Egr CHRYSLER VOYAGER 1996 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1237 of 1938

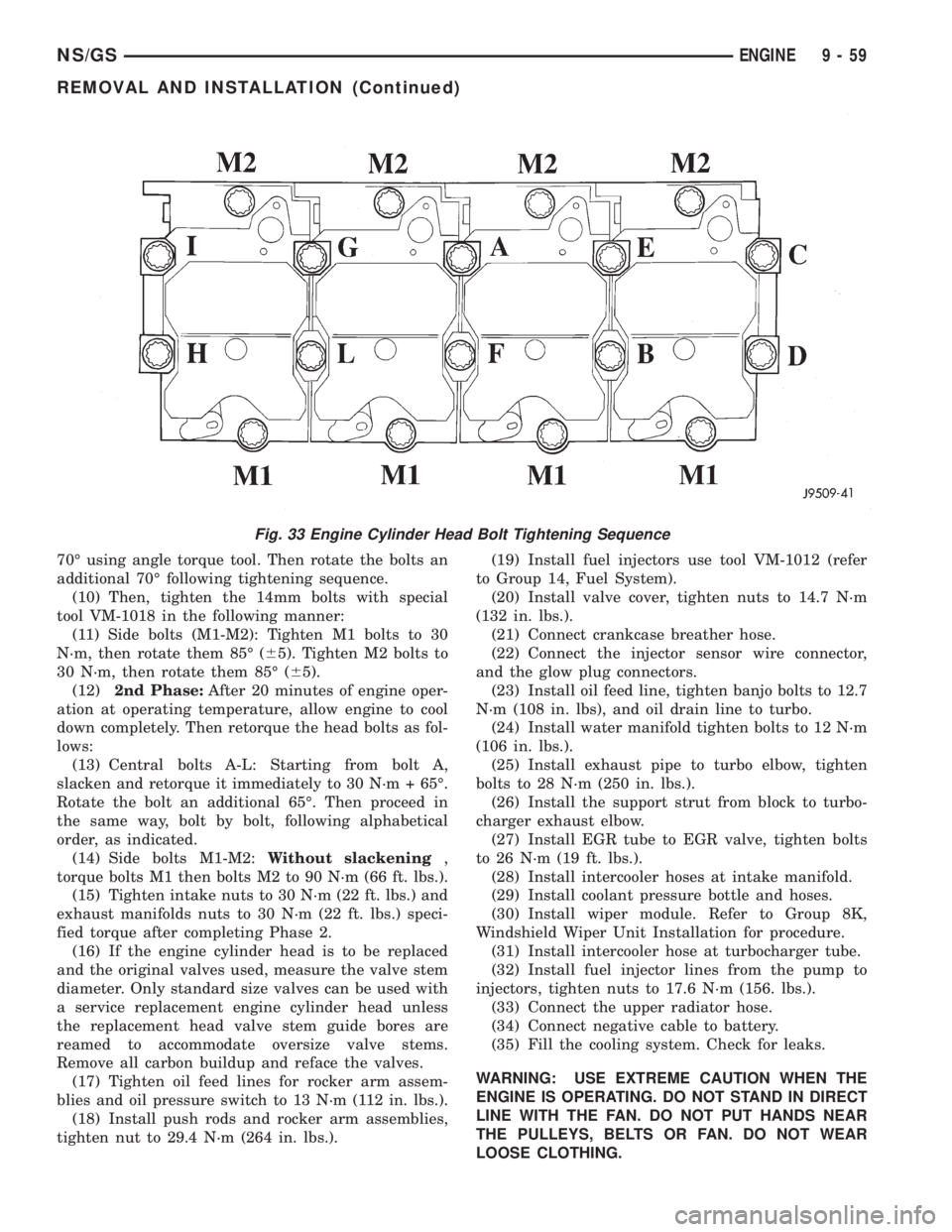

70É using angle torque tool. Then rotate the bolts an

additional 70É following tightening sequence.

(10) Then, tighten the 14mm bolts with special

tool VM-1018 in the following manner:

(11) Side bolts (M1-M2): Tighten M1 bolts to 30

N´m, then rotate them 85É (65). Tighten M2 bolts to

30 N´m, then rotate them 85É (65).

(12)2nd Phase:After 20 minutes of engine oper-

ation at operating temperature, allow engine to cool

down completely. Then retorque the head bolts as fol-

lows:

(13) Central bolts A-L: Starting from bolt A,

slacken and retorque it immediately to 30 N´m + 65É.

Rotate the bolt an additional 65É. Then proceed in

the same way, bolt by bolt, following alphabetical

order, as indicated.

(14) Side bolts M1-M2:Without slackening,

torque bolts M1 then bolts M2 to 90 N´m (66 ft. lbs.).

(15) Tighten intake nuts to 30 N´m (22 ft. lbs.) and

exhaust manifolds nuts to 30 N´m (22 ft. lbs.) speci-

fied torque after completing Phase 2.

(16) If the engine cylinder head is to be replaced

and the original valves used, measure the valve stem

diameter. Only standard size valves can be used with

a service replacement engine cylinder head unless

the replacement head valve stem guide bores are

reamed to accommodate oversize valve stems.

Remove all carbon buildup and reface the valves.

(17) Tighten oil feed lines for rocker arm assem-

blies and oil pressure switch to 13 N´m (112 in. lbs.).

(18) Install push rods and rocker arm assemblies,

tighten nut to 29.4 N´m (264 in. lbs.).(19) Install fuel injectors use tool VM-1012 (refer

to Group 14, Fuel System).

(20) Install valve cover, tighten nuts to 14.7 N´m

(132 in. lbs.).

(21) Connect crankcase breather hose.

(22) Connect the injector sensor wire connector,

and the glow plug connectors.

(23) Install oil feed line, tighten banjo bolts to 12.7

N´m (108 in. lbs), and oil drain line to turbo.

(24) Install water manifold tighten bolts to 12 N´m

(106 in. lbs.).

(25) Install exhaust pipe to turbo elbow, tighten

bolts to 28 N´m (250 in. lbs.).

(26) Install the support strut from block to turbo-

charger exhaust elbow.

(27) Install EGR tube to EGR valve, tighten bolts

to 26 N´m (19 ft. lbs.).

(28) Install intercooler hoses at intake manifold.

(29) Install coolant pressure bottle and hoses.

(30) Install wiper module. Refer to Group 8K,

Windshield Wiper Unit Installation for procedure.

(31) Install intercooler hose at turbocharger tube.

(32) Install fuel injector lines from the pump to

injectors, tighten nuts to 17.6 N´m (156. lbs.).

(33) Connect the upper radiator hose.

(34) Connect negative cable to battery.

(35) Fill the cooling system. Check for leaks.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

Fig. 33 Engine Cylinder Head Bolt Tightening Sequence

NS/GSENGINE 9 - 59

REMOVAL AND INSTALLATION (Continued)

