weight CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1120 of 1938

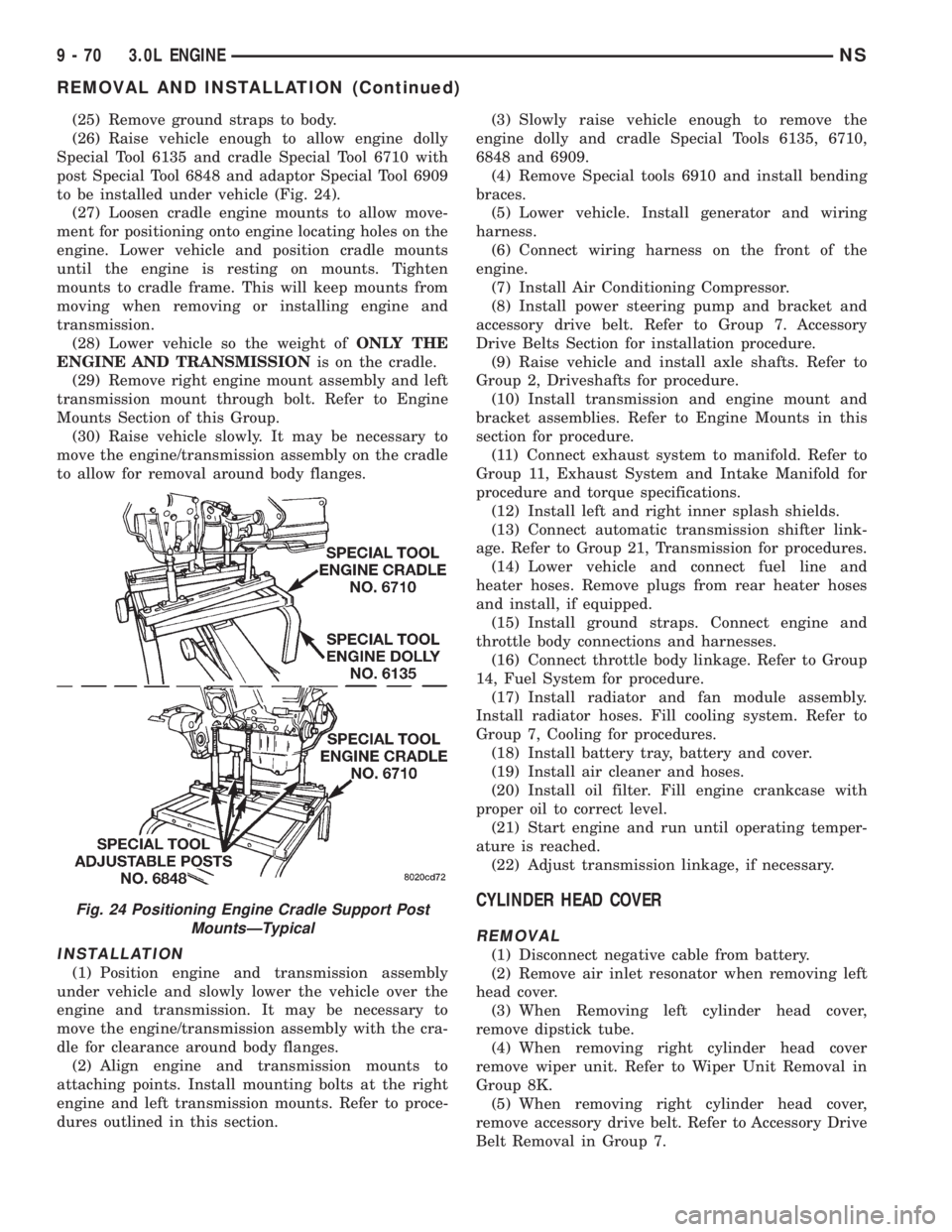

(25) Remove ground straps to body.

(26) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 24).

(27) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(28) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(29) Remove right engine mount assembly and left

transmission mount through bolt. Refer to Engine

Mounts Section of this Group.

(30) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909.

(4) Remove Special tools 6910 and install bending

braces.

(5) Lower vehicle. Install generator and wiring

harness.

(6) Connect wiring harness on the front of the

engine.

(7) Install Air Conditioning Compressor.

(8) Install power steering pump and bracket and

accessory drive belt. Refer to Group 7. Accessory

Drive Belts Section for installation procedure.

(9) Raise vehicle and install axle shafts. Refer to

Group 2, Driveshafts for procedure.

(10) Install transmission and engine mount and

bracket assemblies. Refer to Engine Mounts in this

section for procedure.

(11) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(12) Install left and right inner splash shields.

(13) Connect automatic transmission shifter link-

age. Refer to Group 21, Transmission for procedures.

(14) Lower vehicle and connect fuel line and

heater hoses. Remove plugs from rear heater hoses

and install, if equipped.

(15) Install ground straps. Connect engine and

throttle body connections and harnesses.

(16) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(17) Install radiator and fan module assembly.

Install radiator hoses. Fill cooling system. Refer to

Group 7, Cooling for procedures.

(18) Install battery tray, battery and cover.

(19) Install air cleaner and hoses.

(20) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(21) Start engine and run until operating temper-

ature is reached.

(22) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove air inlet resonator when removing left

head cover.

(3) When Removing left cylinder head cover,

remove dipstick tube.

(4) When removing right cylinder head cover

remove wiper unit. Refer to Wiper Unit Removal in

Group 8K.

(5) When removing right cylinder head cover,

remove accessory drive belt. Refer to Accessory Drive

Belt Removal in Group 7.

Fig. 24 Positioning Engine Cradle Support Post

MountsÐTypical

9 - 70 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1144 of 1938

crankshaft seal, provides front oil pan closure, water

pump mounting.

CYLINDER HEADS:Cylinder heads are designed

to create high flow combustion chambers to improve

performance, while minimizing the change to the

burn rate of the chamber. Valve seat and guides are

inserts. A steel flanged composition type gasket is

used between head and block.

CYLINDER HEAD COVERS:The covers are

sealed with steel reinforced silicon rubber gaskets.INTAKE MANIFOLD:The intake manifold is a

tuned two-piece semi-permanent mold aluminum

casting with individual primary runners leading from

a plenum to the cylinders. The manifold is designed

to boost torque in the 3600 rpm range and contrib-

utes to the engine's broad, flat torque curve, which

was desired for excellent engine tractability, response

and usable power output.

The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution.

VALVE TRAIN:Valve train design incorporates

the use of hydraulic roller tappets. Rocker arms are

installed on a rocker arm shaft attached to the cylin-

der head with four bolts and retainers. Viton valve

stem seals provide valve sealing. Conventional type

pushrods, retainers and valve stem locks are used.

Unique beehive style valve spring are used with

lightweight retainers for improved high RPM perfor-

mance.

EXHAUST MANIFOLDS:Exhaust manifolds are

log type with a crossover and is attached directly to

the cylinder heads.

DIAGNOSIS AND TESTING

HYDRAULIC TAPPETS

The valve train includes roller tappet assemblies,

aligning yokes and yoke retainer.

