light CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1161 of 4284

the brake pedal is applied the test will be run at 40

km/h (24 mph) regardless of brake switch state. If,

during the dynamic test, the brake pedal is applied,

the driver may feel the test through brake pedal

pulsations. This is a normal condition.

If any component exhibits a trouble condition

during system initialization or dynamic check, the

CAB will illuminate the ABS warning indicator and

TRAC OFF lamp if equipped.

3.3.6 DIAGNOSTIC MODE

To enter diagnostic mode, a vehicle speed must be

below 10 km/h (6 mph) and no ABS condition

present. If vehicle speed is not below 10 km/h

(6 mph), a ªNo Responseº message could be dis-

played by the DRBIIIt. The following are charac-

teristics of diagnostic mode:

± The amber ABS warning indicator will blink

rapidly (about 1/2 second ON and 1/2 second

OFF). If a hard trouble code, such as Valve

Power Feed Failure code is present, the indi-

cator will be illuminated without blinking un-

til the trouble condition is cleared.

± Antilock operation is disabled.

± The HCU valves cannot be actuated when the

vehicle speed is above 8 km/h (5 mph). If valve

actuation is attempted above 8 km/h (5 mph), a

ªNo Responseº message will be displayed on

the DRBIIIt.

3.4 DIAGNOSTIC TROUBLE CODES

The controller antilock brake may report any of

the following diagnostic trouble codes:

