display CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1696 of 4284

CAUTION: If welding work is to be performed on the

vehicle, using an electric arc welder, the CAB con-

nector should be disconnected during the welding

operation.

CAUTION: Many components of the ABS System

are not serviceable and must be replaced as an

assembly. Do not disassemble any component

which is not designed to be serviced.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: Brake fluid will damage painted surfaces.

If brake fluid is spilled on any painted surface,

wash off with water immediately.

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING

The base brake's hydraulic system must be bled

anytime air enters the hydraulic system. The ABS

though, particularly the ICU (HCU), should only be

bled when the HCU is replaced or removed from the

vehicle. The ABS must always be bled anytime it is

suspected that the HCU has ingested air. Under

most circumstances that require the bleeding of the

brakes hydraulic system, only the base brake

hydraulic system needs to be bled.

It is important to note that excessive air in the

brake system will cause a soft or spongy feeling

brake pedal.

During the brake bleeding procedure, be sure the

brake fluid level remains close to the FULL level in

the master cylinder fluid reservoir. Check the fluid

level periodically during the bleeding procedure and

add DOT 3 brake fluid as required.

The ABS must be bled as two independent braking

systems. The non-ABS portion of the brake systemwith ABS is to be bled the same as any non-ABS sys-

tem.

The ABS portion of the brake system must be bled

separately. Use the following procedure to properly

bleed the brake hydraulic system including the ABS.

BLEEDING

When bleeding the ABS system, the following

bleeding sequence must be followed to insure com-

plete and adequate bleeding.

(1) Make sure all hydraulic fluid lines are installed

and properly torqued.

(2) Connect the DRBIIItscan tool to the diagnos-

tics connector. The diagnostic connector is located

under the lower steering column cover to the left of

the steering column.

(3) Using the DRB, check to make sure the CAB

does not have any fault codes stored. If it does, clear

them using the DRB.

WARNING: WHEN BLEEDING THE BRAKE SYSTEM

WEAR SAFETY GLASSES. A CLEAR BLEED TUBE

MUST BE ATTACHED TO THE BLEEDER SCREWS

AND SUBMERGED IN A CLEAR CONTAINER FILLED

PART WAY WITH CLEAN BRAKE FLUID. DIRECT

THE FLOW OF BRAKE FLUID AWAY FROM YOUR-

SELF AND THE PAINTED SURFACES OF THE VEHI-

CLE. BRAKE FLUID AT HIGH PRESSURE MAY

COME OUT OF THE BLEEDER SCREWS WHEN

OPENED.

(4) Bleed the base brake system using the stan-

dard pressure or manual bleeding procedure. (Refer

to 5 - BRAKES - BASE - STANDARD PROCEDURE)

(5) Using the DRB, select ANTILOCK BRAKES,

followed by MISCELLANEOUS, then BLEED

BRAKES. Follow the instructions displayed. When

the scan tool displays TEST COMPLETED, discon-

nect the scan tool and proceed.

(6) Bleed the base brake system a second time.

Check brake fluid level in the reservoir periodically

to prevent emptying, causing air to enter the hydrau-

lic system.

(7) Fill the master cylinder reservoir to the full

level.

(8) Test drive the vehicle to be sure the brakes are

operating correctly and that the brake pedal does not

feel spongy.

5 - 70 BRAKES - ABSRS

BRAKES - ABS (Continued)

