diagram CHRYSLER VOYAGER 1996 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1355 of 1938

PCM. If OK, replace MAP sensor. If not OK, repair or

replace the wire harness as required.

HEATED OXYGEN SENSOR

Use an ohmmeter to test the heating element of

the oxygen sensors. Disconnect the electrical connec-

tor from each oxygen sensor. The white wires in the

sensor connector are the power and ground circuits

for the heater. Connect the ohmmeter test leads to

terminals of the white wires in the heated oxygen

sensor connector. Replace the heated oxygen sensor if

the resistance is not between 4 and 7 ohms.

KNOCK SENSOR

The engine knock sensor is affected by a number of

factors. A few of these are: ignition timing, cylinder

pressure, fuel octane, etc. The knock sensor gener-

ates an AC voltage whose amplitude increases with

the increase of engine knock. The knock sensor can

be tested with a digital voltmeter. The RMS voltage

starts at about 20mVac (at about 700 rpm) and

increases to approximately 600 mVac (5000 rpm). If

the output falls outside of this range a DTC will be

set.

CAMSHAFT AND CRANKSHAFT POSITION SENSOR

Refer to Group 8D, Ignition for Diagnosis and Test-

ing of Camshaft and Crankshaft Sensors.

ENGINE COOLANT TEMPERATURE SENSOR

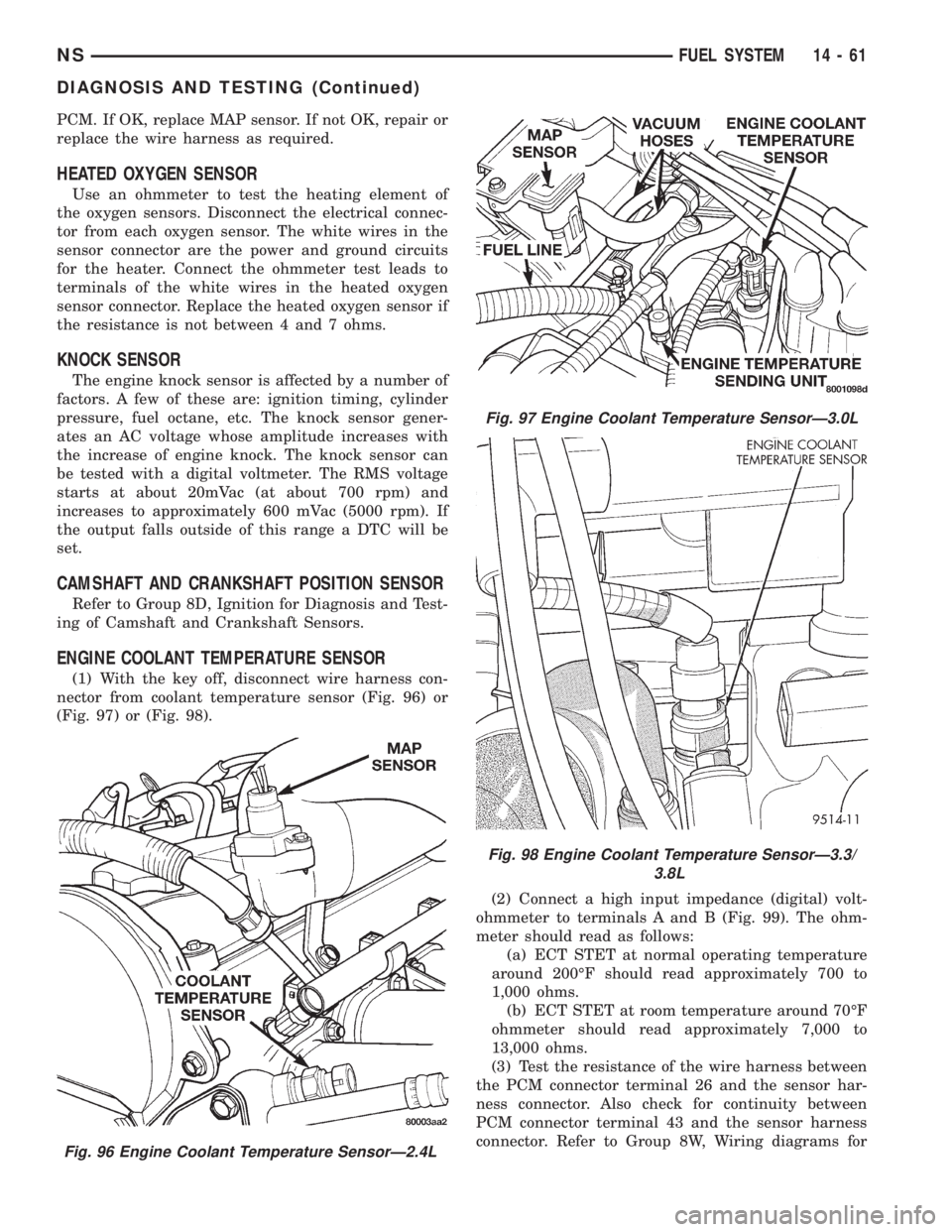

(1) With the key off, disconnect wire harness con-

nector from coolant temperature sensor (Fig. 96) or

(Fig. 97) or (Fig. 98).