CLUSTER LAMP FAILURE

VALVE POWER FEED FAILURE

BUS SYSTEM COMMUNICATION FAILURE

CAB INTERNAL FAILURE

LEFT FRONT SENSOR CIRCUIT FAILURE

LEFT FRONT WHEEL SPEED SIGNAL

FAILURE

LEFT REAR SENSOR CIRCUIT FAILURE

LEFT REAR WHEEL SPEED SIGNAL

FAILURE

PUMP CIRCUIT FAILURE

RIGHT FRONT SENSOR CIRCUIT FAILURE

RIGHT FRONT WHEEL SPEED SIGNAL

FAILURE

RIGHT REAR SENSOR CIRCUIT FAILURE

RIGHT REAR WHEEL SPEED SIGNAL

FAILURE

SYSTEM OVERVOLTAGE

SYSTEM UNDERVOLTAGE

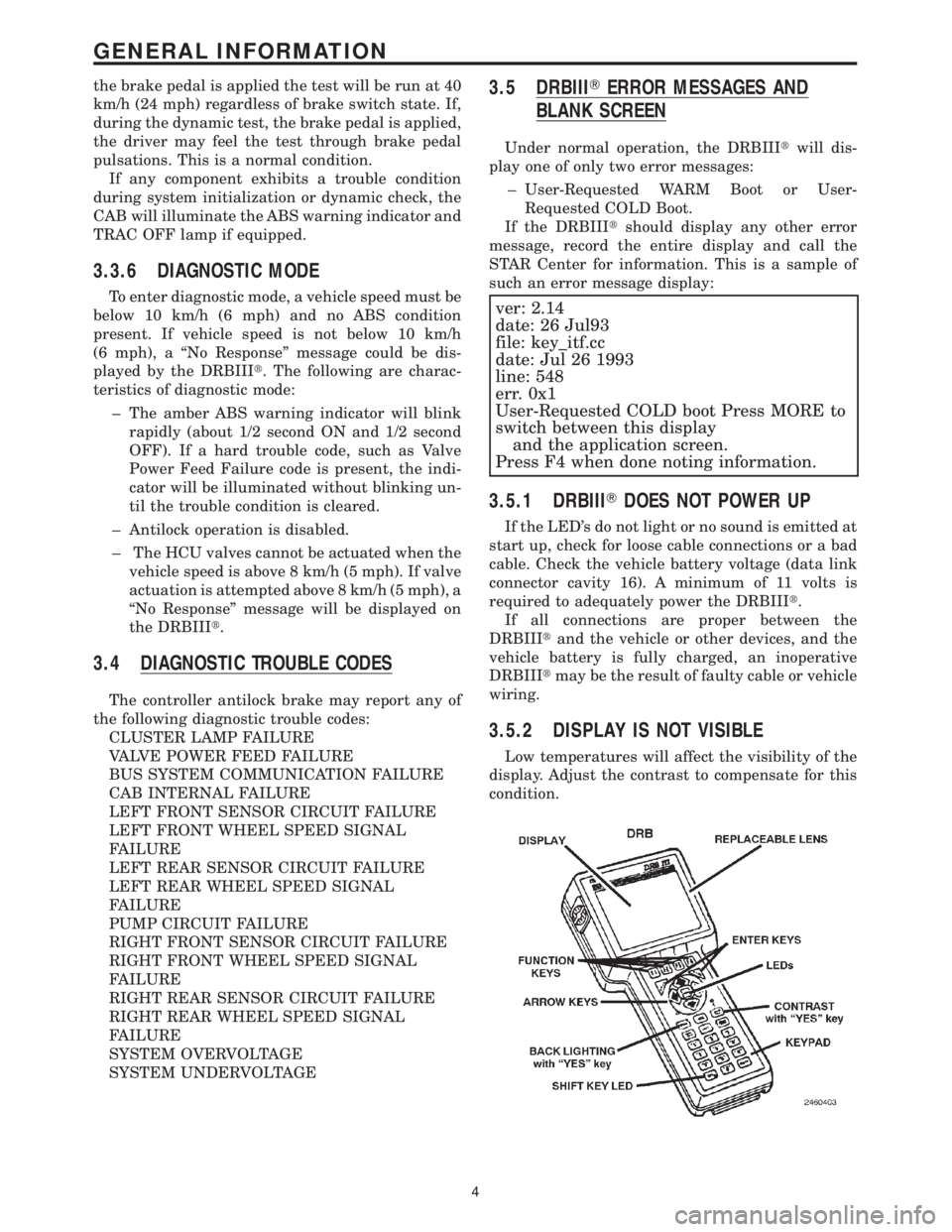

3.5 DRBIIITERROR MESSAGES AND

BLANK SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot.

If the DRBIIItshould display any other error

message, record the entire display and call the

STAR Center for information. This is a sample of

such an error message display:

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err. 0x1

User-Requested COLD boot Press MORE to

switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRBIIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of faulty cable or vehicle

wiring.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4

GENERAL INFORMATION

Page 1163 of 4284

4.3 WARNINGS

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is ``off ''. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation, this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

4.3.2 ROAD TESTING A COMPLAINT

VEHICLE

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

WARNING: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRB SCREEN WHILE IN MOTION.

DO NOT HANG THE DRBIIITFROM THE

REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

4.4 DIAGNOSIS

1. Your diagnostic test procedure must begin with a

thorough visual inspection of the ABS system for

damaged components or disconnected connec-

tors. The brake lamps must be operational, and

if they are not, repair them prior to continuing.

2. Connect the DRBIIItto the data link connector,

which is located under the dash to the left of the

steering column. If the DRBIIItdoes not power

up, check the power and ground supplies to the

connector.

3. Turn the ignition on. Select ªAntilock Brakesº. If

the DRBIIItdisplays ªNo Responseº condition

you must diagnose that first.

4. Read and record all ABS diagnostic trouble

codes. If the ªCAB Power Feed Circuitº diagnos-

tic trouble code is present, it must be repaired

prior to addressing any other DTC's. If any

additional DTC's are present, proceed to theappropriate test by locating the matching test in

the Table of Contents and begin to diagnose the

symptom.

5. If there are no diagnostic trouble codes present,

identify the customer complaint. Select ªInputs/

Outputsº and read the brake switch input as you

press and release the brake pedal. If the display

does not match the state of the pedal, perform

the proper test by locating the matching test in

the Table of Contents and begin to diagnose the

symptom. If a problem exists with the yellow

ªABSº warning indicator or the red ªBrakeº

indicator exists, refer to the proper tests by

locating the matching test in the Table of Con-

tents and begin to diagnose the symptom. Read

the traction control switch input as you press

and release the switch. If the display does not

match the state of the indicator perform the

proper test by locating the matching test in the

Table of Contents and begin to diagnose the

symptom.

6. If no other problems are found, it will be neces-

sary to road test the vehicle. Perform several

antilock stops from above 50 Km/h (30 mph) and

then repeat step 4. If any diagnostic trouble

codes are present, proceed to the appropriate test.

7. The following conditions should be considered

ªNORMALº operation, and no repairs should be

attempted to correct them.

± Brake pedal feedback during an ABS stop

(clicking, vibrating).

± Clicking, groaning or buzzing at 25 Km/h (15

mph) or 40 Km/h (24 mph) (drive off self test).

± Groaning noise during an ABS stop.

± Slight brake pedal drop and pop noise when

ignition is initially turned on.

± Brake pedal ratcheting down at the end of an

ABS stop.

8. If the complaint is ABS ªcyclingº at the end of a

stop at low speeds, it may be caused by a

marginal wheel speed sensor signal. The sensor

air gap, tone wheel condition, and/or brakes

hanging up are possible causes of this condition.