Roller tappet alignment is maintained by machined

flats on tappet body being fitted in pairs into six

Fig. 2 Engine Oiling System

Fig. 1 Engine Identification

9 - 94 3.3/3.8L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1155 of 1938

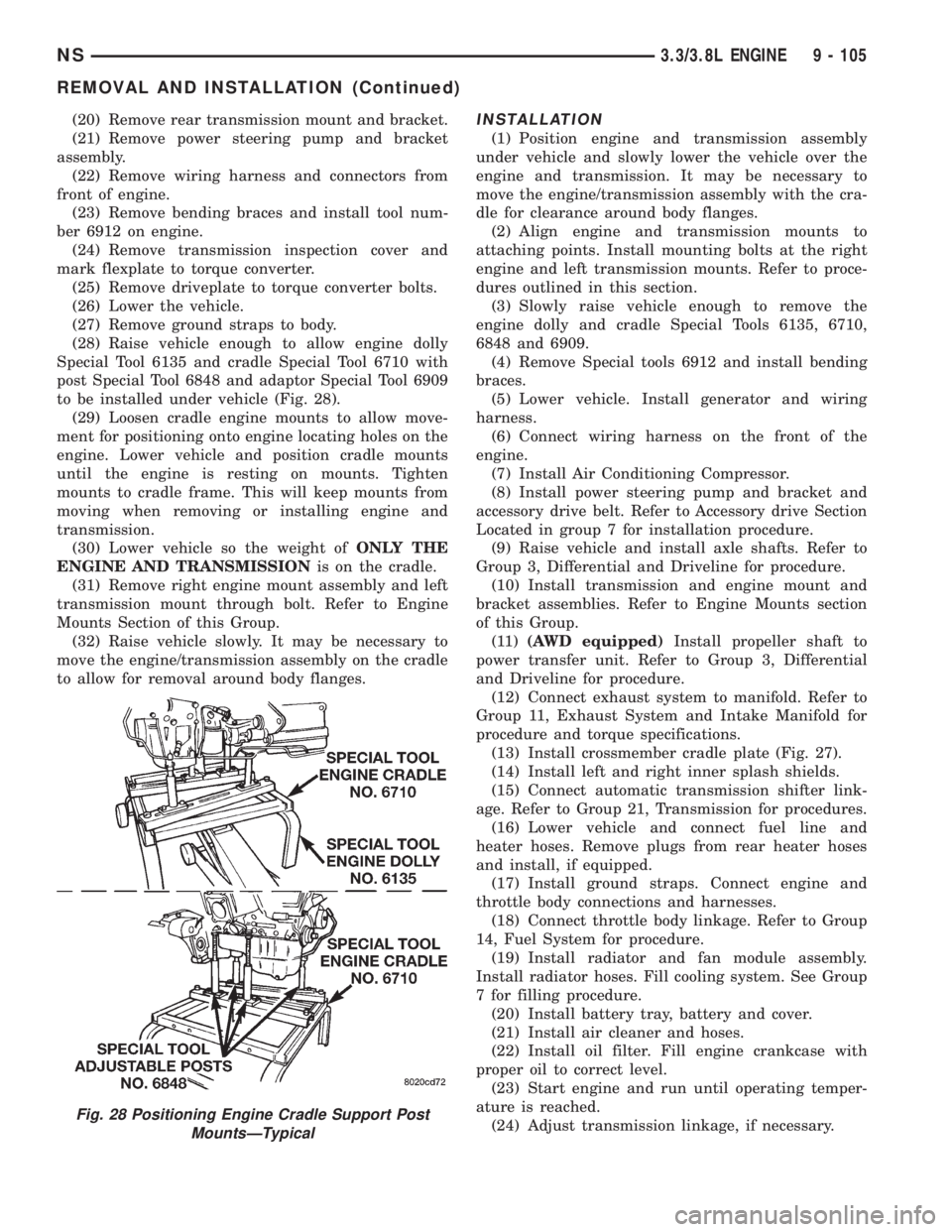

(20) Remove rear transmission mount and bracket.

(21) Remove power steering pump and bracket

assembly.

(22) Remove wiring harness and connectors from

front of engine.

(23) Remove bending braces and install tool num-

ber 6912 on engine.

(24) Remove transmission inspection cover and

mark flexplate to torque converter.

(25) Remove driveplate to torque converter bolts.

(26) Lower the vehicle.

(27) Remove ground straps to body.

(28) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 28).

(29) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(30) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(31) Remove right engine mount assembly and left

transmission mount through bolt. Refer to Engine

Mounts Section of this Group.

(32) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around body flanges.INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909.

(4) Remove Special tools 6912 and install bending

braces.

(5) Lower vehicle. Install generator and wiring

harness.

(6) Connect wiring harness on the front of the

engine.

(7) Install Air Conditioning Compressor.

(8) Install power steering pump and bracket and

accessory drive belt. Refer to Accessory drive Section

Located in group 7 for installation procedure.

(9) Raise vehicle and install axle shafts. Refer to

Group 3, Differential and Driveline for procedure.

(10) Install transmission and engine mount and

bracket assemblies. Refer to Engine Mounts section

of this Group.

(11)(AWD equipped)Install propeller shaft to

power transfer unit. Refer to Group 3, Differential

and Driveline for procedure.

(12) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(13) Install crossmember cradle plate (Fig. 27).

(14) Install left and right inner splash shields.

(15) Connect automatic transmission shifter link-

age. Refer to Group 21, Transmission for procedures.

(16) Lower vehicle and connect fuel line and

heater hoses. Remove plugs from rear heater hoses

and install, if equipped.

(17) Install ground straps. Connect engine and

throttle body connections and harnesses.

(18) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(19) Install radiator and fan module assembly.

Install radiator hoses. Fill cooling system. See Group

7 for filling procedure.

(20) Install battery tray, battery and cover.

(21) Install air cleaner and hoses.

(22) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(23) Start engine and run until operating temper-

ature is reached.

(24) Adjust transmission linkage, if necessary.

Fig. 28 Positioning Engine Cradle Support Post

MountsÐTypical

NS3.3/3.8L ENGINE 9 - 105

REMOVAL AND INSTALLATION (Continued)

