shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1590 of 1938

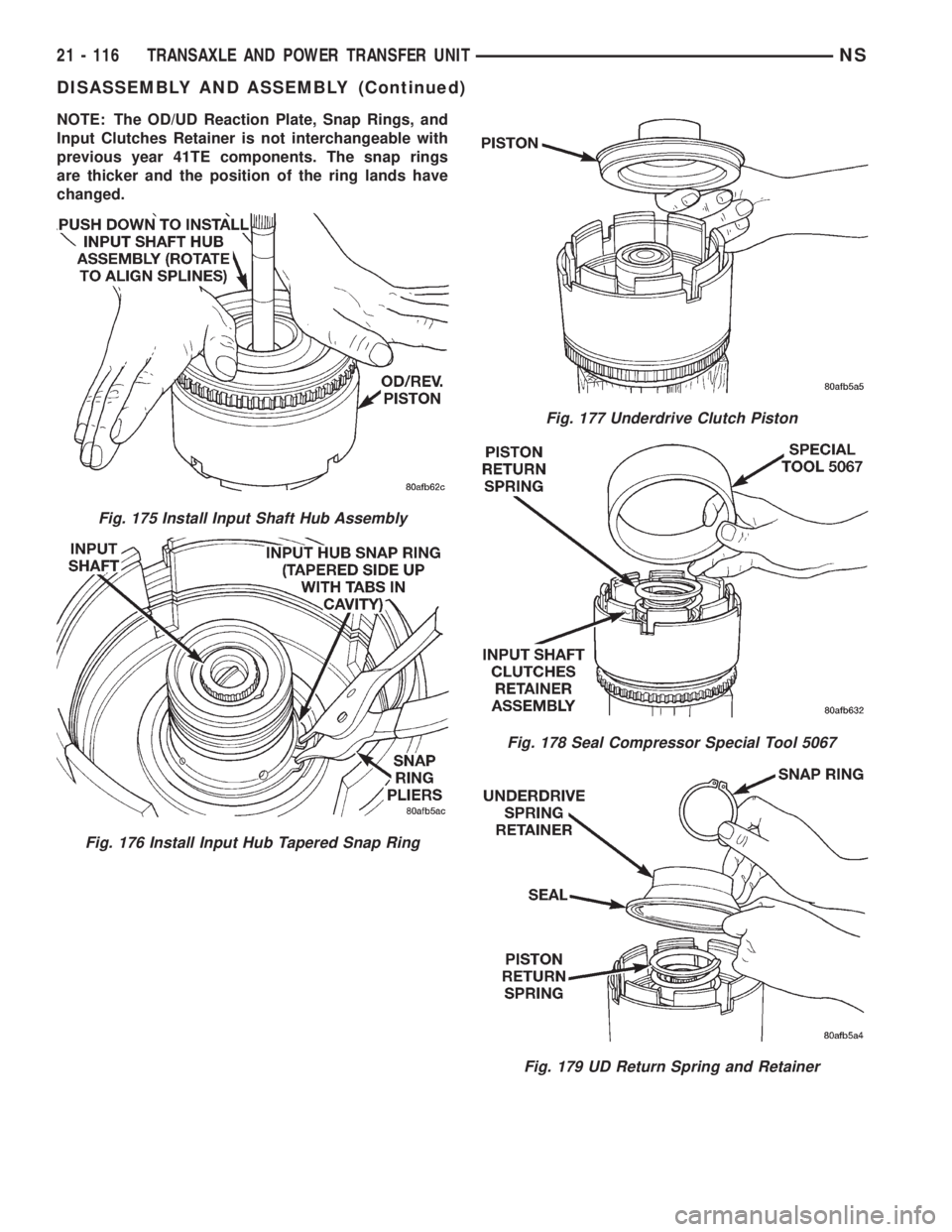

NOTE: The OD/UD Reaction Plate, Snap Rings, and

Input Clutches Retainer is not interchangeable with

previous year 41TE components. The snap rings

are thicker and the position of the ring lands have

changed.

