CHRYSLER VOYAGER 2000 Diagnostic Manual

Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 251 of 364

Symptom:

* CHECKING MAP SENSOR CALIBRATION

POSSIBLE CAUSES

MAP SENSOR DEFECTIVE

TEST ACTION APPLICABILITY

1 Ignition Off

Tee-in a Vacuum Gauge to a Manifold Vacuum source.

Start the engine.

Allow engine to idle.

Note: If engine will not idle, maintain a constant RPM above idle.

Using the DRB, read MAP Sensor Vacuum.

Is the reading within 1 inch of the teed-in Vacuum Gauge?All

Ye s®Go To 2

No®Replace the MAP Sensor.

Perform Verification Test VER-2A.

2 Ignition Off

Disconnect the MAP Sensor Harness Connector.

Ignition On.

Using a voltmeter, measure the 5±volt supply circuit.

Is the voltage above 4.0 volts?All

Ye s®Test Complete.

No®Repair the open 5±volt supply circuit.

Perform Verification Test VER-2A.

245

DRIVEABILITY

ProCarManuals.com

Page 252 of 364

Symptom:

* CHECKING MINIMUM IDLE AIR FLOW

POSSIBLE CAUSES

MINIMUM AIR FLOW IS WITHIN ACCEPTABLE RANGE

THROTTLE BODY DEFECTIVE (MIN AIR FLOW OUT OF RANGE)

TEST ACTION APPLICABILITY

1 Start the engine and allow it to reach operating temperature.

Perform the Minimum Air Flow test as described in service information.

Is idle RPM within the range shown in the chart?All

Ye s®Throttle Body minimum air flow is set correctly.

No®Go To 2

2 Ignition Off

Remove Throttle Body per service information.

Note: Clean Throttle Body in a well ventilated area and wear rubber gloves.

While holding the Throttle open, spray entire Throttle Body Bore with Mopar parts

cleaner.

Using a soft scuff pad, clean the Throttle Body Bore and Throttle Plate.

Using compressed air, dry the Throttle Body and install Throttle Body on manifold.

Start the engine and allow it to reach operating temperature.

With the DRB, enter System Test and perform the Minimum Air Flow Test.

Is the idle RPM within the range shown in the chart?All

Ye s®Test Complete.

No®Replace Throttle Body.

Perform Verification Test VER-2A.

246

DRIVEABILITY

ProCarManuals.com

Page 253 of 364

Symptom:

* CHECKING OXYGEN SENSOR HEATER

POSSIBLE CAUSES

1/2 O2 SENSOR VOLTAGE BTWN 0.4 V & 0.6 V

1/1 O2 SENSOR DEFECTIVE

1/2 O2 SENSOR DEFECTIVE

ASD RELAY OUTPUT CIRCUIT OPEN (1/1 O2 SEN)

ASD RELAY OUTPUT CIRCUIT OPEN (1/2 O2 SEN)

HEATER GROUND CIRCUIT OPEN (1/1 O2 SEN)

HEATER GROUND CIRCUIT OPEN (1/2 O2 SEN)

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, actuate the ASD O2 Sensor Heater test.

Wait two minutes for O2 Sensor voltage to stabilize.

Read the Upstream O2 Sensor voltage.

Is the voltage of the Upstream O2 Sensor between 0.4 and 0.6 volts?All

Ye s®Go To 2

No®Go To 5

2Note: The O2 Sensor voltage staying between 0.4 V and 0.6 V indicates a

problem with that Sensor Circuit.

Ignition Off

Disconnect the Upstream O2 Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Turn key on.

With the DRB, actuate the O2 Sensor Heater test.

Using a Voltmeter, measure the ASD Relay Output Circuit at Sensor Connector.

Is the voltage above 10.0 volts?All

Ye s®Go To 3

No®Repair the open ASD Relay Output Circuit from O2 sensor

connector back to splice.

Perform Powertrain Verification Test VER-2A.

