CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1291 of 4284

TEST ACTION APPLICABILITY

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

72

DRIVEABILITY - DIESEL

P0235-BOOST PRESSURE SENSOR SUPPLY VOLTAGE TOO HIGH OR

LOW Ð

Continued

Page 1292 of 4284

Symptom:

P0335-CKP POSITION SENSOR CIRCUIT OVERSPEED RECOGNI-

TION

When Monitored and Set Condition:

P0335-CKP POSITION SENSOR CIRCUIT OVERSPEED RECOGNITION

When Monitored: With the engine running.

Set Condition: The engine speed sensor signal indicates engine speed is above 5100 RPM

for at least 500 milliseconds. NOTE: Engine damage is possible when the engine speed

exceeds 5100 RPM.

POSSIBLE CAUSES

CHECK FOR OTHER DTCS

ENGINE CONTROL MODULE

OPEN SHIELD CIRCUIT

REPLACE THE CRANKSHAFT POSITION SENSOR

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1CAUTION: Engine damage is possible when engine speed exceeds 5000

RPM.

NOTE: This DTC indicates the Engine Speed Sensor has seen an engine

speed above 5000 RPM. This can occur if the vehicle is in 5th gear and the

vehicle operator performs a downshift and accidentally downshifts from

5th gear to 2nd gear.

Turn the ignition on.

With the DRB, check for other Engine Speed Sensor DTCs.

Are other Engine Speed Sensor DTCs present?All

Ye s®Refer to symptom list for problems related to other DTCs before

continuing.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 2

2 Turn the ignition on.

With the DRB, erase ECM DTCs.

Test drive the vehicle and monitor the DRB for ECM DTCs.

Did this DTC reset?All

Ye s®Go To 3

No®Go To 5

73

DRIVEABILITY - DIESEL

Page 1293 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the CKP Sensor harness connector.

Measure the resistance of the Shield circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 4

No®Repair the Shield circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4 Replace the Crankshaft Position Sensor in accordance with the Service Information.

With the DRB, erase ECM DTCs.

Perform several drive cycles, turning the ignition off for at least 10 seconds between

each drive cycle.

Monitor the DRB for ECM DTCs.

Did this DTC reset?All

Ye s®Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®The repair is complete. Refer to the Service Information to check

for engine mechanical problems that may have occurred due to

excessive engine speed.

Perform ROAD TEST VERIFICATION - VER-2.

5WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Check the Engine Speed Sensor wiring harness for incorrect routing which may

