CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3921 of 4284

TEST ACTION APPLICABILITY

12NOTE: Inspect the exhaust system for leaks.

WARNING: KEEP CLEAR OF THE ENGINE'S MOVING PARTS.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

127

DRIVEABILITY - GAS

P0401 - EGR SYSTEM FAILURE ÐContinued

Page 3922 of 4284

Symptom:

P0403 - EGR SOLENOID CIRCUIT

When Monitored and Set Condition:

P0403 - EGR SOLENOID CIRCUIT

When Monitored: Engine running. Battery voltage greater than 10 volts.

Set Condition: The EGR solenoid control circuit is not in the expected state when

requested to operate by the PCM.

POSSIBLE CAUSES

INTERMITTENT CONDITION

EGR SOLENOID

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

EGR SOLENOID CONTROL CKT SHORTED TO VOLTAGE

EGR SOLENOID CONTROL CKT SHORT TO GND

EGR SOLENOID CONTROL CKT OPEN

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Turn the ignition on.

Turn all accessories off.

Using a 12 volt Test Light connected to the Fused Ignition Switch Output circuit,

probe the EGR Solenoid Control circuit.

With the DRB, actuate the EGR solenoid.

Does the 12 volt test light flash on and off?All

Ye s®Inspect the EGR Valve Back Pressure hose and tube for obstruc-

tions or damage. If OK, replace the EGR Solenoid.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

