change time CHRYSLER VOYAGER 2001 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 906 of 4284

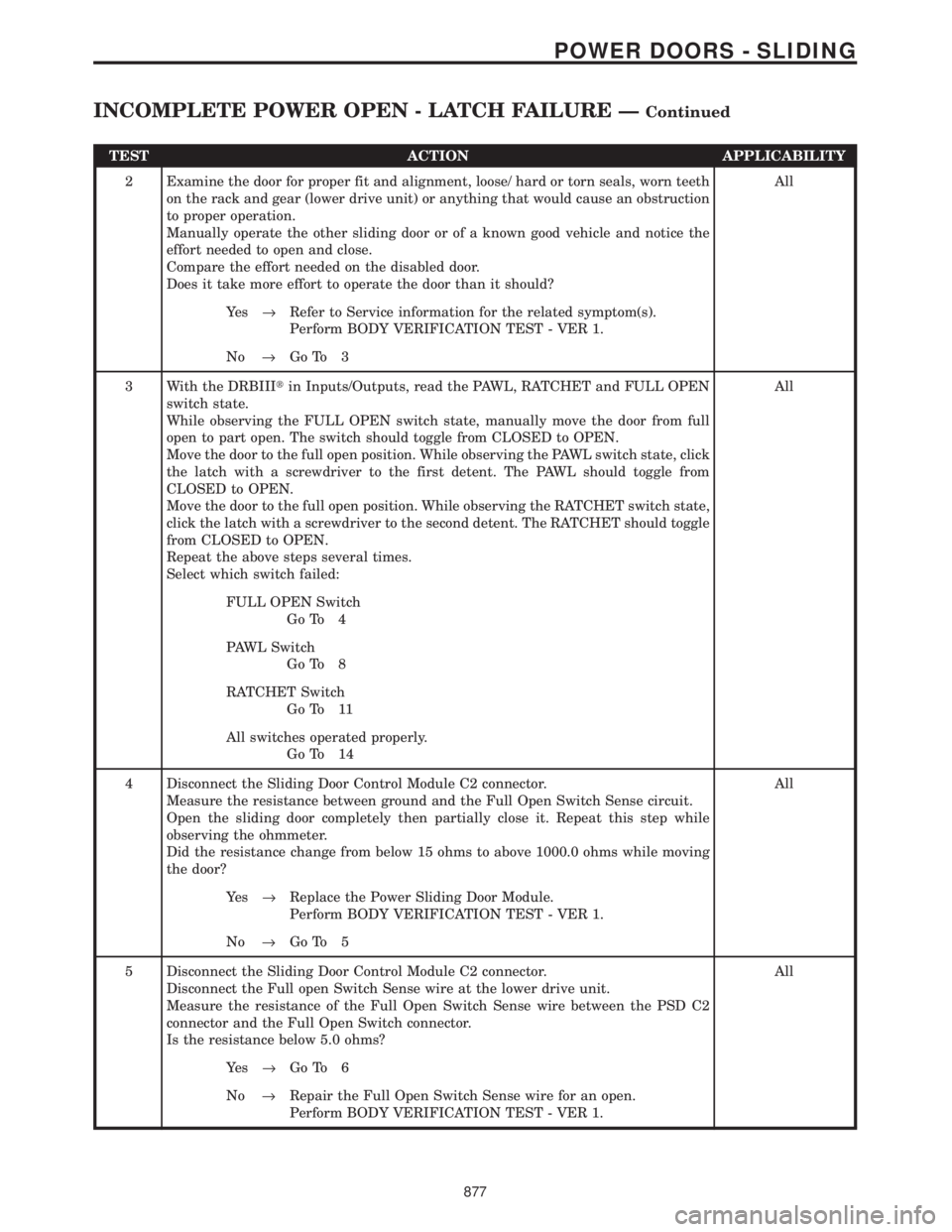

TEST ACTION APPLICABILITY

2 Examine the door for proper fit and alignment, loose/ hard or torn seals, worn teeth

on the rack and gear (lower drive unit) or anything that would cause an obstruction

to proper operation.

Manually operate the other sliding door or of a known good vehicle and notice the

effort needed to open and close.

