wheel CHRYSLER VOYAGER 2001 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1184 of 4284

TEST ACTION APPLICABILITY

3 With the DRBIIIt, read DTCs.

Did the DTC reoccur?All

Ye s®

No®Go To 4

4 Turn the ignition off.

Visually inspect wheel speed sensor.

Visually inspect tone wheel.

Visually inspect wiring harness.

Visually inspect brakes for locking up due to lining contamination or overheating.

Inspect all Components for defects which may cause a Signal DTC to set.

Is any Component Damaged?All

Ye s®Repair as necessary. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Test Complete.

27

BRAKES (CAB)

RIGHT REAR WHEEL SPEED SIGNAL FAILURE ÐContinued

Page 1196 of 4284

Symptom:

*TRAC ON INDICATOR NEVER/ALWAYS ON

POSSIBLE CAUSES

CAB -- INTERNAL FAULT

CHECK TRACTION CONTROL SYSTEM

CLUSTER FAILS SELF TEST

CAB - NO TRAC MESSAGE

TEST ACTION APPLICABILITY

1NOTE: The DRBIIItmust be able to communicate with the CAB prior to

performing this test.

NOTE: Note: If any CAB DTC's are present, they must be repaired prior to

performing this test.

Perform the KEY-ON bulb test.

Did the TRAC Indicator illuminate and then go out?All

Ye s®Go To 2

No®Go To 3

2 Make sure the Traction Control system has not been deactivated with the TRAC OFF

switch.

NOTE: The purpose of this test is to determine if the Traction Control

system is operating.

With the DRBIIItin Inputs/Outputs, read the ABS Pump Motor voltage state.

Accelerate sufficient to cause drive wheel slip.

Does the TRAC Indicator illuminate and the DRBIIItdisplay approximately 9 volts?All

Ye s®The traction control system is functioning normally.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

3NOTE: The purpose of this test is to perform the Instrument Cluster self

test.

Depress and hold the Odometer Reset Button.

Turn the Key from OFF to ON and then back to OFF.

Release the Odometer Reset Button.

Do the Instrument Cluster Indicators and Gauges activate and deactivate?All

Ye s®Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Instrument Cluster in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

39

BRAKES (CAB)

