CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 571 of 1938

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicle are solid state. When checking

voltages in these circuits use a meter with a 10-me-

gohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: - Most of the electrical components used

in today's vehicle are Solid State. When checking

resistance in these circuits use a meter with a 10-

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle

electrical system can cause damage to the equip-

ment and provide false readings.

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 6). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²Terminals in the wiring assembly are fully

seated into the connector/component and locked in

position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt and moisture²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation covering.

²Wiring broken inside of the insulation

TROUBLESHOOTING TESTS

Before beginning any tests on a vehicles electrical

system use the Wiring Diagrams and study the cir-

cuit. Also refer to the Troubleshooting Wiring Prob-

lems in this section.

TESTING FOR VOLTAGE POTENTIAL

(1) Connect the ground lead of a voltmeter to a

known good ground (Fig. 7).

(2) Connect the other lead of the voltmeter to the

selected test point. The vehicle ignition may need to

be turned ON to check voltage. Refer to the appropri-

ate test procedure.

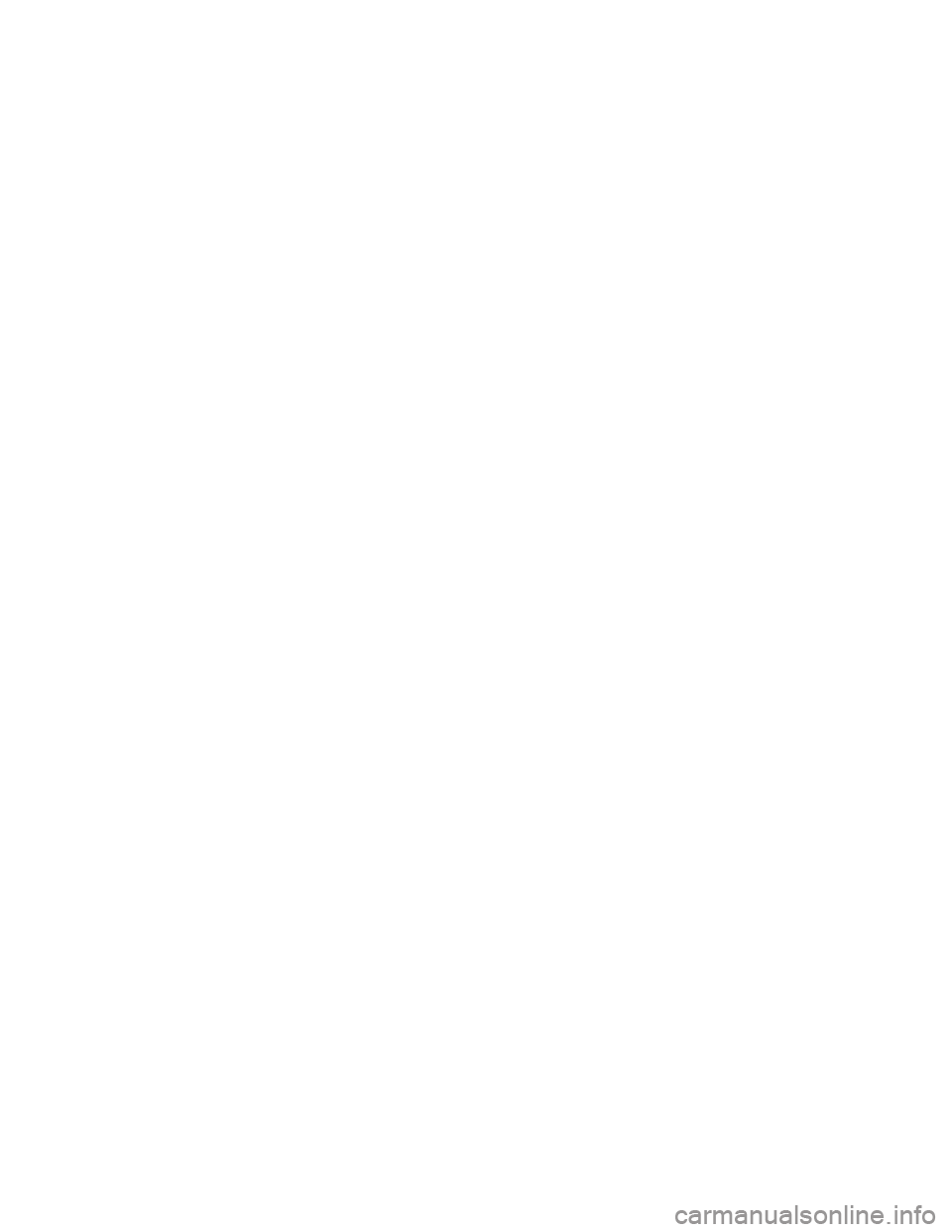

TESTING FOR CONTINUITY

(1) Remove the fuse for the circuit being checked

or, disconnect the battery.

(2) Connect one lead of the ohmmeter to one side

of the circuit being tested (Fig. 8).

(3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

TESTING FOR A SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

Fig. 6 Probing Tool

Fig. 7 Testing for Voltage Potential

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 9

DIAGNOSIS AND TESTING (Continued)

Page 572 of 1938

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting the items in the fuse circuit

one at a time. When the fuse blows the circuit with

the short to ground has been isolated.