Compare the effort needed on the disabled door.

Does it take more effort to operate the door than it should?All

Ye s®Refer to Service information for the related symptom(s).

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 With the DRBIIItin Inputs/Outputs, read the PAWL, RATCHET and FULL OPEN

switch state.

While observing the FULL OPEN switch state, manually move the door from full

open to part open. The switch should toggle from CLOSED to OPEN.

Move the door to the full open position. While observing the PAWL switch state, click

the latch with a screwdriver to the first detent. The PAWL should toggle from

CLOSED to OPEN.

Move the door to the full open position. While observing the RATCHET switch state,

click the latch with a screwdriver to the second detent. The RATCHET should toggle

from CLOSED to OPEN.

Repeat the above steps several times.

Select which switch failed:All

FULL OPEN Switch

Go To 4

PAWL Switch

Go To 8

RATCHET Switch

Go To 11

All switches operated properly.

Go To 14

4 Disconnect the Sliding Door Control Module C2 connector.

Measure the resistance between ground and the Full Open Switch Sense circuit.

Open the sliding door completely then partially close it. Repeat this step while

observing the ohmmeter.

Did the resistance change from below 15 ohms to above 1000.0 ohms while moving

the door?All

Ye s®Replace the Power Sliding Door Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Disconnect the Sliding Door Control Module C2 connector.

Disconnect the Full open Switch Sense wire at the lower drive unit.

Measure the resistance of the Full Open Switch Sense wire between the PSD C2

connector and the Full Open Switch connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Full Open Switch Sense wire for an open.

Perform BODY VERIFICATION TEST - VER 1.

