drain bolt CHRYSLER VOYAGER 2001 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3107 of 4284

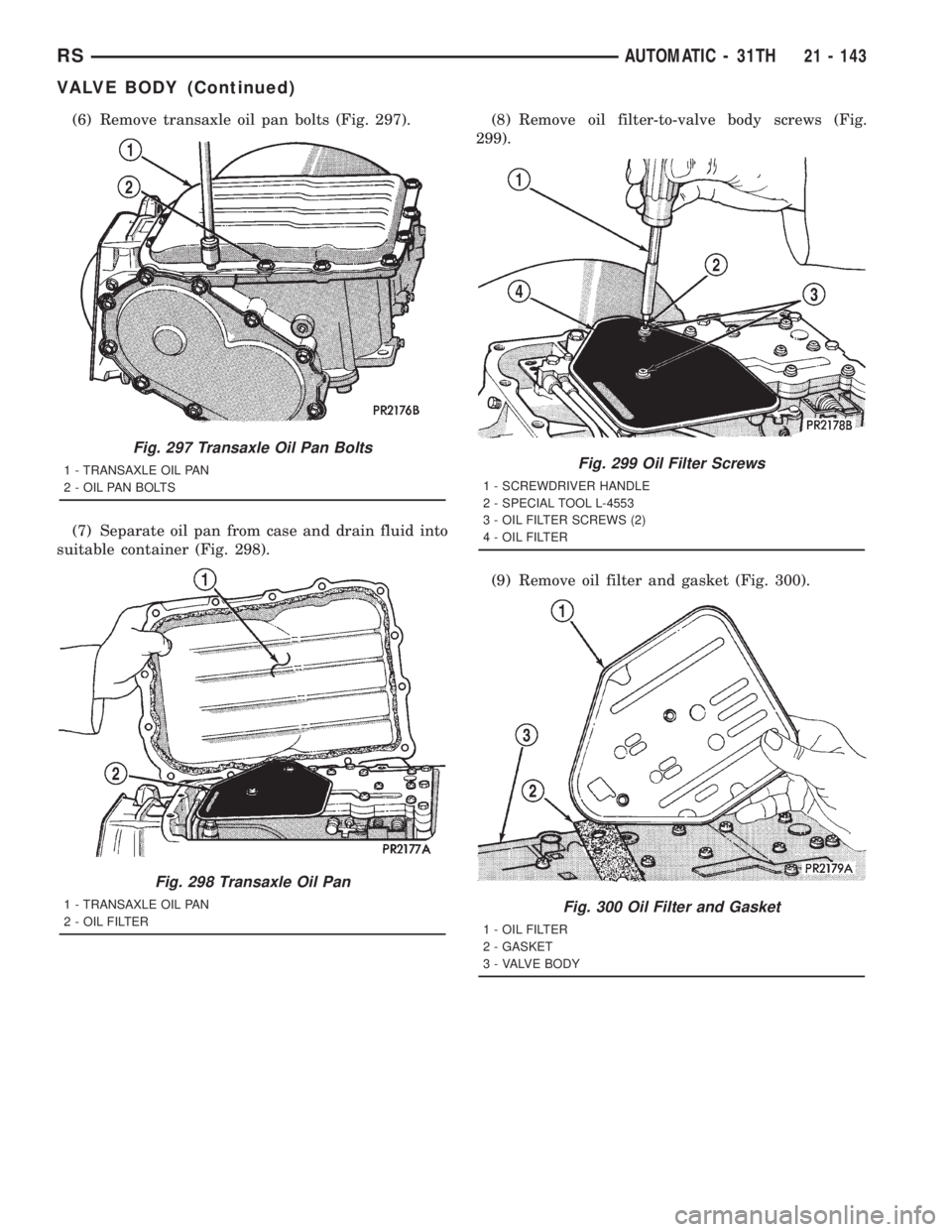

(6) Remove transaxle oil pan bolts (Fig. 297).

(7) Separate oil pan from case and drain fluid into

suitable container (Fig. 298).(8) Remove oil filter-to-valve body screws (Fig.

299).

(9) Remove oil filter and gasket (Fig. 300).

Fig. 297 Transaxle Oil Pan Bolts

1 - TRANSAXLE OIL PAN

2 - OIL PAN BOLTS

Fig. 298 Transaxle Oil Pan

1 - TRANSAXLE OIL PAN

2 - OIL FILTER

Fig. 299 Oil Filter Screws

1 - SCREWDRIVER HANDLE

2 - SPECIAL TOOL L-4553

3 - OIL FILTER SCREWS (2)

4 - OIL FILTER

Fig. 300 Oil Filter and Gasket

1 - OIL FILTER

2 - GASKET

3 - VALVE BODY

RSAUTOMATIC - 31TH21 - 143

VALVE BODY (Continued)

Page 3130 of 4284

(4) Remove fluid level indicator/tube assembly.

Plug opening to prevent debris from entering trans-

axle.

(5) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug lines

and fittings to prevent debris from entering transaxle

or cooler circuit. A service splice kit will be installed

upon reassembly.

(6) Disconnect input and output shaft speed sensor

connectors (Fig. 10).

(7) Disconnect transmission range sensor (TRS)

connector (Fig. 10).

(8) Disconnect solenoid/pressure switch assembly

connector (Fig. 10).

(9) Disconnect gear shift cable from manual valve

lever and upper mount bracket (Fig. 11).

(10) Disconnect crankshaft position sensor (if

equipped).

(11) Reposition leak detection pump harness and

hoses.

(12) Remove wiper module assembly to gain access

to and remove rear mount bracket bolts. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL)

(13) Remove rear mount bracket-to-transaxle case

bolts (Fig. 12).

(14) Remove transaxle upper bellhousing-to-block

bolts.

(15) Raise vehicle on hoist.

(16) Remove transaxle oil pan and drain fluid into

suitable container.

(17) Remove front wheel/tire assemblies.

