wheel bolt torque CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1457 of 1938

CAUTION: Proper torque on the cradle plate to

suspension cradle mounting bolts is very impor-

tant.

(8) Install cradle plate on front suspension cradle

and install the 10 cradle plate to cradle attaching

bolts and nuts (Fig. 8). Tighten all attaching bolts to

a torque of 165 N´m (123 ft. lbs.).

(9) Install the bracket (Fig. 9) attaching the power

steering fluid tubes to the front suspension cradle.

CAUTION:

(10) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig. 4).

(11) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamp is installed on return tube past the upset

bead on the tube.Tighten the screw clamp to a

torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 4). This is required

to prevent the power steering hoses from being

overheated.

(12) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(13) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N´m (95 ft. lbs.).

(14) Lower the vehicle to a level were the interior

of vehicle is accessible.

(15) Using the intermediate coupler, turn the front

wheels of the vehicle to the left until the intermedi-

ate coupler shaft is properly aligned with the steer-

ing column coupler. Assemble the steering column

shaft coupler (Fig. 3) onto the steering gear interme-

diate coupler. Install steering column coupler to

intermediate shaft retaining pinch bolt (Fig. 3).

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

CAUTION: Do not use automatic transmission fluid

in the power steering system. Only use Mopar,

Power Steering Fluid or an exact equivalent prod-

uct.

(16) Fill power steering pump fluid reservoir to the

proper level.

(17) Start the engine and let run for a few seconds.

Then turn the engine off.(18) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(19) Raise front wheels of vehicle off the ground.

(20) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(21) Add power steering fluid if necessary.

(22) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(23) Stop the engine. Check the fluid level and

refill as required.

(24) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(25) Fill power steering reservoir to correct level

with Mopart, Power Steering Fluid, or equivalent.

(26) Adjust toe (Refer to Group 2 Suspension).

DISASSEMBLY AND ASSEMBLY

STEERING GEAR INNER TIE ROD BOOT

DISASSEMBLE

NOTE: The removal and installation of the inner tie

rod boot must be performed with the steering gear

assembly removed from the vehicle.

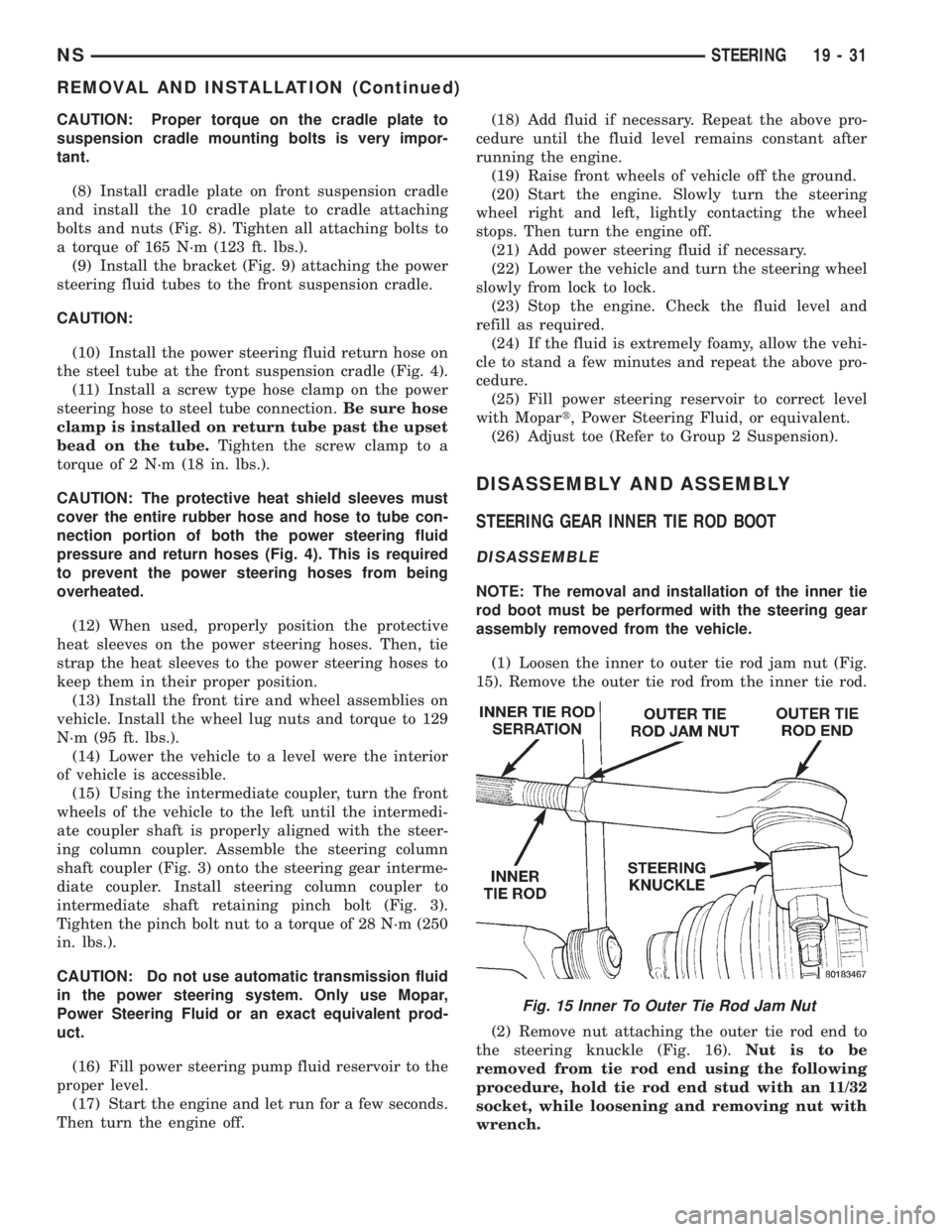

(1) Loosen the inner to outer tie rod jam nut (Fig.

15). Remove the outer tie rod from the inner tie rod.

(2) Remove nut attaching the outer tie rod end to

the steering knuckle (Fig. 16).Nut is to be

removed from tie rod end using the following

procedure, hold tie rod end stud with an 11/32

socket, while loosening and removing nut with

wrench.

