diagram CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 531 of 1938

MEMORY SEAT AND MIRROR SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

DESCRIPTION AND OPERATION

MEMORY SELECTOR SWITCHES............ 3

POSITION SENSING SEAT AND RECLINER

POTENTIOMETERS..................... 4

POWER SIDE VIEW MIRROR POSITION

SENSING............................. 3

SEAT AND RECLINER SWITCHES............ 4

DIAGNOSIS AND TESTING

CIRCUIT DESCRIPTION.................... 7DIAGNOSTIC MODE...................... 5

MEMORY SELECTOR SWITCHES............ 4

SEAT AND RECLINER POSITION SENSING.... 9

SIDE VIEW MIRROR SWITCH STUCK......... 4

SERVICE PROCEDURES

REMOTE KEYLESS ENTRY (RKE) DATA LINK . . . 9

REMOVAL AND INSTALLATION

MEMORY SWITCHES..................... 10

SEAT TRACK ASSEMBLY.................. 10

GENERAL INFORMATION

INTRODUCTION

Memory Seat and Mirrors system is available only

on Town and Country (Luxury Class) vehicles.

Refer to Group 8W, Wiring Diagrams for circuit

information and component locations. Refer to the

proper Body Diagnostic Procedures manual for addi-

tional diagnostic information.

The Memory Seat/Mirror Module (MSM Module) is

mounted under the driver's seat, on the inboard

upper track with Torx head screws. The MSM Mod-

ule provides the driver with an adjustable seat,

recliner, and power side view mirror positioning con-

troller that remembers stored positions and will

recall those positions on command.

The Memory Seat/Mirror Module reads all seat and

recliner switch inputs and operates the seat and

recliner motors in response to switch actuation. The

MSM Module monitors position sensing potentiome-

ters (mounted on the motors) for seat and recliner

positioning.

The MSM Module operates the power side view

mirror motors through solid state drivers (electronic

switches) in the recall mode only, and follows the

glass face position by means of rheostats built into

the motor pack assembly of the mirrors. Normal elec-

trical operation of the mirrors is accomplished by

actuation of the power mirror switch.

The Memory Seat/Mirror Module monitors the mem-

ory switches and has the capability to store desired

positions in non-volatile memory in response to a valid

input sequence. Refer to Memory Selector Switches (1,

2, and S) and Remote Keyless Entry (RKE) Data Link.

The memory seat/mirror module also can activate the

previously described motors in response to a recall

request from an individual memory switch.

The Memory Seat/Mirror Module monitors a data

link between the RKE receiver and the Body Control

Module (BCM) and will respond to stored information

or modify stored information when requested by a

valid data stream.

The Memory Seat/Mirror Module is connected to

the system through a seat wiring harness that inter-

faces will all of the components within the seat struc-

ture, and with electrical distribution wiring harness

connections to the non-seat mounted components.

The module operates the seat and recliner motors

through relays: four dedicated to track forward/rear-

ward, track front up/down, track rear up/down, and

recliner forward/rearward. A fifth relay controls the

direction of operation of those motors.

DESCRIPTION AND OPERATION

POWER SIDE VIEW MIRROR POSITION SENSING

The mirror switch on the instrument panel oper-

ates the outside rear view mirrors independently of

the memory seat/mirror module. The module acti-

vates the mirror motors only when in its recall mode.

The side view mirrors have position sensing rheo-

stats built into each side view mirror vertical and

horizontal motor assembly. These rheostats provide a

sense voltage to the memory seat/mirror module that

indicates where the mirror is moving to or where its

position is at when the module is activated but the

mirror motor is not moving.

MEMORY SELECTOR SWITCHES

The memory selector switches are mounted on the

driver's door trim panel within easy reach of the

driver. They provide a means to set or recall either of

NSPOWER SEATS 8R - 3

Page 543 of 1938

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

CHIME SYSTEM DIAGNOSIS............... 1

DOME LAMP ON CHIME.................. 2

ENGINE TEMPERATURE CRITICAL CHIME.... 2

EXTERIOR LAMPS ON CHIME.............. 2KEY-IN IGNITION CHIME.................. 2

LOW OIL PRESSURE CHIME OPERATION..... 2

SEAT BELT CHIME....................... 2

SEAT BELT LAMP........................ 2

TURN SIGNAL ON CHIME................. 3

WARNING LAMP ANNOUNCEMENT CHIME . . . 3

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO GROUP 8M, RESTRAINT SYS-

TEMS FOR SAFETY PRECAUTIONS AND WARN-

INGS TO OBSERVE WHEN SERVICING AIRBAG

RELATED COMPONENTS.