Fig. 175 Install Input Shaft Hub Assembly

Fig. 176 Install Input Hub Tapered Snap Ring

Fig. 177 Underdrive Clutch Piston

Fig. 178 Seal Compressor Special Tool 5067

Fig. 179 UD Return Spring and Retainer

21 - 116 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1595 of 1938

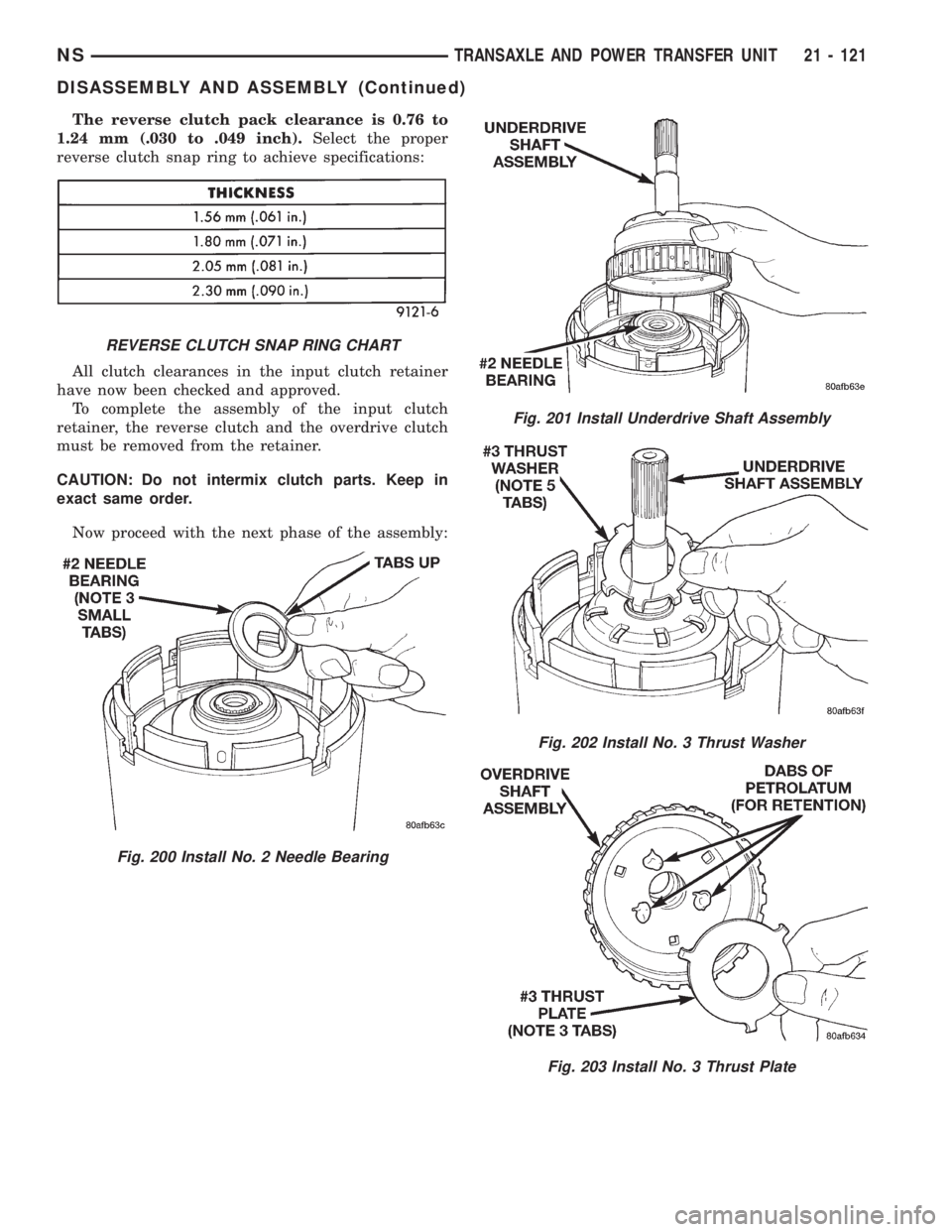

The reverse clutch pack clearance is 0.76 to

1.24 mm (.030 to .049 inch).Select the proper

reverse clutch snap ring to achieve specifications:

All clutch clearances in the input clutch retainer

have now been checked and approved.

To complete the assembly of the input clutch

retainer, the reverse clutch and the overdrive clutch

must be removed from the retainer.

CAUTION: Do not intermix clutch parts. Keep in

exact same order.

Now proceed with the next phase of the assembly:

REVERSE CLUTCH SNAP RING CHART

Fig. 200 Install No. 2 Needle Bearing

Fig. 201 Install Underdrive Shaft Assembly

Fig. 202 Install No. 3 Thrust Washer

Fig. 203 Install No. 3 Thrust Plate

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 121

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1596 of 1938

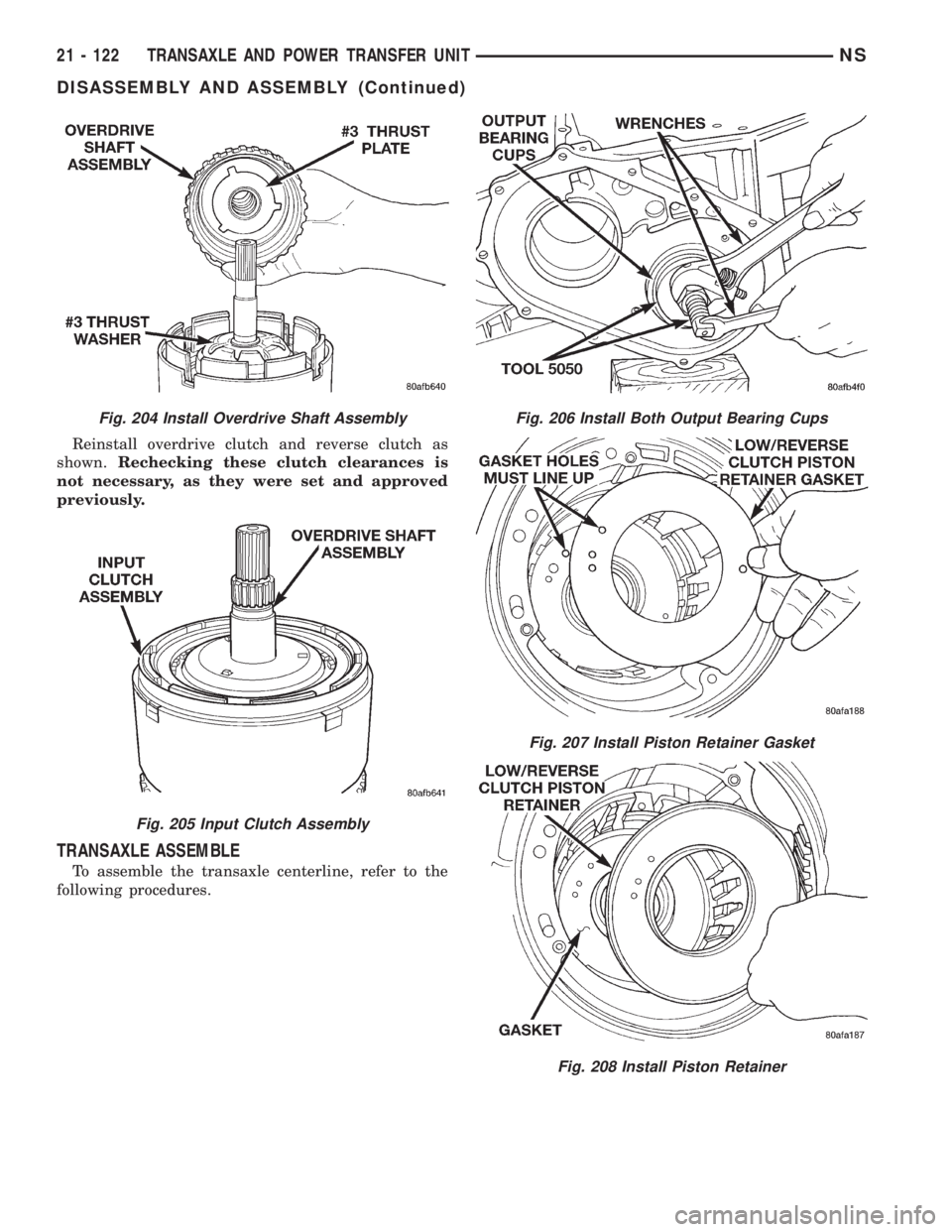

Reinstall overdrive clutch and reverse clutch as

shown.Rechecking these clutch clearances is

not necessary, as they were set and approved

previously.

TRANSAXLE ASSEMBLE

To assemble the transaxle centerline, refer to the

following procedures.