Fig. 15 Inner To Outer Tie Rod Jam Nut

NSSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)

Page 1460 of 1938

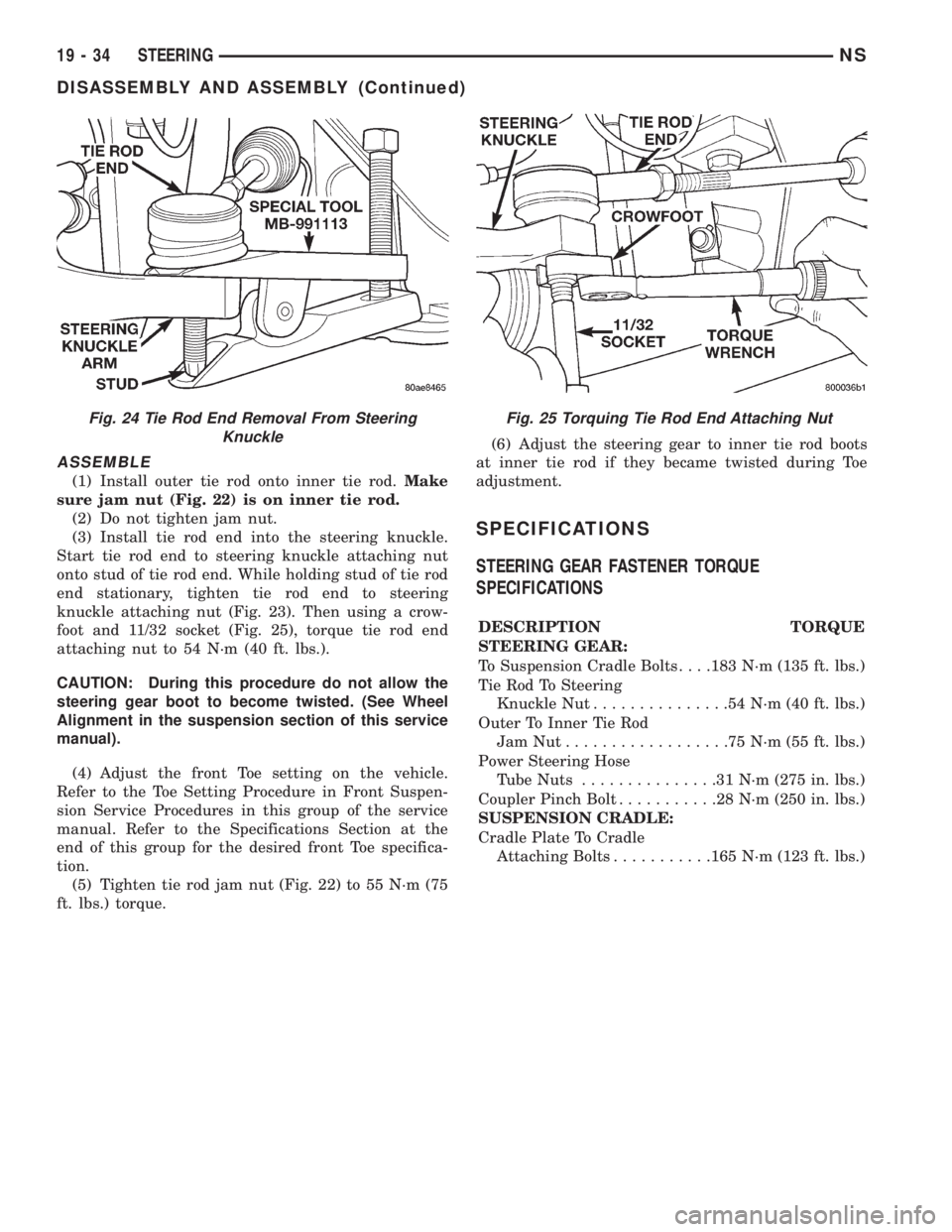

ASSEMBLE

(1) Install outer tie rod onto inner tie rod.Make

sure jam nut (Fig. 22) is on inner tie rod.

(2) Do not tighten jam nut.

(3) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 23). Then using a crow-

foot and 11/32 socket (Fig. 25), torque tie rod end

attaching nut to 54 N´m (40 ft. lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(4) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

(5) Tighten tie rod jam nut (Fig. 22) to 55 N´m (75

ft. lbs.) torque.(6) Adjust the steering gear to inner tie rod boots

at inner tie rod if they became twisted during Toe

adjustment.

SPECIFICATIONS

STEERING GEAR FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STEERING GEAR:

To Suspension Cradle Bolts. . . .183 N´m (135 ft. lbs.)

Tie Rod To Steering

Knuckle Nut...............54N´m(40ft.lbs.)

Outer To Inner Tie Rod

JamNut..................75N´m(55ft.lbs.)

Power Steering Hose

Tube Nuts...............31N´m(275 in. lbs.)

Coupler Pinch Bolt...........28N´m(250 in. lbs.)

SUSPENSION CRADLE:

Cradle Plate To Cradle

Attaching Bolts...........165 N´m (123 ft. lbs.)

Fig. 24 Tie Rod End Removal From Steering

KnuckleFig. 25 Torquing Tie Rod End Attaching Nut

19 - 34 STEERINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1471 of 1938

(23) Install the 3 bolts (1 in each spoke of the

steering wheel) attaching the air bag module to the

steering wheel. Tighten the 3 air bag module attach-

ing nuts to a torque of 11 N´m (100 in. lbs.).

(24) Install the steering column cover liner (Fig. 4)

on the lower instrument panel. Install and securely

tighten the 10 bolts (Fig. 4) attaching the steering

column cover liner to the instrument panel.

(25) Install the park brake pedal release cable on

the park brake release lever in the lower steering col-

umn cover (Fig. 3).

(26) Install the lower steering column trim panel

on the lower instrument panel. Install and securely

the screws attaching the lower steering column cover

to the instrument panel (Fig. 2).

(27) Connect negative (ground) cable on the bat-

tery terminal.SPECIFICATIONS

STEERING COLUMN FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STEERING WHEEL:

Retaining Nut...............61N´m(45ft.lbs.)

STEERING COLUMN ASSEMBLY:

Mounting Bracket

Attaching Nuts............12N´m(105 in. lbs.)

Flex Coupler Pinch Bolt.......27N´m(240 in. lbs.)

Airbag Module Attaching Nuts . .11 N´m (100 in. lbs.)

NSSTEERING 19 - 45

REMOVAL AND INSTALLATION (Continued)

Page 1494 of 1938

(5) Continuity should exist only with transaxle in

Reverse position.

(6) No continuity should exist from either pin to

the case.

