battery CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 267 of 1938

²Body Control Module

²Remote Keyless Entry Module

(8) Disconnect one component at time, to see if any

component is at fault. If the high reading is not elim-

inated there is a short circuit in the wiring. Refer to

Group 8W, wiring diagrams.

(9) Remove interior and brake lamp fuses. Install

the fuses. The milliampere reading should be 2-4 mA.

If reading is higher than 4 mA:

(a) Disconnect PCM.

(b) If reading is OK, replace PCM.

(c) If reading does not change there is a short

circuit to the PCM. Refer to Group 8W, Wiring Dia-

grams.

BATTERY LOAD TEST

A fully charged battery must have cranking capac-

ity, to provide the starter motor and ignition system

enough power to start the engine over a broad range

of ambient temperatures. A battery load test will ver-

ify the actual cranking capability of the battery.

WARNING: IF BATTERY SHOWS SIGNS OF FREEZ-

ING, LEAKING, LOOSE POSTS, OR EXCESSIVELY

LOW ELECTROLYTE LEVEL, DO NOT TEST. ACID

BURNS OR AN EXPLOSIVE CONDITION MAY

RESULT.

(1) Remove both battery cables, negative cable

first. The battery top, cables and posts should be

clean. Test battery with a hydrometer. If battery

charge is low the charge battery. Refer to Battery

Charging Procedures.(2) Connect a Volt/Ammeter/Load tester to the bat-

tery posts (Fig. 6). Rotate the load control knob of the

Carbon pile rheostat to apply a 300 amp load. Apply

this load for 15 seconds to remove the surface charge

from the battery, and return the control knob to off

(Fig. 7).

(3) Allow the battery to stabilize for 2 minutes,

and then verify open circuit voltage.

(4) Rotate the load control knob on the tester to

maintain 50% of the battery cold crank rating for 15

seconds (Fig. 8). Record the loaded voltage reading

and return the load control to off. Refer to the Bat-

tery Specifications at the rear of this Group.

(5) Voltage drop will vary according to battery

temperature at the time of the load test. Battery

temperature can be estimated by the temperature of

exposure over the preceding several hours. If the bat-

tery has been charged or boosted a few minutes prior

to the test, the battery would be slightly warmer.

Refer to Load Test Voltage Chart for proper loaded

voltage reading.

Fig. 5 Milliampere Meter ConnectionFig. 6 Volt-Ammeter Load Tester Connections

Fig. 7 Remove Surface Charge From Battery

NS/GSBATTERY 8A - 5

DIAGNOSIS AND TESTING (Continued)

Page 268 of 1938

(6) If battery passes load test, it is in good condi-

tion and further tests are not necessary. If it fails

load test, it should be replaced.

BATTERY OPEN CIRCUIT VOLTAGE TEST

An open circuit voltage no load test shows the

state of charge of a battery and whether it is ready

for a load test at 50 percent of the battery's cold

crank rating. Refer to Battery Load Test. If a battery

has open circuit voltage reading of 12.4 volts or

greater, and will not pass the load test, replace the

battery because it is defective. To test open circuit

voltage, perform the following operation.

(1) Remove both battery cables, negative cable

first. Battery top, cables and posts should be clean. If

green dot is not visible in indicator, charge the bat-

tery. Refer to Battery Charging Procedures.

(2) Connect a Volt/Ammeter/Load tester to the bat-

tery posts (Fig. 6). Rotate the load control knob of the

Carbon pile rheostat to apply a 300 amp load. Apply

this load for 15 seconds to remove the surface charge

from the battery, and return the control knob to off

(Fig. 7).(3) Allow the battery to stabilize for 2 minutes,

and then verify the open circuit voltage (Fig. 9).

(4) This voltage reading will approximate the state

of charge of the battery. It will not reveal battery

cranking capacity (Fig. 10).

SERVICE PROCEDURES

BATTERY CHARGING

WARNING: DO NOT CHARGE A BATTERY THAT

HAS EXCESSIVELY LOW ELECTROLYTE LEVEL.

BATTERY MAY SPARK INTERNALLY AND

EXPLODE. EXPLOSIVE GASES FORM OVER THE

BATTERY. DO NOT SMOKE, USE FLAME, OR CRE-

ATE SPARKS NEAR BATTERY. DO NOT ASSIST

BOOST OR CHARGE A FROZEN BATTERY. BAT-

TERY CASING MAY FRACTURE. BATTERY ACID IS

POISON, AND MAY CAUSE SEVERE BURNS. BAT-

TERIES CONTAIN SULFURIC ACID. AVOID CON-

TACT WITH SKIN, EYES, OR CLOTHING. IN THE

EVENT OF CONTACT, FLUSH WITH WATER AND

CALL PHYSICIAN IMMEDIATELY. KEEP OUT OF

REACH OF CHILDREN.

Fig. 8 Load 50% Cold Crank Rating

Load Test Temperature

Minimum VoltageTemperature

ÉF ÉC

9.6 volts 70É and

above21É and

above

9.5 volts 60É 16É

9.4 volts 50É 10É

9.3 volts 40É 4É

9.1 volts 30É -1É

8.9 volts 20É -7É

8.7 volts 10É -12É

8.5 volts 0É -18É

Fig. 9 Testing Open Circuit Voltage

Fig. 10 Battery Open Circuit Voltage

8A - 6 BATTERYNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 269 of 1938

CAUTION: Disconnect the battery NEGATIVE cable

first (Fig. 4) before charging battery to avoid dam-

age to electrical systems. Do not exceed 16.0 volts

while charging battery. Refer to the instructions

supplied with charging equipment

A battery is considered fully charged when it will

meet all the following requirements.