Page 1167 of 1938

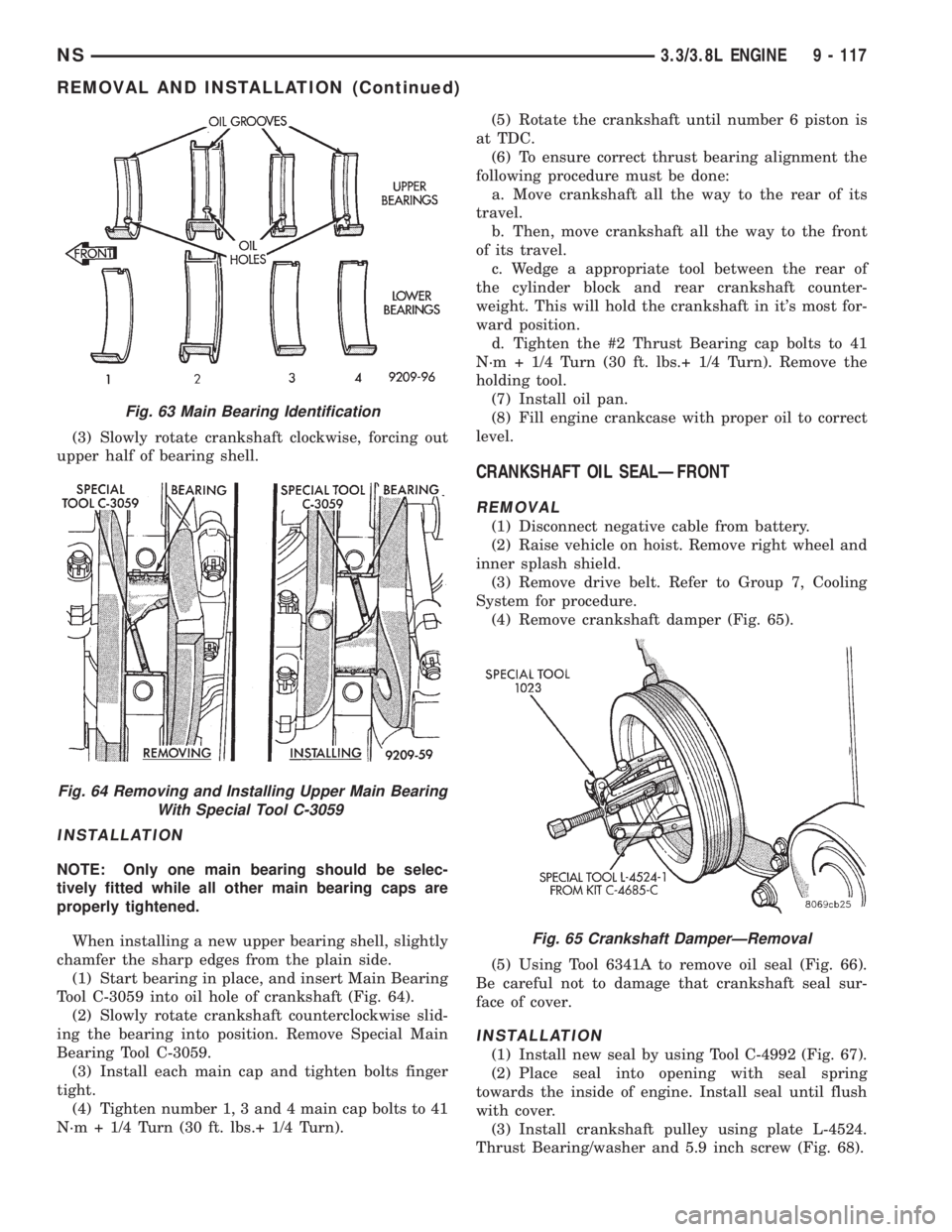

(3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

NOTE: Only one main bearing should be selec-

tively fitted while all other main bearing caps are

properly tightened.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 64).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

(3) Install each main cap and tighten bolts finger

tight.

(4) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).(5) Rotate the crankshaft until number 6 piston is

at TDC.

(6) To ensure correct thrust bearing alignment the

following procedure must be done:

a. Move crankshaft all the way to the rear of its

travel.

b. Then, move crankshaft all the way to the front

of its travel.

c. Wedge a appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.

d. Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(7) Install oil pan.

(8) Fill engine crankcase with proper oil to correct

level.

CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.

(3) Remove drive belt. Refer to Group 7, Cooling

System for procedure.

(4) Remove crankshaft damper (Fig. 65).

(5) Using Tool 6341A to remove oil seal (Fig. 66).

Be careful not to damage that crankshaft seal sur-

face of cover.

INSTALLATION

(1) Install new seal by using Tool C-4992 (Fig. 67).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

(3) Install crankshaft pulley using plate L-4524.

Thrust Bearing/washer and 5.9 inch screw (Fig. 68).

Fig. 63 Main Bearing Identification

Fig. 64 Removing and Installing Upper Main Bearing

With Special Tool C-3059

Fig. 65 Crankshaft DamperÐRemoval

NS3.3/3.8L ENGINE 9 - 117

REMOVAL AND INSTALLATION (Continued)

Page 1173 of 1938

ADJUSTMENTS

ENGINE MOUNTS

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(2) Loosen the right engine mount insulator verti-

cal fastener and the fore and aft fasteners, and the

front engine mount bracket to front crossmember

screws.

(3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. Refer

to Group 2, Suspension and Driveshafts for drive-

shaft identification and related assembly length mea-

suring.

(4) Tighten engine mounts and fasteners in the

following order:

(a) Right engine mount insulator vertical bolts

to 102 N´m (75 ft. lbs.) and the fore and aft bolts to

150 N´m (110 ft. lbs.).

(b) Front engine mount screws to 54 N´m (40 ft.

lbs.) the clearance between the snubbers and the

engine should be 2 mm (0.078 inch.) each side.

(c) Left engine mount through bolt to 75 N´m (55

ft. lbs.).

(5) Recheck driveshaft length.

SPECIFICATIONS

3.3/3.8L ENGINE

Type.........................60É V-6 Engine

Bore±3.3L..................93.0 mm (3.66 in.)

Bore±3.8L.................96.0 mm (3.779 in.)

Stroke±3.3L...............81.0 mm (3.188 in.)

Stroke±3.8L...............87.0 mm (3.425 in.)

Compression Ratio±3.3L.................8.9:1

Compression Ratio±3.8L.................9.6:1

Displacement±3.3L..........3.3L (201 Cubic in.)

Displacement±3.8L..........3.8L (231 Cubic in.)

Brake Horsepower±3.3L........158 @ 4850 RPM

Brake Horsepower±3.8L........180 @ 4400 RPM

Torque±3.3L............203 lb. ft. @ 3600 RPM

Torque±3.8L............240 lb. ft. @ 3600 RPM

Firing Order....................1±2±3±4±5±6

Compression Pressure.Refer to Engine Performance

in Standard Service Procedures.

Cylinder Number (Front to Rear)

Front Bank...........................2,4,6

Rear Bank............................1,3,6

Cylinder Block

Cylinder Bore (Standard)±3.3L.........93.0 mm

(3.66 in.)

Cylinder Bore (Standard)±3.8L.........96.0 mm

(3.779 in.)

Out-of-Round (Max.)........0.076 mm (0.003 in.)

Taper (Max.)..............0.051 mm (0.002 in.)

Cylinder Bore Oversize (Max.).........0.508 mm

(0.020 in.)

Tappet Bore Diameter.....22.9896 - 23.0099 mm

(0.9051 - 0.9059 in.)

Pistons

Type Material.......Aluminum Alloy Tin Coated

Clearance at Size Location......0.025 - 0.057 mm

(0.001 - 0.0022 in.)

Weight (Standard Only)±3.3L......38165 grams

(13.439460.1764 oz.)

Weight (Standard Only)±3.8L......43865 grams

(15.450160.1764 oz.)

Pistons for Service..............Standard Only

Piston Pins

Type .......................Press Fit in Rod

(Serviced as an Assembly)

Diameter.........................22.88 mm

(0.9009 - 0.9007 in.)