(2) Connect a high input impedance (digital) volt-

ohmmeter to terminals A and B (Fig. 99). The ohm-

meter should read as follows:

(a) ECT STET at normal operating temperature

around 200ÉF should read approximately 700 to

1,000 ohms.

(b) ECT STET at room temperature around 70ÉF

ohmmeter should read approximately 7,000 to

13,000 ohms.

(3) Test the resistance of the wire harness between

the PCM connector terminal 26 and the sensor har-

ness connector. Also check for continuity between

PCM connector terminal 43 and the sensor harness

connector. Refer to Group 8W, Wiring diagrams for

Fig. 96 Engine Coolant Temperature SensorÐ2.4L

Fig. 97 Engine Coolant Temperature SensorÐ3.0L

Fig. 98 Engine Coolant Temperature SensorÐ3.3/

3.8L

NSFUEL SYSTEM 14 - 61

DIAGNOSIS AND TESTING (Continued)

Page 1421 of 1938

²When the PCM energizes the Diesel PCM and

other relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

TESTING

The following procedure applies to the Diesel PCM

and other relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be between 75

65 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the Die-

sel PCM and other relay circuits. Refer to group 8W,

Wiring Diagrams.

BOOST PRESSURE SENSOR

If the boost pressure sensor fails, the PCM records

a DTC into memory and continues to operate the

engine in one of the three ªlimp-inº modes. When the

PCM is operating in this mode, a loss of power will

be present, as if the turbocharger was not operating.

The best method for diagnosing faults with the boost

pressure sensor is with the DRB III scan tool.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

VEHICLE SPEED SENSOR TEST

To perform a test of the sensor and its related cir-

cuitry, refer to DRB scan tool.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

DIAGNOSTIC TROUBLE CODES

For a list of Diagnostic Trouble Codes (DTC's),

refer to Group 25, Emission Control System for infor-

mation. See On-Board Diagnostics.

REMOVAL AND INSTALLATION

DIESEL PCM RELAY

The Diesel PCM relay is located in the PDC. For

the location of the relay within the PDC, refer to

label on PDC cover.

A/C CLUTCH RELAY

The A/C clutch relay is located in the PDC. For the

location of the relay within the PDC, refer to label on

PDC cover.

ENGINE SPEED SENSOR

The engine speed sensor is mounted to the trans-

mission bellhousing at the rear of the engine block

(Fig. 18).

REMOVAL

(1) Disconnect the harness (on the sensor) from

the main electrical harness.

Fig. 17 Diesel PCM and Other Relay Terminals

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 53

DIAGNOSIS AND TESTING (Continued)

Page 1475 of 1938

TRANSAXLE AND POWER TRANSFER UNIT

CONTENTS

page page

31TH AUTOMATIC TRANSAXLE.............. 1

41TE AUTOMATIC TRANSAXLE............. 71POWER TRANSFER UNIT................. 165

31TH AUTOMATIC TRANSAXLE

INDEX

page page

GENERAL INFORMATION

31TH TRANSAXLE........................ 2

FLUID LEVEL AND CONDITION.............. 2

SELECTION OF LUBRICANT................ 3

SPECIAL ADDITIVES...................... 3

DESCRIPTION AND OPERATION

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR

...................... 3

FLOW CONTROL VALVES.................. 3

GEARSHIFT AND PARKING LOCK CONTROLS . . 4

GOVERNOR............................. 4

HYDRAULIC CONTROL SYSTEM............. 3

PRESSURE REGULATING VALVES........... 3

PRESSURE SUPPLY SYSTEM............... 3

TORQUE CONVERTER CLUTCH SOLENOID

WIRING CONNECTOR................... 4

TORQUE CONVERTER CLUTCH............. 3

DIAGNOSIS AND TESTING

CLUTCH AND SERVO AIR PRESSURE TESTS . 15

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA............ 15

HYDRAULIC PRESSURE TESTS............ 13

ROAD TEST............................. 4

THREE SPEED TRANSAXLE DIAGNOSIS AND

TESTS............................... 4

SERVICE PROCEDURES

ALUMINUM THREAD REPAIR.............. 18

FLUID AND FILTER CHANGE............... 16

FLUID DRAIN AND REFILL................. 18

FLUSHING COOLERS AND TUBES.......... 18

OIL PUMP VOLUME CHECK............... 19

REMOVAL AND INSTALLATION

FRONT PUMP OIL SEAL.................. 21

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH........................ 19