128

DRIVEABILITY - GAS

Page 3923 of 4284

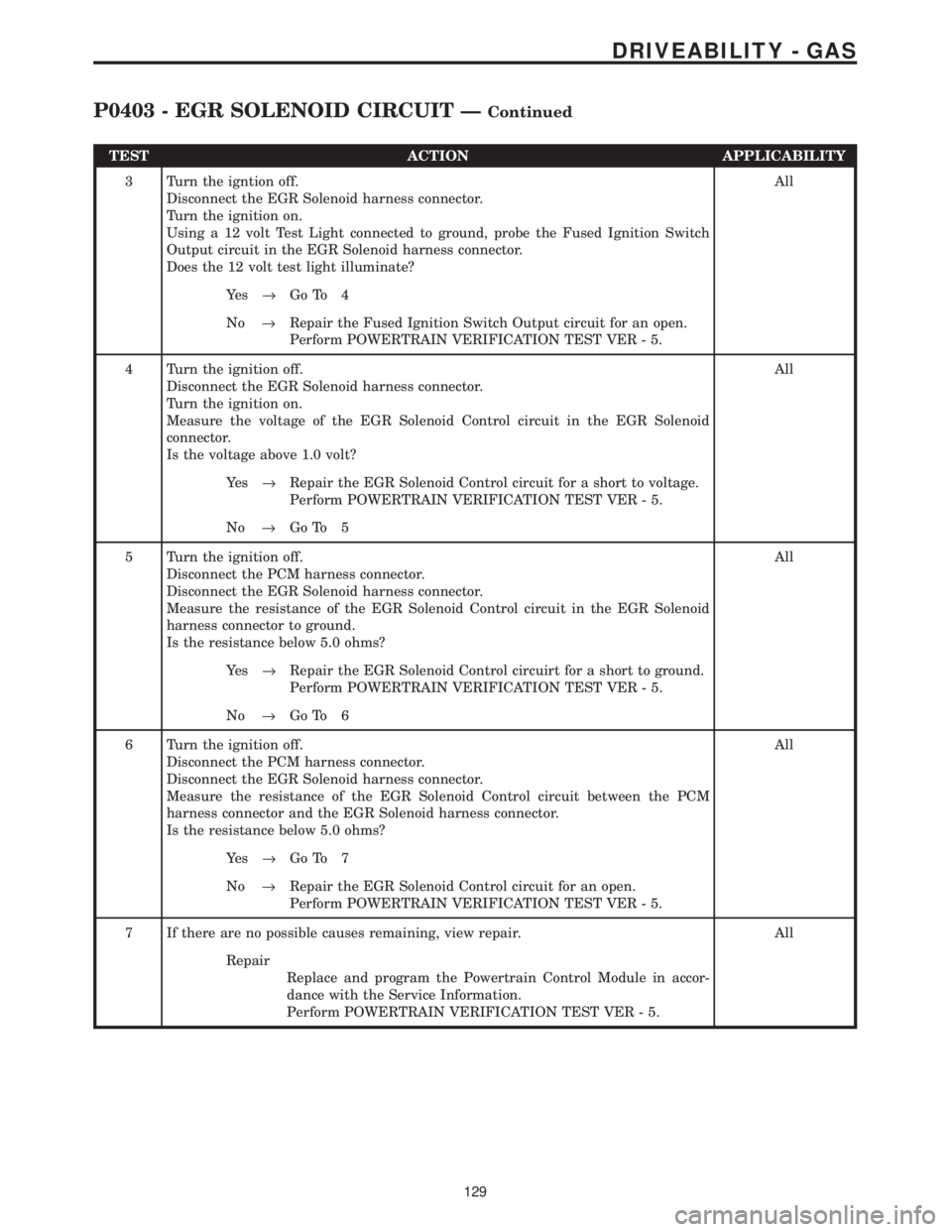

TEST ACTION APPLICABILITY

3 Turn the igntion off.

Disconnect the EGR Solenoid harness connector.

Turn the ignition on.

Using a 12 volt Test Light connected to ground, probe the Fused Ignition Switch

Output circuit in the EGR Solenoid harness connector.

Does the 12 volt test light illuminate?All

Ye s®Go To 4

No®Repair the Fused Ignition Switch Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

4 Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Turn the ignition on.

Measure the voltage of the EGR Solenoid Control circuit in the EGR Solenoid

connector.

Is the voltage above 1.0 volt?All

Ye s®Repair the EGR Solenoid Control circuit for a short to voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the EGR Solenoid harness connector.

Measure the resistance of the EGR Solenoid Control circuit in the EGR Solenoid

harness connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the EGR Solenoid Control circuirt for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the EGR Solenoid harness connector.

Measure the resistance of the EGR Solenoid Control circuit between the PCM

harness connector and the EGR Solenoid harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 7

No®Repair the EGR Solenoid Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

129

DRIVEABILITY - GAS

P0403 - EGR SOLENOID CIRCUIT ÐContinued

Page 3924 of 4284

TEST ACTION APPLICABILITY

8NOTE: Inspect the exhaust system for leaks.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

130

DRIVEABILITY - GAS

P0403 - EGR SOLENOID CIRCUIT ÐContinued

Page 3925 of 4284

Symptom:

P0420-1/1 CATALYTIC CONVERTER EFFICIENCY

When Monitored and Set Condition:

P0420-1/1 CATALYTIC CONVERTER EFFICIENCY

When Monitored: After engine warm up to 70ÉC (158ÉF), 180 seconds of open throttle

operation, at a speed greater than 18 mph and less than 55 mph, with the engine at

1200-1700 rpm and MAP vacuum between 15.0 and 21.0 inches of mercury (Hg).

Set Condition: As catalyst efficiency deteriorates, the switch rate of the downstream O2

sensor approaches that of the upstream O2 sensor. If at any point during the test the

switch ratio reaches a predetermined value a counter is incremented by one.

POSSIBLE CAUSES

INTERMITTENT CONDITION

VISUALLY INSPECT CATALYTIC CONVERTER

EXHAUST LEAK

ENGINE MECHANICAL CONDITION

AGING O2 SENSOR

CATALYTIC CONVERTER

TEST ACTION APPLICABILITY

1NOTE: If a O2 Sensor DTC(s) set along with the Catalytic Converter

Efficiency DTC diagnose the O2 Sensor DTC(s) before continuing.

NOTE: Check for contaminates that may have damaged the O2 Sensor and

Catalytic Converter: contaminated fuel, unapproved silicone, oil and cool-

ant, repair necessary.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Inspect the Catalytic Converter for the following damage.

Damage Catalytic Converter, dent and holes.

Severe discoloration caused by overheating the Catalytic Converter.

Catalytic Converter broke internally.

Leaking Catalytic Converter.

Were any problems found?All

Ye s®Replace the Catalytic Converter. Repair the condition that may

have caused the failure.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

131

DRIVEABILITY - GAS

Page 3926 of 4284

TEST ACTION APPLICABILITY

3 Start the engine.

Inspect the exhaust for leak between the engine and the O2 sensor.

Inspect the exhaust for leaks between the engine and the appropriate rear O2 Sensor.

Are there any exhaust leaks?All

Ye s®Repair or replace the leaking exhaust parts as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Check the exhaust for excessive smoke caused by an internal problem in the engine.

Is a engine mechanical condition present?All

Ye s®Repair the engine mechanical condition as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 A new rear O2 Sensor along with an aging front O2 Sensor may cause the DTC to set.

