ECU CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 572 of 1938

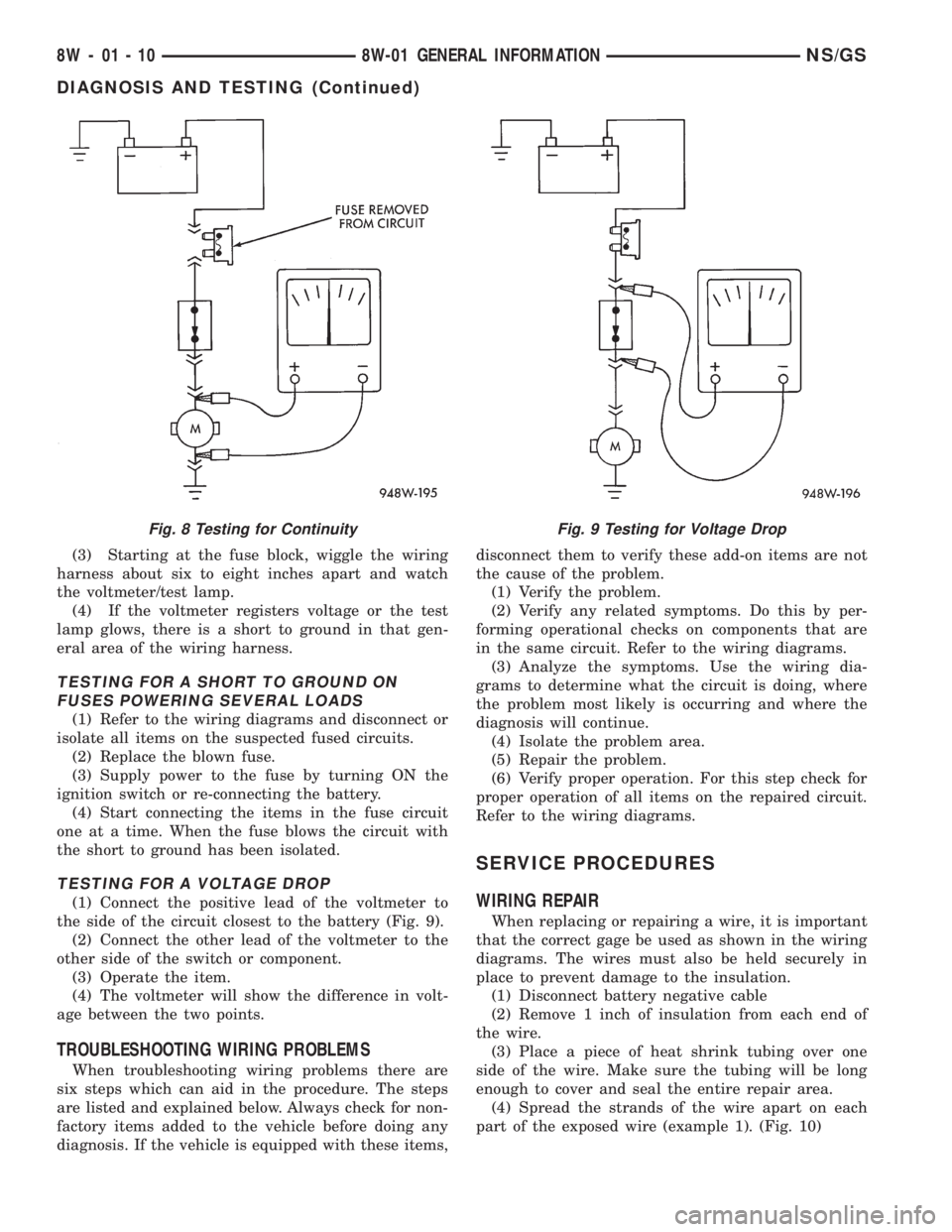

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting the items in the fuse circuit

one at a time. When the fuse blows the circuit with

the short to ground has been isolated.

TESTING FOR A VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 9).

(2) Connect the other lead of the voltmeter to the

other side of the switch or component.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the repaired circuit.

Refer to the wiring diagrams.

SERVICE PROCEDURES

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gage be used as shown in the wiring

diagrams. The wires must also be held securely in

place to prevent damage to the insulation.