Fig. 9 Coolant Recovery Bottle

1 - UPPER BOLT ATTACHING TO BATTERY TRAY

2 - COOLANT RECOVERY/RESERVE CONTAINER

3 - UPPER BOLT

4 - HOSE

5 - LOWER BOLT (QTY. 2)

6 - LEFT SIDE FRAME RAIL

Fig. 10 Component Connector LocationÐTypical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 11 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

21 - 166 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

Page 3211 of 4284

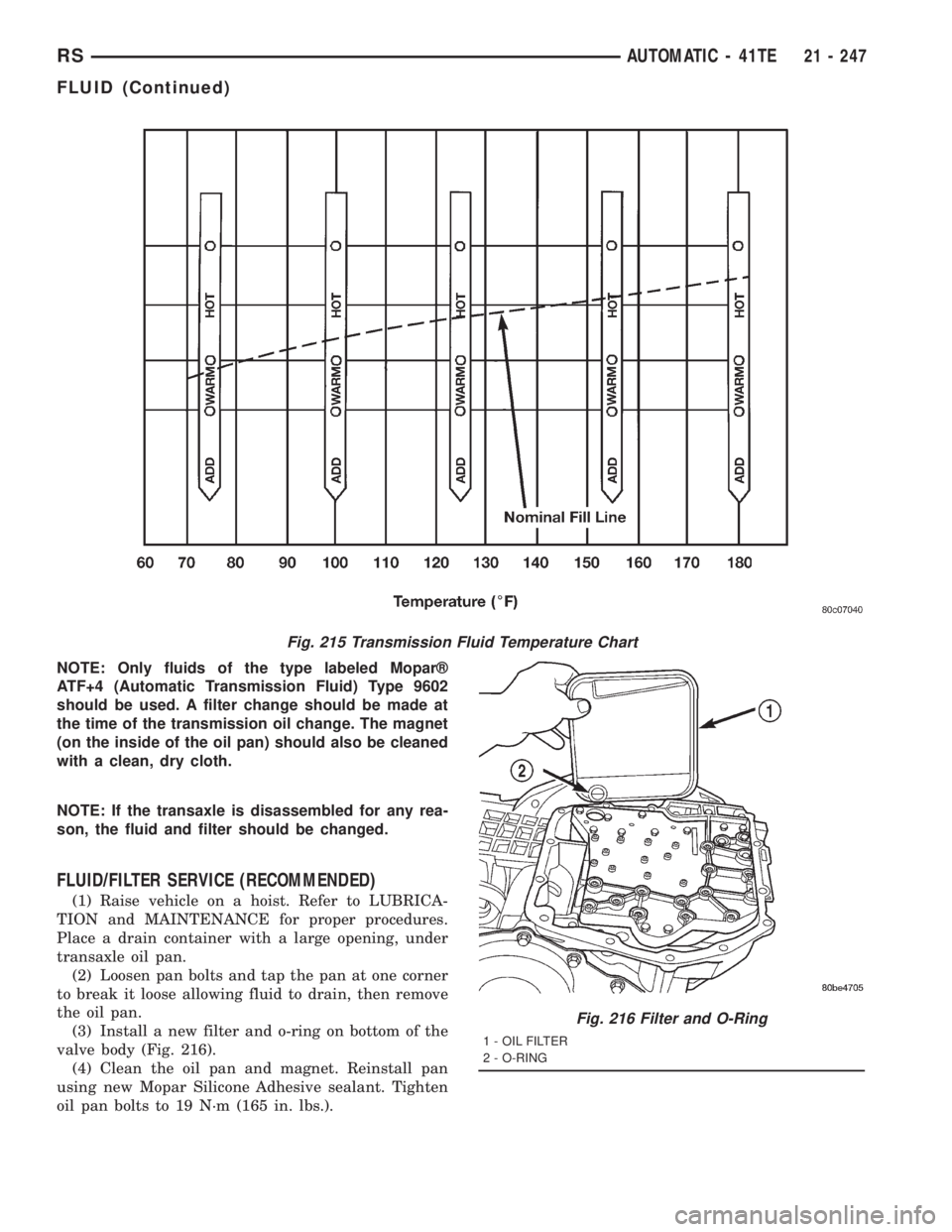

NOTE: Only fluids of the type labeled Moparž

ATF+4 (Automatic Transmission Fluid) Type 9602

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Install a new filter and o-ring on bottom of the

valve body (Fig. 216).

(4) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.).

Fig. 215 Transmission Fluid Temperature Chart

Fig. 216 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

RSAUTOMATIC - 41TE21 - 247

FLUID (Continued)

Page 3277 of 4284

DIAGNOSIS AND TESTING - COMMON

PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

²Improper operation

HARD SHIFTING

Hard shifting may be caused by a misadjusted

crossover cable. If hard shifting is accompanied by

gear clash, synchronizer clutch and stop rings or gear

teeth may be worn or damaged.

Hard shifting may also be caused by a binding or

broken shift cover mechanism. Remove shift cover

and verify smooth operation. Replace as necessary.

Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, keys, balls, or springs can cause shift prob-

lems.

NOISY OPERATION

Transaxle noise is most often a result of worn or

damaged components. Chipped, broken gear or syn-

chronizer teeth, and brinnelled, spalled bearings all

cause noise.

Abnormal wear and damage to the internal compo-

nents is frequently the end result of insufficient

lubricant.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, or worn teeth

on the drive gears or synchronizer components. Incor-

rect assembly also causes gear disengagement. Check

for missing snap rings.