The chime system provides the driver with warn-

ing chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

The Chime Warning/Reminder System is diagnosed

using a scan tool (DRB). Refer to the proper Body

Diagnostic Procedures manual for testing procedures

and scan tool usage instructions.

DIAGNOSIS AND TESTING

CHIME SYSTEM DIAGNOSIS

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVER'S SEAT BELT IS

NOT BUCKLED.

(1) Using a scan tool (DRB), check for tone in any

other function.

(2) Using a voltmeter, check for voltage:

(a) Pin 9 of the internal 32 way connector of the

BCM for battery feed.(b) Pin 8 of the internal 32 way connector of the

BCM for ignition feed.

(c) If voltage OK, go to step Step 3

(d) If NO voltage repair as necessary. Refer to

Group 8W, Wiring Diagrams for component loca-

tions and circuit information.

(3) Check driver's seat belt buckle switch input for

a closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Repair as necessary.

NO FASTEN SEAT BELT LAMP WHEN

IGNITION SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

FASTEN SEAT BELT LAMP OR TONE

CONTINUES FOR MORE THAN 10 SECONDS

AFTER SEAT BELTS ARE FASTENED AND

DRIVER'S DOOR IS CLOSED.

(1) Check left door ajar switch for no ground when

switch is depressed.

(a) If continuity replace door ajar switch.

(b) If NO continuity replace BCM for tone condi-

tion, or replace mechanical instrument panel for

lamp condition.

(c) Replace BCM for tone condition.

(d) Replace mechanical instrument cluster for

lamp condition.

NO TONE WHEN PARK OR HEADLAMPS ARE

ON AND DRIVER'S DOOR IS OPEN.

(1) Check left door ajar switch for good ground

when driver's door is open. Repair as necessary.

NSCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 547 of 1938

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

DIAGNOSIS AND TESTING

CATALYST OVERHEAT WARNING CHIME.... 1

CHIME SYSTEM DIAGNOSIS.............. 1

DOME LAMP ON CHIME................. 2

ENGINE TEMPERATURE CRITICAL CHIME . . . 2EXTERIOR LAMPS ON CHIME............. 2

KEY-IN IGNITION CHIME................. 2

LOW OIL PRESSURE CHIME OPERATION . . . 2

SEAT BELT CHIME...................... 3

SEAT BELT LAMP...................... 3

TURN SIGNAL ON CHIME................ 3

WARNING LAMP ANNOUNCEMENT CHIME . . 3

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO GROUP 8M, RESTRAINT SYS-

TEMS FOR SAFETY PRECAUTIONS AND WARN-

INGS TO OBSERVE WHEN SERVICING AIRBAG

RELATED COMPONENTS.

The chime system provides the driver with warn-

ing chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Catalyst Overheating

The Chime Warning/Reminder System is diagnosed

using a scan tool (DRB). Refer to the proper Body

Diagnostic Procedures manual for testing procedures

and scan tool usage instructions.

DIAGNOSIS AND TESTING

CATALYST OVERHEAT WARNING CHIME

The Catalyst Overheat Warning Chime will act as

a warning to the driver that the vehicle's catalyst

has entered an overheat condition. The Powertrain

Control Module (PCM) will enable or disable this fea-

ture for the appropriate vehicles. Right hand drive

gas vehicles only. The Body Control Module (BCM)

will monitor the CCD bus for status and signal a cat-

alyst overheat condition with continuous warning

chime when the following conditions are met:²Ignition switch in the ON position

²Engine running at 420 to 480 rpm for 10 sec-

onds

²CCD status and with a chime rate of one chime

per second.

CHIME SYSTEM DIAGNOSIS

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVER'S SEAT BELT IS

NOT BUCKLED.

(1) Using a scan tool (DRB), check for tone in any

other function.