²It has an open circuit voltage charge of at least

12.4 volts (Fig. 10).

²It passes the 15 second load test, refer to the

Load Test Temperature chart.

²The specific gravity reading is 1.285 plus 0.015

or minus 0.010.

Battery electrolyte will bubble inside of battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive.

Some battery chargers are equipped with polarity

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat-

tery state of charge is too low for the polarity sensor

to detect, the sensor must be bypassed for charger to

operate. Refer to operating instructions provided

with battery charger being used.

CAUTION: Do not overcharge Battery.

Test the battery until the specific gravity reading

is 1.285 plus 0.015 or minus 0.010.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. Refer to Battery Load Test in this Group. If

the battery passes the load test, return the battery to

use. If battery will not endure a load test, it must be

replaced. Properly clean and inspect battery hold

downs, tray, terminals, cables, posts, and top before

completing service.

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless procedure is

properly followed, a good battery may be needlessly

replaced (Fig. 11).

(1) Measure the voltage at battery posts with a

voltmeter accurate to 1/10 volt (Fig. 12). If below 10

volts, charge current will be low, and it could take

some time before it accepts a current in excess of a

few milliamperes. Such low current may not be

detectable on amp meters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry that prevents operation

unless charger is connected to battery posts correctly.

A completely discharged battery may not haveenough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

(3) Battery chargers vary in the amount of voltage

and current they provide. For the time required for

the battery to accept measurable charger current at

various voltages, refer to (Fig. 11). If charge current

is still not measurable after charging times, the bat-

tery should be replaced. If charge current is measur-

able during charging time, the battery may be good,

and charging should be completed in the normal

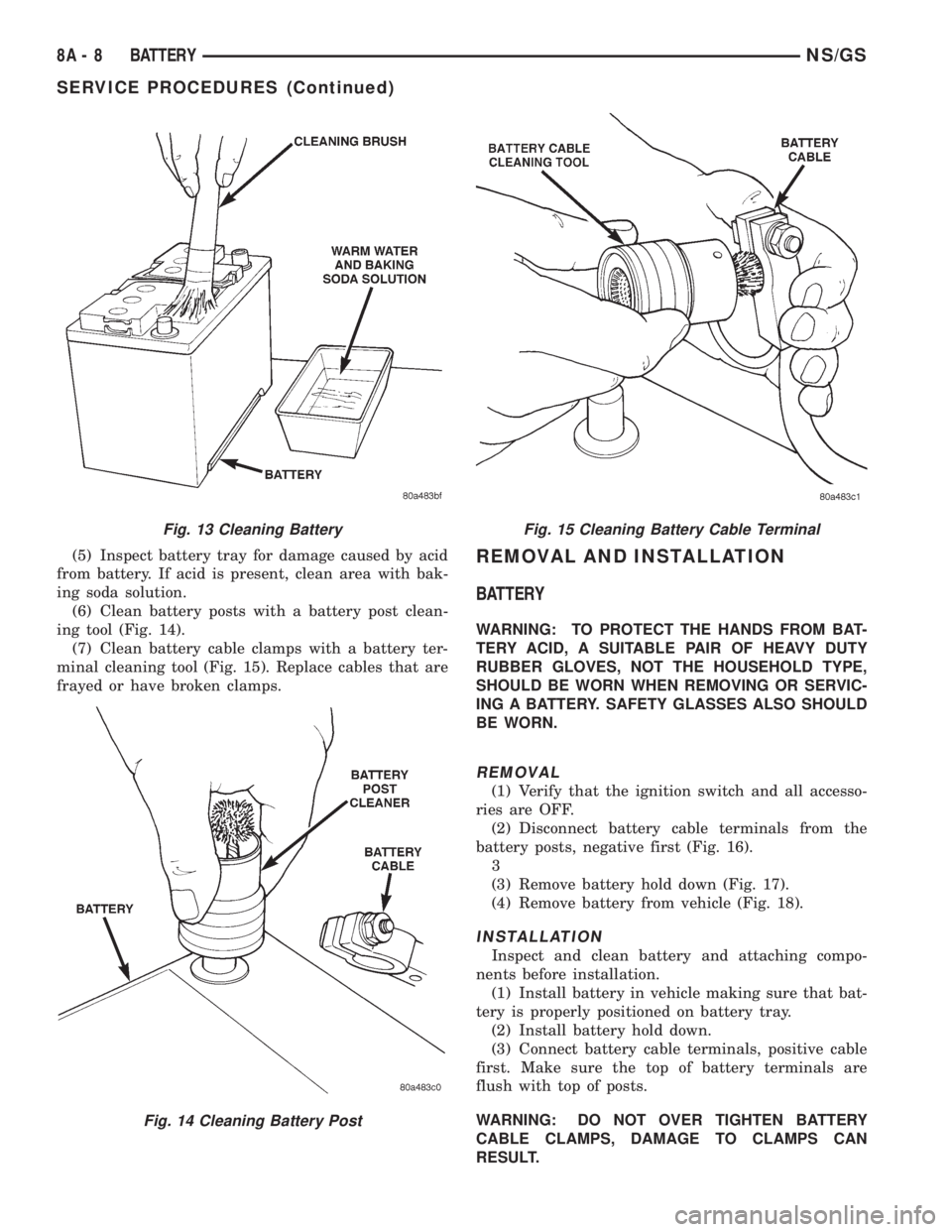

manner.VISUAL INSPECTION

CAUTION: Do not allow baking soda solution to

enter vent holes, as damage to battery can result.