877

POWER DOORS - SLIDING

INCOMPLETE POWER OPEN - LATCH FAILURE ÐContinued

Page 993 of 4284

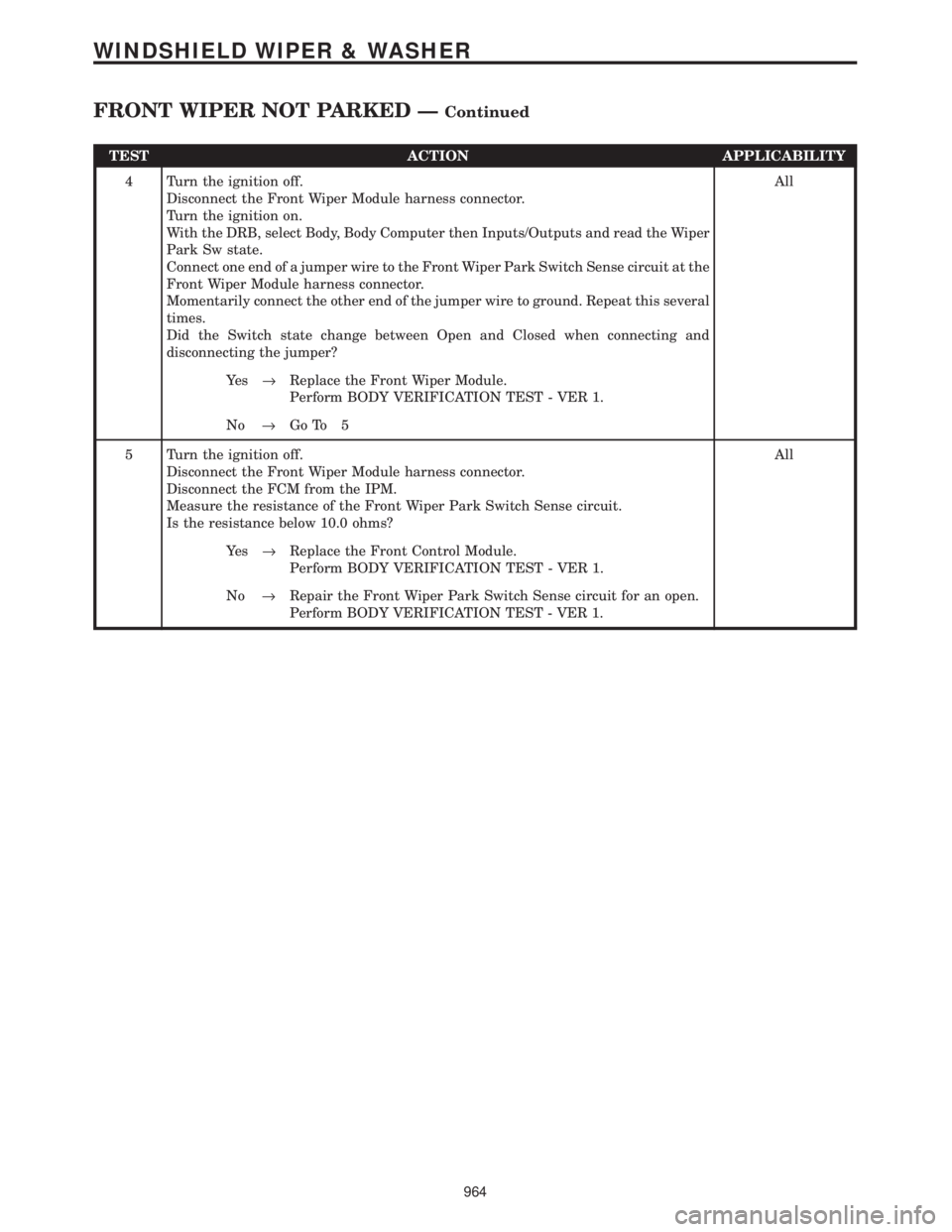

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Front Wiper Module harness connector.

Turn the ignition on.

With the DRB, select Body, Body Computer then Inputs/Outputs and read the Wiper

Park Sw state.

Connect one end of a jumper wire to the Front Wiper Park Switch Sense circuit at the

Front Wiper Module harness connector.

Momentarily connect the other end of the jumper wire to ground. Repeat this several

times.

Did the Switch state change between Open and Closed when connecting and

disconnecting the jumper?All

Ye s®Replace the Front Wiper Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

Disconnect the Front Wiper Module harness connector.

Disconnect the FCM from the IPM.

Measure the resistance of the Front Wiper Park Switch Sense circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Repair the Front Wiper Park Switch Sense circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

964

WINDSHIELD WIPER & WASHER

FRONT WIPER NOT PARKED ÐContinued

Page 1158 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions, and graphics

needed to diagnose Mark 20 Antilock Braking Sys-

tem (ABS) and Mark 20 Antilock Braking System

with Traction Control. The diagnostics in this man-

ual are based on the failure condition or symptom

being present at time of diagnosis.

Please follow the recommendations below when

choosing your diagnostic path.

1. First make sure the DRBIIItis communicating

with the CAB. If the DRBIIItdisplays a ªNo

Responseº condition, you must diagnose that

first.

2. Read DTC's (diagnostic trouble codes) with the

DRBIIIt.

3. If no DTC's are present, identify the customer

complaint.

4. Once the DTC or customer complaint is identi-

fied, locate the matching test in the Table of

Contents and begin to diagnose the symptom.

All component location views are in Section 8.0.

All connector pinouts are in Section 9.0. All sche-

matics are in Section 10.0.

An * placed before the symptom description indi-

cates a concern with no associated DTC.

When repairs are required, refer to the appropri-

ate service manual for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added; carry over sys-

tems may be enhanced. READ THIS MANUAL

BEFORE TRYING TO DIAGNOSE A VEHICLE

CODE. It is recommended that you review the

entire manual to become familiar with all new and

changed diagnostic procedures.

After using this book, if you have any comments

or recommendations, please fill out the form at the

back of the book and mail it back to us.

1.1 SYSTEM COVERAGE

This diagnostic procedure manual covers the an-

tilock braking system (ABS) and traction control

system found on: 2001 Chrysler Town and Country,

Dodge Caravan and Grand Caravan.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the controller antilock brake module

is done in six basic steps:

²verification of complaint

²verification of any related symptoms

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

2.0 IDENTIFICATION OF

SYSTEM

Vehicles equipped with the Teves Mark 20 an-

tilock brake system can be identified by the pres-

ence of the controller antilock brake module located

beneath the master cylinder.

