wheel CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2632 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

9 - 8 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 2636 of 4284

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) (Refer to 9

- ENGINE/ENGINE BLOCK/CONNECTING ROD

BEARINGS - STANDARD PROCEDURE)

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

(9) Disconnect automatic transmission cooler lines

and plug.(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(18) Remove axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)

(19) Drain engine oil and remove oil filter. (Refer

to 9 - ENGINE/LUBRICATION/OIL - STANDARD

PROCEDURE)

(20) Remove crossmember cradle plate (Fig. 6).

(21) Disconnect exhaust pipe from manifold (Fig.

7).

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 2639 of 4284

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Connect automatic transmission cooler lines

to transaxle.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

(32) Fill engine crankcase with proper oil to cor-

rect level.

(33) Start engine and run until operating temper-

ature is reached.

(34) Adjust transmission linkage, if necessary.

1 - SPECIAL TOOL POSTS 6848 4 - SPECIAL TOOL 6710 CRADLE

2 - SPECIAL TOOL 6135 DOLLY 5 - SPECIAL TOOL 6848 - POST CONTACT ON PAN RAIL

3 - SPECIAL TOOL POSTS 6848

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

RSENGINE 2.4L9-15

ENGINE 2.4L (Continued)

Page 2660 of 4284

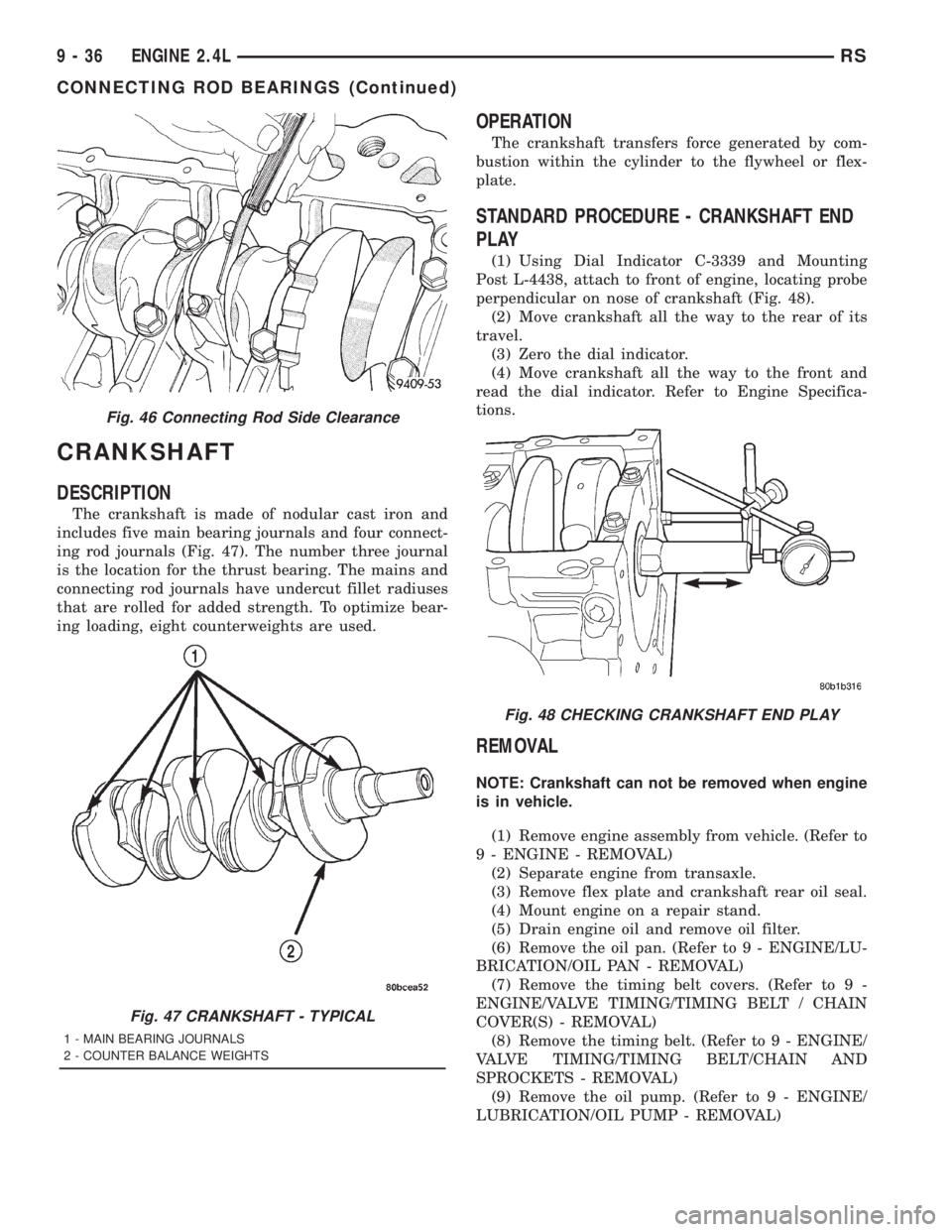

CRANKSHAFT

DESCRIPTION

The crankshaft is made of nodular cast iron and

includes five main bearing journals and four connect-

ing rod journals (Fig. 47). The number three journal

is the location for the thrust bearing. The mains and

connecting rod journals have undercut fillet radiuses

that are rolled for added strength. To optimize bear-

ing loading, eight counterweights are used.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder to the flywheel or flex-

plate.

STANDARD PROCEDURE - CRANKSHAFT END

PLAY

(1) Using Dial Indicator C-3339 and Mounting

Post L-4438, attach to front of engine, locating probe

perpendicular on nose of crankshaft (Fig. 48).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

REMOVAL

NOTE: Crankshaft can not be removed when engine

is in vehicle.

(1) Remove engine assembly from vehicle. (Refer to

9 - ENGINE - REMOVAL)

(2) Separate engine from transaxle.

(3) Remove flex plate and crankshaft rear oil seal.

(4) Mount engine on a repair stand.

(5) Drain engine oil and remove oil filter.

(6) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)