(2) Using a voltmeter, check for voltage:

(a) Pin 9 of the internal 32 way connector of the

BCM for battery feed.

(b) Pin 8 of the internal 32 way connector of the

BCM for ignition feed.

(c) If voltage OK, go to step Step 3

(d) If NO voltage repair as necessary. Refer to

Group 8W, Wiring Diagrams for component loca-

tions and circuit information.

(3) Check driver's seat belt buckle switch input for

a closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Repair as necessary.

NO FASTEN SEAT BELT LAMP WHEN

IGNITION SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

NS/GSCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 553 of 1938

²Stores transmitter data in permanent memory -

retraining is not required even if the battery dies or

is disconnected.

To operate, simply press the appropriate button on

the Universal Transmitter. The red LED will light up

while the signal is being transmitted.

NOTE: For security reasons, you are able to erase

the trained frequencies.

DIAGNOSIS AND TESTING

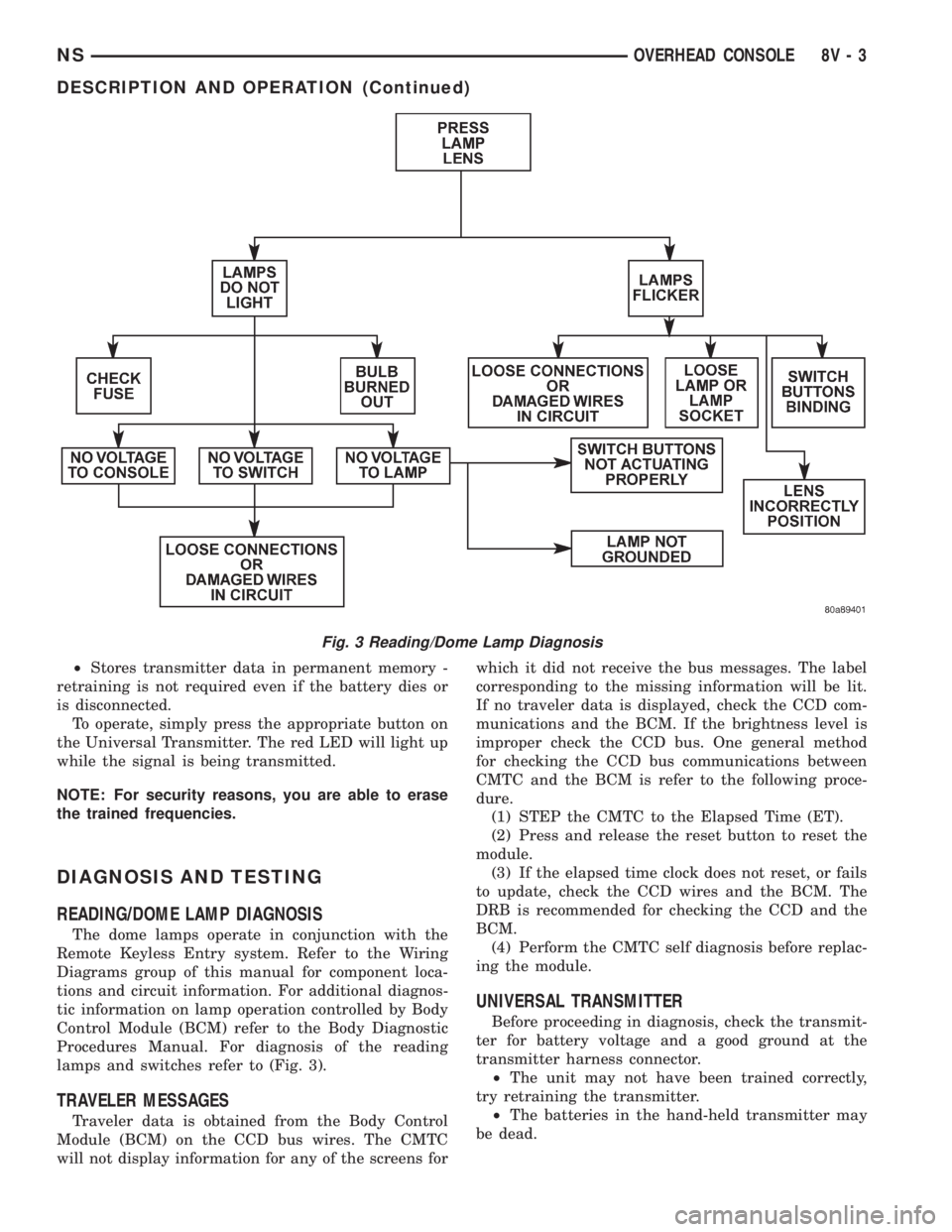

READING/DOME LAMP DIAGNOSIS

The dome lamps operate in conjunction with the

Remote Keyless Entry system. Refer to the Wiring

Diagrams group of this manual for component loca-

tions and circuit information. For additional diagnos-

tic information on lamp operation controlled by Body

Control Module (BCM) refer to the Body Diagnostic

