fuel injection CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1402 of 1938

KNOCK SENSORÐPCM INPUTÐ2.0L ENGINE

Refer to the Knock Sensor for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

MANIFOLD ABSOLUTE PRESSURE (MAP

SENSOR)ÐPCM INPUTÐ2.0L ENGINE

Refer to the Manifold Absolute Pressure and

Intake Air Temperature sensors for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

SPEED CONTROLÐPCM INPUTÐ2.0L ENGINE

Refer to the Speed Control for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

Fig. 3 Engine Coolant Temperature SensorÐ2.0L

engine

Fig. 4 Upstream Heated Oxygen SensorÐ2.0L

Engine

Fig. 5 Downstream Heated Oxygen SensorÐ2.0L

Engine

Fig. 6 Knock SensorÐ2.0L engine

Fig. 7 MAP/IAT sensorÐ2.0L engine

14 - 34 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1403 of 1938

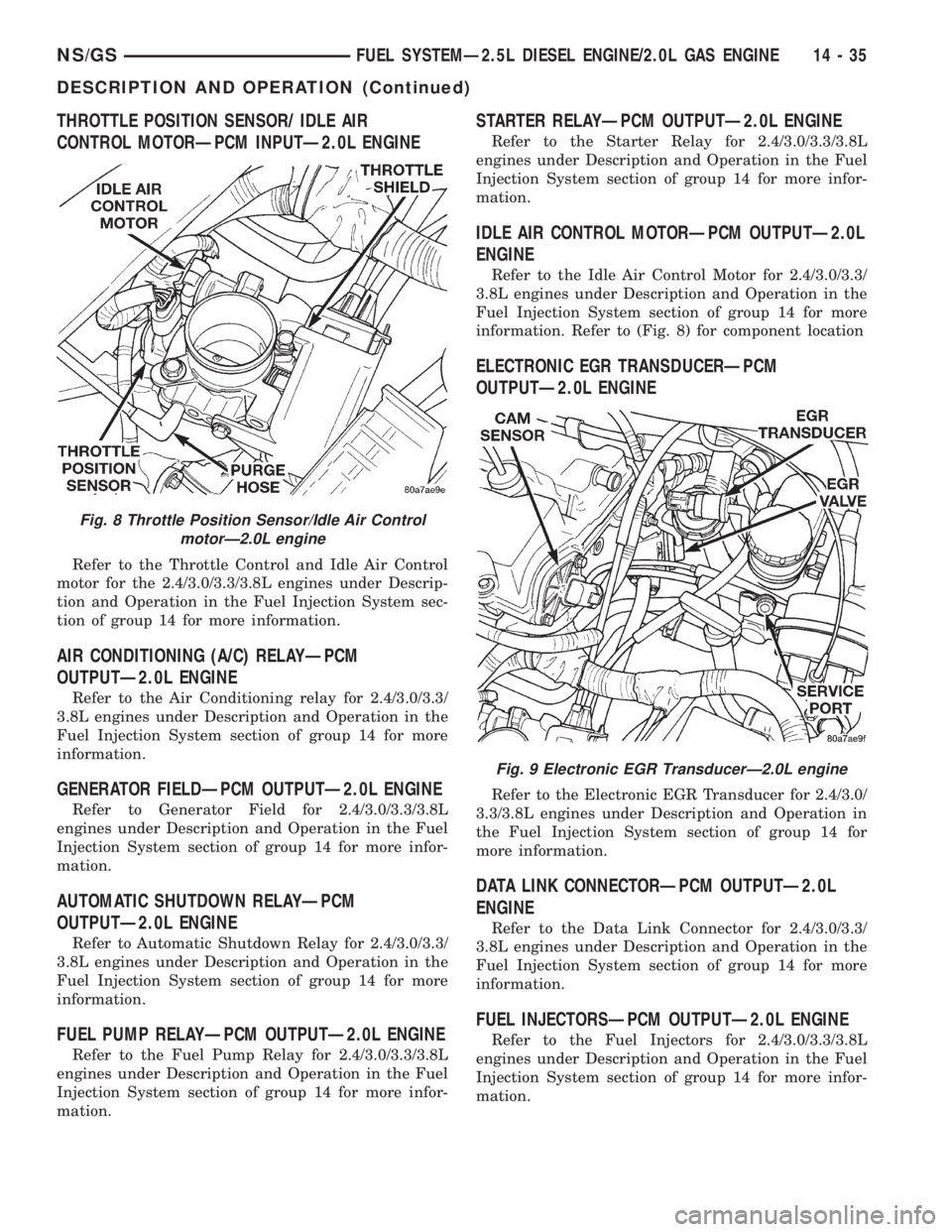

THROTTLE POSITION SENSOR/ IDLE AIR

CONTROL MOTORÐPCM INPUTÐ2.0L ENGINE

Refer to the Throttle Control and Idle Air Control

motor for the 2.4/3.0/3.3/3.8L engines under Descrip-

tion and Operation in the Fuel Injection System sec-

tion of group 14 for more information.