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

3.1 TEVES MARK 20 SYSTEM

DESCRIPTION

The controller antilock brake module is used to

monitor wheel speeds and to modulate (control)

hydraulic pressure in each brake channel. The

modulated hydraulic pressure is used to prevent

wheel lock-up during braking.

The Teves Mark 20 system uses a diagonal split

hydraulic brake system.

In the standard brake mode

the master cylinder primary circuit supplies pressure

to the right front and left rear wheel brakes, and the

secondary master cylinder circuit supplies pressure

to the left front and right rear wheel brakes.

3.2 TRACTION CONTROL SYSTEM (TCS)

DESCRIPTION

The main purpose of traction control is to reduce

wheel slip and maintain traction at the driven

wheels when road surfaces are slippery. The trac-

tion control system reduces wheel slip by braking

the wheel that is losing traction. The system is

designed to operate at speeds below 56 km/h (35

mph).

The Controller Antilock Brake (CAB) monitors

wheel speeds. If, during acceleration, the module

detects front (drive) wheel slip and the brakes are

not applied, the CAB will enter traction control

mode. Traction control works in the following order

when drive wheel slip is detected.

1. Close the (normally open) isolation valves.

2. Start pump/motor and supply volume/pressure

to front hydraulic circuits (pump runs continu-

ously during traction control).

3. Open and close build and decay valves to main-

tain minimum wheel slip and maximum trac-

tion.

1

GENERAL INFORMATION

Page 1162 of 4284

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

important to block the wheels on front-wheel drive

vehicles; the parking brake does not hold the drive

wheels.

When servicing a vehicle, always wear eye pro-

tection, and remove any metal jewelry such as

rings, watchbands or bracelets that might make an

inadvertent electrical contact.

When diagnosing a chassis problem, it is impor-

tant to follow approved procedures where applica-

ble. These procedures can be found in the service

manual. Following these procedures is very impor-

tant to the safety of individuals performing diag-

nostic tests.

4.2.2 VEHICLE PREPARATION FOR

TESTING

Make sure the vehicle being tested has a fully

charged battery. If is does not, false diagnostic codes

or error messages may occur.

4.2.3 SERVICING SUB-ASSEMBLIES

Some components of the chassis system are in-

tended to be serviced as an assembly only. Attempt-

ing to remove or repair certain system sub-

components may result in personal injury and/or

improper system operation. Only those components

with approved repair and installation procedures in

the service manual should be serviced.

4.2.4 DRBIIITSAFETY INFORMATION

WARNING: EXCEEDING THE LIMITS OF THE

DRB MULTIMETER IS DANGEROUS. IT CAN

EXPOSE YOU TO SERIOUS OR POSSIBLY

FATAL INJURY. CAREFULLY READ AND

UNDERSTAND THE CAUTIONS AND THE

SPECIFICATION LIMITS.

²Follow the vehicle manufacturer 's service speci-

fications at all times.

²Do not use the DRBIIItif it has been damaged.

²Do not use the test leads if the insulation is

damaged or if metal is exposed.

²To avoid electrical shock, do not touch the test

leads, tips, or the circuit being tested.

²Choose the proper range and functions for the

measurement. Do not try voltage or current mea-

surements that may exceed the rated capacity.

²Do not exceed the limits shown in the table below:

FUNCTION INPUT LIMIT

Volts 0 - 500 peak volts AC

0 - 500 volts DC

Ohms (resistance)* 0 -1.12 megohms

Frequency Measured

Frequency Generated0-10kHz

Temperature -58 - 1100ÉF

-50 - 600ÉC

* Ohms cannot be measured if voltage is present.

Ohms can be measured only in a non-powered

circuit.

²Voltage between any terminal and ground must

not exceed 500v DC or 500v peak AC.

²Use caution when measuring voltage above 25v

DC or 25v AC.

²Use the low current shunt to measure circuits up

to 10A. Use the high current clamp to measure

circuits exceeding 10A.

²When testing for the presence of voltage or cur-

rent, make sure the meter is functioning cor-

rectly. Take a reading of a known voltage or

current before accepting a zero reading.