TRANSAXLE AND TORQUE CONVERTER

REMOVAL............................ 20

VEHICLE SPEED SENSOR PINION GEAR..... 19DISASSEMBLY AND ASSEMBLY

ACCUMULATOR-RECONDITION............ 36

DIFFERENTIAL REPAIR................... 46

FRONT CLUTCH-RECONDITION............ 32

FRONT PLANETARY & ANNULUS GEAR-

RECONDITION........................ 35

KICKDOWN SERVO (CONTROLLED LOAD)-

RECONDITION........................ 37

LOW/REVERSE (REAR)

SERVO-RECONDITION.................. 36

OIL PUMP-RECONDITION................. 31

OUTPUT SHAFT REPAIR.................. 43

PARKING PAWL......................... 42

REAR CLUTCH-RECONDITION............. 33

TRANSAXLE........................... 21

TRANSFER SHAFT REPAIR................ 38

VALVE BODY RECONDITION............... 27

CLEANING AND INSPECTION

VALVE BODY........................... 50

ADJUSTMENTS

BAND ADJUSTMENT..................... 51

BEARING ADJUSTMENT PROCEDURES...... 52

DIFFERENTIAL BEARING................. 53

GEARSHIFT CABLE ADJUSTMENT.......... 51

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS....................... 52

OUTPUT SHAFT BEARING................ 52

THROTTLE PRESSURE LINKAGE

ADJUSTMENT......................... 51

TRANSFER SHAFT BEARING.............. 54

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC SCHEMATIC . . 56

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE............. 64

31TH TORQUE SPECIFICATIONS........... 65