(1) Disconnect battery negative cable

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

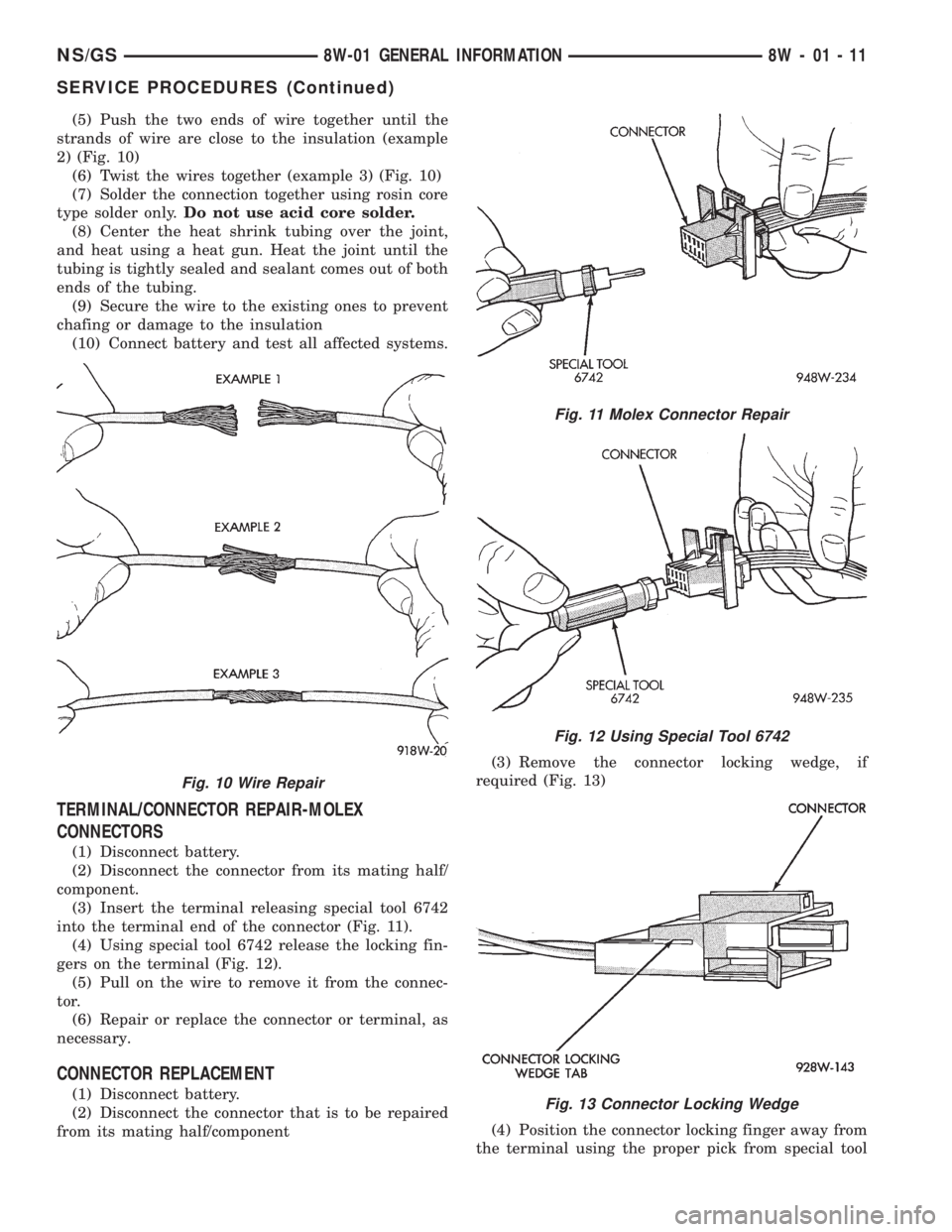

(4) Spread the strands of the wire apart on each

part of the exposed wire (example 1). (Fig. 10)

Fig. 8 Testing for ContinuityFig. 9 Testing for Voltage Drop

8W - 01 - 10 8W-01 GENERAL INFORMATIONNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 573 of 1938

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (example

2) (Fig. 10)

(6) Twist the wires together (example 3) (Fig. 10)

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint,

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation

(10) Connect battery and test all affected systems.

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Insert the terminal releasing special tool 6742

into the terminal end of the connector (Fig. 11).

(4) Using special tool 6742 release the locking fin-

gers on the terminal (Fig. 12).

(5) Pull on the wire to remove it from the connec-

tor.

(6) Repair or replace the connector or terminal, as

necessary.

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component(3) Remove the connector locking wedge, if

required (Fig. 13)

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

Fig. 10 Wire Repair

Fig. 11 Molex Connector Repair

Fig. 12 Using Special Tool 6742

Fig. 13 Connector Locking Wedge

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 11

SERVICE PROCEDURES (Continued)