(1) Clean top of battery with a solution of warm

water and baking soda.

(2) Apply soda solution with a bristle brush and

allow to soak until acid deposits loosen (Fig. 13).

(3) Rinse soda solution from battery with clear

water and blot battery dry with paper toweling. Dis-

pose of toweling in a safe manner. Refer to the

WARNINGS on top of battery.

(4) Inspect battery case and cover for cracks, leak-

age or damaged hold down ledge. If battery is dam-

aged replace it.

Fig. 11 Charging Rate

Fig. 12 Voltmeter Accurate to 1/10 Volt (Connected)

NS/GSBATTERY 8A - 7

SERVICE PROCEDURES (Continued)

Page 270 of 1938

(5) Inspect battery tray for damage caused by acid

from battery. If acid is present, clean area with bak-

ing soda solution.

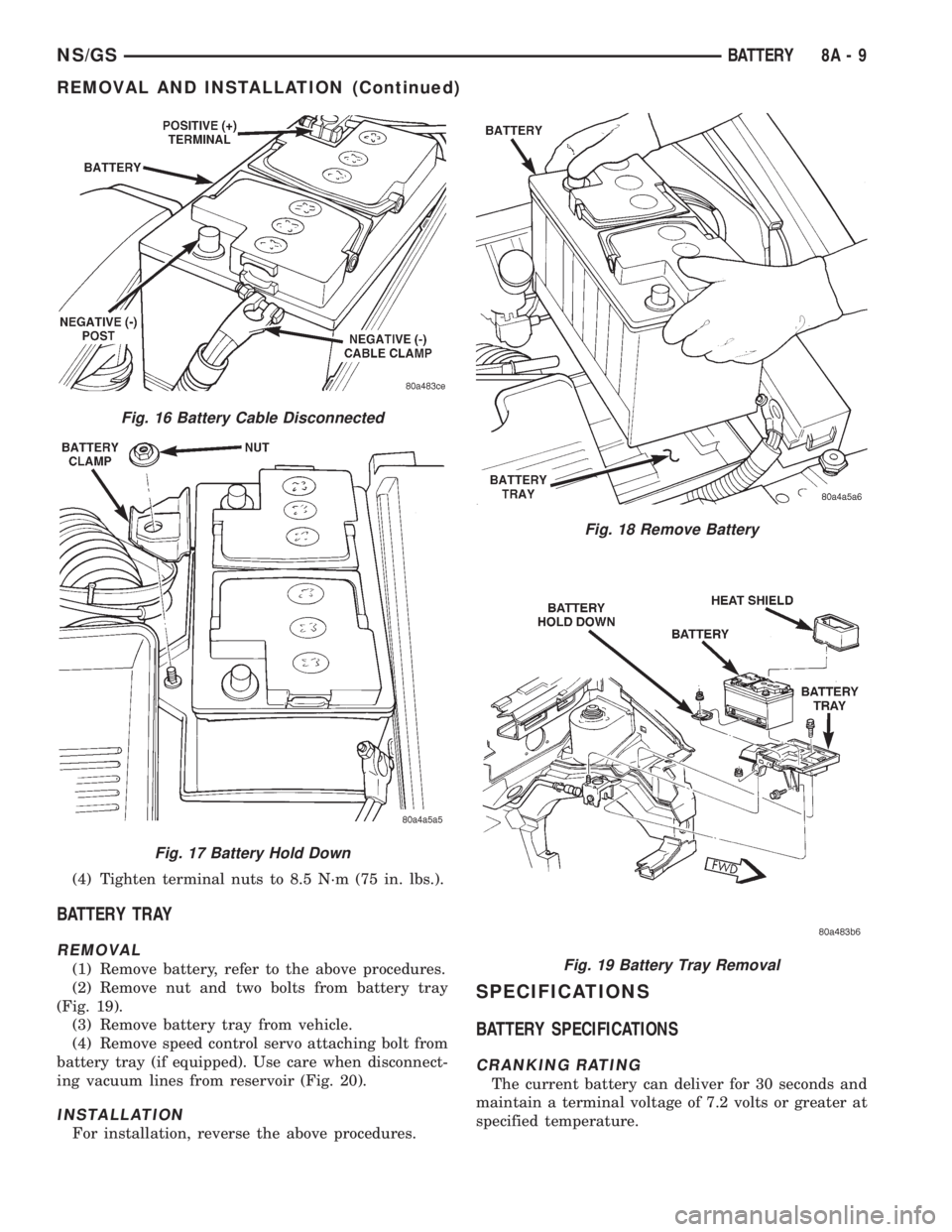

(6) Clean battery posts with a battery post clean-

ing tool (Fig. 14).