Length±3.3L................67.25 - 67.75 mm

(2.648 - 2.667 in.)

Lenth±3.8L.................71.25 - 71.75 mm

(2.805 - 2.824 in.)

Clearance in Piston @ 70É......0.006 - 0.019 mm

(0.0002 - 0.0007 in.)

Clearance in Rod................(Interference)

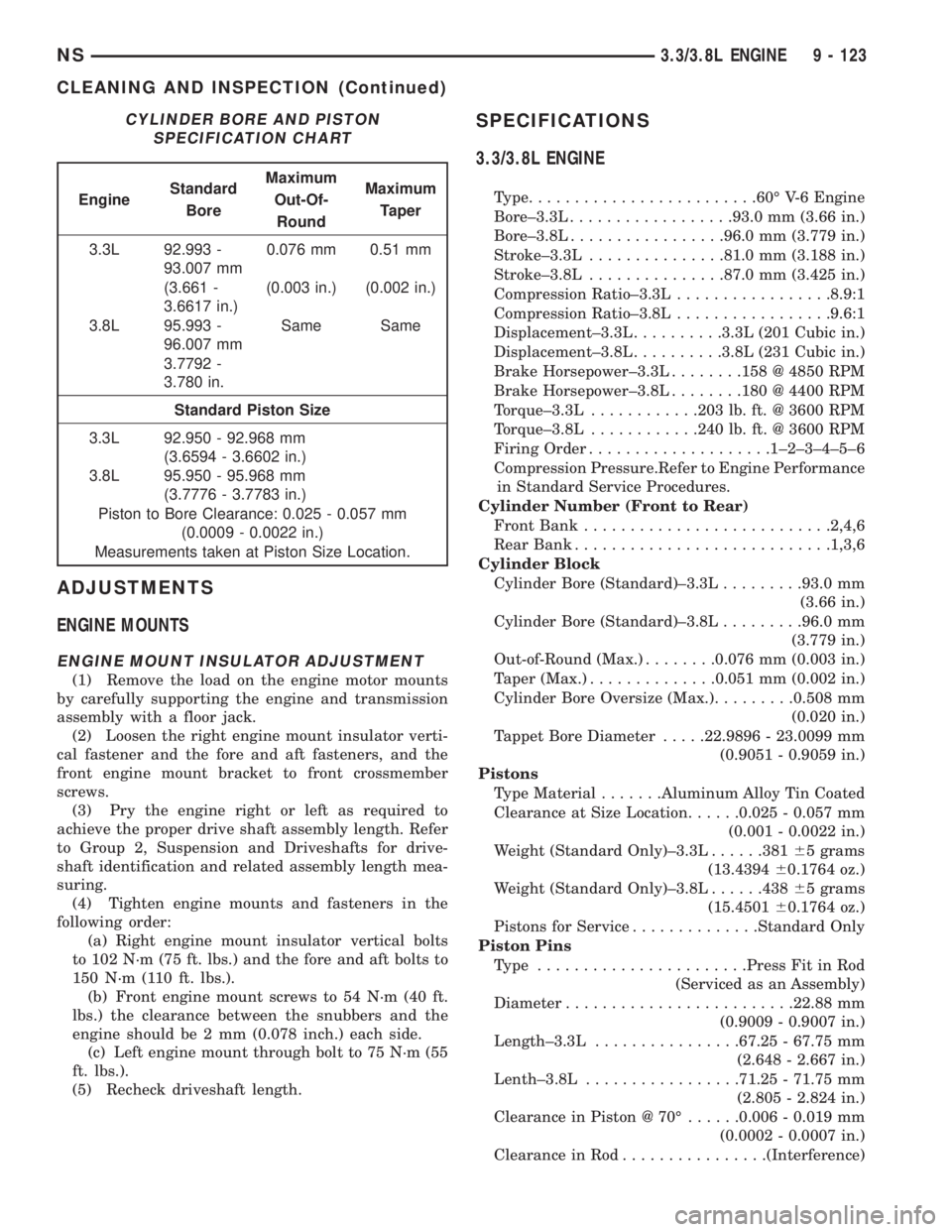

CYLINDER BORE AND PISTON

SPECIFICATION CHART

EngineStandard

BoreMaximum

Out-Of-

RoundMaximum

Taper

3.3L 92.993 -

93.007 mm0.076 mm 0.51 mm

(3.661 -

3.6617 in.)(0.003 in.) (0.002 in.)

3.8L 95.993 -

96.007 mmSame Same

3.7792 -

3.780 in.

Standard Piston Size

3.3L 92.950 - 92.968 mm

(3.6594 - 3.6602 in.)

3.8L 95.950 - 95.968 mm

(3.7776 - 3.7783 in.)

Piston to Bore Clearance: 0.025 - 0.057 mm

(0.0009 - 0.0022 in.)

Measurements taken at Piston Size Location.

NS3.3/3.8L ENGINE 9 - 123

CLEANING AND INSPECTION (Continued)