Page 1248 of 1938

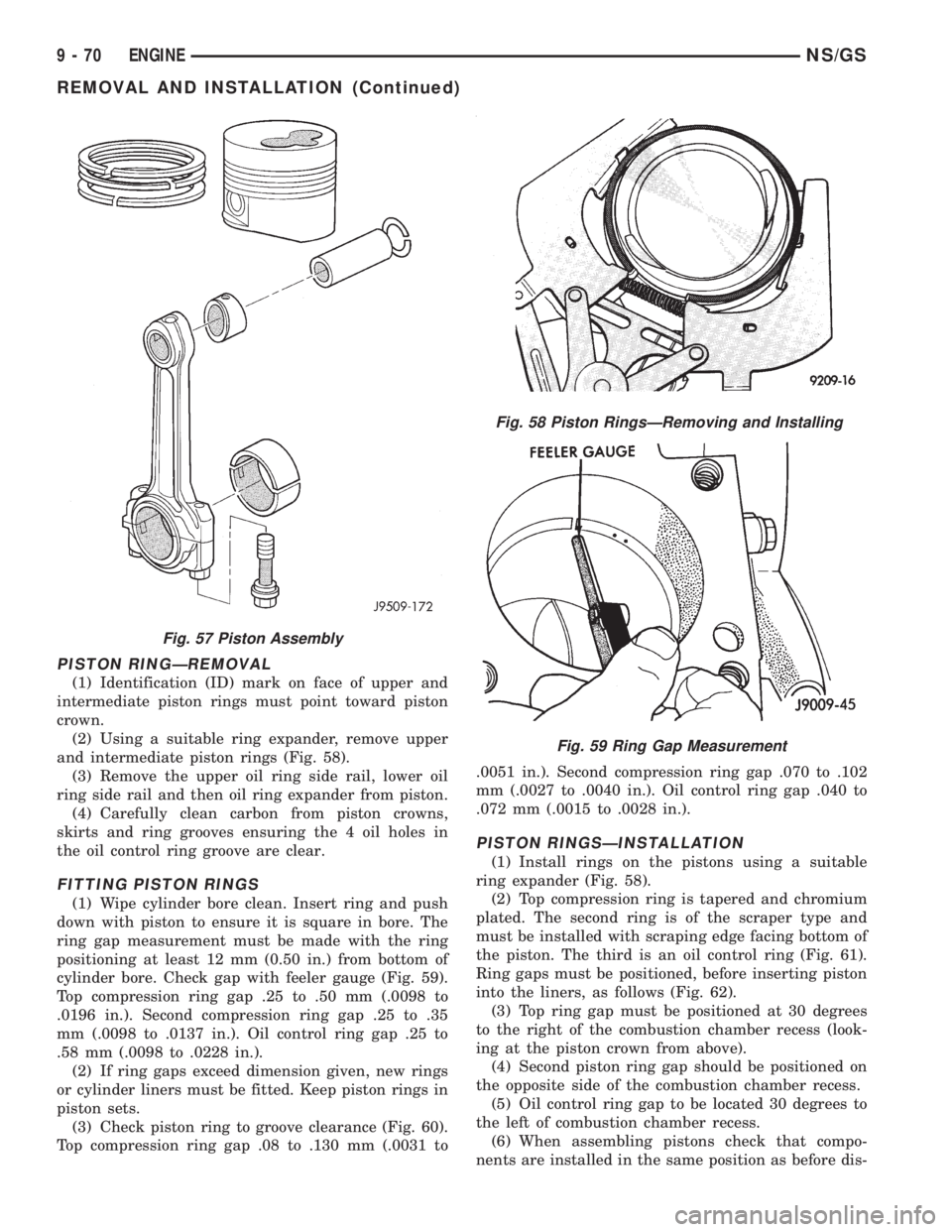

PISTON RINGÐREMOVAL

(1) Identification (ID) mark on face of upper and

intermediate piston rings must point toward piston

crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 58).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Carefully clean carbon from piston crowns,

skirts and ring grooves ensuring the 4 oil holes in

the oil control ring groove are clear.

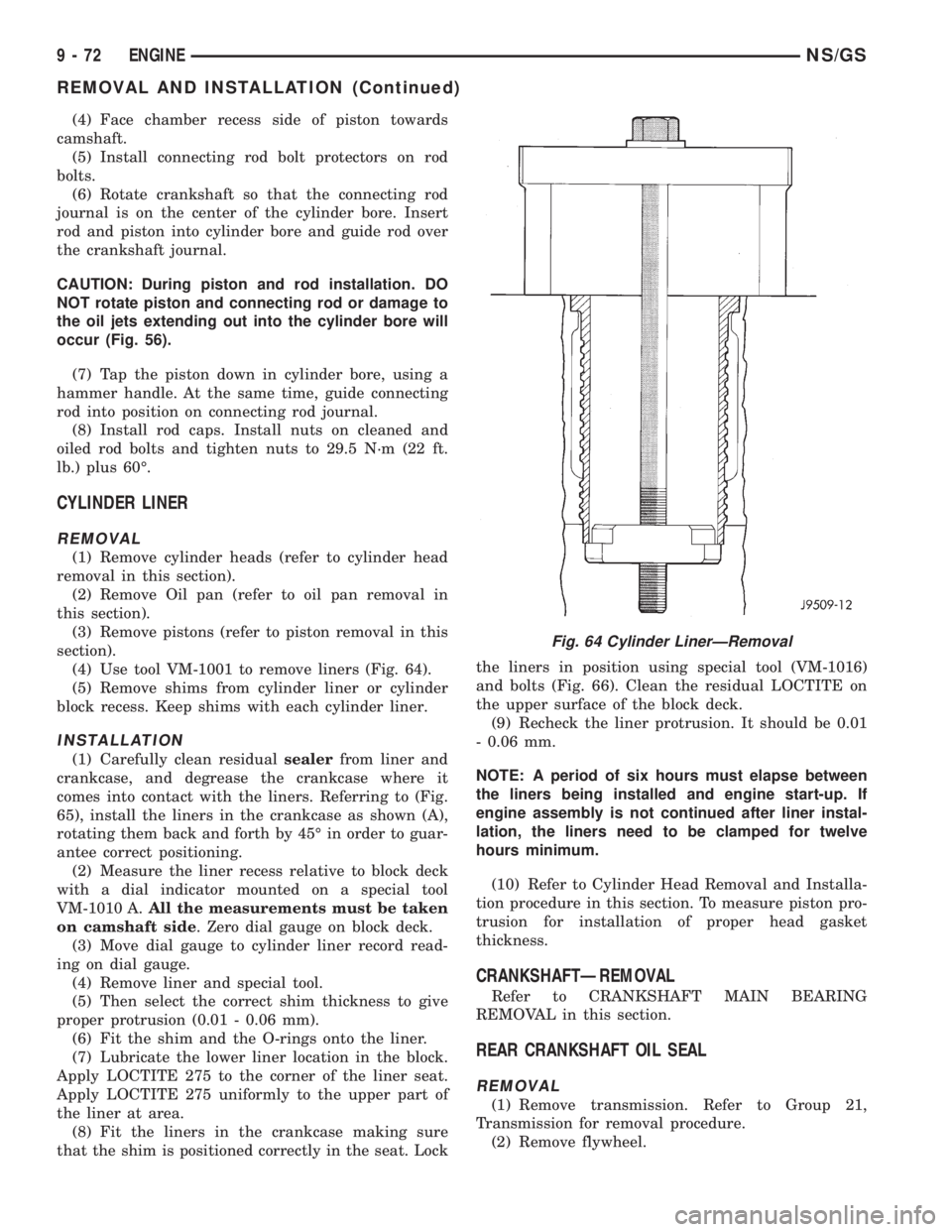

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 in.) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 59).

Top compression ring gap .25 to .50 mm (.0098 to

.0196 in.). Second compression ring gap .25 to .35

mm (.0098 to .0137 in.). Oil control ring gap .25 to

.58 mm (.0098 to .0228 in.).

(2) If ring gaps exceed dimension given, new rings

or cylinder liners must be fitted. Keep piston rings in

piston sets.

(3) Check piston ring to groove clearance (Fig. 60).

Top compression ring gap .08 to .130 mm (.0031 to.0051 in.). Second compression ring gap .070 to .102

mm (.0027 to .0040 in.). Oil control ring gap .040 to

.072 mm (.0015 to .0028 in.).

PISTON RINGSÐINSTALLATION

(1) Install rings on the pistons using a suitable

ring expander (Fig. 58).

(2) Top compression ring is tapered and chromium

plated. The second ring is of the scraper type and

must be installed with scraping edge facing bottom of

the piston. The third is an oil control ring (Fig. 61).

Ring gaps must be positioned, before inserting piston

into the liners, as follows (Fig. 62).

(3) Top ring gap must be positioned at 30 degrees

to the right of the combustion chamber recess (look-

ing at the piston crown from above).

(4) Second piston ring gap should be positioned on

the opposite side of the combustion chamber recess.

(5) Oil control ring gap to be located 30 degrees to

the left of combustion chamber recess.