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

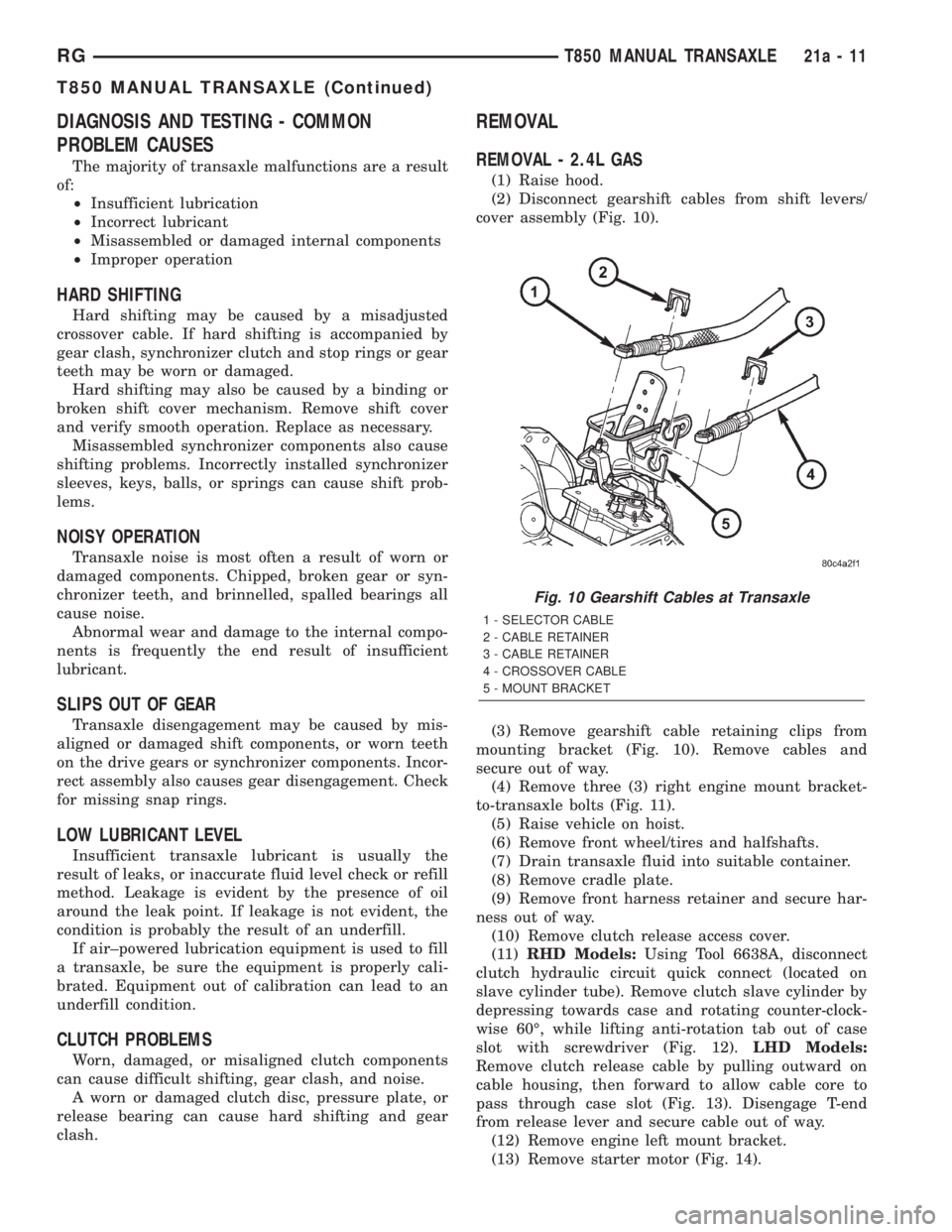

REMOVAL

REMOVAL - 2.4L GAS

(1) Raise hood.

(2) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 10).

(3) Remove gearshift cable retaining clips from

mounting bracket (Fig. 10). Remove cables and

secure out of way.

(4) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 11).

(5) Raise vehicle on hoist.

(6) Remove front wheel/tires and halfshafts.

(7) Drain transaxle fluid into suitable container.

(8) Remove cradle plate.

(9) Remove front harness retainer and secure har-

ness out of way.

(10) Remove clutch release access cover.

(11)RHD Models:Using Tool 6638A, disconnect

clutch hydraulic circuit quick connect (located on

slave cylinder tube). Remove clutch slave cylinder by

depressing towards case and rotating counter-clock-

wise 60É, while lifting anti-rotation tab out of case

slot with screwdriver (Fig. 12).LHD Models:

Remove clutch release cable by pulling outward on

cable housing, then forward to allow cable core to

pass through case slot (Fig. 13). Disengage T-end

from release lever and secure cable out of way.

(12) Remove engine left mount bracket.

(13) Remove starter motor (Fig. 14).

Fig. 10 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

RGT850 MANUAL TRANSAXLE21a-11

T850 MANUAL TRANSAXLE (Continued)