Page 1200 of 4284

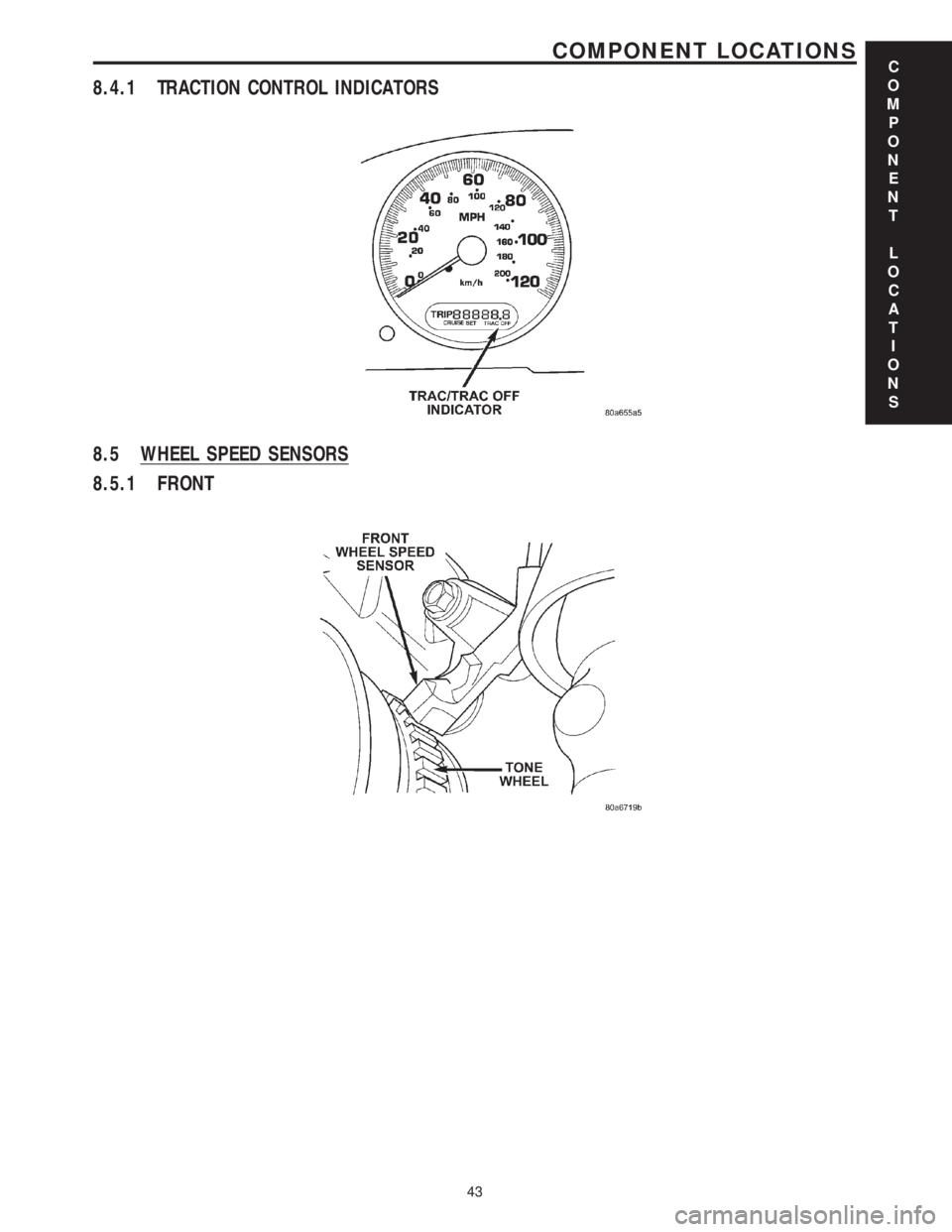

8.4.1 TRACTION CONTROL INDICATORS

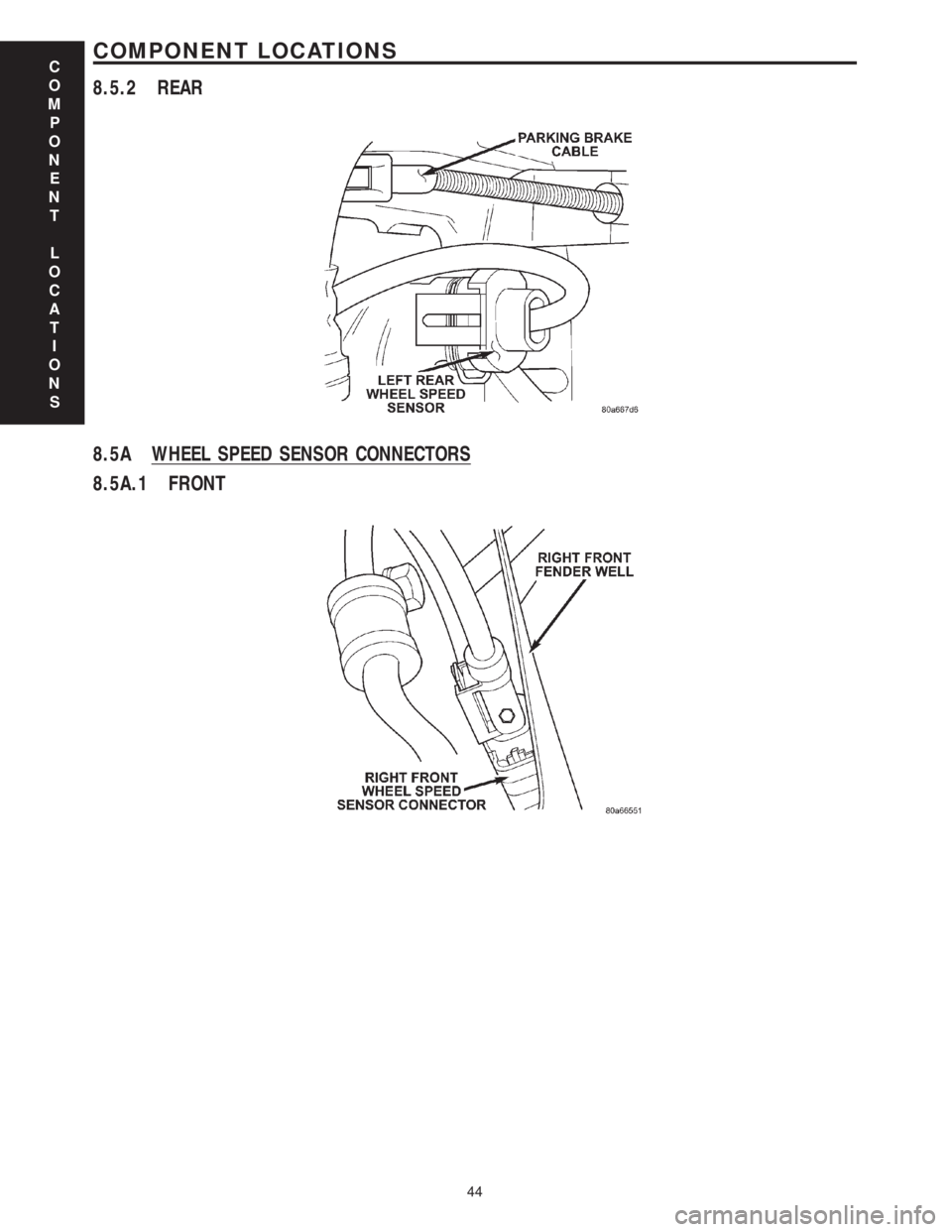

8.5 WHEEL SPEED SENSORS

8.5.1 FRONT

C

O

M

P

O

N

E

N

T

L

O

C

A

T

I

O

N

S

43

COMPONENT LOCATIONS

Page 1201 of 4284

8.5.2 REAR

8.5A WHEEL SPEED SENSOR CONNECTORS

8.5A.1 FRONT

C

O

M

P

O

N

E

N

T

L

O

C

A

T

I

O

N

S

44

COMPONENT LOCATIONS

Page 1204 of 4284

9.0 CONNECTOR PINOUTS

CONTROLLER ANTILOCK BRAKE - BLACK 24 WAYCAV CIRCUIT FUNCTION

1 Z107 12BK/DG GROUND

2 B1 18DG/OR RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

3 B2 18DG/LB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

4- -

5 D25 18WT/VT PCI BUS

6 B6 18DG/WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

7 B7 18DG/VT RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

8- -

9 A111 12DG/RD FUSED B(+)

10 F500 18DG/PK FUSED IGNITION SWITCH OUTPUT

11 - -

12 - -

13 - -

14 - -