AIR CONDITIONING (A/C) RELAYÐPCM

OUTPUTÐ2.0L ENGINE

Refer to the Air Conditioning relay for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

GENERATOR FIELDÐPCM OUTPUTÐ2.0L ENGINE

Refer to Generator Field for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

AUTOMATIC SHUTDOWN RELAYÐPCM

OUTPUTÐ2.0L ENGINE

Refer to Automatic Shutdown Relay for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

FUEL PUMP RELAYÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Fuel Pump Relay for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

STARTER RELAYÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Starter Relay for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

IDLE AIR CONTROL MOTORÐPCM OUTPUTÐ2.0L

ENGINE

Refer to the Idle Air Control Motor for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information. Refer to (Fig. 8) for component location

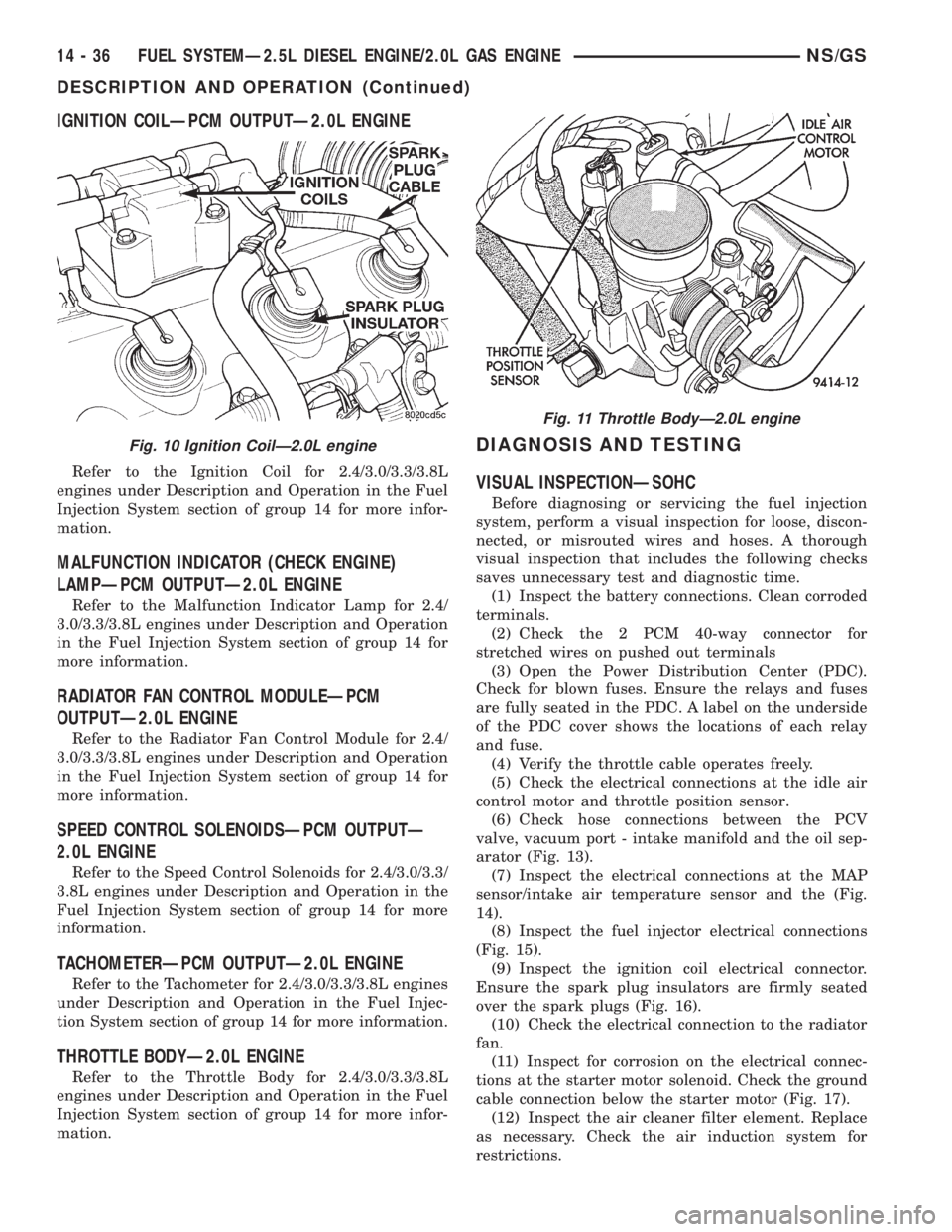

ELECTRONIC EGR TRANSDUCERÐPCM

OUTPUTÐ2.0L ENGINE

Refer to the Electronic EGR Transducer for 2.4/3.0/

3.3/3.8L engines under Description and Operation in

the Fuel Injection System section of group 14 for

more information.

DATA LINK CONNECTORÐPCM OUTPUTÐ2.0L

ENGINE

Refer to the Data Link Connector for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

FUEL INJECTORSÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Fuel Injectors for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

Fig. 8 Throttle Position Sensor/Idle Air Control

motorÐ2.0L engine

Fig. 9 Electronic EGR TransducerÐ2.0L engine

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 35

DESCRIPTION AND OPERATION (Continued)

Page 1404 of 1938

IGNITION COILÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Ignition Coil for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Malfunction Indicator Lamp for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

RADIATOR FAN CONTROL MODULEÐPCM

OUTPUTÐ2.0L ENGINE

Refer to the Radiator Fan Control Module for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

SPEED CONTROL SOLENOIDSÐPCM OUTPUTÐ

2.0L ENGINE

Refer to the Speed Control Solenoids for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

TACHOMETERÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Tachometer for 2.4/3.0/3.3/3.8L engines

under Description and Operation in the Fuel Injec-

tion System section of group 14 for more information.