(7) Clean battery cable clamps with a battery ter-

minal cleaning tool (Fig. 15). Replace cables that are

frayed or have broken clamps.REMOVAL AND INSTALLATION

BATTERY

WARNING: TO PROTECT THE HANDS FROM BAT-

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES, NOT THE HOUSEHOLD TYPE,

SHOULD BE WORN WHEN REMOVING OR SERVIC-

ING A BATTERY. SAFETY GLASSES ALSO SHOULD

BE WORN.

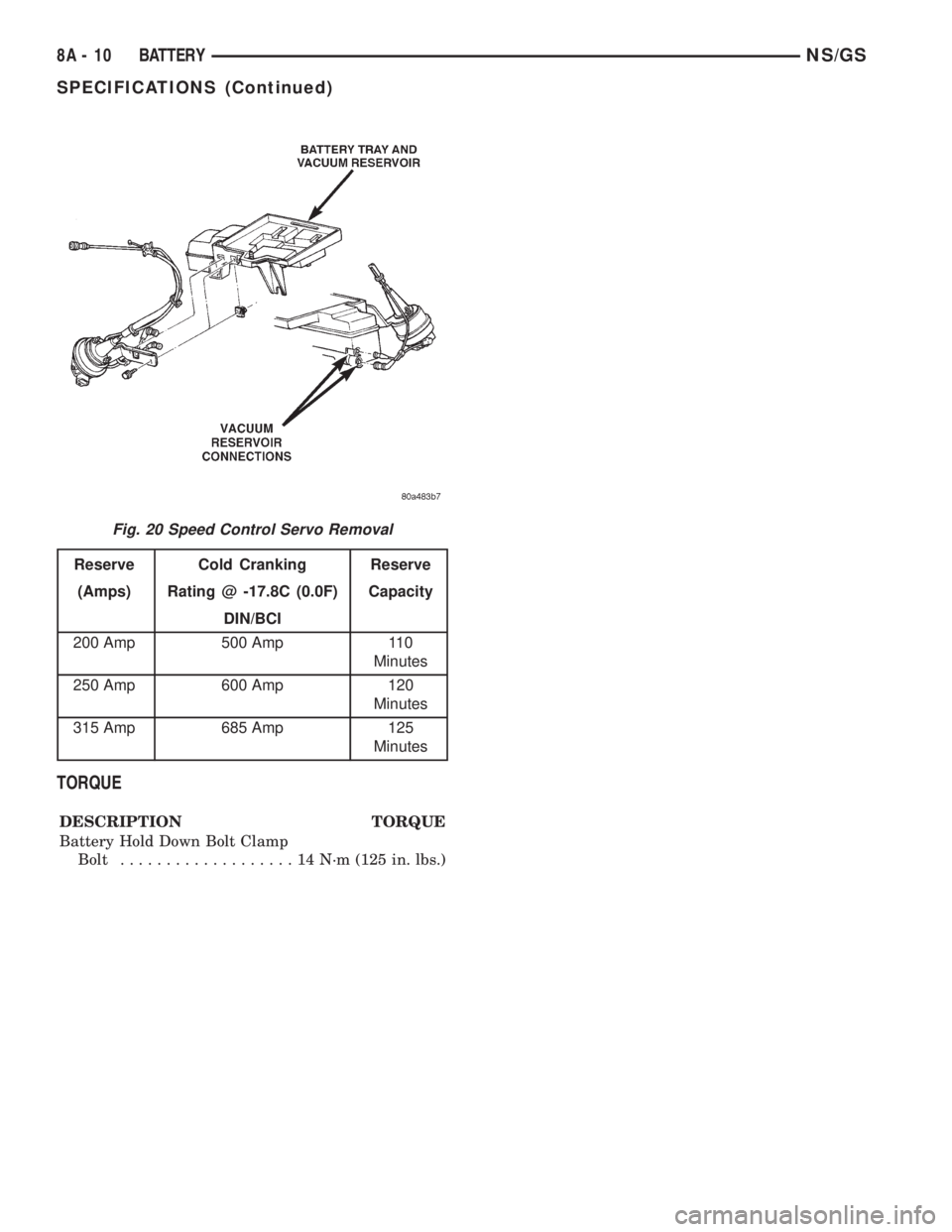

REMOVAL

(1) Verify that the ignition switch and all accesso-

ries are OFF.

(2) Disconnect battery cable terminals from the

battery posts, negative first (Fig. 16).

3

(3) Remove battery hold down (Fig. 17).

(4) Remove battery from vehicle (Fig. 18).

INSTALLATION

Inspect and clean battery and attaching compo-

nents before installation.

(1) Install battery in vehicle making sure that bat-

tery is properly positioned on battery tray.

(2) Install battery hold down.

(3) Connect battery cable terminals, positive cable

first. Make sure the top of battery terminals are

flush with top of posts.

WARNING: DO NOT OVER TIGHTEN BATTERY

CABLE CLAMPS, DAMAGE TO CLAMPS CAN

RESULT.

Fig. 13 Cleaning Battery

Fig. 14 Cleaning Battery Post

Fig. 15 Cleaning Battery Cable Terminal

8A - 8 BATTERYNS/GS

SERVICE PROCEDURES (Continued)

Page 271 of 1938

(4) Tighten terminal nuts to 8.5 N´m (75 in. lbs.).

BATTERY TRAY

REMOVAL

(1) Remove battery, refer to the above procedures.

(2) Remove nut and two bolts from battery tray

(Fig. 19).