15 - -

16 Z127 12BK/DG GROUND

17 - -

18 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

19 B3 18DG/YL LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

20 B4 18DG/GY LEFT REAR WHEEL SPEED SENSOR SIGNAL

21 - -

22 B8 18DG/TN LEFT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

23 B9 18DG/LG LEFT FRONT WHEEL SPEED SENSOR SIGNAL

24 A107 12TN/RD FUSED B(+)

DATA LINK CONNECTOR - WHITE 16 WAYCAV CIRCUIT FUNCTION

1- -

2 D25 20WT/VT PCI BUS

3- -

4 Z11 18BK/LG GROUND

5 Z111 18BK/WT GROUND

6 D20 20WT/LG SCI RECEIVE

7 D21 20WT/BR SCI TRANSMIT

8- -

9 D23 20WT/BR FLASH PROGRAM ENABLE

10 - -

11 - -

12 - -

13 - -

14 D16 20WT/OR SCI RECEIVE

15 - -

16 A105 20DB/RD FUSED B(+)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

47

CONNECTOR PINOUTS

Page 1205 of 4284

DIAGNOSTIC JUNCTION PORT - BLACK 16 WAYCAV CIRCUIT FUNCTION

1 D25 20WT/VT PCI BUS (PCM/SKIM)

2 D25 20WT/VT PCI BUS (HVAC)

3 D25 20WT/VT PCI BUS (RADIO)

