shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1609 of 1938

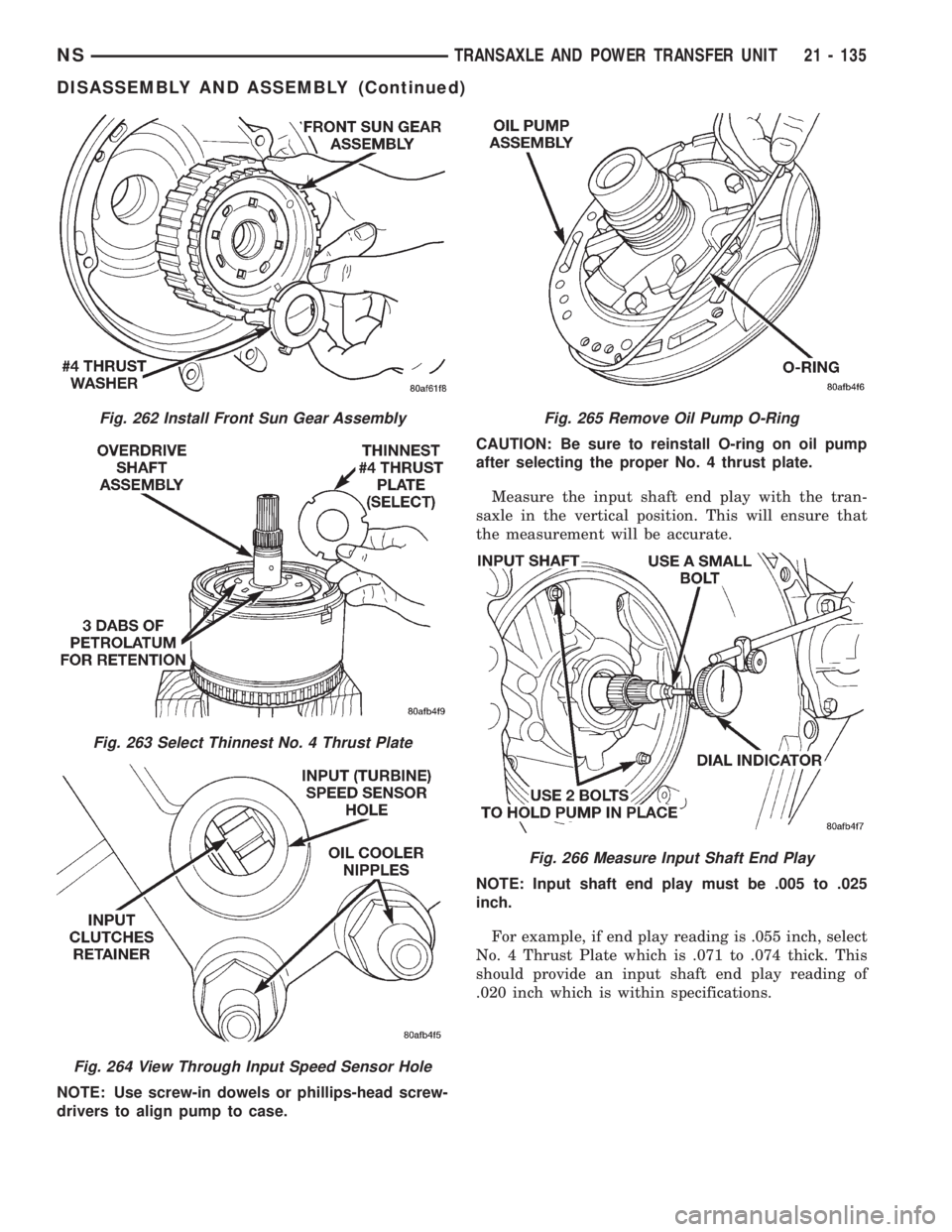

NOTE: Use screw-in dowels or phillips-head screw-

drivers to align pump to case.CAUTION: Be sure to reinstall O-ring on oil pump

after selecting the proper No. 4 thrust plate.

Measure the input shaft end play with the tran-

saxle in the vertical position. This will ensure that

the measurement will be accurate.

NOTE: Input shaft end play must be .005 to .025

inch.

For example, if end play reading is .055 inch, select

No. 4 Thrust Plate which is .071 to .074 thick. This

should provide an input shaft end play reading of

.020 inch which is within specifications.

Fig. 262 Install Front Sun Gear Assembly

Fig. 263 Select Thinnest No. 4 Thrust Plate

Fig. 264 View Through Input Speed Sensor Hole

Fig. 265 Remove Oil Pump O-Ring

Fig. 266 Measure Input Shaft End Play

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 135

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1613 of 1938

(1) Install transaxle solenoid pack (Fig. 284).

(2) Install input and output speed sensors.

This concludes the assembly of the transaxle cen-

terline.

DIFFERENTIAL REPAIR

NOTE: The differential is serviced as an assembly.

The only parts that are serviceable within the differ-

ential are the differential bearing cups and cones. If

any other part fails within the differential, you must

replace the differential assembly along with the

transfer shaft.

DISASSEMBLE

The transfer shaft should be removed for differen-

tial repair and bearing turning torque checking.

(1) Remove the differential cover and bolts (Fig.

285) (Fig. 286).

(2) Remove the differential bearing retainer and

bolts (Fig. 287) (Fig. 288).(3) Using a plastic hammer, remove extension

housing/adapter plate on the right side of the tran-

saxle.