Page 1806 of 4284

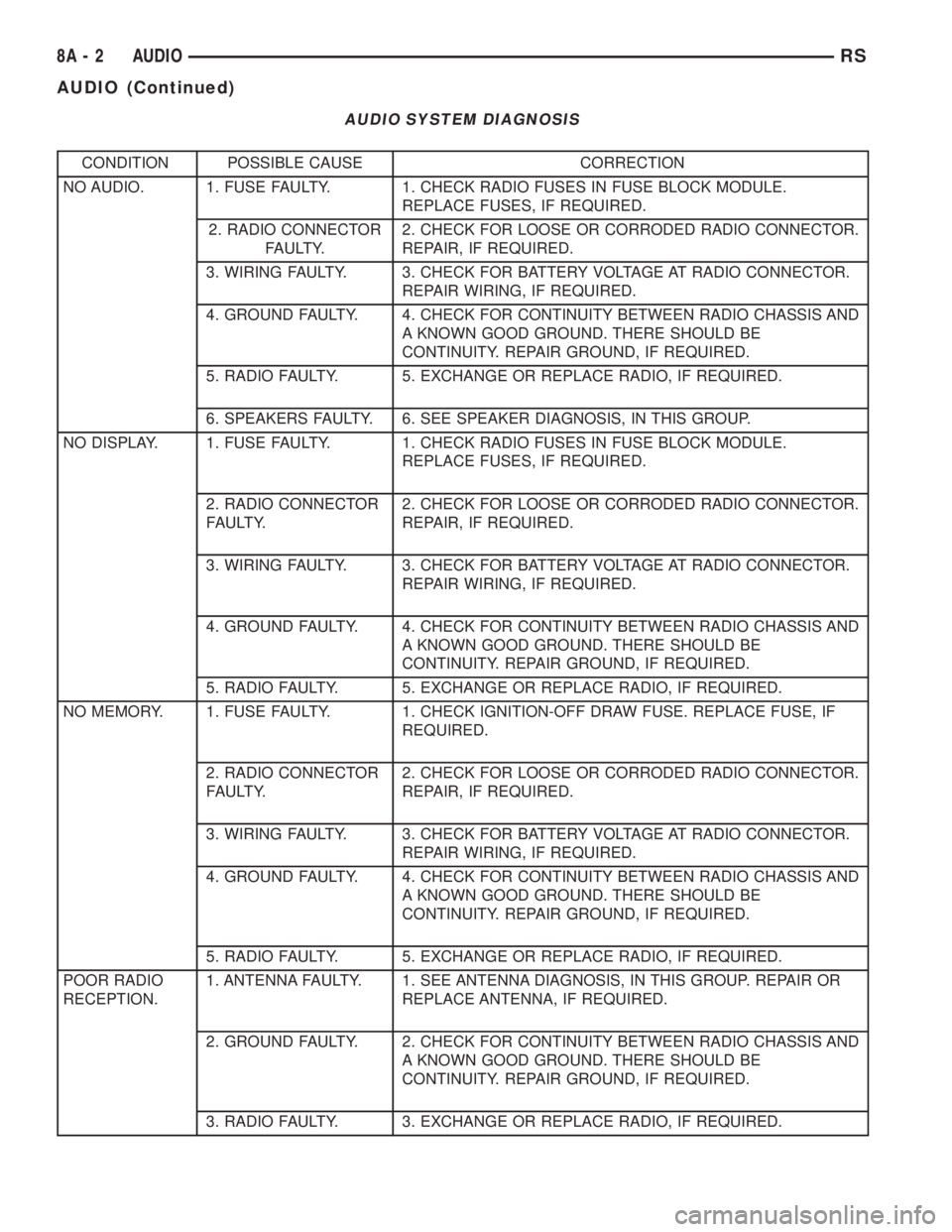

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO MEMORY. 1. FUSE FAULTY. 1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

POOR RADIO

RECEPTION.1. ANTENNA FAULTY. 1. SEE ANTENNA DIAGNOSIS, IN THIS GROUP. REPAIR OR

REPLACE ANTENNA, IF REQUIRED.

2. GROUND FAULTY. 2. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

3. RADIO FAULTY. 3. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

8A - 2 AUDIORS

AUDIO (Continued)

Page 1810 of 4284

CD CHANGER

DESCRIPTION

The 4 Disc In-Dash CD Changer (if equipped) is

located in the instrument panel below the radio. The

remote changer does not use a cartridge or magazine

for the CD's. Up to 4 CD's can be directly loaded into

this unit.

OPERATION

Due to its compact design, the CD changer can

carry out only one operation at a time. For example,

you can not load a new disc while playing another at

the same time. Each operation happens sequentially.

The radio unit provides control over all features of

the CD changer with the exception of the CD load

and eject functions, which are controlled by buttons

located on the front of the CD changer. All features

you would expect, such as Disc Up/Down, Track

Up/Down, Random and Scan are controlled by the

radio, which also displays all relevant CD changer

information on the radio display.

The CD changer contains a Load/Eject button and

an indicator LED for each of the four disc positions

as well as an illuminated disc opening. The individ-

ual LED indicates whether a CD is currently loaded

in that particular chamber of the CD changer. Press-

ing the individual Load/Eject button for a particular

chamber will eject a disc currently present in that

chamber. If the chamber is currently empty, actuat-

ing the Load/Eject button will position that chamber

to receive and load a new disc in that chamber.