4 D25 20WT/VT PCI BUS (ORC)

5 D25 20WT/VT PCI BUS (CLUSTER)

6 D25 20WT/VT PCI BUS (BCM)

7 D25 20WT/VT PCI BUS (DLC)

8 D25 20WT/VT PCI BUS (OVERHEAD CONSOLE)

9 D25 20WT/VT PCI BUS (IPM)

10 D25 20WT/VT PCI BUS (LSIACM)

11 D25 20WT/VT PCI BUS (MEMORY SEAT/MIRROR)

12 D25 20WT/VT PCI BUS (PWR DOOR/ LT, RT LIFTGATE)

13 D25 20WT/VT PCI BUS (RSIACM)

14 - -

15 - -

16 - -

INTELLIGENT POWER MODULE C4 - GRAY 10 WAYCAV CIRCUIT FUNCTION

1 Z127 12BK/DG GROUND

2 T750 12YL/GY ENGINE STARTER MOTOR RELAY OUTPUT

3 K342 16BR/WT AUTOMATIC SHUTDOWN RELAY OUTPUT

4 F500 18DG/PK (ANTILOCK

BRAKES)FUSED IGNITION SWITCH RELAY OUTPUT (RUN)

5- -

6 D25 16WT/VT (ANTILOCK

BRAKES)PCI BUS

7 A107 12TN/RD (ANTILOCK

BRAKES)FUSED B(+)

8 A111 12DG/RD (ANTILOCK

BRAKES)FUSED B(+)

9 A701 14BR/RD FUSED B(+)

10 - -

LEFT FRONT WHEEL SPEED SENSOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B9 18DG/LG LEFT FRONT WHEEL SPEED SENSOR SIGNAL

