CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1271 of 2399

OPERATION

The balance shafts are driven by the crankshaft

via a roller chain and sprockets. The balance shafts

are connected by helical gears. The dual counter

rotating shafts decrease second order vertical shak-

ing forces caused by component movement.

REMOVAL

BALANCE SHAFTS/CHAIN/SPROCKETS

NOTE: For service procedures requiring only tem-

porary relocation of carrier assembly refer to BAL-

ANCE SHAFT CARRIER procedure below.

(1) Drain engine oil.

(2) Remove the oil pan and pick-up tube (Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(3) If replacing crankshaft sprocket, remove oil

pump (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - REMOVAL).

(4) Remove chain cover, guide and tensioner (Fig.

128).(5) Remove screw retaining balance shaft drive

sprocket (Fig. 129). Remove chain and sprocket.

(6) Using two wide pry bars, work the crankshaft

sprocket back and forth until it is off the crankshaft-

shaft.

(7) Remove gear cover retaining stud (double

ended to also retain chain guide). Remove cover and

balance shaft gears (Fig. 130).

(8) Remove rear cover and balance shafts (Fig.

131).

(9) Remove four carrier to crankcase attaching

bolts to separate carrier from engine bedplate.

BALANCE SHAFT CARRIER

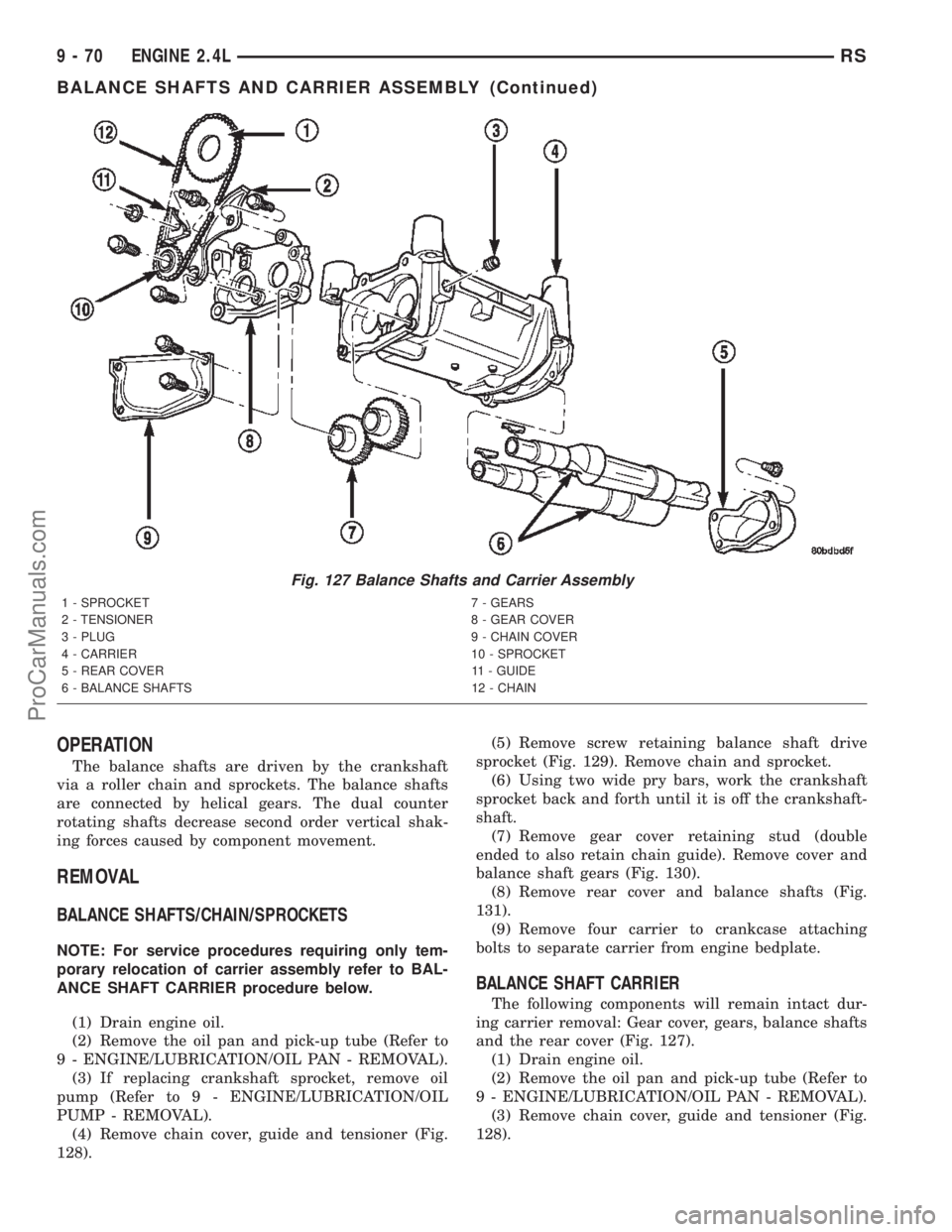

The following components will remain intact dur-

ing carrier removal: Gear cover, gears, balance shafts

and the rear cover (Fig. 127).

(1) Drain engine oil.

(2) Remove the oil pan and pick-up tube (Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(3) Remove chain cover, guide and tensioner (Fig.

128).

Fig. 127 Balance Shafts and Carrier Assembly

1 - SPROCKET 7 - GEARS

2 - TENSIONER 8 - GEAR COVER

3 - PLUG 9 - CHAIN COVER

4 - CARRIER 10 - SPROCKET

5 - REAR COVER 11 - GUIDE

6 - BALANCE SHAFTS 12 - CHAIN

9 - 70 ENGINE 2.4LRS

BALANCE SHAFTS AND CARRIER ASSEMBLY (Continued)

ProCarManuals.com

Page 1272 of 2399

(4) Remove screw retaining balance shaft drive

sprocket (Fig. 129).

(5) Move balance shaft inboard through drive