Review the vehicles repair history.

Has the rear O2 Sensor been replace without replacing the front O2 Sensor?All

Ye s®Replace the O2 Sensor as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 If there are no possible cause remaining, view repair. All

Repair

replace the Catalytic Converter.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: Check for contaminates that may have damaged the O2 Sensor and

Catalytic Converter: contaminated fuel, unapproved silicone, oil and cool-

ant, repair necessary.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

A new rear O2 Sensor along with a aging front O2 Sensor may cause the DTC to set.

Review repair history of the vehicle and repair as necessary.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

132

DRIVEABILITY - GAS

P0420-1/1 CATALYTIC CONVERTER EFFICIENCY ÐContinued

Page 3927 of 4284

Symptom:

P0441-EVAP PURGE FLOW MONITOR

When Monitored and Set Condition:

P0441-EVAP PURGE FLOW MONITOR

When Monitored: With engine temperature greater than 71ÉC (160ÉF), fuel control in

closed loop, engine idling for 200 seconds, no low fuel, MAP less than 23.6 inches mercury

and barometric altitude less than 8,000 feet.

Set Condition: After having passed the Leak Detection Pump (LDP) test, no air flow

through the evaporative system is detected by the evap monitor.

POSSIBLE CAUSES

INTERMITTENT CONDITION

EVAP PURGE SOLENOID LEAKS/STUCK OPEN

EVAP PURGE SOLENOID STUCK CLOSED

EVAP PURGE SOLENOID VACUUM SUPPLY

EVAP PURGE HOSE SOLENOID TO CANISTER

EVAP PURGE HOSE CANISTER TO FUEL TANK

EVAP CANISTER

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip Counter displayed and equal to zero?All

Ye s®Go To 2

No®Go To 8

2NOTE: After disconnecting the Evap Purge Solenoid vacuum connections,

inspect the lines and solenoid for any signs of contamination from the EVAP

Canister. This may indicate a faulty rollover valve. Replace/repair as

necessary.

Turn the ignition off.

Disconnect the vacuum hoses at the Evap Purge Solenoid.

Using a hand vacuum pump, apply 10 inches of vacuum to the Evap Purge Solenoid

vacuum source port on the component side.

Does the Evap Purge Solenoid hold vacuum?All

Ye s®Go To 3

No®Replace the Evap Purge Solenoid.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