cause EMI interference.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

74

DRIVEABILITY - DIESEL

P0335-CKP POSITION SENSOR CIRCUIT OVERSPEED RECOGNITION

Ð

Continued

Page 1294 of 4284

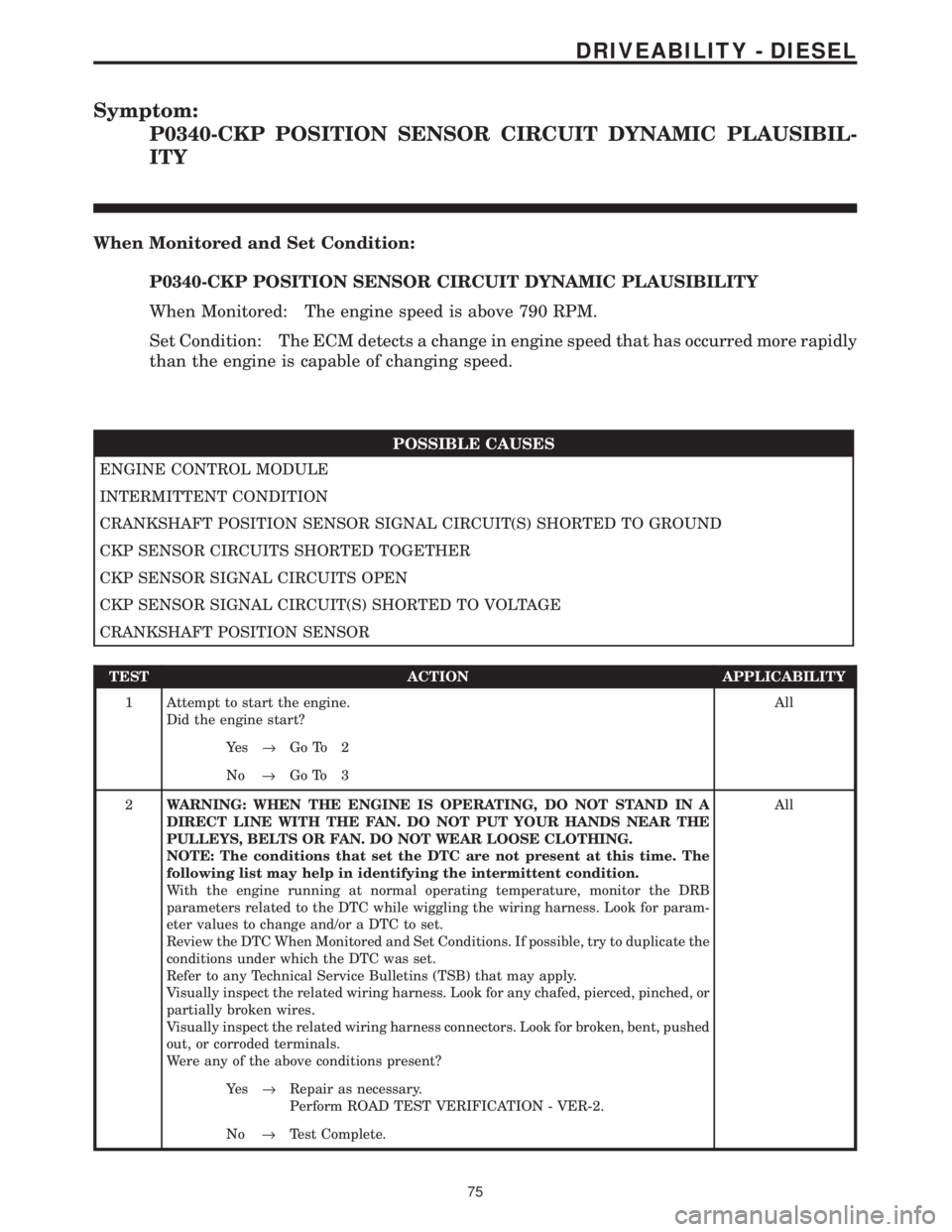

Symptom:

P0340-CKP POSITION SENSOR CIRCUIT DYNAMIC PLAUSIBIL-

ITY

When Monitored and Set Condition:

P0340-CKP POSITION SENSOR CIRCUIT DYNAMIC PLAUSIBILITY

When Monitored: The engine speed is above 790 RPM.

Set Condition: The ECM detects a change in engine speed that has occurred more rapidly

than the engine is capable of changing speed.