chain sprocket. Sprocket will hang in lower chain

loop.

(6) Remove carrier to crankcase attaching bolts to

remove carrier.

INSTALLATION

BALANCE SHAFT INSTALLATION/TIMING

Balance shaft and carrier assembly installation is

the reverse of the removal procedure.During instal-

lation crankshaft-to-balance shaft timing must

be established. Refer to Timing procedure in

this section.

(1) With balance shafts installed in carrier (Fig.

127) position carrier on crankcase and install four

attaching bolts and tighten to 54 N´m (40 ft. lbs.).

(2) Turn balance shafts until both shaft key ways

are up, parallel to vertical centerline of engine.

Install short hub drive gear on sprocket driven shaft

and long hub gear on gear driven shaft. After instal-

lation gear and balance shaft keyways must be upwith gear timing marks meshed as shown in (Fig.

132).

(3) Install gear cover and tighten double ended

stud/washer fastener to 12 N´m (105 in. lbs.).

Fig. 128 Chain Cover, Guide and Tensioner

1 - STUD

2 - TENSIONER (ADJUSTER)

3 - GEAR COVER

4 - ADJUST SCREW

5 - PIVOT SCREW

6 - CHAIN COVER (CUTAWAY)

7 - GUIDE

Fig. 129 Drive Chain and Sprockets

1 - NICKEL PLATED LINK AND MARK

2 - GEAR/SPROCKET SCREWS

3 - NICKEL PLATED LINK AND DOT

Fig. 130 Gear Cover and Gears

1 - STUD (DOUBLE ENDED)

2 - DRIVE GEAR

3 - DRIVEN GEAR

4 - CARRIER DOWEL

5 - GEAR(S)

6 - GEAR COVER

RSENGINE 2.4L9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY (Continued)

ProCarManuals.com

Page 1273 of 2399

(4) Align flat on balance shaft drive sprocket to the

flat on crankshaft (Fig. 133).

(5) Install balance shaft drive sprocket on crank-

shaft using Special Tool 6052 (Fig. 134).

(6) Turn crankshaft until number 1 cylinder is at

top dead center (TDC). The timing marks on the

chain sprocket should line up with the parting line

on the left side of number one main bearing cap.

(Fig. 135).

(7) Place chain over crankshaft sprocket so that

the plated link of the chain is over the number 1 cyl-inder timing mark on the balance shaft crankshaft

sprocket (Fig. 135).