Fig. 204 Install Overdrive Shaft Assembly

Fig. 205 Input Clutch Assembly

Fig. 206 Install Both Output Bearing Cups

Fig. 207 Install Piston Retainer Gasket

Fig. 208 Install Piston Retainer

21 - 122 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1597 of 1938

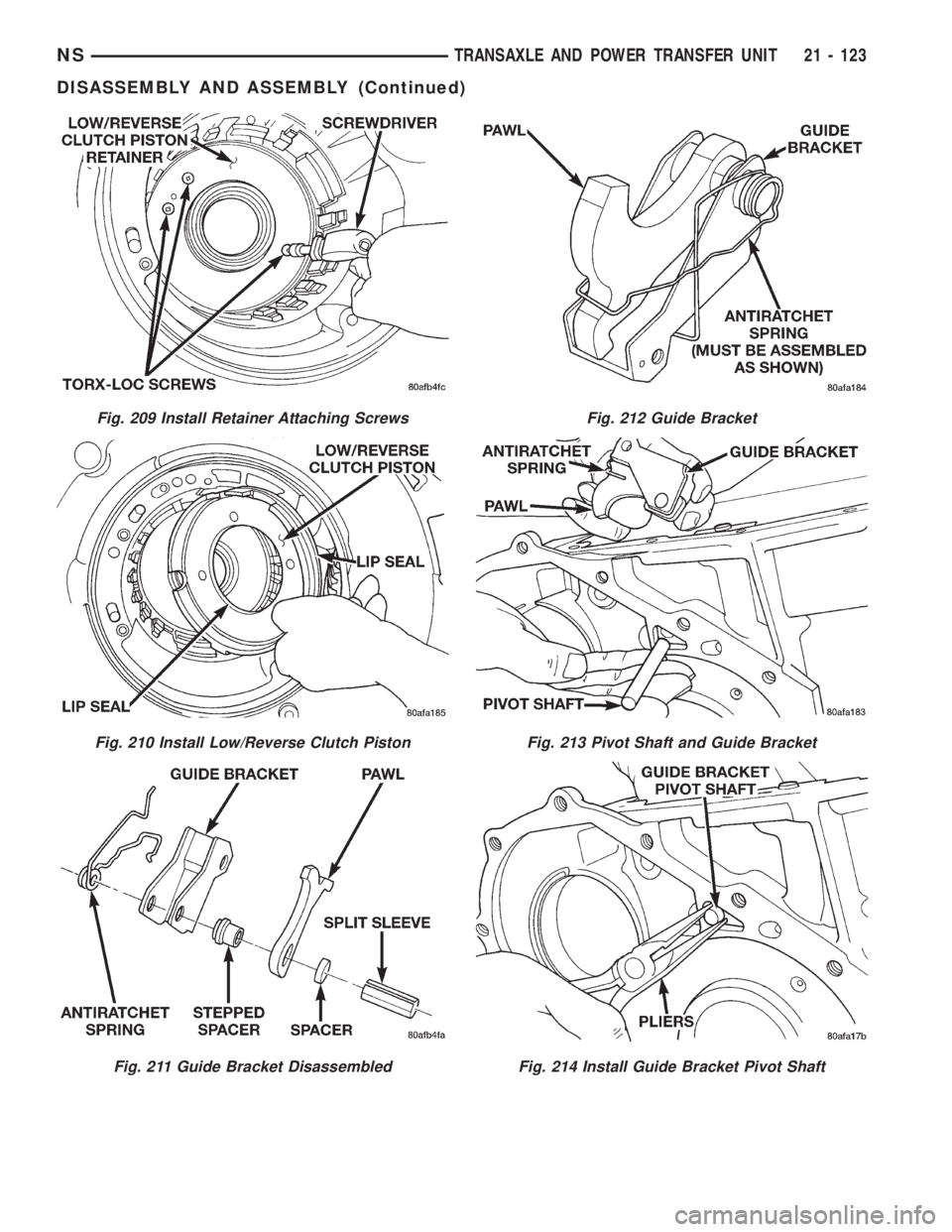

Fig. 209 Install Retainer Attaching Screws

Fig. 210 Install Low/Reverse Clutch Piston

Fig. 211 Guide Bracket Disassembled

Fig. 212 Guide Bracket

Fig. 213 Pivot Shaft and Guide Bracket

Fig. 214 Install Guide Bracket Pivot Shaft

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 123

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1598 of 1938

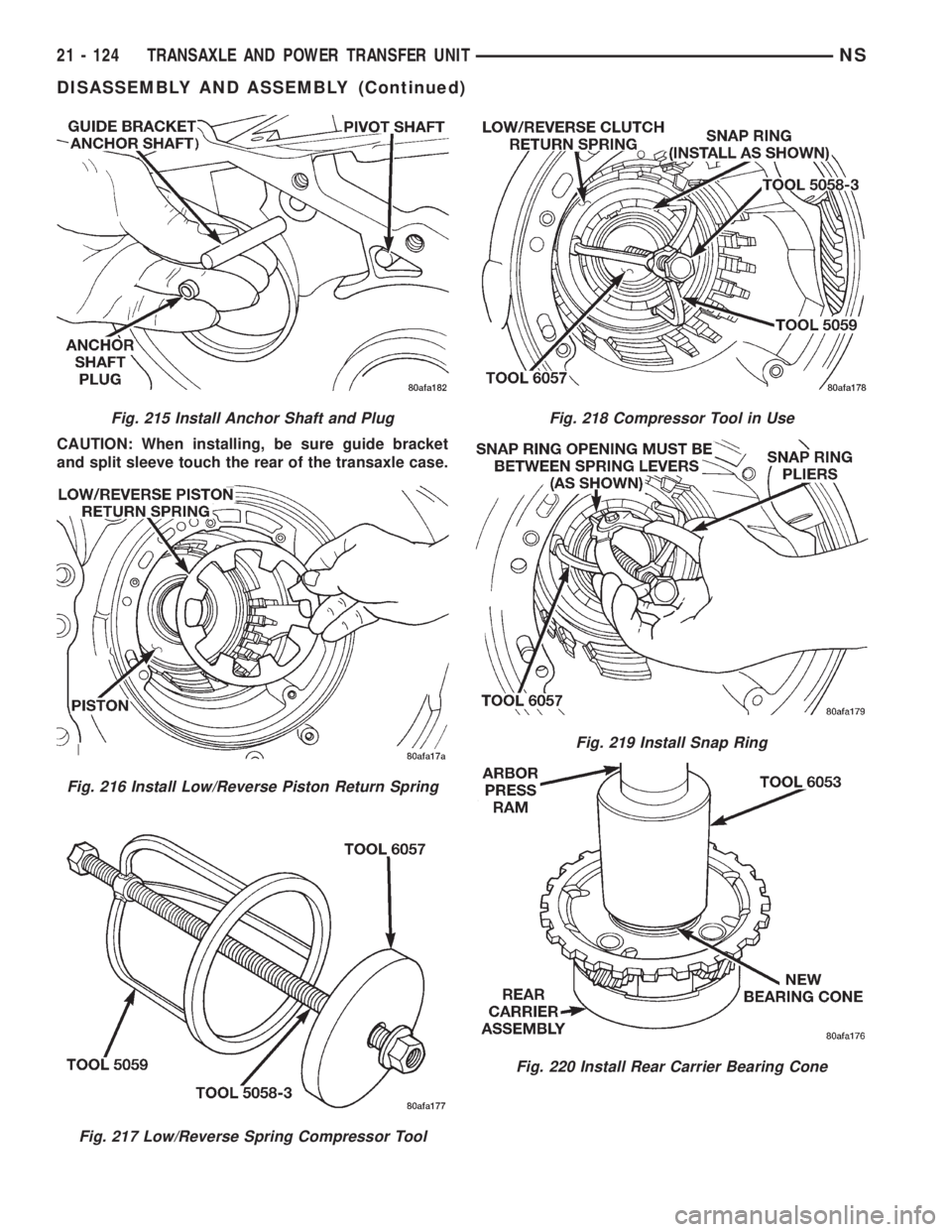

CAUTION: When installing, be sure guide bracket

and split sleeve touch the rear of the transaxle case.

Fig. 215 Install Anchor Shaft and Plug

Fig. 216 Install Low/Reverse Piston Return Spring

Fig. 217 Low/Reverse Spring Compressor Tool

Fig. 218 Compressor Tool in Use

Fig. 219 Install Snap Ring

Fig. 220 Install Rear Carrier Bearing Cone

21 - 124 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1602 of 1938

Fig. 231 Install Strap Bolts

Fig. 232 Turn Stirrup Clockwise Against Flats Of

Output Gear Retaining Bolt

Fig. 233 Tighten Stirrup Strap Bolts To 23 N´m

(200 in. lbs.)