Page 3281 of 4284

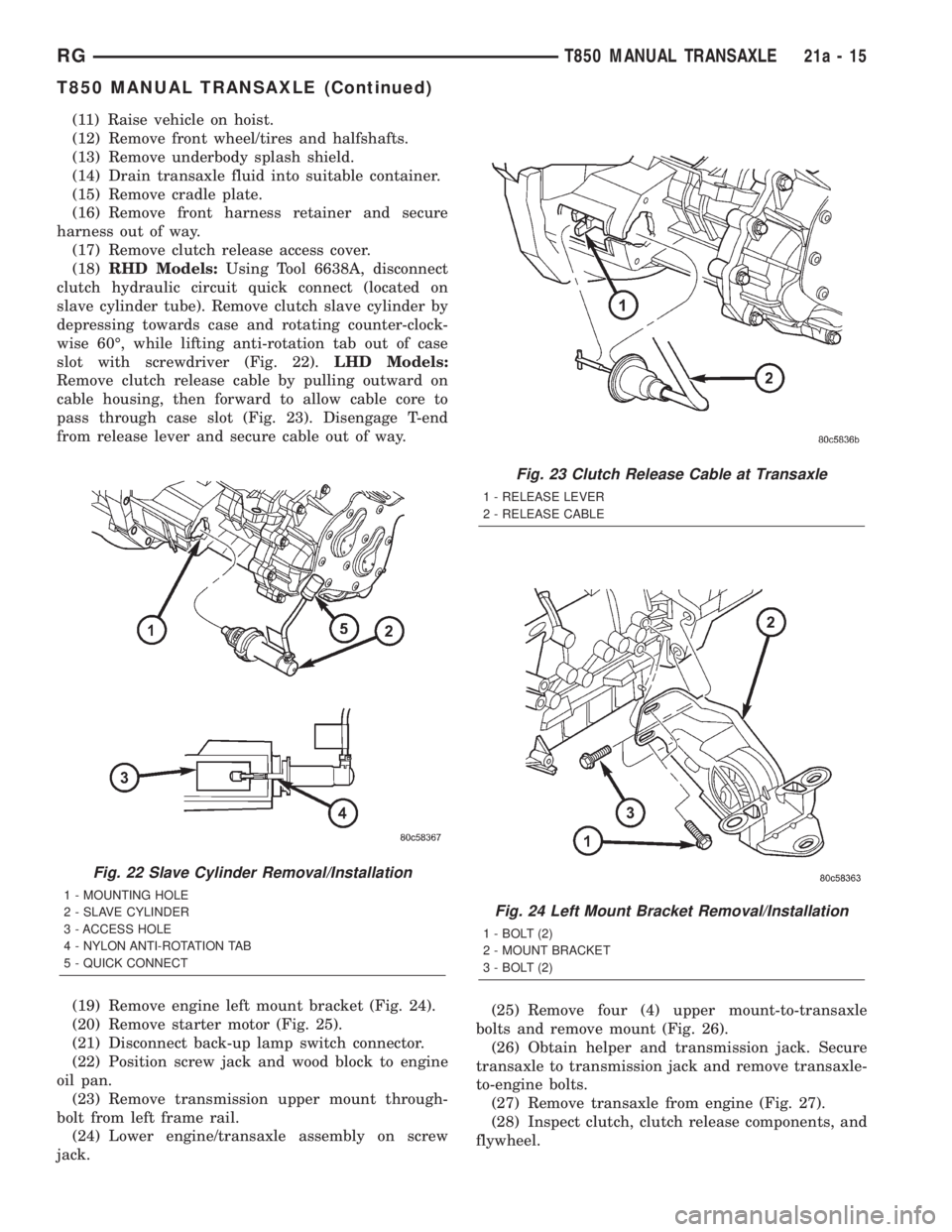

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove cradle plate.

(16) Remove front harness retainer and secure

harness out of way.

(17) Remove clutch release access cover.

(18)RHD Models:Using Tool 6638A, disconnect

clutch hydraulic circuit quick connect (located on

slave cylinder tube). Remove clutch slave cylinder by

depressing towards case and rotating counter-clock-

wise 60É, while lifting anti-rotation tab out of case

slot with screwdriver (Fig. 22).LHD Models:

Remove clutch release cable by pulling outward on

cable housing, then forward to allow cable core to

pass through case slot (Fig. 23). Disengage T-end

from release lever and secure cable out of way.

(19) Remove engine left mount bracket (Fig. 24).

(20) Remove starter motor (Fig. 25).

(21) Disconnect back-up lamp switch connector.

(22) Position screw jack and wood block to engine

oil pan.

(23) Remove transmission upper mount through-

bolt from left frame rail.

(24) Lower engine/transaxle assembly on screw

jack.(25) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 26).

(26) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(27) Remove transaxle from engine (Fig. 27).

(28) Inspect clutch, clutch release components, and

flywheel.

Fig. 22 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 23 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

Fig. 24 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

RGT850 MANUAL TRANSAXLE21a-15

T850 MANUAL TRANSAXLE (Continued)