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE............. 66

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 1

Page 1530 of 1938

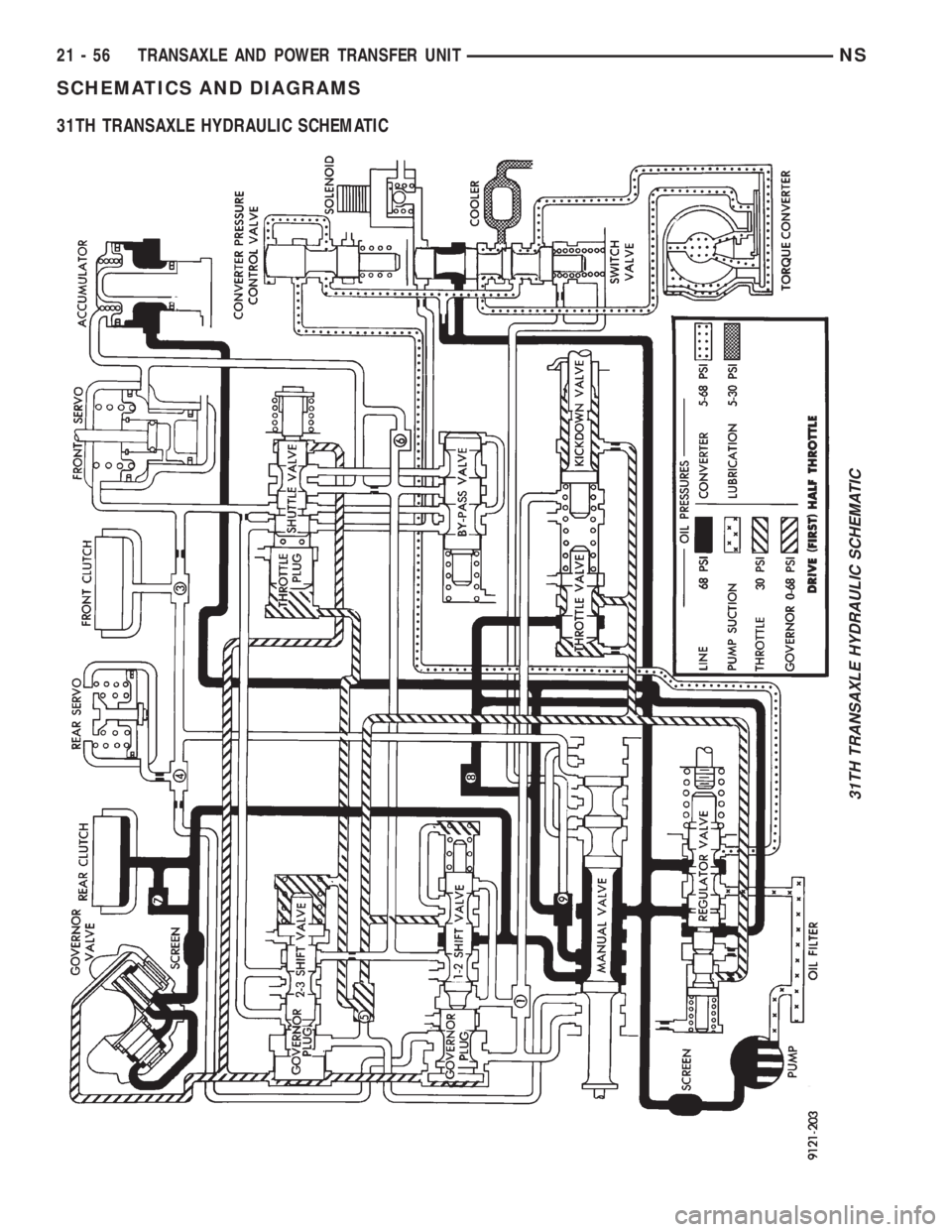

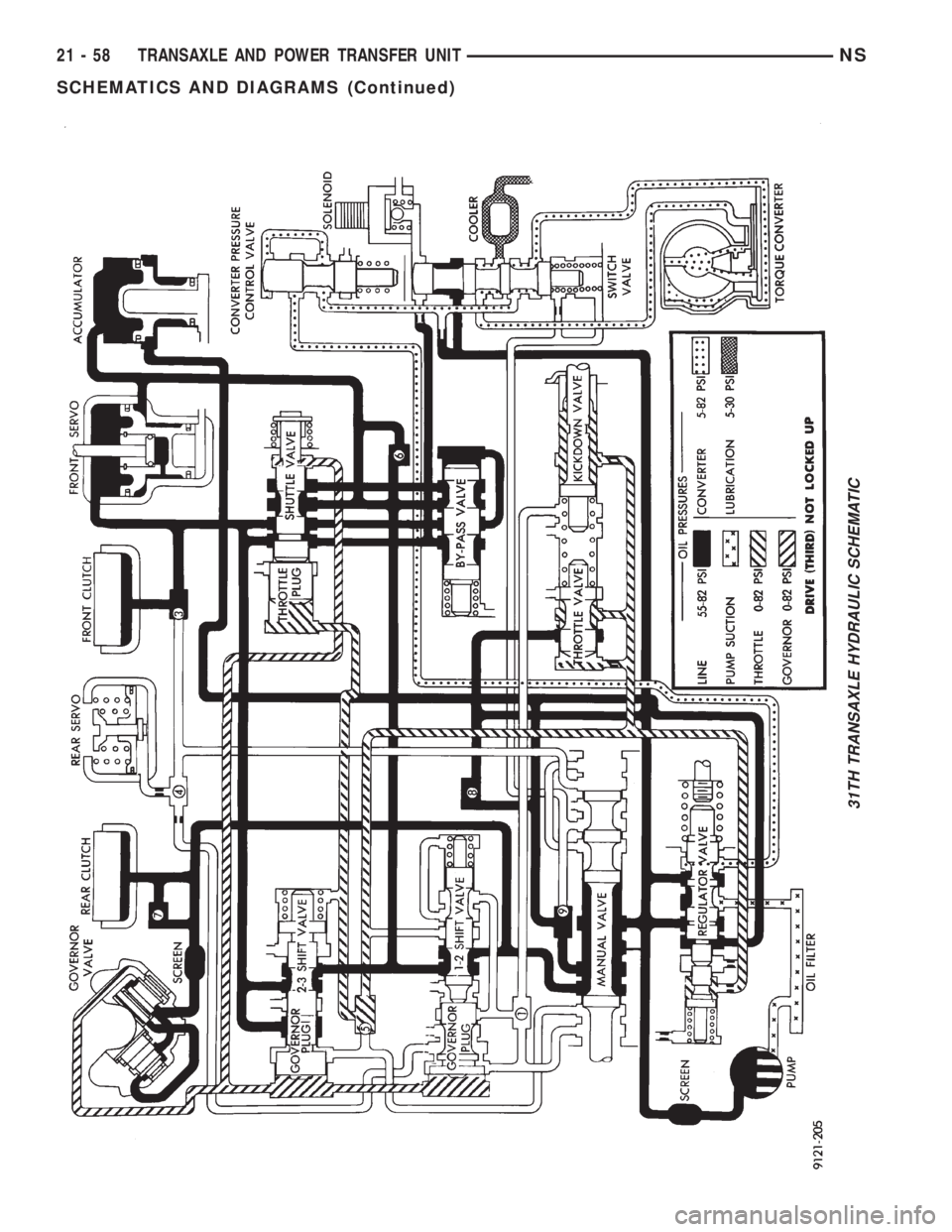

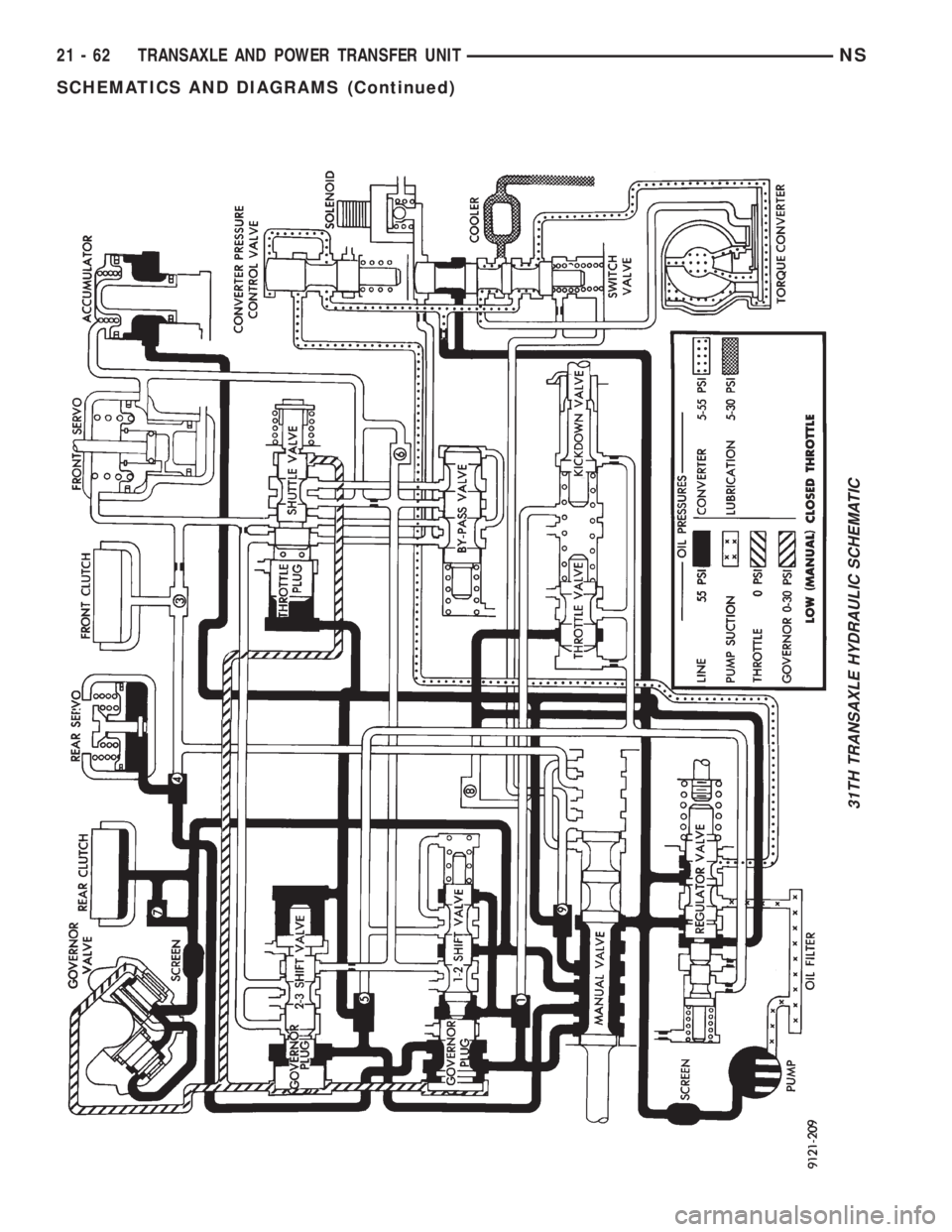

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC SCHEMATIC

31TH TRANSAXLE HYDRAULIC SCHEMATIC

21 - 56 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1531 of 1938

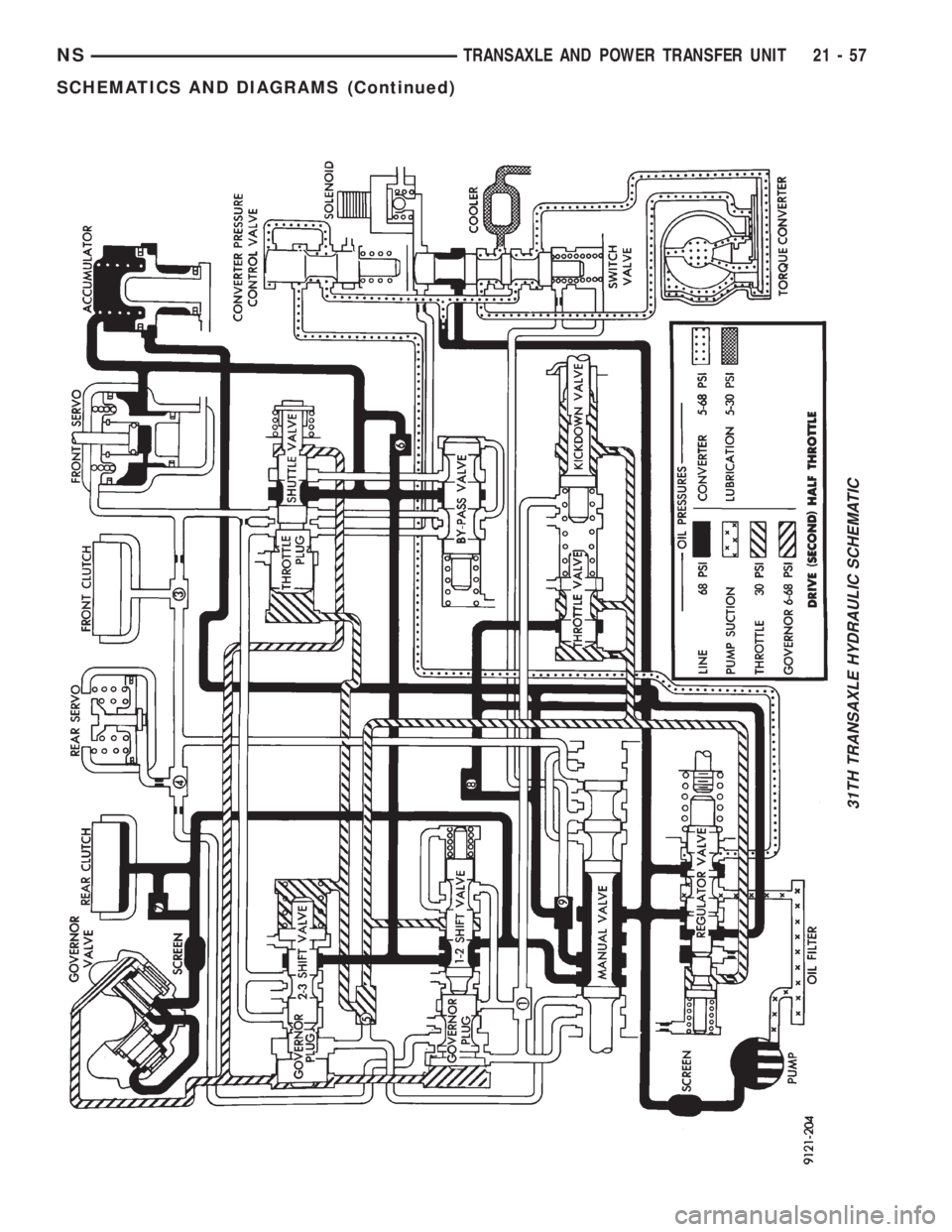

31TH TRANSAXLE HYDRAULIC SCHEMATIC

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 57

SCHEMATICS AND DIAGRAMS (Continued)

Page 1532 of 1938

31TH TRANSAXLE HYDRAULIC SCHEMATIC

21 - 58 TRANSAXLE AND POWER TRANSFER UNITNS

SCHEMATICS AND DIAGRAMS (Continued)