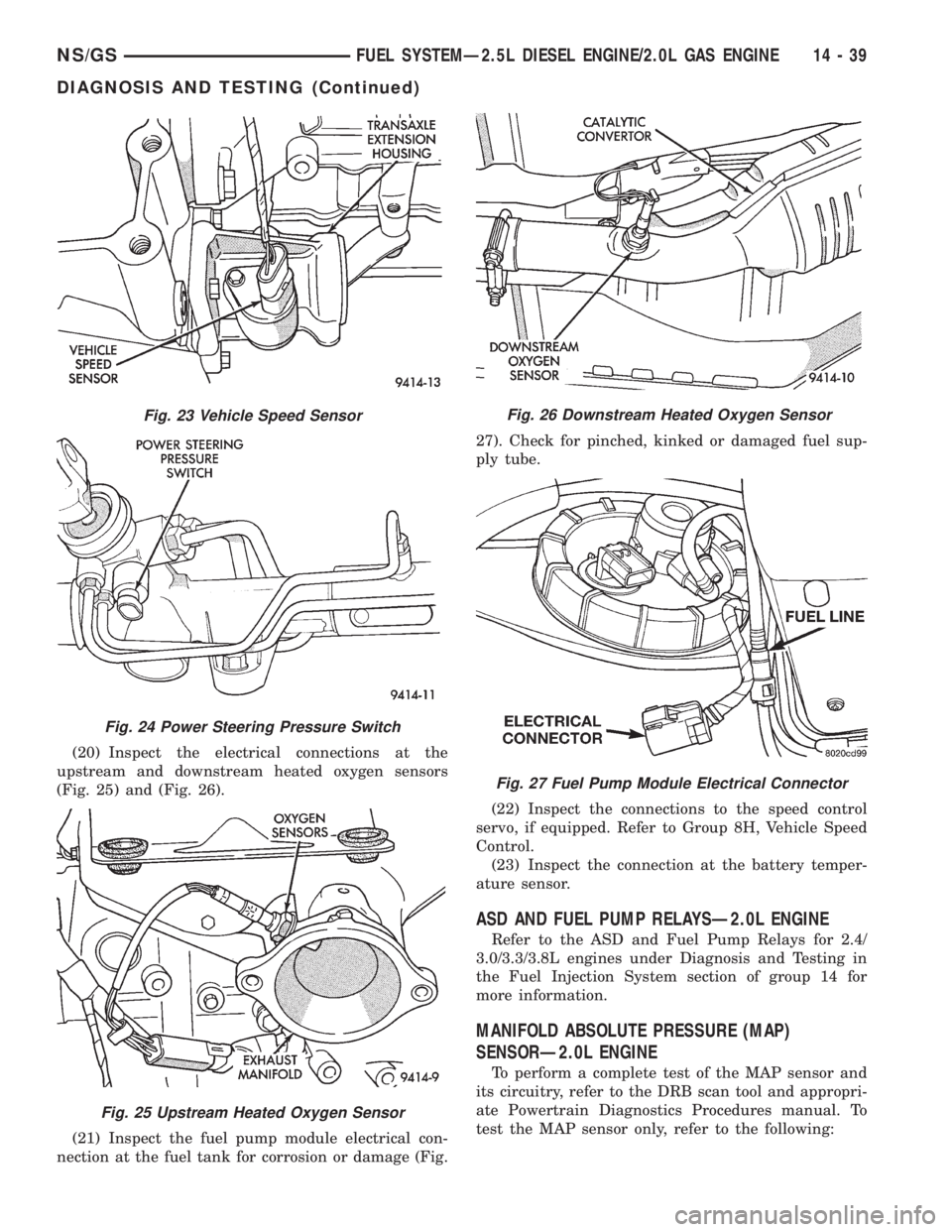

THROTTLE BODYÐ2.0L ENGINE

Refer to the Throttle Body for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐSOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses. A thorough

visual inspection that includes the following checks

saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals.

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC. A label on the underside

of the PDC cover shows the locations of each relay

and fuse.

(4) Verify the throttle cable operates freely.

(5) Check the electrical connections at the idle air

control motor and throttle position sensor.

(6) Check hose connections between the PCV

valve, vacuum port - intake manifold and the oil sep-

arator (Fig. 13).

(7) Inspect the electrical connections at the MAP

sensor/intake air temperature sensor and the (Fig.

14).

(8) Inspect the fuel injector electrical connections

(Fig. 15).

(9) Inspect the ignition coil electrical connector.

Ensure the spark plug insulators are firmly seated

over the spark plugs (Fig. 16).

(10) Check the electrical connection to the radiator

fan.

(11) Inspect for corrosion on the electrical connec-

tions at the starter motor solenoid. Check the ground

cable connection below the starter motor (Fig. 17).

(12) Inspect the air cleaner filter element. Replace

as necessary. Check the air induction system for

restrictions.