(7) Remove the timing belt covers. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(8) Remove the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(9) Remove the oil pump. (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL)

Fig. 46 Connecting Rod Side Clearance

Fig. 47 CRANKSHAFT - TYPICAL

1 - MAIN BEARING JOURNALS

2 - COUNTER BALANCE WEIGHTS

Fig. 48 CHECKING CRANKSHAFT END PLAY

9 - 36 ENGINE 2.4LRS

CONNECTING ROD BEARINGS (Continued)

Page 2671 of 4284

²Step 3: Final torque collar to transaxle bolts to

101 N´m (75 ft. lbs.)

²Step 4: Final torque collar to oil pan bolts to 54

N´m (40 ft. lbs.).

(2) Install engine front mount bracket and insula-

tor. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - INSTALLATION)

(3) Lower vehicle.

ENGINE MOUNTING

DESCRIPTION

The engine mounting system consist of four

mounts; right and a left side support the powertrain,

and a front and a rear mount control powertrain

torque. The right side mount is a hydro-type (Fig.

79), all others are of molded rubber material.

FRONT MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the front engine mount through bolt

from the insulator (Fig. 80).

(3) Remove the engine front mount bolts and

remove the insulator assembly (Fig. 80).(4) Remove the front mounting bracket from

engine, if necessary (Fig. 80).

INSTALLATION

(1) Install the front mount bracket to engine, if

removed (Fig. 80).

(2) Install the insulator mount assembly (Fig. 80).

(3) Install the front engine mount through bolt to

the insulator (Fig. 80).

(4) Lower the vehicle.

LEFT MOUNT

REMOVAL

(1) Raise the vehicle on hoist.

(2) Remove the left front wheel.

(3) Remove the left mount through bolt access

cover.

(4) Support the transaxle with a suitable jack.

(5) Remove the engine front mount through bolt to

allow left mount removal clearance (Fig. 90).

(6) Remove the left mount through frame rail bolt

(Fig. 81).

(7) Lower transaxle for access to horizontal bolts.

Fig. 79 Engine Hydro-type Mount - Right Side

1 - BOLT

2 - BOLT

3 - FRAME RAIL

4 - RIGHT MOUNT - 2.4L ENGINE

5 - RIGHT MOUNT - 3.3/3.8L ENGINE

Fig. 80 Front Mount and Bracket

1 - BRACKET - FRONT MOUNT

2 - NUT - 68 N´m (50 ft. lbs.)

3 - BOLT - 54 N´m (40 ft. lbs.)

4 - MOUNT - FRONT INSULATOR

5 - BOLT - 68 N´m (50 ft. lbs.)

6 - BOLT - 68 N´m (50 ft. lbs.)

7 - FRONT CROSSMEMBER

RSENGINE 2.4L9-47

STRUCTURAL COLLAR (Continued)

Page 2672 of 4284

(8) Remove the horizontal bolts from the mount to

the transaxle (Fig. 82) or (Fig. 83).

NOTE: To remove mount, additional lowering of

transaxle may be required.

(9) Remove left mount.