2 B8 18DG/TN LEFT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

48

CONNECTOR PINOUTS

Page 1206 of 4284

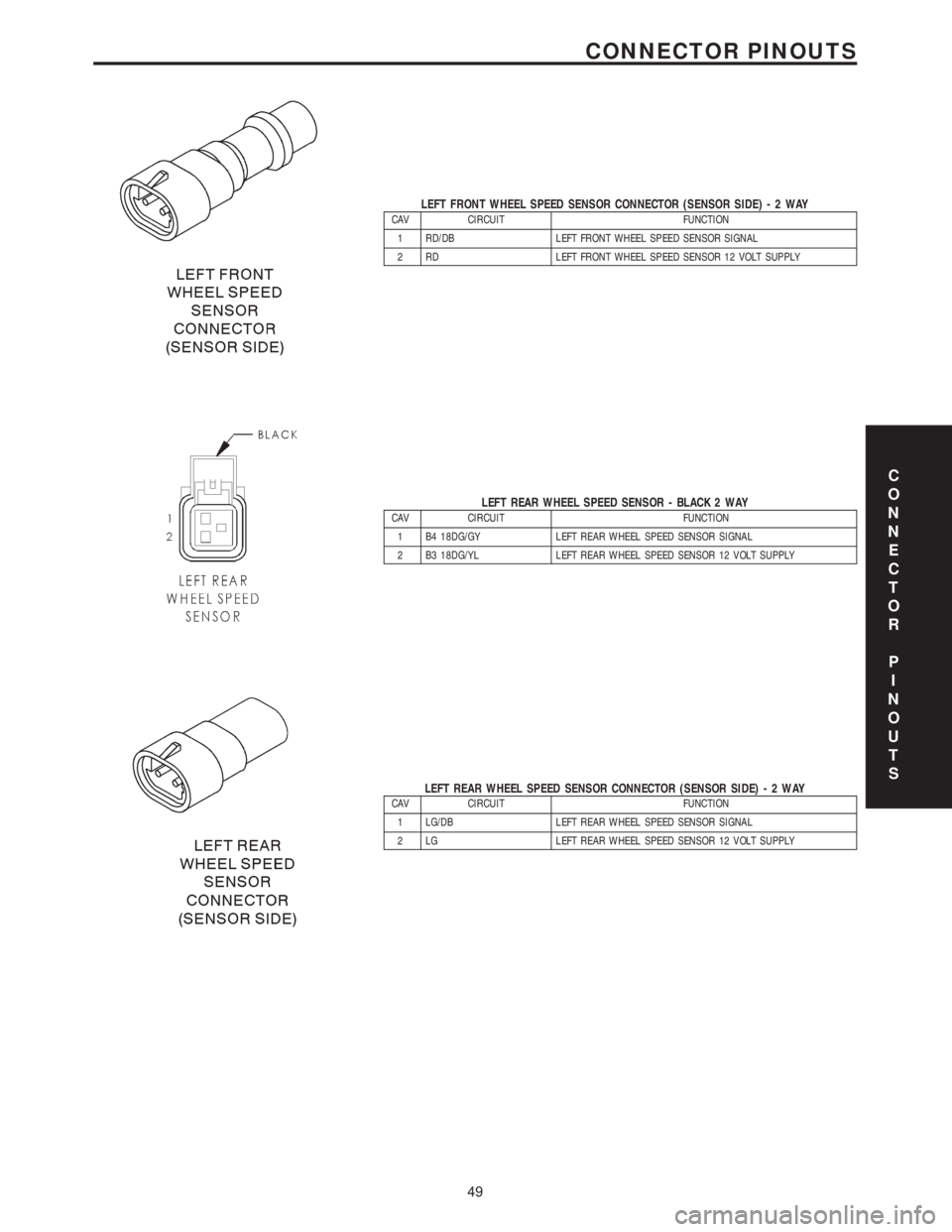

LEFT FRONT WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 RD/DB LEFT FRONT WHEEL SPEED SENSOR SIGNAL

2 RD LEFT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

LEFT REAR WHEEL SPEED SENSOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B4 18DG/GY LEFT REAR WHEEL SPEED SENSOR SIGNAL