Fig. 10 Ignition CoilÐ2.0L engine

Fig. 11 Throttle BodyÐ2.0L engine

14 - 36 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1407 of 1938

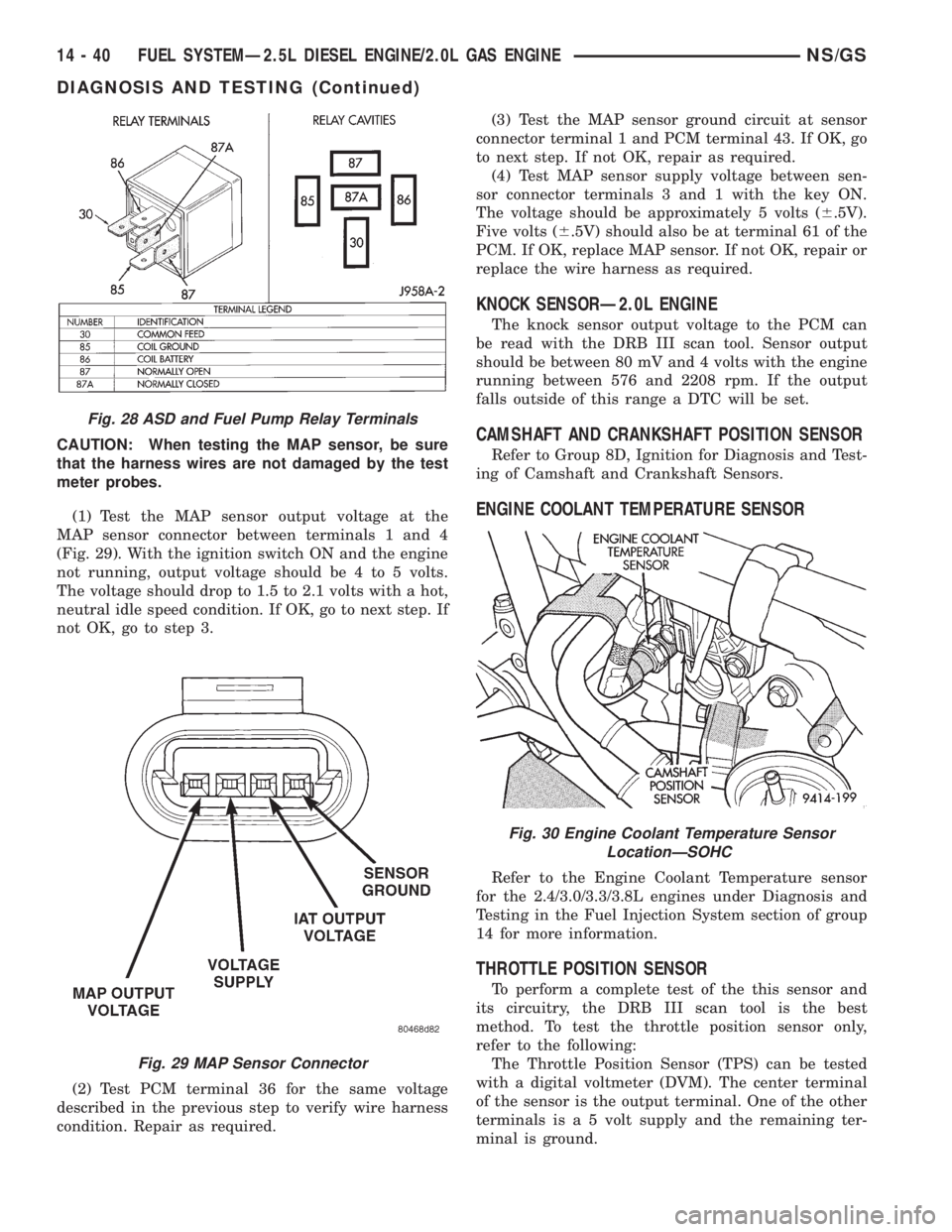

(20) Inspect the electrical connections at the

upstream and downstream heated oxygen sensors

(Fig. 25) and (Fig. 26).

(21) Inspect the fuel pump module electrical con-

nection at the fuel tank for corrosion or damage (Fig.27). Check for pinched, kinked or damaged fuel sup-

ply tube.

(22) Inspect the connections to the speed control

servo, if equipped. Refer to Group 8H, Vehicle Speed

Control.

(23) Inspect the connection at the battery temper-

ature sensor.

ASD AND FUEL PUMP RELAYSÐ2.0L ENGINE

Refer to the ASD and Fuel Pump Relays for 2.4/

3.0/3.3/3.8L engines under Diagnosis and Testing in

the Fuel Injection System section of group 14 for

more information.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.0L ENGINE

To perform a complete test of the MAP sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the MAP sensor only, refer to the following:

Fig. 23 Vehicle Speed Sensor

Fig. 24 Power Steering Pressure Switch

Fig. 25 Upstream Heated Oxygen Sensor

Fig. 26 Downstream Heated Oxygen Sensor

Fig. 27 Fuel Pump Module Electrical Connector

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 39

DIAGNOSIS AND TESTING (Continued)

Page 1408 of 1938

CAUTION: When testing the MAP sensor, be sure

that the harness wires are not damaged by the test

meter probes.

(1) Test the MAP sensor output voltage at the

MAP sensor connector between terminals 1 and 4

(Fig. 29). With the ignition switch ON and the engine

not running, output voltage should be 4 to 5 volts.

The voltage should drop to 1.5 to 2.1 volts with a hot,

neutral idle speed condition. If OK, go to next step. If

not OK, go to step 3.

(2) Test PCM terminal 36 for the same voltage

described in the previous step to verify wire harness

condition. Repair as required.(3) Test the MAP sensor ground circuit at sensor

connector terminal 1 and PCM terminal 43. If OK, go

to next step. If not OK, repair as required.

(4) Test MAP sensor supply voltage between sen-

sor connector terminals 3 and 1 with the key ON.

The voltage should be approximately 5 volts (6.5V).

Five volts (6.5V) should also be at terminal 61 of the

PCM. If OK, replace MAP sensor. If not OK, repair or

replace the wire harness as required.

KNOCK SENSORÐ2.0L ENGINE

The knock sensor output voltage to the PCM can

be read with the DRB III scan tool. Sensor output

should be between 80 mV and 4 volts with the engine

running between 576 and 2208 rpm. If the output

falls outside of this range a DTC will be set.

CAMSHAFT AND CRANKSHAFT POSITION SENSOR

Refer to Group 8D, Ignition for Diagnosis and Test-

ing of Camshaft and Crankshaft Sensors.

ENGINE COOLANT TEMPERATURE SENSOR

Refer to the Engine Coolant Temperature sensor

for the 2.4/3.0/3.3/3.8L engines under Diagnosis and

Testing in the Fuel Injection System section of group

14 for more information.

THROTTLE POSITION SENSOR

To perform a complete test of the this sensor and

its circuitry, the DRB III scan tool is the best

method. To test the throttle position sensor only,

refer to the following:

The Throttle Position Sensor (TPS) can be tested

with a digital voltmeter (DVM). The center terminal

of the sensor is the output terminal. One of the other

terminals is a 5 volt supply and the remaining ter-

minal is ground.