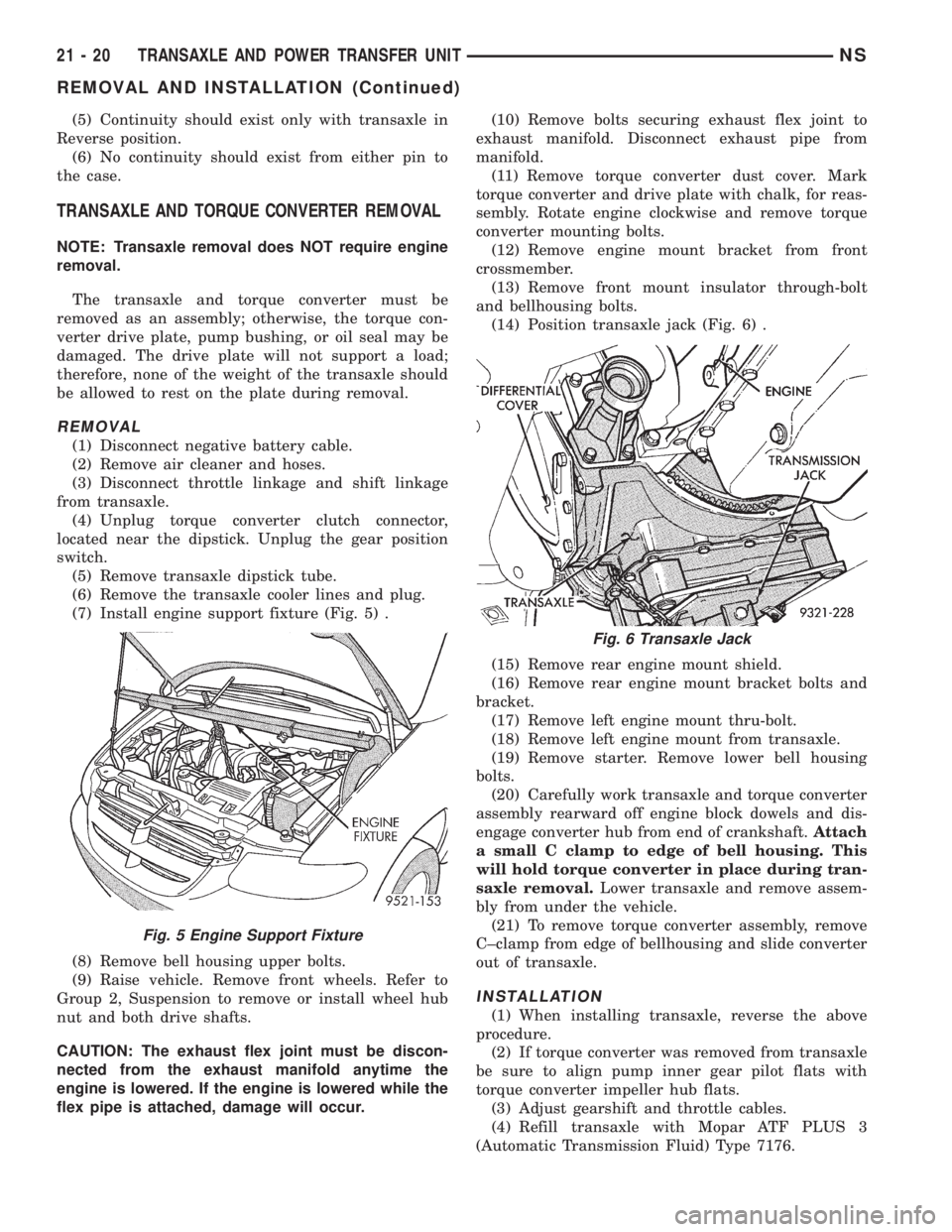

TRANSAXLE AND TORQUE CONVERTER REMOVAL

NOTE: Transaxle removal does NOT require engine

removal.

The transaxle and torque converter must be

removed as an assembly; otherwise, the torque con-

verter drive plate, pump bushing, or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the plate during removal.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner and hoses.

(3) Disconnect throttle linkage and shift linkage

from transaxle.

(4) Unplug torque converter clutch connector,

located near the dipstick. Unplug the gear position

switch.

(5) Remove transaxle dipstick tube.

(6) Remove the transaxle cooler lines and plug.

(7) Install engine support fixture (Fig. 5) .

(8) Remove bell housing upper bolts.

(9) Raise vehicle. Remove front wheels. Refer to

Group 2, Suspension to remove or install wheel hub

nut and both drive shafts.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.(10) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(11) Remove torque converter dust cover. Mark

torque converter and drive plate with chalk, for reas-

sembly. Rotate engine clockwise and remove torque

converter mounting bolts.

(12) Remove engine mount bracket from front

crossmember.

(13) Remove front mount insulator through-bolt

and bellhousing bolts.

(14) Position transaxle jack (Fig. 6) .

(15) Remove rear engine mount shield.

(16) Remove rear engine mount bracket bolts and

bracket.

(17) Remove left engine mount thru-bolt.

(18) Remove left engine mount from transaxle.

(19) Remove starter. Remove lower bell housing

bolts.

(20) Carefully work transaxle and torque converter

assembly rearward off engine block dowels and dis-

engage converter hub from end of crankshaft.Attach

a small C clamp to edge of bell housing. This

will hold torque converter in place during tran-

saxle removal.Lower transaxle and remove assem-

bly from under the vehicle.

(21) To remove torque converter assembly, remove

C±clamp from edge of bellhousing and slide converter

out of transaxle.

INSTALLATION

(1) When installing transaxle, reverse the above

procedure.

(2) If torque converter was removed from transaxle

be sure to align pump inner gear pilot flats with

torque converter impeller hub flats.

(3) Adjust gearshift and throttle cables.

(4) Refill transaxle with Mopar ATF PLUS 3

(Automatic Transmission Fluid) Type 7176.