9. After a road test in which no problems were

found, refer to any Technical Service Bulletins

that may apply.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box)

jumper wires

ohmmeter

voltmeter

test light

6

GENERAL INFORMATION

Page 1172 of 4284

POSSIBLE CAUSES

CAB - INTERNAL FAULT

INTERMITTENT CIRCUIT DTC

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase DTC's.

Turn the ignition off.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Does the DRBIIItdisplay a Wheel Speed Sensor Circuit Failure DTC?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Inspect the affected Wheel Speed Sensor and Connector.

Is the Sensor or Connector Damaged?All

Ye s®Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Disconnect the affected Wheel Speed Sensor connector.

Note: Check connector - Clean/repair as necessary.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Sensor 12 volt Supply

circuit.

Measure the resistance between ground and the Sensor Signal circuit.

Was the test light bright and the resistance between 100 and 300 ohms?All

Ye s®Replace the Wheel Speed Sensor in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the affected Wheel Speed Sensor connector.

Note: Check connector - Clean/repair as necessary.

Disconnect the CAB connector.

Note: Check connector - Clean/repair as necessary.

Turn the ignition on.

Check the Wheel Speed Sensor 12 volt Supply and Signal circuits for a short to

battery, ground, to each other and for an open.

For the purposes of this test, a short to ground must be below 15k ohms.

Was any circuit short or open found?All

Ye s®Repair the Wheel Speed Sensor circuit short or open.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

15

BRAKES (CAB)

LEFT FRONT SENSOR CIRCUIT FAILURE ÐContinued

Page 1180 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the CAB connector.

Note: Check connector - Clean/repair as necessary.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Pump Motor Fused B+

circuit.

Does the test light illuminate brightly?All

Ye s®Go To 8

No®Repair the Fused B(+) circuit for an open. The vehicle must be

driven at 25 km/h (15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

8 If there are no possible causes remaining, view repair. All

Repair

Replace the Controller Anti-Lock Brake in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

23

BRAKES (CAB)