3 Ignition Off

Disconnect the Upstream O2 Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance between the Heater Ground Circuit and

a good ground.

Is the resistance below 5.0 ohms?All

Ye s®Go To 4

No®Repair the open Heater Ground Circuit to the Upstream O2

Sensor.

Perform Powertrain Verification Test VER-2A.

247

DRIVEABILITY

ProCarManuals.com

Page 254 of 364

TEST ACTION APPLICABILITY

4 If there are no potential causes remaining, the Upstream O2 Sensor is assumed to be

defective.

View repair options.All

Repair

Replace the Upstream O2 Sensor.

Perform Powertrain Verification Test VER-2A.

5 Ignition Off

Turn key on.

With the DRB, actuate the O2 Sensor Heater test.

Wait two minutes for O2 Sensor voltage to stabilize.

With the DRB, read the Downstream O2 Sensor voltage.

Is the voltage of the Downstream O2 Sensor between 0.4 and 0.6 volts?All

Ye s®Go To 6

No®Test complete.

6Note: The O2 Sensor voltage staying between 0.4 and 0.6 V indicates a

problem with that Sensor Circuit.

Ignition Off

Disconnect the Downstream O2 Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Turn key on.

With the DRB, actuate the O2 Sensor Heater test.

Using a Voltmeter, measure the ASD Relay Output Circuit in Sensor Connector.

Is the voltage above 10.0 volts?All

Ye s®Go To 7

No®Repair the open ASD Relay Output Circuit from O2 Sensor

Connector back to splice.

Perform Powertrain Verification Test VER-2A.

7 Ignition Off

Disconnect the Downstream O2 Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance between the Heater Ground Circuit and

a good ground.

Is the resistance below 5.0 ohms?All

Ye s®Go To 8

No®Repair the open Heater Ground Circuit to the Downstream O2

Sensor.

Perform Powertrain Verification Test VER-2A.

8 If there are no potential causes remaining, the Downstream O2 Sensor is assumed to

be defective.

View repair options.All

Repair

Replace the Downstream O2 Sensor.

Perform Powertrain Verification Test VER-2A.

248

DRIVEABILITY

* CHECKING OXYGEN SENSOR HEATER ÐContinued

ProCarManuals.com

Page 255 of 364

Symptom:

* CHECKING PARK/NEUTRAL POSITION SWITCH

POSSIBLE CAUSES

DISPLAY SHOWS9P/N9AND9D/R9

TRANSMISSION RANGE SENSOR DEFECTIVE

PARK/NEUTRAL POSITION SWITCH SENSE CIRCUIT OPEN

PARK/NEUTRAL SWITCH SENSE CIRCUIT SHORT TO GROUND

PCM DEF (P/N POSN SW)

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, read Park/Neutral Position Switch state.

While moving the gear selector through all gear positions, watch DRB display.

Does the display show9P/N9and9D/R9?All

Ye s®Park/Neutral Position Switch normal, test pass.

No®Go To 2

2 Ignition Off

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between the Park/Neutral Position Switch Sense Circuit at

the Powertrain Control Module Connector and ground.

While moving gear selector through all gear positions, watch the ohmmeter.

Did the display stay below 5.0 ohms at all times?All

Ye s®Go To 3

No®Go To 5

3 Ignition Off

Disconnect the negative Battery cable.

Disconnect the Powertrain Control Module.

Disconnect the Transmission Control Module.

Measure the resistance between the Park/Neutral Position Switch Sense Circuit at

the PCM harness connector and ground.

Ignition On.

Move the gear selector through all gear positions.

Did the ohmmeter display above 5.0 ohms to below 5.0 ohms?All

Ye s®Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-2A.

No®Go To 4

249

DRIVEABILITY

ProCarManuals.com

Page 256 of 364

TEST ACTION APPLICABILITY

4 Ignition Off

Disconnect the Powertrain Control Module.

Disconnect the Transmission Range Sensor.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between the Park/Neutral Position Switch Sense Circuit at

the Powertrain Control Module Connector and ground.

