shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 36 of 1938

CONDITION POSSIBLE CAUSES CORRECTION

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended

pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel

camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free Play 1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to

specified torque

4. Loose or worn steering shaft

coupler4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering

pump drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering

coupler7. Replace steering coupler

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment factors. The following part

inspection and the necessary corrections should be

made to those parts which influence the steering of

the vehicle.

(1) Check and inflate all tires to recommended

pressure. All tires should be the same size and in

good condition and have approximately the same

wear. Note the type of tread wear which will aid in

diagnosing, see Wheels and Tires, Group 22.

(2) Check front wheel and tire assembly for radial

runout.

(3) Inspect lower ball joints and all steering link-

age for looseness.

(4) Check for broken or sagged front and rear

springs.(5) Check vehicle ride height to verify it is within

specifications.

(6) AlignmentMUSTonly be checked after the

vehicle has the following areas inspected and or

adjusted. Recommended tire pressures, full tank of

fuel, no passenger or luggage compartment load and

is on a level floor or a properly calibrated alignment

rack.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER AND CAMBER

Front suspension Caster and Camber settings on

this vehicle are determined at the time the vehicle is

designed. This is done by determining the precise

2 - 4 SUSPENSIONNS

DIAGNOSIS AND TESTING (Continued)

Page 42 of 1938

Mc PHERSON STRUT ASSEMBLY

The front suspension of the vehicle is supported by

coil springs positioned around the strut assembly.

The springs are contained between an upper seat,

located just below the top strut mount assembly and

a lower spring seat on the strut fluid reservoir.

The top of each strut assembly is bolted to the

upper fender reinforcement (strut tower) through a

rubber isolated mount.

The bottom of the strut assembly attaches to the

steering knuckle with two through bolts. Caster is a

fixed setting on all vehicles and is not adjustable

when an alignment is performed. In the event the

camber setting on a vehicle requires adjustment, a

service strut is available which will provide a method

by which the camber can be adjusted.

The strut assemblies on this vehicle are inter-con-

nected by the front stabilizer bar through 2 link

assemblies attaching the struts to the stabilizer bar.

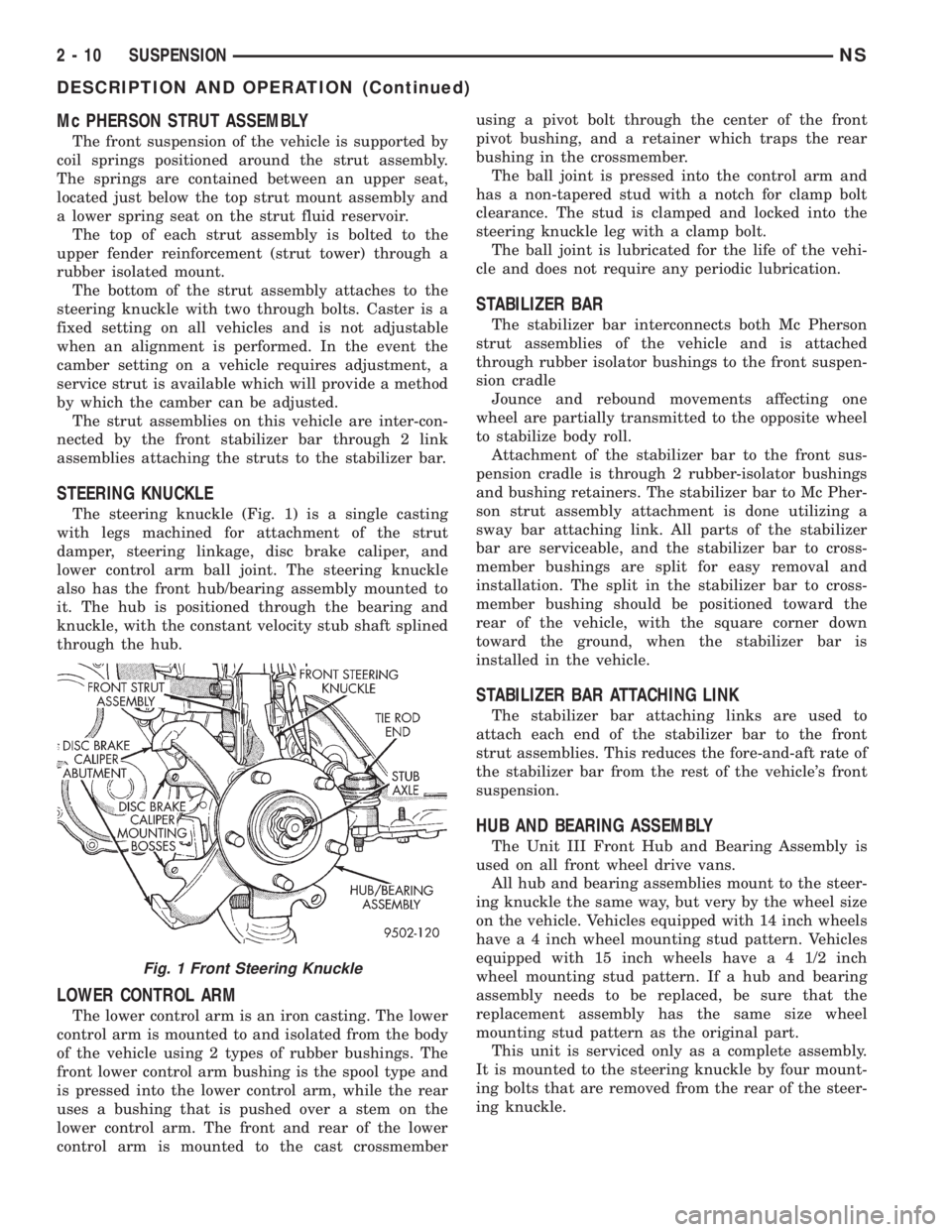

STEERING KNUCKLE

The steering knuckle (Fig. 1) is a single casting

with legs machined for attachment of the strut

damper, steering linkage, disc brake caliper, and

lower control arm ball joint. The steering knuckle

also has the front hub/bearing assembly mounted to

it. The hub is positioned through the bearing and

knuckle, with the constant velocity stub shaft splined

through the hub.

LOWER CONTROL ARM

The lower control arm is an iron casting. The lower

control arm is mounted to and isolated from the body

of the vehicle using 2 types of rubber bushings. The

front lower control arm bushing is the spool type and

is pressed into the lower control arm, while the rear

uses a bushing that is pushed over a stem on the

lower control arm. The front and rear of the lower

control arm is mounted to the cast crossmemberusing a pivot bolt through the center of the front

pivot bushing, and a retainer which traps the rear

bushing in the crossmember.

The ball joint is pressed into the control arm and

has a non-tapered stud with a notch for clamp bolt

clearance. The stud is clamped and locked into the

steering knuckle leg with a clamp bolt.