²When measuring current, connect the meter in

series with the load.

²Disconnect the live test lead before disconnecting

the common test lead.

²When using the meter function, keep the

DRBIIItaway from spark plug or coil wires to

avoid measuring error from outside interference.

5

GENERAL INFORMATION

Page 1174 of 4284

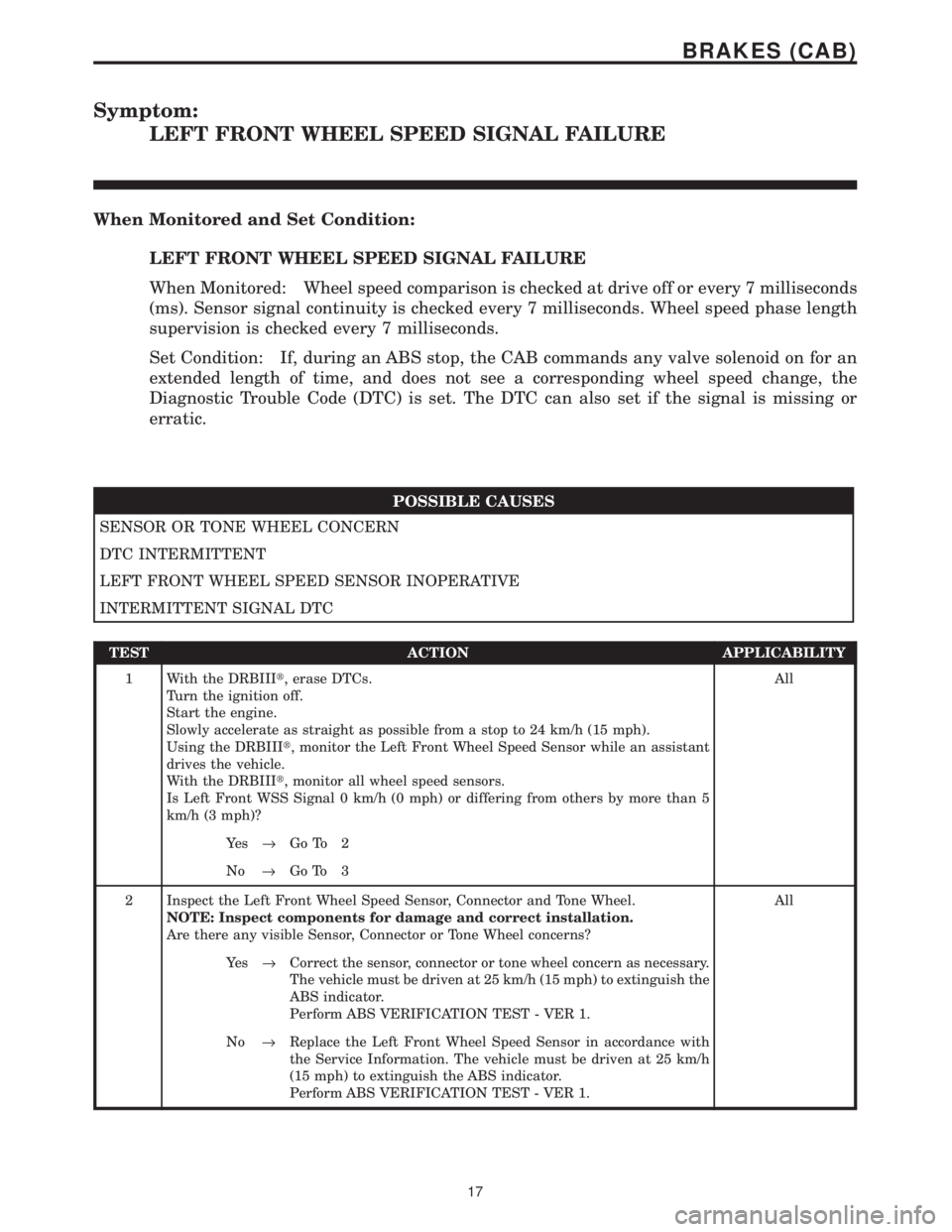

Symptom:

LEFT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

LEFT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Sensor signal continuity is checked every 7 milliseconds. Wheel speed phase length

supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

LEFT FRONT WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Left Front Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Left Front WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Left Front Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Front Wheel Speed Sensor in accordance with

the Service Information. The vehicle must be driven at 25 km/h

(15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

17

BRAKES (CAB)

Page 1176 of 4284

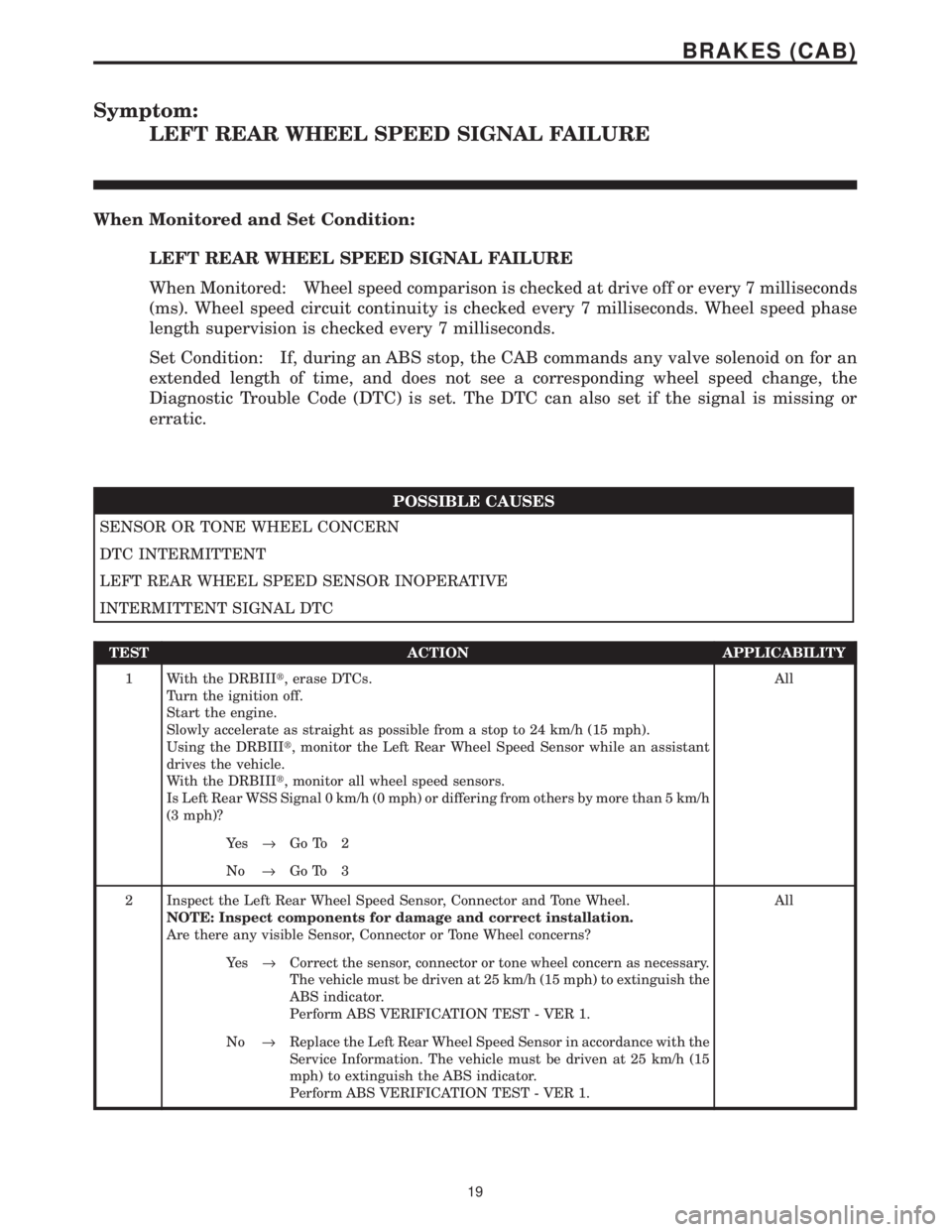

Symptom:

LEFT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

LEFT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed circuit continuity is checked every 7 milliseconds. Wheel speed phase

length supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

LEFT REAR WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Left Rear Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Left Rear WSS Signal 0 km/h (0 mph) or differing from others by more than 5 km/h

(3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Left Rear Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Rear Wheel Speed Sensor in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

19

BRAKES (CAB)

Page 1181 of 4284

Symptom:

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed continuity is checked every 7 milliseconds. Wheel speed phase length

supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

RIGHT FRONT WHEEL SPEED SENSOR INOPERATIVE

CAB - WON'T RESPOND TO RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Right Front Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Right Front WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Right Front Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Right Front Wheel Speed Sensor in accordance with

the Service Information. The vehicle must be driven at 25 km/h

(15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

24

BRAKES (CAB)

Page 1183 of 4284

Symptom:

RIGHT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

RIGHT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed circuit continuity is checked every 7 milliseconds. Wheel speed phase

length supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

RIGHT REAR WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Right Rear Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Right Rear WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Right Rear Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Rear Wheel Speed Sensor in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

26

BRAKES (CAB)

Page 1220 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions and graphics

needed to diagnose engine control module (ECM)

and sentry key immobilizer system (SKIS) prob-

lems; they are no start, diagnostic trouble code

(DTC), and no trouble code problems for the ECM.

The diagnostics in this manual are based on the

trouble condition or symptom being present at the

time of diagnosis.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added; carryover sys-

tems may be enhanced. IT IS RECOMMENDED

THAT YOU REVIEW THE ENTIRE MANUAL TO

BECOME FAMILIAR WITH ALL NEW AND

CHANGED DIAGNOSTIC PROCEDURES.

This manual is designed to begin all diagnosis at

the DTC TEST, which is located at the beginning of

Section 7.0. This will cover all the necessary re-

quirements to begin a logical diagnostic path for

each problem. If there is a diagnostic trouble code

(DTC) detected, it will direct you to the trouble code

test. If there are no DTCs present, it will direct you

by symptom to a no trouble code test.

This book reflects many suggested changes from

readers of past issues. After using this book, if you

have any comments or recommendations, please fill

out the form at the back of the book and mail it back

to us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers all

2001 RG body vehicles equipped with the 2.5L VM

diesel engine.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the engine control module (ECM)

and sentry key immobilizer system (SKIS) is done

in six basic steps:

²verification of complaint

²verification of any related symptom

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

NOTE: All tests in this manual should be per-

formed with the engine at operating temperature,

unless specified within a particular test.

2.0 IDENTIFICATION OF

SYSTEM

The ECM is located in the left side of the engine

compartment between the left front headlamp and

the intelligent power module. The sentry key immo-

bilizer module (SKIM) is located below the steering

column behind the steering wheel.

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

3.1 GENERAL DESCRIPTION

The 2.5L VM diesel engine system is equipped

with the latest in technical advances. The on-board

diagnostics incorporated in the engine control mod-

ule and SKIM are intended to assist the field

technician in repairing vehicle problems by the

quickest means.

The engine system incorporates a common rail

fuel delivery design. This design utilizes electroni-

cally controlled solenoid valve type fuel injectors.

Each injector is controlled individually by the ECM.

Injector timing and fuel quantity are controlled by

the ECM based on inputs from the various sensors.

The precision control of the injectors by the ECM

helps to reduce the engine noise, odor and smoke.

3.2 FUNCTIONAL OPERATION

3.2.1 ECM ON-BOARD DIAGNOSTICS

The ECM has been programmed to monitor many

different circuits of the diesel fuel injection system.

This monitoring is called on-board diagnostics.

Certain criteria must be met for a trouble code to

be entered into the ECM memory. The criteria may

be a range of: engine rpm, engine temperature, time

or other input signals to the ECM. If all of the

criteria for monitoring a system or circuit are met,

and a problem is sensed, then a DTC will be stored

in the ECM memory.

It is possible that a DTC for a monitored circuit

may not be entered into the ECM memory, even

though a malfunction has occurred. This may hap-

pen when the monitoring criteria has not been met.