Page 3304 of 4284

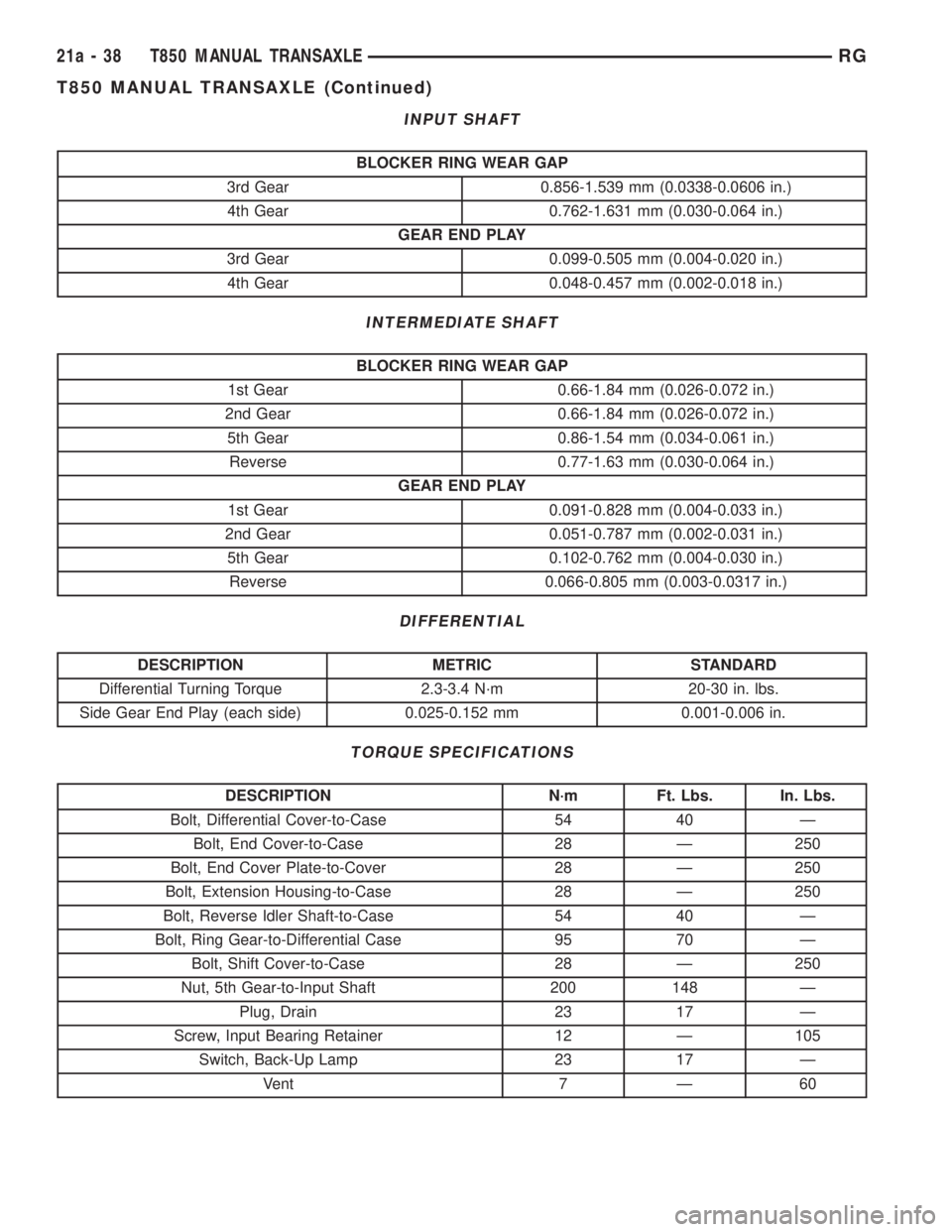

INPUT SHAFT

BLOCKER RING WEAR GAP

3rd Gear 0.856-1.539 mm (0.0338-0.0606 in.)

4th Gear 0.762-1.631 mm (0.030-0.064 in.)

GEAR END PLAY

3rd Gear 0.099-0.505 mm (0.004-0.020 in.)

4th Gear 0.048-0.457 mm (0.002-0.018 in.)

INTERMEDIATE SHAFT

BLOCKER RING WEAR GAP

1st Gear 0.66-1.84 mm (0.026-0.072 in.)

2nd Gear 0.66-1.84 mm (0.026-0.072 in.)

5th Gear 0.86-1.54 mm (0.034-0.061 in.)

Reverse 0.77-1.63 mm (0.030-0.064 in.)

GEAR END PLAY

1st Gear 0.091-0.828 mm (0.004-0.033 in.)

2nd Gear 0.051-0.787 mm (0.002-0.031 in.)

5th Gear 0.102-0.762 mm (0.004-0.030 in.)

Reverse 0.066-0.805 mm (0.003-0.0317 in.)

DIFFERENTIAL

DESCRIPTION METRIC STANDARD

Differential Turning Torque 2.3-3.4 N´m 20-30 in. lbs.

Side Gear End Play (each side) 0.025-0.152 mm 0.001-0.006 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential Cover-to-Case 54 40 Ð