Fig. 283 Install Pan Bolts

Fig. 284 Install Solenoid Pack

Fig. 285 Differential Cover Bolts

Fig. 286 Remove Differential Cover

Fig. 287 Differential Retainer Bolts

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 139

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1616 of 1938

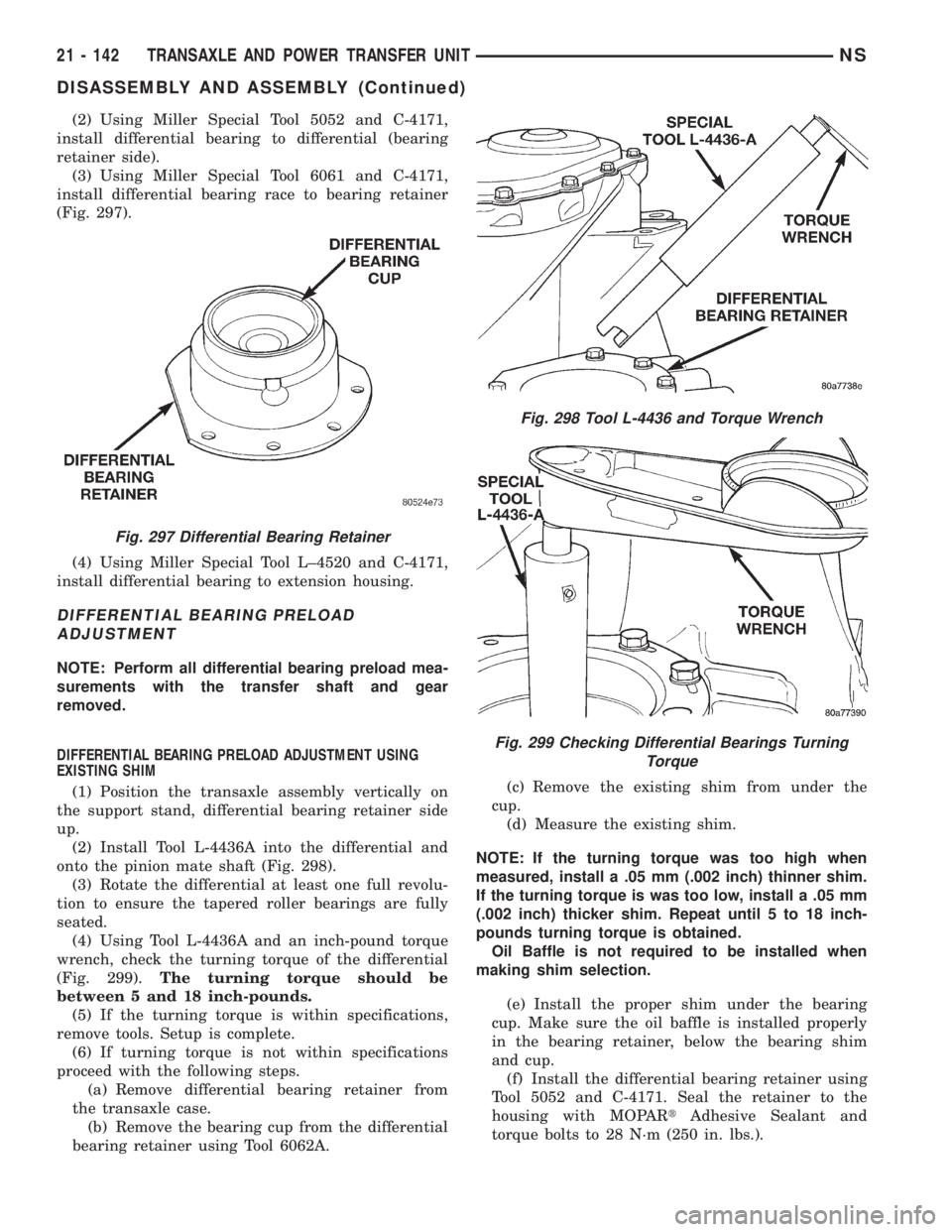

(2) Using Miller Special Tool 5052 and C-4171,

install differential bearing to differential (bearing

retainer side).

(3) Using Miller Special Tool 6061 and C-4171,

install differential bearing race to bearing retainer

(Fig. 297).

(4) Using Miller Special Tool L±4520 and C-4171,

install differential bearing to extension housing.

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT

NOTE: Perform all differential bearing preload mea-

surements with the transfer shaft and gear

removed.

DIFFERENTIAL BEARING PRELOAD ADJUSTMENT USING

EXISTING SHIM

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft (Fig. 298).

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential

(Fig. 299).The turning torque should be

between 5 and 18 inch-pounds.

(5) If the turning torque is within specifications,

remove tools. Setup is complete.

(6) If turning torque is not within specifications

proceed with the following steps.

(a) Remove differential bearing retainer from

the transaxle case.

(b) Remove the bearing cup from the differential

bearing retainer using Tool 6062A.(c) Remove the existing shim from under the

cup.

(d) Measure the existing shim.

NOTE: If the turning torque was too high when

measured, install a .05 mm (.002 inch) thinner shim.

If the turning torque is was too low, install a .05 mm

(.002 inch) thicker shim. Repeat until 5 to 18 inch-

pounds turning torque is obtained.

Oil Baffle is not required to be installed when

making shim selection.

(e) Install the proper shim under the bearing

cup. Make sure the oil baffle is installed properly

in the bearing retainer, below the bearing shim

and cup.

(f) Install the differential bearing retainer using

Tool 5052 and C-4171. Seal the retainer to the

housing with MOPARtAdhesive Sealant and

torque bolts to 28 N´m (250 in. lbs.).