Page 723 of 1938

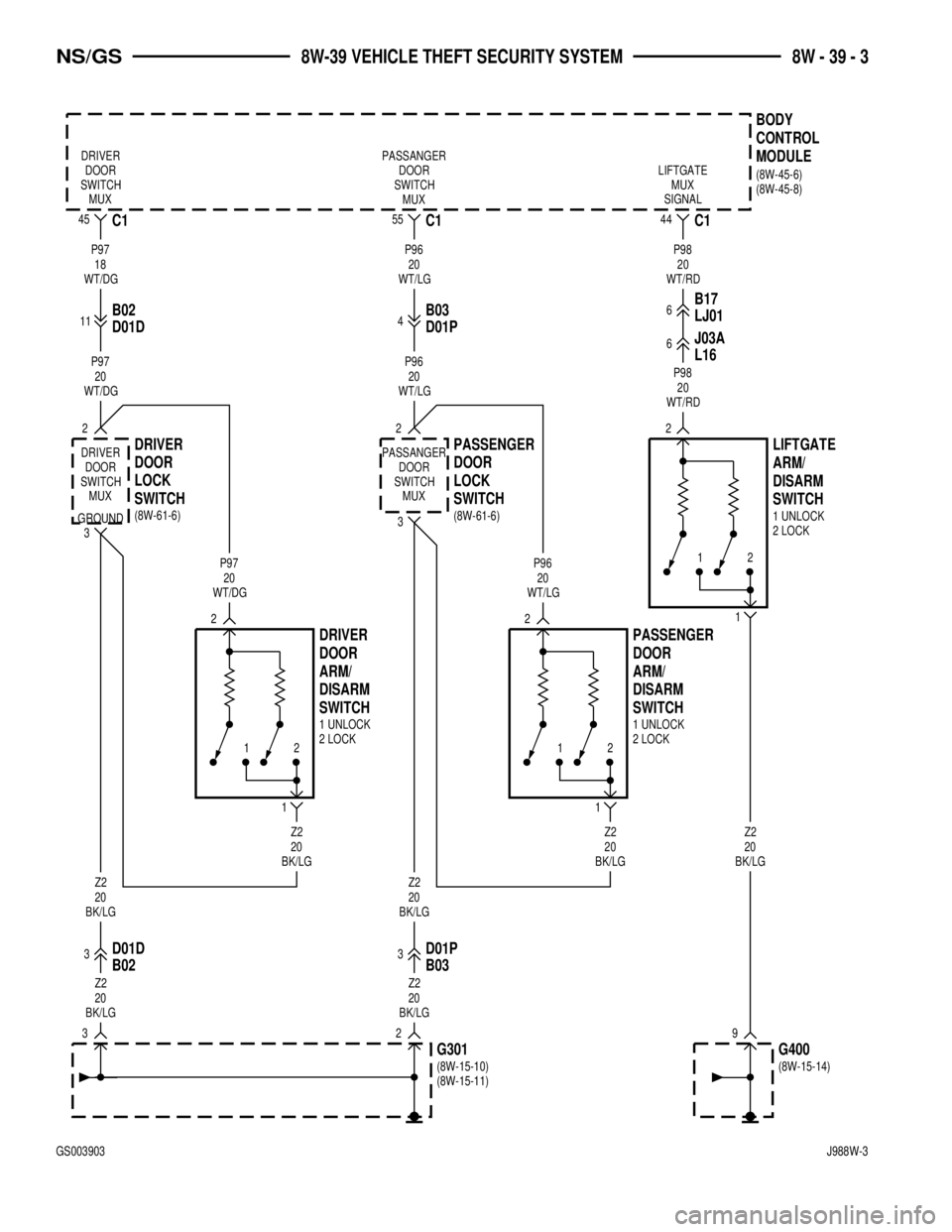

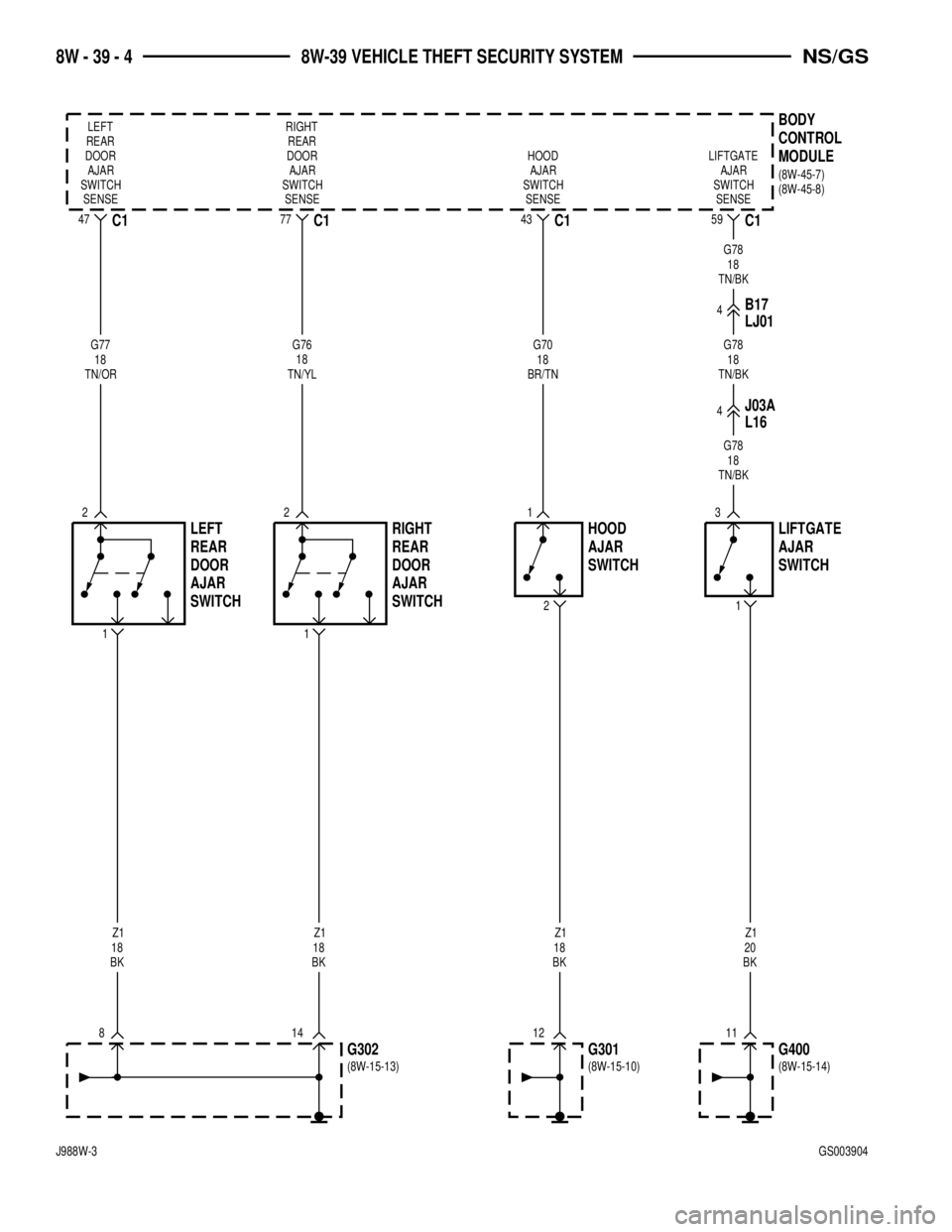

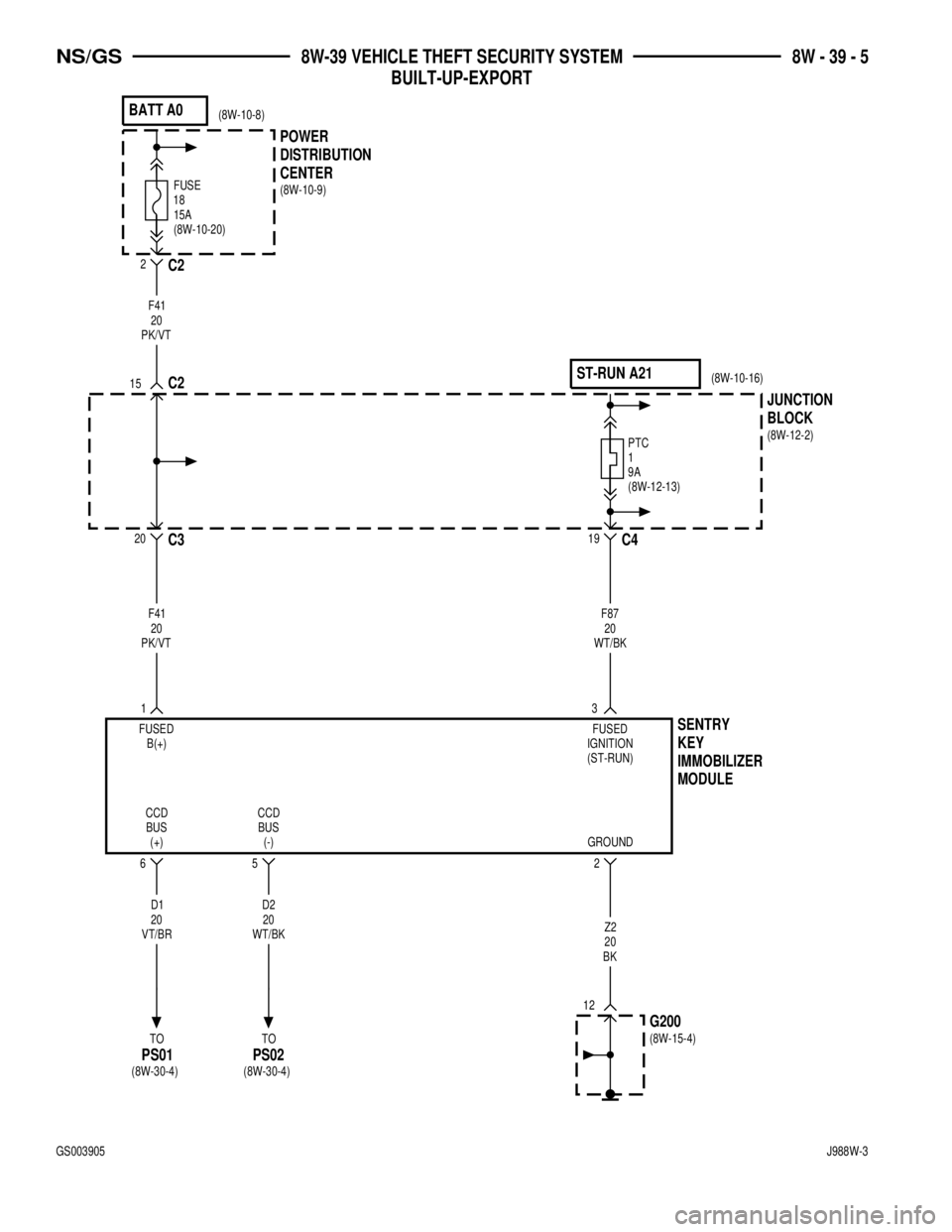

8W-39 VEHICLE THEFT SECURITY SYSTEM

Component Page

Body Control Module...............8W-39-2, 3, 4

BS19...............................8W-39-2

Clockspring..........................8W-39-2

Driver Door Ajar Switch................8W-39-2

Driver Door Arm/Disarm Switch..........8W-39-3

Driver Door Lock Switch................8W-39-3

Fuse 9 (PDC).........................8W-39-2

Fuse 18 (PDC)........................8W-39-5

Fuse 28 (PDC)........................8W-39-2

G200...............................8W-39-5

G301...........................8W-39-2, 3, 4

G302...............................8W-39-4

G400.............................8W-39-3, 4

High Note Horn.......................8W-39-2

Hood Ajar Switch.....................8W-39-4

Horn Relay..........................8W-39-2

Horn Switch.........................8W-39-2