The ECM compares input signal voltages from

each input device with specifications (the estab-

lished high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored

in the ECM memory.

1

GENERAL INFORMATION

Page 1221 of 4284

3.2.2 ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For

example, the ECM must calculate a different fuel

quantity and fuel timing for engine idle condition

than it would for a wide open throttle condition.

There are several different modes of operation that

determine how the ECM responds to the various

input signals.

Ignition Switch On (Engine Off)

When the ignition switch is turned on, the ECM

activates the glow plug relay for a time period that

is determined by engine coolant temperature, atmo-

spheric temperature and battery voltage. The ECM

also activates the lift pump to prime the fuel sys-

tem.

Engine Start-up Mode

The ECM uses the engine temperature sensor

and the crankshaft position sensor (engine speed)

inputs to determine fuel injection quantity.

Normal Driving Modes

Engine idle, warm-up, acceleration, deceleration

and wide open throttle modes are controlled based

on all of the sensor inputs to the ECM. The ECM

uses these sensor inputs to adjust fuel quantity and

fuel injector timing.

Overheat Protection Mode

If engine temperature is above 106É C (223É F)

and vehicle speed is above 40 km/h (25 MPH) the

ECM will activate the high speed fan and will limit

fuel quantity for engine protection.

Limp-In Mode

If there is a fault detected with the accelerator

pedal position sensor, the ECM will set the engine

speed at 1100 RPM.

Overspeed Detection Mode

If the ECM detects engine RPM that exceeds

5000 RPM, the ECM will set a DTC in memory and

limit engine RPM to no more that 2500 RPM until

the DTC(s) is cleared.

After-Run Mode

The ECM transfers RAM information to ROM

and performs an Input/Output state check.

3.2.3 MONITORED CIRCUITS

The ECM is able to monitor and identify most

driveability related trouble conditions. Some cir-

cuits are directly monitored through ECM feedback

circuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those stateswith expected values. Other systems are monitored

indirectly when the ECM conducts a rationality test

to identify problems.

Although most subsystems of the engine control

module are either directly or indirectly monitored,

there may be occasions when diagnostic trouble

codes are not immediately identified. For a trouble

code to set, a specific set of conditions must occur

and unless these conditions occur, a DTC will not

set.

3.2.4 SKIS OVERIVEW

The sentry key immobilizer system (SKIS) is

designed to prevent unauthorized vehicle opera-

tion. The system consists of a sentry key immobi-

lizer module (SKIM), ignition key(s) equipped with

a transponder chip and the ECM. When the ignition

switch is turned on, the SKIM interrogates the

ignition key. If the ignition key is Valid or Invalid,

the SKIM sends a PCI Bus message to the ECM

indicating ignition key status. Upon receiving this

message the ECM will terminate engine operation

or allow the engine to continue to operate.

3.2.5 SKIS ON-BOARD DIAGNOSTICS

The sentry key immobilizer module (SKIM) has

been programmed to transmit and monitor many

different coded messages as well as PCI Bus mes-

sages. This monitoring is called On-Board Diagnos-

tics. Certain criteria must be met for a DTC to be

entered into SKIM memory. The criteria may be a

range of; input voltage, PCI Bus message or coded

messages to the SKIM. If all of the criteria for

monitoring a circuit or function are met and a fault

is detected, a DTC will be stored in the SKIM

memory.

3.2.6 SKIS OPERATION

When ignition power is supplied to the SKIM, the

SKIM performs an internal self-test. After the self-

test is complete, the SKIM energizes the antenna

(this activates the transponder chip) and sends a

challenge to the transponder chip. The transponder

chip responds to the challenge by generating an

encrypted response message using the following:

Secret Key - This is an electronically stored value

(identification number) that is unique to each SKIS.

The secret key is stored in the SKIM, ECM and all

ignition key transponders.

Challenge - This is a random number that is gen-

erated by the SKIM at each ignition key cycle.

The secret key and challenge are the two vari-

ables used in the algorithm that produces the

encrypted response message. The transponder uses

the crypto algorithm to receive, decode and respond

to the message sent by SKIM. After responding to

the coded message, the transponder sends a tran-

2

GENERAL INFORMATION