The ball joint is lubricated for the life of the vehi-

cle and does not require any periodic lubrication.

STABILIZER BAR

The stabilizer bar interconnects both Mc Pherson

strut assemblies of the vehicle and is attached

through rubber isolator bushings to the front suspen-

sion cradle

Jounce and rebound movements affecting one

wheel are partially transmitted to the opposite wheel

to stabilize body roll.

Attachment of the stabilizer bar to the front sus-

pension cradle is through 2 rubber-isolator bushings

and bushing retainers. The stabilizer bar to Mc Pher-

son strut assembly attachment is done utilizing a

sway bar attaching link. All parts of the stabilizer

bar are serviceable, and the stabilizer bar to cross-

member bushings are split for easy removal and

installation. The split in the stabilizer bar to cross-

member bushing should be positioned toward the

rear of the vehicle, with the square corner down

toward the ground, when the stabilizer bar is

installed in the vehicle.

STABILIZER BAR ATTACHING LINK

The stabilizer bar attaching links are used to

attach each end of the stabilizer bar to the front

strut assemblies. This reduces the fore-and-aft rate of

the stabilizer bar from the rest of the vehicle's front

suspension.

HUB AND BEARING ASSEMBLY

The Unit III Front Hub and Bearing Assembly is

used on all front wheel drive vans.

All hub and bearing assemblies mount to the steer-

ing knuckle the same way, but very by the wheel size

on the vehicle. Vehicles equipped with 14 inch wheels

have a 4 inch wheel mounting stud pattern. Vehicles

equipped with 15 inch wheels have a 4 1/2 inch

wheel mounting stud pattern. If a hub and bearing

assembly needs to be replaced, be sure that the

replacement assembly has the same size wheel

mounting stud pattern as the original part.

This unit is serviced only as a complete assembly.

It is mounted to the steering knuckle by four mount-

ing bolts that are removed from the rear of the steer-

ing knuckle.

Fig. 1 Front Steering Knuckle

2 - 10 SUSPENSIONNS

DESCRIPTION AND OPERATION (Continued)

Page 43 of 1938

COIL SPRING

Coil springs are rated separately for each corner or

side of the vehicle depending on optional equipment

and type of vehicle service. During service procedures

when both springs are removed, mark springs to

ensure installation in original position. Each coil

spring comes with a plastic sleeve on the second coil

of the spring. This plastic sleeve is a noise insulator

for the coil spring.

NOTE: If coil springs require replacement, be sure

that the springs needing replacement, are replaced

with springs meeting the correct load rating for the

vehicle and its specific options.

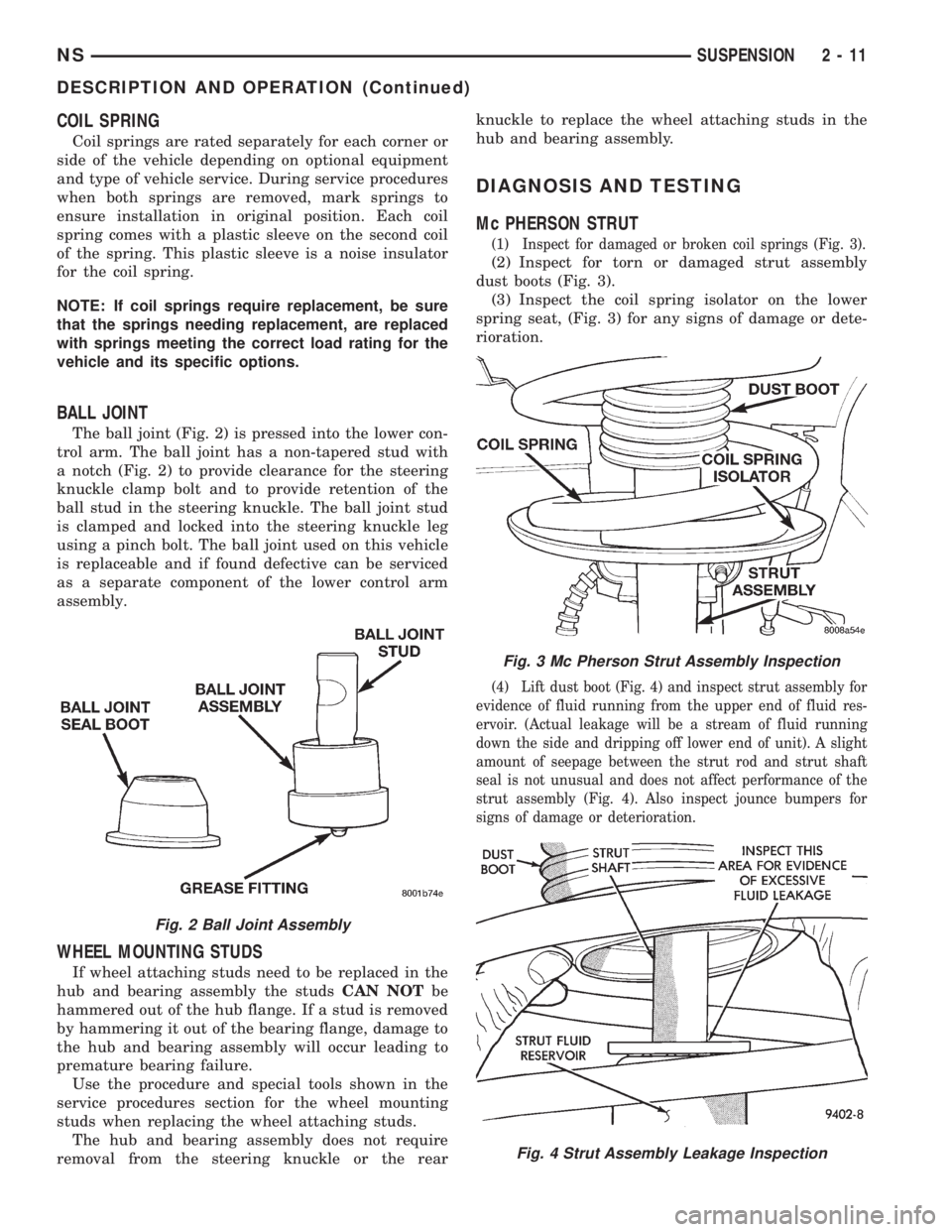

BALL JOINT

The ball joint (Fig. 2) is pressed into the lower con-

trol arm. The ball joint has a non-tapered stud with

a notch (Fig. 2) to provide clearance for the steering

knuckle clamp bolt and to provide retention of the

ball stud in the steering knuckle. The ball joint stud

is clamped and locked into the steering knuckle leg

using a pinch bolt. The ball joint used on this vehicle

is replaceable and if found defective can be serviced

as a separate component of the lower control arm

assembly.

