wheel CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2798 of 4284

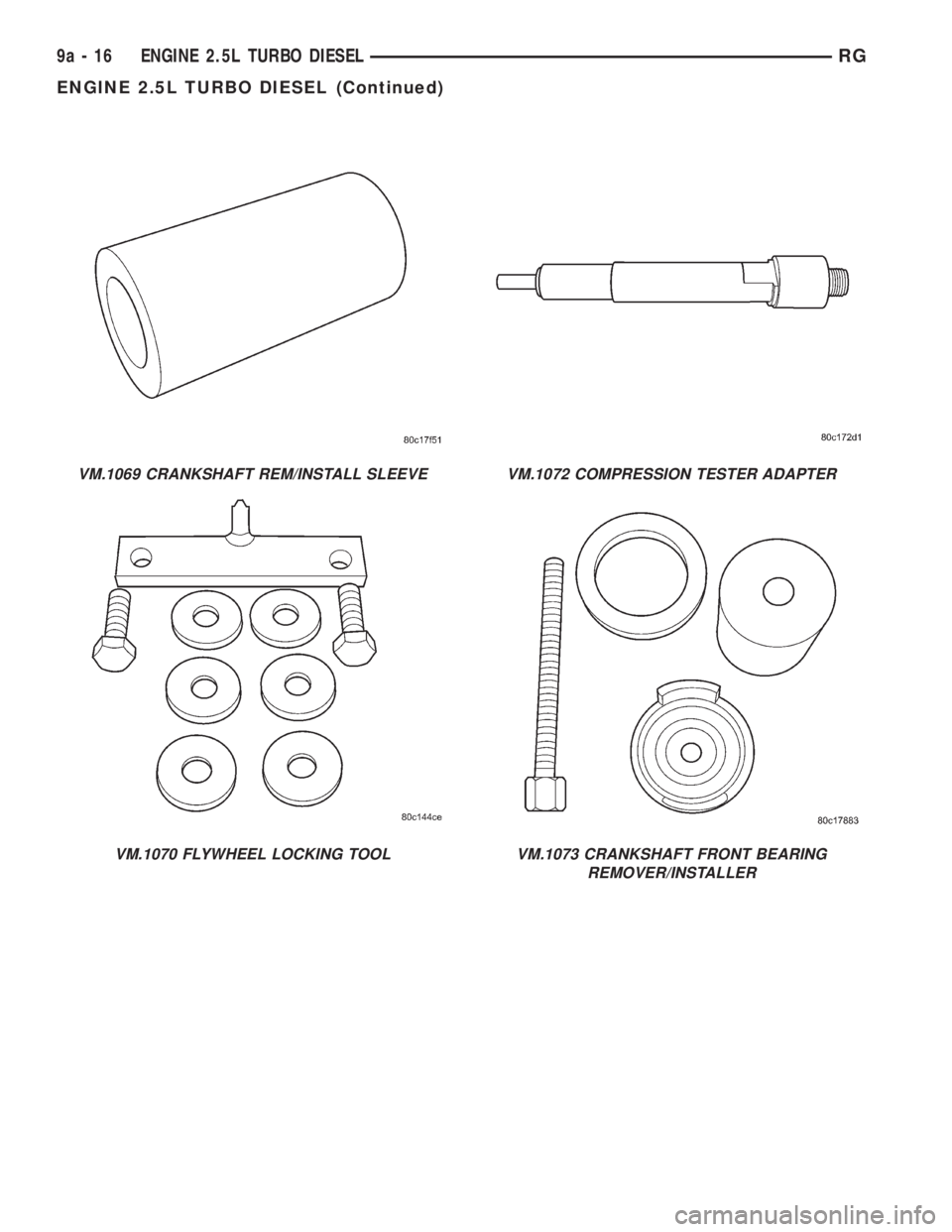

VM.1069 CRANKSHAFT REM/INSTALL SLEEVE

VM.1070 FLYWHEEL LOCKING TOOL

VM.1072 COMPRESSION TESTER ADAPTER

VM.1073 CRANKSHAFT FRONT BEARING

REMOVER/INSTALLER

9a - 16 ENGINE 2.5L TURBO DIESELRG

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2799 of 4284

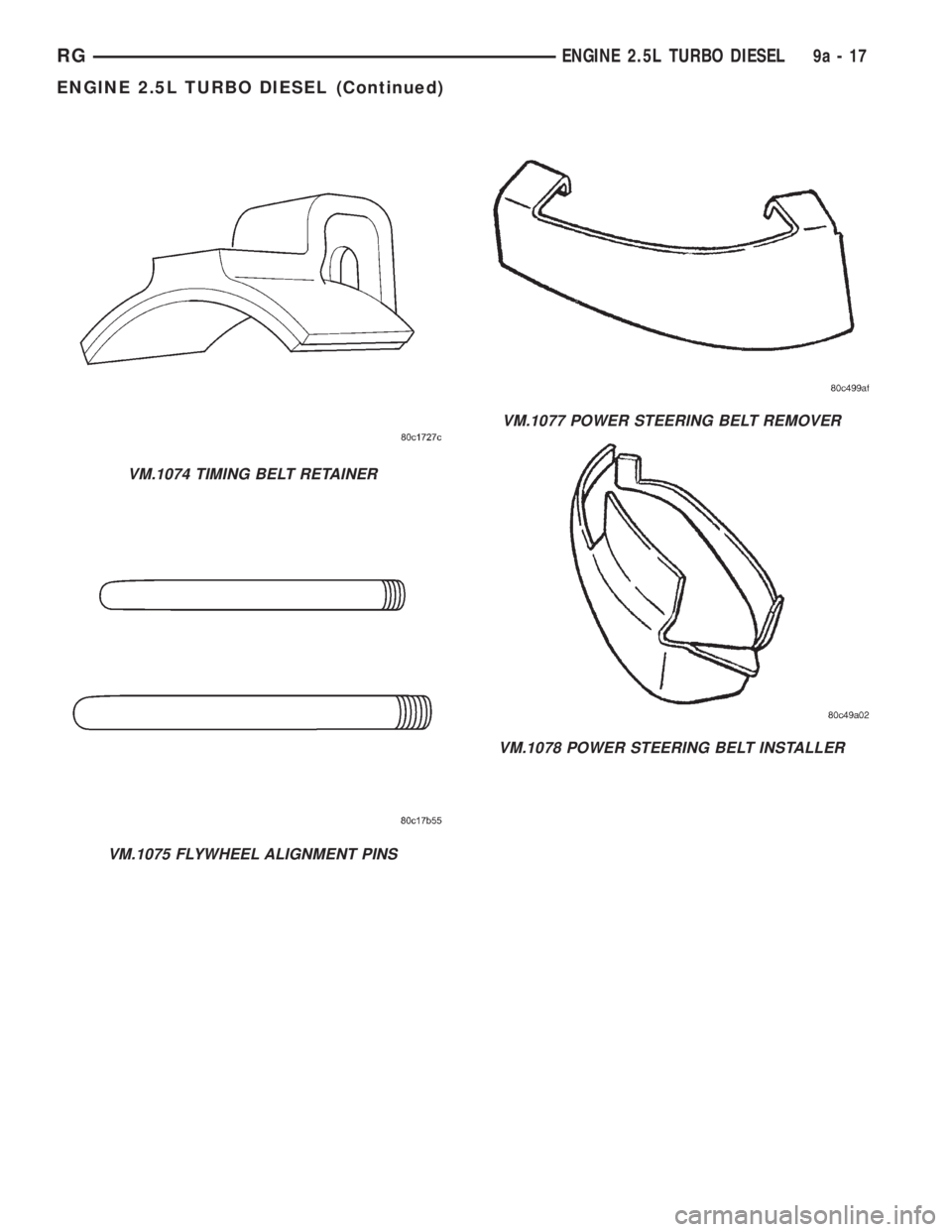

VM.1074 TIMING BELT RETAINER

VM.1075 FLYWHEEL ALIGNMENT PINS

VM.1077 POWER STEERING BELT REMOVER

VM.1078 POWER STEERING BELT INSTALLER

RGENGINE 2.5L TURBO DIESEL9a-17

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2813 of 4284

INSPECTION

Clean each lifter assembly in cleaning solvent to

remove all varnish and sludge deposits. Inspect for

indications of scuffing on the side and base of each

lifter body.

INSTALLATION

(1) Install rocker arm and lifter assemblies in

lifter bores.