Procedures Manual. For diagnosis of the reading

lamps and switches refer to (Fig. 3).

TRAVELER MESSAGES

Traveler data is obtained from the Body Control

Module (BCM) on the CCD bus wires. The CMTC

will not display information for any of the screens forwhich it did not receive the bus messages. The label

corresponding to the missing information will be lit.

If no traveler data is displayed, check the CCD com-

munications and the BCM. If the brightness level is

improper check the CCD bus. One general method

for checking the CCD bus communications between

CMTC and the BCM is refer to the following proce-

dure.

(1) STEP the CMTC to the Elapsed Time (ET).

(2) Press and release the reset button to reset the

module.

(3) If the elapsed time clock does not reset, or fails

to update, check the CCD wires and the BCM. The

DRB is recommended for checking the CCD and the

BCM.

(4) Perform the CMTC self diagnosis before replac-

ing the module.

UNIVERSAL TRANSMITTER

Before proceeding in diagnosis, check the transmit-

ter for battery voltage and a good ground at the

transmitter harness connector.

²The unit may not have been trained correctly,

try retraining the transmitter.

²The batteries in the hand-held transmitter may

be dead.

Fig. 3 Reading/Dome Lamp Diagnosis

NSOVERHEAD CONSOLE 8V - 3

DESCRIPTION AND OPERATION (Continued)