INSTALLATION

(1) Install left mount on transaxle (Fig. 82) or (Fig.

83).

(2) Raise transaxle with jack until left mount is in

position.

(3) Install left mount through bolt (Fig. 81).

(4) Install left mount through bolt access cover.

(5) Install front mount through bolt (Fig. 80).

(6) Install left front wheel.

(7) Lower vehicle.

REAR MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the rear mount heat shield (Fig. 84).

(3) Remove the through bolt from the mount and

rear mount bracket (Fig. 85).

(4) Remove the mount bolts (Fig. 85).

(5) Remove the rear mount (Fig. 85).

(6) For rear mount bracket removal, remove the

bolts attaching bracket to transaxle (Fig. 86).

(7) Remove rear mount bracket.

INSTALLATION

(1) Install rear mount bracket, if removed (Fig.

86).

(2) Install the rear mount and bolts (Fig. 85).

Tighten bolts to 54 N´m (40 ft. lbs.).

(3) Install the mount through bolt to the mount

and bracket (Fig. 85). Tighten through bolt to 54 N´m

(40 ft. lbs.).

(4) Install the rear mount heat shield (Fig. 84).

Fig. 81 LEFT MOUNT TO BRACKET

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

Fig. 82 LEFT MOUNT - 31TH TRANSAXLE

1 - LEFT MOUNT ASEMBLY

2 - BOLT - 54 N´m (40 ft. lbs.)

3 - TRANSAXLE - 31TH

Fig. 83 LEFT MOUNT - 41TE TRANSAXLE

1 - LEFT MOUNT ASSEMBLY

2 - BOLT - 54 N´m (40 ft. lbs.)

3 - TRANSAXLE - 41TE

9 - 48 ENGINE 2.4LRS

LEFT MOUNT (Continued)

Page 2685 of 4284

INSTALLATION

REAR COVER

(1) Install timing belt rear cover and bolts (Fig.

115).

CAUTION: Do not use an impact wrench for tighten-

ing camshaft sprocket bolt. Damage to the timing

locating pin can occur. Hand tighten using a

wrench ONLY.

(2) Install camshaft sprockets. Hold sprockets with

Special Tool 6848 and tighten center bolt to 101 N´m

(75 ft. lbs.).

(3) Install timing belt idler pulley and tighten

mounting bolt to 61 N´m (45 ft. lbs.).

(4) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

(5) Install engine mount bracket and tighten bolts

to 61 N´m (45 ft. lbs.) (Fig. 113).

(6) Install front covers.

FRONT COVER

(1) Install timing belt front covers (Fig. 112).

Tighten fasteners to 7 N´m (60 in. lbs.).

(2) Install generator drive belt tensioner. (Refer to

7 - COOLING/ACCESSORY DRIVE/BELT TEN-

SIONERS - INSTALLATION)

(3) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

TIMING BELT AND

SPROCKET(S)

REMOVAL - TIMING BELT

(1) Remove air cleaner upper cover, housing, and

clean air tube.

(2) Remove make-up air hose from cylinder head

cover.

(3) Raise vehicle on hoist.

(4) Remove right front wheel.

(5) Remove right inner splash shield.

(6) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELT TENSION-

ERS - REMOVAL)

(7) Remove crankshaft vibration damper. (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(8) Remove air conditioner/generator belt tensioner

and pulley assembly. (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS - REMOVAL)

(9) Remove timing belt lower front cover bolts and

remove cover. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - REMOVAL)

(10) Lower vehicle.

(11) Remove bolts attaching timing belt upper

front cover and remove cover. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL)

(12) Remove right engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

REMOVAL)

(13) Remove engine mount bracket (Fig. 116).

CAUTION: When aligning crankshaft and camshaft

timing marks always rotate engine from crankshaft.

Camshaft should not be rotated after timing belt is

removed. Damage to valve components may occur.

Always align timing marks before removing timing

belt.

(14) Before the removal of the timing belt, rotate

crankshaft until the TDC mark on oil pump housing

aligns with the TDC mark on crankshaft sprocket

(trailing edge of sprocket tooth) (Fig. 117).

Fig. 115 Timing Belt Rear Cover

1 - BOLTS - REAR COVER 7 N´m (60 in. lbs.)

2 - BOLTS - REAR COVER 28 N´m (250 in .lbs.)

3 - TIMING BELT TENSIONER

RSENGINE 2.4L9-61

TIMING BELT COVER(S) (Continued)

Page 2688 of 4284

(5) Remove the pull pin or Allen wrench from the

belt tensioner.