(2) Install cylinder head cover/intake manifold

(Fig. 33) (Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(3) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(5) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(6) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(7) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(8) Install front wiper unit (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(9) Connect negative battery cable.

ENGINE BLOCK

DESCRIPTION

The 2.5L CRD Diesel engine uses a cast iron

engine block with wet cast iron cylinder liners (Fig.

34).

CRANKSHAFT

DESCRIPTION

The crankshaft is a forged steel splayed type

design with five main bearing journals. The crank-

shaft is located at the bottom of the engine block and

is held in place with three main bearing supports

(Fig. 35).

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

Fig. 34 ENGINE BLOCK

Fig. 35 CRANKSHAFT ASSEMBLY

1 - CRANKSHAFT SUPPORT HALVE

2 - MAIN BEARING HALVE

3 - CRANKSHAFT

4 - MAIN BEARING HALVE

5 - CRANKSHAFT SUPPORT HALVE

6 - MAIN BEARING SUPPORT BOLTS

7 - WASHERS

RGENGINE 2.5L TURBO DIESEL9a-31

HYDRAULIC LIFTERS (Continued)

Page 2814 of 4284

STANDARD PROCEDURE - CHECKING

CRANKSHAFT END PLAY

(1) Mount a dial indicator to a stationary point at

rear of engine. Locate the probe perpendicular

against the flywheel (Fig. 36).

(2) Move the crankshaft all the way to the front of

its travel.

(3) Zero the dial indicator.

(4) Move the crankshaft all the way to the rear

and read dial indicator. For crankshaft end play

clearances (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

REMOVAL

(1) Remove engine from vehicle (Refer to 9 -

ENGINE - REMOVAL).

(2) Mount engine on an engine stand.

(3) Drain engine oil and remove oil filter.

(4) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(5) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(6) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(7) Remove cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(8) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(9) Remove flywheel.

(10) Remove rear main bearing support/adapter

plate retaining bolts and remove adapter plate (Fig.

37).

(11) Remove rear main bearing support by thread-

ing two retaining bolts in holes provided. Tighten

bolts equally to push main bearing support out of

block (Fig. 38).

(12) Remove front engine cover (Refer to 9 -

ENGINE/ENGINE BLOCK/ENGINE COVER -

REMOVAL).

(13) Remove crankshaft sprocket.

Fig. 36 CHECKING CRANKSHAFT END PLAY

1 - DIAL INDICATOR

2 - ADAPTER PLATE

3 - REAR MAIN BEARING SUPPORT

4 - SEALING RING

5 - SEALING RING

6 - ALIGNMENT PIN

7 - CRANKSHAFT

8 - RELUCTOR WHEEL

9 - RELUCTOR WHEEL RETAINING BOLT

10 - REAR MAIN BEARING SUPPORT RETAINING BOLTS

11 - FLYWHEEL

12 - FLYWHEEL BOLTS

9a - 32 ENGINE 2.5L TURBO DIESELRG

CRANKSHAFT (Continued)

Page 2816 of 4284

(5) Install front engine cover (Refer to 9 -

ENGINE/ENGINE BLOCK/ENGINE COVER -

INSTALLATION).

(6) Install rear main bearing support in engine

block.Be sure to align oil hole in rear main

bearing support with hole in block.

(7) Install adapter plate and retaining bolts (Fig.

37). Torque bolts to 27.5N´m.

(8) Install flywheel.

(9) Install piston and connecting rod assemblies

(Refer to 9 - ENGINE/ENGINE BLOCK/PISTON &

CONNECTING ROD - INSTALLATION).

(10) Install oil jets (Refer to 9 - ENGINE/LUBRI-

CATION/OIL JET - INSTALLATION).

(11) Install balance shaft assembly (Refer to 9 -

ENGINE/VALVE TIMING/BALANCE SHAFT -

INSTALLATION).

(12) Install oil pump pickup tube (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - INSTALLA-

TION).

(13) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(14) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(15) Install cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - INSTALLATION).

(16) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(17) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .(18) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(19) Install engine in vehicle.

(20) Fill engine oil with proper oil to correct level.

CYLINDER LINERS

DESCRIPTION

The cylinder wall liner used on this engine is of

the wet design. O-rings are used to seal the liner to

the engine block.

REMOVAL

(1) Remove engine from vehicle.

(2) With engine completely disassembled, use spe-

cial tool VM.1001 to remove liner assembly (Fig. 41).