Page 561 of 1938

WIRING DIAGRAMS

CONTENTS

page page

AIR CONDITIONING-HEATER.......... 8W-42-1

AIRBAG SYSTEM................... 8W-43-1

ANTI-LOCK BRAKES................. 8W-35-1

AUDIO SYSTEM.................... 8W-47-1

BODY CONTROL MODULE............ 8W-45-1

CHARGING SYSTEM................. 8W-20-1

COMPONENT INDEX................. 8W-02-1

CONNECTOR/GROUND LOCATIONS..... 8W-90-1

CONNECTOR PIN-OUTS.............. 8W-80-1

FRONT LIGHTING................... 8W-50-1

FUEL/IGNITION SYSTEM............. 8W-30-1

GENERAL INFORMATION............. 8W-01-1

GROUND DISTRIBUTION............. 8W-15-1

HORN/CIGAR LIGHTER/POWER OUTLET . 8W-41-1

INSTRUMENT CLUSTER.............. 8W-40-1

INTERIOR LIGHTING................. 8W-44-1

JUNCTION BLOCK................... 8W-12-1

MESSAGE CENTER.................. 8W-46-1OVERHEAD CONSOLE................ 8W-49-1

POWER DISTRIBUTION.............. 8W-10-1

POWER DOOR LOCKS............... 8W-61-1

POWER MIRRORS.................. 8W-62-1

POWER SEAT...................... 8W-63-1

POWER WINDOWS.................. 8W-60-1

REAR LIGHTING.................... 8W-51-1

SPLICE INFORMATION............... 8W-70-1

SPLICE LOCATIONS................. 8W-95-1

STARTING SYSTEM................. 8W-21-1

TRAILER TOW...................... 8W-54-1

TRANSMISSION CONTROL SYSTEM.... 8W-31-1

TURN SIGNALS..................... 8W-52-1

VEHICLE SPEED CONTROL........... 8W-33-1

VEHICLE THEFT SECURITY SYSTEM.... 8W-39-1

WINDOW DEFOGGERS............... 8W-48-1

WIPERS........................... 8W-53-1

NS/GSWIRING DIAGRAMS 8W - 1

Page 563 of 1938

8W-01 GENERAL INFORMATION

INDEX

page page

DESCRIPTION AND OPERATION

CIRCUIT FUNCTIONS..................... 4

CIRCUIT INFORMATION................... 4

CONNECTOR INFORMATION............... 7

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES.................... 8

INTRODUCTION......................... 1

NOTES, CAUTIONS, and WARNINGS......... 7

POSITIVE TEMPERATURE COEFFICIENT...... 8

SECTION IDENTIFICATION................. 5

SPLICE LOCATIONS...................... 7

SYMBOLS.............................. 5

TAKE OUTS............................. 8

TERMINOLOGY.......................... 7

DIAGNOSIS AND TESTING

INTERMITTENT AND POOR CONNECTIONS.... 9TROUBLESHOOTING TESTS................ 9

TROUBLESHOOTING TOOLS............... 8

TROUBLESHOOTING WIRING PROBLEMS.... 10

SERVICE PROCEDURES

CONNECTOR AND TERMINAL REPLACEMENT . 12

CONNECTOR REPLACEMENT.............. 11

DIODE REPLACEMENT................... 14

TERMINAL REPLACEMENT................ 13

TERMINAL/CONNECTOR REPAIR- AUGAT

CONNECTORS........................ 12

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS........................ 11

WIRING REPAIR........................ 10

SPECIAL TOOLS

WIRING/TERMINAL...................... 14

DESCRIPTION AND OPERATION

INTRODUCTION

Chrysler wiring diagrams are designed to provide

information regarding the vehicles wiring content. In

order to effectively use Chrysler wiring diagrams to

diagnose and repair a Chrysler vehicle, it is impor-

tant to understand all of their features and charac-

teristics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page.

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition.Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around a component indi-

cates that the component being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 1