(6) When assembling pistons check that compo-

nents are installed in the same position as before dis-

Fig. 57 Piston Assembly

Fig. 58 Piston RingsÐRemoving and Installing

Fig. 59 Ring Gap Measurement

9 - 70 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1250 of 1938

(4) Face chamber recess side of piston towards

camshaft.

(5) Install connecting rod bolt protectors on rod

bolts.

(6) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston into cylinder bore and guide rod over

the crankshaft journal.

CAUTION: During piston and rod installation. DO

NOT rotate piston and connecting rod or damage to

the oil jets extending out into the cylinder bore will

occur (Fig. 56).

(7) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(8) Install rod caps. Install nuts on cleaned and

oiled rod bolts and tighten nuts to 29.5 N´m (22 ft.

lb.) plus 60É.

CYLINDER LINER

REMOVAL

(1) Remove cylinder heads (refer to cylinder head

removal in this section).

(2) Remove Oil pan (refer to oil pan removal in

this section).

(3) Remove pistons (refer to piston removal in this

section).

(4) Use tool VM-1001 to remove liners (Fig. 64).

(5) Remove shims from cylinder liner or cylinder

block recess. Keep shims with each cylinder liner.

INSTALLATION

(1) Carefully clean residualsealerfrom liner and

crankcase, and degrease the crankcase where it

comes into contact with the liners. Referring to (Fig.

65), install the liners in the crankcase as shown (A),

rotating them back and forth by 45É in order to guar-

antee correct positioning.

(2) Measure the liner recess relative to block deck

with a dial indicator mounted on a special tool

VM-1010 A.All the measurements must be taken

on camshaft side. Zero dial gauge on block deck.

(3) Move dial gauge to cylinder liner record read-

ing on dial gauge.

(4) Remove liner and special tool.

(5) Then select the correct shim thickness to give

proper protrusion (0.01 - 0.06 mm).

(6) Fit the shim and the O-rings onto the liner.

(7) Lubricate the lower liner location in the block.

Apply LOCTITE 275 to the corner of the liner seat.

Apply LOCTITE 275 uniformly to the upper part of

the liner at area.

(8) Fit the liners in the crankcase making sure

that the shim is positioned correctly in the seat. Lockthe liners in position using special tool (VM-1016)

and bolts (Fig. 66). Clean the residual LOCTITE on

the upper surface of the block deck.

(9) Recheck the liner protrusion. It should be 0.01

- 0.06 mm.

NOTE: A period of six hours must elapse between

the liners being installed and engine start-up. If

engine assembly is not continued after liner instal-

lation, the liners need to be clamped for twelve

hours minimum.

(10) Refer to Cylinder Head Removal and Installa-

tion procedure in this section. To measure piston pro-

trusion for installation of proper head gasket

thickness.

CRANKSHAFTÐREMOVAL

Refer to CRANKSHAFT MAIN BEARING

REMOVAL in this section.

REAR CRANKSHAFT OIL SEAL

REMOVAL

(1) Remove transmission. Refer to Group 21,

Transmission for removal procedure.

(2) Remove flywheel.

Fig. 64 Cylinder LinerÐRemoval

9 - 72 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1255 of 1938

(3.6196-3.6200 in.). Maximum wear limit .05mm

(.0019 in.).

(2) Check piston pin bores in piston for roundness.

Make 3 checks at 120É intervals. Maximum out of

roundness .05mm (.0019in.).

(3) The piston diameter should be measured

approximately 15 mm (.590 in.) up from the base.

(4) Skirt wear should not exceed 0.1 mm (.00039

in.).

(5) The clearance between the cylinder liner and

piston should not exceed 0.25 mm (.0009 in.).

(6) Make sure the weight of the pistons does not

differ by more than 5 g.

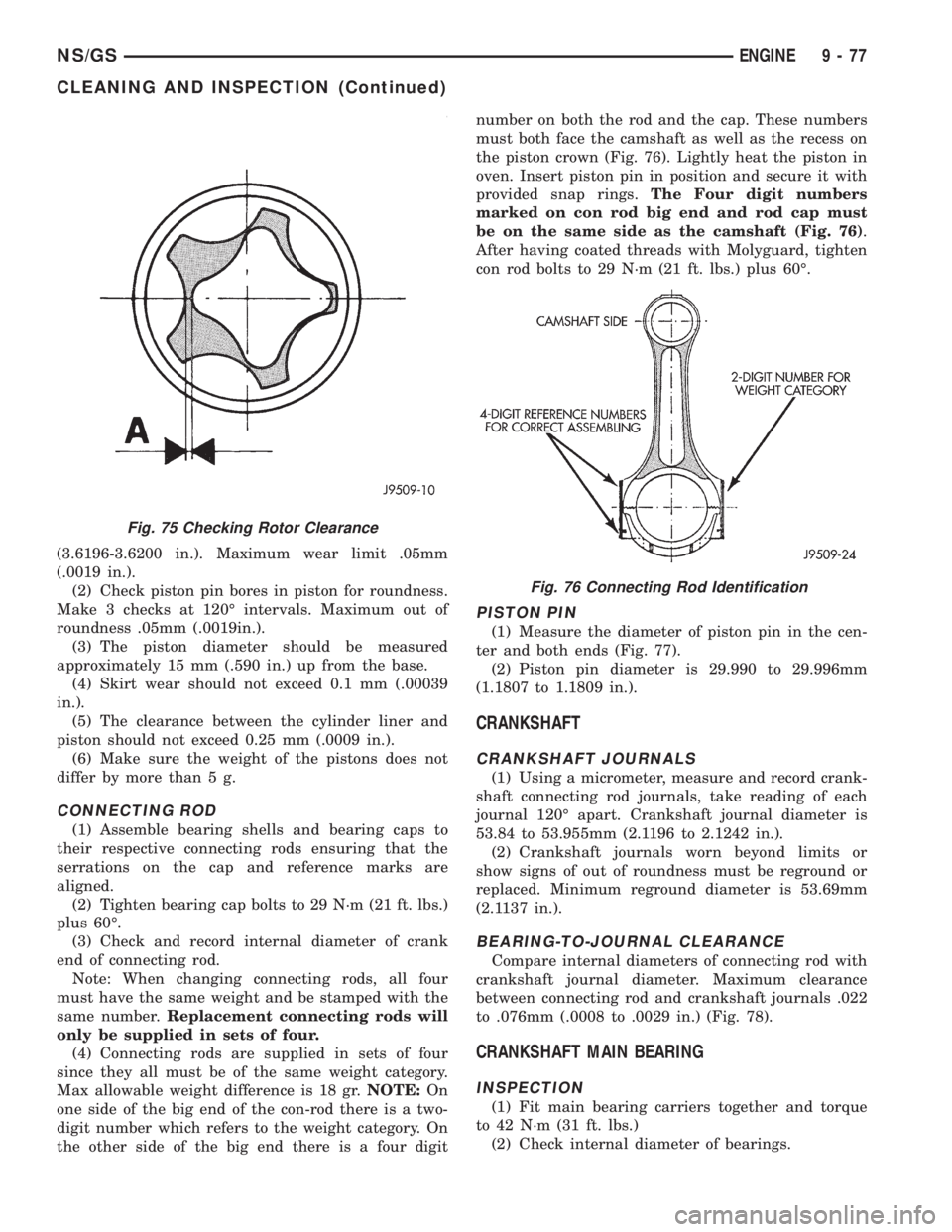

CONNECTING ROD

(1) Assemble bearing shells and bearing caps to

their respective connecting rods ensuring that the

serrations on the cap and reference marks are

aligned.

(2) Tighten bearing cap bolts to 29 N´m (21 ft. lbs.)

plus 60É.

(3) Check and record internal diameter of crank

end of connecting rod.

Note: When changing connecting rods, all four

must have the same weight and be stamped with the

same number.Replacement connecting rods will

only be supplied in sets of four.

(4) Connecting rods are supplied in sets of four

since they all must be of the same weight category.