133

DRIVEABILITY - GAS

Page 3928 of 4284

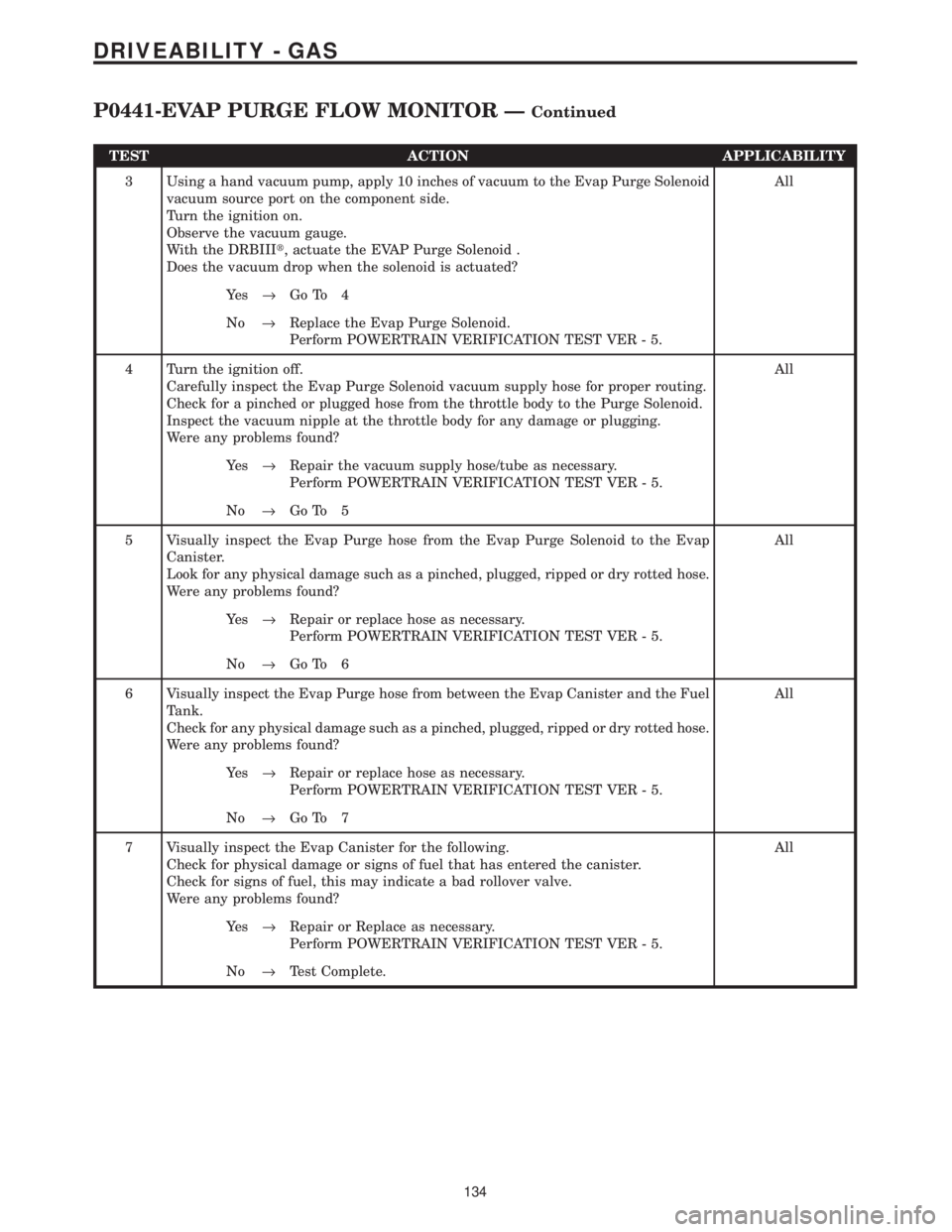

TEST ACTION APPLICABILITY

3 Using a hand vacuum pump, apply 10 inches of vacuum to the Evap Purge Solenoid

vacuum source port on the component side.

Turn the ignition on.

Observe the vacuum gauge.

With the DRBIIIt, actuate the EVAP Purge Solenoid .

Does the vacuum drop when the solenoid is actuated?All

Ye s®Go To 4

No®Replace the Evap Purge Solenoid.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

4 Turn the ignition off.

Carefully inspect the Evap Purge Solenoid vacuum supply hose for proper routing.

Check for a pinched or plugged hose from the throttle body to the Purge Solenoid.

Inspect the vacuum nipple at the throttle body for any damage or plugging.

Were any problems found?All

Ye s®Repair the vacuum supply hose/tube as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Visually inspect the Evap Purge hose from the Evap Purge Solenoid to the Evap

Canister.

Look for any physical damage such as a pinched, plugged, ripped or dry rotted hose.

Were any problems found?All

Ye s®Repair or replace hose as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 Visually inspect the Evap Purge hose from between the Evap Canister and the Fuel

Tank.

Check for any physical damage such as a pinched, plugged, ripped or dry rotted hose.

Were any problems found?All

Ye s®Repair or replace hose as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

7 Visually inspect the Evap Canister for the following.

Check for physical damage or signs of fuel that has entered the canister.

Check for signs of fuel, this may indicate a bad rollover valve.

Were any problems found?All

Ye s®Repair or Replace as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

134

DRIVEABILITY - GAS

P0441-EVAP PURGE FLOW MONITOR ÐContinued

Page 3929 of 4284

TEST ACTION APPLICABILITY

8WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

Perform a wiggle test of the Evap Purge Solenoid wiring while the circuit is actuated

with the DRBIIIt. Listen for the solenoid to quit actuating. Also watch for the Good

Trip Counter to change to 0.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