WHEEL MOUNTING STUDS

If wheel attaching studs need to be replaced in the

hub and bearing assembly the studsCAN NOTbe

hammered out of the hub flange. If a stud is removed

by hammering it out of the bearing flange, damage to

the hub and bearing assembly will occur leading to

premature bearing failure.

Use the procedure and special tools shown in the

service procedures section for the wheel mounting

studs when replacing the wheel attaching studs.

The hub and bearing assembly does not require

removal from the steering knuckle or the rearknuckle to replace the wheel attaching studs in the

hub and bearing assembly.

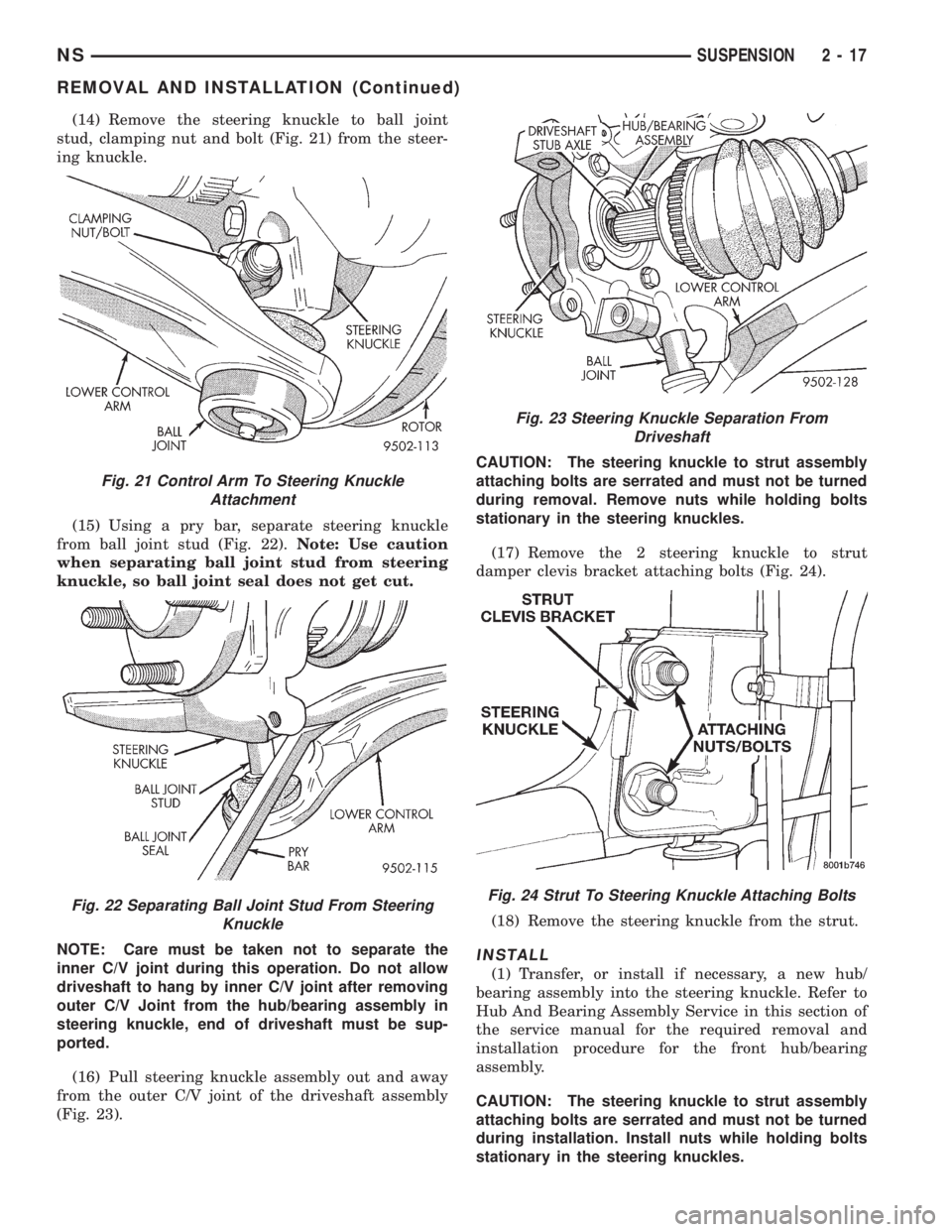

DIAGNOSIS AND TESTING

Mc PHERSON STRUT

(1) Inspect for damaged or broken coil springs (Fig. 3).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 3).

(3) Inspect the coil spring isolator on the lower

spring seat, (Fig. 3) for any signs of damage or dete-

rioration.

(4) Lift dust boot (Fig. 4) and inspect strut assembly for

evidence of fluid running from the upper end of fluid res-

ervoir. (Actual leakage will be a stream of fluid running

down the side and dripping off lower end of unit). A slight

amount of seepage between the strut rod and strut shaft

seal is not unusual and does not affect performance of the

strut assembly (Fig. 4). Also inspect jounce bumpers for

signs of damage or deterioration.

Fig. 2 Ball Joint Assembly

Fig. 3 Mc Pherson Strut Assembly Inspection

Fig. 4 Strut Assembly Leakage Inspection

NSSUSPENSION 2 - 11

DESCRIPTION AND OPERATION (Continued)

Page 49 of 1938

(14) Remove the steering knuckle to ball joint

stud, clamping nut and bolt (Fig. 21) from the steer-

ing knuckle.

(15) Using a pry bar, separate steering knuckle

from ball joint stud (Fig. 22).Note: Use caution

when separating ball joint stud from steering

knuckle, so ball joint seal does not get cut.

NOTE: Care must be taken not to separate the

inner C/V joint during this operation. Do not allow

driveshaft to hang by inner C/V joint after removing

outer C/V Joint from the hub/bearing assembly in

steering knuckle, end of driveshaft must be sup-

ported.

(16) Pull steering knuckle assembly out and away

from the outer C/V joint of the driveshaft assembly

(Fig. 23).CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during removal. Remove nuts while holding bolts

stationary in the steering knuckles.

(17) Remove the 2 steering knuckle to strut

damper clevis bracket attaching bolts (Fig. 24).

(18) Remove the steering knuckle from the strut.

INSTALL

(1) Transfer, or install if necessary, a new hub/

bearing assembly into the steering knuckle. Refer to

Hub And Bearing Assembly Service in this section of

the service manual for the required removal and

installation procedure for the front hub/bearing

assembly.

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckles.

