belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1384 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Install a substitute relay in place of the Fuel Heater Relay.

Disconnect the ECM harness connectors.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fuel Heater Relay Output

circuit.

Is the test light on?All

Ye s®Replace the initial Fuel Heater Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

5 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Crankcase Vent Heater harness connector.

Disconnect the Fuel Heater harness connector.

Remove the Fuel Heater Relay from the IPM.

Measure the resistance between ground and the Battery(+) Sense circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 6

No®Repair the Battery(+) Sense circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

165

DRIVEABILITY - DIESEL

P1511-BATTERY SENSE LINE 1 VOLTAGE TOO LOW ÐContinued

Page 1386 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the IPM.

Turn the ignition on.

Measure the voltage on ECM harness connector C1 cavities 4 and 5.

Is the voltage below 2.0 volts on both circuits?All

Ye s®Go To 5

No®Repair the ECM/PCM Relay Output circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

5 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the IPM.

Measure the resistance between ground and the ECM/PCM Relay Control circuit.

Is the resistance above 100k ohms?All

Ye s®Replace the ECM/PCM Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No®Repair the ECM/PCM Relay Control circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

6WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

167

DRIVEABILITY - DIESEL

P1605-IGNITION SWITCH PLAUSIBILITY ÐContinued

Page 1388 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition on.

With the DRBIIIt, erase ECM DTCs.

Turn the ignition on and off several times pausing 10 seconds between each key cycle.

With the DRBIIIt, read the ECM DTCs.

Are any P1685 DTCs present?All

Ye s®Go To 3

No®Go To 4

3 Replace and program the SKIM in accordance with the Service Information.

Turn the ignition on.

With the DRBIIIt, erase ECM DTCs.

Turn the ignition on and off several times pausing for 10 seconds between key cycles.

With the DRBIIIt, read ECM DTCs.

Are there any P1685 DTC's present?All

Ye s®Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

4WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

169

DRIVEABILITY - DIESEL

P1685-SKIM SYSTEM INVALID KEY CODE RECEIVED ÐContinued

Page 1393 of 4284

TEST ACTION APPLICABILITY

9 Turn the ignition on.

With the DRB III, read the PEDAL OUTPUT VOLTS.

With the accelerator pedal in the idle position, slowly depress the accelerator pedal

until the pedal is fully depressed.

NOTE: The PEDAL OUTPUT VOLTS should increase smoothly as the pedal

is depressed.

Does the voltage increase smoothly with the accelerator pedal travel?All

Ye s®Go To 10

No®Replace the Accelerator Pedal Position Sensor in accordance with

the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

10 Turn the ignition on.

With the DRB III, select Engine and with the custom display feature select Low Idle

Switch input and the Accel Pedal %.

Slowly depress and release the accelerator pedal several times while monitoring the

DRB III display.

NOTE: The Low Idle Switch state should change between 5% and 10% of

Accelerator Pedal position.

Did the Low Idle Switch state change between 5% and 10% of Accelerator Pedal

position?All

Ye s®Go To 11

No®Replace the Accelerator Pedal Position Sensor.

Perform ROAD TEST VERIFICATION - VER-2.

11WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

12 Turn the ignition off.

Disconnect the APP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the APP Sensor Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 13

No®Repair the APP Sensor Signal circuit for an open

Perform ROAD TEST VERIFICATION - VER-2.