Page 566 of 1938

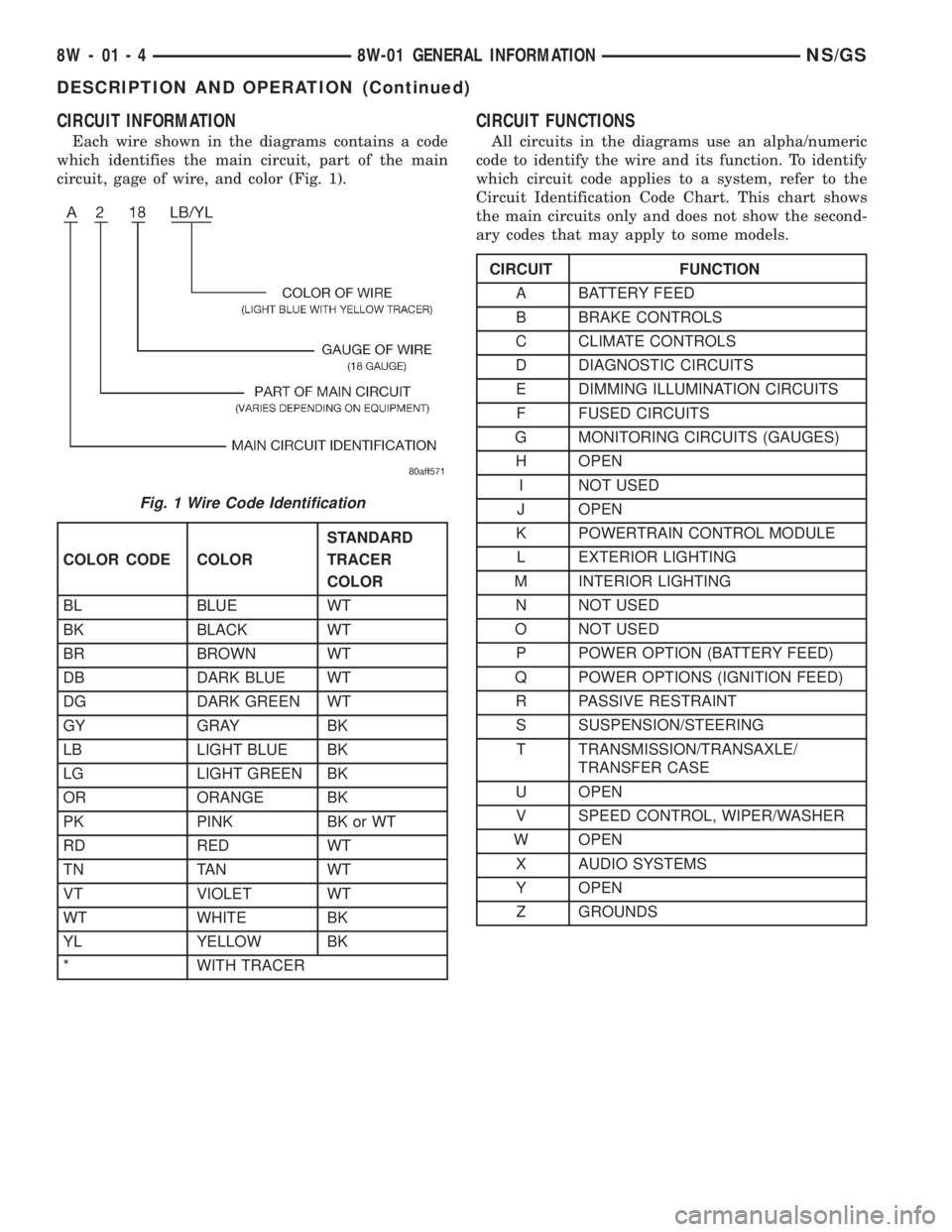

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 1).

CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

Fig. 1 Wire Code Identification

COLOR CODE COLORSTANDARD

TRACER

COLOR

BL BLUE WT

BK BLACK WT

BR BROWN WT

DB DARK BLUE WT

DG DARK GREEN WT

GY GRAY BK

LB LIGHT BLUE BK

LG LIGHT GREEN BK

OR ORANGE BK

PK PINK BK or WT

RD RED WT

TN TAN WT

VT VIOLET WT

WT WHITE BK

YL YELLOW BK

* WITH TRACER

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS (GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY FEED)

Q POWER OPTIONS (IGNITION FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W-01 GENERAL INFORMATIONNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 567 of 1938