PUMP CIRCUIT FAILURE ÐContinued

Page 1190 of 4284

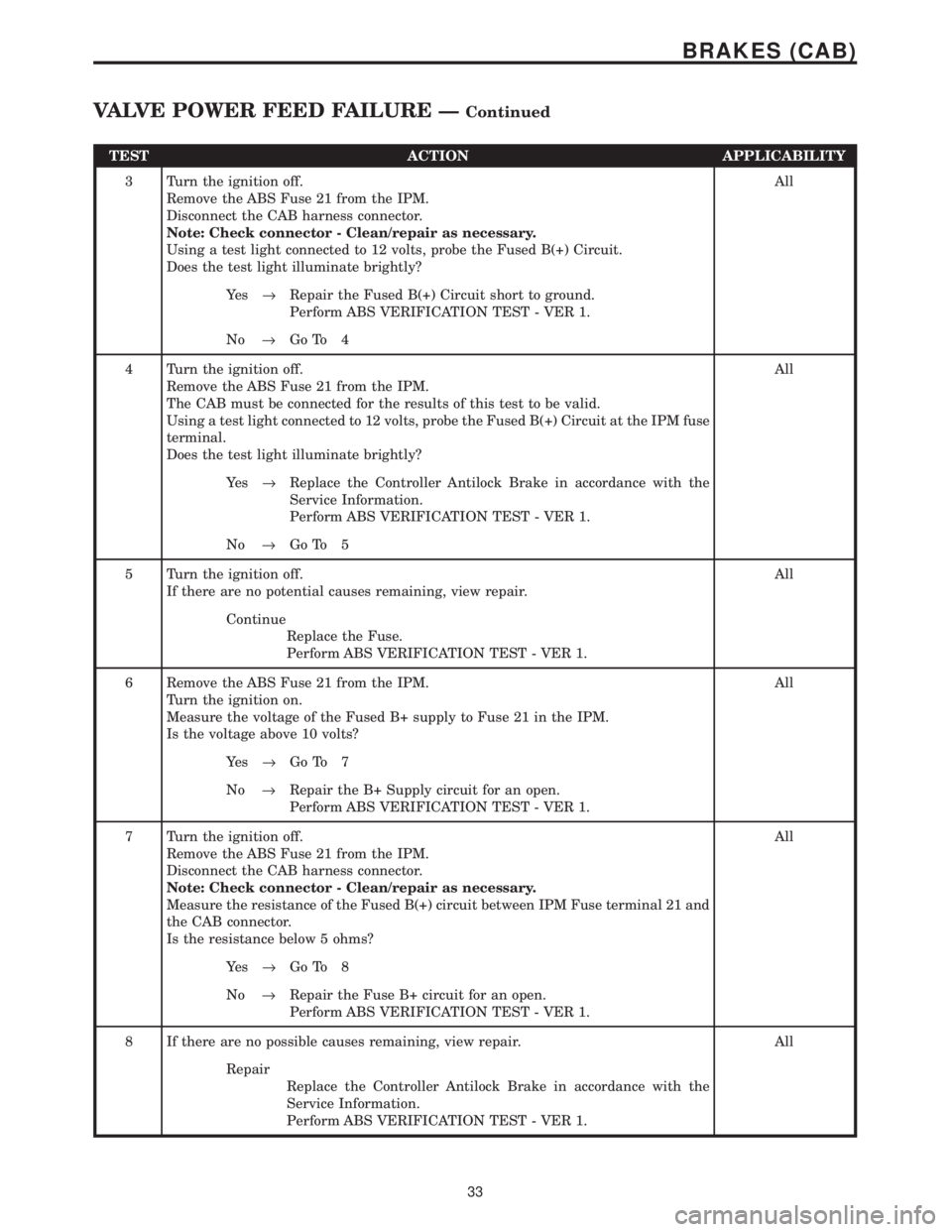

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the ABS Fuse 21 from the IPM.

Disconnect the CAB harness connector.

Note: Check connector - Clean/repair as necessary.

Using a test light connected to 12 volts, probe the Fused B(+) Circuit.

Does the test light illuminate brightly?All

Ye s®Repair the Fused B(+) Circuit short to ground.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Remove the ABS Fuse 21 from the IPM.

The CAB must be connected for the results of this test to be valid.

Using a test light connected to 12 volts, probe the Fused B(+) Circuit at the IPM fuse

terminal.

Does the test light illuminate brightly?All

Ye s®Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

If there are no potential causes remaining, view repair.All

Continue

Replace the Fuse.

Perform ABS VERIFICATION TEST - VER 1.

6 Remove the ABS Fuse 21 from the IPM.

Turn the ignition on.

Measure the voltage of the Fused B+ supply to Fuse 21 in the IPM.

Is the voltage above 10 volts?All

Ye s®Go To 7

No®Repair the B+ Supply circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

7 Turn the ignition off.

Remove the ABS Fuse 21 from the IPM.

Disconnect the CAB harness connector.

Note: Check connector - Clean/repair as necessary.

Measure the resistance of the Fused B(+) circuit between IPM Fuse terminal 21 and

the CAB connector.

Is the resistance below 5 ohms?All

Ye s®Go To 8

No®Repair the Fuse B+ circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

8 If there are no possible causes remaining, view repair. All

Repair

Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

33

BRAKES (CAB)