Max allowable weight difference is 18 gr.NOTE:On

one side of the big end of the con-rod there is a two-

digit number which refers to the weight category. On

the other side of the big end there is a four digitnumber on both the rod and the cap. These numbers

must both face the camshaft as well as the recess on

the piston crown (Fig. 76). Lightly heat the piston in

oven. Insert piston pin in position and secure it with

provided snap rings.The Four digit numbers

marked on con rod big end and rod cap must

be on the same side as the camshaft (Fig. 76).

After having coated threads with Molyguard, tighten

con rod bolts to 29 N´m (21 ft. lbs.) plus 60É.

PISTON PIN

(1) Measure the diameter of piston pin in the cen-

ter and both ends (Fig. 77).

(2) Piston pin diameter is 29.990 to 29.996mm

(1.1807 to 1.1809 in.).

CRANKSHAFT

CRANKSHAFT JOURNALS

(1) Using a micrometer, measure and record crank-

shaft connecting rod journals, take reading of each

journal 120É apart. Crankshaft journal diameter is

53.84 to 53.955mm (2.1196 to 2.1242 in.).

(2) Crankshaft journals worn beyond limits or

show signs of out of roundness must be reground or

replaced. Minimum reground diameter is 53.69mm

(2.1137 in.).

BEARING-TO-JOURNAL CLEARANCE

Compare internal diameters of connecting rod with

crankshaft journal diameter. Maximum clearance

between connecting rod and crankshaft journals .022

to .076mm (.0008 to .0029 in.) (Fig. 78).

CRANKSHAFT MAIN BEARING

INSPECTION

(1) Fit main bearing carriers together and torque

to 42 N´m (31 ft. lbs.)

(2) Check internal diameter of bearings.

Fig. 75 Checking Rotor Clearance

Fig. 76 Connecting Rod Identification

NS/GSENGINE 9 - 77

CLEANING AND INSPECTION (Continued)

Page 1258 of 1938

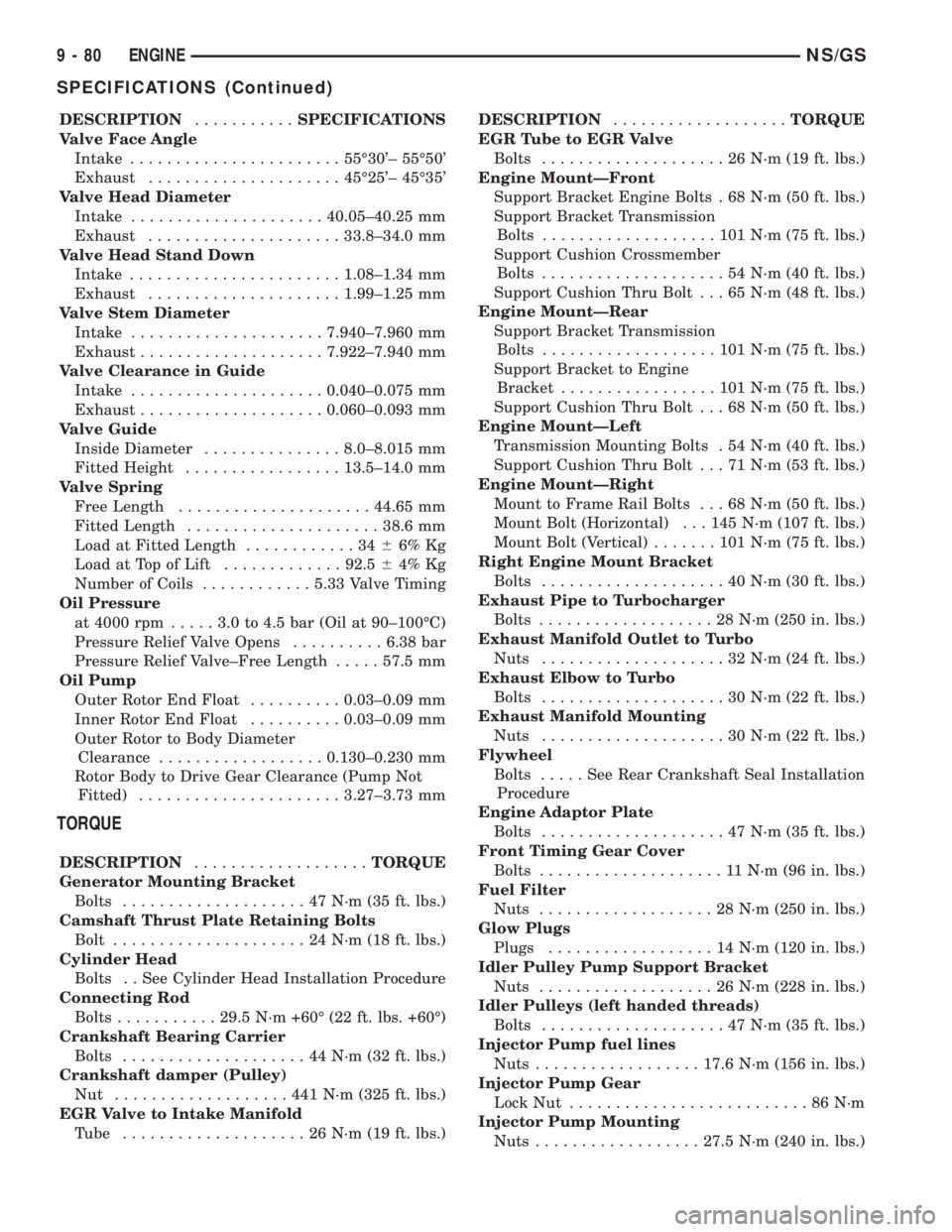

DESCRIPTION...........SPECIFICATIONS

Valve Face Angle

Intake.......................55É30'± 55É50'

Exhaust.....................45É25'± 45É35'

Valve Head Diameter

Intake.....................40.05±40.25 mm

Exhaust.....................33.8±34.0 mm

Valve Head Stand Down

Intake.......................1.08±1.34 mm

Exhaust.....................1.99±1.25 mm

Valve Stem Diameter

Intake.....................7.940±7.960 mm

Exhaust....................7.922±7.940 mm

Valve Clearance in Guide

Intake.....................0.040±0.075 mm

Exhaust....................0.060±0.093 mm

Valve Guide

Inside Diameter...............8.0±8.015 mm

Fitted Height.................13.5±14.0 mm

Valve Spring

Free Length.....................44.65 mm

Fitted Length.....................38.6 mm

Load at Fitted Length............3466% Kg

Load at Top of Lift.............92.564% Kg

Number of Coils............5.33 Valve Timing

Oil Pressure

at 4000 rpm.....3.0to4.5bar(Oil at 90±100ÉC)

Pressure Relief Valve Opens..........6.38 bar

Pressure Relief Valve±Free Length.....57.5 mm

Oil Pump

Outer Rotor End Float..........0.03±0.09 mm

Inner Rotor End Float..........0.03±0.09 mm

Outer Rotor to Body Diameter

Clearance..................0.130±0.230 mm

Rotor Body to Drive Gear Clearance (Pump Not

Fitted)......................3.27±3.73 mm

TORQUE

DESCRIPTION...................TORQUE

Generator Mounting Bracket

Bolts....................47N´m(35ft.lbs.)

Camshaft Thrust Plate Retaining Bolts

Bolt.....................24N´m(18ft.lbs.)

Cylinder Head

Bolts . . See Cylinder Head Installation Procedure

Connecting Rod

Bolts...........29.5 N´m +60É (22 ft. lbs. +60É)

Crankshaft Bearing Carrier

Bolts....................44N´m(32ft.lbs.)

Crankshaft damper (Pulley)

Nut ...................441N´m(325 ft. lbs.)

EGR Valve to Intake Manifold

Tube ....................26N´m(19ft.lbs.)DESCRIPTION...................TORQUE

EGR Tube to EGR Valve

Bolts....................26N´m(19ft.lbs.)

Engine MountÐFront

Support Bracket Engine Bolts . 68 N´m (50 ft. lbs.)

Support Bracket Transmission

Bolts...................101N´m(75ft.lbs.)