Bolt, End Cover-to-Case 28 Ð 250

Bolt, End Cover Plate-to-Cover 28 Ð 250

Bolt, Extension Housing-to-Case 28 Ð 250

Bolt, Reverse Idler Shaft-to-Case 54 40 Ð

Bolt, Ring Gear-to-Differential Case 95 70 Ð

Bolt, Shift Cover-to-Case 28 Ð 250

Nut, 5th Gear-to-Input Shaft 200 148 Ð

Plug, Drain 23 17 Ð

Screw, Input Bearing Retainer 12 Ð 105

Switch, Back-Up Lamp 23 17 Ð

Vent 7 Ð 60

21a - 38 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3736 of 4284

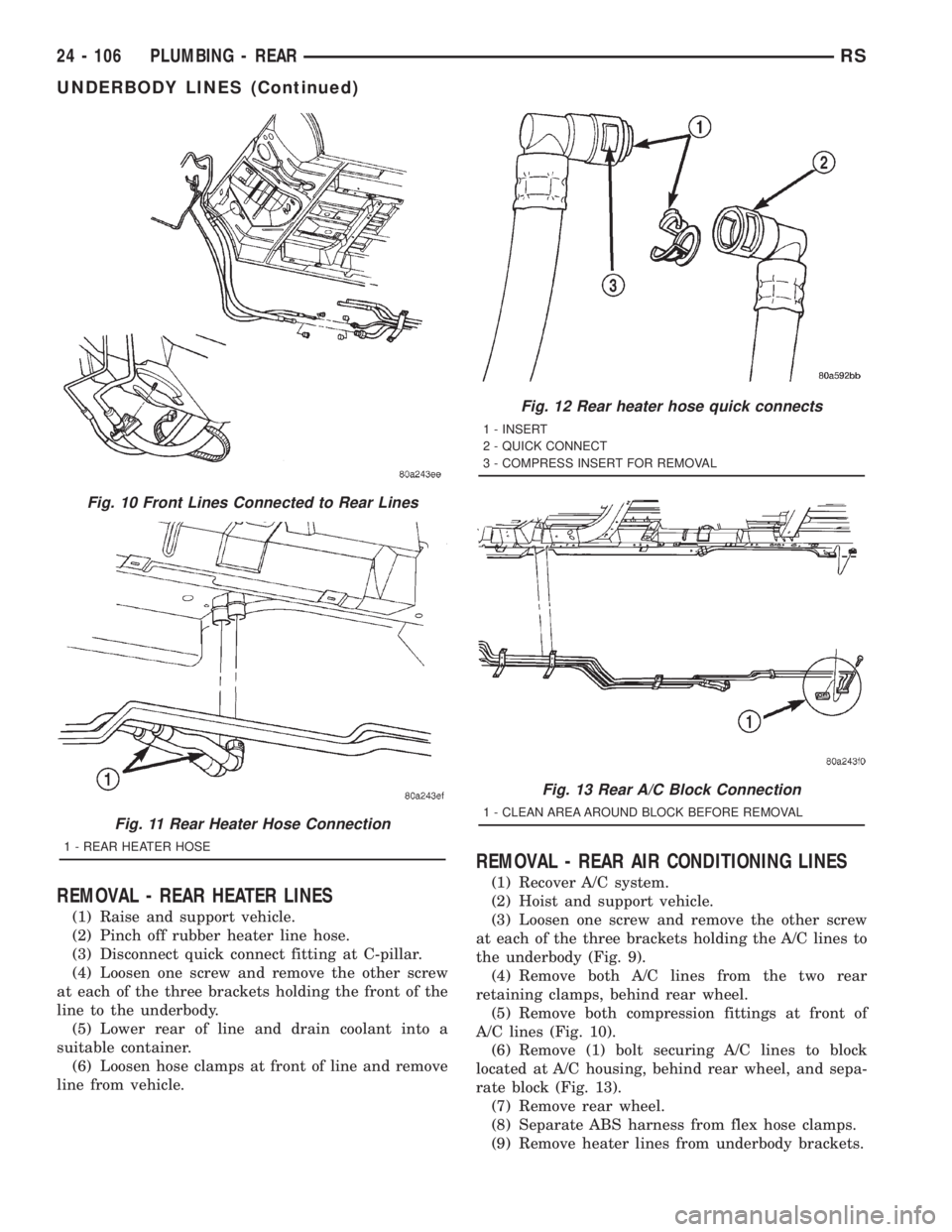

REMOVAL - REAR HEATER LINES

(1) Raise and support vehicle.

(2) Pinch off rubber heater line hose.

(3) Disconnect quick connect fitting at C-pillar.

(4) Loosen one screw and remove the other screw

at each of the three brackets holding the front of the

line to the underbody.

(5) Lower rear of line and drain coolant into a

suitable container.

(6) Loosen hose clamps at front of line and remove

line from vehicle.

REMOVAL - REAR AIR CONDITIONING LINES

(1) Recover A/C system.

(2) Hoist and support vehicle.

(3) Loosen one screw and remove the other screw

at each of the three brackets holding the A/C lines to

the underbody (Fig. 9).

(4) Remove both A/C lines from the two rear

retaining clamps, behind rear wheel.

(5) Remove both compression fittings at front of

A/C lines (Fig. 10).

(6) Remove (1) bolt securing A/C lines to block

located at A/C housing, behind rear wheel, and sepa-

rate block (Fig. 13).

(7) Remove rear wheel.

(8) Separate ABS harness from flex hose clamps.

(9) Remove heater lines from underbody brackets.

Fig. 10 Front Lines Connected to Rear Lines

Fig. 11 Rear Heater Hose Connection

1 - REAR HEATER HOSE

Fig. 12 Rear heater hose quick connects

1 - INSERT

2 - QUICK CONNECT

3 - COMPRESS INSERT FOR REMOVAL

Fig. 13 Rear A/C Block Connection

1 - CLEAN AREA AROUND BLOCK BEFORE REMOVAL

24 - 106 PLUMBING - REARRS

UNDERBODY LINES (Continued)