VALVE POWER FEED FAILURE ÐContinued

Page 1192 of 4284

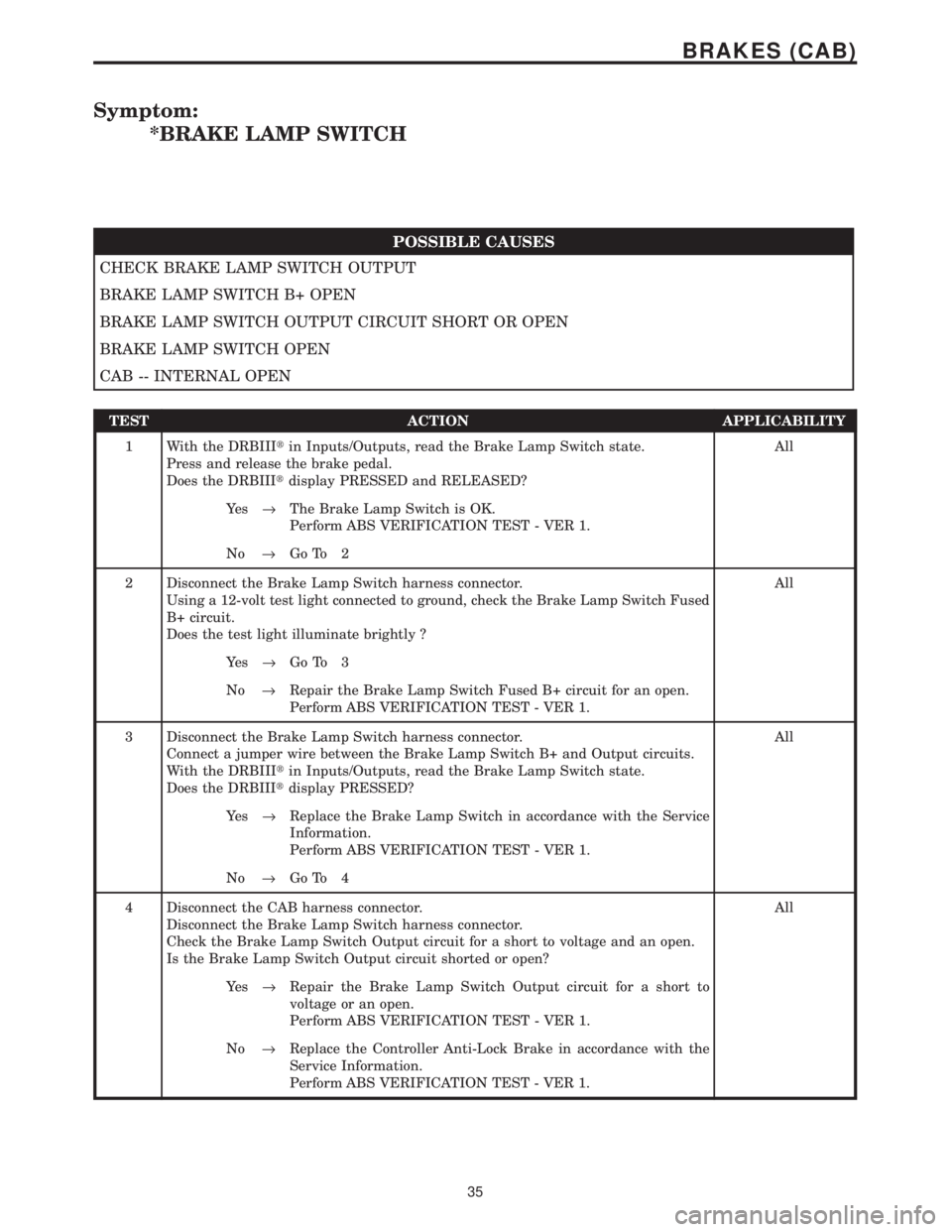

Symptom:

*BRAKE LAMP SWITCH

POSSIBLE CAUSES

CHECK BRAKE LAMP SWITCH OUTPUT

BRAKE LAMP SWITCH B+ OPEN

BRAKE LAMP SWITCH OUTPUT CIRCUIT SHORT OR OPEN

BRAKE LAMP SWITCH OPEN

CAB -- INTERNAL OPEN

TEST ACTION APPLICABILITY

1 With the DRBIIItin Inputs/Outputs, read the Brake Lamp Switch state.

Press and release the brake pedal.

Does the DRBIIItdisplay PRESSED and RELEASED?All

Ye s®The Brake Lamp Switch is OK.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 2

2 Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, check the Brake Lamp Switch Fused

B+ circuit.

Does the test light illuminate brightly ?All

Ye s®Go To 3

No®Repair the Brake Lamp Switch Fused B+ circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

3 Disconnect the Brake Lamp Switch harness connector.

Connect a jumper wire between the Brake Lamp Switch B+ and Output circuits.

With the DRBIIItin Inputs/Outputs, read the Brake Lamp Switch state.

Does the DRBIIItdisplay PRESSED?All

Ye s®Replace the Brake Lamp Switch in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 4

4 Disconnect the CAB harness connector.

Disconnect the Brake Lamp Switch harness connector.

Check the Brake Lamp Switch Output circuit for a short to voltage and an open.

Is the Brake Lamp Switch Output circuit shorted or open?All

Ye s®Repair the Brake Lamp Switch Output circuit for a short to

voltage or an open.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Controller Anti-Lock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

35

BRAKES (CAB)

Page 1193 of 4284

Symptom:

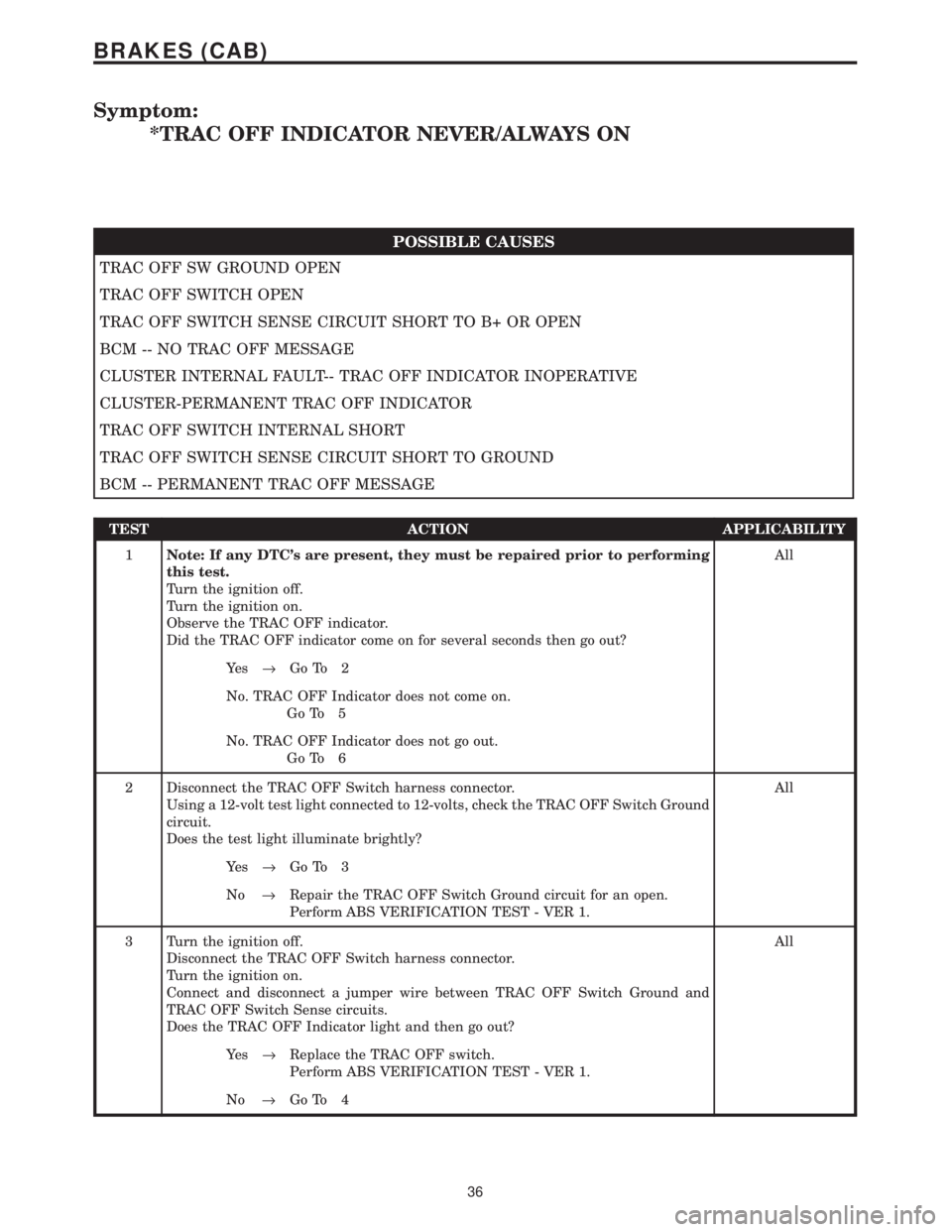

*TRAC OFF INDICATOR NEVER/ALWAYS ON

POSSIBLE CAUSES

TRAC OFF SW GROUND OPEN

TRAC OFF SWITCH OPEN

TRAC OFF SWITCH SENSE CIRCUIT SHORT TO B+ OR OPEN

BCM -- NO TRAC OFF MESSAGE

CLUSTER INTERNAL FAULT-- TRAC OFF INDICATOR INOPERATIVE

CLUSTER-PERMANENT TRAC OFF INDICATOR

TRAC OFF SWITCH INTERNAL SHORT

TRAC OFF SWITCH SENSE CIRCUIT SHORT TO GROUND

BCM -- PERMANENT TRAC OFF MESSAGE

TEST ACTION APPLICABILITY

1Note: If any DTC's are present, they must be repaired prior to performing

this test.

Turn the ignition off.

Turn the ignition on.

Observe the TRAC OFF indicator.

Did the TRAC OFF indicator come on for several seconds then go out?All

Ye s®Go To 2

No. TRAC OFF Indicator does not come on.

Go To 5

No. TRAC OFF Indicator does not go out.

Go To 6

2 Disconnect the TRAC OFF Switch harness connector.

Using a 12-volt test light connected to 12-volts, check the TRAC OFF Switch Ground

circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the TRAC OFF Switch Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

3 Turn the ignition off.

Disconnect the TRAC OFF Switch harness connector.

Turn the ignition on.

Connect and disconnect a jumper wire between TRAC OFF Switch Ground and

TRAC OFF Switch Sense circuits.

Does the TRAC OFF Indicator light and then go out?All

Ye s®Replace the TRAC OFF switch.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 4

36

BRAKES (CAB)

Page 1194 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the TRAC OFF Switch harness connector.

Disconnect the CAB harness connector.

Turn the ignition on.

Check the TRAC OFF Switch Sense circuit for short to B+ and for an open.

Is the Sense circuit shorted or open?All

Ye s®Repair the TRAC OFF Switch Sense circuit for a short to battery

or for an open.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Body Control Module in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

5 Turn the ignition off.

NOTE: The purpose of this test is to perform the Instrument Cluster self

test.