Fig. 297 Differential Bearing Retainer

Fig. 298 Tool L-4436 and Torque Wrench

Fig. 299 Checking Differential Bearings Turning

Torque

21 - 142 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1632 of 1938

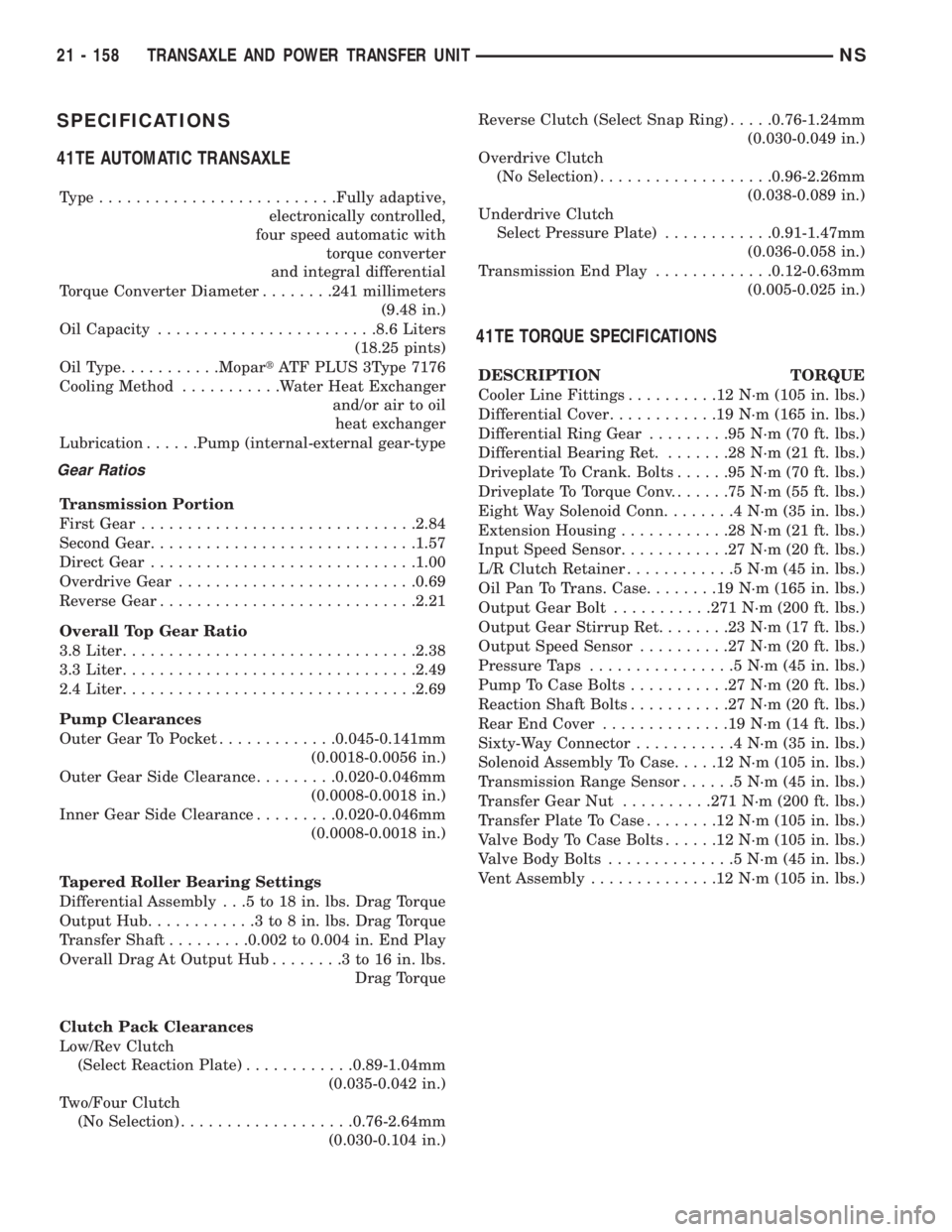

SPECIFICATIONS

41TE AUTOMATIC TRANSAXLE

Type..........................Fully adaptive,

electronically controlled,

four speed automatic with

torque converter

and integral differential

Torque Converter Diameter........241 millimeters

(9.48 in.)

Oil Capacity........................8.6 Liters

(18.25 pints)

OilType...........MopartATF PLUS 3Type 7176

Cooling Method...........Water Heat Exchanger

and/or air to oil

heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.84

Second Gear.............................1.57

Direct Gear.............................1.00

Overdrive Gear..........................0.69

Reverse Gear............................2.21

Overall Top Gear Ratio

3.8 Liter................................2.38

3.3 Liter................................2.49

2.4 Liter................................2.69

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . .5 to 18 in. lbs. Drag Torque

Output Hub............3to8in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.004 in. End Play

Overall Drag At Output Hub........3to16in.lbs.

Drag Torque

Clutch Pack Clearances

Low/Rev Clutch

(Select Reaction Plate)............0.89-1.04mm

(0.035-0.042 in.)

Two/Four Clutch

(No Selection)...................0.76-2.64mm

(0.030-0.104 in.)Reverse Clutch (Select Snap Ring).....0.76-1.24mm

(0.030-0.049 in.)

Overdrive Clutch

(No Selection)...................0.96-2.26mm

(0.038-0.089 in.)

Underdrive Clutch

Select Pressure Plate)............0.91-1.47mm

(0.036-0.058 in.)

Transmission End Play.............0.12-0.63mm

(0.005-0.025 in.)

41TE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Cooler Line Fittings..........12N´m(105 in. lbs.)

Differential Cover............19N´m(165 in. lbs.)

Differential Ring Gear.........95N´m(70ft.lbs.)

Differential Bearing Ret........28N´m(21ft.lbs.)

Driveplate To Crank. Bolts......95N´m(70ft.lbs.)

Driveplate To Torque Conv.......75N´m(55ft.lbs.)

Eight Way Solenoid Conn........4N´m(35in.lbs.)

Extension Housing............28N´m(21ft.lbs.)

Input Speed Sensor............27N´m(20ft.lbs.)

L/R Clutch Retainer............5N´m(45in.lbs.)

Oil Pan To Trans. Case........19N´m(165 in. lbs.)

Output Gear Bolt...........271 N´m (200 ft. lbs.)

Output Gear Stirrup Ret........23N´m(17ft.lbs.)

Output Speed Sensor..........27N´m(20ft.lbs.)

Pressure Taps................5N´m(45in.lbs.)

Pump To Case Bolts...........27N´m(20ft.lbs.)

Reaction Shaft Bolts...........27N´m(20ft.lbs.)

Rear End Cover..............19N´m(14ft.lbs.)

Sixty-Way Connector...........4N´m(35in.lbs.)

Solenoid Assembly To Case.....12N´m(105 in. lbs.)

Transmission Range Sensor......5N´m(45in.lbs.)

Transfer Gear Nut..........271 N´m (200 ft. lbs.)

Transfer Plate To Case........12N´m(105 in. lbs.)

Valve Body To Case Bolts......12N´m(105 in. lbs.)

Valve Body Bolts..............5N´m(45in.lbs.)

Vent Assembly..............12N´m(105 in. lbs.)