(3) Remove battery tray from vehicle.

(4) Remove speed control servo attaching bolt from

battery tray (if equipped). Use care when disconnect-

ing vacuum lines from reservoir (Fig. 20).

INSTALLATION

For installation, reverse the above procedures.

SPECIFICATIONS

BATTERY SPECIFICATIONS

CRANKING RATING

The current battery can deliver for 30 seconds and

maintain a terminal voltage of 7.2 volts or greater at

specified temperature.

Fig. 16 Battery Cable Disconnected

Fig. 17 Battery Hold Down

Fig. 18 Remove Battery

Fig. 19 Battery Tray Removal

NS/GSBATTERY 8A - 9

REMOVAL AND INSTALLATION (Continued)

Page 272 of 1938

TORQUE

DESCRIPTION TORQUE

Battery Hold Down Bolt Clamp

Bolt...................14N´m(125 in. lbs.)

Fig. 20 Speed Control Servo Removal

Reserve Cold Cranking Reserve

(Amps) Rating @ -17.8C (0.0F) Capacity

DIN/BCI

200 Amp 500 Amp 110

Minutes

250 Amp 600 Amp 120

Minutes

315 Amp 685 Amp 125

Minutes

8A - 10 BATTERYNS/GS

SPECIFICATIONS (Continued)

Page 273 of 1938

STARTER

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

SUPPLY CIRCUIT AND CONTROL CIRCUIT.... 1

DIAGNOSIS AND TESTING

CONTROL CIRCUIT TEST.................. 1

FEED CIRCUIT RESISTANCE TEST........... 3

FEED CIRCUIT TEST...................... 4REMOVAL AND INSTALLATION

STARTERÐ2.4L ENGINE.................. 5

STARTERÐ3.0L ENGINE.................. 6

STARTERÐ3.3/3.8L ENGINE............... 6

SPECIFICATIONS

STARTER .............................. 7

TORQUE............................... 7

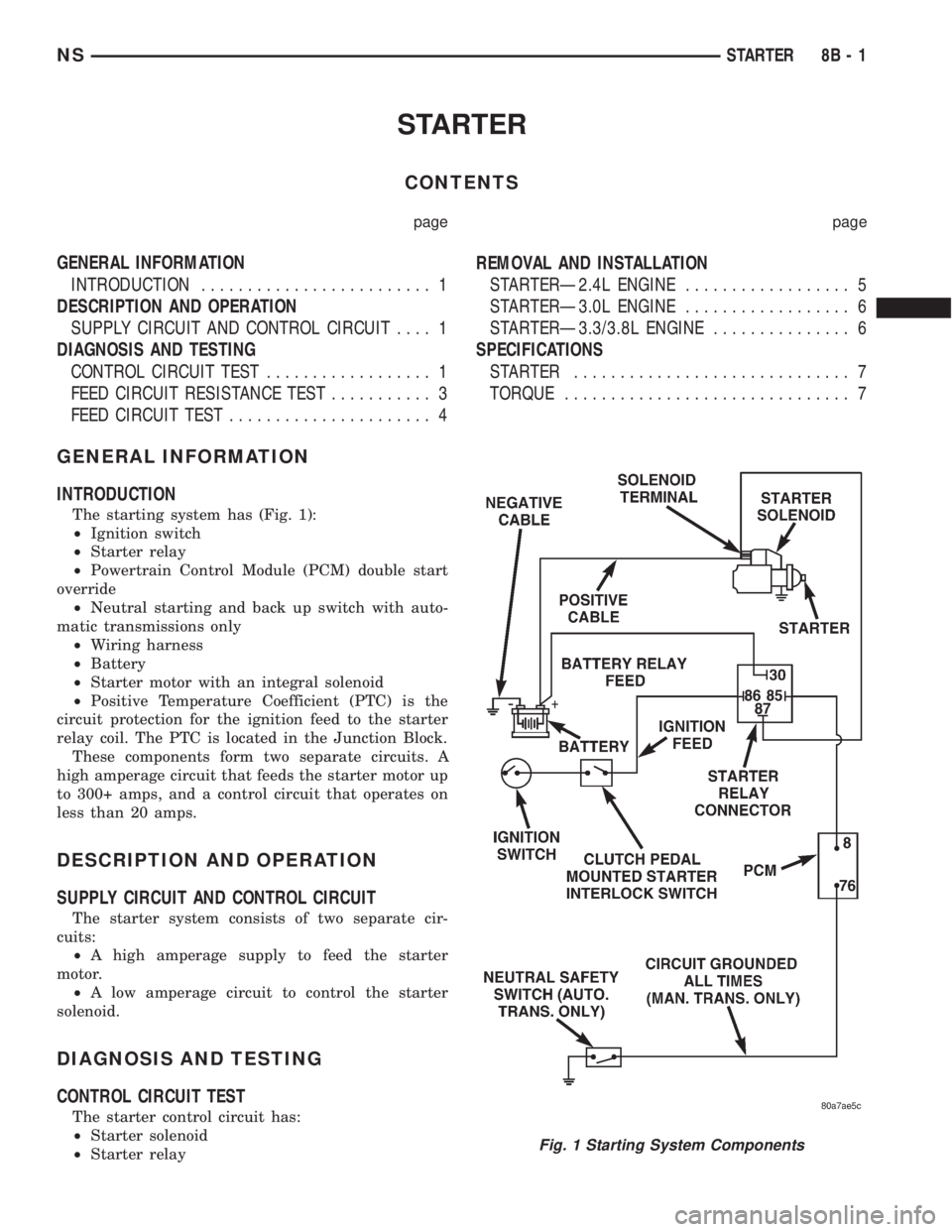

GENERAL INFORMATION

INTRODUCTION

The starting system has (Fig. 1):