(3) Tighten bolt on VM.1001 to remove liner from

block (Fig. 42).

(4) Remove shims from cylinder liner or cylinder

block recess. Keep shims with each cylinder liner.

INSPECTION

The cylinder walls should be checked for out-of-

round and taper with a dial bore gauge. The cylinder

bore out-of-round is 0.100 mm (.0039 in.) maximum

Fig. 40 CRANKSHAFT SUPPORT RETAINERS

1 - CRANKSHAFT SUPPORT RETAINERS

2 - ENGINE BLOCK

Fig. 41 CYLINDER LINER REMOVER

9a - 34 ENGINE 2.5L TURBO DIESELRG

CRANKSHAFT (Continued)

Page 2828 of 4284

INSTALLATION

CRANKSHAFT MAIN BEARINGS

(1) Install bearing halves in crankshaft supports.

(2) Lubricate crankshaft and main bearings with

clean engine oil.

(3) Install crankshaft supports on crankshaft (Fig.

65). Torque bolts to 44.1N´m.

FRONT CRANKSHAFT MAIN BEARING

(1) Using special tool VM.1073, push front crank-

shaft main bearing in engine block (Fig. 66).

(2) Be sure oil hole in bearing lines up with oil gal-

lery in engine block (Fig. 67).

(3) Reassemble engine and install in vehicle.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

This must be done with either the engine or trans-

mission removed from vehicle.

(1) Remove flywheel assembly.

(2) Pry out old crankshaft oil seal.

INSTALLATION

(1) Using special tool VM.1050, install rear crank-

shaft oil seal in rear main bearing support (Fig. 68).

(2) Install engine or tranmission in vehicle.

OIL PAN

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle on hoist.

(3) Drain engine oil from engine.

(4) Remove all oil pan retaining bolts and oil pan

(Fig. 69).

Fig. 64 FRONT MAIN BEARING REMOVAL

1 - VM.1073

2 - FRONT CRANKSHAFT MAIN BEARING

3 - ENGINE BLOCK

Fig. 65 CRANKSHAFT ASSEMBLY

1 - CRANKSHAFT SUPPORT HALVE

2 - MAIN BEARING HALVE

3 - CRANKSHAFT

4 - MAIN BEARING HALVE

5 - CRANKSHAFT SUPPORT HALVE

6 - MAIN BEARING SUPPORT BOLTS

7 - WASHERS

9a - 46 ENGINE 2.5L TURBO DIESELRG

CRANKSHAFT MAIN BEARINGS (Continued)

Page 2836 of 4284

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Refill engine oil to proper level.

(6) Connect negative battery cable.

INTAKE MANIFOLD

DESCRIPTION

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - DESCRIPTION)

REMOVAL

(1) (Refer to 9 - ENGINE/CYLINDER HEAD/CYL-

INDER HEAD COVER(S) - REMOVAL)

INSTALLATION

(1) (Refer to 9 - ENGINE/CYLINDER HEAD/CYL-

INDER HEAD COVER(S) - INSTALLATION)

VALVE TIMING

STANDARD PROCEDURE - LOCKING ENGINE

90É AFTER TDC

(1) Disconnect negative battery cable.

(2) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(3) Rotate engine by hand until special tool

VM.1068 can be install in engine block as shown

(Fig. 83). This will lock the engine at 90É after TDC.

(4) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(5) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

Fig. 82 OIL JET REMOVAL/INSTALLATION

1 - SPECIAL TOOL VM.1060

2 - OIL JET

3 - CONNECTING ROD

4 - CRANKSHAFT

Fig. 83 TDC AND 90 DEGREES AFTER TDC

ALIGNMENT PIN LOCATION

1 - ENGINE BLOCK

2 - VM.1051 TDC PIN OR VM.1068 90 DEGREES ATDC PIN

3 - FLYWHEEL

9a - 54 ENGINE 2.5L TURBO DIESELRG

OIL JET (Continued)

Page 2839 of 4284

INSTALLATION

(1) Before installation of the balance shaft assem-

bly, the # 1 cylinder must be brought to TDC. Using

special tool VM.1051, roll engine over by hand until

tool can be inserted into engine block locking fly-

wheel from turning (Fig. 88). Once the # 1 cylinder is

brought to TDC, the balance shaft assembly can be

installed.