Support Cushion Crossmember

Bolts....................54N´m(40ft.lbs.)

Support Cushion Thru Bolt . . . 65 N´m (48 ft. lbs.)

Engine MountÐRear

Support Bracket Transmission

Bolts...................101N´m(75ft.lbs.)

Support Bracket to Engine

Bracket.................101N´m(75ft.lbs.)

Support Cushion Thru Bolt . . . 68 N´m (50 ft. lbs.)

Engine MountÐLeft

Transmission Mounting Bolts . 54 N´m (40 ft. lbs.)

Support Cushion Thru Bolt . . . 71 N´m (53 ft. lbs.)

Engine MountÐRight

Mount to Frame Rail Bolts . . . 68 N´m (50 ft. lbs.)

Mount Bolt (Horizontal) . . . 145 N´m (107 ft. lbs.)

Mount Bolt (Vertical).......101N´m(75ft.lbs.)

Right Engine Mount Bracket

Bolts....................40N´m(30ft.lbs.)

Exhaust Pipe to Turbocharger

Bolts...................28N´m(250 in. lbs.)

Exhaust Manifold Outlet to Turbo

Nuts....................32N´m(24ft.lbs.)

Exhaust Elbow to Turbo

Bolts....................30N´m(22ft.lbs.)

Exhaust Manifold Mounting

Nuts....................30N´m(22ft.lbs.)

Flywheel

Bolts.....SeeRear Crankshaft Seal Installation

Procedure

Engine Adaptor Plate

Bolts....................47N´m(35ft.lbs.)

Front Timing Gear Cover

Bolts....................11N´m(96in.lbs.)

Fuel Filter

Nuts...................28N´m(250 in. lbs.)

Glow Plugs

Plugs..................14N´m(120 in. lbs.)

Idler Pulley Pump Support Bracket

Nuts...................26N´m(228 in. lbs.)

Idler Pulleys (left handed threads)

Bolts....................47N´m(35ft.lbs.)

Injector Pump fuel lines

Nuts..................17.6 N´m (156 in. lbs.)

Injector Pump Gear

Lock Nut..........................86N´m

Injector Pump Mounting

Nuts..................27.5 N´m (240 in. lbs.)

9 - 80 ENGINENS/GS

SPECIFICATIONS (Continued)

Page 1263 of 1938

EXHAUST SYSTEM AND INTAKE MANIFOLD

CONTENTS

page page

GENERAL INFORMATION

CATALYTIC CONVERTERS................. 1

EXHAUST FLEX-JOINT COUPLING........... 2

EXHAUST GAS RECIRCULATION (EGR)....... 2

EXHAUST SYSTEM....................... 1

HEAT SHIELDS.......................... 2

DESCRIPTION AND OPERATION

INTAKE/EXHAUST MANIFOLDÐ2.4L ENGINE . . 3

INTAKE/EXHAUST MANIFOLDÐ3.0L ENGINE . . 3

INTAKE/EXHAUST MANIFOLDÐ3.3/3.8L

ENGINES............................. 3

DIAGNOSIS AND TESTING

EXHAUST SYSTEM....................... 3REMOVAL AND INSTALLATION

EXHAUST MANIFOLDÐ2.4L ENGINE........ 8

EXHAUST MANIFOLDÐ3.0L ENGINE....... 11

EXHAUST MANIFOLDSÐ3.3/3.8L ENGINE . . . 16

EXHAUST PIPES, MUFFLERS AND TAILPIPES . 4

INTAKE MANIFOLD LOWERÐ2.4L ENGINE.... 6

INTAKE MANIFOLDÐ3.0L ENGINE.......... 8

INTAKE MANIFOLDÐ3.3/3.8L ENGINE...... 12

UPPER INTAKE MANIFOLDÐ2.4L ENGINE.... 4

CLEANING AND INSPECTION

EXHAUST MANIFOLD.................... 17

INTAKE MANIFOLD...................... 17

SPECIFICATIONS

TORQUE CHART........................ 18

GENERAL INFORMATION

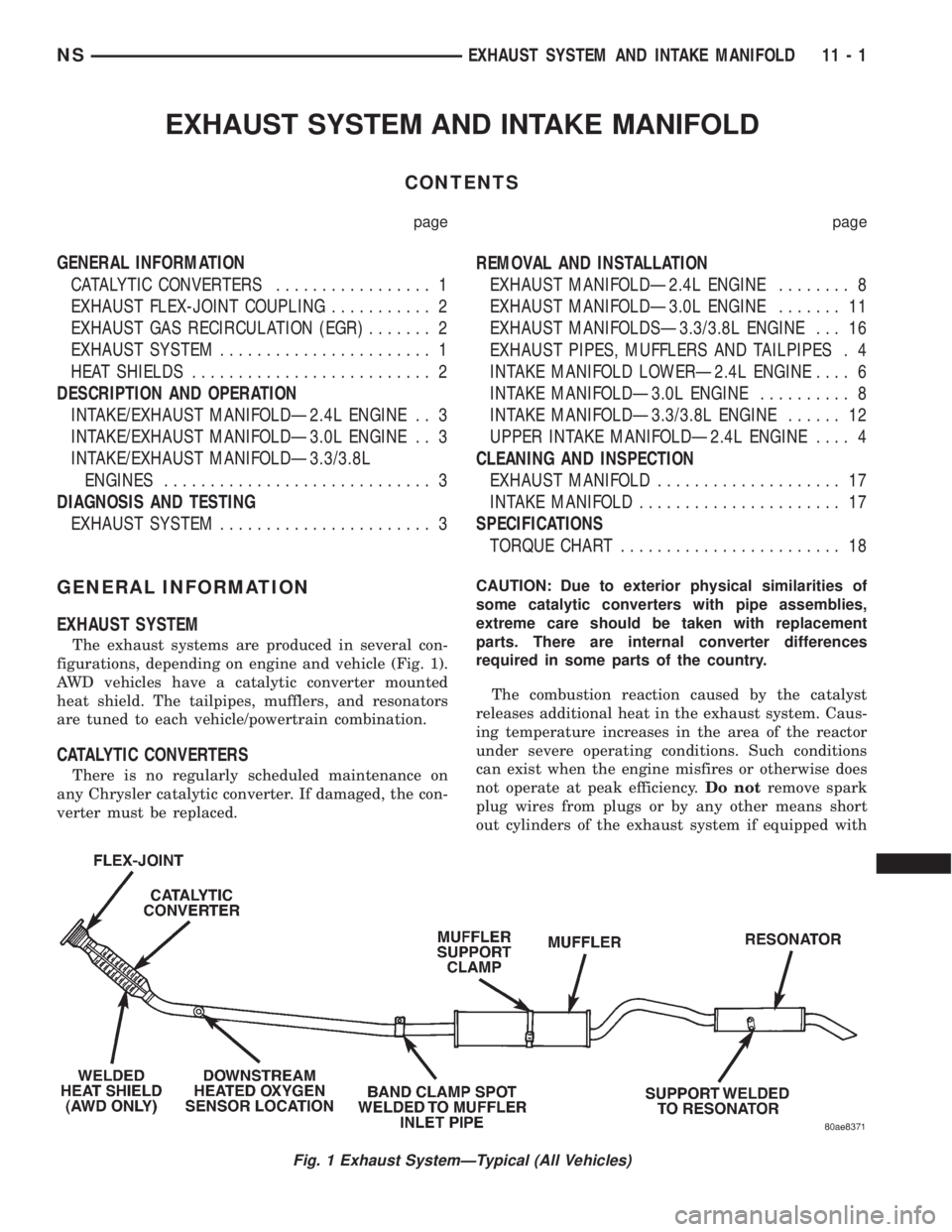

EXHAUST SYSTEM

The exhaust systems are produced in several con-

figurations, depending on engine and vehicle (Fig. 1).

AWD vehicles have a catalytic converter mounted

heat shield. The tailpipes, mufflers, and resonators

are tuned to each vehicle/powertrain combination.