²Ignition switch

²Starter relay

²Powertrain Control Module (PCM) double start

override

²Neutral starting and back up switch with auto-

matic transmissions only

²Wiring harness

²Battery

²Starter motor with an integral solenoid

²Positive Temperature Coefficient (PTC) is the

circuit protection for the ignition feed to the starter

relay coil. The PTC is located in the Junction Block.

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

DESCRIPTION AND OPERATION

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

DIAGNOSIS AND TESTING

CONTROL CIRCUIT TEST

The starter control circuit has:

²Starter solenoid

²Starter relay

Fig. 1 Starting System Components

NSSTARTER 8B - 1

Page 274 of 1938

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Clutch Pedal Position Switch with manual

transmissions

²Ignition switch

²Battery

²All related wiring and connections

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the in the Power Distribution Center

(PDC). Refer to the PDC cover for the proper relay

location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.

(3) Raise the vehicle.

(4) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(5) Lower the vehicle.

(6) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(7) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not or solenoid chatters, check

wiring and connectors from starter relay to starter

solenoid for loose or corroded connections. Particu-

larly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION/NEUTRAL

WITH THE PARKING BRAKE APPLIED

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

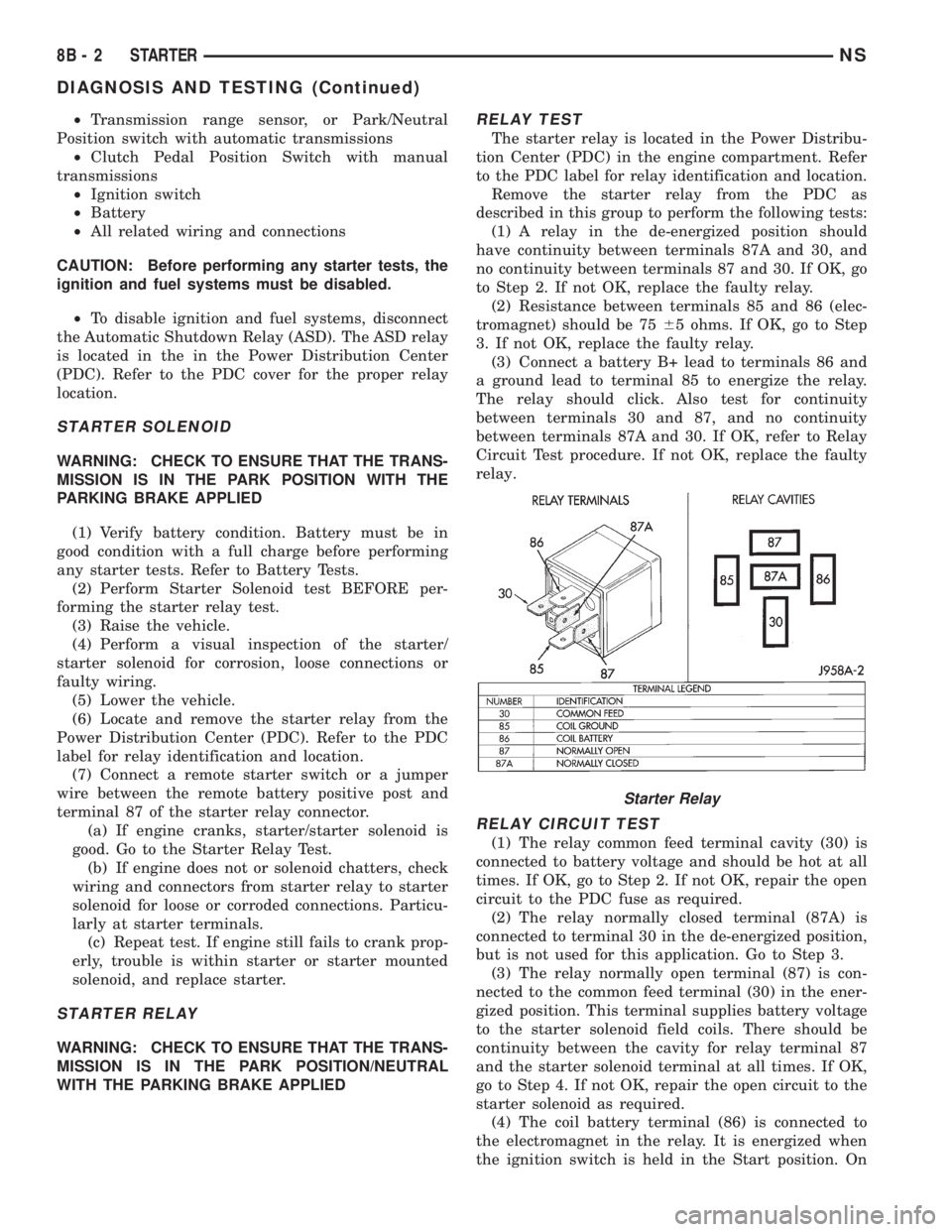

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 86 and

a ground lead to terminal 85 to energize the relay.