Fig. 234 Bend Tabs On Strap Up Against Flats Of

Bolts

Fig. 235 Install Transfer Shaft Bearing Cone

Fig. 236 Install Bearing Cup To Shaft

21 - 128 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1603 of 1938

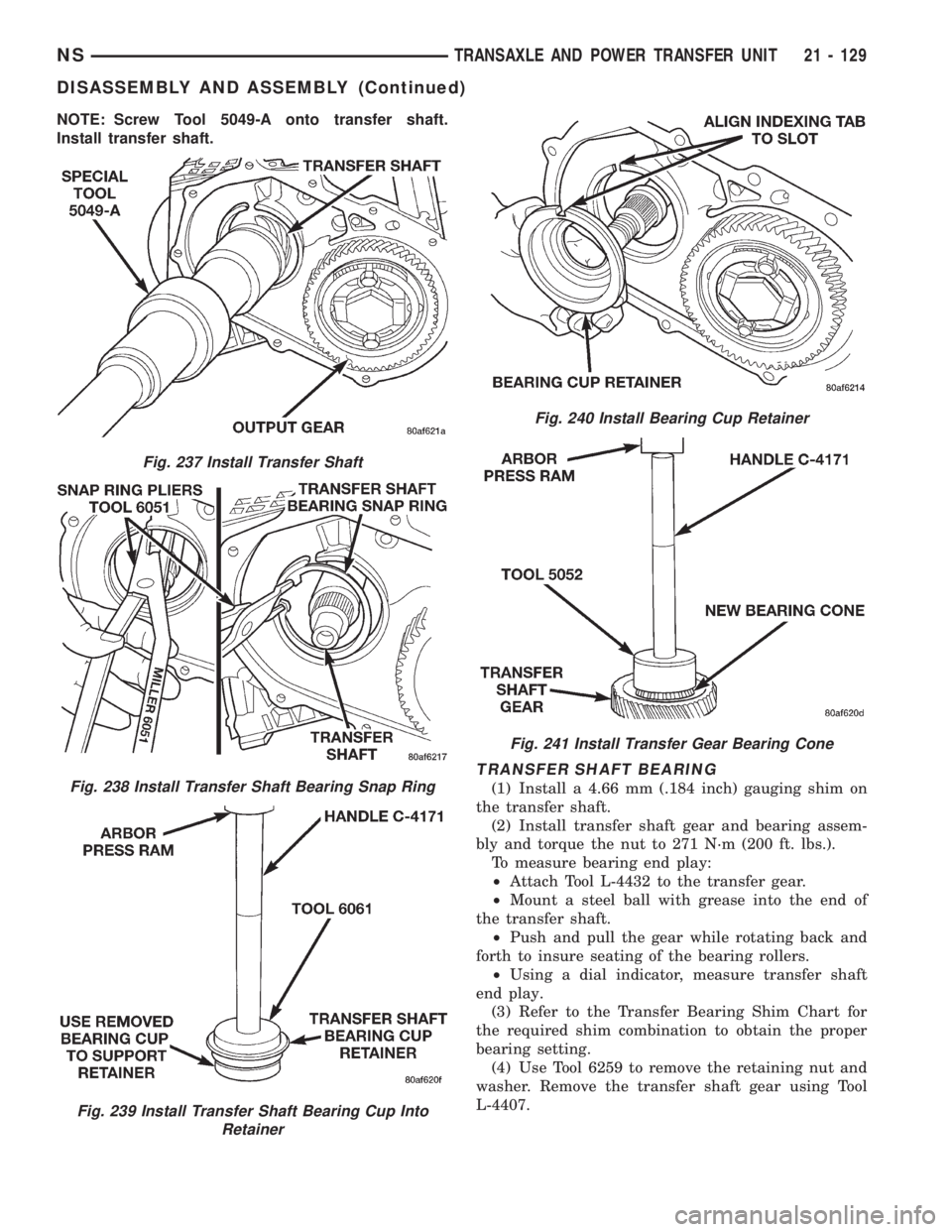

NOTE: Screw Tool 5049-A onto transfer shaft.

Install transfer shaft.

TRANSFER SHAFT BEARING

(1) Install a 4.66 mm (.184 inch) gauging shim on

the transfer shaft.

(2) Install transfer shaft gear and bearing assem-

bly and torque the nut to 271 N´m (200 ft. lbs.).

To measure bearing end play:

²Attach Tool L-4432 to the transfer gear.

²Mount a steel ball with grease into the end of

the transfer shaft.

²Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

²Using a dial indicator, measure transfer shaft

end play.

(3) Refer to the Transfer Bearing Shim Chart for

the required shim combination to obtain the proper

bearing setting.

(4) Use Tool 6259 to remove the retaining nut and

washer. Remove the transfer shaft gear using Tool

L-4407.