Fig. 21 Control Arm To Steering Knuckle

Attachment

Fig. 22 Separating Ball Joint Stud From Steering

Knuckle

Fig. 23 Steering Knuckle Separation From

Driveshaft

Fig. 24 Strut To Steering Knuckle Attaching Bolts

NSSUSPENSION 2 - 17

REMOVAL AND INSTALLATION (Continued)

Page 50 of 1938

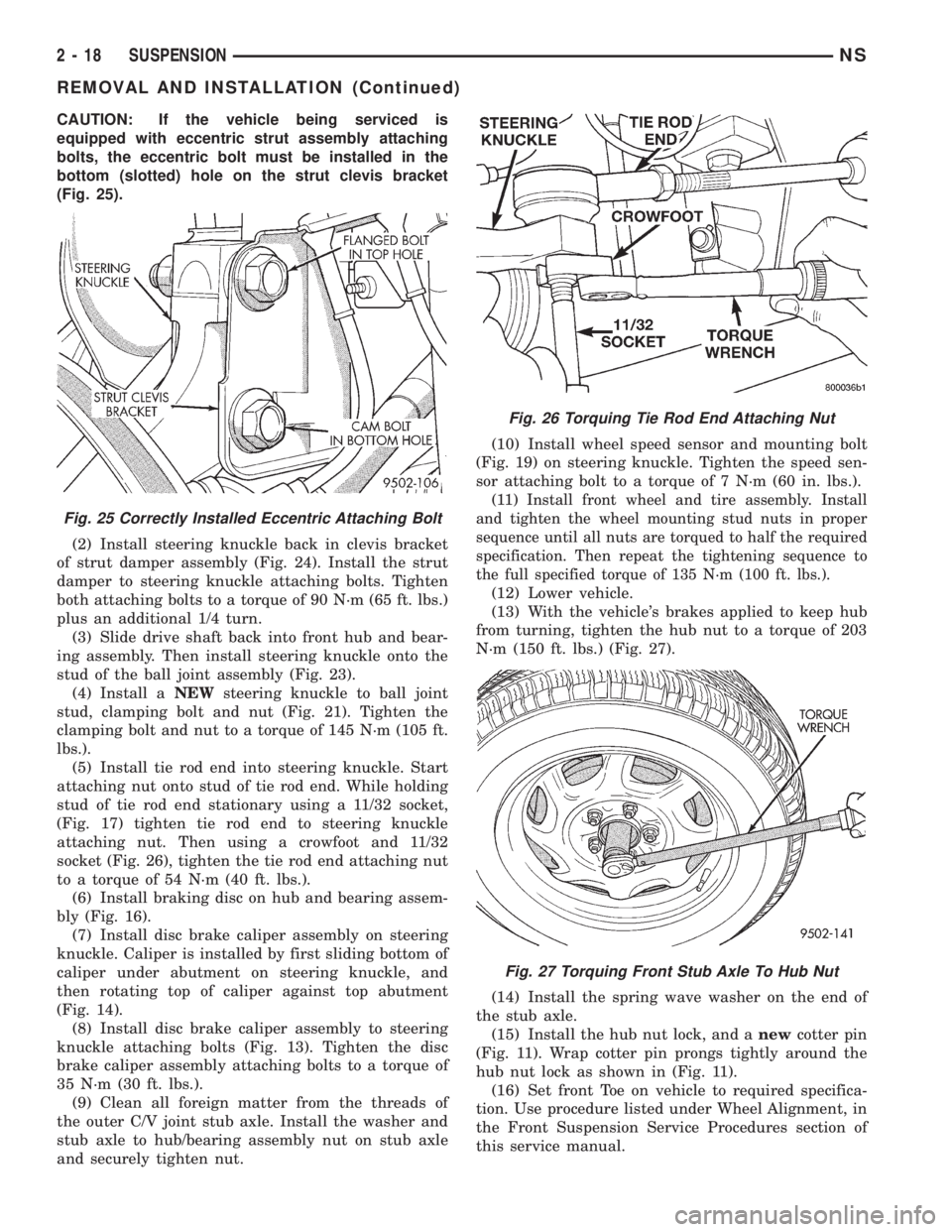

CAUTION: If the vehicle being serviced is

equipped with eccentric strut assembly attaching

bolts, the eccentric bolt must be installed in the

bottom (slotted) hole on the strut clevis bracket

(Fig. 25).

(2) Install steering knuckle back in clevis bracket

of strut damper assembly (Fig. 24). Install the strut

damper to steering knuckle attaching bolts. Tighten

both attaching bolts to a torque of 90 N´m (65 ft. lbs.)

plus an additional 1/4 turn.

(3) Slide drive shaft back into front hub and bear-

ing assembly. Then install steering knuckle onto the

stud of the ball joint assembly (Fig. 23).

(4) Install aNEWsteering knuckle to ball joint

stud, clamping bolt and nut (Fig. 21). Tighten the

clamping bolt and nut to a torque of 145 N´m (105 ft.

lbs.).