(2) With balance shaft assembly on work bench.

Insert special tool VM.1056 into balance shaft assem-

bly (Fig. 89). This will ensure proper balance shaft

and crankshaft timing after assembly.

(3) Install balance shaft assembly and retaining

bolts (Fig. 87). Torque bolts to 32.4N´m.

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Refill engine oil to proper level.

(6) Connect negative battery cable.

TIMING BELT / CHAIN

COVER(S)

REMOVAL - TIMING BELT OUTER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover retaining bolts

and remove cover (Fig. 90).

REMOVAL - TIMING BELT INNER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 88 TDC AND 90 DEGREES AFTER TDC

ALIGNMENT PIN LOCATION

1 - ENGINE BLOCK

2 - VM.1051 TDC PIN OR VM.1068 90 DEGREES ATDC PIN

3 - FLYWHEEL

Fig. 89 BALANCE SHAFT ALIGNMENT PIN VM.1056

1 - VM.1056

2 - BALANCE SHAFT ASSEMBLY

RGENGINE 2.5L TURBO DIESEL9a-57

BALANCE SHAFT (Continued)

Page 2852 of 4284

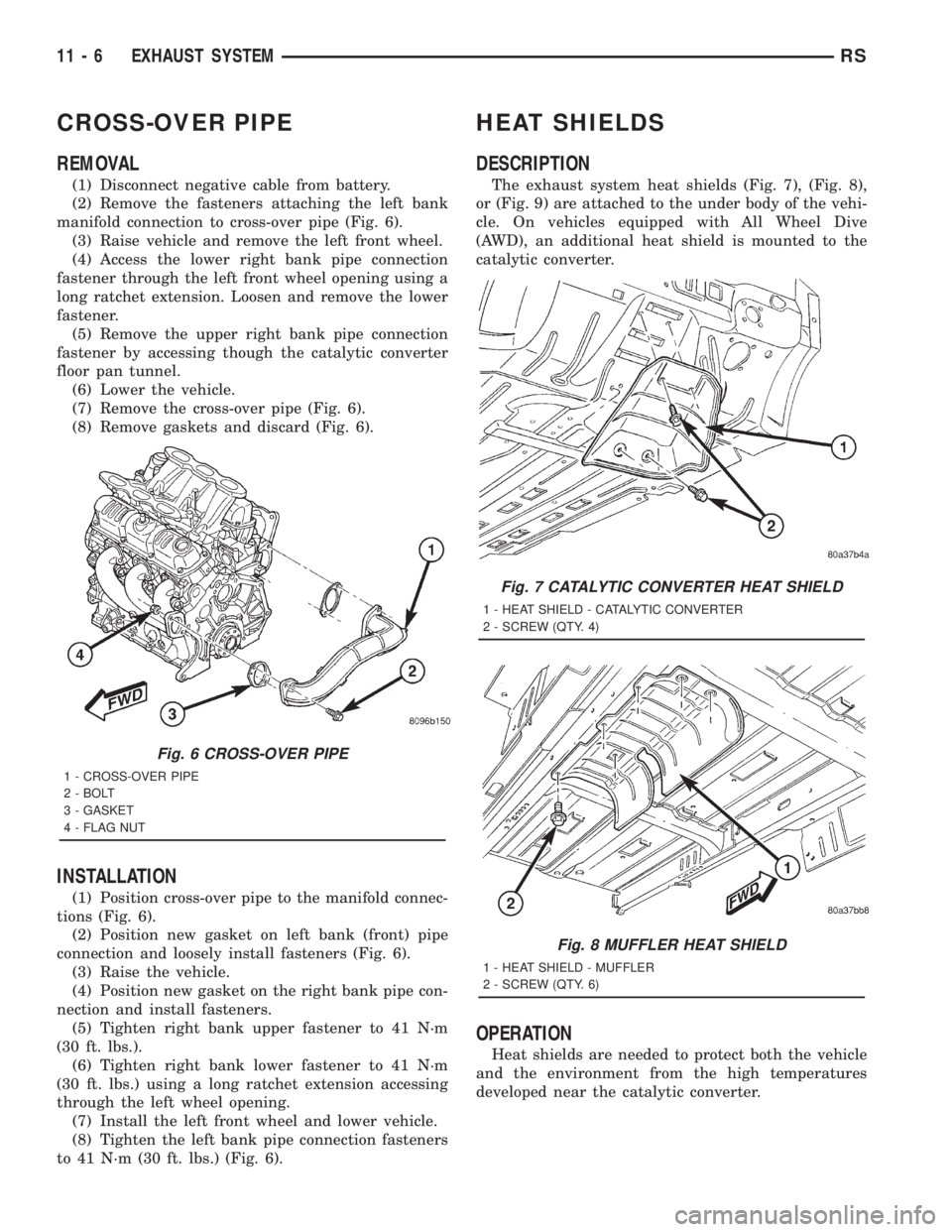

CROSS-OVER PIPE

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the fasteners attaching the left bank

manifold connection to cross-over pipe (Fig. 6).

(3) Raise vehicle and remove the left front wheel.

(4) Access the lower right bank pipe connection

fastener through the left front wheel opening using a

long ratchet extension. Loosen and remove the lower

fastener.

(5) Remove the upper right bank pipe connection