Fig. 28 ASD and Fuel Pump Relay Terminals

Fig. 29 MAP Sensor Connector

Fig. 30 Engine Coolant Temperature Sensor

LocationÐSOHC

14 - 40 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1411 of 1938

FUEL INJECTION SYSTEMÐ2.5L DIESEL ENGINE

INDEX

page page

GENERAL INFORMATION

INTRODUCTION....................... 43

DESCRIPTION AND OPERATION

AIR CONDITIONING (A/C) CONTROLSÐ

PCM INPUTS........................ 47

AIR CONDITIONING RELAYÐPCM OUTPUT . . 48

BATTERY VOLTAGEÐPCM INPUT.......... 45

BOOST PRESSURE SENSOR............. 45

BRAKE SWITCHÐPCM INPUT............. 47

DATA LINK CONNECTORÐ

PCM INPUT AND OUTPUT.............. 47

DIESEL PCM RELAYÐPCM INPUT......... 48

ENGINE COOLANT GAUGEÐPCM OUTPUT . . 48

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT......................... 46

ENGINE OIL PRESSURE GAUGEÐ

PCM OUTPUT........................ 48

ENGINE SPEED SENSORÐPCM INPUT..... 46

EXHAUST GAS RECIRCULATION (EGR)

SOLENOIDÐPCM OUTPUT............. 50

FIVE VOLT POWERÐPCM OUTPUT........ 48

FUEL INJECTOR SENSORÐGROUND...... 46

FUEL TIMING SOLENOIDÐPCM OUTPUT.... 48

GLOW PLUG LAMPÐPCM OUTPUT........ 48

GLOW PLUG RELAYÐPCM OUTPUT....... 49

GLOW PLUGS......................... 49

IGNITION CIRCUIT SENSEÐPCM INPUT.... 45

NEEDLE MOVEMENT OR INSTRUMENTED

FIRST INJECTORÐPCM INPUT.......... 45

POWER GROUND...................... 45

POWERTRAIN CONTROL MODULE (PCM) . . . 44

SENSOR RETURNÐPCM INPUT (ANALOG

GROUND)........................... 45SIGNAL GROUNDÐPCM INPUT........... 45

SPEED CONTROLÐPCM INPUTS.......... 48

SPEED CONTROLÐPCM OUTPUTS........ 48

START SIGNALÐPCM INPUT............. 45

TACHOMETERÐPCM OUTPUT............ 49

VEHICLE SPEED SENSORÐPCM INPUT.... 47

VEHICLE THEFT ALARM................. 45

DIAGNOSIS AND TESTING

BOOST PRESSURE SENSOR............. 53

DIAGNOSTIC TROUBLE CODES........... 53

DIESEL DIAGNOSTICS.................. 50

DIESEL PCM RELAY TEST............... 50

ENGINE COOLANT TEMPERATURE

SENSOR TEST....................... 50

ENGINE SPEED SENSOR TEST........... 50

GLOW PLUG RELAY TEST............... 51

GLOW PLUG TEST..................... 51

RELAYSÐOPERATION/TESTING........... 52

VEHICLE SPEED SENSOR TEST........... 53

REMOVAL AND INSTALLATION

A/C CLUTCH RELAY.................... 53

DIESEL PCM RELAY.................... 53

ENGINE COOLANT TEMPERATURE

SENSOR............................ 54

ENGINE SPEED SENSOR................ 53

GLOW PLUG RELAY.................... 55

GLOW PLUGS......................... 54

POWERTRAIN CONTROL MODULE (PCM) . . . 55

VEHICLE SPEED SENSOR............... 55

SPECIFICATIONS

GLOW PLUG CURRENT DRAW............ 56

TORQUE CHARTÐ2.5L DIESEL............ 57

GENERAL INFORMATION

INTRODUCTION

This section will cover components either regulated

or controlled by the Powertrain Control Module

(PCM). The fuel heater relay, fuel heater and fuel

gauge are not operated by the PCM. These compo-

nents are controlled by the ignition (key) switch. All

other fuel system electrical components necessary to

operate the engine are controlled or regulated by the

PCM. Refer to the following PCM description for

more information.

Certain fuel system component failures may cause

a no start, or prevent the engine from running. It is

important to know that the PCM has a featurewhere, if possible, it will ignore the failed sensor, set

a code related to the sensor, and operate the engine

in a ªLimp Homeº mode. When the PCM is operating

in a ªLimp Homeº mode, the Diesel Glow Plug lamp

on the instrument panel will be constantly illumi-

nated, and the engine will most likely have a notice-

able loss of performance. An example of this would be

an Accelerator Pedal Position Sensor failure, and in

that situation, the engine would run at a constant

1100 RPM, regardless of the actual position of the

pedal. This is the most extreme of the three ªLimp

Homeº modes.

In addition to indicating that the glow plugs are

hot enough to start combustion, the Glow Plug Lamp

is also used in the diagnosis of the PCM, and when

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 43

Page 1413 of 1938

BOOST PRESSURE SENSOR

The Boost Pressure Sensor is mounted to the top of

the intake manifold. (Fig. 2) It is a sensor that mea-

sures both manifold vacuum and turbo boost, and it

also contains an integrated intake air temperature

sensor. The Boost Pressure Sensor takes the place of

the Mass Air Flow (MAF). In the Intake Air Temper-

ature Sensor component, there is a ceramic element

that changes its resistance based on temperature.

The ceramic element is part of an electronic circuit

connected to the PCM, and has a voltage applied to

it. The ceramic element is exposed to the air inside

the intake. This air has a cooling effect on the

ceramic element, and its resistance changes. This

causes the voltage flowing through the intake air

temperature circuit to vary. The voltage signal pro-

duced by the Intake Air Temperature Sensor changes

inversely to the temperature, and is measured by the

PCM. As a general rule, when the temperature of the

air in the intake is high, the voltage signal produced

by the Intake Air Temperature Sensor is low. The

component of the Boost Pressure Sensor that mea-

sures manifold vacuum and turbo boost produces a

voltage signal that is proportional to the pressure in

the inake manifold. When the intake manifold pres-

sure is low, the voltage is low, and when the pressure

is high, the voltage is high. The PCM uses the volt-

age signals from the Boost Pressure Sensor, and the

Intake Air Temperature Sensor to determine the

amount of air flowing through the intake manifold.