Fig. 5 Engine Support Fixture

Fig. 6 Transaxle Jack

21 - 20 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1564 of 1938

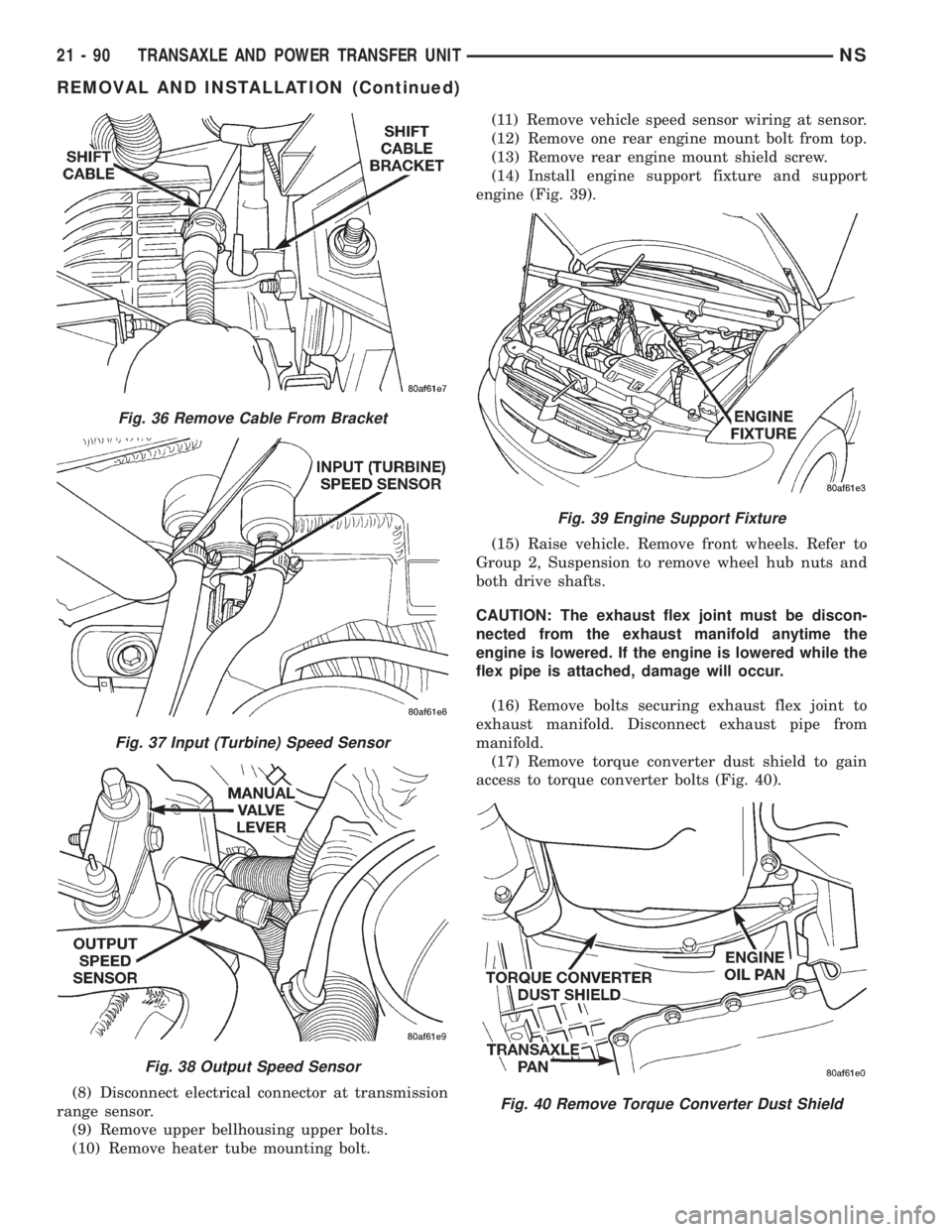

(8) Disconnect electrical connector at transmission

range sensor.

(9) Remove upper bellhousing upper bolts.

(10) Remove heater tube mounting bolt.(11) Remove vehicle speed sensor wiring at sensor.

(12) Remove one rear engine mount bolt from top.

(13) Remove rear engine mount shield screw.

(14) Install engine support fixture and support

engine (Fig. 39).

(15) Raise vehicle. Remove front wheels. Refer to

Group 2, Suspension to remove wheel hub nuts and

both drive shafts.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.

(16) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(17) Remove torque converter dust shield to gain

access to torque converter bolts (Fig. 40).

Fig. 36 Remove Cable From Bracket

Fig. 37 Input (Turbine) Speed Sensor

Fig. 38 Output Speed Sensor

Fig. 39 Engine Support Fixture

Fig. 40 Remove Torque Converter Dust Shield

21 - 90 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1775 of 1938

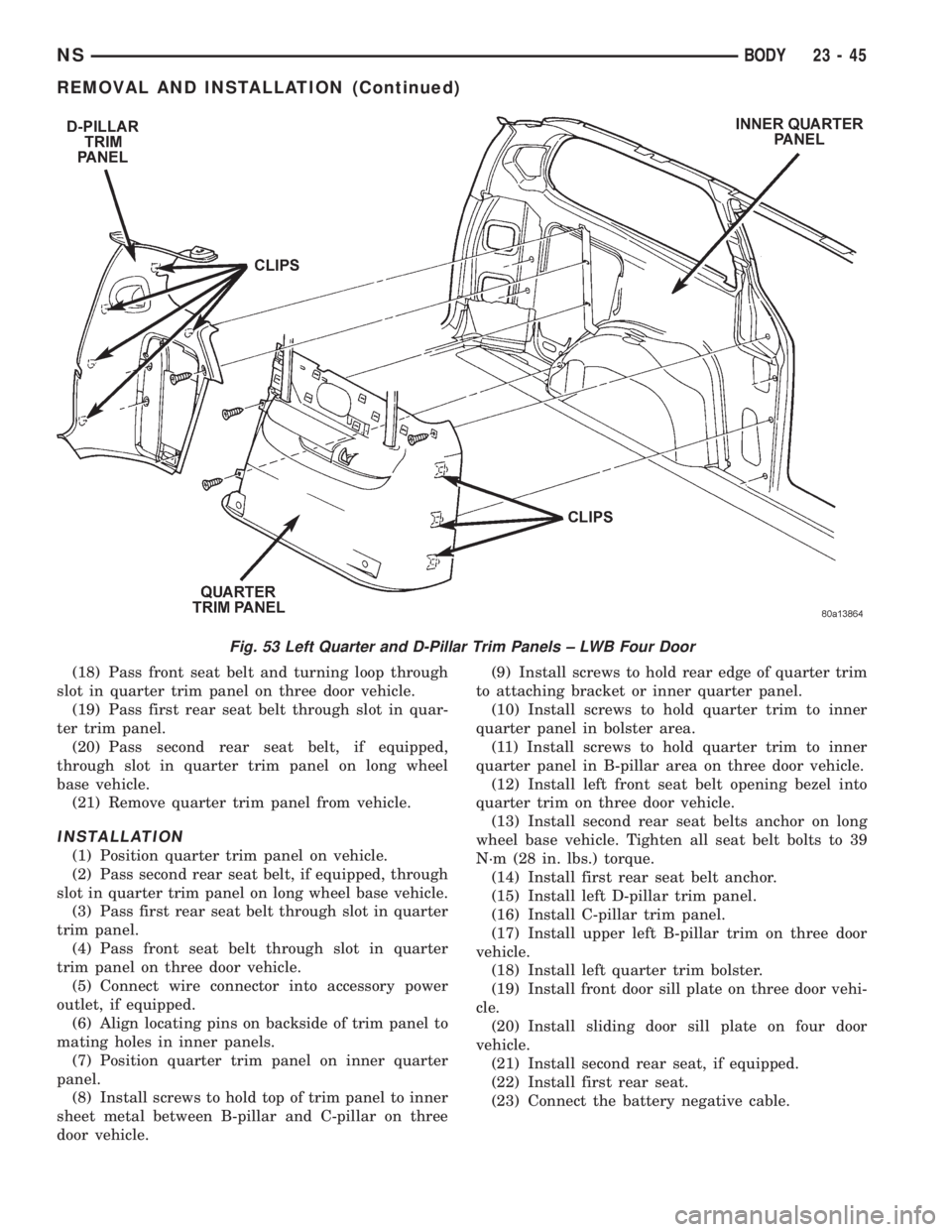

(18) Pass front seat belt and turning loop through

slot in quarter trim panel on three door vehicle.