SECTION IDENTIFICATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

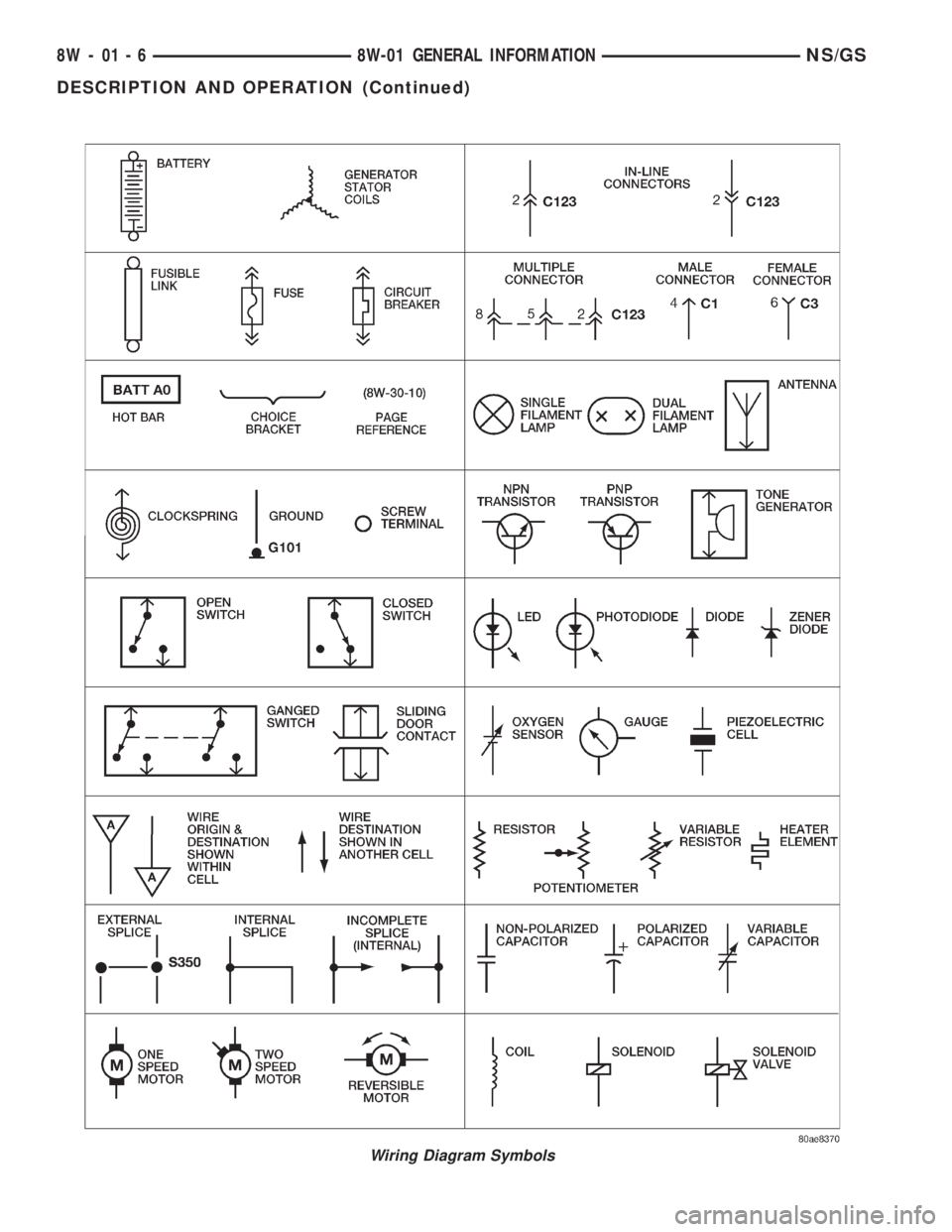

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world.

GROUP TOPIC

8W-01 thru 8W-09 General Information and

Diagram Overview

8W-10 thru 8W-19 Main Sources of Power and

Vehicle Grounding

8W-20 thru 8W-29 Starting and Charging

8W-30 thru 8W-39 Powertrain/Drivetrain

Systems

8W-40 thru 8W-49 Body Electrical items and A/C

8W-50 thru 8W-59 Exterior Lighting, Wipers, and

Trailer Tow

8W-60 thru 8W-69 Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-90 Connector Locations

(including grounds)

8W-95 Splice Locations

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 5

DESCRIPTION AND OPERATION (Continued)

Page 568 of 1938

Wiring Diagram Symbols

8W - 01 - 6 8W-01 GENERAL INFORMATIONNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 569 of 1938

TERMINOLOGY

This a list of terms with there definitions used in

the wiring diagrams.

Built-Up-Export.........Vehicles Built For Sale In

Markets Other Than North America

Except-Built-Up-Export.....Vehicles Built For Sale

In North America

LHD..................Left Hand Drive Vehicles

RHD.................Right Hand Drive Vehicles

ATX . . . .Automatic Transmission-Front Wheel Drive

MTX......Manual Transmission-Front Wheel Drive

AT......Automatic Transmission-Rear Wheel Drive

MT .......Manual Transmission-Rear Wheel Drive

SOHC.............Single Over Head Cam Engine

DOHC.............Dual Over Head Cam Engine

CONNECTOR INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located on theengine com-

partment harnessareC100series numbers.

²Connectors located on theinstrument panel

harnessareC200series numbers.

²Connectors located on thebody harnessare

C300series numbers.

²Jumper harness connectorsareC400series

numbers.

²Grounds and ground connectorsare identi-

fied with aªGºand follow the same series number-

ing as the in-line connector.