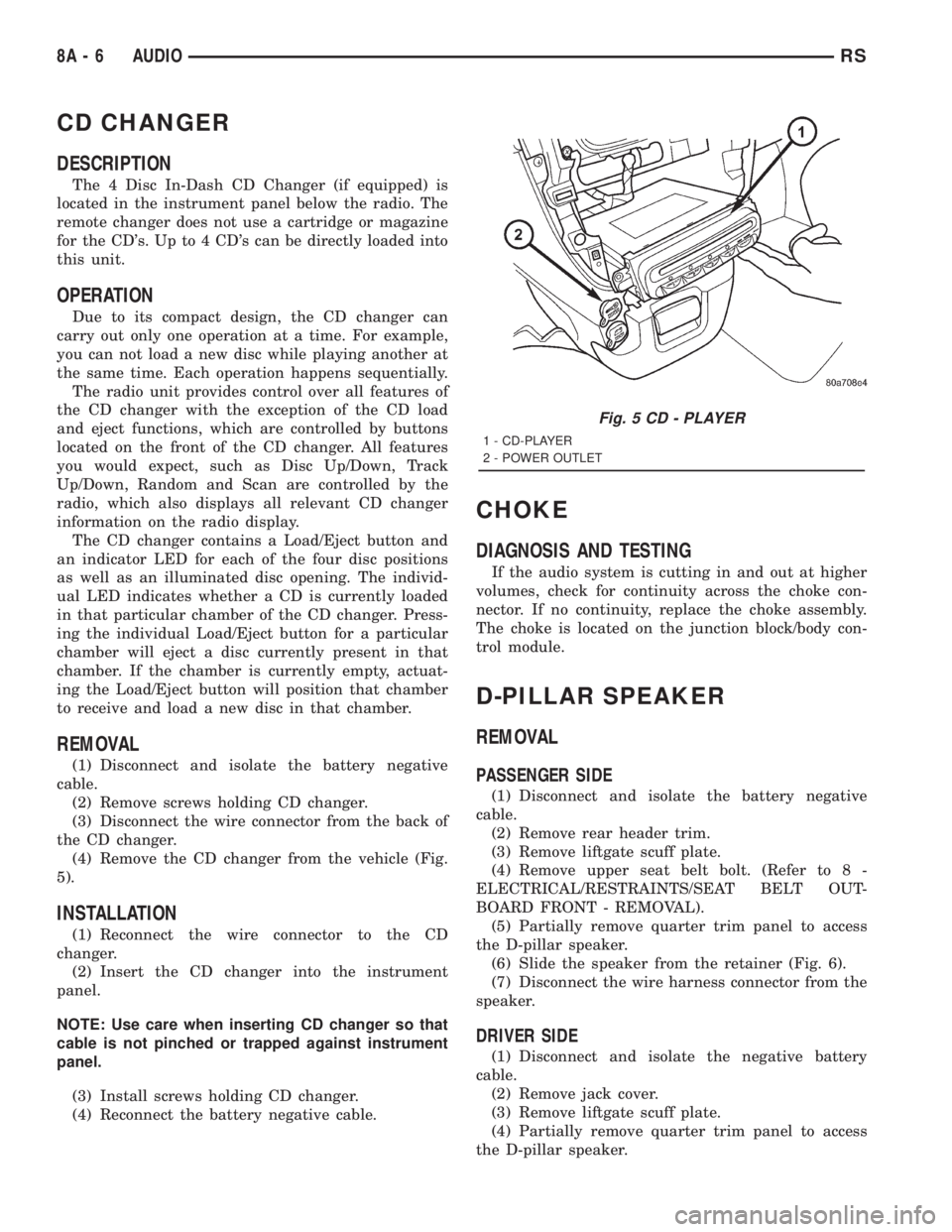

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding CD changer.

(3) Disconnect the wire connector from the back of

the CD changer.

(4) Remove the CD changer from the vehicle (Fig.

5).

INSTALLATION

(1) Reconnect the wire connector to the CD

changer.

(2) Insert the CD changer into the instrument

panel.

NOTE: Use care when inserting CD changer so that

cable is not pinched or trapped against instrument

panel.