POSSIBLE CAUSES

ENGINE CONTROL MODULE

INTERMITTENT CONDITION

CRANKSHAFT POSITION SENSOR SIGNAL CIRCUIT(S) SHORTED TO GROUND

CKP SENSOR CIRCUITS SHORTED TOGETHER

CKP SENSOR SIGNAL CIRCUITS OPEN

CKP SENSOR SIGNAL CIRCUIT(S) SHORTED TO VOLTAGE

CRANKSHAFT POSITION SENSOR

TEST ACTION APPLICABILITY

1 Attempt to start the engine.

Did the engine start?All

Ye s®Go To 2

No®Go To 3

2WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

75

DRIVEABILITY - DIESEL

Page 1295 of 4284

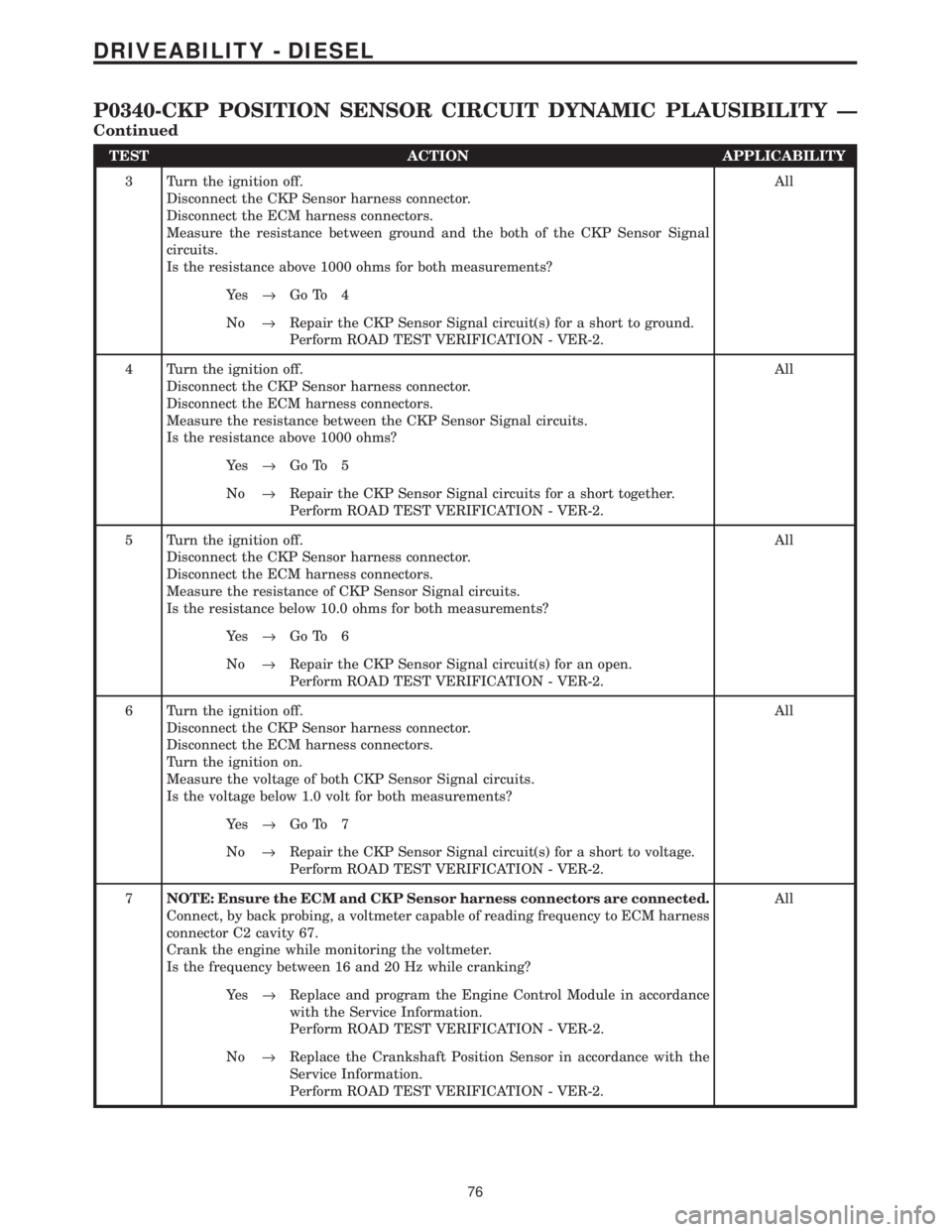

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the both of the CKP Sensor Signal

circuits.

Is the resistance above 1000 ohms for both measurements?All

Ye s®Go To 4

No®Repair the CKP Sensor Signal circuit(s) for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between the CKP Sensor Signal circuits.

Is the resistance above 1000 ohms?All

Ye s®Go To 5

No®Repair the CKP Sensor Signal circuits for a short together.

Perform ROAD TEST VERIFICATION - VER-2.

5 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of CKP Sensor Signal circuits.

Is the resistance below 10.0 ohms for both measurements?All

Ye s®Go To 6

No®Repair the CKP Sensor Signal circuit(s) for an open.

Perform ROAD TEST VERIFICATION - VER-2.

6 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Disconnect the ECM harness connectors.

Turn the ignition on.

Measure the voltage of both CKP Sensor Signal circuits.

Is the voltage below 1.0 volt for both measurements?All

Ye s®Go To 7

No®Repair the CKP Sensor Signal circuit(s) for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

7NOTE: Ensure the ECM and CKP Sensor harness connectors are connected.

Connect, by back probing, a voltmeter capable of reading frequency to ECM harness

connector C2 cavity 67.

Crank the engine while monitoring the voltmeter.

Is the frequency between 16 and 20 Hz while cranking?All

Ye s®Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Replace the Crankshaft Position Sensor in accordance with the

Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

76

DRIVEABILITY - DIESEL

P0340-CKP POSITION SENSOR CIRCUIT DYNAMIC PLAUSIBILITY Ð

Continued

Page 1296 of 4284

Symptom:

P0340-CMP POSITION SENSOR CIRCUIT CMP/CKP SYNC FAIL-

URE

When Monitored and Set Condition:

P0340-CMP POSITION SENSOR CIRCUIT CMP/CKP SYNC FAILURE

When Monitored: With the engine running.

Set Condition: The ECM determines that the camshaft position sensor signal frequency

is not plausible with the crankshaft position sensor signal frequency.