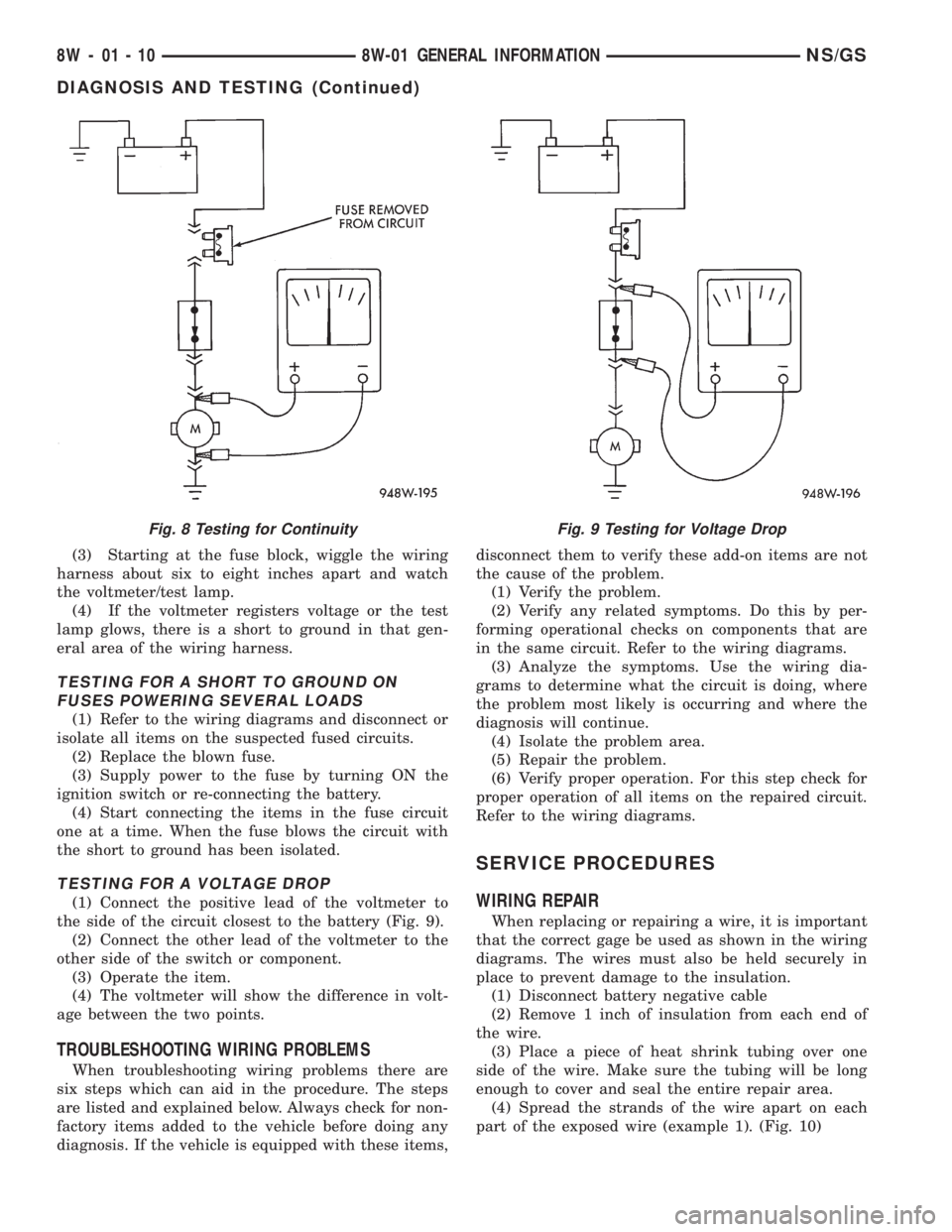

TESTING FOR A VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 9).

(2) Connect the other lead of the voltmeter to the

other side of the switch or component.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the repaired circuit.

Refer to the wiring diagrams.