The relay should click. Also test for continuity

between terminals 30 and 87, and no continuity

between terminals 87A and 30. If OK, refer to Relay

Circuit Test procedure. If not OK, replace the faulty

relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position. On

Starter Relay

8B - 2 STARTERNS

DIAGNOSIS AND TESTING (Continued)

Page 275 of 1938

vehicles with a manual transmission, the clutch

pedal must be fully depressed for this test. Check for

battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position, and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK with an

automatic transmission, check for an open or short

circuit to the ignition switch and repair, if required.

If the circuit to the ignition switch is OK, see the

Ignition Switch Test procedure in this group. If not

OK with a manual transmission, check the circuit

between the relay and the clutch pedal position

switch for an open or a short. If the circuit is OK, see

the Clutch Pedal Position Switch Test procedure in

this group.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with an

automatic transmission, it is grounded through the

park/neutral position switch only when the gearshift

selector lever is in the Park or Neutral positions. On

vehicles with a manual transmission, it is grounded

at all times. Check for continuity to ground at the

cavity for relay terminal 85. If not OK with an auto-

matic transmission, check for an open or short circuit

to the park/neutral position switch and repair, if

required. If the circuit is OK, see the Park/Neutral

Position Switch Test procedure in this group. If not

OK with a manual transmission, repair the circuit to

ground as required.

SAFETY SWITCHES

For diagnostics,

²Clutch Pedal Position Switch, refer to Group 6,

Clutch.

²Park/Neutral Position Switch, refer to Group 21,

Transaxle

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to Group 8D, Ignition

Systems or Group 8W, Wiring Diagrams. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

Refer to Group 8A, Battery for proper procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Group 8W, Wiring Diagrams,

FEED CIRCUIT RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

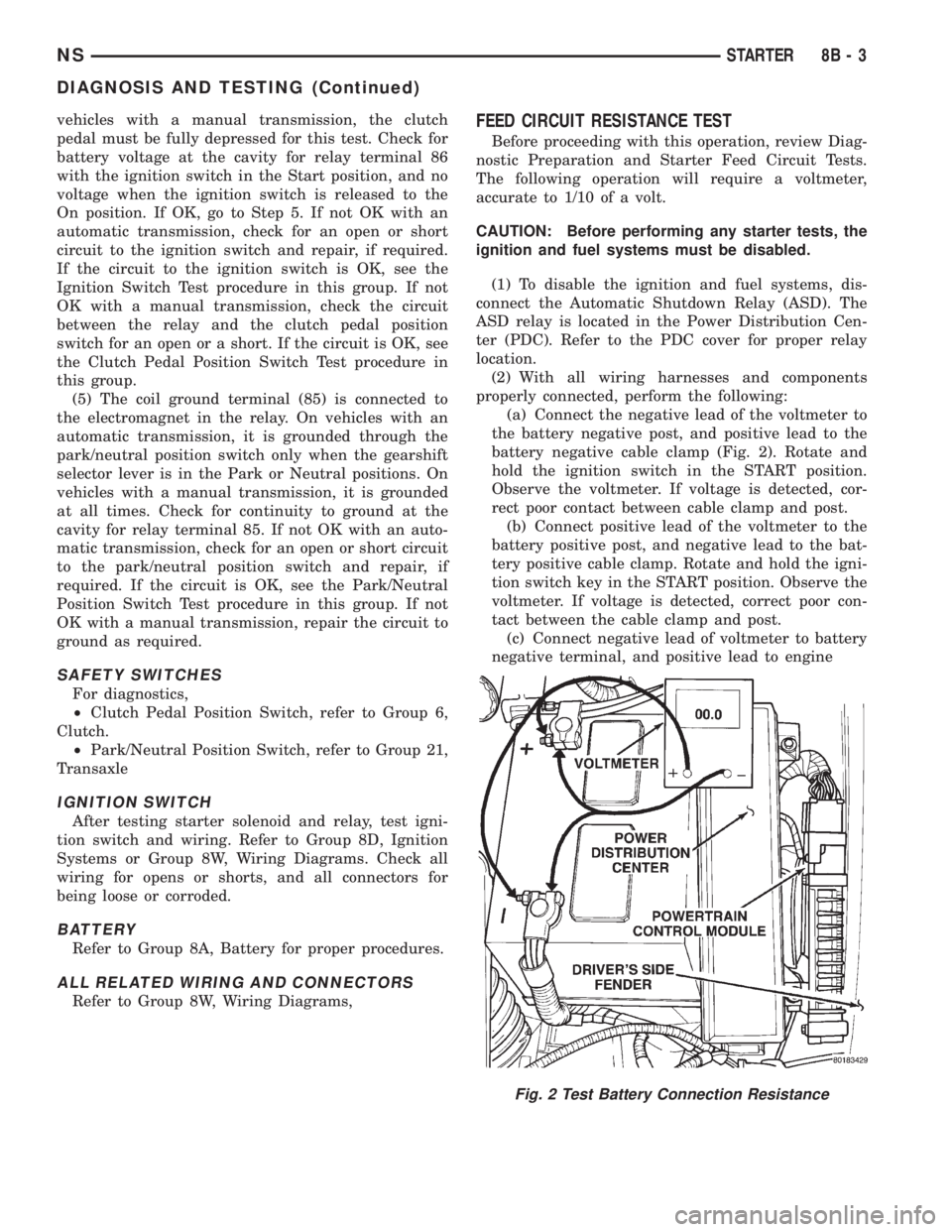

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp (Fig. 2). Rotate and

hold the ignition switch in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

Fig. 2 Test Battery Connection Resistance

NSSTARTER 8B - 3

DIAGNOSIS AND TESTING (Continued)