(3) Install screws holding CD changer.

(4) Reconnect the battery negative cable.

CHOKE

DIAGNOSIS AND TESTING

If the audio system is cutting in and out at higher

volumes, check for continuity across the choke con-

nector. If no continuity, replace the choke assembly.

The choke is located on the junction block/body con-

trol module.

D-PILLAR SPEAKER

REMOVAL

PASSENGER SIDE

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear header trim.

(3) Remove liftgate scuff plate.

(4) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).

(5) Partially remove quarter trim panel to access

the D-pillar speaker.

(6) Slide the speaker from the retainer (Fig. 6).

(7) Disconnect the wire harness connector from the

speaker.

DRIVER SIDE

(1) Disconnect and isolate the negative battery

cable.

(2) Remove jack cover.

(3) Remove liftgate scuff plate.

(4) Partially remove quarter trim panel to access

the D-pillar speaker.

Fig. 5 CD - PLAYER

1 - CD-PLAYER

2 - POWER OUTLET

8A - 6 AUDIORS

Page 1826 of 4284

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition to the RUN

position for one hour then enter the correct PIN.

(Ensure all accessories are turned off. Also monitor

the battery state and connect a battery charger if

necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRB III will ask, Is odometer reading

between XX and XX? Select the YES or NO button on

the DRB III. If NO is selected, the DRB III will read,

Enter odometer Reading

the odometer reading from the Instrument Panel and

press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, the SKIM must be replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle keys will need to be replaced

and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

If ignition key programming is unsuccessful, the

DRB III will display one of the following messages:

Programming Not Attempted - The DRB III

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

Programming Key Failed (Possible Used Key From

Wrong Vehicle) - SKIM is unable to program key due

to one of the following:

²faulty ignition key transponder

²ignition key is programmed to another vehicle.

8 Keys Already Learned, Programming Not Done -

SKIM transponder ID memory is full.

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is concealed

below the driver side end of the instrument panel in

the passenger compartment, where it is secured to

the dash panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

8E - 2 ELECTRONIC CONTROL MODULESRS

ELECTRONIC CONTROL MODULES (Continued)