SERVICE PROCEDURES

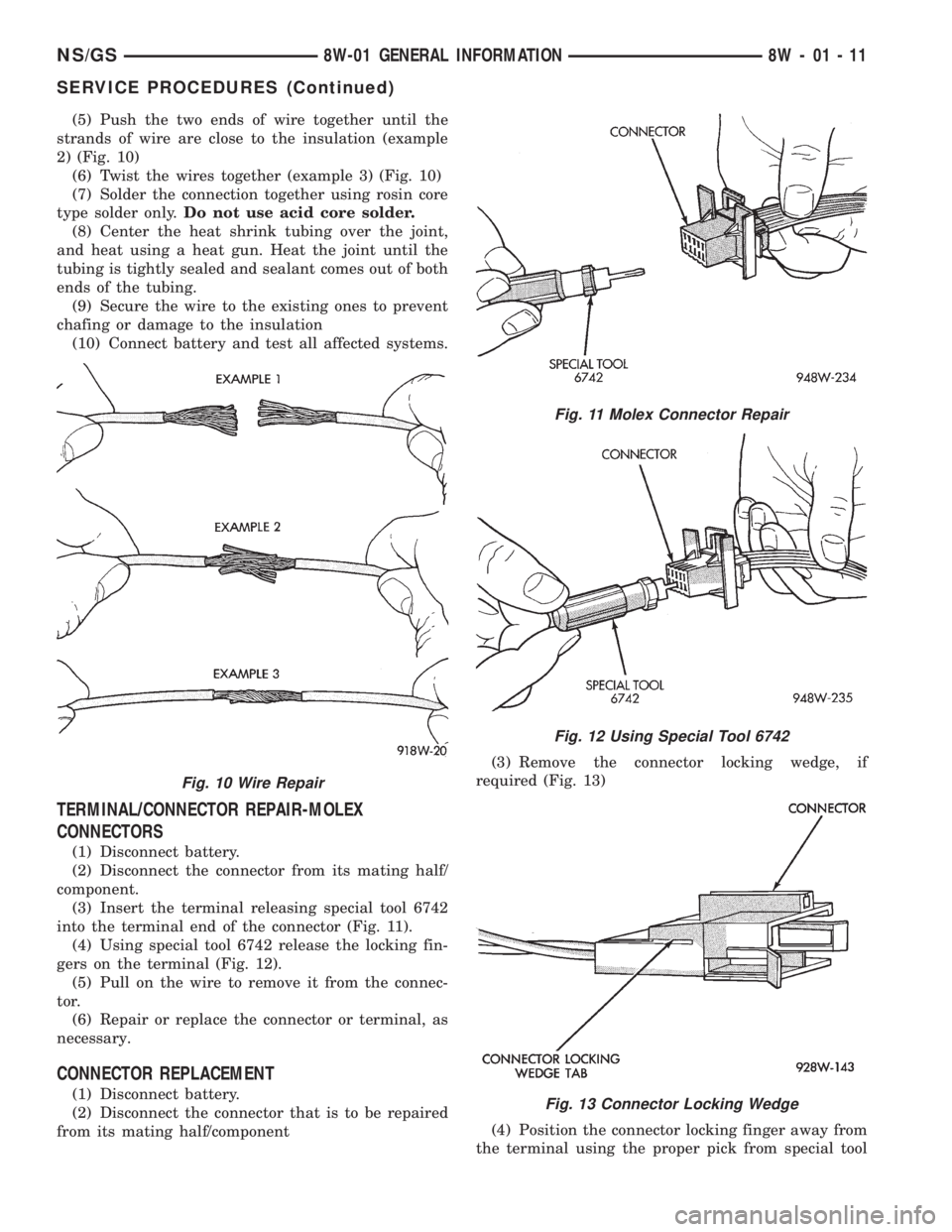

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gage be used as shown in the wiring

diagrams. The wires must also be held securely in

place to prevent damage to the insulation.

(1) Disconnect battery negative cable

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(4) Spread the strands of the wire apart on each

part of the exposed wire (example 1). (Fig. 10)

Fig. 8 Testing for ContinuityFig. 9 Testing for Voltage Drop

8W - 01 - 10 8W-01 GENERAL INFORMATIONNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 573 of 1938

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (example

2) (Fig. 10)

(6) Twist the wires together (example 3) (Fig. 10)

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint,

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation

(10) Connect battery and test all affected systems.

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Insert the terminal releasing special tool 6742

into the terminal end of the connector (Fig. 11).

(4) Using special tool 6742 release the locking fin-

gers on the terminal (Fig. 12).

(5) Pull on the wire to remove it from the connec-

tor.

(6) Repair or replace the connector or terminal, as

necessary.

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component(3) Remove the connector locking wedge, if

required (Fig. 13)

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

Fig. 10 Wire Repair

Fig. 11 Molex Connector Repair

Fig. 12 Using Special Tool 6742

Fig. 13 Connector Locking Wedge

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 11

SERVICE PROCEDURES (Continued)

Page 574 of 1938

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 14) (Fig. 15).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9)

Connect connector to its mating half/component.

(10) Connect battery and test all affected systems.