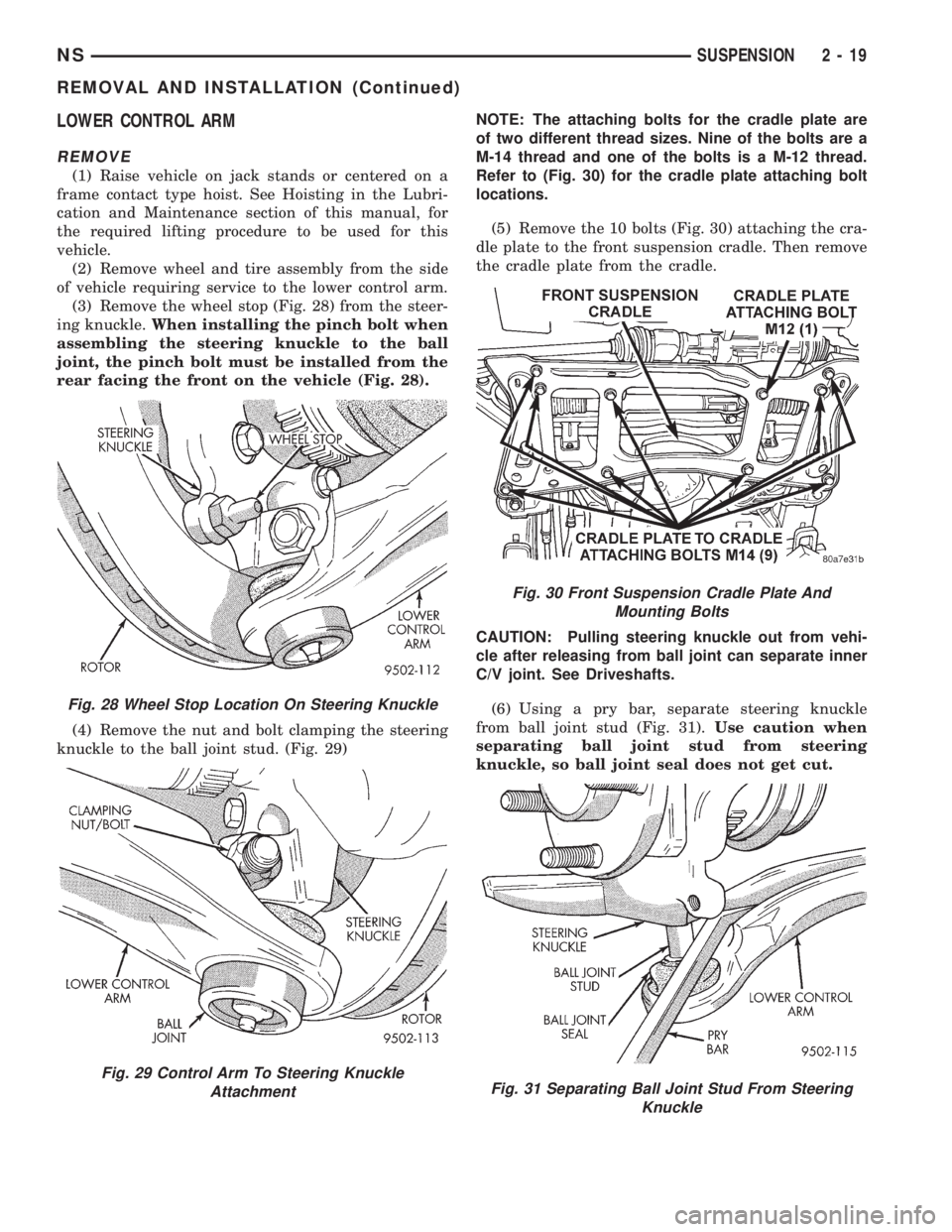

(5) Install tie rod end into steering knuckle. Start

attaching nut onto stud of tie rod end. While holding

stud of tie rod end stationary using a 11/32 socket,

(Fig. 17) tighten tie rod end to steering knuckle

attaching nut. Then using a crowfoot and 11/32

socket (Fig. 26), tighten the tie rod end attaching nut

to a torque of 54 N´m (40 ft. lbs.).

(6) Install braking disc on hub and bearing assem-

bly (Fig. 16).

(7) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding bottom of

caliper under abutment on steering knuckle, and

then rotating top of caliper against top abutment

(Fig. 14).

(8) Install disc brake caliper assembly to steering

knuckle attaching bolts (Fig. 13). Tighten the disc

brake caliper assembly attaching bolts to a torque of

35 N´m (30 ft. lbs.).

(9) Clean all foreign matter from the threads of

the outer C/V joint stub axle. Install the washer and

stub axle to hub/bearing assembly nut on stub axle

and securely tighten nut.(10) Install wheel speed sensor and mounting bolt

(Fig. 19) on steering knuckle. Tighten the speed sen-

sor attaching bolt to a torque of 7 N´m (60 in. lbs.).

(11)

Install front wheel and tire assembly. Install

and tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half the required

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(12) Lower vehicle.

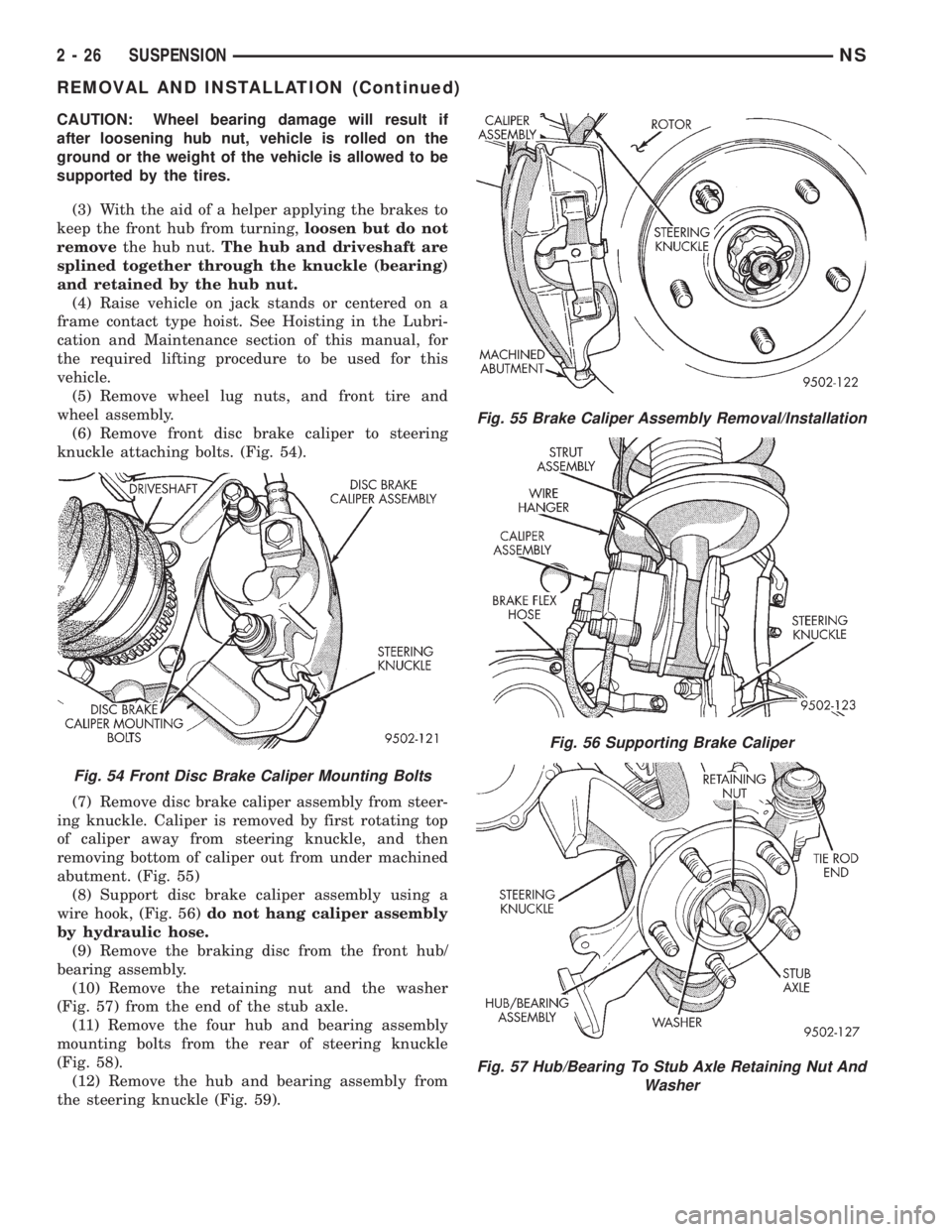

(13) With the vehicle's brakes applied to keep hub

from turning, tighten the hub nut to a torque of 203

N´m (150 ft. lbs.) (Fig. 27).

(14) Install the spring wave washer on the end of

the stub axle.

(15) Install the hub nut lock, and anewcotter pin

(Fig. 11). Wrap cotter pin prongs tightly around the

hub nut lock as shown in (Fig. 11).