fastener by accessing though the catalytic converter

floor pan tunnel.

(6) Lower the vehicle.

(7) Remove the cross-over pipe (Fig. 6).

(8) Remove gaskets and discard (Fig. 6).

INSTALLATION

(1) Position cross-over pipe to the manifold connec-

tions (Fig. 6).

(2) Position new gasket on left bank (front) pipe

connection and loosely install fasteners (Fig. 6).

(3) Raise the vehicle.

(4) Position new gasket on the right bank pipe con-

nection and install fasteners.

(5) Tighten right bank upper fastener to 41 N´m

(30 ft. lbs.).

(6) Tighten right bank lower fastener to 41 N´m

(30 ft. lbs.) using a long ratchet extension accessing

through the left wheel opening.

(7) Install the left front wheel and lower vehicle.

(8) Tighten the left bank pipe connection fasteners

to 41 N´m (30 ft. lbs.) (Fig. 6).

HEAT SHIELDS

DESCRIPTION

The exhaust system heat shields (Fig. 7), (Fig. 8),

or (Fig. 9) are attached to the under body of the vehi-

cle. On vehicles equipped with All Wheel Dive

(AWD), an additional heat shield is mounted to the

catalytic converter.

OPERATION

Heat shields are needed to protect both the vehicle

and the environment from the high temperatures

developed near the catalytic converter.

Fig. 6 CROSS-OVER PIPE

1 - CROSS-OVER PIPE

2 - BOLT

3 - GASKET

4 - FLAG NUT

Fig. 7 CATALYTIC CONVERTER HEAT SHIELD

1 - HEAT SHIELD - CATALYTIC CONVERTER

2 - SCREW (QTY. 4)

Fig. 8 MUFFLER HEAT SHIELD

1 - HEAT SHIELD - MUFFLER

2 - SCREW (QTY. 6)