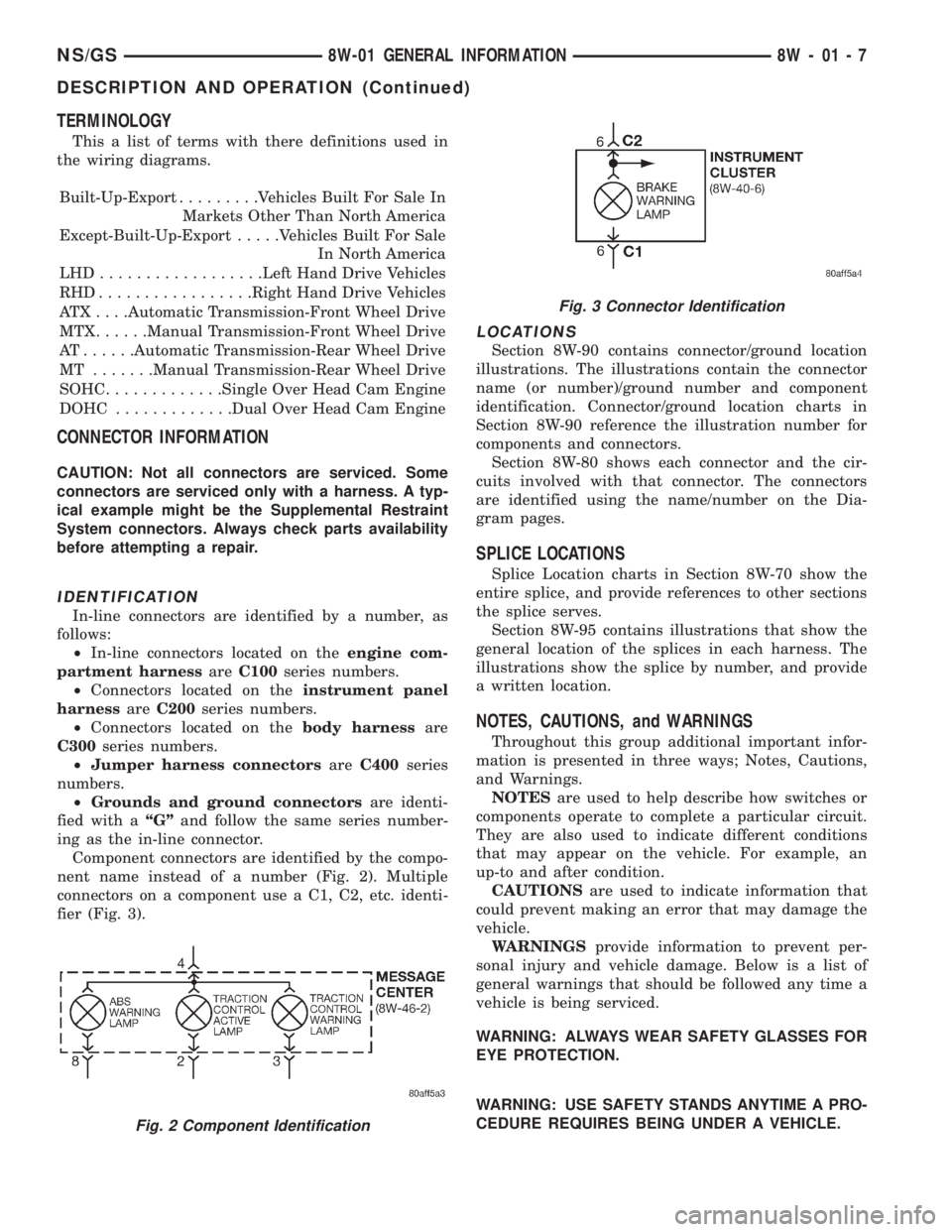

Component connectors are identified by the compo-

nent name instead of a number (Fig. 2). Multiple

connectors on a component use a C1, C2, etc. identi-

fier (Fig. 3).

LOCATIONS

Section 8W-90 contains connector/ground location

illustrations. The illustrations contain the connector

name (or number)/ground number and component

identification. Connector/ground location charts in

Section 8W-90 reference the illustration number for

components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the Dia-

gram pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

NOTES, CAUTIONS, and WARNINGS

Throughout this group additional important infor-

mation is presented in three ways; Notes, Cautions,

and Warnings.

NOTESare used to help describe how switches or

components operate to complete a particular circuit.

They are also used to indicate different conditions

that may appear on the vehicle. For example, an

up-to and after condition.

CAUTIONSare used to indicate information that

could prevent making an error that may damage the

vehicle.

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.

Fig. 2 Component Identification

Fig. 3 Connector Identification

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 7

DESCRIPTION AND OPERATION (Continued)