174

DRIVEABILITY - DIESEL

P2120-ACC PEDAL POSITION SENSOR 1 CKT PLAUSIBILITY ÐContinued

Page 1421 of 4284

TEST ACTION APPLICABILITY

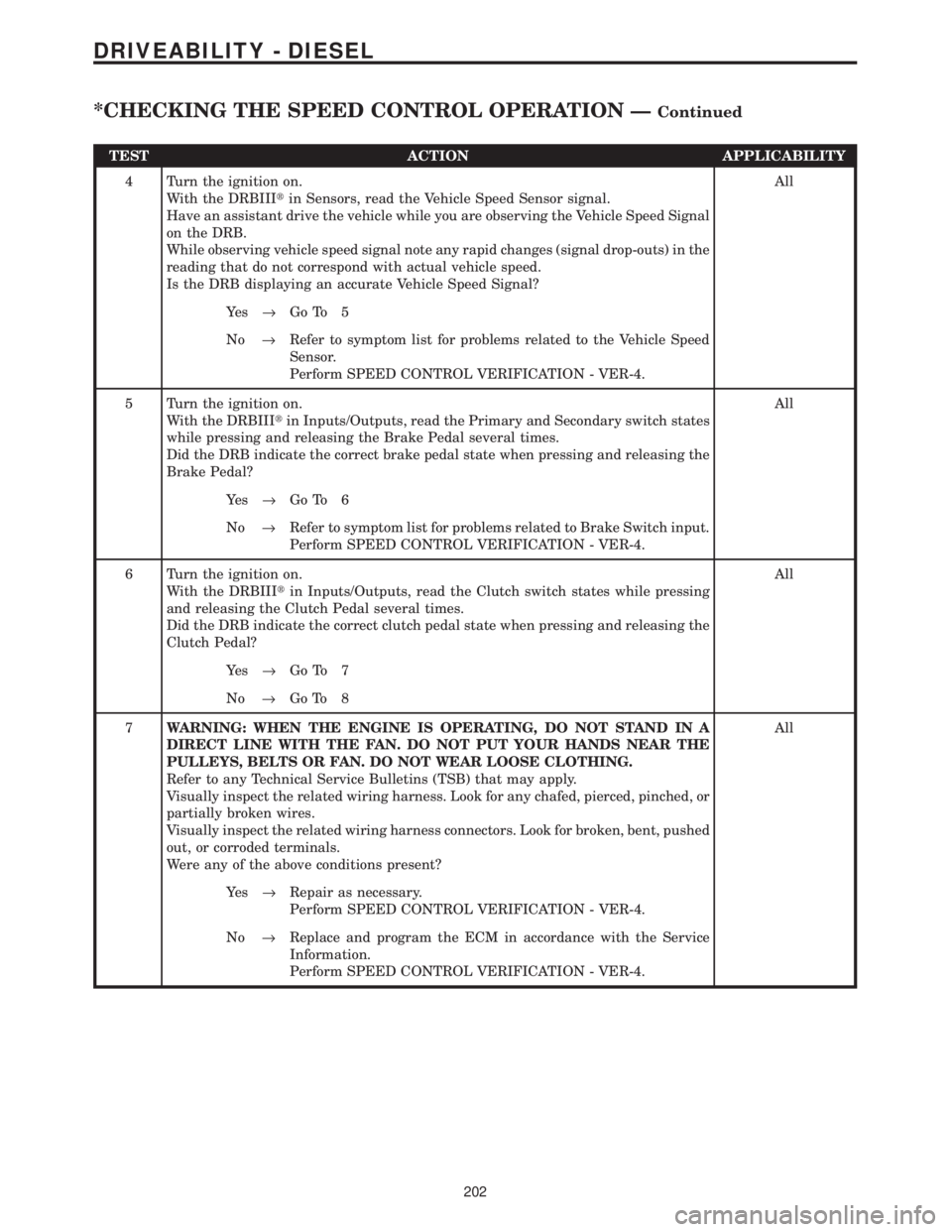

4 Turn the ignition on.

With the DRBIIItin Sensors, read the Vehicle Speed Sensor signal.

Have an assistant drive the vehicle while you are observing the Vehicle Speed Signal

on the DRB.

While observing vehicle speed signal note any rapid changes (signal drop-outs) in the

reading that do not correspond with actual vehicle speed.

Is the DRB displaying an accurate Vehicle Speed Signal?All

Ye s®Go To 5

No®Refer to symptom list for problems related to the Vehicle Speed

Sensor.

Perform SPEED CONTROL VERIFICATION - VER-4.

5 Turn the ignition on.

With the DRBIIItin Inputs/Outputs, read the Primary and Secondary switch states

while pressing and releasing the Brake Pedal several times.

Did the DRB indicate the correct brake pedal state when pressing and releasing the

Brake Pedal?All

Ye s®Go To 6

No®Refer to symptom list for problems related to Brake Switch input.

Perform SPEED CONTROL VERIFICATION - VER-4.

6 Turn the ignition on.

With the DRBIIItin Inputs/Outputs, read the Clutch switch states while pressing

and releasing the Clutch Pedal several times.

Did the DRB indicate the correct clutch pedal state when pressing and releasing the

Clutch Pedal?All

Ye s®Go To 7

No®Go To 8

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform SPEED CONTROL VERIFICATION - VER-4.

No®Replace and program the ECM in accordance with the Service

Information.

Perform SPEED CONTROL VERIFICATION - VER-4.