POSSIBLE CAUSES

CHECK CAMSHAFT POSITION SENSOR SIGNAL

CHECK CRANKSHAFT POSITION SENSOR SIGNAL

CHECKING CKP SENSOR FOR DAMAGE

CHECKING CMP SENSOR FOR DAMAGE

ENGINE CONTROL MODULE

GEAR ALIGNMENT

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Attempt to start the engine.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display this DTC?All

Ye s®Go To 3

No®Go To 2

2 Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Test drive the vehicle.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display this DTC?All

Ye s®Go To 3

No®Go To 8

3 Turn the ignition off.

Remove the CMP Sensor.

Inspect the camshaft Position Sensor for conditions such as loose mounting screws,

damage or debris, also check the camshaft for cracked teeth.

Is there any evidence of these conditions?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 4

77

DRIVEABILITY - DIESEL

Page 1297 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Remove the CKP Sensor.

Inspect the Crankshaft Position Sensor for conditions such as loose mounting screws,

damage or debris.

Is there any evidence of these conditions?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

5 Turn the ignition off.

Using the DRB lab scope, backprobe the CMP Sensor Signal circuit at the CMP

Sensor harness connector.

Start the engine, if the engine will not start, crank the engine for several seconds

while monitoring the DRB.

NOTE: Refer to Charts and Graphs to view a correct CMP Sensor signal.

Does the DRB display a steady clean CMP Signal pattern?All

Ye s®Go To 6

No®Perform Test for DTC P0340-Camshaft Position Sensor Circuit

Static Plausibility.

Perform ROAD TEST VERIFICATION - VER-2.

6 Turn the ignition off.

Using the DRB lab scope, backprobe both of the CKP Sensor Signal circuits at the

CKP Sensor harness connector.

NOTE: Refer to Charts and Graphs to view a correct CKP Sensor signal.

Start the engine, if the engine will not start, crank the engine for several seconds

while monitoring the DRB.

Does the DRB display a steady clean CKP Signal pattern for each circuit?All

Ye s®Go To 7

No®Perform Test for DTC P0340-Crankshaft Position Sensor Circuit

Dynamic Plausibility.

Perform ROAD TEST VERIFICATION - VER-2.

7 Refer to the Service Information and check alignment of the camshaft sprocket,

crankshaft sprocket and injection pump sprocket.

Are all of the sprockets aligned correctly?All

Ye s®Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Repair or adjust as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