Junction Block......................8W-39-2, 5Component Page

Left Rear Door Ajar Switch..............8W-39-4

Liftgate Ajar Switch...................8W-39-4

Liftgate Arm/Disarm Switch.............8W-39-3

Low Note Horn.......................8W-39-2

Memory Seat/Mirror Module.............8W-39-2

Message Center.......................8W-39-2

Passenger Door Ajar Switch.............8W-39-2

Passenger Door Arm/Disarm Switch.......8W-39-3

Passenger Door Lock Switch.............8W-39-3

Power Distribution Center.............8W-39-2, 5

PS01...............................8W-39-5

PS02...............................8W-39-5

PTC 1 (JB)..........................8W-39-5

Remote Keyless Entry Module...........8W-39-2

Right Rear Door Ajar Switch.............8W-39-4

Sentry Key Immobilizer Module..........8W-39-5

VTSS Lamp..........................8W-39-2

NS/GS8W - 39 VEHICLE THEFT SECURITY SYSTEM 8W - 39 - 1

Page 724 of 1938

8587

3086

RELAY HORN

C248C2

20A

FUSE

9

BATT A0

POWER

DISTRIBUTION

CENTER

13 12

VTSS

LAMP

CENTER MESSAGE

28FUSE10A

C35

JUNCTION

BLOCK

6C4

13C1

C2

169

BODY

CONTROL

MODULE

VTSS

LAMP

DRIVERFUSED

B (+) RELAYHORN

18

CONTROL

M1

20

PKG69

22

BK/OR

M1

20

PK

C116

MODULE MIRROR

SEAT/

MEMORY

M1

20

PK

C24

GY/OR20 X4

79C1 C148

SENSE SWITCHAJAR DRIVER

DOOR DOOR PASSENGER

AJAR

SWITCH

SENSE

DRIVER

DOOR

AJAR

SWITCH

SWITCH AJAR

DOOR PASSENGER

G75

18

TNG74

18

TN/RD

HORN NOTE

LOW HIGH

NOTE

HORN

X2

18

DG/RD

X2

18

DG/RDX2

18

DG/RD

BS19

A A

BB

Z1

18

BK

Z1

18

BK

G301

FUSED

B (+)

1 13

HORN

SWITCH CLOCKSPRING

X3

20

BK/RD

20C2

1X3

20

BK/RD

CONTROLRELAYHORN

*7 *8

* RHD

C2

3

MODULE ENTRY

KEYLESS

REMOTE

7P50

NOT

USED

M1

20

PK

M1

22

PK

(8W-10-30) (8W-10-8)

(8W-10-9)

(8W-10-10)

(8W-46-2) (8W-10-11)

(8W-12-2)

(8W-45-3)

(8W-45-7)(8W-62-3)

(8W-63-4)

(8W-15-10)

(8W-15-11)(8W-41-2) (8W-41-2)(8W-61-5) (8W-12-20)