(16) Set front Toe on vehicle to required specifica-

tion. Use procedure listed under Wheel Alignment, in

the Front Suspension Service Procedures section of

this service manual.

Fig. 25 Correctly Installed Eccentric Attaching Bolt

Fig. 26 Torquing Tie Rod End Attaching Nut

Fig. 27 Torquing Front Stub Axle To Hub Nut

2 - 18 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 51 of 1938

LOWER CONTROL ARM

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove wheel and tire assembly from the side

of vehicle requiring service to the lower control arm.

(3) Remove the wheel stop (Fig. 28) from the steer-

ing knuckle.When installing the pinch bolt when

assembling the steering knuckle to the ball

joint, the pinch bolt must be installed from the

rear facing the front on the vehicle (Fig. 28).

(4) Remove the nut and bolt clamping the steering

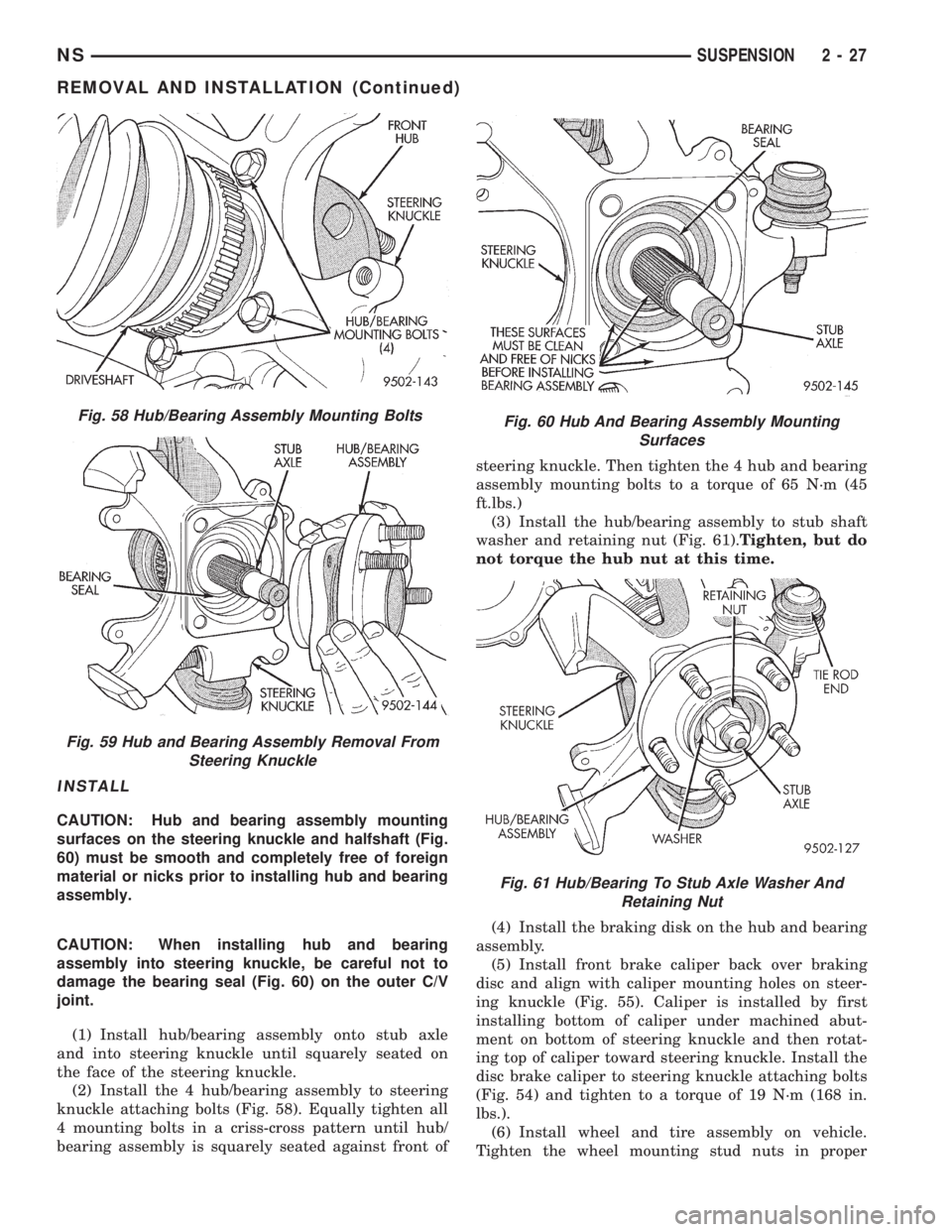

knuckle to the ball joint stud. (Fig. 29)NOTE: The attaching bolts for the cradle plate are

of two different thread sizes. Nine of the bolts are a

M-14 thread and one of the bolts is a M-12 thread.

Refer to (Fig. 30) for the cradle plate attaching bolt

locations.

(5) Remove the 10 bolts (Fig. 30) attaching the cra-

dle plate to the front suspension cradle. Then remove

the cradle plate from the cradle.

CAUTION: Pulling steering knuckle out from vehi-

cle after releasing from ball joint can separate inner

C/V joint. See Driveshafts.

(6) Using a pry bar, separate steering knuckle

from ball joint stud (Fig. 31).Use caution when

separating ball joint stud from steering

knuckle, so ball joint seal does not get cut.

Fig. 28 Wheel Stop Location On Steering Knuckle

Fig. 29 Control Arm To Steering Knuckle

Attachment

Fig. 30 Front Suspension Cradle Plate And

Mounting Bolts

Fig. 31 Separating Ball Joint Stud From Steering

Knuckle

NSSUSPENSION 2 - 19

REMOVAL AND INSTALLATION (Continued)

Page 58 of 1938

CAUTION: Wheel bearing damage will result if

after loosening hub nut, vehicle is rolled on the

ground or the weight of the vehicle is allowed to be

supported by the tires.

(3) With the aid of a helper applying the brakes to

keep the front hub from turning,loosen but do not

removethe hub nut.The hub and driveshaft are

splined together through the knuckle (bearing)

and retained by the hub nut.

(4) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(5) Remove wheel lug nuts, and front tire and

wheel assembly.

(6) Remove front disc brake caliper to steering

knuckle attaching bolts. (Fig. 54).

(7) Remove disc brake caliper assembly from steer-

ing knuckle. Caliper is removed by first rotating top

of caliper away from steering knuckle, and then

removing bottom of caliper out from under machined

abutment. (Fig. 55)

(8) Support disc brake caliper assembly using a

wire hook, (Fig. 56)do not hang caliper assembly

by hydraulic hose.

(9) Remove the braking disc from the front hub/

bearing assembly.

(10) Remove the retaining nut and the washer

(Fig. 57) from the end of the stub axle.