Fig. 237 Install Transfer Shaft

Fig. 238 Install Transfer Shaft Bearing Snap Ring

Fig. 239 Install Transfer Shaft Bearing Cup Into

Retainer

Fig. 240 Install Bearing Cup Retainer

Fig. 241 Install Transfer Gear Bearing Cone

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 129

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1604 of 1938

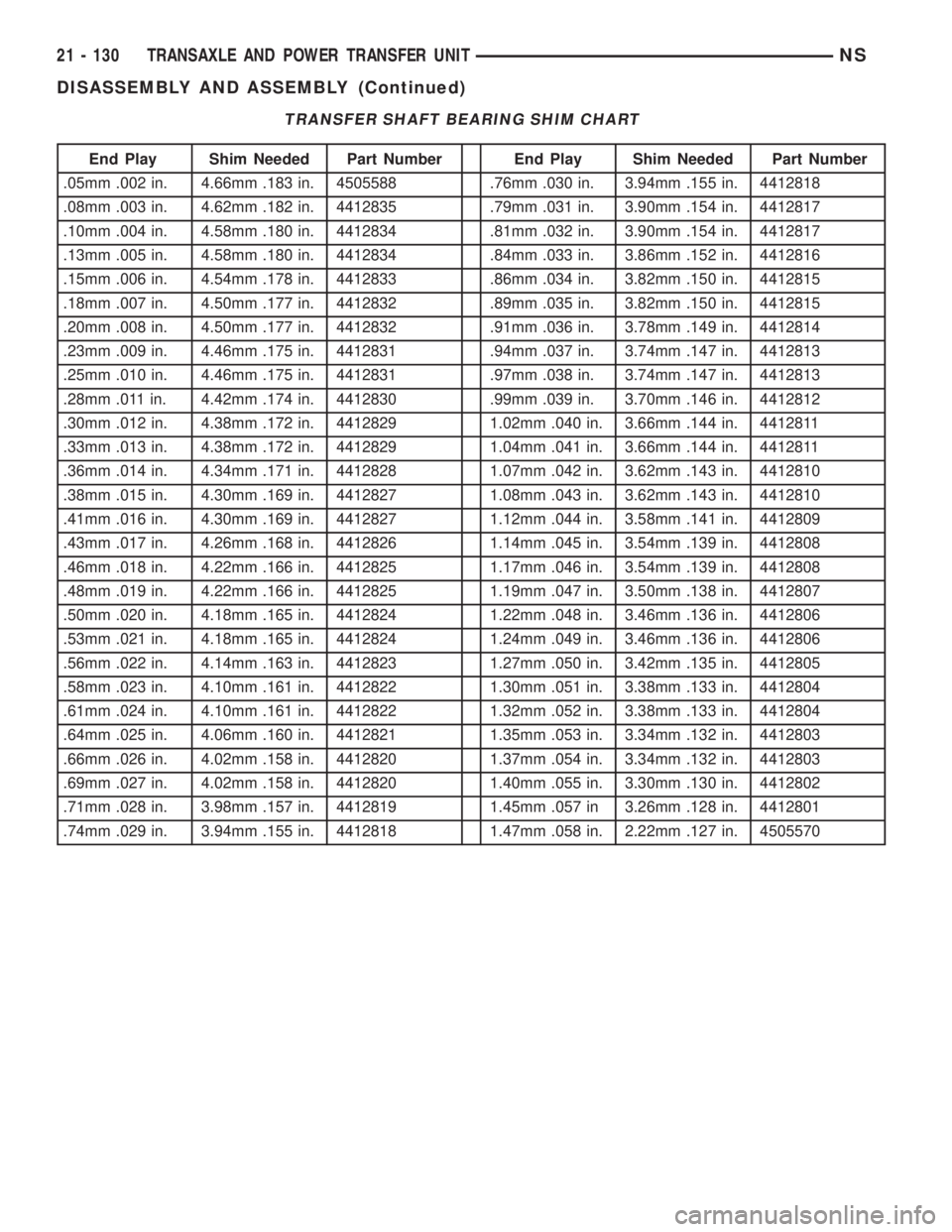

TRANSFER SHAFT BEARING SHIM CHART

End Play Shim Needed Part Number End Play Shim Needed Part Number

.05mm .002 in. 4.66mm .183 in. 4505588 .76mm .030 in. 3.94mm .155 in. 4412818

.08mm .003 in. 4.62mm .182 in. 4412835 .79mm .031 in. 3.90mm .154 in. 4412817

.10mm .004 in. 4.58mm .180 in. 4412834 .81mm .032 in. 3.90mm .154 in. 4412817

.13mm .005 in. 4.58mm .180 in. 4412834 .84mm .033 in. 3.86mm .152 in. 4412816

.15mm .006 in. 4.54mm .178 in. 4412833 .86mm .034 in. 3.82mm .150 in. 4412815

.18mm .007 in. 4.50mm .177 in. 4412832 .89mm .035 in. 3.82mm .150 in. 4412815

.20mm .008 in. 4.50mm .177 in. 4412832 .91mm .036 in. 3.78mm .149 in. 4412814

.23mm .009 in. 4.46mm .175 in. 4412831 .94mm .037 in. 3.74mm .147 in. 4412813

.25mm .010 in. 4.46mm .175 in. 4412831 .97mm .038 in. 3.74mm .147 in. 4412813

.28mm .011 in. 4.42mm .174 in. 4412830 .99mm .039 in. 3.70mm .146 in. 4412812

.30mm .012 in. 4.38mm .172 in. 4412829 1.02mm .040 in. 3.66mm .144 in. 4412811

.33mm .013 in. 4.38mm .172 in. 4412829 1.04mm .041 in. 3.66mm .144 in. 4412811

.36mm .014 in. 4.34mm .171 in. 4412828 1.07mm .042 in. 3.62mm .143 in. 4412810

.38mm .015 in. 4.30mm .169 in. 4412827 1.08mm .043 in. 3.62mm .143 in. 4412810

.41mm .016 in. 4.30mm .169 in. 4412827 1.12mm .044 in. 3.58mm .141 in. 4412809

.43mm .017 in. 4.26mm .168 in. 4412826 1.14mm .045 in. 3.54mm .139 in. 4412808

.46mm .018 in. 4.22mm .166 in. 4412825 1.17mm .046 in. 3.54mm .139 in. 4412808