While moving gear selector through all gear positions, watch the ohmmeter.

Did the display still remain below 5.0 ohms?All

Ye s®Repair P/N Switch Sense Ckt for a short to ground.

Perform Powertrain Verification Test VER-2A.

No®Test Complete.

5 Ignition Off

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between the Park/Neutral Position Switch Sense Circuit at

the Powertrain Control Module Connector and ground.

While moving gear selector through all gear positions, watch the ohmmeter.

Did the display switch from below 5.0 ohms to above 5.0 ohms?All

Ye s®Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-2A.

No®Go To 6

6 Ignition Off

Disconnect the Powertrain Control Module.

Disconnect the Transmission Range Sensor (TRS) Connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Park/Neutral Position Switch Sense Circuit from the

PCM Connector to the TRS Connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 7

No®Repair open P/N Position Switch Sense Ckt.

Perform Powertrain Verification Test VER-2A.

7 If there are no potential causes remaining, the Transmission Range Sensor or the

P/N Switch is assumed to be defective.

View repair options.All

Repair

Replace the Transmission Range Sensor or P/N Switch.

Perform Powertrain Verification Test VER-2A.

250

DRIVEABILITY

* CHECKING PARK/NEUTRAL POSITION SWITCH ÐContinued

ProCarManuals.com

Page 257 of 364

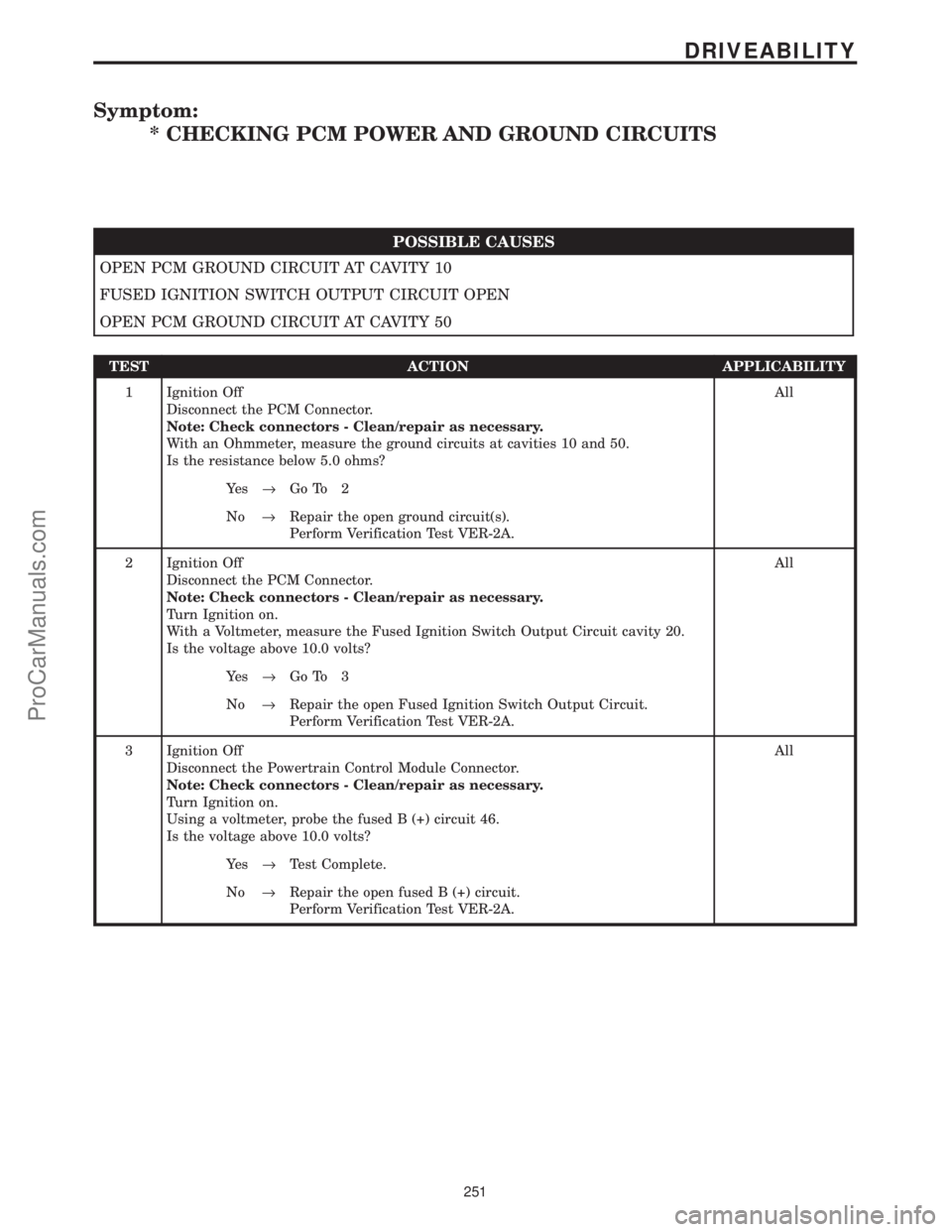

Symptom:

* CHECKING PCM POWER AND GROUND CIRCUITS

POSSIBLE CAUSES

OPEN PCM GROUND CIRCUIT AT CAVITY 10

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

OPEN PCM GROUND CIRCUIT AT CAVITY 50

TEST ACTION APPLICABILITY

1 Ignition Off

Disconnect the PCM Connector.

Note: Check connectors - Clean/repair as necessary.

With an Ohmmeter, measure the ground circuits at cavities 10 and 50.

Is the resistance below 5.0 ohms?All

Ye s®Go To 2

No®Repair the open ground circuit(s).