Page 3748 of 4284

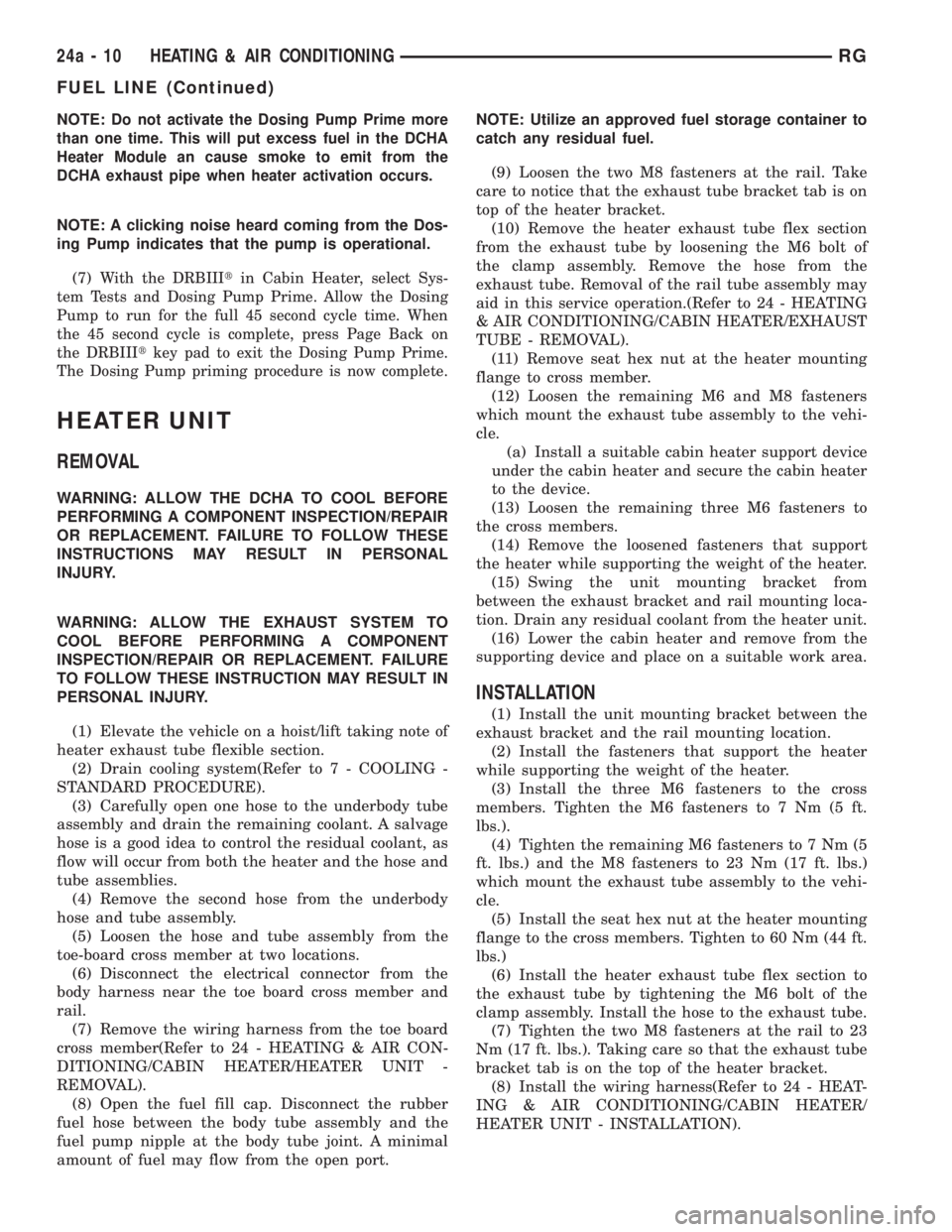

NOTE:Do not activate the Dosing Pump Prime more

than one time. This will put excess fuel in the DCHA

Heater Module an cause smoke to emit from the

DCHA exhaust pipe when heater activation occurs.

NOTE: A clicking noise heard coming from the Dos-

ing Pump indicates that the pump is operational.

(7)

With the DRBIIItin Cabin Heater, select Sys-

tem Tests and Dosing Pump Prime. Allow the Dosing

Pump to run for the full 45 second cycle time. When

the 45 second cycle is complete, press Page Back on

the DRBIIItkey pad to exit the Dosing Pump Prime.

The Dosing Pump priming procedure is now complete.

HEATER UNIT

REMOVAL

WARNING: ALLOW THE DCHA TO COOL BEFORE

PERFORMING A COMPONENT INSPECTION/REPAIR

OR REPLACEMENT. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN PERSONAL

INJURY.

WARNING: ALLOW THE EXHAUST SYSTEM TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR OR REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTION MAY RESULT IN

PERSONAL INJURY.

(1) Elevate the vehicle on a hoist/lift taking note of

heater exhaust tube flexible section.

(2) Drain cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Carefully open one hose to the underbody tube

assembly and drain the remaining coolant. A salvage

hose is a good idea to control the residual coolant, as

flow will occur from both the heater and the hose and

tube assemblies.

(4) Remove the second hose from the underbody

hose and tube assembly.

(5) Loosen the hose and tube assembly from the

toe-board cross member at two locations.

(6) Disconnect the electrical connector from the

body harness near the toe board cross member and

rail.

(7) Remove the wiring harness from the toe board

cross member(Refer to 24 - HEATING & AIR CON-

DITIONING/CABIN HEATER/HEATER UNIT -

REMOVAL).

(8) Open the fuel fill cap. Disconnect the rubber

fuel hose between the body tube assembly and the

fuel pump nipple at the body tube joint. A minimal

amount of fuel may flow from the open port.NOTE: Utilize an approved fuel storage container to

catch any residual fuel.

(9) Loosen the two M8 fasteners at the rail. Take

care to notice that the exhaust tube bracket tab is on

top of the heater bracket.

(10) Remove the heater exhaust tube flex section

from the exhaust tube by loosening the M6 bolt of

the clamp assembly. Remove the hose from the

exhaust tube. Removal of the rail tube assembly may

aid in this service operation.(Refer to 24 - HEATING

& AIR CONDITIONING/CABIN HEATER/EXHAUST

TUBE - REMOVAL).

(11) Remove seat hex nut at the heater mounting

flange to cross member.

(12) Loosen the remaining M6 and M8 fasteners

which mount the exhaust tube assembly to the vehi-

cle.

(a) Install a suitable cabin heater support device

under the cabin heater and secure the cabin heater

to the device.

(13) Loosen the remaining three M6 fasteners to

the cross members.

(14) Remove the loosened fasteners that support

the heater while supporting the weight of the heater.

(15) Swing the unit mounting bracket from

between the exhaust bracket and rail mounting loca-

tion. Drain any residual coolant from the heater unit.

(16) Lower the cabin heater and remove from the

supporting device and place on a suitable work area.

INSTALLATION

(1) Install the unit mounting bracket between the

exhaust bracket and the rail mounting location.

(2) Install the fasteners that support the heater

while supporting the weight of the heater.

(3) Install the three M6 fasteners to the cross

members. Tighten the M6 fasteners to 7 Nm (5 ft.

lbs.).

(4) Tighten the remaining M6 fasteners to 7 Nm (5

ft. lbs.) and the M8 fasteners to 23 Nm (17 ft. lbs.)

which mount the exhaust tube assembly to the vehi-

cle.

(5) Install the seat hex nut at the heater mounting

flange to the cross members. Tighten to 60 Nm (44 ft.

lbs.)

(6) Install the heater exhaust tube flex section to

the exhaust tube by tightening the M6 bolt of the

clamp assembly. Install the hose to the exhaust tube.

(7) Tighten the two M8 fasteners at the rail to 23

Nm (17 ft. lbs.). Taking care so that the exhaust tube

bracket tab is on the top of the heater bracket.

(8) Install the wiring harness(Refer to 24 - HEAT-

ING & AIR CONDITIONING/CABIN HEATER/

HEATER UNIT - INSTALLATION).

24a - 10 HEATING & AIR CONDITIONINGRG

FUEL LINE (Continued)

Page 3780 of 4284

OPERATION

The engines use Exhaust Gas Recirculation (EGR)

systems. The EGR system reduces oxides of nitrogen

(NOx) in engine exhaust and helps prevent detona-

tion (engine knock). Under normal operating condi-tions, engine cylinder temperature can reach more

than 3000ÉF. Formation of NOx increases proportion-

ally with combustion temperature. To reduce the

emission of these oxides, the cylinder temperature

must be lowered. The system allows a predetermined

amount of hot exhaust gas to recirculate and dilute

the incoming air/fuel mixture. The diluted air/fuel

mixture reduces peak flame temperature during com-

bustion.