21 - 158 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1639 of 1938

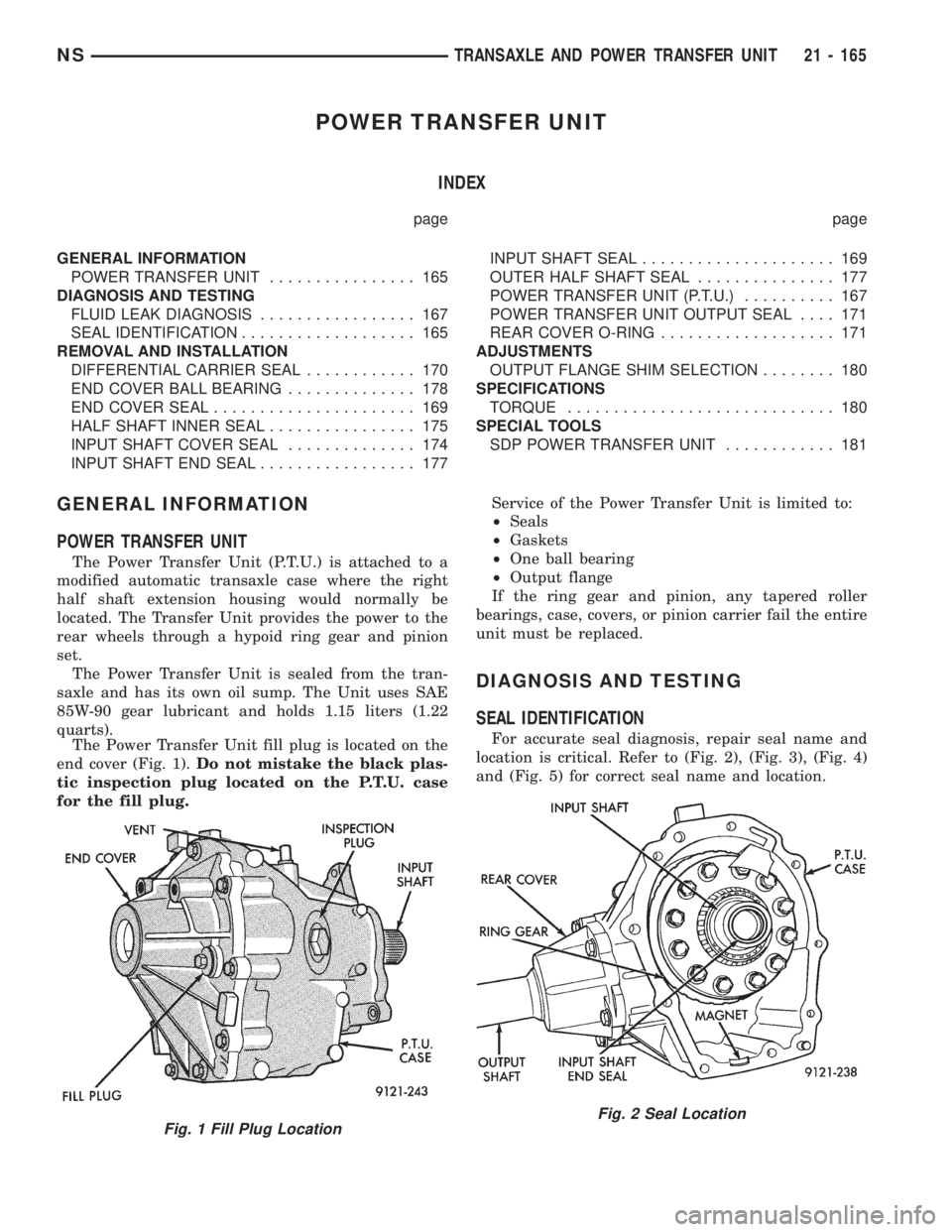

POWER TRANSFER UNIT

INDEX

page page

GENERAL INFORMATION

POWER TRANSFER UNIT................ 165

DIAGNOSIS AND TESTING

FLUID LEAK DIAGNOSIS................. 167

SEAL IDENTIFICATION................... 165

REMOVAL AND INSTALLATION

DIFFERENTIAL CARRIER SEAL............ 170

END COVER BALL BEARING.............. 178

END COVER SEAL...................... 169

HALF SHAFT INNER SEAL................ 175

INPUT SHAFT COVER SEAL.............. 174

INPUT SHAFT END SEAL................. 177INPUT SHAFT SEAL..................... 169

OUTER HALF SHAFT SEAL............... 177

POWER TRANSFER UNIT (P.T.U.).......... 167

POWER TRANSFER UNIT OUTPUT SEAL.... 171

REAR COVER O-RING................... 171

ADJUSTMENTS

OUTPUT FLANGE SHIM SELECTION........ 180

SPECIFICATIONS

TORQUE............................. 180

SPECIAL TOOLS

SDP POWER TRANSFER UNIT............ 181

GENERAL INFORMATION

POWER TRANSFER UNIT

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located. The Transfer Unit provides the power to the

rear wheels through a hypoid ring gear and pinion

set.

The Power Transfer Unit is sealed from the tran-

saxle and has its own oil sump. The Unit uses SAE

85W-90 gear lubricant and holds 1.15 liters (1.22

quarts).

The Power Transfer Unit fill plug is located on the

end cover (Fig. 1).Do not mistake the black plas-

tic inspection plug located on the P.T.U. case

for the fill plug.Service of the Power Transfer Unit is limited to:

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

DIAGNOSIS AND TESTING

SEAL IDENTIFICATION

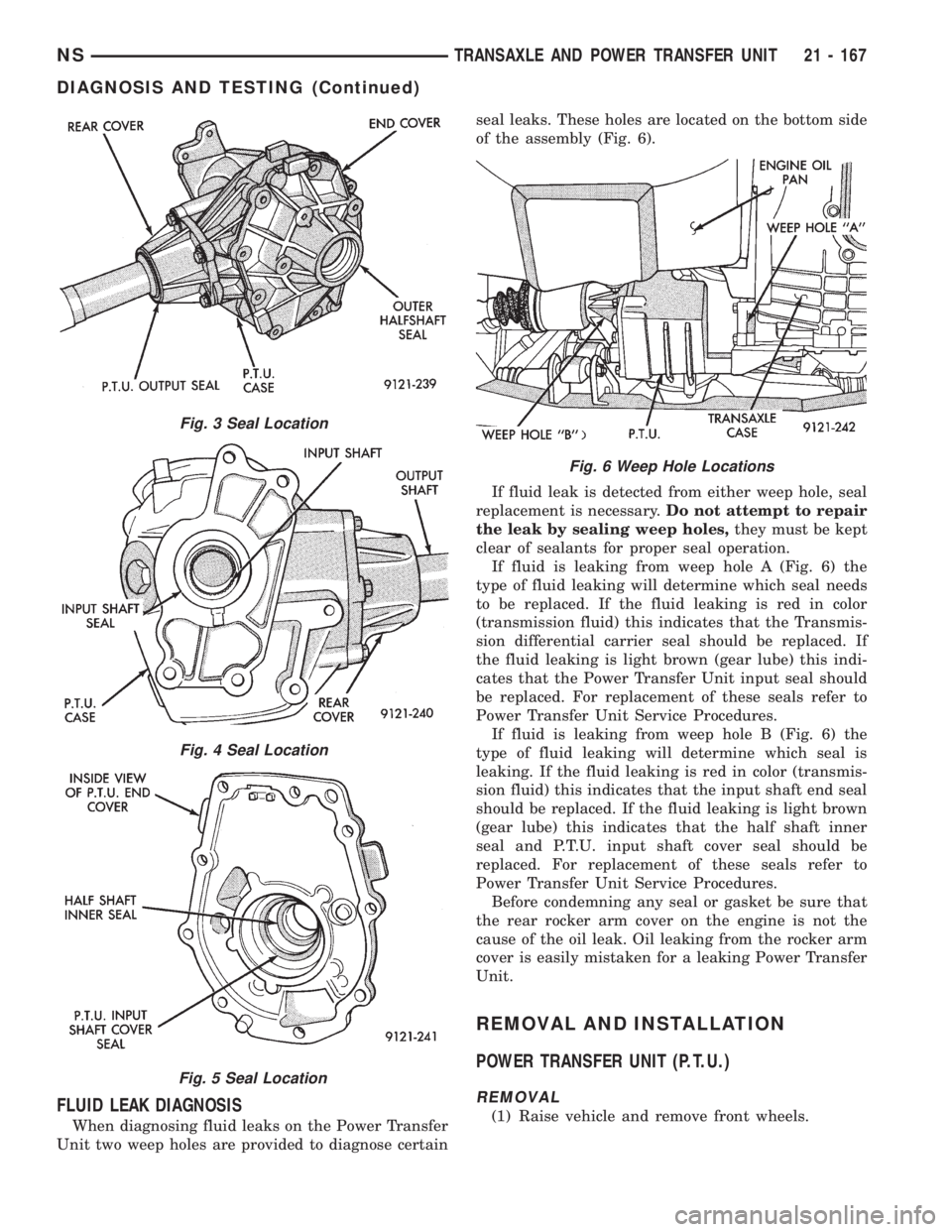

For accurate seal diagnosis, repair seal name and

location is critical. Refer to (Fig. 2), (Fig. 3), (Fig. 4)

and (Fig. 5) for correct seal name and location.