(8) Place balance shaft sprocket into the timing

chain (Fig. 135) and align the timing mark on the

sprocket (dot) with the (lower) plated link on the

chain.

NOTE: The lower plated link is 8 links from the

upper link.

Fig. 131 Balance Shaft - Removal/Installation

1 - REAR COVER

2 - CARRIER

3 - BALANCE SHAFT

Fig. 132 Gear Timing

1 - KEY WAYS UP

2 - GEAR ALIGNMENT DOTS

Fig. 133 Balance Shaft Sprocket Alignment to

Crankshaft

1 - ALIGN FLATS

Fig. 134 Balance Shaft Drive

1 - SPROCKET

2 - SPECIAL TOOL 6052

9 - 72 ENGINE 2.4LRS

BALANCE SHAFTS AND CARRIER ASSEMBLY (Continued)

ProCarManuals.com

Page 1274 of 2399

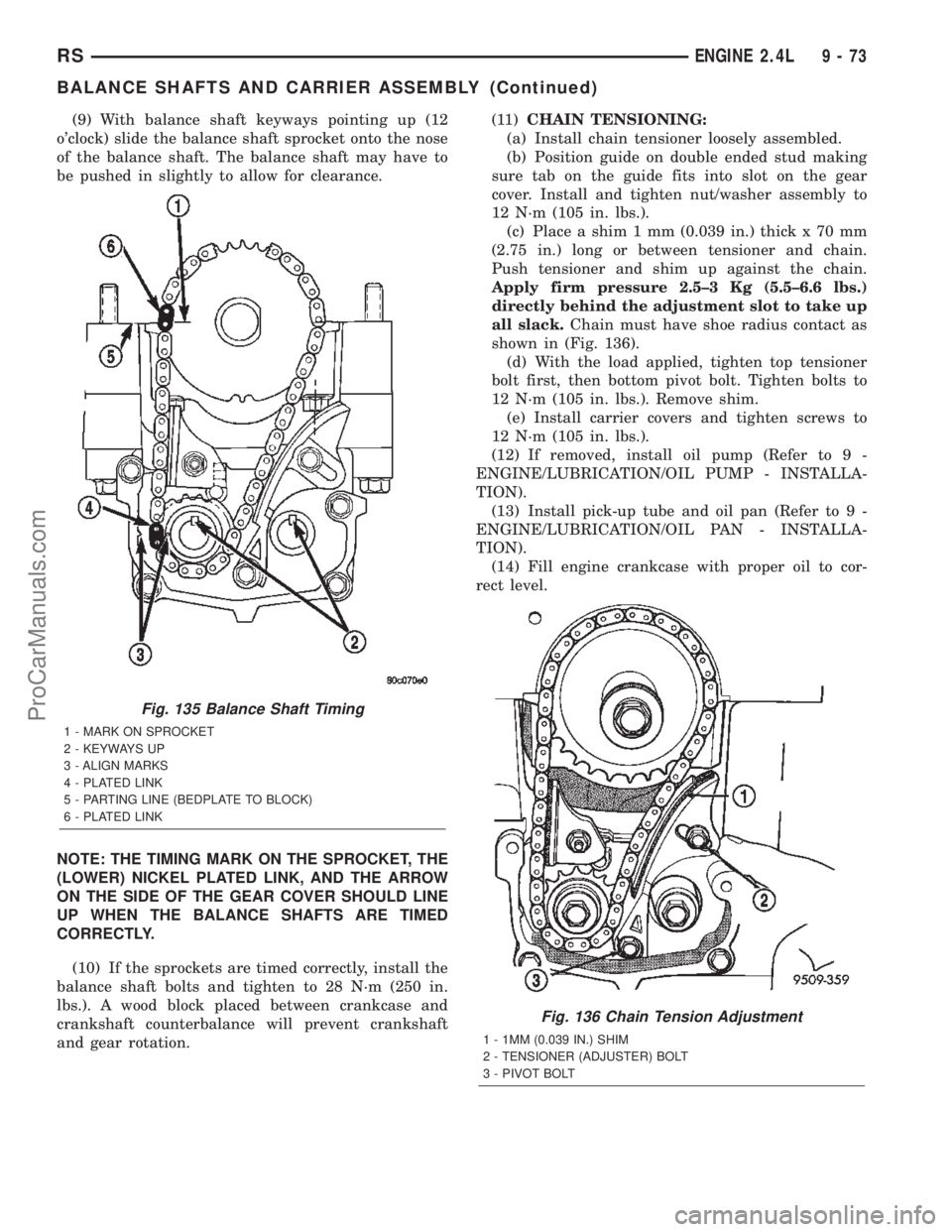

(9) With balance shaft keyways pointing up (12

o'clock) slide the balance shaft sprocket onto the nose

of the balance shaft. The balance shaft may have to

be pushed in slightly to allow for clearance.

NOTE: THE TIMING MARK ON THE SPROCKET, THE

(LOWER) NICKEL PLATED LINK, AND THE ARROW

ON THE SIDE OF THE GEAR COVER SHOULD LINE

UP WHEN THE BALANCE SHAFTS ARE TIMED

CORRECTLY.

(10) If the sprockets are timed correctly, install the

balance shaft bolts and tighten to 28 N´m (250 in.