Depress and hold the Odometer Reset Button.

Turn the Key from OFF to ON and then back to OFF.

Release the Odometer Reset Button.

Do the Instrument Cluster Indicators and Gauges activate and deactivate?All

Ye s®Replace the Body Control Module in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Instrument Cluster in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

6NOTE: The purpose of this test is to perform the Instrument Cluster self

test.

Depress and hold the Odometer Reset Button.

Turn the Key from OFF to ON and then back to OFF.

Release the Odometer Reset Button.

Do the Instrument Cluster Indicators and Gauges activate and deactivate?All

Ye s®Go To 7

No®Replace the Instrument Cluster in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

7 Turn the ignition off.

Disconnect the TRAC OFF Switch harness connector.

Turn the ignition on.

Does the TRAC OFF Indicator light and then go out?All

Ye s®Replace the TRAC OFF switch.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 8

37

BRAKES (CAB)

*TRAC OFF INDICATOR NEVER/ALWAYS ON ÐContinued

Page 1225 of 4284

J1850 COMMUNICATION BUS SPI ERROR

J1850 COMMUNICATION BUS RECEIVE TIME-

OUT

J1850 COMMUNICATION BUS UNAUTHO-

RIZED RESET

EEPROM PLAUSIBILITY CHECKSUM ERROR

EEPROM PLAUSIBILITY VIN CHECKSUM

ERROR

EEPROM PLAUSIBILITY COMMUNICATION

ERROR

EEPROM PLAUSIBILITY WRITE ERROR

EEPROM PLAUSIBILITY VARIATION NUM-

BER ERROR

EEPROM PLAUSIBILITY CODE WORD IN-

CORRECT OR MISSING

SKIM SYSTEM SKIM ERROR

SKIM SYSTEM WRITE ACCESS TO EEPROM

FAILURE

SKIM SYSTEM INVALID SECRET KEY IN EE-

PROM

SKIM SYSTEM KEY COMMUNICATION

TIMED OUT

SKIM SYSTEM INVALID KEY CODE RE-

CEIVED

EEPROM RECOVERY OCCURRED

EEPROM REDUNDANT OVERRUN MONI-

TORING

EEPROM QUANTITY STOP

EEPROM COMMUNICATION ERROR

EEPROM COMMUNICATION NOT VERIFIED

ACC PEDAL POSITION SENSOR 1 CKT SIG-

NAL VOLTAGE TOO HIGH

ACC PEDAL POSITION SENSOR 1 CKT SIG-

NAL VOLTAGE TOO LOW

ACC PEDAL POSITION SENSOR 1 CKT SUP-

PLY VOLTAGE TOO HIGH OR LOW

ACC PEDAL POSITION SENSOR 1 CKT PLAU-

SIBILITY WITH POTENTIOMETER

ACC PEDAL POSITION SENSOR 1 CKT PLAU-

SIBILITY WITH BRAKE SWITCH

ACC PEDAL POSITION SENSOR 1 CKT PLAU-

SIBILITY

3.3.4 SKIM DIAGNOSTIC TROUBLE CODES

ANTENNA FAILURE

COP FAILURE

EEPROM FAILURE

PCM STATUS FAILURE

INTERNAL FAULT

RAM FAILURE

ROLLING CODE FAILURE

SERIAL LINK EXTERNAL FAULT

SERIAL LINK INTERNAL FAULT

STACK OVERFLOW FAILURE

TRANSPONDER COMMUNICATION FAILURE

TRANSPONDER CRC (CYCLIC REDUN-

DANCY CHECK) FAILURE

TRANSPONDER ID MISMATCHTRANSPONDER RESPONSE MISMATCH

VIN MISMATCH

3.3.5 HANDLING NO TROUBLE CODE

PROBLEMS

After reading Section 3.0 (System Description

and Functional Operation), you should have a bet-

ter understanding of the theory and operation of the

on-board diagnostics, and how this relates to the

diagnosis of a vehicle that may have a driveability-

related symptom or complaint.