(19) Pass first rear seat belt through slot in quar-

ter trim panel.

(20) Pass second rear seat belt, if equipped,

through slot in quarter trim panel on long wheel

base vehicle.

(21) Remove quarter trim panel from vehicle.

INSTALLATION

(1) Position quarter trim panel on vehicle.

(2) Pass second rear seat belt, if equipped, through

slot in quarter trim panel on long wheel base vehicle.

(3) Pass first rear seat belt through slot in quarter

trim panel.

(4) Pass front seat belt through slot in quarter

trim panel on three door vehicle.

(5) Connect wire connector into accessory power

outlet, if equipped.

(6) Align locating pins on backside of trim panel to

mating holes in inner panels.

(7) Position quarter trim panel on inner quarter

panel.

(8) Install screws to hold top of trim panel to inner

sheet metal between B-pillar and C-pillar on three

door vehicle.(9) Install screws to hold rear edge of quarter trim

to attaching bracket or inner quarter panel.

(10) Install screws to hold quarter trim to inner

quarter panel in bolster area.

(11) Install screws to hold quarter trim to inner

quarter panel in B-pillar area on three door vehicle.

(12) Install left front seat belt opening bezel into

quarter trim on three door vehicle.

(13) Install second rear seat belts anchor on long

wheel base vehicle. Tighten all seat belt bolts to 39

N´m (28 in. lbs.) torque.

(14) Install first rear seat belt anchor.

(15) Install left D-pillar trim panel.

(16) Install C-pillar trim panel.

(17) Install upper left B-pillar trim on three door

vehicle.

(18) Install left quarter trim bolster.

(19) Install front door sill plate on three door vehi-

cle.

(20) Install sliding door sill plate on four door

vehicle.

(21) Install second rear seat, if equipped.

(22) Install first rear seat.

(23) Connect the battery negative cable.

Fig. 53 Left Quarter and D-Pillar Trim Panels ± LWB Four Door

NSBODY 23 - 45

REMOVAL AND INSTALLATION (Continued)

Page 1785 of 1938

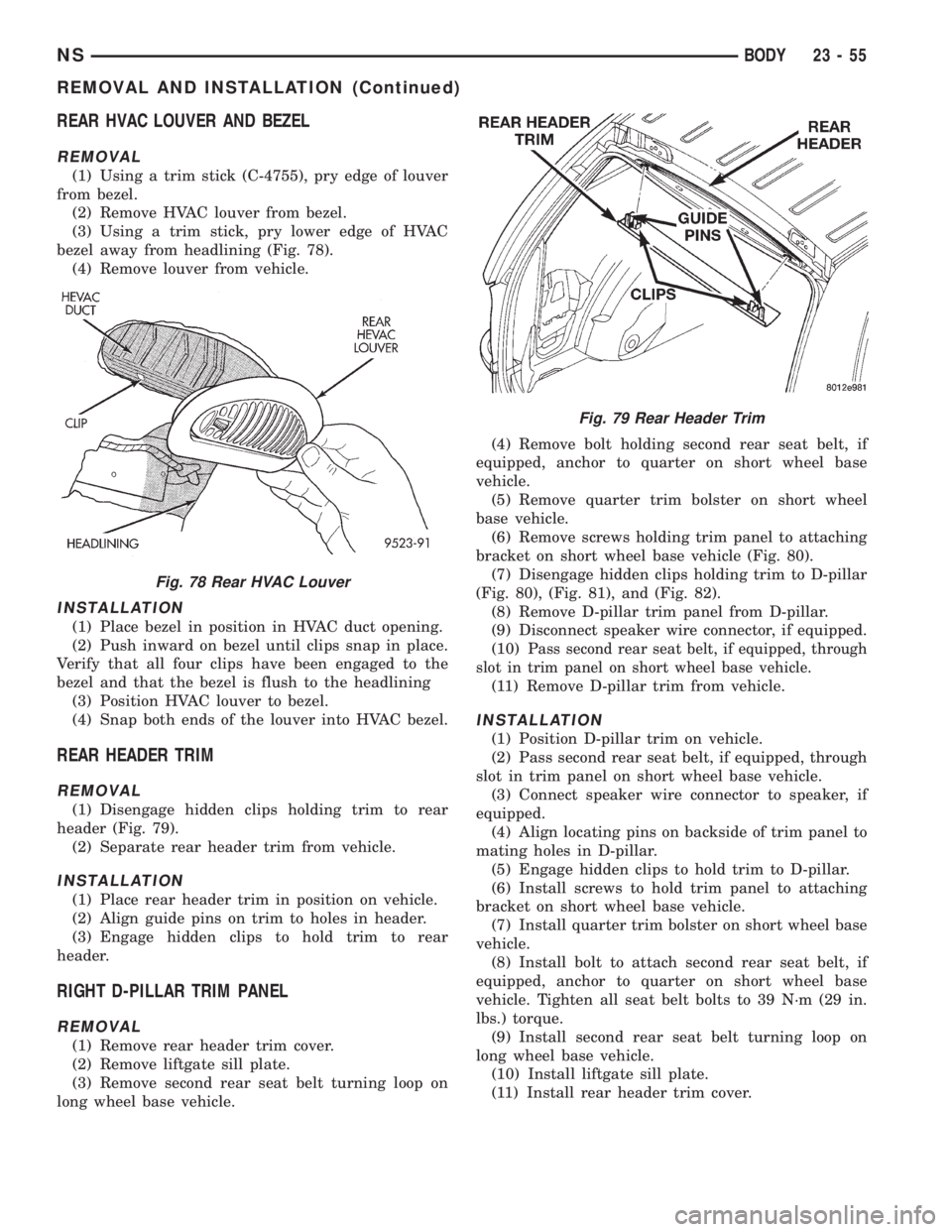

REAR HVAC LOUVER AND BEZEL

REMOVAL

(1) Using a trim stick (C-4755), pry edge of louver

from bezel.

(2) Remove HVAC louver from bezel.