Page 1181 of 1938

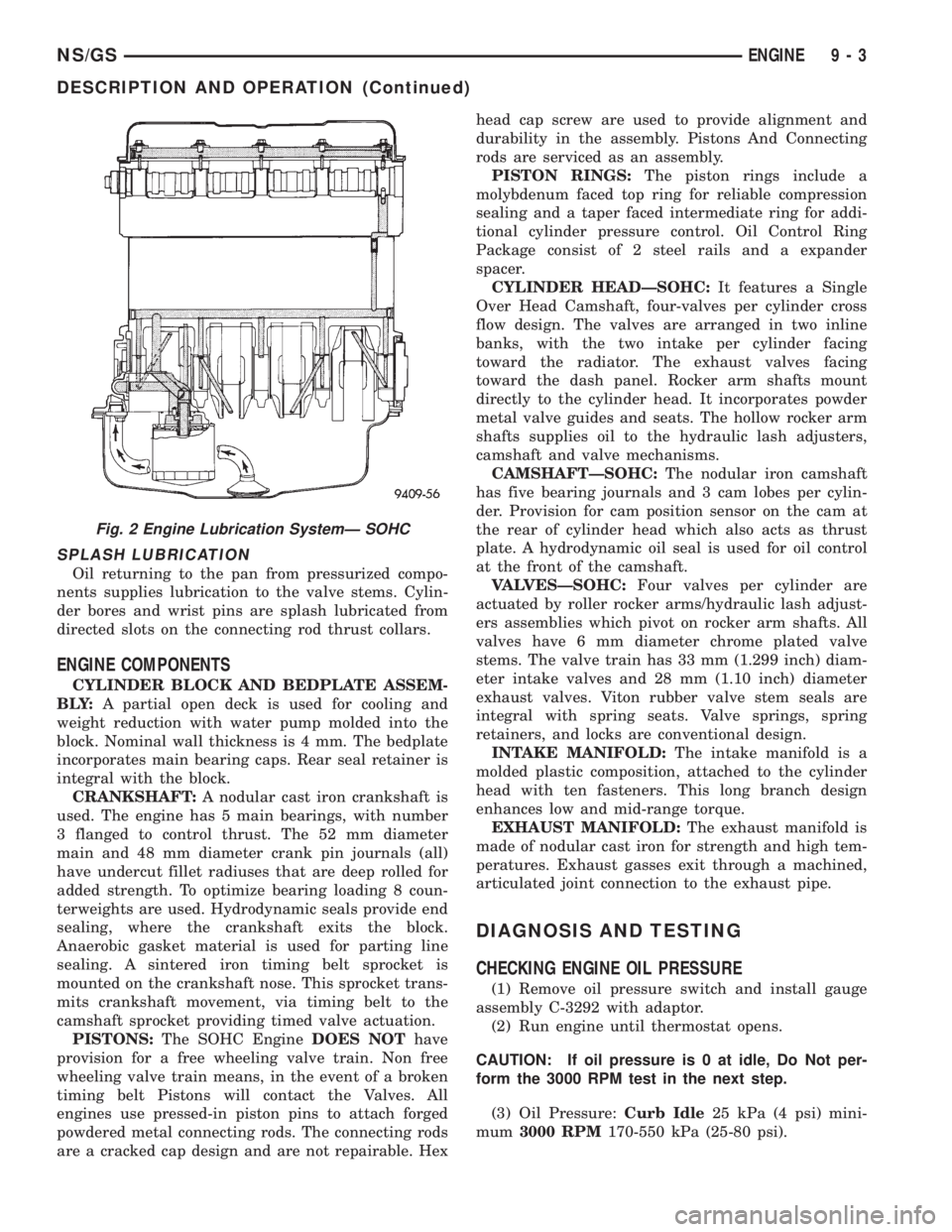

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A partial open deck is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4 mm. The bedplate

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket trans-

mits crankshaft movement, via timing belt to the

camshaft sprocket providing timed valve actuation.

PISTONS:The SOHC EngineDOES NOThave

provision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hexhead cap screw are used to provide alignment and

durability in the assembly. Pistons And Connecting

rods are serviced as an assembly.

PISTON RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package consist of 2 steel rails and a expander

spacer.

CYLINDER HEADÐSOHC:It features a Single

Over Head Camshaft, four-valves per cylinder cross

flow design. The valves are arranged in two inline

banks, with the two intake per cylinder facing

toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFTÐSOHC:The nodular iron camshaft

has five bearing journals and 3 cam lobes per cylin-

der. Provision for cam position sensor on the cam at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVESÐSOHC:Four valves per cylinder are

actuated by roller rocker arms/hydraulic lash adjust-

ers assemblies which pivot on rocker arm shafts. All

valves have 6 mm diameter chrome plated valve

stems. The valve train has 33 mm (1.299 inch) diam-

eter intake valves and 28 mm (1.10 inch) diameter

exhaust valves. Viton rubber valve stem seals are

integral with spring seats. Valve springs, spring

retainers, and locks are conventional design.

INTAKE MANIFOLD:The intake manifold is a

molded plastic composition, attached to the cylinder

head with ten fasteners. This long branch design

enhances low and mid-range torque.

EXHAUST MANIFOLD:The exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

Fig. 2 Engine Lubrication SystemÐ SOHC

NS/GSENGINE 9 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1203 of 1938

filter on until gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

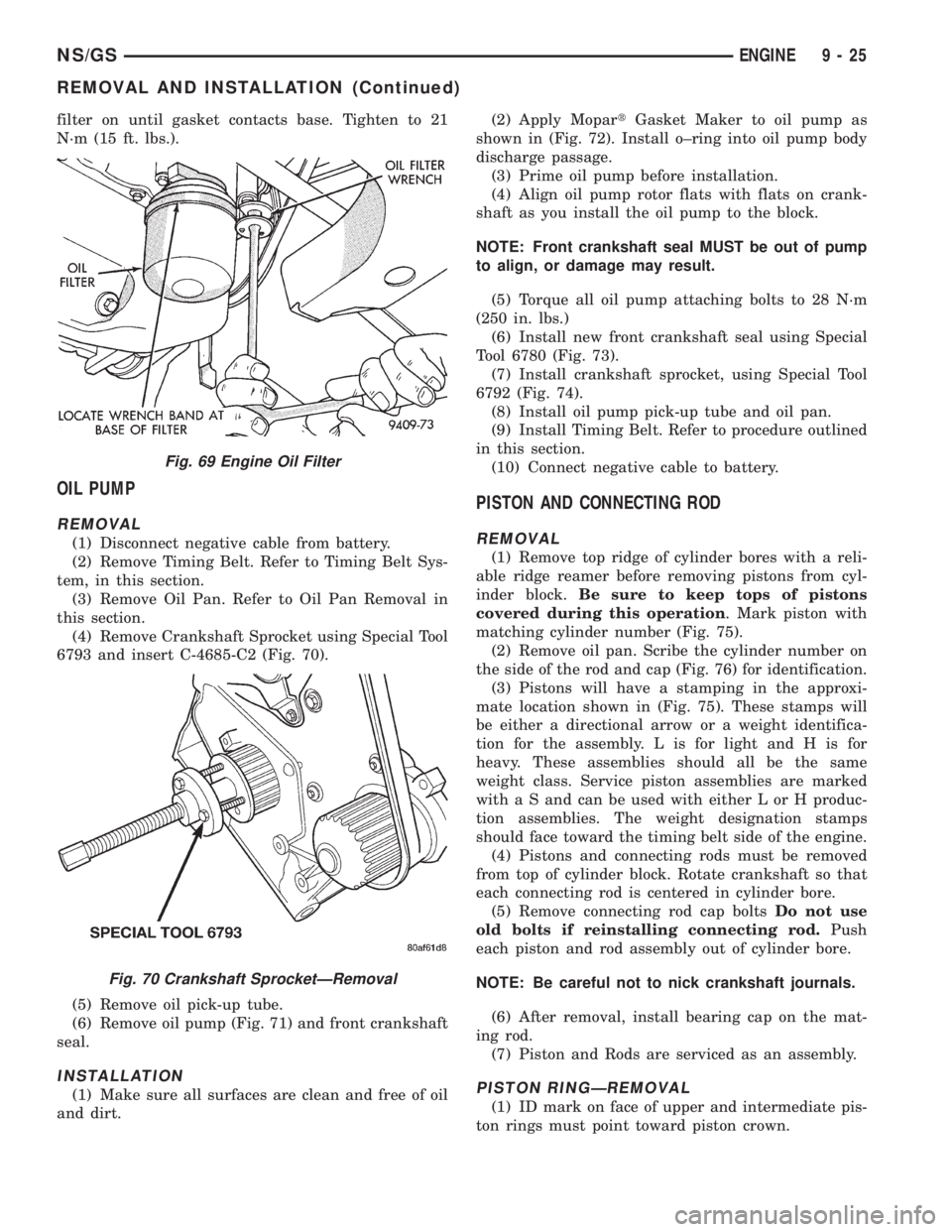

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove Timing Belt. Refer to Timing Belt Sys-

tem, in this section.

(3) Remove Oil Pan. Refer to Oil Pan Removal in

this section.

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 70).

(5) Remove oil pick-up tube.

(6) Remove oil pump (Fig. 71) and front crankshaft

seal.