Fig. 1 Fill Plug LocationFig. 2 Seal Location

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 165

Page 1641 of 1938

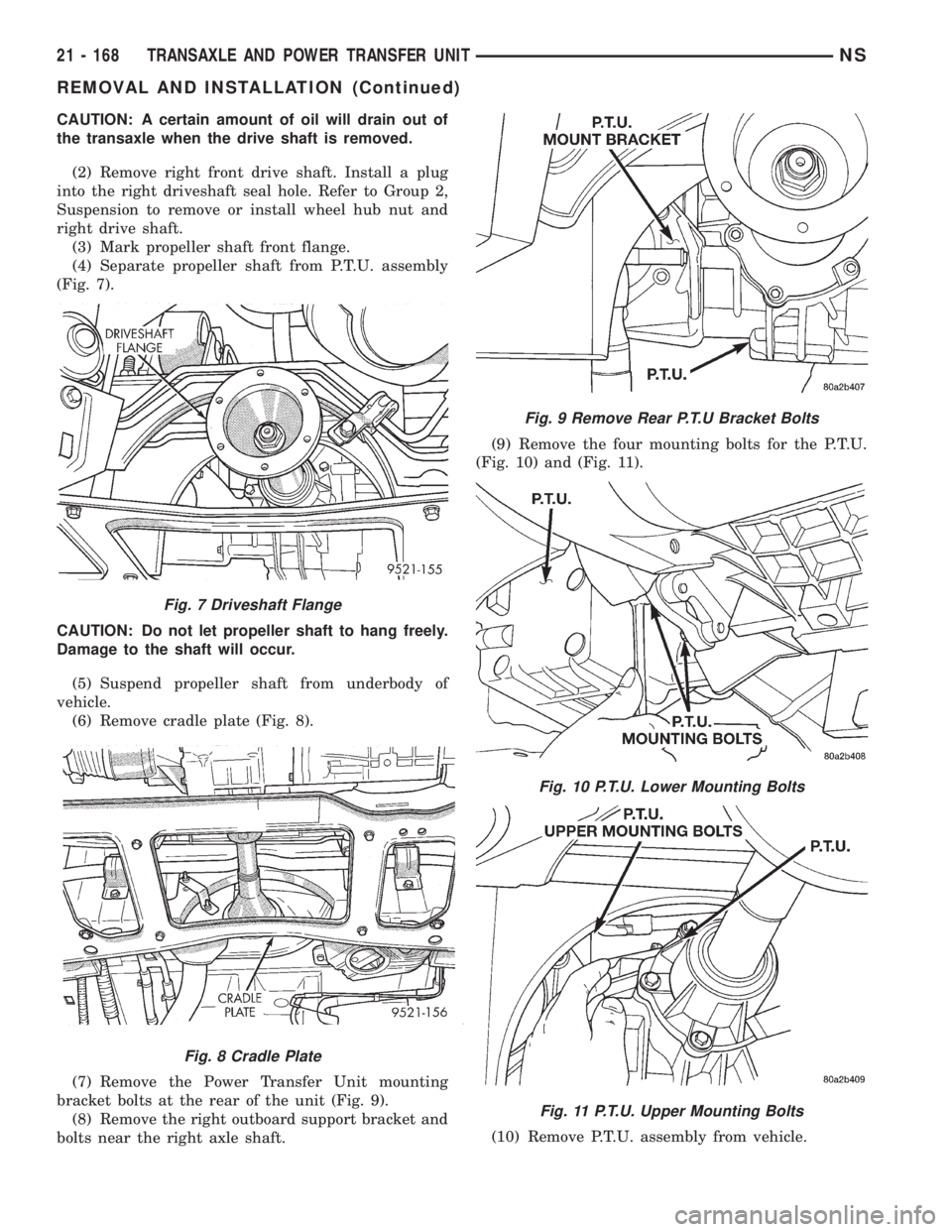

FLUID LEAK DIAGNOSIS

When diagnosing fluid leaks on the Power Transfer

Unit two weep holes are provided to diagnose certainseal leaks. These holes are located on the bottom side

of the assembly (Fig. 6).

If fluid leak is detected from either weep hole, seal

replacement is necessary.Do not attempt to repair

the leak by sealing weep holes,they must be kept

clear of sealants for proper seal operation.

If fluid is leaking from weep hole A (Fig. 6) the

type of fluid leaking will determine which seal needs

to be replaced. If the fluid leaking is red in color

(transmission fluid) this indicates that the Transmis-

sion differential carrier seal should be replaced. If

the fluid leaking is light brown (gear lube) this indi-

cates that the Power Transfer Unit input seal should

be replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

If fluid is leaking from weep hole B (Fig. 6) the

type of fluid leaking will determine which seal is

leaking. If the fluid leaking is red in color (transmis-

sion fluid) this indicates that the input shaft end seal

should be replaced. If the fluid leaking is light brown

(gear lube) this indicates that the half shaft inner

seal and P.T.U. input shaft cover seal should be

replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

Before condemning any seal or gasket be sure that

the rear rocker arm cover on the engine is not the

cause of the oil leak. Oil leaking from the rocker arm

cover is easily mistaken for a leaking Power Transfer

Unit.

REMOVAL AND INSTALLATION

POWER TRANSFER UNIT (P.T.U.)

REMOVAL

(1) Raise vehicle and remove front wheels.

Fig. 3 Seal Location

Fig. 4 Seal Location

Fig. 5 Seal Location

Fig. 6 Weep Hole Locations

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 167

DIAGNOSIS AND TESTING (Continued)

Page 1642 of 1938

CAUTION: A certain amount of oil will drain out of

the transaxle when the drive shaft is removed.

(2) Remove right front drive shaft. Install a plug

into the right driveshaft seal hole. Refer to Group 2,

Suspension to remove or install wheel hub nut and

right drive shaft.

(3) Mark propeller shaft front flange.

(4) Separate propeller shaft from P.T.U. assembly

(Fig. 7).

CAUTION: Do not let propeller shaft to hang freely.

Damage to the shaft will occur.

(5) Suspend propeller shaft from underbody of

vehicle.

(6) Remove cradle plate (Fig. 8).

(7) Remove the Power Transfer Unit mounting

bracket bolts at the rear of the unit (Fig. 9).

(8) Remove the right outboard support bracket and

bolts near the right axle shaft.(9) Remove the four mounting bolts for the P.T.U.

(Fig. 10) and (Fig. 11).

(10) Remove P.T.U. assembly from vehicle.

Fig. 7 Driveshaft Flange

Fig. 8 Cradle Plate

Fig. 9 Remove Rear P.T.U Bracket Bolts

Fig. 10 P.T.U. Lower Mounting Bolts

Fig. 11 P.T.U. Upper Mounting Bolts

21 - 168 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1643 of 1938

INSTALLATION

(1) To install, reverse removal procedure. Check

transaxle fluid and P.T.U. fluid and fill to level.

(2) Refer to the Specifications section for the

proper torque specifications.