.48mm .019 in. 4.22mm .166 in. 4412825 1.19mm .047 in. 3.50mm .138 in. 4412807

.50mm .020 in. 4.18mm .165 in. 4412824 1.22mm .048 in. 3.46mm .136 in. 4412806

.53mm .021 in. 4.18mm .165 in. 4412824 1.24mm .049 in. 3.46mm .136 in. 4412806

.56mm .022 in. 4.14mm .163 in. 4412823 1.27mm .050 in. 3.42mm .135 in. 4412805

.58mm .023 in. 4.10mm .161 in. 4412822 1.30mm .051 in. 3.38mm .133 in. 4412804

.61mm .024 in. 4.10mm .161 in. 4412822 1.32mm .052 in. 3.38mm .133 in. 4412804

.64mm .025 in. 4.06mm .160 in. 4412821 1.35mm .053 in. 3.34mm .132 in. 4412803

.66mm .026 in. 4.02mm .158 in. 4412820 1.37mm .054 in. 3.34mm .132 in. 4412803

.69mm .027 in. 4.02mm .158 in. 4412820 1.40mm .055 in. 3.30mm .130 in. 4412802

.71mm .028 in. 3.98mm .157 in. 4412819 1.45mm .057 in 3.26mm .128 in. 4412801

.74mm .029 in. 3.94mm .155 in. 4412818 1.47mm .058 in. 2.22mm .127 in. 4505570

21 - 130 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1605 of 1938

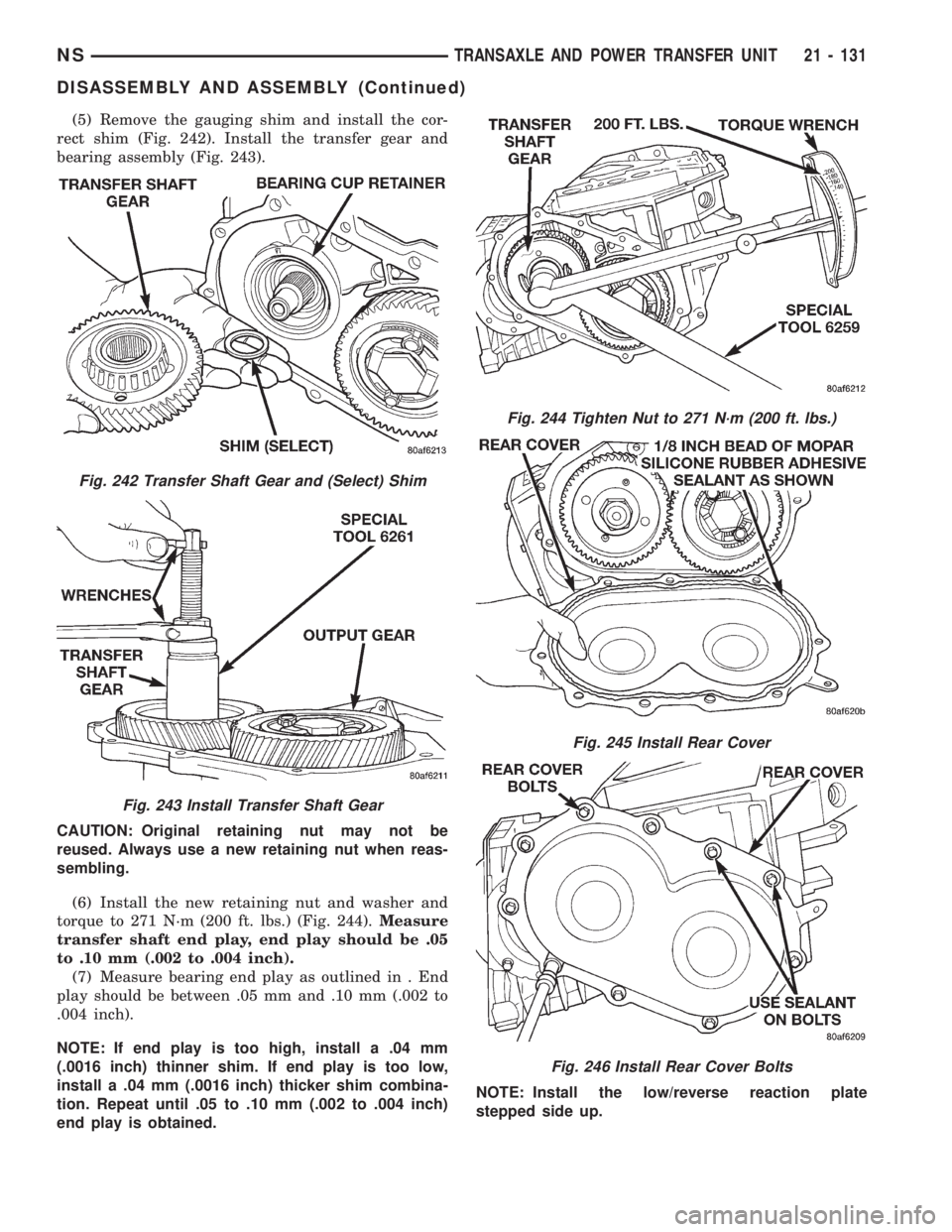

(5) Remove the gauging shim and install the cor-

rect shim (Fig. 242). Install the transfer gear and

bearing assembly (Fig. 243).

CAUTION: Original retaining nut may not be

reused. Always use a new retaining nut when reas-

sembling.

(6) Install the new retaining nut and washer and

torque to 271 N´m (200 ft. lbs.) (Fig. 244).Measure

transfer shaft end play, end play should be .05

to .10 mm (.002 to .004 inch).

(7) Measure bearing end play as outlined in . End

play should be between .05 mm and .10 mm (.002 to

.004 inch).

NOTE: If end play is too high, install a .04 mm

(.0016 inch) thinner shim. If end play is too low,

install a .04 mm (.0016 inch) thicker shim combina-

tion. Repeat until .05 to .10 mm (.002 to .004 inch)

end play is obtained.NOTE: Install the low/reverse reaction plate

stepped side up.