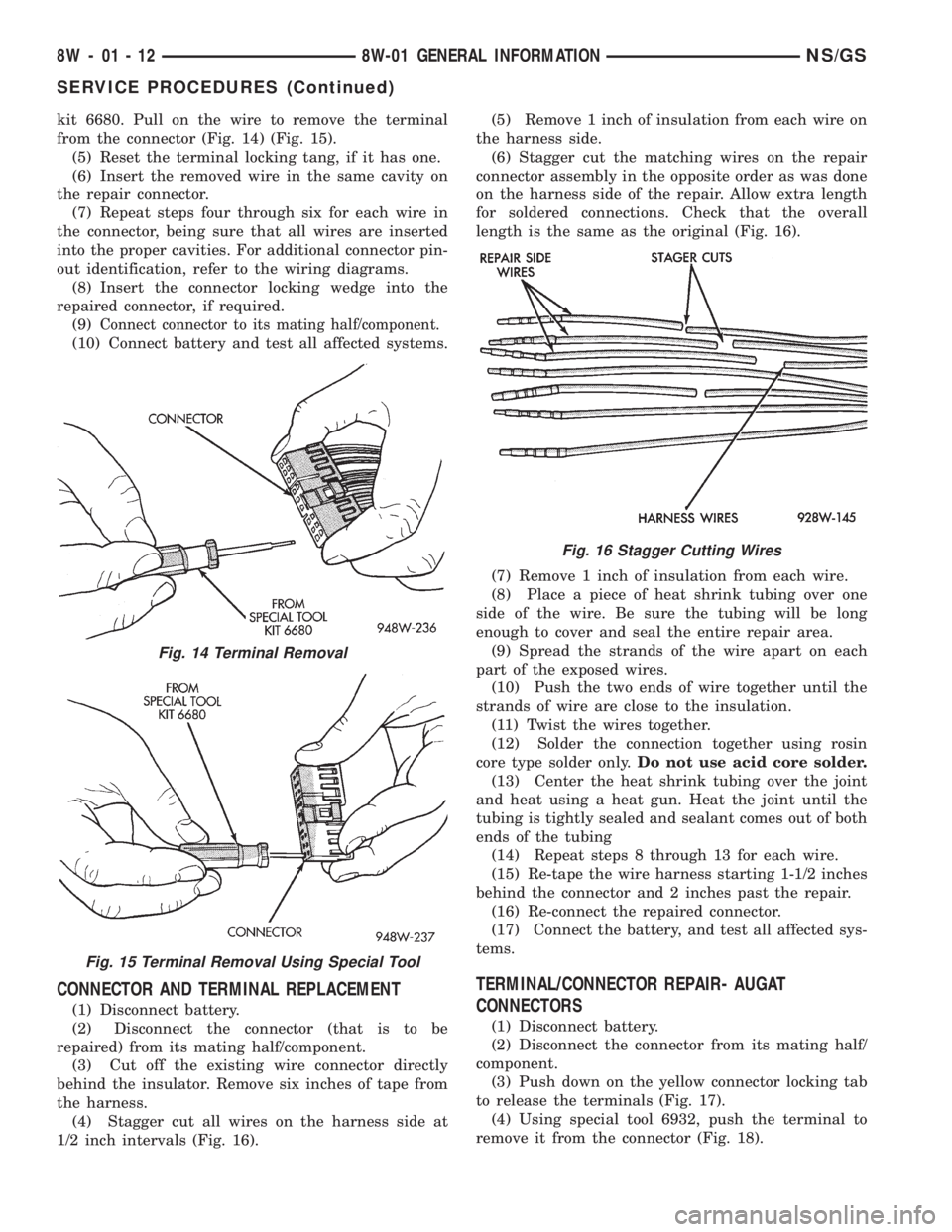

CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

(4) Stagger cut all wires on the harness side at

1/2 inch intervals (Fig. 16).(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 16).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

(17) Connect the battery, and test all affected sys-

tems.

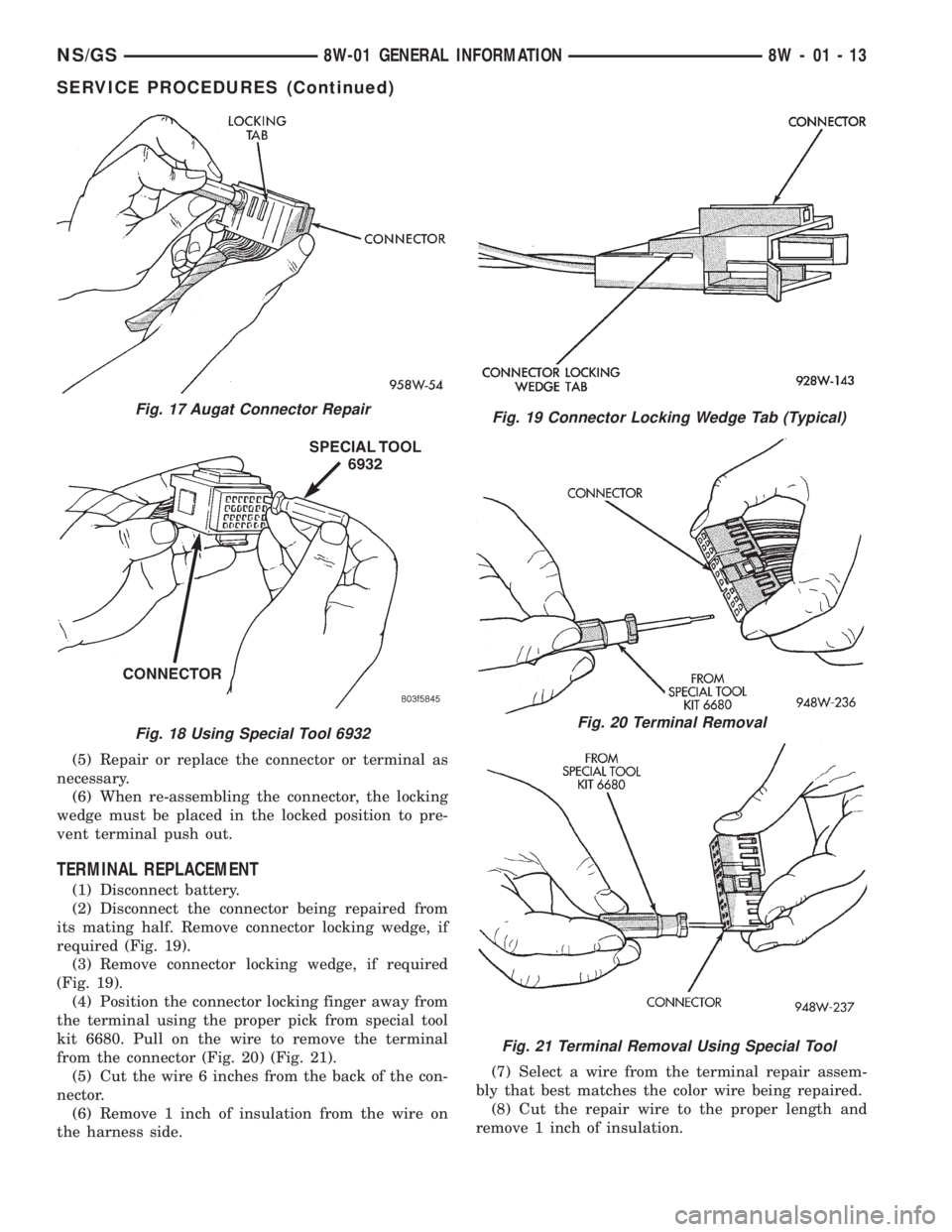

TERMINAL/CONNECTOR REPAIR- AUGAT

CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Push down on the yellow connector locking tab

to release the terminals (Fig. 17).