2 B3 18DG/YL LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

LEFT REAR WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 LG/DB LEFT REAR WHEEL SPEED SENSOR SIGNAL

2 LG LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

49

CONNECTOR PINOUTS

Page 1209 of 4284

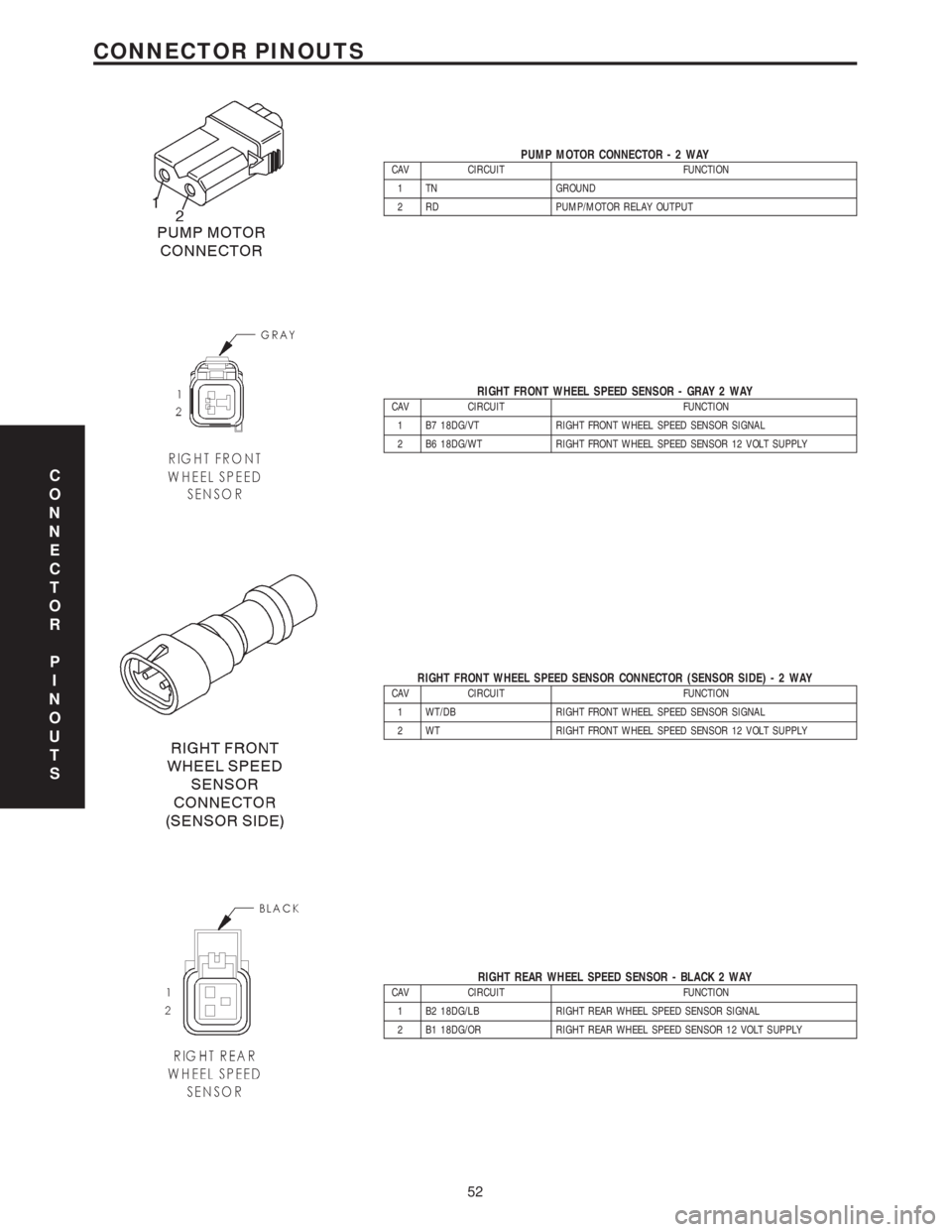

PUMP MOTOR CONNECTOR-2WAYCAV CIRCUIT FUNCTION

1 TN GROUND

2 RD PUMP/MOTOR RELAY OUTPUT

RIGHT FRONT WHEEL SPEED SENSOR - GRAY 2 WAYCAV CIRCUIT FUNCTION

1 B7 18DG/VT RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

2 B6 18DG/WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

RIGHT FRONT WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 WT/DB RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

2 WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT SUPPLY

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B2 18DG/LB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