135

DRIVEABILITY - GAS

P0441-EVAP PURGE FLOW MONITOR ÐContinued

Page 3930 of 4284

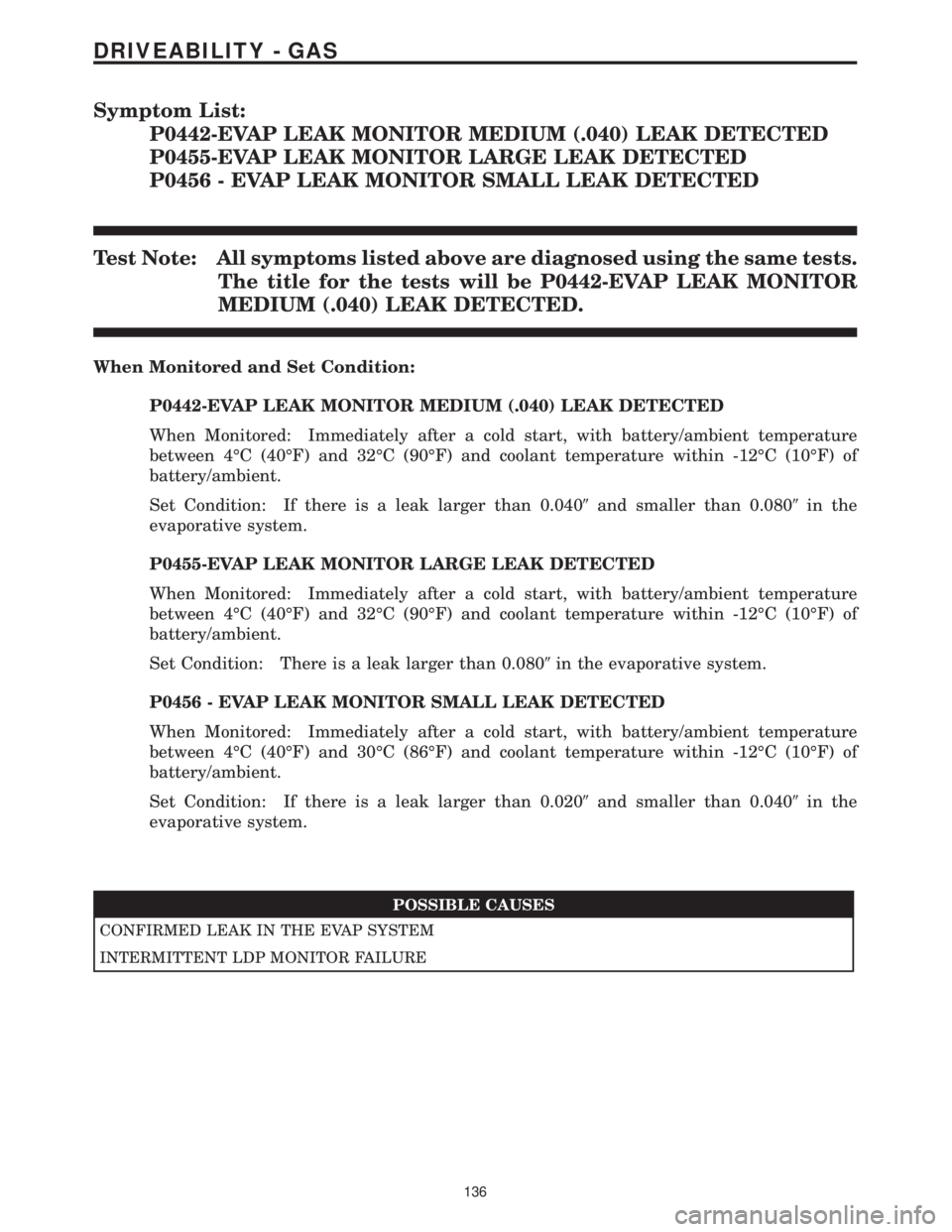

Symptom List:

P0442-EVAP LEAK MONITOR MEDIUM (.040) LEAK DETECTED

P0455-EVAP LEAK MONITOR LARGE LEAK DETECTED

P0456 - EVAP LEAK MONITOR SMALL LEAK DETECTED

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0442-EVAP LEAK MONITOR

MEDIUM (.040) LEAK DETECTED.

When Monitored and Set Condition:

P0442-EVAP LEAK MONITOR MEDIUM (.040) LEAK DETECTED

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4ÉC (40ÉF) and 32ÉC (90ÉF) and coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: If there is a leak larger than 0.0409and smaller than 0.0809in the

evaporative system.

P0455-EVAP LEAK MONITOR LARGE LEAK DETECTED

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4ÉC (40ÉF) and 32ÉC (90ÉF) and coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: There is a leak larger than 0.0809in the evaporative system.

P0456 - EVAP LEAK MONITOR SMALL LEAK DETECTED

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4ÉC (40ÉF) and 30ÉC (86ÉF) and coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: If there is a leak larger than 0.0209and smaller than 0.0409in the

evaporative system.

POSSIBLE CAUSES

CONFIRMED LEAK IN THE EVAP SYSTEM

INTERMITTENT LDP MONITOR FAILURE

136

DRIVEABILITY - GAS