Page 1834 of 4284

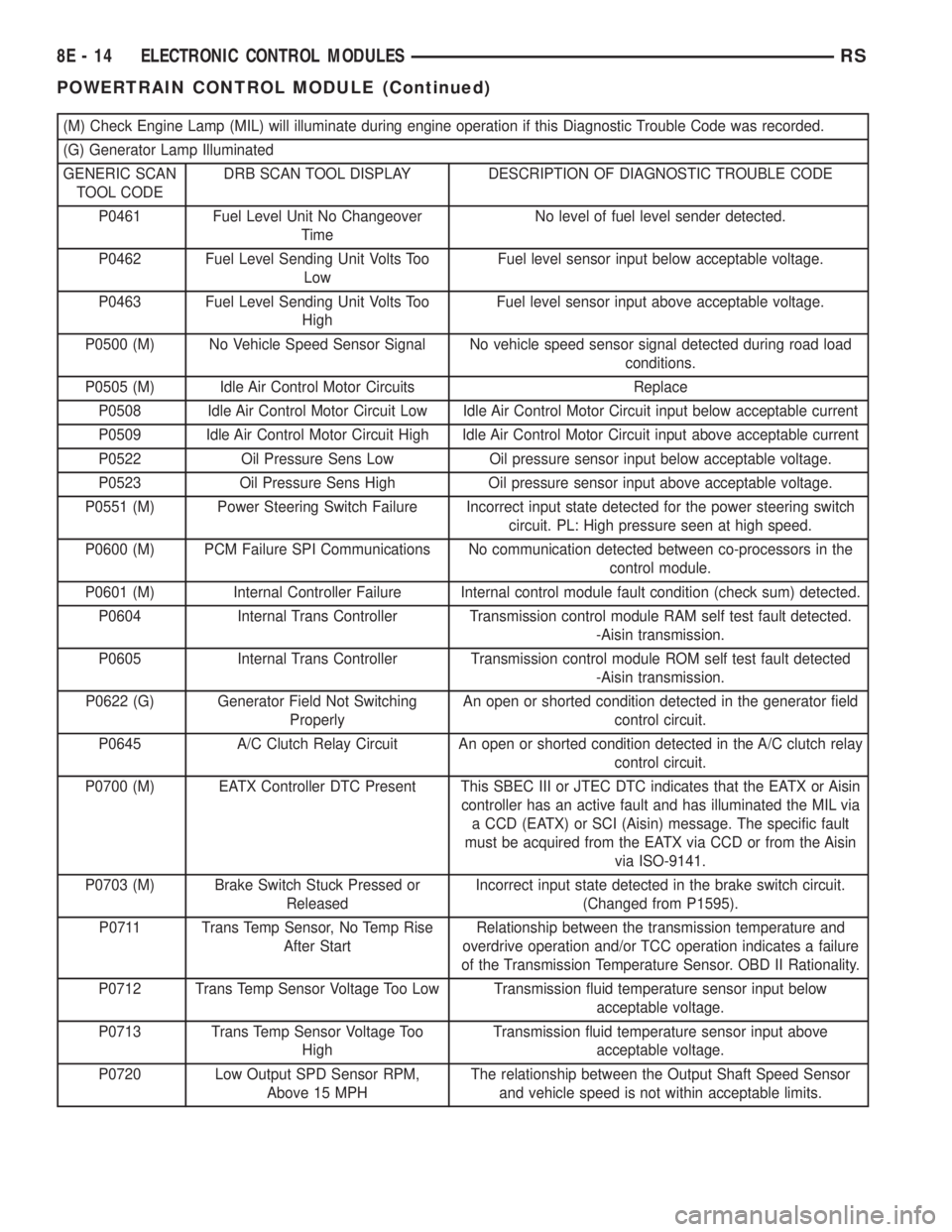

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0071 Ambient Temp Sensor Preformance Ambient change less than 3É C in 200 Miles

P0106 (M) Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

P0111 (M) Intake Air Temp Sensor Preformance Intake Air change less than 3É C in 200 Miles

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage High Intake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 Engine Coolant Temp Performance A rationatilty error has been detected in the coolant temp

sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the minimum

acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0122 (M) Throttle Position Sensor Voltage

LowThrottle position sensor input below the acceptable voltage

range.

P0123 (M) Throttle Position Sensor Voltage

HighThrottle position sensor input above the maximum

acceptable voltage.

P0125 (M) Engine Coolant Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0130 1/1 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

P0135 (M) 1/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0136 1/2 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P0137 (M) 1/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0138 (M) 1/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0139 (M) 1/2 O2 Sensor Slow Response Oxygen sensor response not as expected.

8E - 10 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 1835 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0140 (M) 1/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0141 (M) 1/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0143 1/3 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0144 1/3 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0145 1/3 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0146 1/3 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0147 1/3 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0151 (M) 2/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0152 (M) 2/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage sustained above normal

operating range.

P0153 (M) 2/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0154 (M) 2/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0155 (M) 2/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0157 (M) 2/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0158 (M) 2/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0159 2/2 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0160 (M) 2/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0161 (M) 2/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0165 Starter Relay Control Circuit An open or shorted condition detected in the starter relay

control circuit.

P0171 (M) 1/1 Fuel System Lean A lean air/fuel mixture has been indicated by an abnormally

rich correction factor.

P0172 (M) 1/1 Fuel System Rich A rich air/fuel mixture has been indicated by an abnormally

lean correction factor.

P0174 (M) 2/1 Fuel System Lean A lean air/fuel mixture has been indicated by an abnormally

rich correction factor.

P0175 (M) 2/1 Fuel System Rich A rich air/fuel mixture has been indicated by an abnormally

lean correction factor.

P0178 Water in Fuel Sensor Voltage Too

LowFlex fuel sensor input below minimum acceptable voltage.

P0179 Flex Fuel Sensor Volts Too High Flex fuel sensor input above maximum acceptable voltage.

RSELECTRONIC CONTROL MODULES8E-11

POWERTRAIN CONTROL MODULE (Continued)

Page 1836 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0182 CNG Temp Sensor Voltage Too Low Compressed natural gas temperature sensor voltage below

acceptable voltage.

P0183 CNG Temp Sensor Voltage Too High Compressed natural gas temperature sensor voltage above

acceptable voltage.

P0201 (M) Injector #1 Control Circuit An open or shorted condition detected in control circuit for

injector #1 or the INJ 1 injector bank.