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 72). Install o±ring into oil pump body

discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 73).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 74).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

(10) Connect negative cable to battery.

PISTON AND CONNECTING ROD

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 75).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 76) for identification.

(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 75). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

(6) After removal, install bearing cap on the mat-

ing rod.

(7) Piston and Rods are serviced as an assembly.

PISTON RINGÐREMOVAL

(1) ID mark on face of upper and intermediate pis-

ton rings must point toward piston crown.

Fig. 69 Engine Oil Filter

Fig. 70 Crankshaft SprocketÐRemoval

NS/GSENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1206 of 1938

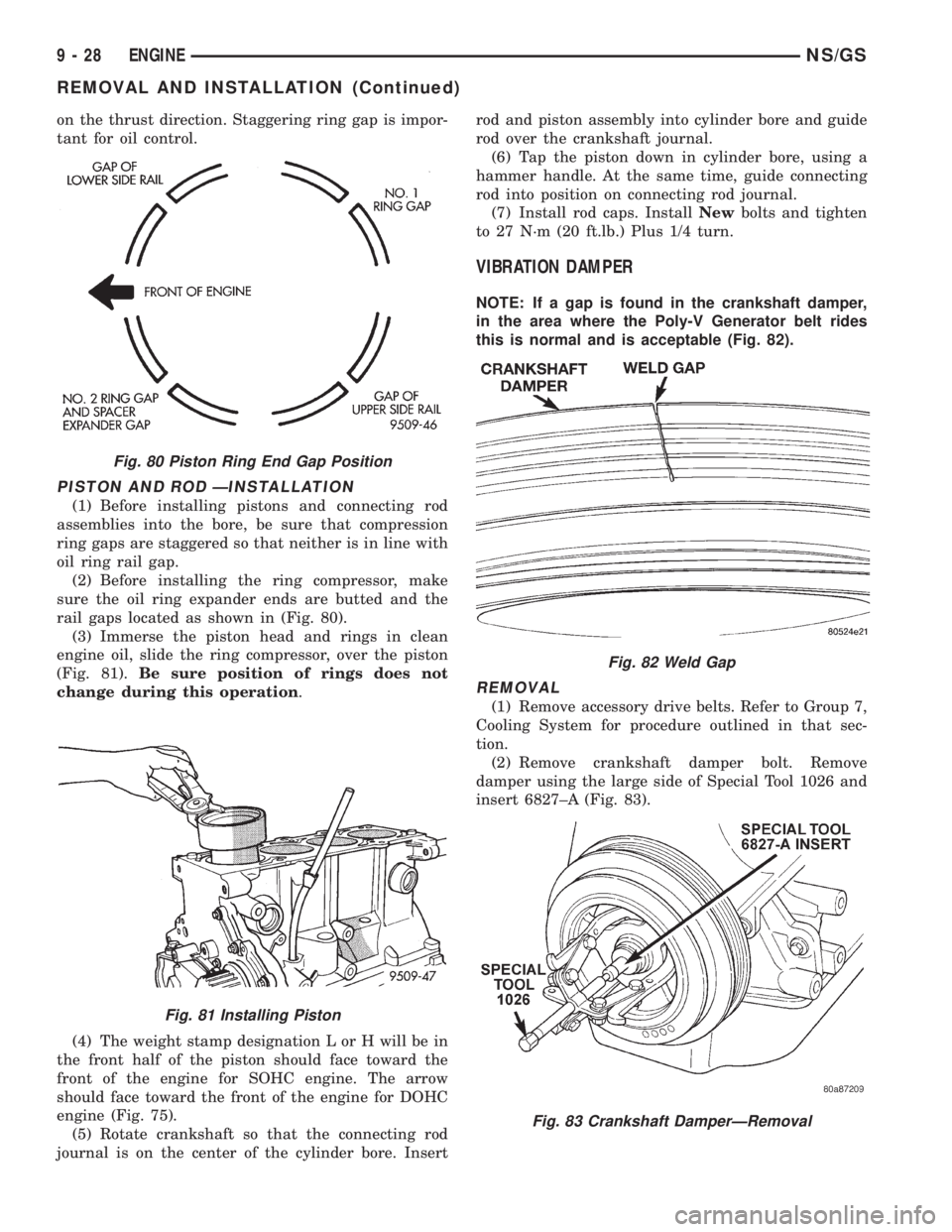

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND ROD ÐINSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 80).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 81).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine for SOHC engine. The arrow

should face toward the front of the engine for DOHC

engine (Fig. 75).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insertrod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(7) Install rod caps. InstallNewbolts and tighten

to 27 N´m (20 ft.lb.) Plus 1/4 turn.

VIBRATION DAMPER

NOTE: If a gap is found in the crankshaft damper,

in the area where the Poly-V Generator belt rides

this is normal and is acceptable (Fig. 82).

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827±A (Fig. 83).

Fig. 80 Piston Ring End Gap Position

Fig. 81 Installing Piston

Fig. 82 Weld Gap

Fig. 83 Crankshaft DamperÐRemoval

9 - 28 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1212 of 1938

CYLINDER BLOCK AND BORE

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, Refer to Engine

Core Plugs outlined in this section.

(3) Examine block and cylinder bores for cracks or

fractures.