Page 1533 of 1938

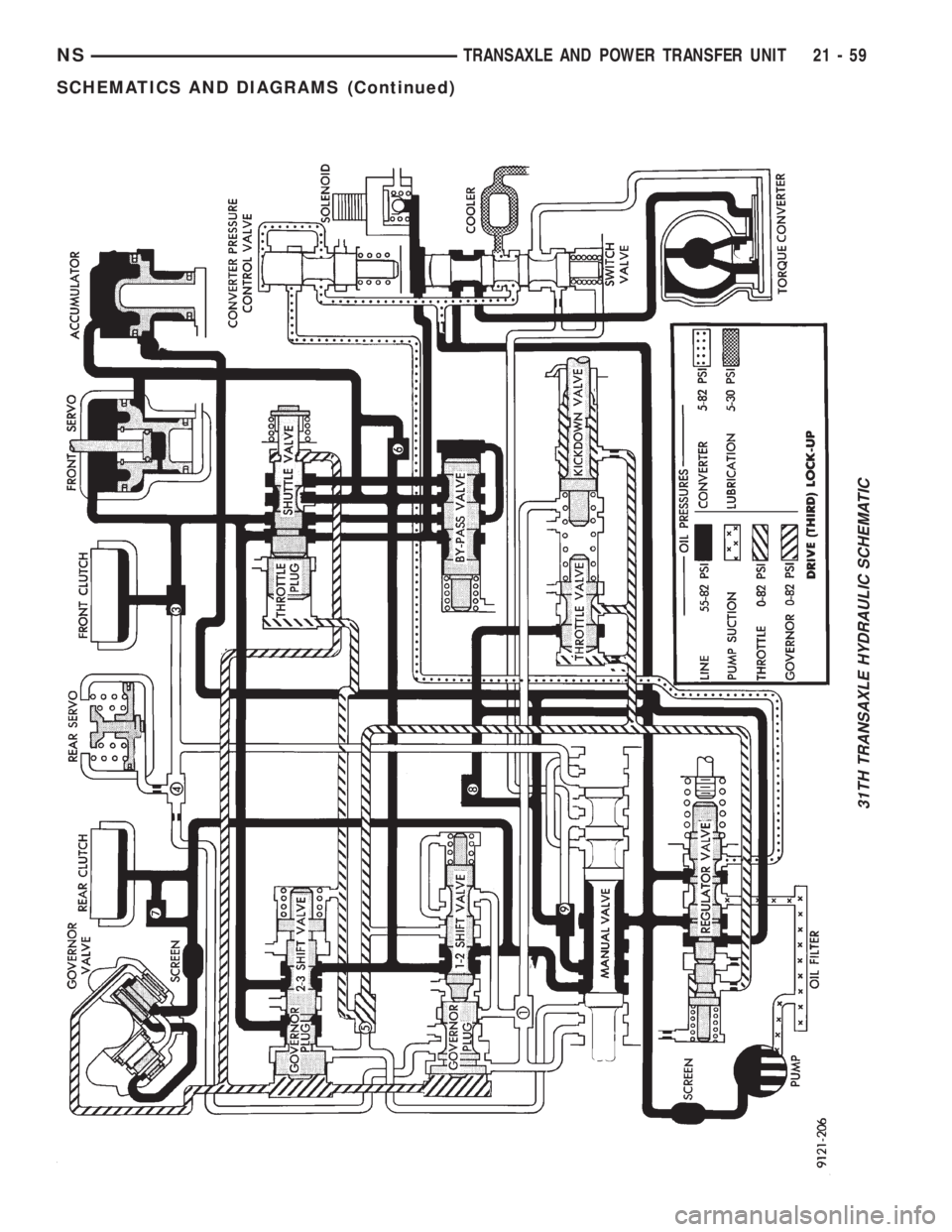

31TH TRANSAXLE HYDRAULIC SCHEMATIC

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 59

SCHEMATICS AND DIAGRAMS (Continued)

