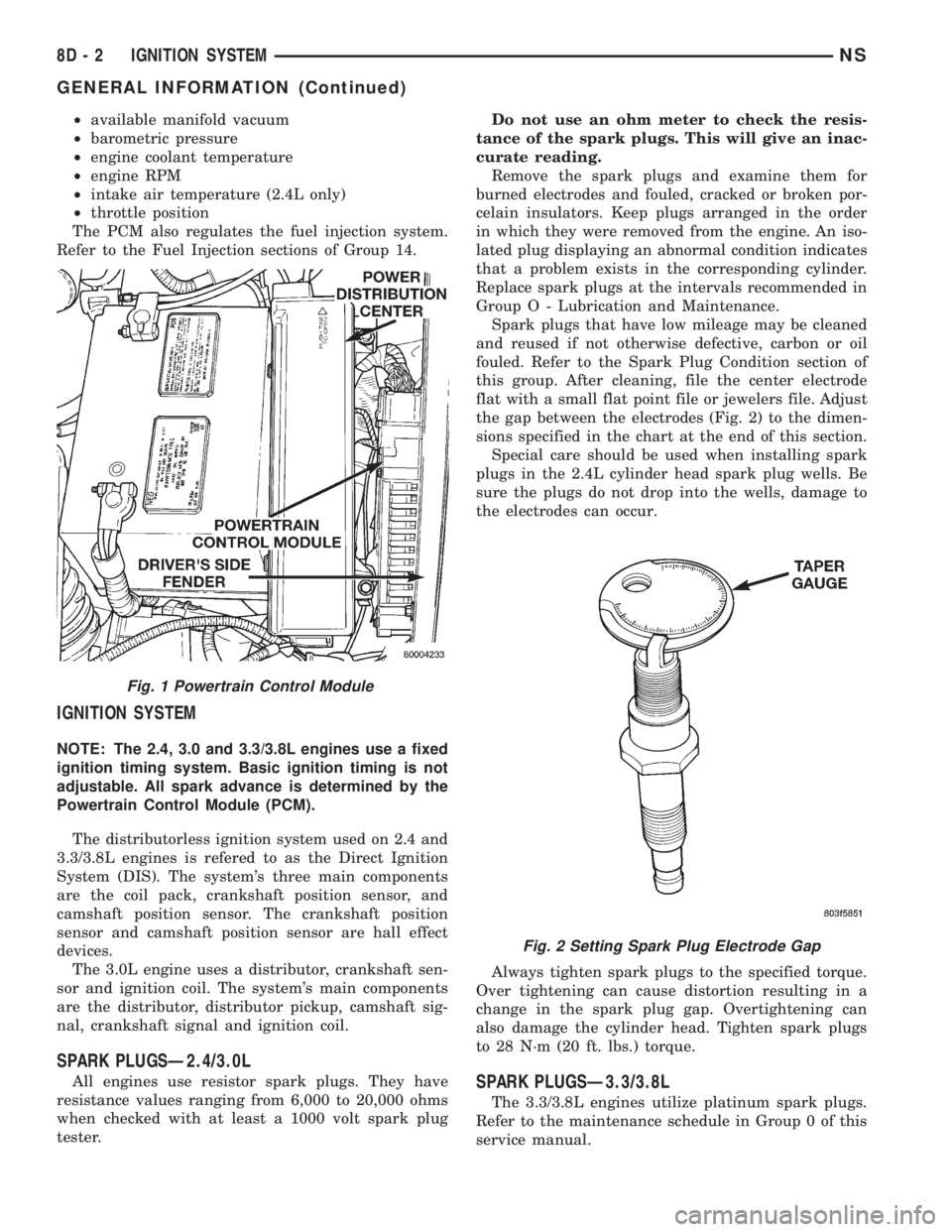

the gap between the electrodes (Fig. 2) to the dimen-

sions specified in the chart at the end of this section.

Special care should be used when installing spark

plugs in the 2.4L cylinder head spark plug wells. Be

sure the plugs do not drop into the wells, damage to

the electrodes can occur.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap. Overtightening can

also damage the cylinder head. Tighten spark plugs

to 28 N´m (20 ft. lbs.) torque.SPARK PLUGSÐ3.3/3.8L

The 3.3/3.8L engines utilize platinum spark plugs.

Refer to the maintenance schedule in Group 0 of this

service manual.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)