lbs.). A wood block placed between crankcase and

crankshaft counterbalance will prevent crankshaft

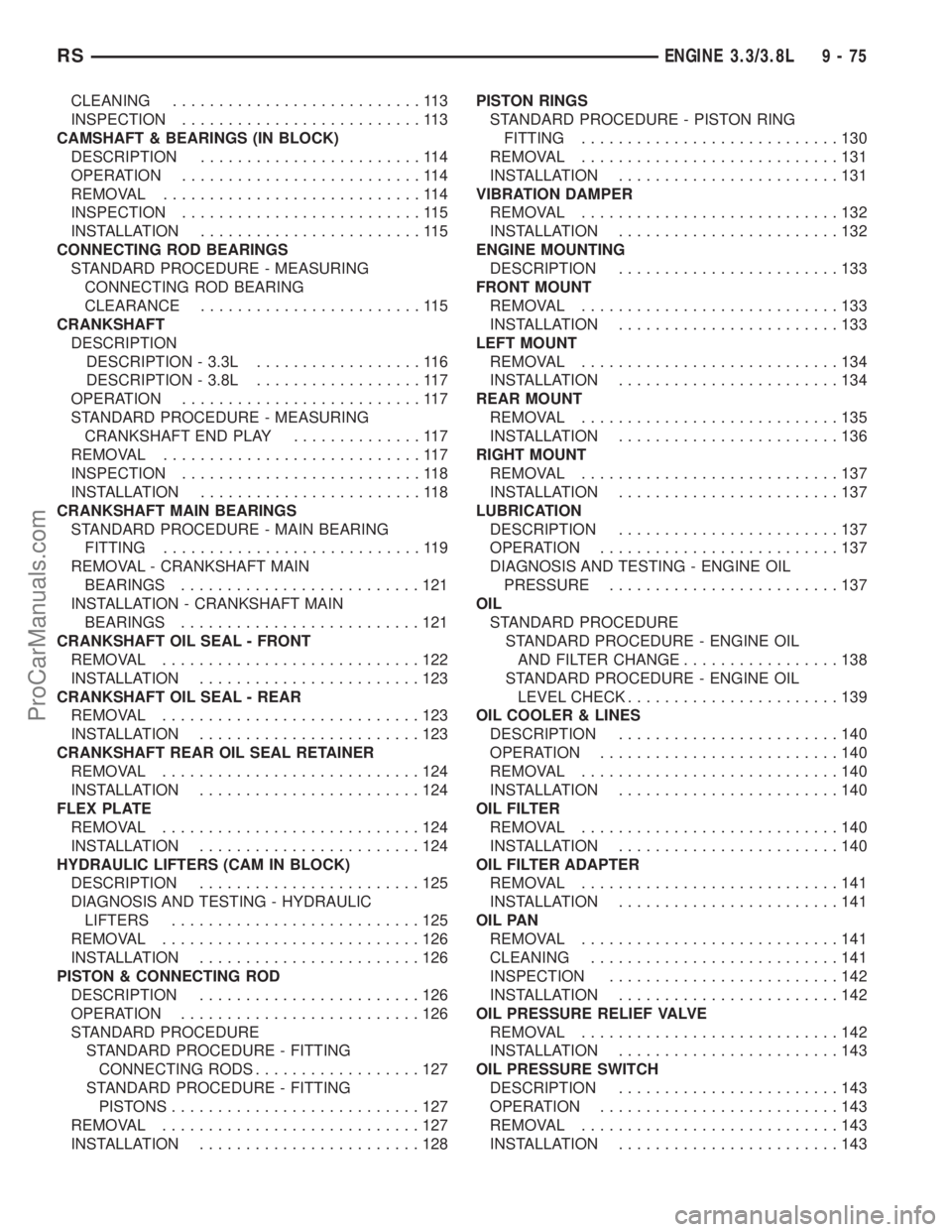

and gear rotation.(11)CHAIN TENSIONING:

(a) Install chain tensioner loosely assembled.

(b) Position guide on double ended stud making

sure tab on the guide fits into slot on the gear

cover. Install and tighten nut/washer assembly to

12 N´m (105 in. lbs.).

(c) Place a shim 1 mm (0.039 in.) thick x 70 mm

(2.75 in.) long or between tensioner and chain.

Push tensioner and shim up against the chain.

Apply firm pressure 2.5±3 Kg (5.5±6.6 lbs.)

directly behind the adjustment slot to take up

all slack.Chain must have shoe radius contact as

shown in (Fig. 136).

(d) With the load applied, tighten top tensioner

bolt first, then bottom pivot bolt. Tighten bolts to

12 N´m (105 in. lbs.). Remove shim.

(e) Install carrier covers and tighten screws to

12 N´m (105 in. lbs.).

(12) If removed, install oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - INSTALLA-

TION).

(13) Install pick-up tube and oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(14) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 135 Balance Shaft Timing

1 - MARK ON SPROCKET

2 - KEYWAYS UP

3 - ALIGN MARKS

4 - PLATED LINK

5 - PARTING LINE (BEDPLATE TO BLOCK)

6 - PLATED LINK

Fig. 136 Chain Tension Adjustment

1 - 1MM (0.039 IN.) SHIM

2 - TENSIONER (ADJUSTER) BOLT

3 - PIVOT BOLT

RSENGINE 2.4L9-73

BALANCE SHAFTS AND CARRIER ASSEMBLY (Continued)

ProCarManuals.com

Page 1275 of 2399

ENGINE 3.3/3.8L

TABLE OF CONTENTS

page page

ENGINE 3.3/3.8L

DESCRIPTION.........................76

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION...........77

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE...........78

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL.............80

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION....................82

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST........83

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST...............................83