8W - 39 - 2 8W-39 VEHICLE THEFT SECURITY SYSTEMNS/GS

J988W-3GS003902

Page 725 of 1938

BK/LG20 Z2

9

G400

WT/RD20 P98

6J03A

L16

LJ01 B176

WT/RD20 P98

C144SIGNALMUX LIFTGATE

BK/LG20 Z2BK/LG20 Z2Z2

20

BK/LG

2

SWITCH LOCK

DOOR PASSENGER

3

B03 D01P3

Z2

20

BK/LG

55C1

P96

20

WT/LG

4B03

D01P

P96

20

WT/LG

P96

20

WT/LG

BK/LG20 Z2

3D01D

B02

BK/LG20 Z2

G301

WT/DG20 P97

3

DRIVER

DOOR

LOCK

SWITCH

2

WT/DG20 P97

D01D B0211

WT/DG18 P97 DRIVER

BODY

CONTROL

MODULE

C145

DOOR

SWITCH

MUX

SWITCH DISARM

ARM/

LIFTGATE

1 2

2 1

12

2

1

PASSENGER

DOOR

ARM/

DISARM

SWITCH SWITCH DISARM

ARM/

DOOR

DRIVER

1 2

2 1

2 31 UNLOCK

2 LOCK 2 LOCK1 UNLOCK2 LOCK 1 UNLOCK PASSANGER

DOOR

SWITCH

MUX

MUX SWITCHDOOR DRIVER PASSANGER

DOOR

SWITCH

MUX

GROUND

(8W-15-14) (8W-61-6)

(8W-15-10)

(8W-15-11) (8W-61-6)(8W-45-6)

(8W-45-8)

NS/GS8W-39 VEHICLE THEFT SECURITY SYSTEM 8W - 39 - 3

GS003903J988W-3

Page 726 of 1938

TN/BK18 G78

BK20Z1

G400

SWITCH AJAR

LIFTGATE

3

1

Z1

18

BK

G301

G70

18

BR/TN

C143SENSE SWITCHAJAR HOOD

L16 J03A4

TN/BK18 G78

4B17

LJ01

SENSE SWITCHAJAR LIFTGATE

59C1

TN/BK18 G78

G302

BK18Z1BK18Z1REAR RIGHT

C177

DOOR

AJAR

SWITCH

SENSE

G76

18

TN/YL

TN/OR18 G77

2

SWITCH AJAR

HOOD

12

RIGHT

REAR

DOOR

AJAR

SWITCH

11

SWITCH AJAR

DOOR

REAR

LEFT

2

SENSE SWITCHAJAR DOOR

47C1

MODULE

CONTROL

BODY

LEFT

REAR

814 1211

(8W-15-14) (8W-15-10) (8W-15-13)(8W-45-7)

(8W-45-8)

8W - 39 - 4 8W-39 VEHICLE THEFT SECURITY SYSTEMNS/GS

J988W-3GS003904

Page 727 of 1938

18FUSE15A

BATT A0

12

CENTER

DISTRIBUTION

POWER

2C2

15C2

F41

20

PK/VT

20C3

PTC

1

9A

ST-RUN A21

BLOCK JUNCTION

C4

19

MODULE IMMOBILIZER

KEY

SENTRY

1F41

20

PK/VT3

F87

20

WT/BK

FUSED

B(+)FUSED

IGNITION

(ST-RUN)

CCD

BUS

(+) (-)BUS CCD

GROUND

Z2

20

BK

G200

2 56

D1

20

VT/BR

D2

20

WT/BK

TO

PS01

TO

PS02

(8W-10-20)(8W-10-8)

(8W-10-9)

(8W-12-13)(8W-10-16)

(8W-12-2)

(8W-15-4)

(8W-30-4) (8W-30-4)

NS/GS8W-39 VEHICLE THEFT SECURITY SYSTEM

BUILT-UP-EXPORT8W - 39 - 5

GS003905J988W-3

Page 1052 of 1938

made to seal the area between the bedplate and cyl-

inder block without disturbing the bearing clearance

or alignment of these components.

GASKET DISASSEMBLY

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some

instances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

SURFACE PREPARATION

Scrape clean or wire brush all gasket surfaces to

remove all loose material. Inspect stamped parts to

ensure gasket rails are flat. Gasket surfaces must be

free of oil and dirt. Make sure old gasket material is

removed from blind attaching holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing the material off location.

TheMopartSilicone Rubber Adhesive Sealant

gasket material or equivalent should be applied in a

continuous bead approximately 3 mm (0.120 in.) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.) drop

is placed in the center of the gasket contact area.

Uncured sealant may be removed with a shop towels.

Components should be torqued in place while the

sealant is still wet to the touch (within 10 minutes).