11 - 6 EXHAUST SYSTEMRS

Page 2856 of 4284

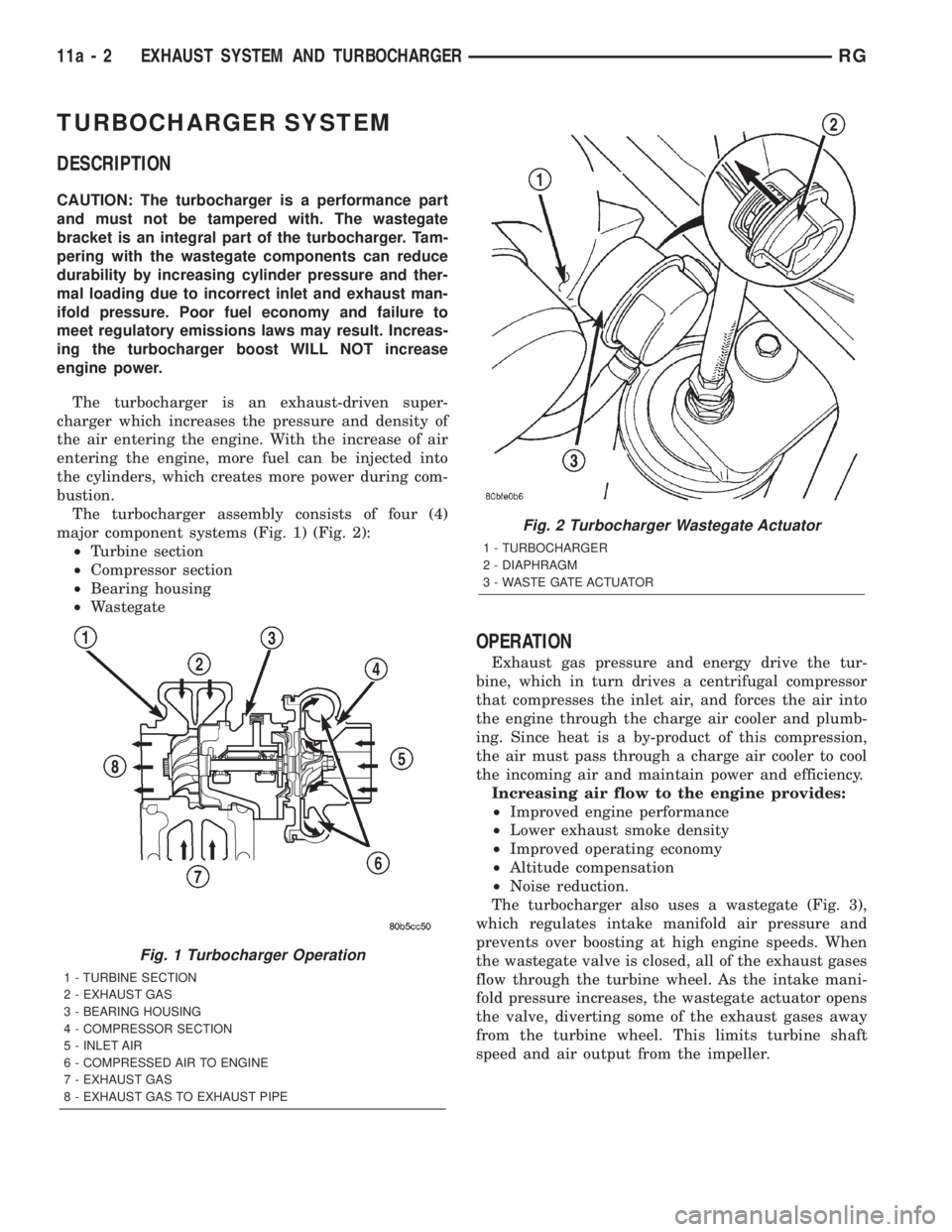

TURBOCHARGER SYSTEM

DESCRIPTION

CAUTION: The turbocharger is a performance part

and must not be tampered with. The wastegate

bracket is an integral part of the turbocharger. Tam-

pering with the wastegate components can reduce

durability by increasing cylinder pressure and ther-

mal loading due to incorrect inlet and exhaust man-

ifold pressure. Poor fuel economy and failure to

meet regulatory emissions laws may result. Increas-

ing the turbocharger boost WILL NOT increase

engine power.

The turbocharger is an exhaust-driven super-

charger which increases the pressure and density of

the air entering the engine. With the increase of air

entering the engine, more fuel can be injected into

the cylinders, which creates more power during com-

bustion.

The turbocharger assembly consists of four (4)

major component systems (Fig. 1) (Fig. 2):

²Turbine section

²Compressor section

²Bearing housing

²Wastegate

OPERATION

Exhaust gas pressure and energy drive the tur-

bine, which in turn drives a centrifugal compressor

that compresses the inlet air, and forces the air into

the engine through the charge air cooler and plumb-

ing. Since heat is a by-product of this compression,

the air must pass through a charge air cooler to cool

the incoming air and maintain power and efficiency.

Increasing air flow to the engine provides:

²Improved engine performance

²Lower exhaust smoke density

²Improved operating economy

²Altitude compensation

²Noise reduction.

The turbocharger also uses a wastegate (Fig. 3),

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opens

the valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

Fig. 1 Turbocharger Operation

1 - TURBINE SECTION

2 - EXHAUST GAS

3 - BEARING HOUSING

4 - COMPRESSOR SECTION

5 - INLET AIR

6 - COMPRESSED AIR TO ENGINE

7 - EXHAUST GAS

8 - EXHAUST GAS TO EXHAUST PIPE

Fig. 2 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

11a - 2 EXHAUST SYSTEM AND TURBOCHARGERRG