(4) Using special tool 6932, push the terminal to

remove it from the connector (Fig. 18).

Fig. 14 Terminal Removal

Fig. 15 Terminal Removal Using Special Tool

Fig. 16 Stagger Cutting Wires

8W - 01 - 12 8W-01 GENERAL INFORMATIONNS/GS

SERVICE PROCEDURES (Continued)

Page 575 of 1938

(5) Repair or replace the connector or terminal as

necessary.

(6) When re-assembling the connector, the locking

wedge must be placed in the locked position to pre-

vent terminal push out.

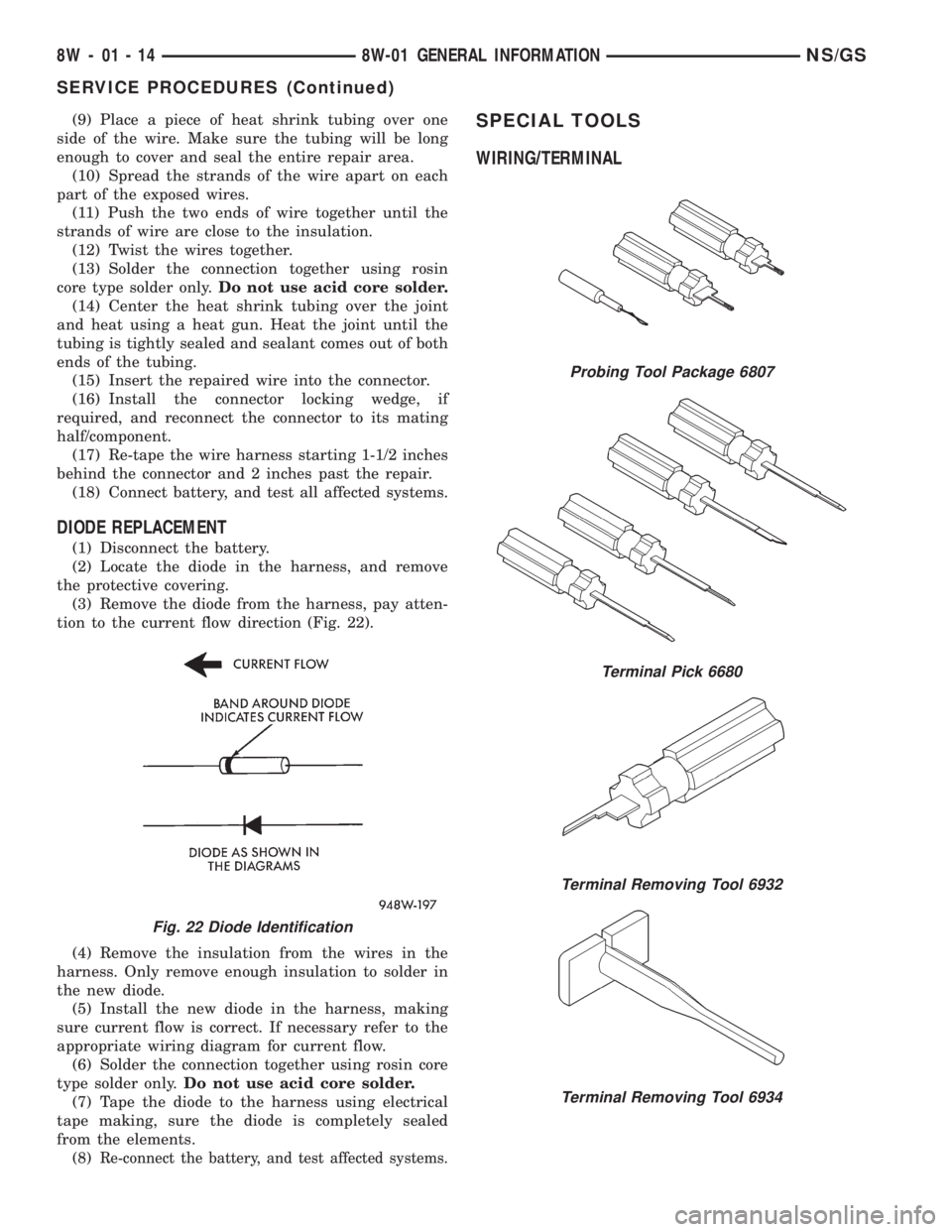

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired from

its mating half. Remove connector locking wedge, if

required (Fig. 19).

(3) Remove connector locking wedge, if required

(Fig. 19).

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 20) (Fig. 21).

(5) Cut the wire 6 inches from the back of the con-

nector.

(6) Remove 1 inch of insulation from the wire on

the harness side.(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

Fig. 17 Augat Connector Repair

Fig. 18 Using Special Tool 6932

Fig. 19 Connector Locking Wedge Tab (Typical)

Fig. 20 Terminal Removal

Fig. 21 Terminal Removal Using Special Tool

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)

Page 576 of 1938

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires.