(11) Remove the four hub and bearing assembly

mounting bolts from the rear of steering knuckle

(Fig. 58).

(12) Remove the hub and bearing assembly from

the steering knuckle (Fig. 59).

Fig. 54 Front Disc Brake Caliper Mounting Bolts

Fig. 55 Brake Caliper Assembly Removal/Installation

Fig. 56 Supporting Brake Caliper

Fig. 57 Hub/Bearing To Stub Axle Retaining Nut And

Washer

2 - 26 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 59 of 1938

INSTALL

CAUTION: Hub and bearing assembly mounting

surfaces on the steering knuckle and halfshaft (Fig.

60) must be smooth and completely free of foreign

material or nicks prior to installing hub and bearing

assembly.

CAUTION: When installing hub and bearing

assembly into steering knuckle, be careful not to

damage the bearing seal (Fig. 60) on the outer C/V

joint.

(1) Install hub/bearing assembly onto stub axle

and into steering knuckle until squarely seated on

the face of the steering knuckle.

(2) Install the 4 hub/bearing assembly to steering

knuckle attaching bolts (Fig. 58). Equally tighten all

4 mounting bolts in a criss-cross pattern until hub/

bearing assembly is squarely seated against front ofsteering knuckle. Then tighten the 4 hub and bearing

assembly mounting bolts to a torque of 65 N´m (45

ft.lbs.)

(3) Install the hub/bearing assembly to stub shaft

washer and retaining nut (Fig. 61).Tighten, but do

not torque the hub nut at this time.

(4) Install the braking disk on the hub and bearing

assembly.

(5) Install front brake caliper back over braking

disc and align with caliper mounting holes on steer-

ing knuckle (Fig. 55). Caliper is installed by first

installing bottom of caliper under machined abut-

ment on bottom of steering knuckle and then rotat-

ing top of caliper toward steering knuckle. Install the

disc brake caliper to steering knuckle attaching bolts

(Fig. 54) and tighten to a torque of 19 N´m (168 in.

lbs.).

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

Fig. 58 Hub/Bearing Assembly Mounting Bolts

Fig. 59 Hub and Bearing Assembly Removal From

Steering Knuckle

Fig. 60 Hub And Bearing Assembly Mounting

Surfaces

Fig. 61 Hub/Bearing To Stub Axle Washer And

Retaining Nut

NSSUSPENSION 2 - 27

REMOVAL AND INSTALLATION (Continued)

Page 60 of 1938

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(7) Lower vehicle to the ground.

CAUTION: When tightening hub/bearing assembly

to stub shaft retaining nut, do not exceed the max-

imum torque of 244 N´m (180 ft. lbs.).

(8) With vehicle brakes applied to keep vehicle

from moving, torque stub shaft to hub/bearing assem-

bly retaining nut to 244 N´m (180 ft. lbs.).

(9) Check the Toe setting on the vehicle and reset

if not within specifications.

FRONT WHEEL MOUNTING STUDS

REMOVE

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

CAN NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature bearing failure.

The following procedure and special tools shown

MUST BEused when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual for

the required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire assembly from

the vehicle.

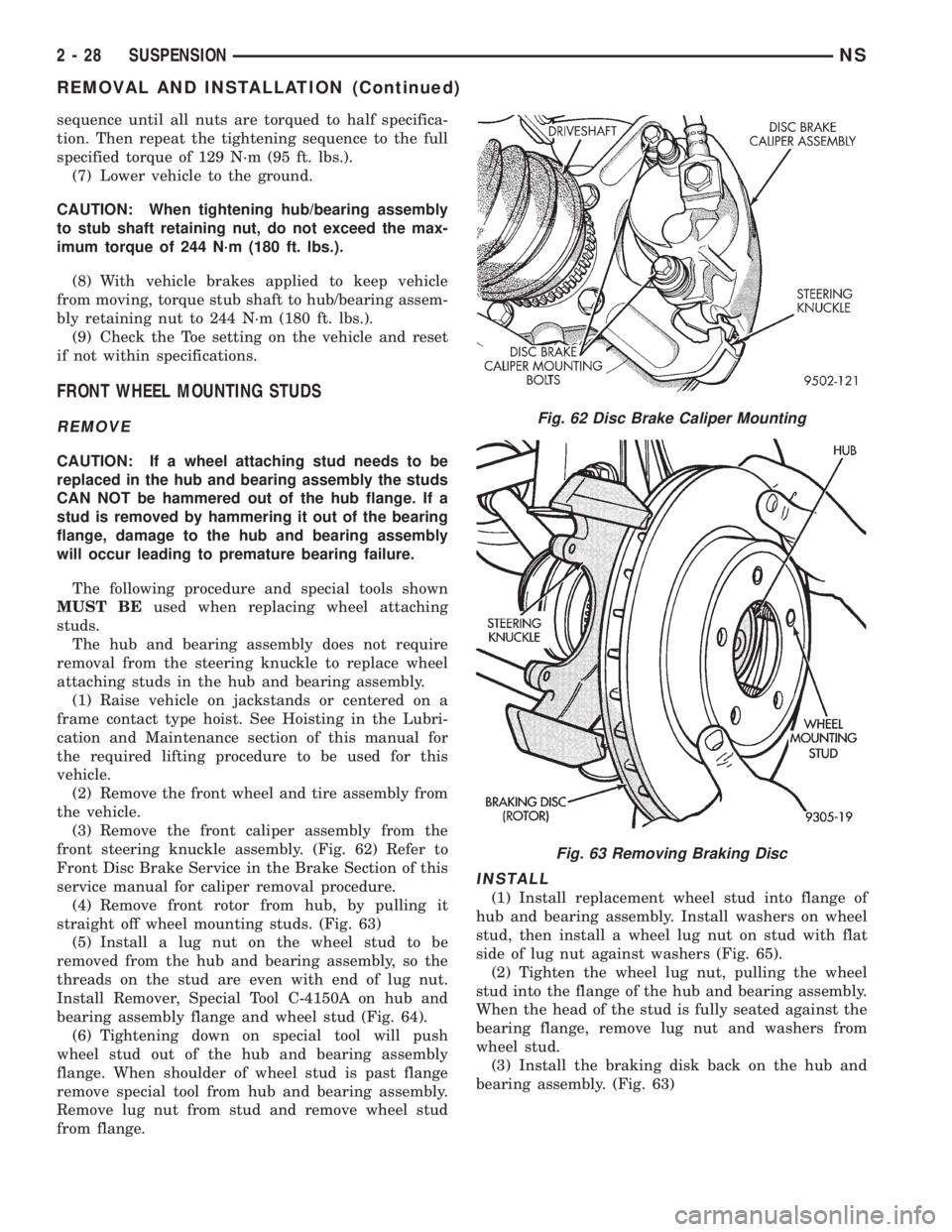

(3) Remove the front caliper assembly from the

front steering knuckle assembly. (Fig. 62) Refer to

Front Disc Brake Service in the Brake Section of this

service manual for caliper removal procedure.