Perform Verification Test VER-2A.

2 Ignition Off

Disconnect the PCM Connector.

Note: Check connectors - Clean/repair as necessary.

Turn Ignition on.

With a Voltmeter, measure the Fused Ignition Switch Output Circuit cavity 20.

Is the voltage above 10.0 volts?All

Ye s®Go To 3

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Verification Test VER-2A.

3 Ignition Off

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

Turn Ignition on.

Using a voltmeter, probe the fused B (+) circuit 46.

Is the voltage above 10.0 volts?All

Ye s®Test Complete.

No®Repair the open fused B (+) circuit.

Perform Verification Test VER-2A.

251

DRIVEABILITY

ProCarManuals.com

Page 258 of 364

Symptom:

* CHECKING SECONDARY IGNITION

POSSIBLE CAUSES

SECONDARY IGNITION OUT OF SPECIFICATION

IGNITION COIL DEFECTIVE

SECONDARY IGNITION SYSTEM DEFECTIVE (WATER TEST)

TEST ACTION APPLICABILITY

1 Ignition Off.

Connect a suitable Engine Analyzer to the Engine.

Start Engine.

Allow Engine to idle.

Note: If the Engine will not idle, maintain a constant RPM above idle.

Note: Set the Scope to read, display or parade pattern.

Follow the equipment manufacturer's procedure for pattern analysis.

Is the secondary ignition pattern ok?All

Ye s®Go To 2

No®Repair the indicated component in the Secondary Ignition Sys-

tem.

Perform Powertrain Verification Test VER-2A.

2 Ignition Off

Connect a suitable Engine Analyzer to the engine.

Start the Engine and allow it to idle.

Note: If the engine will not idle, maintain a constant RPM above idle.

Set scope to read display or parade pattern.

Follow the equipment manufacturer's procedure for pattern analysis.

Note: Do not spray the Inductive Pickup.

With a spray bottle, spray the Ignition Cables with water and monitor Ignition

Pattern.

Did the Ignition Pattern change?All

Ye s®Repair the indicated component in the Secondary Ignition Sys-

tem.

Perform Powertrain Verification Test VER-2A.