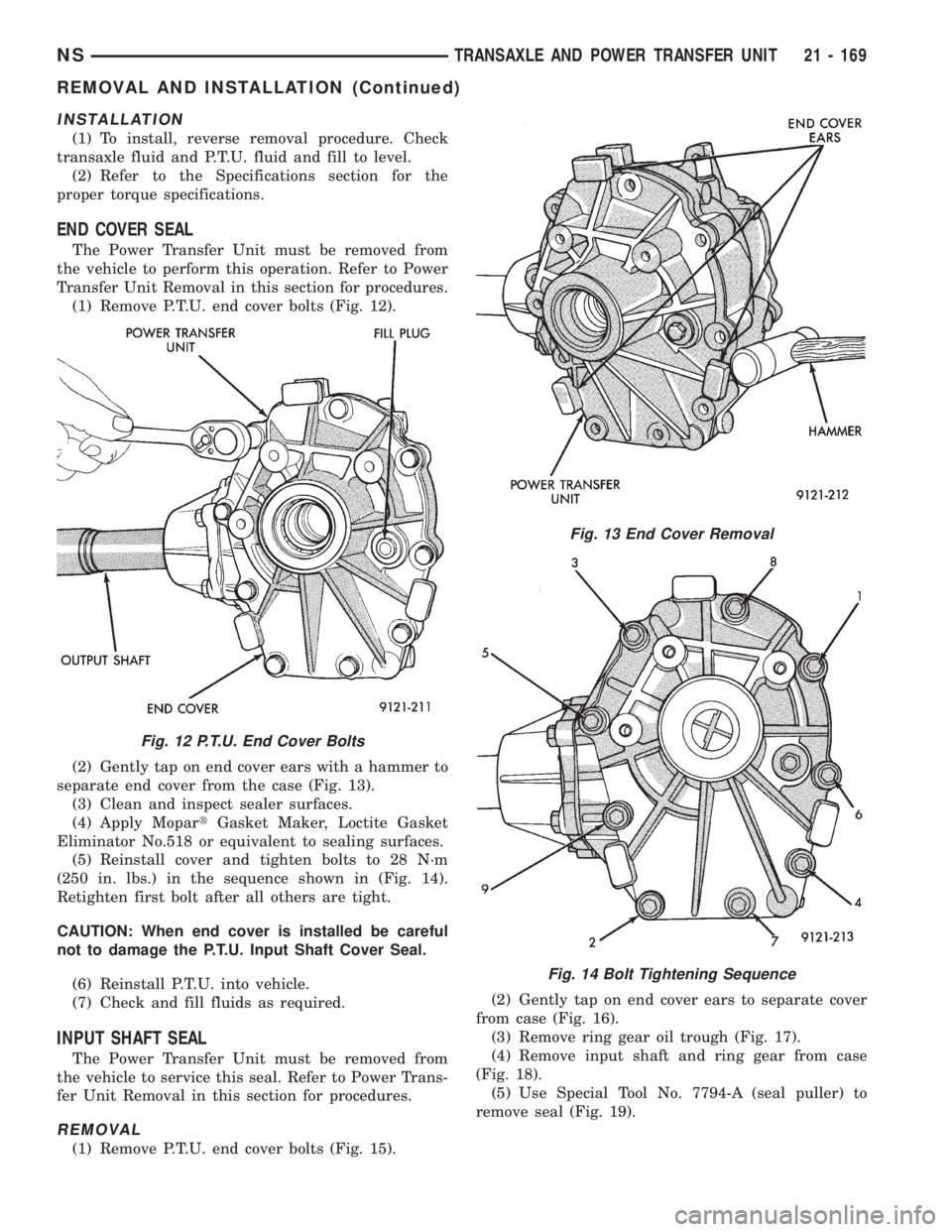

END COVER SEAL

The Power Transfer Unit must be removed from

the vehicle to perform this operation. Refer to Power

Transfer Unit Removal in this section for procedures.

(1) Remove P.T.U. end cover bolts (Fig. 12).

(2) Gently tap on end cover ears with a hammer to

separate end cover from the case (Fig. 13).

(3) Clean and inspect sealer surfaces.

(4) Apply MopartGasket Maker, Loctite Gasket

Eliminator No.518 or equivalent to sealing surfaces.

(5) Reinstall cover and tighten bolts to 28 N´m

(250 in. lbs.) in the sequence shown in (Fig. 14).

Retighten first bolt after all others are tight.

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. into vehicle.

(7) Check and fill fluids as required.

INPUT SHAFT SEAL

The Power Transfer Unit must be removed from

the vehicle to service this seal. Refer to Power Trans-

fer Unit Removal in this section for procedures.

REMOVAL

(1) Remove P.T.U. end cover bolts (Fig. 15).(2) Gently tap on end cover ears to separate cover

from case (Fig. 16).

(3) Remove ring gear oil trough (Fig. 17).

(4) Remove input shaft and ring gear from case

(Fig. 18).

(5) Use Special Tool No. 7794-A (seal puller) to

remove seal (Fig. 19).

Fig. 12 P.T.U. End Cover Bolts

Fig. 13 End Cover Removal

Fig. 14 Bolt Tightening Sequence

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 169

REMOVAL AND INSTALLATION (Continued)