P0202 (M) Injector #2 Control Circuit An open or shorted condition detected in control circuit for

injector #2 or the INJ 2 injector bank.

P0203 (M) Injector #3 Control Circuit An open or shorted condition detected in control circuit for

injector #3 or the INJ 3 injector bank.

P0204 (M) Injector #4 Control Circuit Injector #4 or INJ 4 injector bank output driver stage does

not respond properly to the control signal.

P0205 (M) Injector #5 Control Circuit Injector #5 output driver stage does not respond properly to

the control signal.

P0206 (M) Injector #6 Control Circuit Injector #6 output driver stage does not respond properly to

the control signal.

P0207 Injector #7 Control Circuit Injector #7 output driver stage does not respond properly to

the control signal.

P0208 Injector #8 Control Circuit Injector #8 output driver stage does not respond properly to

the control signal.

P0209 Injector #9 Control Circuit Injector #9 output driver stage does not respond properly to

the control signal.

P0210 Injector #10 Control Circuit Injector #10 output driver stage does not respond properly to

the control signal.

P0300 (M) Multiple Cylinder Mis-fire Misfire detected in multiple cylinders.

P0301 (M) CYLINDER #1 MISFIRE Misfire detected in cylinder #1.

P0302 (M) CYLINDER #2 MISFIRE Misfire detected in cylinder #2.

P0303 (M) CYLINDER #3 MISFIRE Misfire detected in cylinder #3.

P0304 (M) CYLINDER #4 MISFIRE Misfire detected in cylinder #4.

P0305 (M) CYLINDER #5 MISFIRE Misfire detected in cylinder #5.

P0306 (M) CYLINDER #6 MISFIRE Misfire detected in cylinder #6.

P0307 (M) CYLINDER #7 MISFIRE Misfire detected in cylinder #7

P0308 (M) CYLINDER #8 MISFIRE Misfire detected in cylinder #8.

P0309 (M) CYLINDER #9 MISFIRE Misfire detected in cylinder #9.

P0310 (M) CYLINDER #10 MISFIRE Misfire detected in cylinder #10.

P0320 No Crank Referance Signal at PCM No reference signal (crankshaft position sensor) detected

during engine cranking.

P0325 Knock Sensor #1 Circuit Knock sensor (#1) signal above or below minimum

acceptable threshold voltage at particular engine speeds.

P0330 Knock Sensor #2 Circuit Knock sensor (#2) signal above or below minimum

acceptable threshold voltage at particular engine speeds.

P0340 (M) No Cam Signal At PCM No fuel sync

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 1837 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0350 Ignition Coil Draws Too Much

CurrentA coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil # 1 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil # 2 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil # 3 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil # 4 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil # 5 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil # 6 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 Ignition Coil # 7 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 Ignition Coil # 8 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0401 (M) EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 (M) EGR Solenoid Circuit An open or shorted condition detected in the EGR solenoid

control circuit.

P0404 (M) EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR duty

cycle.

P0405 (M) EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

P0406 (M) EGR Position Sensor Volts Too High EGR position sensor input above the acceptable voltage

range.

P0412 Secondary Air Solenoid Circuit An open or shorted condition detected in the secondary air

(air switching/aspirator) solenoid control circuit.

P0420 (M) 1/1 Catalytic Converter Efficiency Catalyst 1/1 efficiency below required level.

P0432 (M) 1/2 Catalytic Converter Efficiency Catalyst 2/1 efficiency below required level.

P0441 (M) Evap Purge Flow Monitor Insufficient or excessive vapor flow detected during

evaporative emission system operation.

P0442 (M) Evap Leak Monitor 0.040 Leak

DetectedA 0.040 leak has been detected in the evaporative system.

P0443 (M) Evap Purge Solenoid Circuit An open or shorted condition detected in the EVAP purge

solenoid control circuit.

P0455 (M) Evap Leak Monitor Large Leak

DetectedA large leak has been detected in the evaporative system.

P0456 Evap Leak Monitor 0.020 Leak

DetectedA 0.020 leak has been detected in the evaporative system.

P0460 Fuel Level Unit No Change Over

MilesNo movement of fuel level sender detected.

RSELECTRONIC CONTROL MODULES8E-13

POWERTRAIN CONTROL MODULE (Continued)

Page 1838 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0461 Fuel Level Unit No Changeover

TimeNo level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too

LowFuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road load

conditions.