VEHICLE THEFT ALARM

The PCM can learn if the vehicle has a Vehicle

Theft Alarm (VTA) system. Once it detects the vehi-

cle having VTA,the controller can ONLY BE

USED ON VEHICLES WITH VTA.If the PCM is put it on a vehicle without VTA the

Glow Plug Lamp will start to blink and the vehicle

will not start.

The PCM cannot be flashed to remove the VTA.

BATTERY VOLTAGEÐPCM INPUT

The battery voltage input provides power to the

PCM. It also informs the PCM what voltage level is

being supplied by the generator once the vehicle is

running.

The battery input also provides the voltage that is

needed to keep the PCM memory alive. The memory

stores Diagnostic Trouble Code (DTC) messages.

Trouble codes will still be stored even if the battary

voltage is lost.

SENSOR RETURNÐPCM INPUT (ANALOG

GROUND)

Sensor Return provides a low noise Analog ground

reference for all system sensors.

SIGNAL GROUNDÐPCM INPUT

Signal ground provides a low noise ground to the

data link connector.

IGNITION CIRCUIT SENSEÐPCM INPUT

The ignition circuit sense input signals the PCM

that the ignition (key) switch has been turned to the

ON position. This signal initiates the glow plug con-

trol routine to begin the ªpre±heatº cycle.

START SIGNALÐPCM INPUT

This input tells the PCM that the engine starter is

being operated. This in turn will start the glow plug

ªpost±heatº cycle.

POWER GROUND

Provides a common ground for power devices (sole-

noid and relay devices).

NEEDLE MOVEMENT OR INSTRUMENTED FIRST

INJECTORÐPCM INPUT

This input from the PCM supplies a constant 30

mA electrical current source for the first injector sen-

sor. It will vary the voltage to this sensor when it

senses a mechanical movement within the injector

needle (pintle) of the number±1 cylinder fuel injector.

When this voltage has been determined by the PCM,

it will then control an output to the fuel timing sole-

noid (the fuel timing solenoid is located on the fuel

injection pump). Also refer to Fuel Injection Pump for

additional information.

The first injector sensor is a magnetic (inductive)

type.

Fig. 2 Boost Pressure Sensor Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 45

DESCRIPTION AND OPERATION (Continued)

Page 1414 of 1938

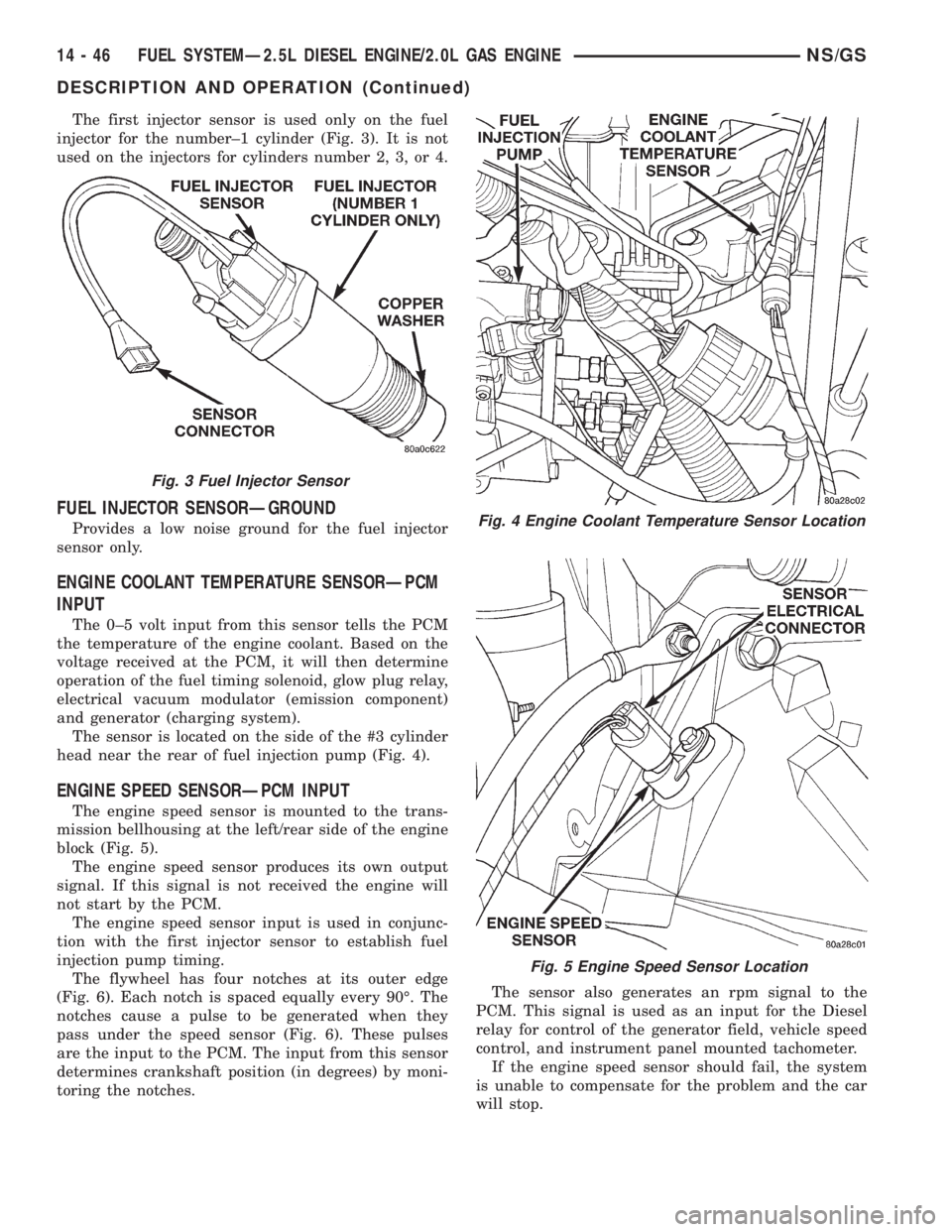

The first injector sensor is used only on the fuel

injector for the number±1 cylinder (Fig. 3). It is not

used on the injectors for cylinders number 2, 3, or 4.