Page 1534 of 1938

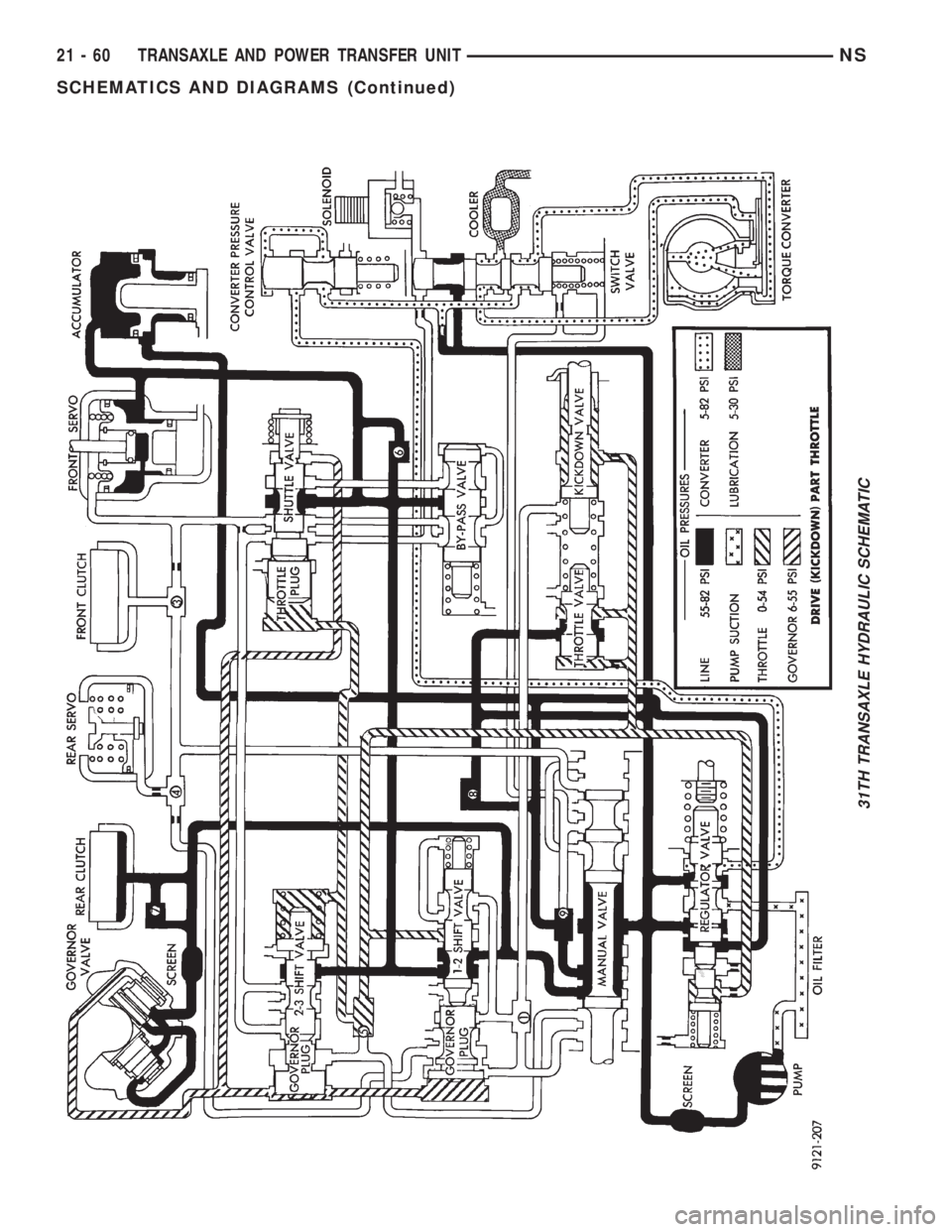

31TH TRANSAXLE HYDRAULIC SCHEMATIC

21 - 60 TRANSAXLE AND POWER TRANSFER UNITNS

SCHEMATICS AND DIAGRAMS (Continued)