(3) Using a trim stick, pry lower edge of HVAC

bezel away from headlining (Fig. 78).

(4) Remove louver from vehicle.

INSTALLATION

(1) Place bezel in position in HVAC duct opening.

(2) Push inward on bezel until clips snap in place.

Verify that all four clips have been engaged to the

bezel and that the bezel is flush to the headlining

(3) Position HVAC louver to bezel.

(4) Snap both ends of the louver into HVAC bezel.

REAR HEADER TRIM

REMOVAL

(1) Disengage hidden clips holding trim to rear

header (Fig. 79).

(2) Separate rear header trim from vehicle.

INSTALLATION

(1) Place rear header trim in position on vehicle.

(2) Align guide pins on trim to holes in header.

(3) Engage hidden clips to hold trim to rear

header.

RIGHT D-PILLAR TRIM PANEL

REMOVAL

(1) Remove rear header trim cover.

(2) Remove liftgate sill plate.

(3) Remove second rear seat belt turning loop on

long wheel base vehicle.(4) Remove bolt holding second rear seat belt, if

equipped, anchor to quarter on short wheel base

vehicle.

(5) Remove quarter trim bolster on short wheel

base vehicle.

(6) Remove screws holding trim panel to attaching

bracket on short wheel base vehicle (Fig. 80).

(7) Disengage hidden clips holding trim to D-pillar

(Fig. 80), (Fig. 81), and (Fig. 82).

(8) Remove D-pillar trim panel from D-pillar.

(9) Disconnect speaker wire connector, if equipped.

(10) P

ass second rear seat belt, if equipped, through

slot in trim panel on short wheel base vehicle.

(11) Remove D-pillar trim from vehicle.

INSTALLATION

(1) Position D-pillar trim on vehicle.

(2) Pass second rear seat belt, if equipped, through

slot in trim panel on short wheel base vehicle.

(3) Connect speaker wire connector to speaker, if

equipped.

(4) Align locating pins on backside of trim panel to

mating holes in D-pillar.

(5) Engage hidden clips to hold trim to D-pillar.

(6) Install screws to hold trim panel to attaching

bracket on short wheel base vehicle.

(7) Install quarter trim bolster on short wheel base

vehicle.

(8) Install bolt to attach second rear seat belt, if

equipped, anchor to quarter on short wheel base

vehicle. Tighten all seat belt bolts to 39 N´m (29 in.

lbs.) torque.

(9) Install second rear seat belt turning loop on

long wheel base vehicle.

(10) Install liftgate sill plate.

(11) Install rear header trim cover.

Fig. 78 Rear HVAC Louver

Fig. 79 Rear Header Trim

NSBODY 23 - 55

REMOVAL AND INSTALLATION (Continued)

Page 1786 of 1938

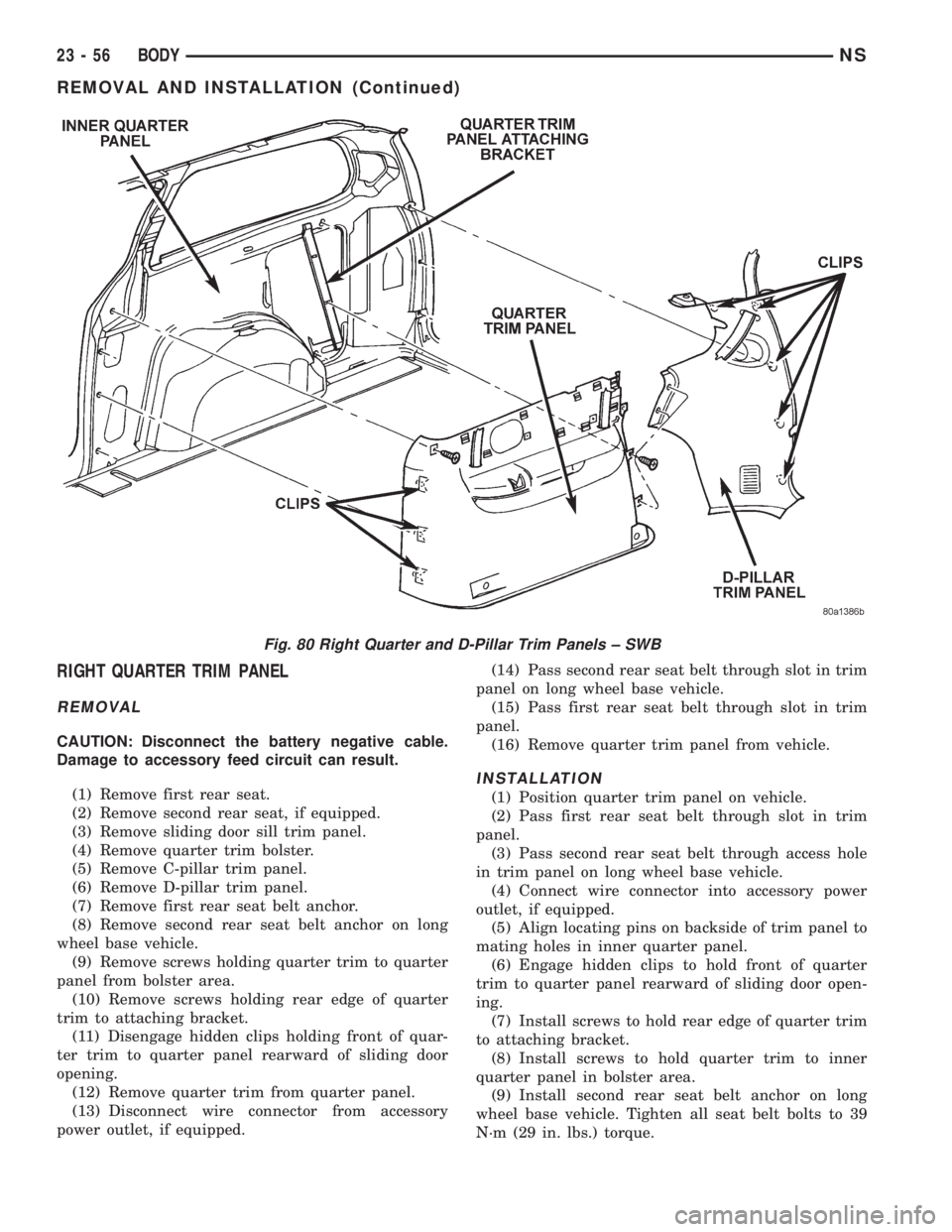

RIGHT QUARTER TRIM PANEL

REMOVAL

CAUTION: Disconnect the battery negative cable.

Damage to accessory feed circuit can result.

(1) Remove first rear seat.