Fig. 242 Transfer Shaft Gear and (Select) Shim

Fig. 243 Install Transfer Shaft Gear

Fig. 244 Tighten Nut to 271 N´m (200 ft. lbs.)

Fig. 245 Install Rear Cover

Fig. 246 Install Rear Cover Bolts

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 131

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1608 of 1938

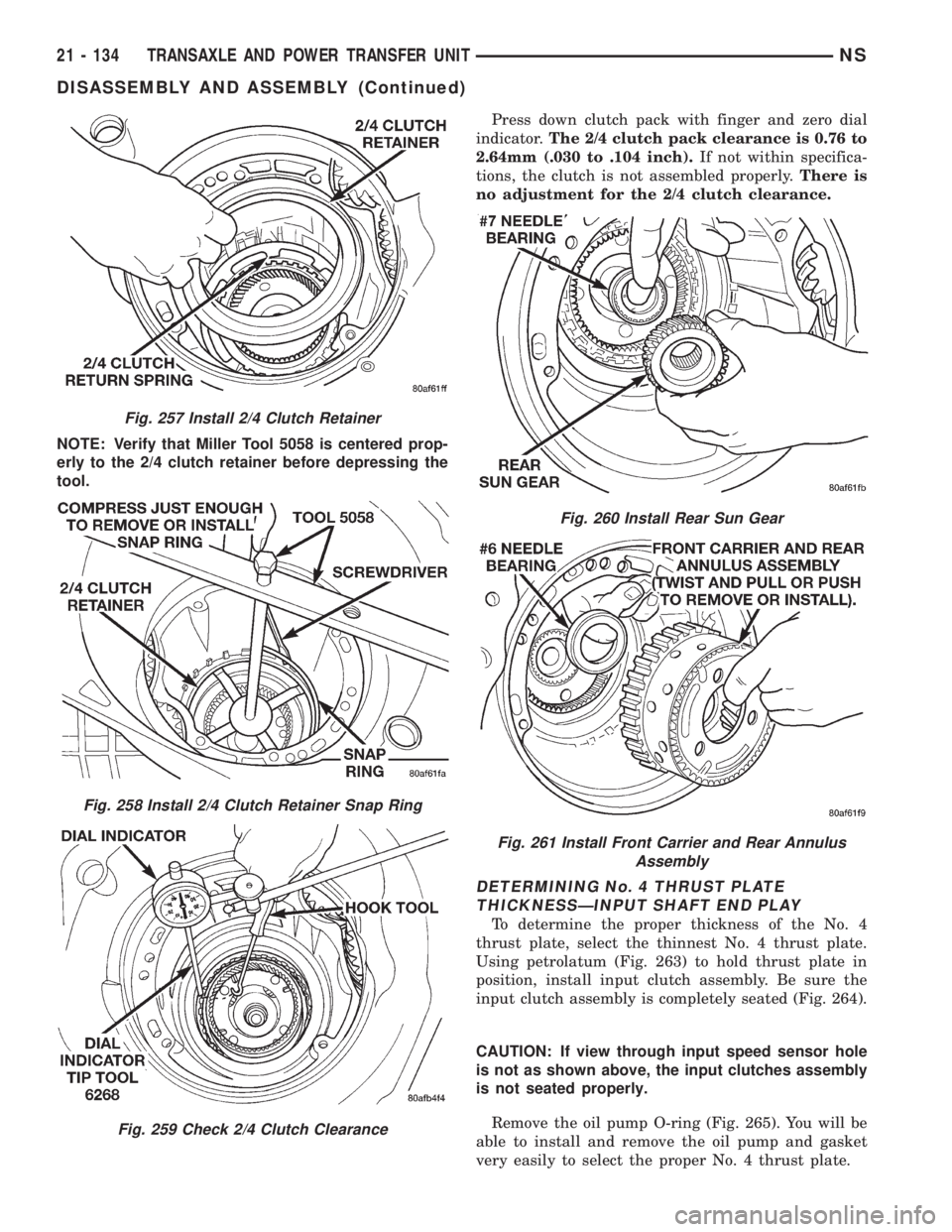

NOTE: Verify that Miller Tool 5058 is centered prop-

erly to the 2/4 clutch retainer before depressing the

tool.Press down clutch pack with finger and zero dial

indicator.The 2/4 clutch pack clearance is 0.76 to

2.64mm (.030 to .104 inch).If not within specifica-

tions, the clutch is not assembled properly.There is

no adjustment for the 2/4 clutch clearance.

DETERMINING No. 4 THRUST PLATE

THICKNESSÐINPUT SHAFT END PLAY

To determine the proper thickness of the No. 4

thrust plate, select the thinnest No. 4 thrust plate.

Using petrolatum (Fig. 263) to hold thrust plate in

position, install input clutch assembly. Be sure the

input clutch assembly is completely seated (Fig. 264).

CAUTION: If view through input speed sensor hole

is not as shown above, the input clutches assembly

is not seated properly.

Remove the oil pump O-ring (Fig. 265). You will be

able to install and remove the oil pump and gasket

very easily to select the proper No. 4 thrust plate.

Fig. 257 Install 2/4 Clutch Retainer

Fig. 258 Install 2/4 Clutch Retainer Snap Ring

Fig. 259 Check 2/4 Clutch Clearance

Fig. 260 Install Rear Sun Gear

Fig. 261 Install Front Carrier and Rear Annulus

Assembly

21 - 134 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)