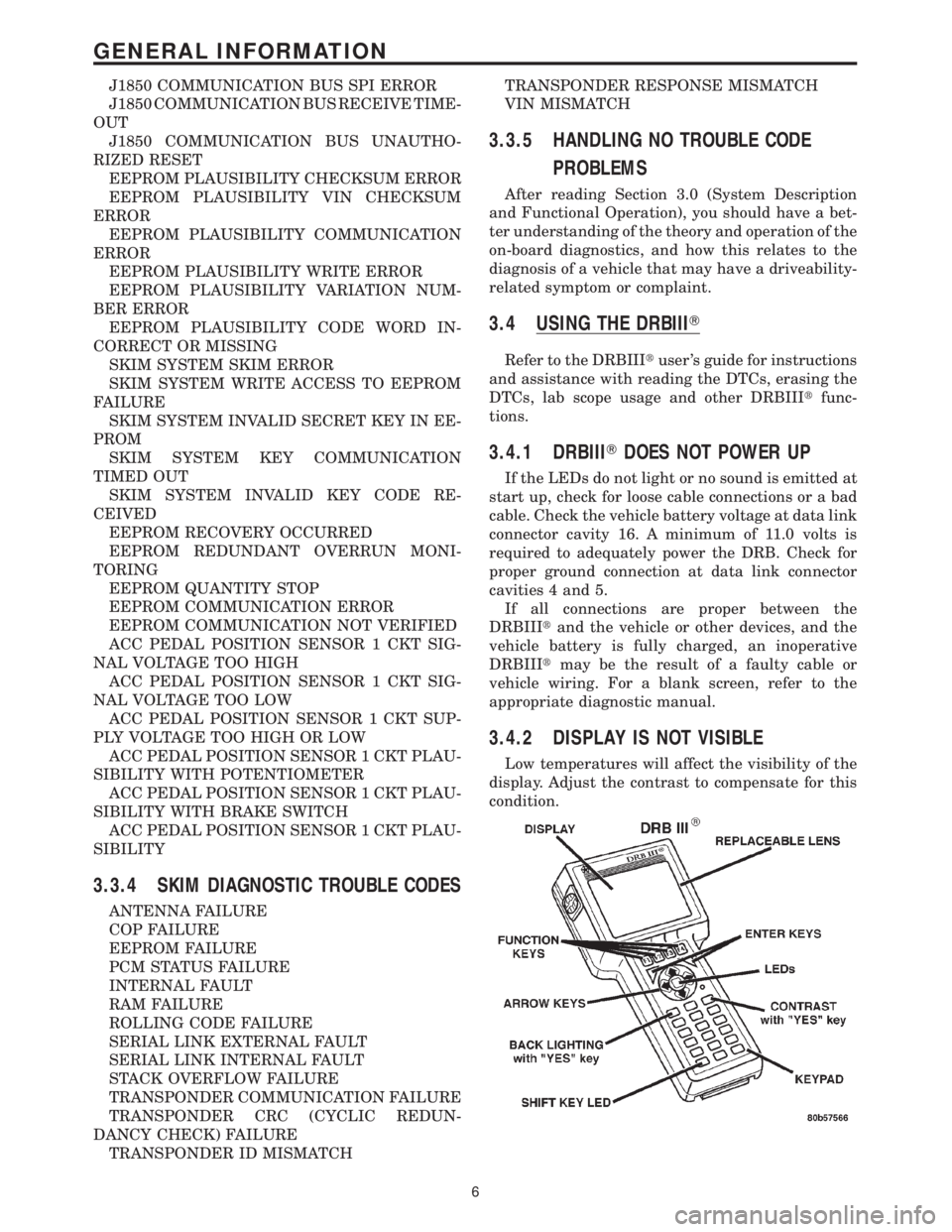

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading the DTCs, erasing the

DTCs, lab scope usage and other DRBIIItfunc-

tions.

3.4.1 DRBIIITDOES NOT POWER UP

If the LEDs do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage at data link

connector cavity 16. A minimum of 11.0 volts is

required to adequately power the DRB. Check for

proper ground connection at data link connector

cavities 4 and 5.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of a faulty cable or

vehicle wiring. For a blank screen, refer to the

appropriate diagnostic manual.

3.4.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

6

GENERAL INFORMATION

Page 1300 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Test drive the vehicle.

With the DRBIIIt, read the ECM DTCs.

Does the DRB III display this DTC?All

Ye s®Go To 3

No®Go To 13

3 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit in CMP Sensor harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Measure the voltage of the CMP Sensor Signal circuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 5

No®Go To 10

5 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the CMP Sensor Signal circuit.

Is the test light on?All

Ye s®Repair the CMP Sensor Signal circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 6

6 Turn the ignition on.

With the DRB III, read the CMP Sensor RPM.

Connect one end of a jumper wire to the CMP signal circuit and tap the other end of

the jumper wire to ground while observing the DRB.

Does the DRB III display an RPM change while tapping the jumper wire to ground?All

Ye s®Go To 7

No®Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

81

DRIVEABILITY - DIESEL

P0340-CMP POSITION SENSOR CIRCUIT SIGNAL FREQUENCY TOO

HIGH Ð

Continued