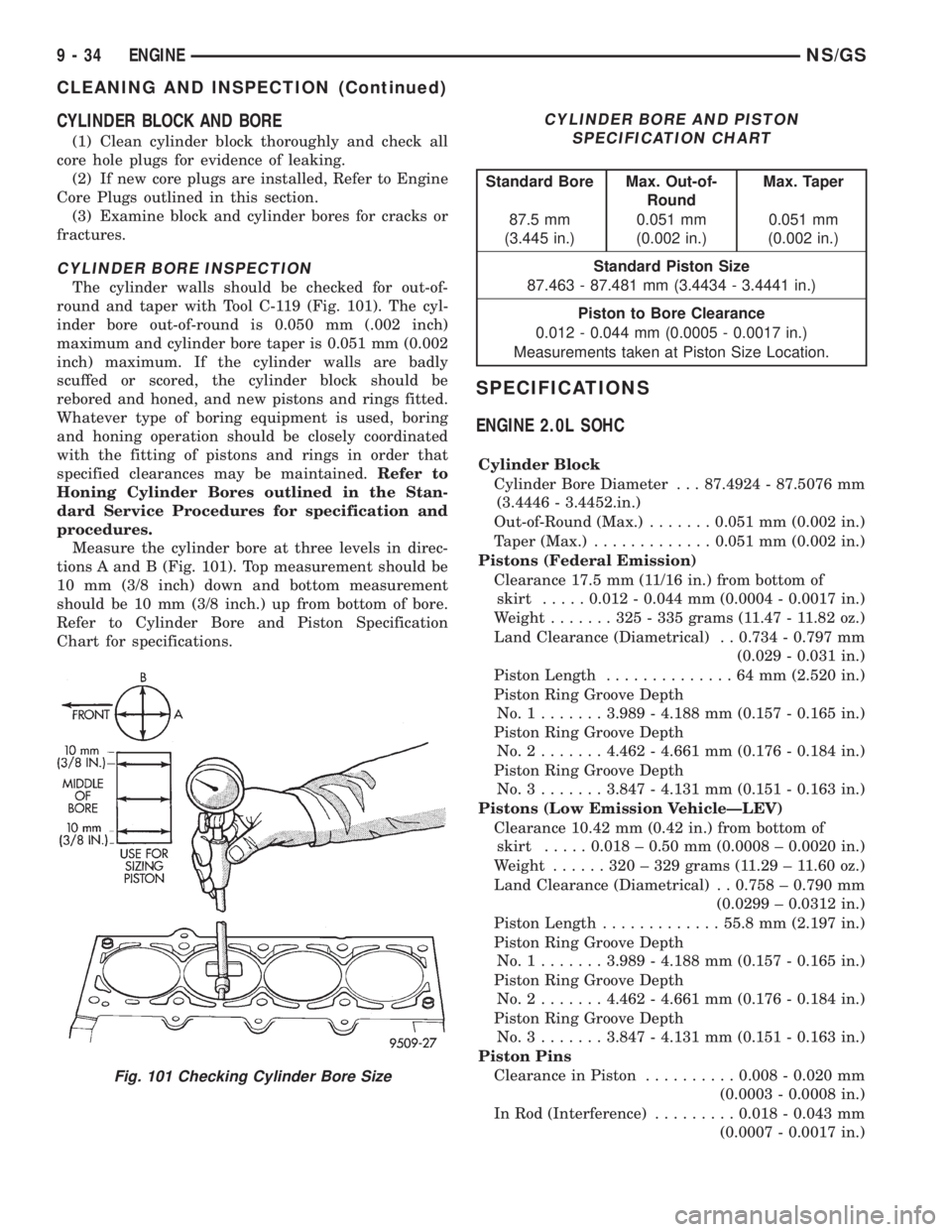

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 101). The cyl-

inder bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

with the fitting of pistons and rings in order that

specified clearances may be maintained.Refer to

Honing Cylinder Bores outlined in the Stan-

dard Service Procedures for specification and

procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 101). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Cylinder Bore and Piston Specification

Chart for specifications.

SPECIFICATIONS

ENGINE 2.0L SOHC

Cylinder Block

Cylinder Bore Diameter . . . 87.4924 - 87.5076 mm

(3.4446 - 3.4452.in.)

Out-of-Round (Max.).......0.051 mm (0.002 in.)

Taper (Max.).............0.051 mm (0.002 in.)

Pistons (Federal Emission)

Clearance 17.5 mm (11/16 in.) from bottom of

skirt.....0.012 - 0.044 mm (0.0004 - 0.0017 in.)

Weight.......325-335grams (11.47 - 11.82 oz.)

Land Clearance (Diametrical) . . 0.734 - 0.797 mm

(0.029 - 0.031 in.)

Piston Length..............64mm(2.520 in.)

Piston Ring Groove Depth

No.1.......3.989 - 4.188 mm (0.157 - 0.165 in.)

Piston Ring Groove Depth

No.2.......4.462 - 4.661 mm (0.176 - 0.184 in.)

Piston Ring Groove Depth

No.3.......3.847 - 4.131 mm (0.151 - 0.163 in.)

Pistons (Low Emission VehicleÐLEV)

Clearance 10.42 mm (0.42 in.) from bottom of

skirt.....0.018 ± 0.50 mm (0.0008 ± 0.0020 in.)

Weight......320±329grams (11.29 ± 11.60 oz.)

Land Clearance (Diametrical) . . 0.758 ± 0.790 mm

(0.0299 ± 0.0312 in.)

Piston Length.............55.8 mm (2.197 in.)

Piston Ring Groove Depth

No.1.......3.989 - 4.188 mm (0.157 - 0.165 in.)

Piston Ring Groove Depth

No.2.......4.462 - 4.661 mm (0.176 - 0.184 in.)

Piston Ring Groove Depth

No.3.......3.847 - 4.131 mm (0.151 - 0.163 in.)

Piston Pins

Clearance in Piston..........0.008 - 0.020 mm

(0.0003 - 0.0008 in.)

In Rod (Interference).........0.018 - 0.043 mm

(0.0007 - 0.0017 in.)

Fig. 101 Checking Cylinder Bore Size

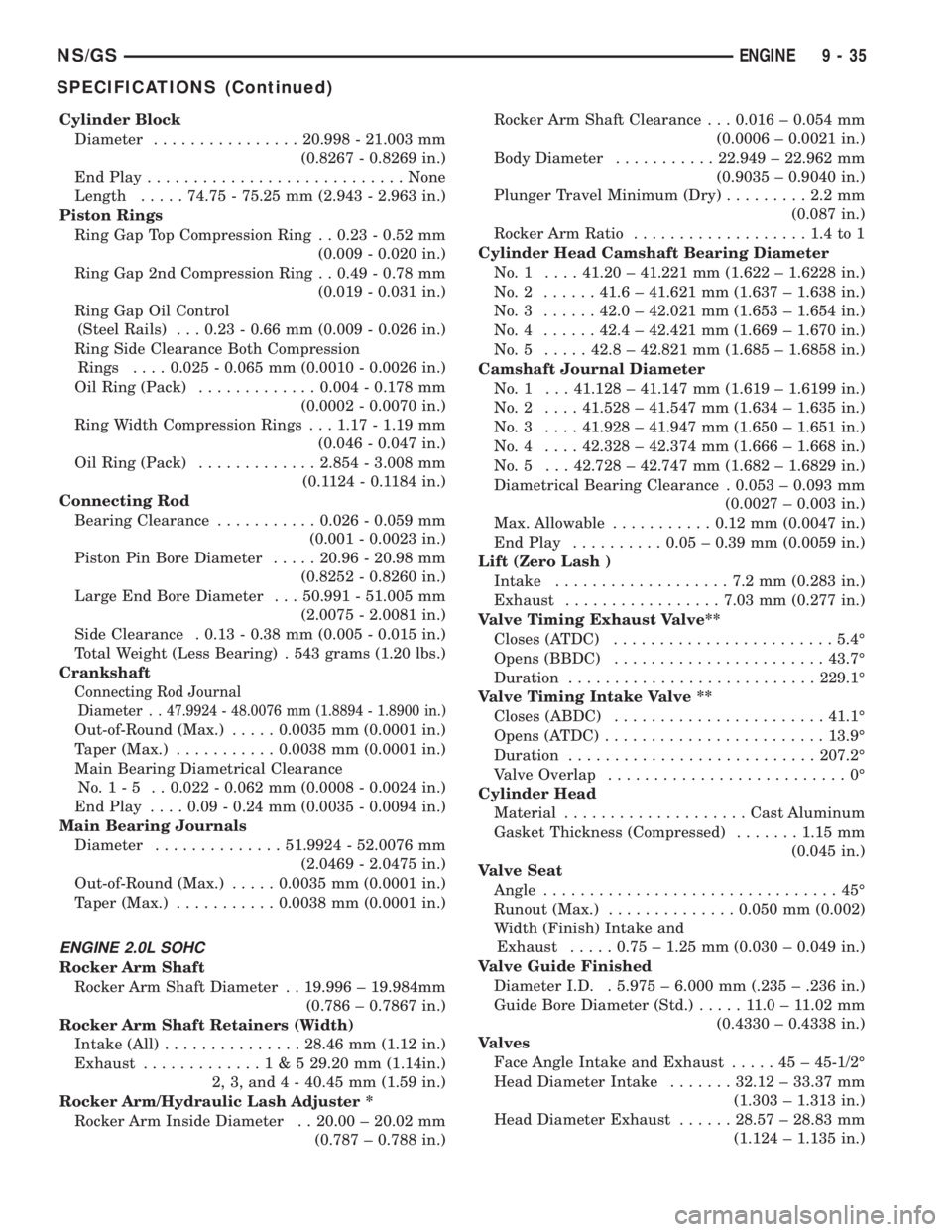

CYLINDER BORE AND PISTON

SPECIFICATION CHART

Standard Bore Max. Out-of-

RoundMax. Taper

87.5 mm

(3.445 in.)0.051 mm

(0.002 in.)0.051 mm

(0.002 in.)