(4) Remove front rotor from hub, by pulling it

straight off wheel mounting studs. (Fig. 63)

(5) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly, so the

threads on the stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 64).

(6) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange. When shoulder of wheel stud is past flange

remove special tool from hub and bearing assembly.

Remove lug nut from stud and remove wheel stud

from flange.

INSTALL

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 65).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the braking disk back on the hub and

bearing assembly. (Fig. 63)

Fig. 62 Disc Brake Caliper Mounting

Fig. 63 Removing Braking Disc

2 - 28 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 62 of 1938

(3) Install the rear brake drum on the hub and

bearing assembly.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(5) Lower vehicle to the ground.

DISASSEMBLY AND ASSEMBLY

Mc PHERSON STRUT

DISASSEMBLY

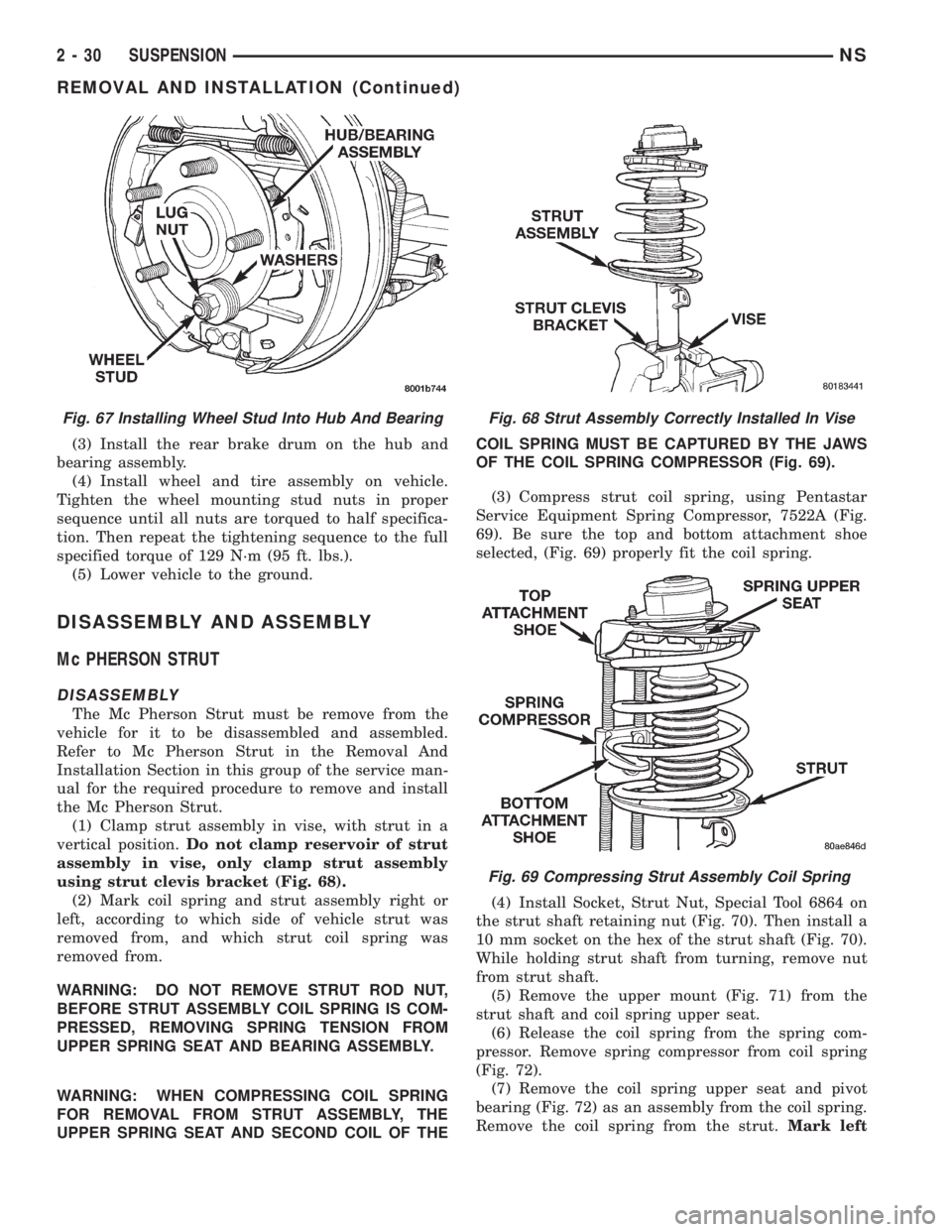

The Mc Pherson Strut must be remove from the

vehicle for it to be disassembled and assembled.

Refer to Mc Pherson Strut in the Removal And

Installation Section in this group of the service man-

ual for the required procedure to remove and install

the Mc Pherson Strut.

(1) Clamp strut assembly in vise, with strut in a

vertical position.Do not clamp reservoir of strut

assembly in vise, only clamp strut assembly

using strut clevis bracket (Fig. 68).

(2) Mark coil spring and strut assembly right or

left, according to which side of vehicle strut was

removed from, and which strut coil spring was

removed from.

WARNING: DO NOT REMOVE STRUT ROD NUT,

BEFORE STRUT ASSEMBLY COIL SPRING IS COM-

PRESSED, REMOVING SPRING TENSION FROM

UPPER SPRING SEAT AND BEARING ASSEMBLY.

WARNING: WHEN COMPRESSING COIL SPRING

FOR REMOVAL FROM STRUT ASSEMBLY, THE

UPPER SPRING SEAT AND SECOND COIL OF THECOIL SPRING MUST BE CAPTURED BY THE JAWS

OF THE COIL SPRING COMPRESSOR (Fig. 69).

(3) Compress strut coil spring, using Pentastar

Service Equipment Spring Compressor, 7522A (Fig.

69). Be sure the top and bottom attachment shoe

selected, (Fig. 69) properly fit the coil spring.

(4) Install Socket, Strut Nut, Special Tool 6864 on

the strut shaft retaining nut (Fig. 70). Then install a

10 mm socket on the hex of the strut shaft (Fig. 70).

While holding strut shaft from turning, remove nut

from strut shaft.

(5) Remove the upper mount (Fig. 71) from the

strut shaft and coil spring upper seat.

(6) Release the coil spring from the spring com-

pressor. Remove spring compressor from coil spring

(Fig. 72).

(7) Remove the coil spring upper seat and pivot

bearing (Fig. 72) as an assembly from the coil spring.

Remove the coil spring from the strut.Mark left

Fig. 67 Installing Wheel Stud Into Hub And BearingFig. 68 Strut Assembly Correctly Installed In Vise

Fig. 69 Compressing Strut Assembly Coil Spring

2 - 30 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)