78

DRIVEABILITY - DIESEL

P0340-CMP POSITION SENSOR CIRCUIT CMP/CKP SYNC FAILURE Ð

Continued

Page 1298 of 4284

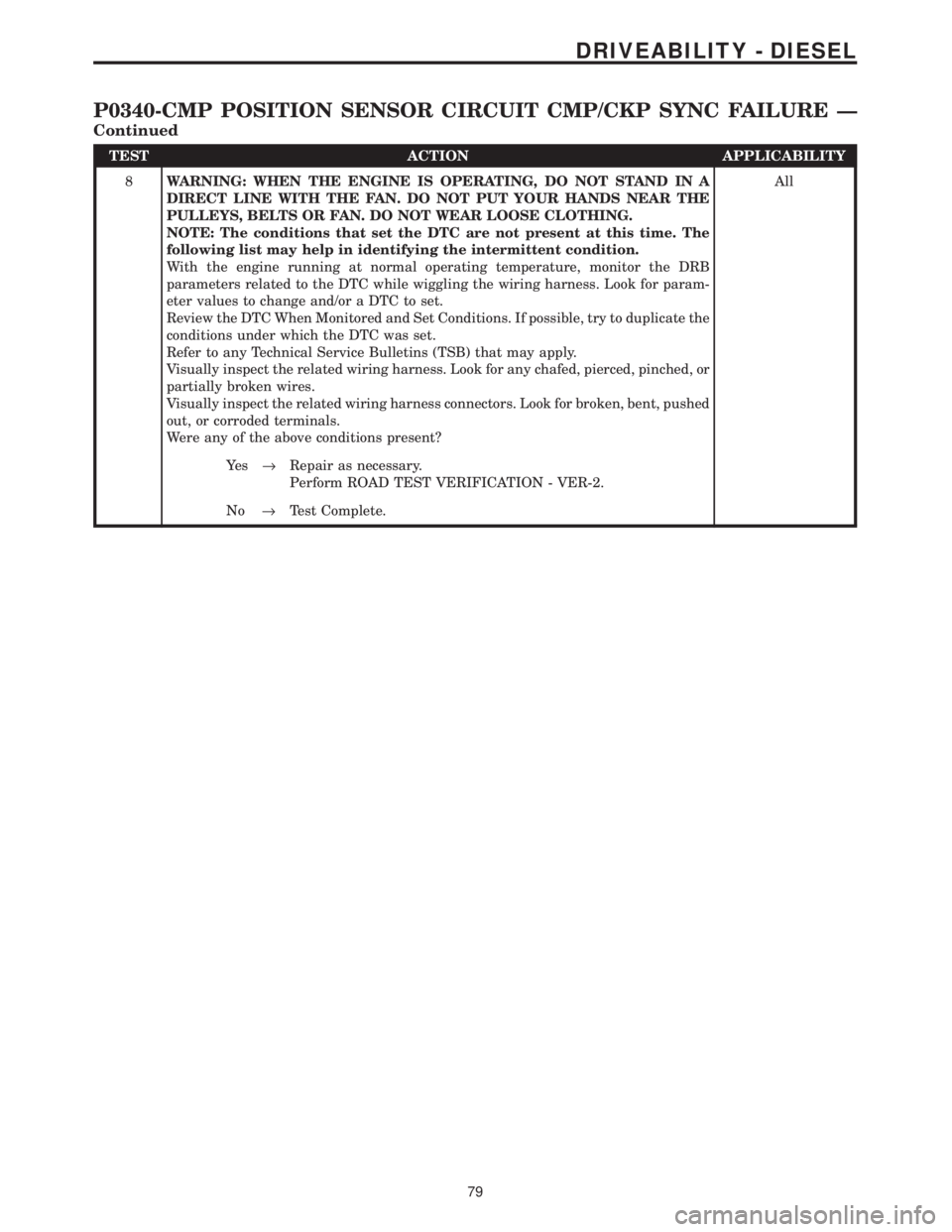

TEST ACTION APPLICABILITY

8WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

79

DRIVEABILITY - DIESEL

P0340-CMP POSITION SENSOR CIRCUIT CMP/CKP SYNC FAILURE Ð

Continued

Page 1299 of 4284

Symptom List:

P0340-CMP POSITION SENSOR CIRCUIT SIGNAL FREQUENCY

TOO HIGH

P0340-CMP POSITION SENSOR CIRCUIT STATIC PLAUSIBILITY

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0340-CMP POSITION SENSOR

CIRCUIT SIGNAL FREQUENCY TOO HIGH.

When Monitored and Set Condition:

P0340-CMP POSITION SENSOR CIRCUIT SIGNAL FREQUENCY TOO HIGH

When Monitored: With the engine running.

Set Condition: The ECM detects more than three camshaft sensor signals within a 10 ms

time period.

POSSIBLE CAUSES

CHECKING FOR DAMAGE

ECM

ECM MONITOR

INTERMITTENT CONDITION

VERIFY ECM/PCM RELAY OUTPUT

CMP SENSOR SIGNAL CIRCUIT OPEN

CAMSHAFT POSITION SENSOR

CMP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

CMP SENSOR OPERATION DURING CRANKING CRANK

ECM SENSOR GROUND CIRCUIT OPEN

CMP SENSOR SIGNAL CIRCUIT SHORTED TO THE SENSOR GROUND CIRCUIT

CMP SENSOR CIRCUIT SHORTED TO VOLTAGE

TEST ACTION APPLICABILITY

1NOTE: The Timing Belt must be correctly installed and operational before

diagnosis can be made. Refer to the Service Information to ensure the

timing belt is properly installed.

Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Attempt to start the engine.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display this DTC?All

Ye s®Go To 3

No®Go To 2

80

DRIVEABILITY - DIESEL

Page 1300 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Test drive the vehicle.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display this DTC?All

Ye s®Go To 3

No®Go To 13

3 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit in CMP Sensor harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Measure the voltage of the CMP Sensor Signal circuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 5

No®Go To 10

5 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the CMP Sensor Signal circuit.

Is the test light on?All

Ye s®Repair the CMP Sensor Signal circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 6

6 Turn the ignition on.

With the DRB III, read the CMP Sensor RPM.

Connect one end of a jumper wire to the CMP signal circuit and tap the other end of

the jumper wire to ground while observing the DRB.

Does the DRB III display an RPM change while tapping the jumper wire to ground?All

Ye s®Go To 7

No®Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

81

DRIVEABILITY - DIESEL

P0340-CMP POSITION SENSOR CIRCUIT SIGNAL FREQUENCY TOO

HIGH Ð

Continued