REMOVAL

(1) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Disconnect EGR valve vacuum line.

(4) Remove EGR cooler to EGR valve retaining

bolts (Fig. 1).

(5) Remove EGR valve retaining nuts (Fig. 1) and

EGR valve.

INSTALLATION

(1) Clean gasket mating surfaces.

(2) Install EGR valve (Fig. 1). Torque nuts to

32.4N´m.

(3) Connect EGR cooler to EGR valve (Fig. 1).

Torque bolts to 32.4N´m

(4) Install front wiper unit (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(5) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION) .

VALVE COOLER

DESCRIPTION

The EGR valve on this engine uses a cooler to cool

the exhaust gases before the returned to the intake

manifold (Fig. 2). The EGR cooler attaches to the

EGR valve and is cooled with engine coolant.

REMOVAL

(1) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(2) Partially drain cooling system (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(3) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL) .

(4) Disconnect coolant supply and return lines at

EGR cooler (Fig. 2).

(5) Remove EGR cooler to exhaust manifold retain-

ing bolt (Fig. 2).

Fig. 1 EGR COMPONENTS

1 - HOSE CLAMP

2 - COOLANT HOSE

3 - HOSE CLAMP

4 - EGR VALVE RETAINING NUT

5 - E G R VA LV E

6 - COOLANT HOSE

7 - EGR VALVE GASKET

8 - EGR VALVE RETAINING STUDS

9 - EGR COOLER RETAINING BOLT

10 - HOSE CLAMP

11 - HOSE CLAMP

12 - EGR COOLER

13 - EGR COOLER TO EGR VALVE RETAINING BOLT

14 - TURBOCHARGER BRACKET

15 - TURBOCHARGER BRACKET RETAINING BOLT

16 - TURBOCHARGER DOWNPIPE

17 - TURBOCHARGER DOWNPIPE RETAINING NUT

18 - DOWNPIPE GASKET

19 - DOWNPIPE STUD

25a - 4 EXHAUST GAS RECIRCULATIONRG

VALVE (Continued)

Page 4114 of 4284

responding element is applied. If a switch fails to

close, it is retested, If it fails the second test, the

code is set.

Transmission Effects:The MIL illuminates and

the transmission system defaults to Relay Open

limp-in mode.

Possible causes:

> Pressure switch sense circuit shorted to battery

between TCM and solenoid pack.

> Low line pressure

> Solenoid Pack

Name of code:P1791(35) - Loss Of Prime

When monitored:If the transmission is slipping

in any forward gear and the pressure switches are

not indicating pressure, a loss of prime test is run.

Set condition:If the transmission begins to slip in

any forward gear, and the pressure switch or

switches that should be closed for a given gear are

open, a loss of prime test begins. All available

elements (in 1st gear L-R, 2-4 and OD, in 2nd, 3rd,

and 4th gear 2-4 and OD) are turned on by the

Transmission Control Module (TCM) to see if pump

prime exists. The code is set if none of the pressure

switches respond. The TCM will continue to run the

loss of prime test until pump pressure returns.

Theory of operation:The loss of prime test is

used to prevent transmission defaults which can be

caused by a lack of pump prime.

Transmission Effects:Vehicle will not move or

transmission slips. Normal operation will continue

if pump prime returns.

Possible causes:

> Low transmission fluid level

> PRNDL indicates a valid OD code in the hydrau-

lic reverse position

> Transmission fluid filter clogged or damaged

> Transmission fluid filter improperly installed

(Bolts loose or O-ring missing)

> Oil pump - If a customer has a problem when the

transmission is cold whereby he shifts to reverse,

gets reverse, and then shifts to OD and does not

get OD (gets a neutral condition), and then can

not get reverse or OD for between 3-20 seconds,

replace the oil pump. High side clearance in the

oil pump will set a code 35. The pump will prime

upon start-up, but as the torque converter purges

air (drain down) the air will leak across the inner

rotor into the pump suction port and cause a loss

of prime right after the shift into OD. After 3- 20

seconds, pump prime will return and normal

operation will continue. The pump should be

replaced only after all other possible causes

above have been checked and verified.Name of code:P1790(36) - Fault Immediately

After Shift

When monitored:After a gear ratio error is

stored.

Set condition:This code is set if the associated

gear ratio code is stored within 1.3 seconds after a

shift.

Theory of operation:This code will only be stored

along with a 50 series code. If this code is set, it

indicates the problem is mechanical in nature.

When this code exists, diagnosing the transmission

should be based on the associated gear ratio code

and primarily mechanical causes should be consid-

ered.

Transmission Effects:None

Possible causes:

> Mechanical causes as listed under associated

gear ratio code.

Name of code:P1775(37) - Solenoid Switch Valve

Latched in TCC Position

When monitored:During an attempted shift into

1st gear.

Set condition:This code is set if three unsuccess-

ful attempts are made to get into 1st gear in one

given key start.

Theory of operation:The solenoid switch valve

(SSV) controls the direction of the transmission

fluid when the L-R/TCC solenoid is energized. The

SSV will be in the downshifted position in 1st gear,

thus directing the fluid to the L-R clutch circuit. In

2nd, 3rd, and 4th, it will be in the upshifted position

and directs the fluid into the torque converter

clutch (TCC).

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement

into the downshifted position. The L-R pressure

switch is monitored to confirm SSV movement. If

movement is not confirmed (the L-R pressure

switch does not close), 2nd gear is substituted for

1st.

Transmission Effects:Transmission will have no

1st gear (2nd gear will be substituted), and no

EMCC operation.

Possible causes:

> PRNDL indicates a valid OD code in the hydrau-

lic reverse position

> Valve body- - Solenoid valve stuck in TCC posi-

tion

> High idle speed

> Solenoid malfunction - L-R pressure switch will

not close

> L-R Pressure Switch Sense circuit shorted to

battery

10

GENERAL INFORMATION