The usage of a locating dowel is recommended during

assembly to prevent smearing of material off loca-

tion.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

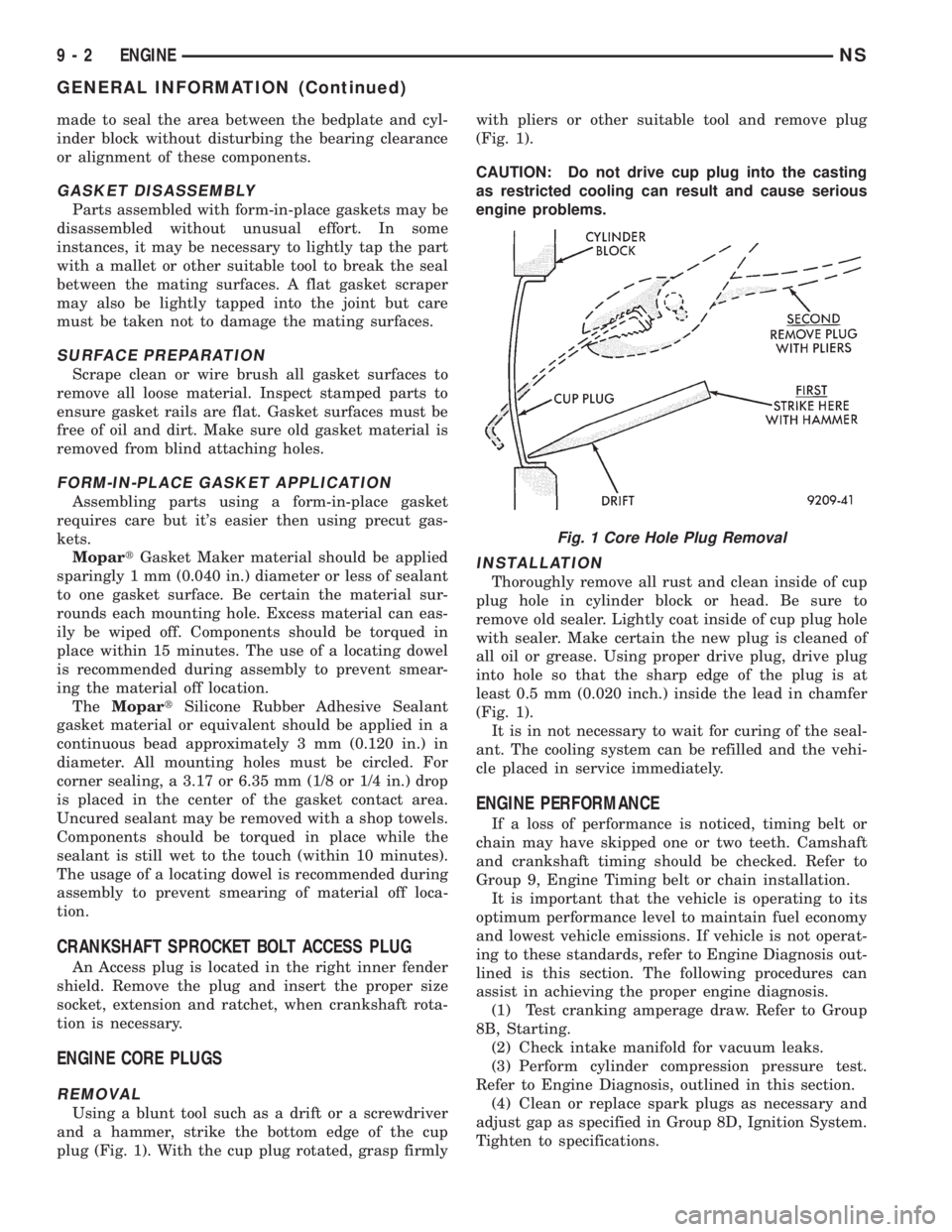

ENGINE CORE PLUGS

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmlywith pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is at

least 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINENS

GENERAL INFORMATION (Continued)

Page 1057 of 1938

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST.............. 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 12

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION

(ENGINE OIL LEAKS IN GENERAL)......... 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET)

NOISE DIAGNOSIS...................... 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