CATALYTIC CONVERTERS

There is no regularly scheduled maintenance on

any Chrysler catalytic converter. If damaged, the con-

verter must be replaced.CAUTION: Due to exterior physical similarities of

some catalytic converters with pipe assemblies,

extreme care should be taken with replacement

parts. There are internal converter differences

required in some parts of the country.

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system. Caus-

ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders of the exhaust system if equipped with

Fig. 1 Exhaust SystemÐTypical (All Vehicles)

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1

Page 1264 of 1938

a catalytic converter. Failure of the catalytic con-

verter can occur due to temperature increases caused

by unburned fuel igniting when passing through the

converter.

The use of the catalysts also involves some non-au-

tomotive problems. Unleaded gasoline must be used

to avoid poisoning the catalyst core. Do not allow

engine to operate at fast idle for extended periods

(over 5 minutes). This condition may result in exces-

sive exhaust system and floor pan temperatures.

EXHAUST GAS RECIRCULATION (EGR)

To assist in the control of oxides of nitrogen (NOx)

in engine exhaust, all engines are equipped with an

exhaust gas recirculation system. The use of exhaust

gas to dilute incoming air/fuel mixtures lowers peak

flame temperatures during combustion, thus limiting

the formation of NOx.

Exhaust gases are taken from opening in the

exhaust manifold passage to the intake manifold.

REFER TO SECTION 25 FOR A COMPLETE

DESCRIPTION, DIAGNOSIS AND SERVICE PRO-

CEDURES ON THE EXHAUST GAS RECIRCULA-

TION SYSTEM AND COMPONENTS.

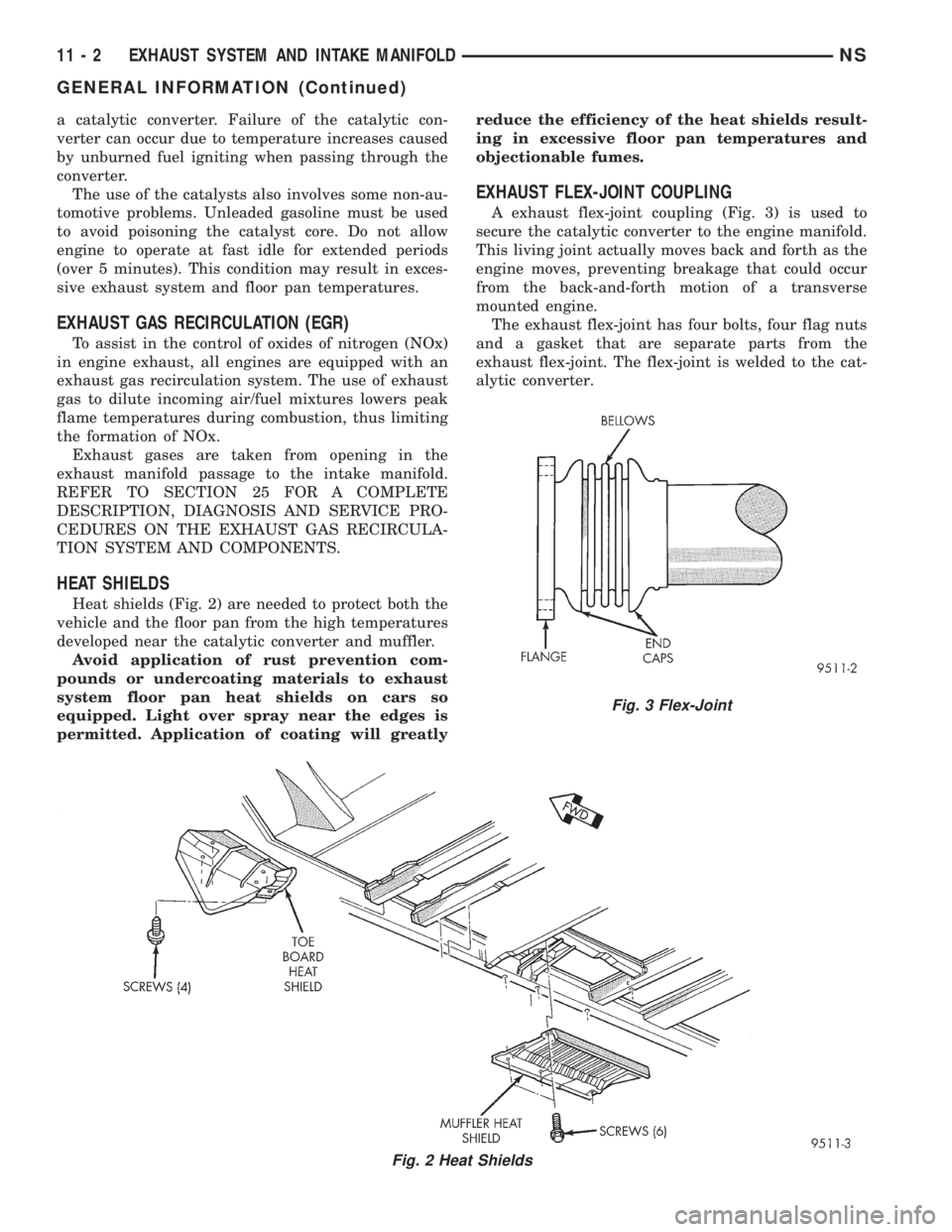

HEAT SHIELDS

Heat shields (Fig. 2) are needed to protect both the

vehicle and the floor pan from the high temperatures

developed near the catalytic converter and muffler.

Avoid application of rust prevention com-

pounds or undercoating materials to exhaust

system floor pan heat shields on cars so

equipped. Light over spray near the edges is

permitted. Application of coating will greatlyreduce the efficiency of the heat shields result-

ing in excessive floor pan temperatures and

objectionable fumes.