(6) Once the timing belt has been installed and

tensioner released, rotate the crankshaft two (2) com-

plete revolutions. Verify that the TDC marks on

crankshaft and timing marks on the camshafts are

aligned as shown in (Fig. 123).

(7) Install engine mount bracket to engine (Fig.

116).

(8) Install timing belt front covers and bolts.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION)

(9) Install air conditioning/generator belt tensioner

and pulley. (Refer to 7 - COOLING/ACCESSORY

DRIVE/BELT TENSIONERS - INSTALLATION)

(10) Install right engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION)(11) Install crankshaft vibration damper. (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION)

(12) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(13) Install drive belt splash shield.

(14) Install right front wheel.

(15) Connect make-up air hose to cylinder head

cover.

(16) Install air cleaner housing, upper cover, and

clean air tube.

TIMING BELT TENSIONER &

PULLEY

REMOVAL

(1) Remove the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(2) Remove timing belt idler pulley.

(3) Hold camshaft sprocket with Special Tool 6847

while removing bolt (Fig. 124). Remove both cam

sprockets.

Fig. 122 Timing Belt - Installation

1 - ROTATE CAMSHAFT SPROCKET TO TAKE UP BELT SLACK

2 - CAMSHAFT TIMING MARKS 1/2 NOTCH LOCATION

3 - CRANKSHAFT AT TDC

4 - INSTALL BELT IN THIS DIRECTION

Fig. 123 Crankshaft and Camshaft Timing

1 - CAMSHAFT TIMING MARKS

2 - CRANKSHAFT TDC MARKS

3 - TRAILING EDGE OF SPROCKET TOOTH

9 - 64 ENGINE 2.4LRS

TIMING BELT AND SPROCKET(S) (Continued)

Page 2697 of 4284

INSPECTION...........................148

INSTALLATION..........................149

EXHAUST MANIFOLD

DESCRIPTION..........................150

OPERATION............................150

EXHAUST MANIFOLD - RIGHT

REMOVAL.............................150

CLEANING.............................151

INSPECTION...........................151

INSTALLATION..........................151

EXHAUST MANIFOLD - LEFT

REMOVAL.............................152

CLEANING.............................152INSPECTION...........................153

INSTALLATION..........................153

VALVE TIMING

STANDARD PROCEDURE.................153

VALVE TIMING VERIFICATION............153

TIMING CHAIN COVER

REMOVAL.............................153

INSTALLATION..........................154

TIMING CHAIN AND SPROCKETS

REMOVAL.............................156

INSPECTION...........................156

INSTALLATION..........................157

ENGINE 3.3/3.8L

DESCRIPTION

The 3.3 Liter (201 cu. in.) and 3.8 Liter (231 cu.

in.) engines are 60É V-6 engines with cast iron cylin-

der blocks and aluminum cylinder heads (Fig. 1). The

engine uses a single, block mounted camshaft with

pushrods to actuate the valves. These engines do not

have provisions for a free wheeling valve train.The firing order is 1±2±3±4±5±6. The cylinders are

numbered from the front of the engine to the rear.

The front cylinder bank is numbered 2, 4, and 6. The

rear cylinder bank is numbered 1, 3, and 5.

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 2).

Fig. 1 3.3/3.8L V-6 Engines

RSENGINE 3.3/3.8L9-73

Page 2700 of 4284

DIAGNOSIS AND TESTING - ENGINE MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in crankcase. 1. Check and correct engine oil level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating temperature.

(c) Change engine oil and filter again.

4. Low oil pressure. 4. Check and correct engine oil level.

5. Dirt in tappets/lash adjusters. 5. Replace rocker arm/hydraulic lash

adjuster assembly.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn tappets/lash adjusters. 7. Install new rocker arm/hydraulic lash

adjuster assembly.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats on valve

faces.9. Grind valve seats and valves.

10. Missing adjuster pivot. 10. Replace rocker arm/hydraulic lash

adjuster assembly.

CONNECTING

ROD NOISE1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil pump

relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating temperature.

(c) Change engine oil and filter again.

5. Excessive bearing clearance. 5. Measure bearings for correct clearance.

Repair as necessary.

6. Connecting rod journal out-of-round. 6. Replace crankshaft or grind surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

MAIN BEARING

NOISE1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil pump

relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating temperature.

(c) Change engine oil and filter again.

5. Excessive bearing clearance. 5. Measure bearings for correct clearance.

Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on flanges.

7. Crankshaft journal out-of-round or worn. 7. Replace crankshaft or grind journals.

8. Loose flywheel or torque converter. 8. Tighten to correct torque.

9 - 76 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)