Page 1535 of 1938

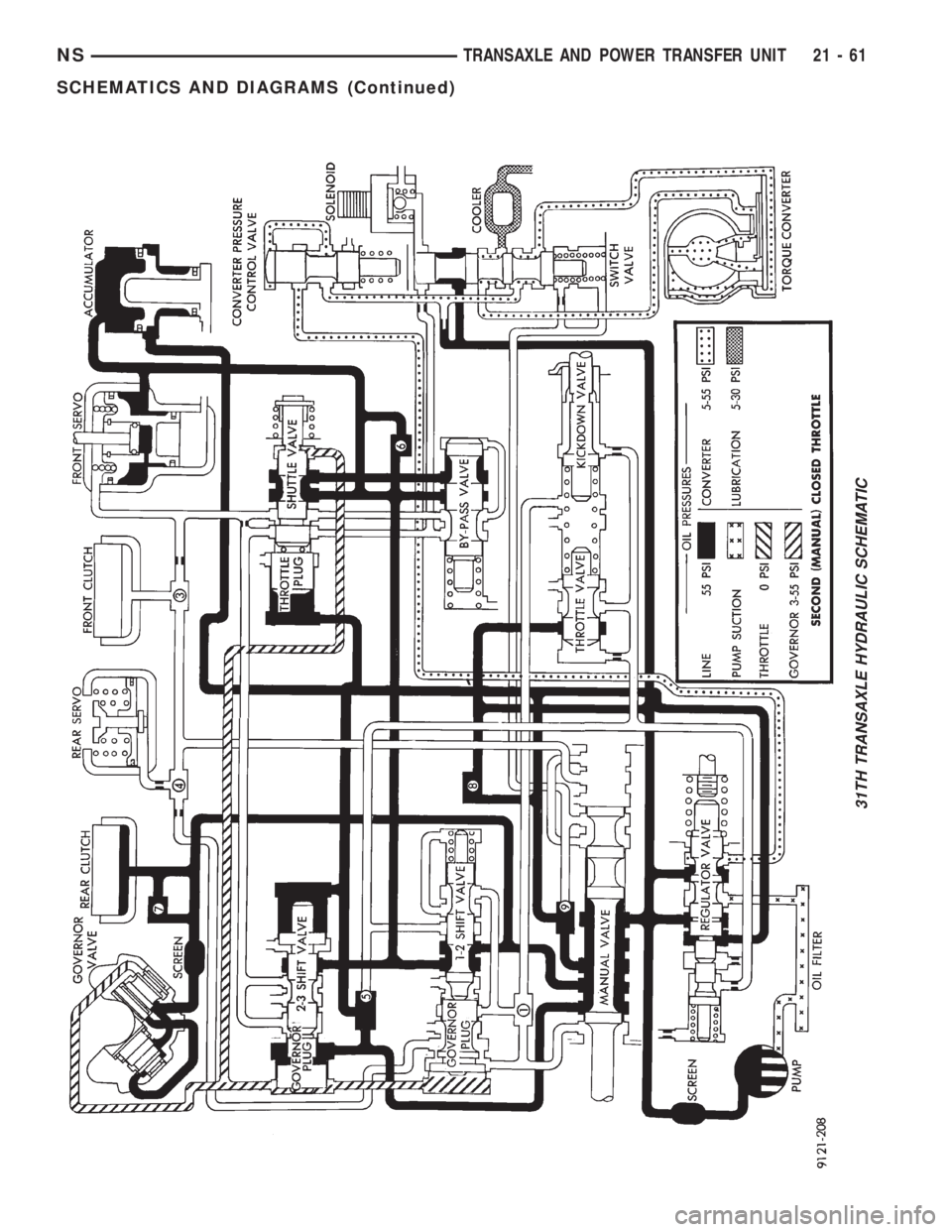

31TH TRANSAXLE HYDRAULIC SCHEMATIC

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 61

SCHEMATICS AND DIAGRAMS (Continued)

Page 1536 of 1938

31TH TRANSAXLE HYDRAULIC SCHEMATIC

21 - 62 TRANSAXLE AND POWER TRANSFER UNITNS

SCHEMATICS AND DIAGRAMS (Continued)