2 B1 18DG/OR RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

52

CONNECTOR PINOUTS

Page 1210 of 4284

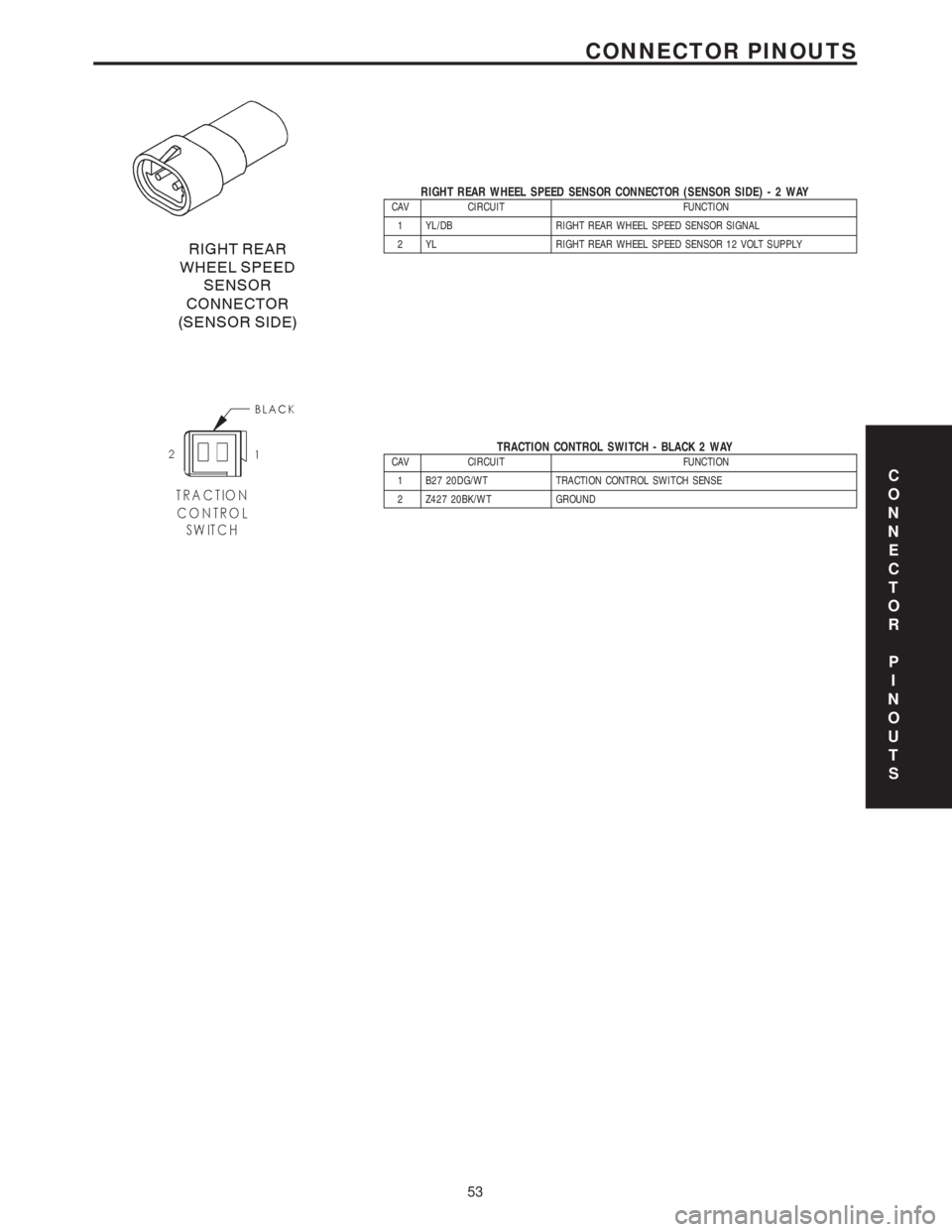

RIGHT REAR WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 YL/DB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

2 YL RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

TRACTION CONTROL SWITCH - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 B27 20DG/WT TRACTION CONTROL SWITCH SENSE

2 Z427 20BK/WT GROUNDC

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

53

CONNECTOR PINOUTS

Page 1220 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions and graphics

needed to diagnose engine control module (ECM)

and sentry key immobilizer system (SKIS) prob-

lems; they are no start, diagnostic trouble code

(DTC), and no trouble code problems for the ECM.

The diagnostics in this manual are based on the

trouble condition or symptom being present at the

time of diagnosis.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added; carryover sys-

tems may be enhanced. IT IS RECOMMENDED

THAT YOU REVIEW THE ENTIRE MANUAL TO

BECOME FAMILIAR WITH ALL NEW AND

CHANGED DIAGNOSTIC PROCEDURES.

This manual is designed to begin all diagnosis at

the DTC TEST, which is located at the beginning of

Section 7.0. This will cover all the necessary re-

quirements to begin a logical diagnostic path for

each problem. If there is a diagnostic trouble code

(DTC) detected, it will direct you to the trouble code

test. If there are no DTCs present, it will direct you

by symptom to a no trouble code test.

This book reflects many suggested changes from

readers of past issues. After using this book, if you

have any comments or recommendations, please fill

out the form at the back of the book and mail it back

to us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers all

2001 RG body vehicles equipped with the 2.5L VM

diesel engine.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the engine control module (ECM)

and sentry key immobilizer system (SKIS) is done

in six basic steps:

²verification of complaint

²verification of any related symptom

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

NOTE: All tests in this manual should be per-

formed with the engine at operating temperature,

unless specified within a particular test.

2.0 IDENTIFICATION OF

SYSTEM

The ECM is located in the left side of the engine

compartment between the left front headlamp and

the intelligent power module. The sentry key immo-

bilizer module (SKIM) is located below the steering

column behind the steering wheel.

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

3.1 GENERAL DESCRIPTION

The 2.5L VM diesel engine system is equipped

with the latest in technical advances. The on-board

diagnostics incorporated in the engine control mod-

ule and SKIM are intended to assist the field

technician in repairing vehicle problems by the

quickest means.

The engine system incorporates a common rail

fuel delivery design. This design utilizes electroni-

cally controlled solenoid valve type fuel injectors.

Each injector is controlled individually by the ECM.

Injector timing and fuel quantity are controlled by

the ECM based on inputs from the various sensors.

The precision control of the injectors by the ECM

helps to reduce the engine noise, odor and smoke.

3.2 FUNCTIONAL OPERATION

3.2.1 ECM ON-BOARD DIAGNOSTICS

The ECM has been programmed to monitor many

different circuits of the diesel fuel injection system.

This monitoring is called on-board diagnostics.

Certain criteria must be met for a trouble code to

be entered into the ECM memory. The criteria may

be a range of: engine rpm, engine temperature, time

or other input signals to the ECM. If all of the

criteria for monitoring a system or circuit are met,

and a problem is sensed, then a DTC will be stored

in the ECM memory.

It is possible that a DTC for a monitored circuit

may not be entered into the ECM memory, even

though a malfunction has occurred. This may hap-

pen when the monitoring criteria has not been met.

The ECM compares input signal voltages from

each input device with specifications (the estab-

lished high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored

in the ECM memory.

1

GENERAL INFORMATION