(2) Remove second rear seat, if equipped.

(3) Remove sliding door sill trim panel.

(4) Remove quarter trim bolster.

(5) Remove C-pillar trim panel.

(6) Remove D-pillar trim panel.

(7) Remove first rear seat belt anchor.

(8) Remove second rear seat belt anchor on long

wheel base vehicle.

(9) Remove screws holding quarter trim to quarter

panel from bolster area.

(10) Remove screws holding rear edge of quarter

trim to attaching bracket.

(11) Disengage hidden clips holding front of quar-

ter trim to quarter panel rearward of sliding door

opening.

(12) Remove quarter trim from quarter panel.

(13) Disconnect wire connector from accessory

power outlet, if equipped.(14) Pass second rear seat belt through slot in trim

panel on long wheel base vehicle.

(15) Pass first rear seat belt through slot in trim

panel.

(16) Remove quarter trim panel from vehicle.

INSTALLATION

(1) Position quarter trim panel on vehicle.

(2) Pass first rear seat belt through slot in trim

panel.

(3) Pass second rear seat belt through access hole

in trim panel on long wheel base vehicle.

(4) Connect wire connector into accessory power

outlet, if equipped.

(5) Align locating pins on backside of trim panel to

mating holes in inner quarter panel.

(6) Engage hidden clips to hold front of quarter

trim to quarter panel rearward of sliding door open-

ing.

(7) Install screws to hold rear edge of quarter trim

to attaching bracket.

(8) Install screws to hold quarter trim to inner

quarter panel in bolster area.

(9) Install second rear seat belt anchor on long

wheel base vehicle. Tighten all seat belt bolts to 39

N´m (29 in. lbs.) torque.

Fig. 80 Right Quarter and D-Pillar Trim Panels ± SWB

23 - 56 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1791 of 1938

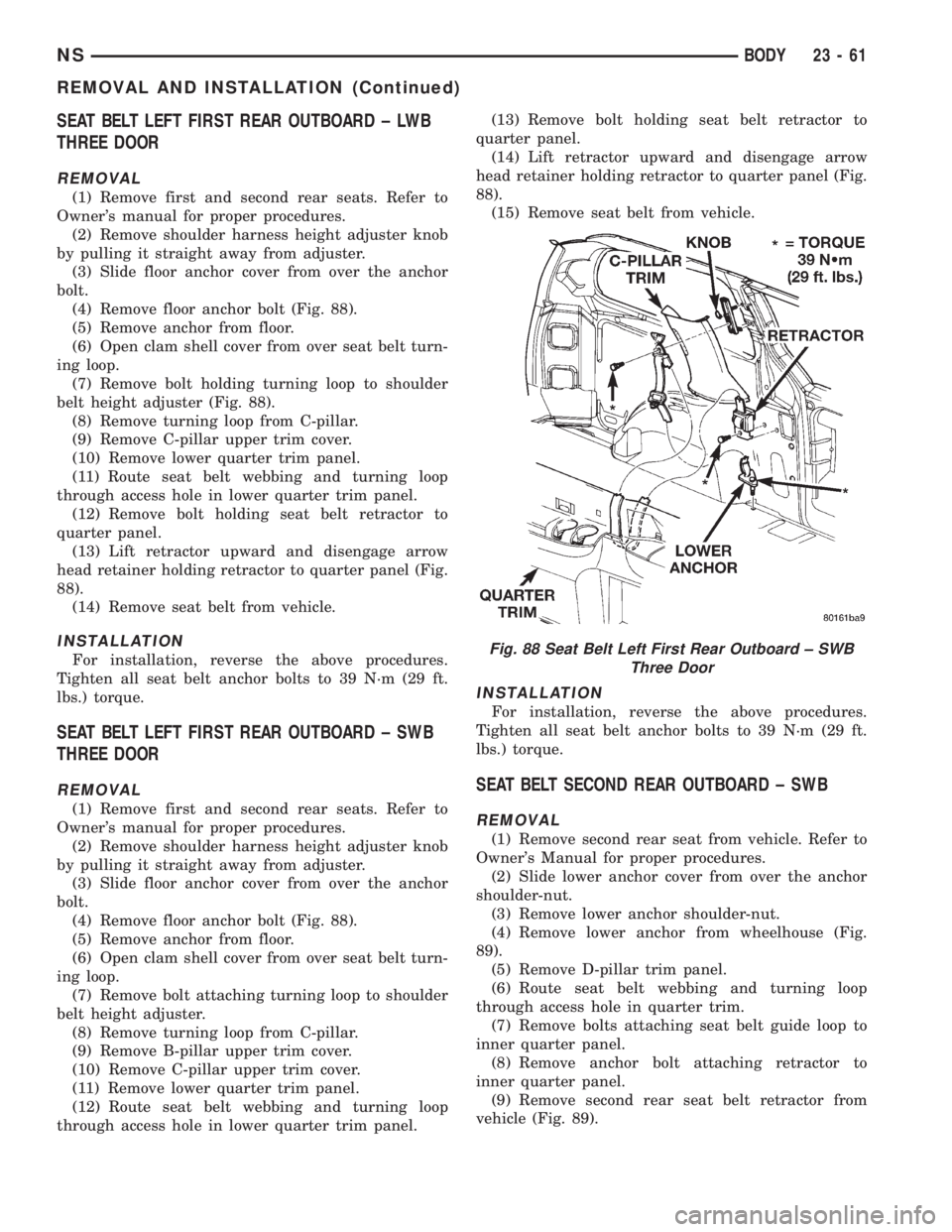

SEAT BELT LEFT FIRST REAR OUTBOARD ± LWB

THREE DOOR

REMOVAL

(1) Remove first and second rear seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 88).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt holding turning loop to shoulder

belt height adjuster (Fig. 88).

(8) Remove turning loop from C-pillar.

(9) Remove C-pillar upper trim cover.

(10) Remove lower quarter trim panel.

(11) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(12) Remove bolt holding seat belt retractor to

quarter panel.

(13) Lift retractor upward and disengage arrow

head retainer holding retractor to quarter panel (Fig.

88).

(14) Remove seat belt from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Tighten all seat belt anchor bolts to 39 N´m (29 ft.

lbs.) torque.

SEAT BELT LEFT FIRST REAR OUTBOARD ± SWB

THREE DOOR

REMOVAL

(1) Remove first and second rear seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 88).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove B-pillar upper trim cover.

(10) Remove C-pillar upper trim cover.

(11) Remove lower quarter trim panel.

(12) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.(13) Remove bolt holding seat belt retractor to

quarter panel.

(14) Lift retractor upward and disengage arrow

head retainer holding retractor to quarter panel (Fig.