P0505 (M) Idle Air Control Motor Circuits Replace

P0508 Idle Air Control Motor Circuit Low Idle Air Control Motor Circuit input below acceptable current

P0509 Idle Air Control Motor Circuit High Idle Air Control Motor Circuit input above acceptable current

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering switch

circuit. PL: High pressure seen at high speed.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in the

control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum) detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault detected.

-Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault detected

-Aisin transmission.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator field

control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch relay

control circuit.

P0700 (M) EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or Aisin

controller has an active fault and has illuminated the MIL via

a CCD (EATX) or SCI (Aisin) message. The specific fault

must be acquired from the EATX via CCD or from the Aisin

via ISO-9141.

P0703 (M) Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595).

P0711 Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a failure

of the Transmission Temperature Sensor. OBD II Rationality.

P0712 Trans Temp Sensor Voltage Too Low Transmission fluid temperature sensor input below

acceptable voltage.

P0713 Trans Temp Sensor Voltage Too

HighTransmission fluid temperature sensor input above

acceptable voltage.

P0720 Low Output SPD Sensor RPM,

Above 15 MPHThe relationship between the Output Shaft Speed Sensor

and vehicle speed is not within acceptable limits.

8E - 14 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 1839 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0740 (M) Torq Con Clu, No RPM Drop at

LockupRelationship between engine and vehicle speeds indicated

failure of torque convertor clutch lock-up system (TCC/PTU

sol).

P0743 Torque Converter Clutch Solenoid/

Trans Relay CircuitsAn open or shorted condition detected in the torque

converter clutch (part throttle unlock) solenoid control circuit.

Shift solenoid C electrical fault - Aisin transmission

P0748 Governor Pressur Sol Control/Trans

Relay CircuitsAn open or shorted condition detected in the Governor

Pressure Solenoid circuit or Trans Relay Circuit in JTEC RE

transmissions.

P0751 O/D Switch Pressed (Lo) More Than

5 MinutesOverdrive override switch input is in a prolonged depressed

state.

P0753 Trans 3-4 Shift Sol/Trans Relay

CircuitsAn open or shorted condition detected in the overdrive

solenoid control circuit or Trans Relay Circuit in JTEC RE

transmissions.

P0756 AW4 Shift Sol B (2-3) Functional

FailureShift solenoid B (2-3) functional fault - Aisin transmission

P0783 3-4 Shift Sol, No RPM Drop at

LockupThe overdrive solenoid is unable to engage the gear change

from 3rd gear to the overdrive gear.

P0801 Reverse Gear Lockout Circuit Open

or ShortAn open or shorted condition detected in the transmission

reverse gear lock-out solenoid control circuit.

P01192 Inlet Air Temp. Circuit Low Inlet Air Temp. sensor input below acceptable voltage

P01193 Inlet Air Temp. Circuit High Inlet Air Temp. sensor input above acceptable voltage.

P1195 (M) 1/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in bank

1/1 during catalyst monitor test. (was P0133)

P1196 (M) 2/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in bank

2/1 during catalyst monitor test. (was P0153)

P1197 1/2 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in bank

1/2 during catalyst monitor test. (was P0139)

P1198 Radiator Temperature Sensor Volts

Too HighRadiator coolant temperature sensor input above the

maximum acceptable voltage.

P1199 Radiator Temperature Sensor Volts

Too LowRadiator coolant temperature sensor input below the

minimum acceptable voltage.

P1281 Engine is Cold Too Long Engine coolant temperature remains below normal operating

temperatures during vehicle travel (Thermostat).

P1282 Fuel Pump Relay Control Circuit An open or shorted condition detected in the fuel pump relay

control circuit.

P1288 Intake Manifold Short Runner

Solenoid CircuitAn open or shorted condition detected in the short runner

tuning valve circuit.

P1289 Manifold Tune Valve Solenoid Circuit An open or shorted condition detected in the manifold tuning

valve solenoid control circuit.

P1290 CNG Fuel System Pressure Too

HighCompressed natural gas system pressure above normal

operating range.

P1291 No Temp Rise Seen From Intake

HeatersEnergizing Heated Air Intake does not change intake air

temperature sensor an acceptable amount.

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)