(11) Push the two ends of wire together until the

strands of wire are close to the insulation.

(12) Twist the wires together.

(13) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge, if

required, and reconnect the connector to its mating

half/component.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(18) Connect battery, and test all affected systems.

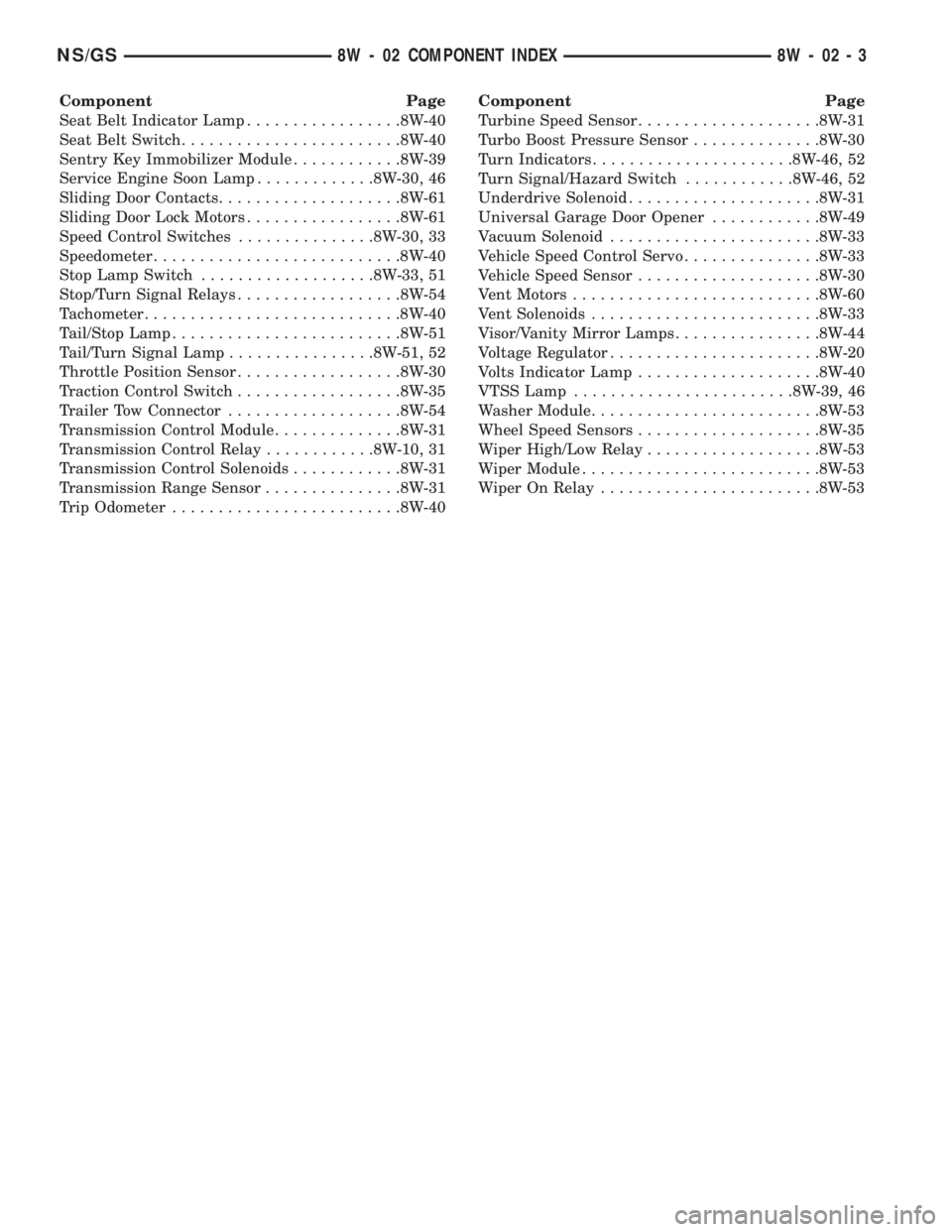

DIODE REPLACEMENT

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 22).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8)

Re-connect the battery, and test affected systems.

SPECIAL TOOLS

WIRING/TERMINAL

Fig. 22 Diode Identification

Probing Tool Package 6807

Terminal Pick 6680

Terminal Removing Tool 6932

Terminal Removing Tool 6934

8W - 01 - 14 8W-01 GENERAL INFORMATIONNS/GS

SERVICE PROCEDURES (Continued)