Standard Piston Size

87.463 - 87.481 mm (3.4434 - 3.4441 in.)

Piston to Bore Clearance

0.012 - 0.044 mm (0.0005 - 0.0017 in.)

Measurements taken at Piston Size Location.

9 - 34 ENGINENS/GS

CLEANING AND INSPECTION (Continued)

Page 1213 of 1938

Cylinder Block

Diameter................20.998 - 21.003 mm

(0.8267 - 0.8269 in.)

End Play............................None

Length.....74.75 - 75.25 mm (2.943 - 2.963 in.)

Piston Rings

Ring Gap Top Compression Ring . . 0.23 - 0.52 mm

(0.009 - 0.020 in.)

Ring Gap 2nd Compression Ring . . 0.49 - 0.78 mm

(0.019 - 0.031 in.)

Ring Gap Oil Control

(Steel Rails) . . . 0.23 - 0.66 mm (0.009 - 0.026 in.)

Ring Side Clearance Both Compression

Rings....0.025 - 0.065 mm (0.0010 - 0.0026 in.)

Oil Ring (Pack).............0.004 - 0.178 mm

(0.0002 - 0.0070 in.)

Ring Width Compression Rings . . . 1.17 - 1.19 mm

(0.046 - 0.047 in.)

Oil Ring (Pack).............2.854 - 3.008 mm

(0.1124 - 0.1184 in.)

Connecting Rod

Bearing Clearance...........0.026 - 0.059 mm

(0.001 - 0.0023 in.)

Piston Pin Bore Diameter.....20.96 - 20.98 mm

(0.8252 - 0.8260 in.)

Large End Bore Diameter . . . 50.991 - 51.005 mm

(2.0075 - 2.0081 in.)

Side Clearance . 0.13 - 0.38 mm (0.005 - 0.015 in.)

Total Weight (Less Bearing) . 543 grams (1.20 lbs.)

Crankshaft

Connecting Rod Journal

Diameter . .

47.9924 - 48.0076 mm (1.8894 - 1.8900 in.)

Out-of-Round (Max.).....0.0035 mm (0.0001 in.)

Taper (Max.)...........0.0038 mm (0.0001 in.)

Main Bearing Diametrical Clearance

No.1-5 ..0.022 - 0.062 mm (0.0008 - 0.0024 in.)

End Play....0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Main Bearing Journals

Diameter..............51.9924 - 52.0076 mm

(2.0469 - 2.0475 in.)

Out-of-Round (Max.).....0.0035 mm (0.0001 in.)

Taper (Max.)...........0.0038 mm (0.0001 in.)

ENGINE 2.0L SOHC

Rocker Arm Shaft

Rocker Arm Shaft Diameter . . 19.996 ± 19.984mm

(0.786 ± 0.7867 in.)

Rocker Arm Shaft Retainers (Width)

Intake (All)...............28.46 mm (1.12 in.)

Exhaust.............1&529.20 mm (1.14in.)

2, 3, and 4 - 40.45 mm (1.59 in.)

Rocker Arm/Hydraulic Lash Adjuster *

Rocker Arm Inside Diameter . . 20.00 ± 20.02 mm

(0.787 ± 0.788 in.)Rocker Arm Shaft Clearance . . . 0.016 ± 0.054 mm

(0.0006 ± 0.0021 in.)

Body Diameter...........22.949 ± 22.962 mm

(0.9035 ± 0.9040 in.)

Plunger Travel Minimum (Dry).........2.2mm

(0.087 in.)

Rocker Arm Ratio...................1.4to1

Cylinder Head Camshaft Bearing Diameter

No.1 ....41.20 ± 41.221 mm (1.622 ± 1.6228 in.)

No.2 ......41.6 ± 41.621 mm (1.637 ± 1.638 in.)

No.3 ......42.0 ± 42.021 mm (1.653 ± 1.654 in.)

No.4 ......42.4 ± 42.421 mm (1.669 ± 1.670 in.)

No.5 .....42.8 ± 42.821 mm (1.685 ± 1.6858 in.)

Camshaft Journal Diameter

No. 1 . . . 41.128 ± 41.147 mm (1.619 ± 1.6199 in.)

No.2 ....41.528 ± 41.547 mm (1.634 ± 1.635 in.)

No.3 ....41.928 ± 41.947 mm (1.650 ± 1.651 in.)

No.4 ....42.328 ± 42.374 mm (1.666 ± 1.668 in.)

No. 5 . . . 42.728 ± 42.747 mm (1.682 ± 1.6829 in.)

Diametrical Bearing Clearance . 0.053 ± 0.093 mm

(0.0027 ± 0.003 in.)

Max. Allowable...........0.12 mm (0.0047 in.)

End Play..........0.05 ± 0.39 mm (0.0059 in.)

Lift (Zero Lash )

Intake...................7.2mm(0.283 in.)

Exhaust.................7.03 mm (0.277 in.)

Valve Timing Exhaust Valve**

Closes (ATDC)........................5.4É

Opens (BBDC).......................43.7É

Duration...........................229.1É

Valve Timing Intake Valve **

Closes (ABDC).......................41.1É

Opens (ATDC)........................13.9É

Duration...........................207.2É

Valve Overlap..........................0É

Cylinder Head

Material....................Cast Aluminum

Gasket Thickness (Compressed).......1.15 mm

(0.045 in.)

Valve Seat

Angle................................45É

Runout (Max.)..............0.050 mm (0.002)

Width (Finish) Intake and

Exhaust.....0.75 ± 1.25 mm (0.030 ± 0.049 in.)

Valve Guide Finished

Diameter I.D. . 5.975 ± 6.000 mm (.235 ± .236 in.)

Guide Bore Diameter (Std.).....11.0±11.02 mm

(0.4330 ± 0.4338 in.)

Valves

Face Angle Intake and Exhaust.....45±45-1/2É

Head Diameter Intake.......32.12 ± 33.37 mm

(1.303 ± 1.313 in.)

Head Diameter Exhaust......28.57 ± 28.83 mm

(1.124 ± 1.135 in.)

NS/GSENGINE 9 - 35

SPECIFICATIONS (Continued)