Page 1644 of 1938

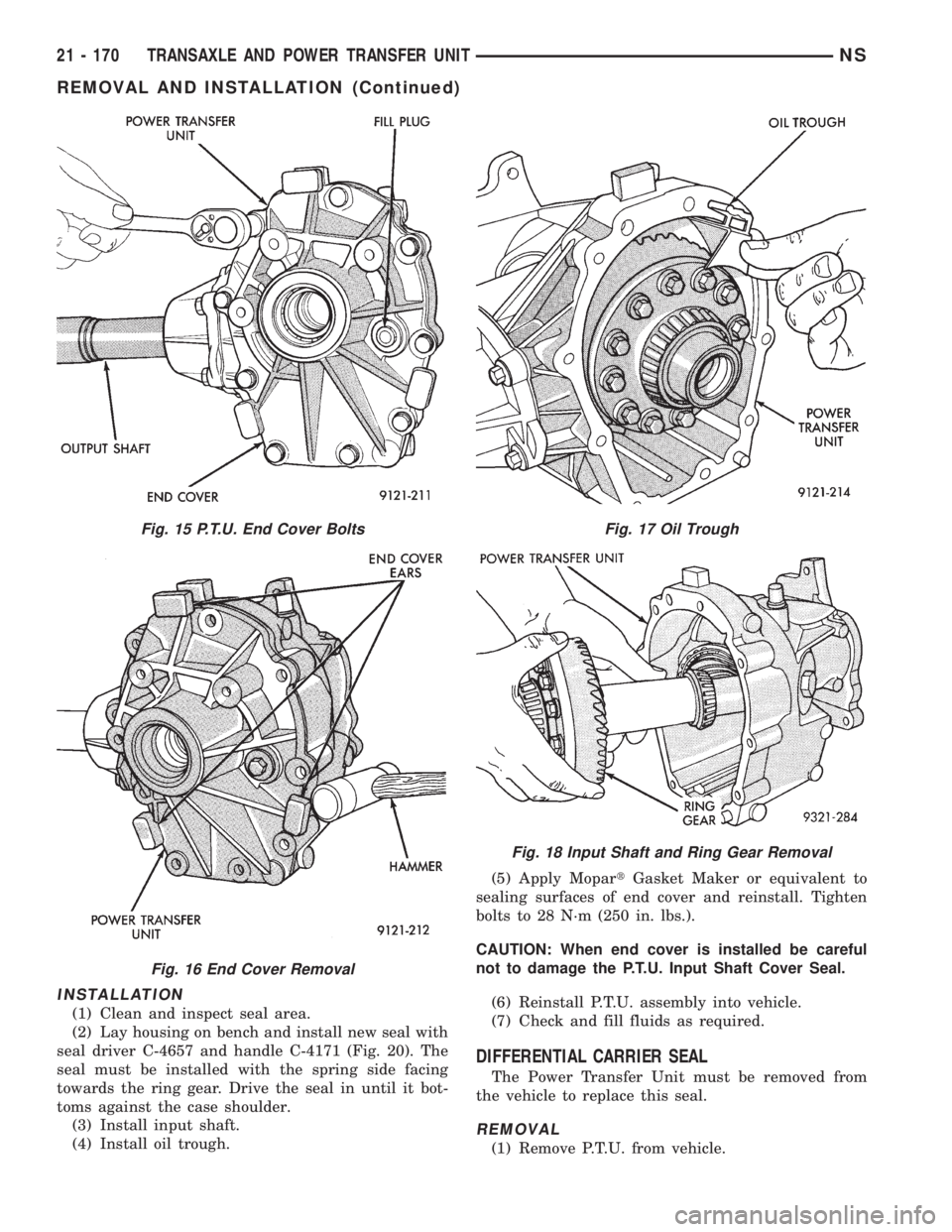

INSTALLATION

(1) Clean and inspect seal area.

(2) Lay housing on bench and install new seal with

seal driver C-4657 and handle C-4171 (Fig. 20). The

seal must be installed with the spring side facing

towards the ring gear. Drive the seal in until it bot-

toms against the case shoulder.

(3) Install input shaft.

(4) Install oil trough.(5) Apply MopartGasket Maker or equivalent to

sealing surfaces of end cover and reinstall. Tighten

bolts to 28 N´m (250 in. lbs.).

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. assembly into vehicle.

(7) Check and fill fluids as required.

DIFFERENTIAL CARRIER SEAL

The Power Transfer Unit must be removed from

the vehicle to replace this seal.

REMOVAL

(1) Remove P.T.U. from vehicle.

Fig. 15 P.T.U. End Cover Bolts

Fig. 16 End Cover Removal

Fig. 17 Oil Trough

Fig. 18 Input Shaft and Ring Gear Removal

21 - 170 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1646 of 1938

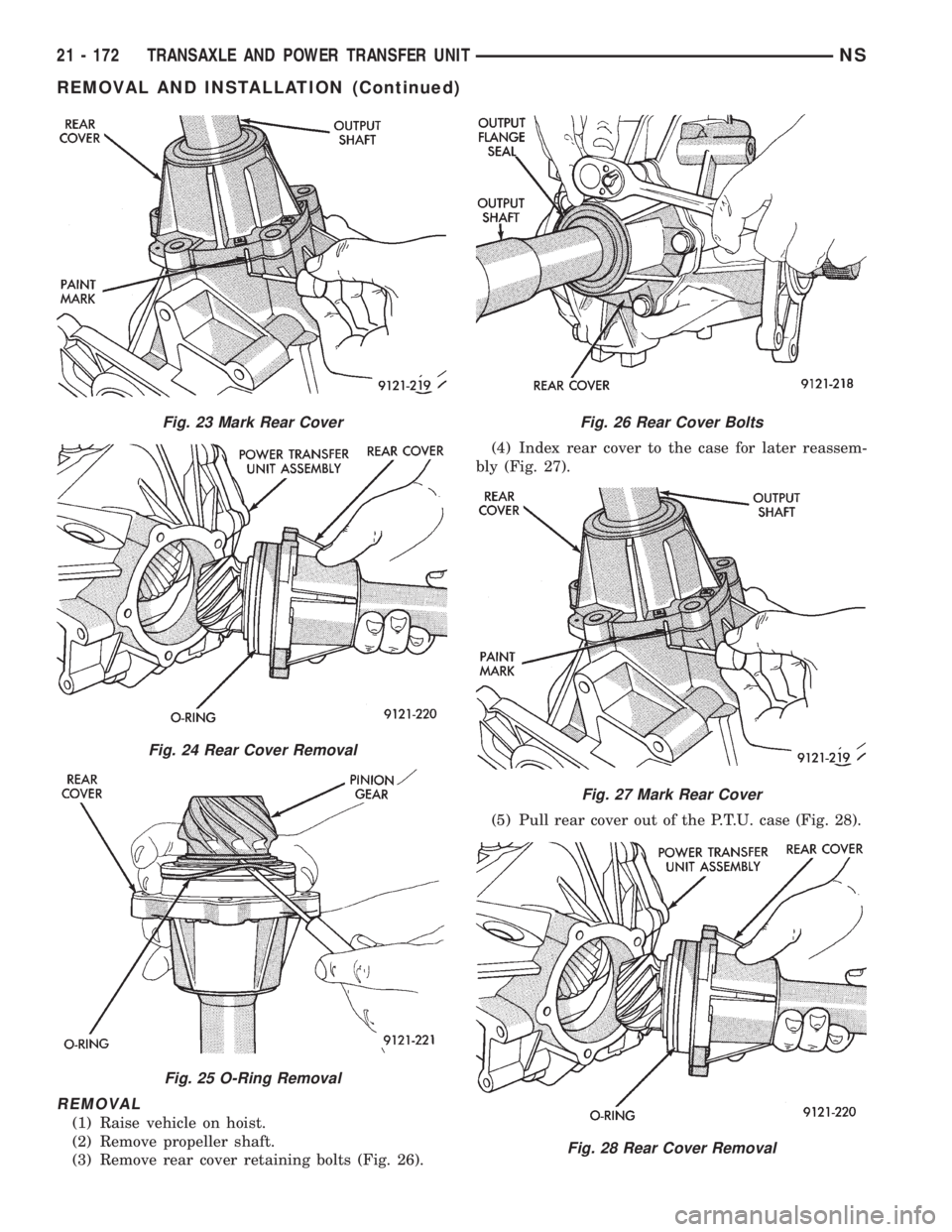

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove propeller shaft.

(3) Remove rear cover retaining bolts (Fig. 26).(4) Index rear cover to the case for later reassem-

bly (Fig. 27).

(5) Pull rear cover out of the P.T.U. case (Fig. 28).

Fig. 23 Mark Rear Cover

Fig. 24 Rear Cover Removal

Fig. 25 O-Ring Removal

Fig. 26 Rear Cover Bolts

Fig. 27 Mark Rear Cover

Fig. 28 Rear Cover Removal

21 - 172 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)