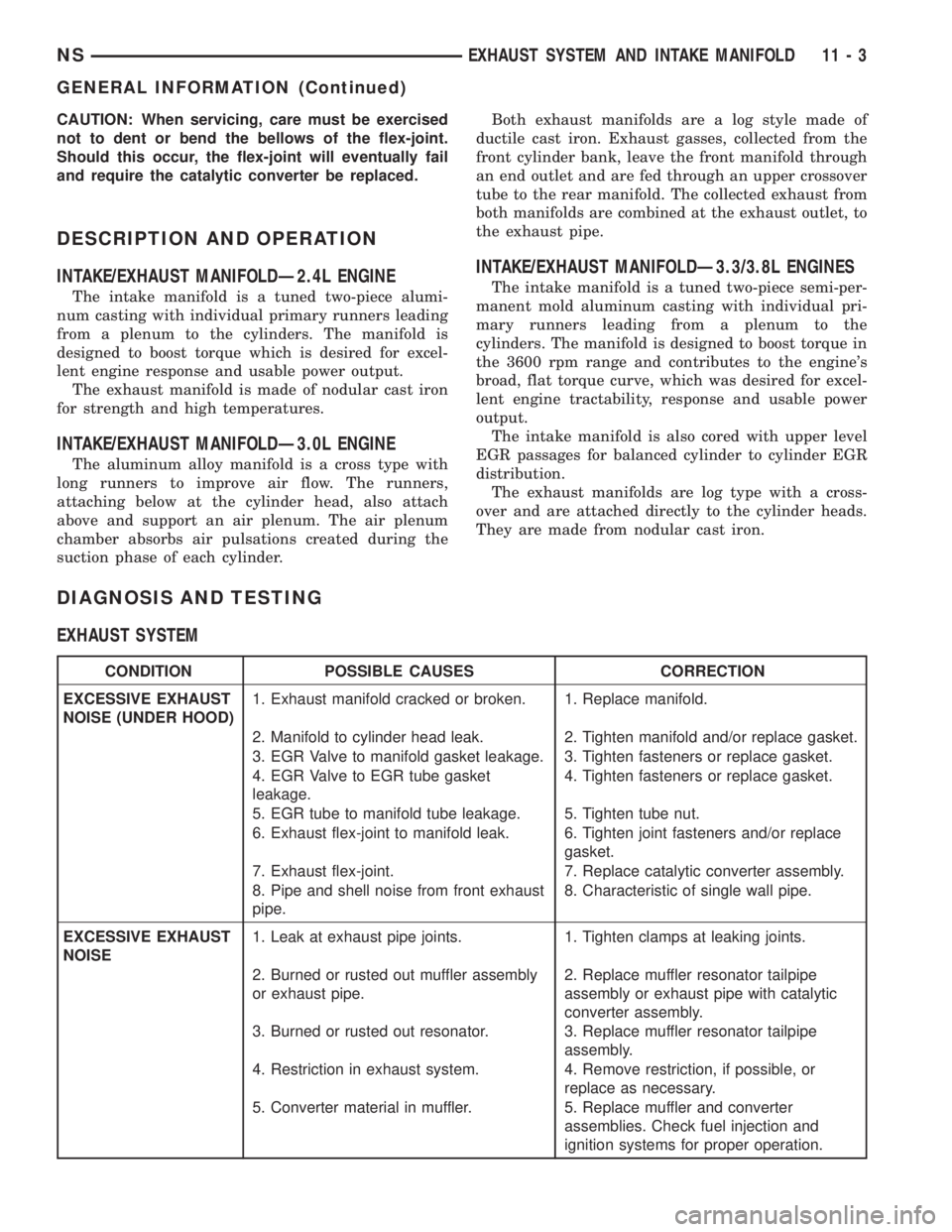

EXHAUST FLEX-JOINT COUPLING

A exhaust flex-joint coupling (Fig. 3) is used to

secure the catalytic converter to the engine manifold.

This living joint actually moves back and forth as the

engine moves, preventing breakage that could occur

from the back-and-forth motion of a transverse

mounted engine.

The exhaust flex-joint has four bolts, four flag nuts

and a gasket that are separate parts from the

exhaust flex-joint. The flex-joint is welded to the cat-

alytic converter.

Fig. 2 Heat Shields

Fig. 3 Flex-Joint

11 - 2 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

GENERAL INFORMATION (Continued)

Page 1265 of 1938

CAUTION: When servicing, care must be exercised

not to dent or bend the bellows of the flex-joint.

Should this occur, the flex-joint will eventually fail

and require the catalytic converter be replaced.

DESCRIPTION AND OPERATION

INTAKE/EXHAUST MANIFOLDÐ2.4L ENGINE

The intake manifold is a tuned two-piece alumi-

num casting with individual primary runners leading

from a plenum to the cylinders. The manifold is

designed to boost torque which is desired for excel-

lent engine response and usable power output.

The exhaust manifold is made of nodular cast iron

for strength and high temperatures.

INTAKE/EXHAUST MANIFOLDÐ3.0L ENGINE

The aluminum alloy manifold is a cross type with

long runners to improve air flow. The runners,

attaching below at the cylinder head, also attach

above and support an air plenum. The air plenum

chamber absorbs air pulsations created during the

suction phase of each cylinder.Both exhaust manifolds are a log style made of

ductile cast iron. Exhaust gasses, collected from the

front cylinder bank, leave the front manifold through

an end outlet and are fed through an upper crossover

tube to the rear manifold. The collected exhaust from

both manifolds are combined at the exhaust outlet, to

the exhaust pipe.

INTAKE/EXHAUST MANIFOLDÐ3.3/3.8L ENGINES

The intake manifold is a tuned two-piece semi-per-

manent mold aluminum casting with individual pri-

mary runners leading from a plenum to the

cylinders. The manifold is designed to boost torque in

the 3600 rpm range and contributes to the engine's

broad, flat torque curve, which was desired for excel-

lent engine tractability, response and usable power

output.

The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution.

The exhaust manifolds are log type with a cross-

over and are attached directly to the cylinder heads.

They are made from nodular cast iron.

DIAGNOSIS AND TESTING

EXHAUST SYSTEM

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST

NOISE (UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. EGR Valve to manifold gasket leakage. 3. Tighten fasteners or replace gasket.

4. EGR Valve to EGR tube gasket

leakage.4. Tighten fasteners or replace gasket.

5. EGR tube to manifold tube leakage. 5. Tighten tube nut.

6. Exhaust flex-joint to manifold leak. 6. Tighten joint fasteners and/or replace

gasket.

7. Exhaust flex-joint. 7. Replace catalytic converter assembly.

8. Pipe and shell noise from front exhaust

pipe.8. Characteristic of single wall pipe.

EXCESSIVE EXHAUST

NOISE1. Leak at exhaust pipe joints. 1. Tighten clamps at leaking joints.

2. Burned or rusted out muffler assembly

or exhaust pipe.2. Replace muffler resonator tailpipe

assembly or exhaust pipe with catalytic

converter assembly.

3. Burned or rusted out resonator. 3. Replace muffler resonator tailpipe

assembly.

4. Restriction in exhaust system. 4. Remove restriction, if possible, or

replace as necessary.

5. Converter material in muffler. 5. Replace muffler and converter

assemblies. Check fuel injection and

ignition systems for proper operation.

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3

GENERAL INFORMATION (Continued)

Page 1274 of 1938

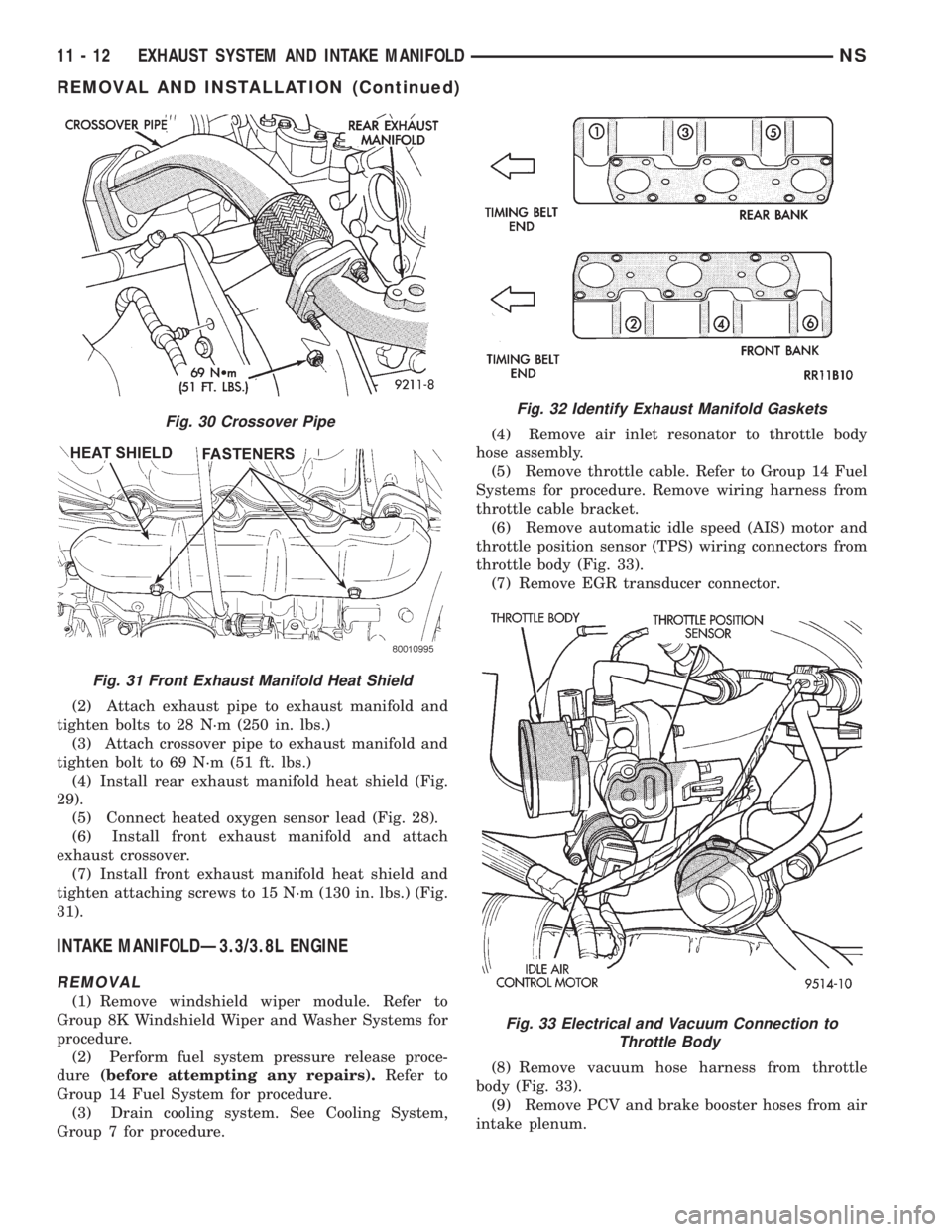

(2) Attach exhaust pipe to exhaust manifold and

tighten bolts to 28 N´m (250 in. lbs.)