Page 577 of 1938

8W-02 COMPONENT INDEX

Component Page

2-4 Pressure Switch.....................8W-31

2-4 Solenoid...........................8W-31

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay...........8W-10, 42

A/C Heater Control.....................8W-42

A/C On Indicator.......................8W-42

A/C Pressure Transducer..............8W-30, 42

A/C Switch............................8W-42

A/C Zone Door Actuator..................8W-42

ABS Warning Lamp..................8W-35, 46

Accelerator Pedal Position Sensor..........8W-30

Airbag Control Module...................8W-43

Airbag Indicator Lamp...................8W-43

Airbag Warning Lamp...................8W-46

All Wheel Drive Solenoid.................8W-31

Ambient Air Temperature Sensor...........8W-49

Ash Receiver Lamp.....................8W-44

Automatic Day/Night Mirror..............8W-44

Automatic Shut Down Relay............8W-10, 30

Splice Information......................8W-70

Back-Up Lamp.........................8W-51

Back-Up Switch.....................8W-44, 51

Battery...............................8W-20

Blend Door Actuator.....................8W-42

Body Control Module....................8W-45

Brake Pressure Switch...................8W-46

Brake Warning Lamp....................8W-46

Camshaft Position Sensor................8W-30

Center Dome Lamp.....................8W-44

Center High Mounted Stop Lamp..........8W-51

Cigar/Accessory Relay...................8W-41

Clockspring.......8W-10, 15, 30, 33, 39, 40, 41, 43

Cluster Illumination Lamps...............8W-40

Clutch Interlock Switch...............8W-12, 21

Clutch Interlock Switch Jumper......8W-12, 21, 31

Clutch Switch.......................8W-30, 33

Combination Flasher/DRL Module. . . .8W-50, 51, 52

Combination Relays.....................8W-54

Compass/Mini-Trip Computer..............8W-49

Control Sleeve Sensor....................8W-30

Controller Anti-Lock Brake...............8W-35

Courtesy Lamp Relay...........8W-10, 12, 44, 50

Crank Case Heater......................8W-30

Crankshaft Position Sensor...............8W-30

Cruise Indicator Lamp...................8W-40

Data Link Connector....................8W-30

Diesel Power Relay...................8W-10, 30

Dome Lamp Switch.....................8W-50

Door Ajar Indicator Lamp................8W-40

Door Ajar Switches................8W-39, 40, 44

Door Lock Relay........................8W-61

Speakers..............................8W-47Component Page

Door Unlock Relay......................8W-61

Oxygen Sensors........................8W-30

Door Ajar Switches.............8W-39, 40, 44, 45

Door Arm/Disarm Switches.............8W-39, 61

Door Courtesy Lamps....................8W-44

Door Lock Motors.......................8W-61

Door Lock Switches.....................8W-61

Door Unlock Relays.....................8W-61

Heated Seat Backs......................8W-63

Heated Seat Cushions...................8W-63

Heated Seat Modules....................8W-63

Heated Seat Switches....................8W-63

Power Mirrors.........................8W-62

Power Seat Switches....................8W-63

Power Window Switches..................8W-60

Seat Motors...........................8W-63

Window Motors........................8W-60

Radiator Fans.........................8W-42

Dump Solenoid.........................8W-33

EGR Solenoid..........................8W-30

Electric Wiper De-Icer...................8W-48

Electronic PRNDL Indicator...............8W-40

Engine Coolant Temperature Gauge.........8W-40

Engine Coolant Temperature Lamp.........8W-46

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-46

Engine Speed Sensor....................8W-30

Engine Starter Motor....................8W-21

Engine Starter Motor Relay............8W-10, 21

Evap Leak Detection Pump...............8W-30

Evap/Purge Solenoid....................8W-30

Evaporator Temperature Sensor............8W-42

Express Down Module...................8W-60

Flexible Fuel Sensor.....................8W-30

Fog Lamps............................8W-50

Fog Lamp Relay........................8W-50

Front Blower Motor.....................8W-42

Front Blower Motor Relay.............8W-10, 42

Front Blower Motor Resistor Block.........8W-42

Front Cigar Lighter/Power Outlet..........8W-41

Front Reading Lamp Defeat Switch.........8W-44

Front Reading Lamps/Switch..............8W-44

Front Washer Motor.....................8W-53

Front Wiper Switch.....................8W-53

Fuel Gauge............................8W-40

Fuel Heater...........................8W-30

Fuel Heater Relay...................8W-10, 30

Fuel Injectors..........................8W-30

Fuel Pump Module......................8W-30

Fuel Pump Relay....................8W-10, 30

Fuel Quantity Actuator..................8W-30

Fuel Shutdown Solenoid..................8W-30

NS/GS8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 578 of 1938

Component Page

Fuel Tank Module...................8W-30, 45

Fuel Temperature Sensor.................8W-30

Fuel Timing Solenoid....................8W-30

Fuses (JB)............................8W-12

Fuses (PDC)...........................8W-10

Fusible Link.....................8W-20, 21, 63

Fusible Link A0........................8W-30

Fusible Link A11.......................8W-10

Fusible Link A54.......................8W-10

Grounds..............................8W-15

Generator.............................8W-20

Glove Box Lamp........................8W-44

Glow Plug Lamp.....................8W-30, 46

Glow Plugs............................8W-30

Glow Plug Relay........................8W-30

Headlamps............................8W-50

Headlamp Dimmer Switch..........8W-10, 46, 50

Headlamp Leveling Motors...............8W-50

Headlamp Switch.......................8W-50

Headlamp Washer......................8W-53

High Beam Indicator....................8W-46

High Beam Relay....................8W-10, 50

Headlamps............................8W-50

Horns................................8W-41

Hood Ajar Switch....................8W-39, 44

Horn Relay.........................8W-39, 41

Horn Switch.....................8W-10, 39, 41

HVAC Control.........................8W-42

Idle Air Control Motor...................8W-30

Ignition Coil Pack.......................8W-30

Ignition Switch.........................8W-10

Instrument Cluster.....................8W-40

Intake Air Temperature Sensor............8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor.....................8W-30