NSENGINE 9 - 7

Page 1145 of 1938

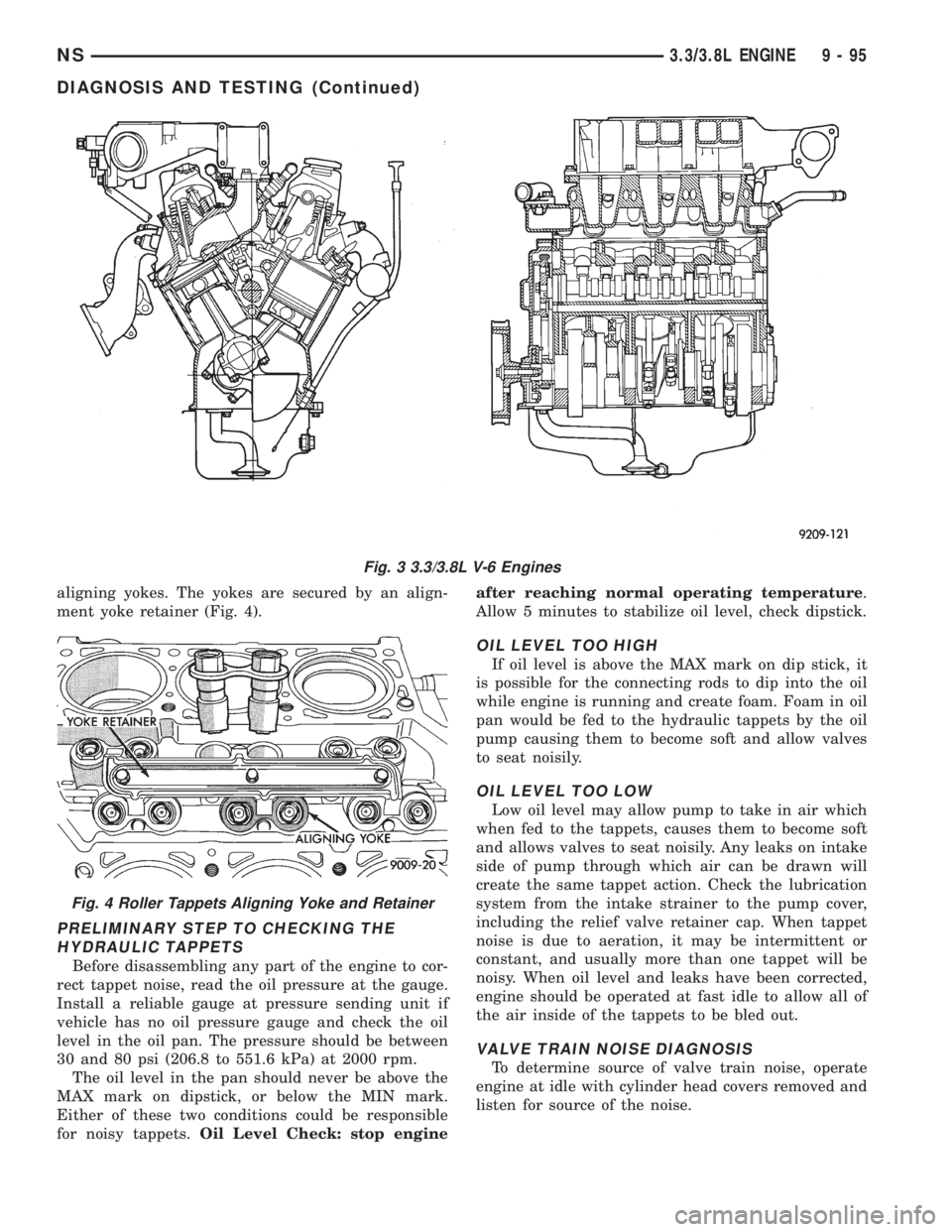

aligning yokes. The yokes are secured by an align-

ment yoke retainer (Fig. 4).

PRELIMINARY STEP TO CHECKING THE

HYDRAULIC TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, read the oil pressure at the gauge.

Install a reliable gauge at pressure sending unit if

vehicle has no oil pressure gauge and check the oil

level in the oil pan. The pressure should be between

30 and 80 psi (206.8 to 551.6 kPa) at 2000 rpm.

The oil level in the pan should never be above the

MAX mark on dipstick, or below the MIN mark.

Either of these two conditions could be responsible

for noisy tappets.Oil Level Check: stop engineafter reaching normal operating temperature.

Allow 5 minutes to stabilize oil level, check dipstick.

OIL LEVEL TOO HIGH

If oil level is above the MAX mark on dip stick, it

is possible for the connecting rods to dip into the oil

while engine is running and create foam. Foam in oil

pan would be fed to the hydraulic tappets by the oil

pump causing them to become soft and allow valves

to seat noisily.

OIL LEVEL TOO LOW

Low oil level may allow pump to take in air which

when fed to the tappets, causes them to become soft

and allows valves to seat noisily. Any leaks on intake

side of pump through which air can be drawn will

create the same tappet action. Check the lubrication

system from the intake strainer to the pump cover,

including the relief valve retainer cap. When tappet

noise is due to aeration, it may be intermittent or

constant, and usually more than one tappet will be

noisy. When oil level and leaks have been corrected,

engine should be operated at fast idle to allow all of

the air inside of the tappets to be bled out.

VALVE TRAIN NOISE DIAGNOSIS

To determine source of valve train noise, operate

engine at idle with cylinder head covers removed and

listen for source of the noise.

Fig. 3 3.3/3.8L V-6 Engines

Fig. 4 Roller Tappets Aligning Yoke and Retainer

NS3.3/3.8L ENGINE 9 - 95

DIAGNOSIS AND TESTING (Continued)