(3) Attach crossover pipe to exhaust manifold and

tighten bolt to 69 N´m (51 ft. lbs.)

(4) Install rear exhaust manifold heat shield (Fig.

29).

(5) Connect heated oxygen sensor lead (Fig. 28).

(6) Install front exhaust manifold and attach

exhaust crossover.

(7) Install front exhaust manifold heat shield and

tighten attaching screws to 15 N´m (130 in. lbs.) (Fig.

31).

INTAKE MANIFOLDÐ3.3/3.8L ENGINE

REMOVAL

(1) Remove windshield wiper module. Refer to

Group 8K Windshield Wiper and Washer Systems for

procedure.

(2) Perform fuel system pressure release proce-

dure(before attempting any repairs).Refer to

Group 14 Fuel System for procedure.

(3) Drain cooling system. See Cooling System,

Group 7 for procedure.(4) Remove air inlet resonator to throttle body

hose assembly.

(5) Remove throttle cable. Refer to Group 14 Fuel

Systems for procedure. Remove wiring harness from

throttle cable bracket.

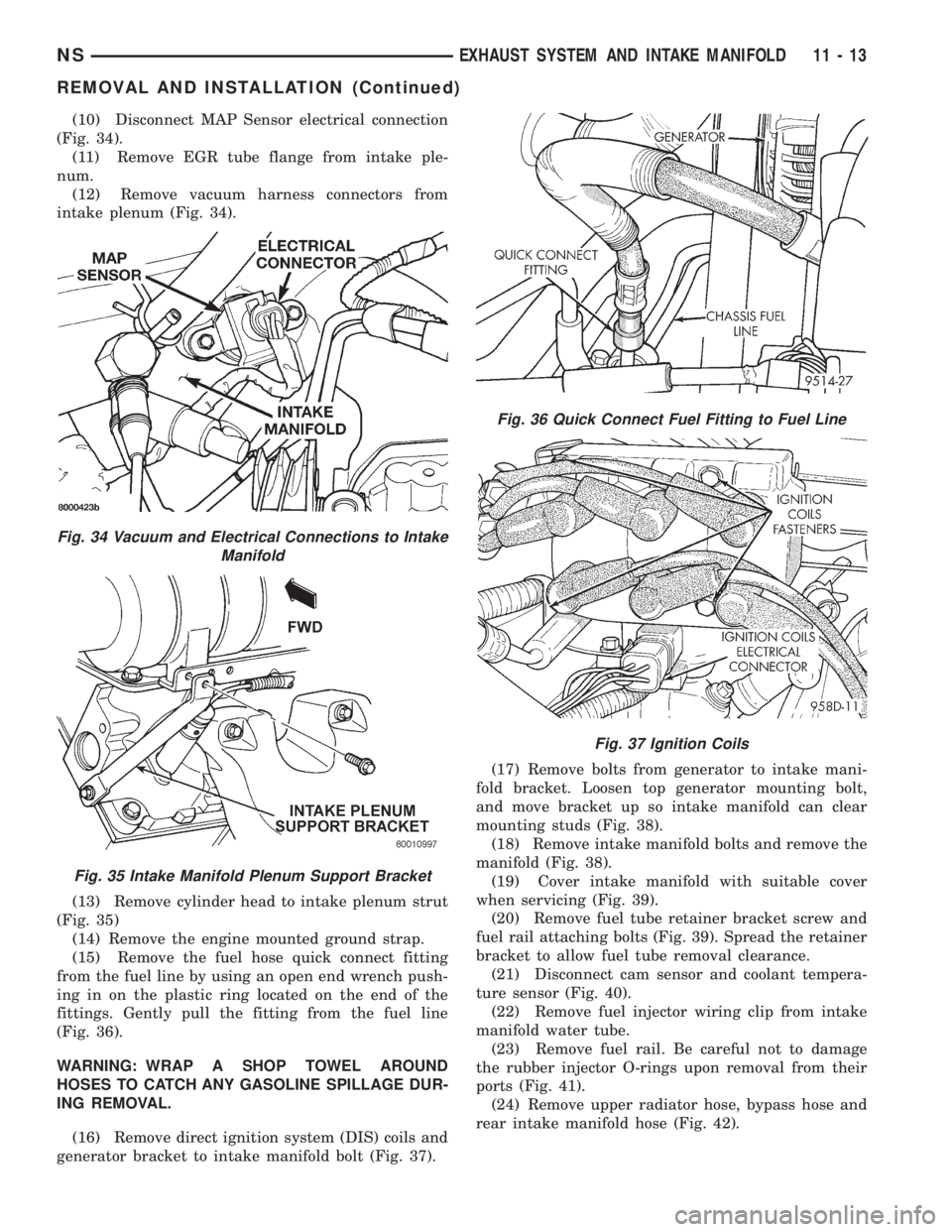

(6) Remove automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors from

throttle body (Fig. 33).

(7) Remove EGR transducer connector.

(8) Remove vacuum hose harness from throttle

body (Fig. 33).

(9) Remove PCV and brake booster hoses from air

intake plenum.

Fig. 30 Crossover Pipe

Fig. 31 Front Exhaust Manifold Heat Shield

Fig. 32 Identify Exhaust Manifold Gaskets

Fig. 33 Electrical and Vacuum Connection to

Throttle Body

11 - 12 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1275 of 1938

(10) Disconnect MAP Sensor electrical connection

(Fig. 34).

(11) Remove EGR tube flange from intake ple-

num.

(12) Remove vacuum harness connectors from

intake plenum (Fig. 34).

(13) Remove cylinder head to intake plenum strut

(Fig. 35)

(14) Remove the engine mounted ground strap.

(15) Remove the fuel hose quick connect fitting

from the fuel line by using an open end wrench push-

ing in on the plastic ring located on the end of the

fittings. Gently pull the fitting from the fuel line

(Fig. 36).

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE DUR-

ING REMOVAL.

(16) Remove direct ignition system (DIS) coils and

generator bracket to intake manifold bolt (Fig. 37).(17) Remove bolts from generator to intake mani-

fold bracket. Loosen top generator mounting bolt,

and move bracket up so intake manifold can clear

mounting studs (Fig. 38).

(18) Remove intake manifold bolts and remove the

manifold (Fig. 38).

(19) Cover intake manifold with suitable cover

when servicing (Fig. 39).

(20) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 39). Spread the retainer

bracket to allow fuel tube removal clearance.

(21) Disconnect cam sensor and coolant tempera-

ture sensor (Fig. 40).

(22) Remove fuel injector wiring clip from intake

manifold water tube.

(23) Remove fuel rail. Be careful not to damage

the rubber injector O-rings upon removal from their

ports (Fig. 41).

(24) Remove upper radiator hose, bypass hose and

rear intake manifold hose (Fig. 42).

Fig. 34 Vacuum and Electrical Connections to Intake

Manifold

Fig. 35 Intake Manifold Plenum Support Bracket

Fig. 36 Quick Connect Fuel Fitting to Fuel Line

Fig. 37 Ignition Coils

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 13

REMOVAL AND INSTALLATION (Continued)