Interior Lamps On Switch................8W-44

Junction Block.........................8W-12

Key-In Halo Lamp......................8W-44

Knock Sensor..........................8W-30

Lamp Assemblies.......................8W-51

License Lamp..........................8W-51

Liftgate Ajar Indicator Lamp..............8W-40

Liftgate Ajar Switch...............8W-39, 40, 44

Liftgate Arm/Disarm Switch............8W-39, 61

Liftgate Flood Lamps....................8W-44

Liftgate Lock Motor.....................8W-61

Low Beam Relay.....................8W-10, 50

Low Coolant Level Switch................8W-45

Low Fuel Warning Indicator Lamp..........8W-40

Low Oil Pressure Lamp..................8W-46

Low Washer Fluid Level Indicator Lamp.....8W-40

Low Washer Fluid Switch.................8W-53

Low/Reverse Pressure Switch..............8W-31

Low/Reverse Solenoid....................8W-31Component Page

Manifold Absolute Pressure Sensor.........8W-30

Memory Power Seat Switch...............8W-63

Seat Sensors...........................8W-63

Memory Seat/Mirror Module...........8W-62, 63

Memory Set Switch..................8W-62, 63

Message Center........................8W-46

Mid Reading Lamps.....................8W-44

Mode Door Actuator.....................8W-42

Name Brand Speaker Relay...............8W-47

Needle Movement Sensor.................8W-30

Odometer.............................8W-40

Output Shaft Speed Sensor...............8W-31

Overdrive Pressure Switch................8W-31

Overdrive Solenoid......................8W-31

Overhead Console.......................8W-49

Park Brake Switch...................8W-46, 50

Park Lamp Relay.........8W-10, 12, 44, 50, 51, 54

Park/Turn Signal Lamps.................8W-50

Airbag Squibs..........................8W-43

Power Distribution Center................8W-10

Power Folding Mirror Switch..............8W-62

Power Mirror Fold Relay.................8W-62

Power Mirror Switch....................8W-62

Power Mirror Unfold Relay...............8W-62

Power Seat Circuit Breaker............8W-62, 63

Powertrain Control Module...............8W-30

PTCs (JB).............................8W-12

Radiator Fan Disconnect.................8W-42

Radiator Fan Relays.....................8W-42

Radio................................8W-47

Radio Choke...........................8W-47

Reading Lamps........................8W-44

Rear A/C Heater Unit....................8W-42

Rear Blower Control Switches.............8W-42

Rear Cigar Lighter/Power Outlet...........8W-41

Rear Defogger On Indicator...............8W-42

Rear Dome Lamp.......................8W-44

Rear Fog Lamp.........................8W-51

Rear Fog Lamp Indicator.................8W-51

Rear Washer Motor.....................8W-53

Rear Washer Switch..................8W-42, 53

Rear Window Defogger...................8W-48

Rear Window Defogger Relay..............8W-48

Rear Window Defogger Switch..........8W-42, 48

Rear Wiper Delay On Indicator.........8W-42, 53

Rear Wiper Delay Switch..............8W-42, 53

Rear Wiper Motor.......................8W-53

Rear Wiper On Indicator..............8W-42, 53

Rear Wiper On Switch................8W-42, 53

Recirculate Mode Indicator................8W-42

Recirculate Mode Switch.................8W-42

Recirculation Door Actuator...............8W-42

Remote Keyless Entry Module.............8W-61

Repeater Lamps.....................8W-51, 52

8W - 02 - 2 8W - 02 COMPONENT INDEXNS/GS

Page 579 of 1938

Component Page

Seat Belt Indicator Lamp.................8W-40

Seat Belt Switch........................8W-40

Sentry Key Immobilizer Module............8W-39

Service Engine Soon Lamp.............8W-30, 46

Sliding Door Contacts....................8W-61

Sliding Door Lock Motors.................8W-61

Speed Control Switches...............8W-30, 33

Speedometer...........................8W-40

Stop Lamp Switch...................8W-33, 51

Stop/Turn Signal Relays..................8W-54

Tachometer............................8W-40

Tail/Stop Lamp.........................8W-51

Tail/Turn Signal Lamp................8W-51, 52

Throttle Position Sensor..................8W-30

Traction Control Switch..................8W-35

Trailer Tow Connector...................8W-54

Transmission Control Module..............8W-31

Transmission Control Relay............8W-10, 31

Transmission Control Solenoids............8W-31

Transmission Range Sensor...............8W-31

Trip Odometer.........................8W-40Component Page

Turbine Speed Sensor....................8W-31

Turbo Boost Pressure Sensor..............8W-30

Turn Indicators......................8W-46, 52

Turn Signal/Hazard Switch............8W-46, 52

Underdrive Solenoid.....................8W-31

Universal Garage Door Opener............8W-49

Vacuum Solenoid.......................8W-33

Vehicle Speed Control Servo...............8W-33

Vehicle Speed Sensor....................8W-30

Vent Motors...........................8W-60

Vent Solenoids.........................8W-33

Visor/Vanity Mirror Lamps................8W-44

Voltage Regulator.......................8W-20

Volts Indicator Lamp....................8W-40

VTSS Lamp........................8W-39, 46

Washer Module.........................8W-53

Wheel Speed Sensors....................8W-35

Wiper High/Low Relay...................8W-53

Wiper Module..........................8W-53

Wiper On Relay........................8W-53

NS/GS8W - 02 COMPONENT INDEX 8W - 02 - 3

Page 580 of 1938