202

DRIVEABILITY - DIESEL

*CHECKING THE SPEED CONTROL OPERATION ÐContinued

Page 1426 of 4284

Symptom:

*ENGINE CRANKS BUT WILL NOT START

POSSIBLE CAUSES

CHECKING FOR ECM CODES

CHECKING FOR SKIM CODES

CHECKING THE ECT SENSOR

CHECKING THE GLOW PLUG OPERATION

ENGINE DRIVE BELT

FUEL INJECTOR DRIVER CIRCUIT(S) SHORTED TO GROUND

FUEL PRESSURE SENSOR

FUEL PRESSURE SENSOR 5-VOLT SUPPLY CIRCUIT OPEN

FUEL PRESSURE SENSOR SIGNAL CIRCUIT OPEN

FUEL SUPPLY CONTAMINATION

FUEL SYSTEM PRESSURE MECHANICAL

FUEL SYSTEM RESTRICTION

SENSOR GROUND OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read the ECM DTCs.

Does the DRBIIItdisplay any ECM DTCs?All

Ye s®Refer to symptom list for problems related to ECM DTC.

Perform NO START VERIFICATION - VER-1.

No®Go To 2

2 Turn the ignition on.

With the DRBIIIt, read the SKIM DTCs.

Does the DRBIIItdisplay any SKIM DTCs?All

Ye s®Refer to symptom list for problems related to SKIM DTC.

Perform NO START VERIFICATION - VER-1.

No®Go To 3

3 Using a temperature probe, check the vehicle temperature near the ECT Sensor.

Turn the ignition on.

With the DRBIIItin Sensors, read the ECT Sensor temperature.

Compare the temperature probe reading with the DRB reading.

Are the two readings within 10ÉC of each other?All

Ye s®Go To 4

No®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

207

DRIVEABILITY - DIESEL

Page 1428 of 4284

TEST ACTION APPLICABILITY

9 Refer to the Service Information and perform the fuel pressure test.

Is the fuel pressure within specification?All

Ye s®Go To 10

No®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

10 Refer to the Service Information and perform the fuel pressure test. Note the test

results.

Using the DRB, read the Fuel Pressure PSI and compare the two readings.

Are the two readings within 500 psi of each other?All

Ye s®Go To 11

No®Go To 12

11 Refer to the Service Information to ensure the Engine Drive Belt is installed correctly

and the camshaft and crankshaft gears are timed correctly.

Were any problems found?All

Ye s®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No®Check the fuel supply for contamination.

Perform NO START VERIFICATION - VER-1.

12 Turn the ignition off.

Disconnect the Fuel Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Fuel Pressure Sensor Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 13

No®Repair the Fuel Pressure Sensor Signal circuit for an open.

Perform NO START VERIFICATION - VER-1.

13 Turn the ignition off.

Disconnect the Fuel Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Fuel Pressure Sensor 5-volt Supply circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 14

No®Repair the Fuel Pressure Sensor 5-volt Supply circuit for an open.

Perform NO START VERIFICATION - VER-1.

14 Turn the ignition off.

Disconnect the Fuel Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Sensor Ground circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace the Fuel Pressure Sensor in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Sensor Ground circuit for an open.

Perform NO START VERIFICATION - VER-1.

209

DRIVEABILITY - DIESEL

*ENGINE CRANKS BUT WILL NOT START ÐContinued

Page 1430 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Relay from the PDC.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK

BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE

ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN.

DO NOT WEAR LOOSE CLOTHING.

Momentarily jumper Starter Relay connector cavities 30 and 87 in the IPM

connector.

Did the engine crank?All

Ye s®Go To 4

No®Go To 11

4 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit while fully depressing the clutch pedal and turning the ignition switch

to the START position.

Does the test light illuminate with the ignition switch in the START position?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Remove the Starter Relay From the PDC.

Install a substitute relay in place of the Starter Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s®Replace the Starter Relay.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, probe ECM harness connector cavity

49 while fully depressing the clutch pedal and turning the ignition switch to the

START position.

Does the test light illuminate while the ignition is in the Start position.All

Ye s®Go To 7

No®Repair the Ignition Switch Start Output circuit to the ECM.

Perform NO START VERIFICATION - VER-1.

211

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1473 of 4284

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts.

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

International Symbols

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

INTERNATIONAL SYMBOLS (Continued)

Page 1483 of 4284

FASTENER USAGE

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 4) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 4 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RGINTRODUCTION5a