Page 276 of 1938

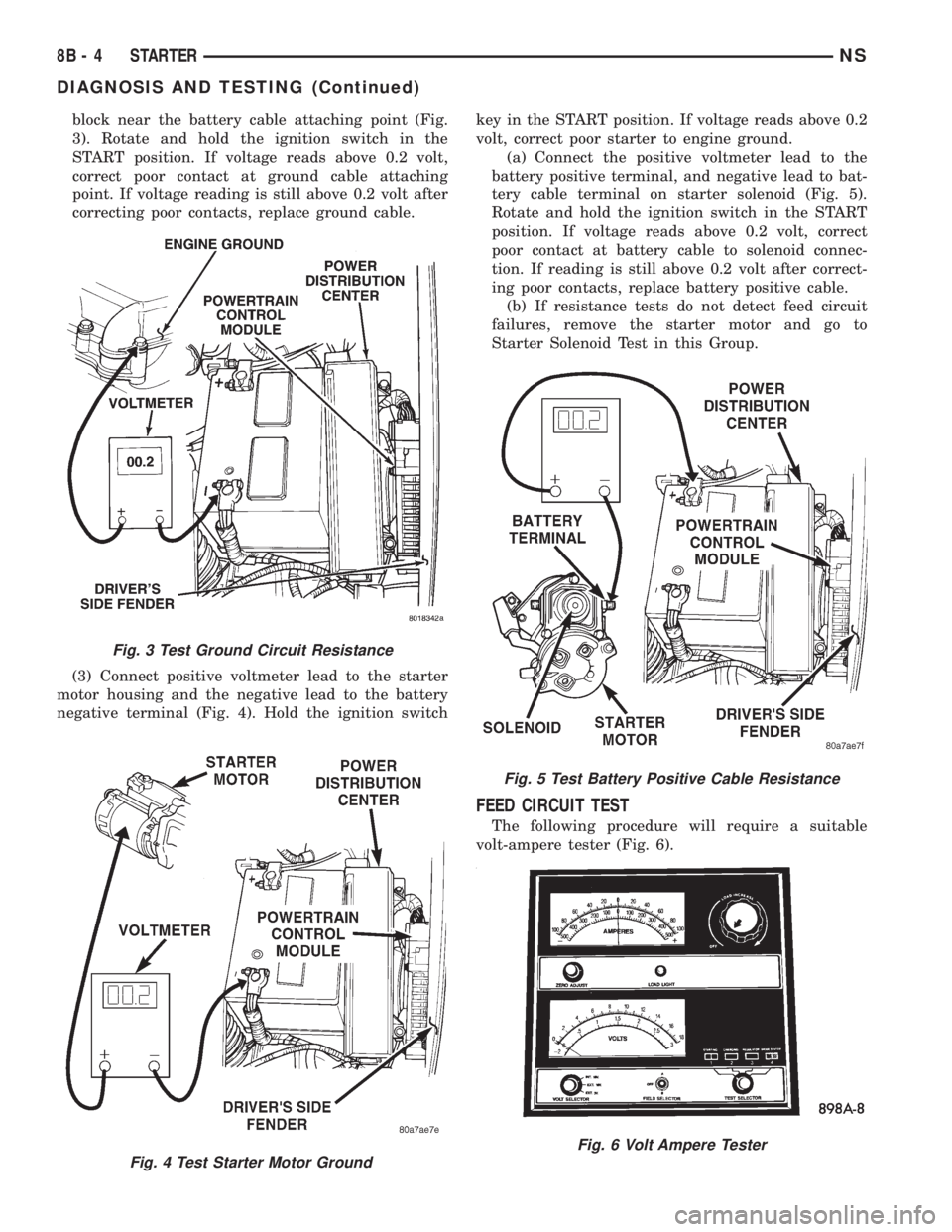

block near the battery cable attaching point (Fig.

3). Rotate and hold the ignition switch in the

START position. If voltage reads above 0.2 volt,

correct poor contact at ground cable attaching

point. If voltage reading is still above 0.2 volt after

correcting poor contacts, replace ground cable.

(3) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal (Fig. 4). Hold the ignition switchkey in the START position. If voltage reads above 0.2

volt, correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid (Fig. 5).

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at battery cable to solenoid connec-

tion. If reading is still above 0.2 volt after correct-

ing poor contacts, replace battery positive cable.

(b) If resistance tests do not detect feed circuit

failures, remove the starter motor and go to

Starter Solenoid Test in this Group.

FEED CIRCUIT TEST

The following procedure will require a suitable

volt-ampere tester (Fig. 6).

Fig. 4 Test Starter Motor Ground

Fig. 3 Test Ground Circuit Resistance

Fig. 5 Test Battery Positive Cable Resistance

Fig. 6 Volt Ampere Tester

8B - 4 STARTERNS

DIAGNOSIS AND TESTING (Continued)