No®Go To 3

3 Ignition Off

Connect a suitable Engine Analyzer to the engine.

Start the engine and allow it to idle.

Note: If the engine will not idle, maintain a constant RPM above idle.

Note: Set the scope to read display or parade pattern.

Follow the equipment manufacturer's procedure for pattern analysis.

Momentarily remove and reinstall the Spark Plug Wires.

While disconnecting each wire, observe the secondary KV line.

Is the open circuit Secondary voltage at least 25KV?All

Ye s®Test Complete.

No®Replace the Ignition Coil.

Perform Powertrain Verification Test VER-2A.

252

DRIVEABILITY

ProCarManuals.com

Page 259 of 364

Symptom:

* CHECKING THE ENGINE MECHANICAL SYSTEMS

POSSIBLE CAUSES

CHECKING ENGINE MECHANICAL SYSTEMS

TEST ACTION APPLICABILITY

1 At this point in the diagnostic test procedure, you have determined that all of the

engine electrical systems are operating as designed; therefore, they are not the cause

of the driveability problem.

The following additional items should be checked as possible mechanical causes of

the problem:

ENGINE VACUUM - must be at least 13 inches in neutral

ENGINE VALVE TIMING - must be within specifications

ENGINE COMPRESSION - must be within specifications

CAMSHAFT LOBES - check for abnormal wear

CRANK SENSOR PICK-UP - check crankshaft slots for debris/deterioration

ENGINE EXHAUST SYSTEM - must be free of any restrictions

ENGINE PCV SYSTEM - must flow freely

ENGINE DRIVE SPROCKETS - must be properly positioned

TORQUE CONVERTER STALL SPEED - must be within specifications

POWER BRAKE BOOSTER - no internal vacuum leaks

FUEL - must be free of contamination

FUEL INJECTOR - plugged or restricted injector; control wire not connected to

correct injector

Note: If you came to this test from the oxygen sensor, and the rich or lean

condition is not caused by one of the first items above, replace the power-

train control module and perform TEST VER-2A (Road Test Verification).

Always look for any Technical Service Bulletins that may relate to the problem.

Did you come from an Oxygen Sensor rich or lean condition test?All

Ye s®Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-2A.

No®Test Complete.

253

DRIVEABILITY

ProCarManuals.com

Page 260 of 364

Symptom:

* CHECKING THROTTLE POSITION SENSOR CALIBRATION

POSSIBLE CAUSES

TPS VOLTAGE CHANGE NOT A SMOOTH TRANSITION

TPS VOLTAGE ABOVE 1.5 V WITH THROTTLE CLOSED

THROTTLE CABLE AND BODY BINDING OR RESTRICTED

TPS VOLTAGE BELOW 3.4 V AT WIDE OPEN THROTTLE

TEST ACTION APPLICABILITY

1 Ignition Off

Check the Throttle Cable and Body for binding or restrictions.

Note: Also check Speed Control Cable if equipped.

Is there any binding or restriction?All

Ye s®Repair as necessary.

Perform Verification Test VER-2A.

No®Go To 2

2 Ignition On, Engine Not Running

While slowly opening the Throttle from closed to wide open, monitor the Throttle

Position Sensor voltage at the DRB.

Was the voltage change a smooth transition?All

Ye s®Go To 3

No®Replace Throttle Position Sensor.

Perform Verification Test VER-2A.

3 Ignition On, Engine Not Running

With the DRB, read the Throttle Position Sensor voltage.

Note: Throttle must be fully closed and against the Throttle Stop.

Is the voltage 1.5 V or less with the Throttle closed?All

Ye s®Go To 4

No®Replace Throttle Position Sensor.

Perform Verification Test VER-2A.

4 Was the maximum voltage at least 3.4 volts at wide open Throttle? All

Ye s®Test Complete.

No®Replace Throttle Position Sensor.

Perform Verification Test VER-2A.

254

DRIVEABILITY

ProCarManuals.com