88).

(15) Remove seat belt from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Tighten all seat belt anchor bolts to 39 N´m (29 ft.

lbs.) torque.

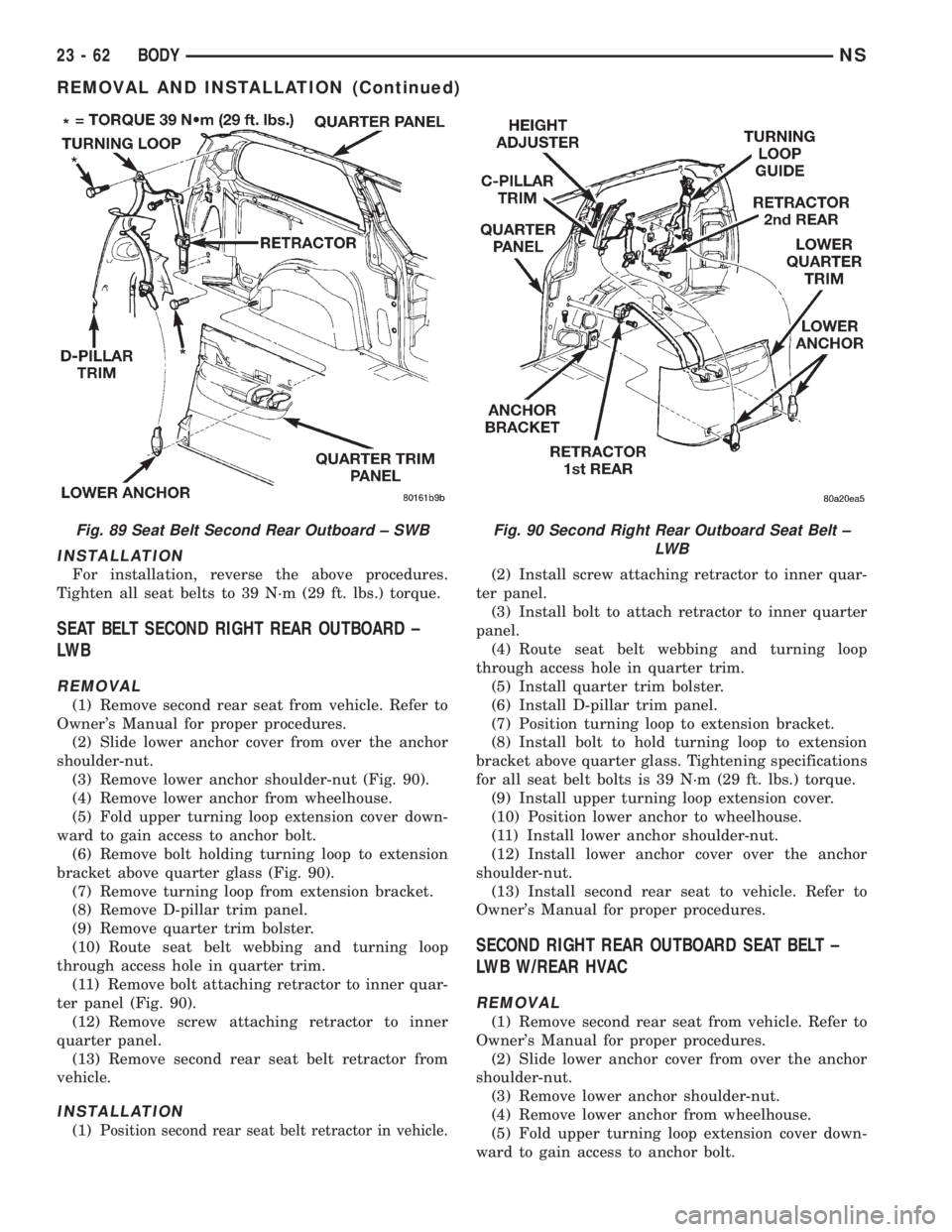

SEAT BELT SECOND REAR OUTBOARD ± SWB

REMOVAL

(1) Remove second rear seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut.

(4) Remove lower anchor from wheelhouse (Fig.

89).

(5) Remove D-pillar trim panel.

(6) Route seat belt webbing and turning loop

through access hole in quarter trim.

(7) Remove bolts attaching seat belt guide loop to

inner quarter panel.

(8) Remove anchor bolt attaching retractor to

inner quarter panel.

(9) Remove second rear seat belt retractor from

vehicle (Fig. 89).

Fig. 88 Seat Belt Left First Rear Outboard ± SWB

Three Door

NSBODY 23 - 61

REMOVAL AND INSTALLATION (Continued)

Page 1792 of 1938

INSTALLATION

For installation, reverse the above procedures.

Tighten all seat belts to 39 N´m (29 ft. lbs.) torque.

SEAT BELT SECOND RIGHT REAR OUTBOARD ±

LW B

REMOVAL

(1) Remove second rear seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut (Fig. 90).

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

(6) Remove bolt holding turning loop to extension

bracket above quarter glass (Fig. 90).

(7) Remove turning loop from extension bracket.

(8) Remove D-pillar trim panel.

(9) Remove quarter trim bolster.

(10) Route seat belt webbing and turning loop

through access hole in quarter trim.

(11) Remove bolt attaching retractor to inner quar-

ter panel (Fig. 90).

(12) Remove screw attaching retractor to inner

quarter panel.

(13) Remove second rear seat belt retractor from

vehicle.

INSTALLATION

(1) Position second rear seat belt retractor in vehicle.

(2) Install screw attaching retractor to inner quar-

ter panel.

(3) Install bolt to attach retractor to inner quarter

panel.

(4) Route seat belt webbing and turning loop

through access hole in quarter trim.

(5) Install quarter trim bolster.

(6) Install D-pillar trim panel.

(7) Position turning loop to extension bracket.

(8) Install bolt to hold turning loop to extension

bracket above quarter glass. Tightening specifications

for all seat belt bolts is 39 N´m (29 ft. lbs.) torque.

(9) Install upper turning loop extension cover.

(10) Position lower anchor to wheelhouse.

(11) Install lower anchor shoulder-nut.

(12) Install lower anchor cover over the anchor

shoulder-nut.

(13) Install second rear seat to vehicle. Refer to

Owner's Manual for proper procedures.

SECOND RIGHT REAR OUTBOARD SEAT BELT ±

LWB W/REAR HVAC

REMOVAL

(1) Remove second rear seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut.

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

Fig. 89 Seat Belt Second Rear Outboard ± SWBFig. 90 Second Right Rear Outboard Seat Belt ±

LW B

23 - 62 BODYNS

REMOVAL AND INSTALLATION (Continued)