FUEL INJECTOR SENSORÐGROUND

Provides a low noise ground for the fuel injector

sensor only.

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The 0±5 volt input from this sensor tells the PCM

the temperature of the engine coolant. Based on the

voltage received at the PCM, it will then determine

operation of the fuel timing solenoid, glow plug relay,

electrical vacuum modulator (emission component)

and generator (charging system).

The sensor is located on the side of the #3 cylinder

head near the rear of fuel injection pump (Fig. 4).

ENGINE SPEED SENSORÐPCM INPUT

The engine speed sensor is mounted to the trans-

mission bellhousing at the left/rear side of the engine

block (Fig. 5).

The engine speed sensor produces its own output

signal. If this signal is not received the engine will

not start by the PCM.

The engine speed sensor input is used in conjunc-

tion with the first injector sensor to establish fuel

injection pump timing.

The flywheel has four notches at its outer edge

(Fig. 6). Each notch is spaced equally every 90É. The

notches cause a pulse to be generated when they

pass under the speed sensor (Fig. 6). These pulses

are the input to the PCM. The input from this sensor

determines crankshaft position (in degrees) by moni-

toring the notches.The sensor also generates an rpm signal to the

PCM. This signal is used as an input for the Diesel

relay for control of the generator field, vehicle speed

control, and instrument panel mounted tachometer.

If the engine speed sensor should fail, the system

is unable to compensate for the problem and the car

will stop.

Fig. 3 Fuel Injector Sensor

Fig. 4 Engine Coolant Temperature Sensor Location

Fig. 5 Engine Speed Sensor Location

14 - 46 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1416 of 1938

The speed sensor generates 8 pulses per sensor

revolution. These signals, in conjunction with a

closed throttle signal from the throttle position sen-

sor, indicate a closed throttle deceleration to the

PCM. When the vehicle is stopped at idle, a closed

throttle signal is received by the PCM (but a speed

sensor signal is not received).

In addition to determining distance and vehicle

speed, the output from the sensor is used to control

speed control operation.

SPEED CONTROLÐPCM INPUTS

The speed control system provides five separate

inputs to the PCM; On/Off, Set, Resume/Accel, Cancel,

and Decel.. The On/Off input informs the PCM that

the speed control system has been activated. The Set

input informs the PCM that a fixed vehicle speed has

been selected. The Resume input indicates to the PCM

that the previous fixed speed is requested.

Speed control operation will start at 50 km/h±142

km/h (35±85 mph). The upper range of operation is

not restricted by vehicle speed. Inputs that affect

speed control operation are vehicle speed sensor and

throttle position sensor.

Refer to Group 8H for further speed control infor-

mation.

DIESEL PCM RELAYÐPCM INPUT

A 12 volt signal at this input indicates to the PCM

that the Diesel relay has been activated. The Diesel

relay is located in the PDC. The PDC is located next

to the battery in the engine compartment. For the

location of the relay within the PDC, refer to label on

PDC cover.

This input is used only to sense that the Diesel

relay is energized. If the PCM does not see 12 volts +

at this input when the Diesel relay should be acti-

vated, it will set a Diagnostic Trouble Code (DTC).

FIVE VOLT POWERÐPCM OUTPUT

This circuit supplies approximately 5 volts to

power the Accelerator Pedal Postion Sensor, Mass Air

Flow Sensor, and A/C Pressure Sensor.

ENGINE COOLANT GAUGEÐPCM OUTPUT

Refer to the Instrument Panel and Gauges group

for additional information.

ENGINE OIL PRESSURE GAUGEÐPCM OUTPUT

Refer to the Instrument Panel and Gauges group

for additional information.

GLOW PLUG LAMPÐPCM OUTPUT

The Glow Plug lamp (malfunction indicator lamp)

illuminates on the message center each time the igni-

tion (key) switch is turned on. It will stay on for

about two seconds as a bulb test.If the PCM receives an incorrect signal, or no sig-

nal from certain sensors or components, the lamp

BLINKS. This is a warning that the PCM has

recorded a system or sensor malfunction. It signals

an immediate need for service. There are only 5

HARD faults that can turn on this lamp to make it

blink.

SPEED CONTROLÐPCM OUTPUTS

These two circuits control the fuel quantity actua-

tor to regulate vehicle speed. Refer to Group 8H for

Speed Control information.

AIR CONDITIONING RELAYÐPCM OUTPUT

This circuit controls a ground signal for operation

of the A/C clutch relay. Also refer to Air Conditioning

(A/C) ControlsÐPCM Input for additional informa-

tion.

The A/C relay is located in the Power Distribution

Center (PDC). The PDC is located next to the battery

in the engine compartment. For the location of the

relay within the PDC, refer to label on PDC cover.

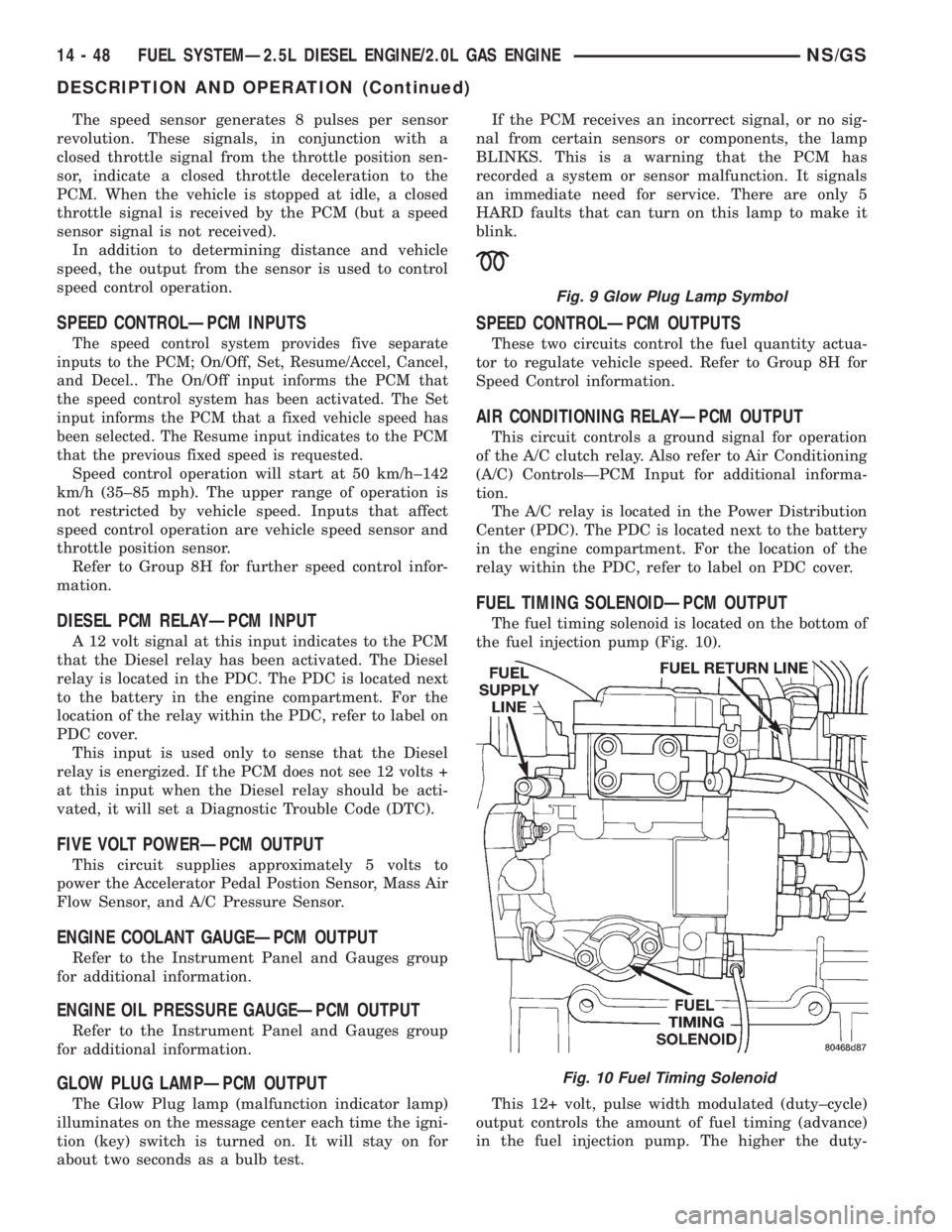

FUEL TIMING SOLENOIDÐPCM OUTPUT

The fuel timing solenoid is located on the bottom of

the fuel injection pump (Fig. 10).

This 12+ volt, pulse width modulated (duty±cycle)

output controls the amount of fuel timing (advance)

in the fuel injection pump. The higher the duty-

Fig. 9 Glow Plug Lamp Symbol

Fig. 10 Fuel Timing Solenoid

14 - 48 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1418 of 1938

the current draw will drop to approximately 9±12

amps per plug.

Total momentary current draw for all four plugs is

approximately 100 amps on a cold engine dropping to

a total of approximately 40 amps after the plugs are

heated.

Electrical operation of the glow plugs are con-

trolled by the glow plug relay. Refer to the previous

Glow Plug RelayÐPCM Output for additional infor-

mation.

EXHAUST GAS RECIRCULATION (EGR)

SOLENOIDÐPCM OUTPUT

This circuit controls operation of the Exhaust Gas

Recirculation (EGR) solenoid. The EGR solenoid (Fig.

11) controls operation of the EGR valve.

Refer to Group 25, Emission Control System for

information. See EGR solenoid.

DIAGNOSIS AND TESTING

DIESEL DIAGONSTICS

The PCM controller does engine off diagonstics

tests, which may be heard for about 60 seconds after

turning the key off.

DIESEL PCM RELAY TEST

To perform a test of the relay and its related cir-

cuitry, refer to the DRB scan tool. To test the relay

only, refer to RelaysÐOperation/Testing in this sec-

tion of the group.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

ENGINE SPEED SENSOR TEST

To perform a test of the engine speed sensor and

its related circuitry, refer to the DRB scan tool.

Diagnostic Trouble Codes:Refer to On-Board

Diagnostics in Group 25, Emission Control System

for a list of Diagnostic Trouble Codes (DTC's) for cer-

tain fuel system components.

ENGINE COOLANT TEMPERATURE SENSOR TEST

The sensor is located on the side of cylinder head

near the rear of fuel injection pump (Fig. 13).

For a list of Diagnostic Trouble Codes (DTC's) for

certain fuel system components, refer to On-Board

Diagnostics in Group 25, Emission Control System.

To test the sensor only, refer to the following:

(1) Disconnect wire harness connector from coolant

temperature sensor.

(2) Test the resistance of the sensor with a high

input impedance (digital) volt±ohmmeter. The resis-

tance (as measured across the sensor terminals)should be less than 1340 ohms with the engine

warm. Refer to the following Sensor Resistance

(OHMS) chart. Replace the sensor if it is not within

the range of resistance specified in the chart.

(3) Test continuity of the wire harness. Do this

between the PCM wire harness connector and the

sensor connector terminal. Also test continuity of

wire harness to the sensor connector terminal. Refer

Fig. 13 Engine Coolant Temperature Sensor

Location

SENSOR RESISTANCE (OHMS)

14 - 50 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)