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................84

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........84

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........85

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE.....................86

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........86

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............86

REMOVAL - ENGINE ASSEMBLY...........87

INSTALLATION - ENGINE ASSEMBLY........90

SPECIFICATIONS

3.3/3.8L ENGINE......................92

SPECIFICATIONS - TORQUE............95

SPECIAL TOOLS

3.3/3.8L ENGINE......................96

AIR CLEANER ELEMENT

REMOVAL.............................99

INSTALLATION.........................99

AIR CLEANER HOUSING

REMOVAL.............................99

INSTALLATION........................100

CYLINDER HEAD

DESCRIPTION........................100

OPERATION..........................100

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET...........................100

REMOVAL - CYLINDER HEAD............100

CLEANING...........................101INSPECTION.........................101

INSTALLATION - CYLINDER HEAD.........102

CYLINDER HEAD COVER(S)

DESCRIPTION........................103

CYLINDER HEAD COVER - RIGHT

REMOVAL............................103

INSTALLATION........................103

CYLINDER HEAD COVER - LEFT

REMOVAL............................105

INSTALLATION........................105

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION........................105

OPERATION..........................105

STANDARD PROCEDURE - REFACING

VALVESANDVALVESEATS ............105

REMOVAL............................106

CLEANING...........................106

INSPECTION.........................106

INSTALLATION........................107

VALVE SPRINGS

DESCRIPTION........................107

OPERATION..........................107

REMOVAL

REMOVAL - CYLINDER HEAD OFF.......108

REMOVAL - CYLINDER HEAD ON........108

INSPECTION.........................109

INSTALLATION

INSTALLATION - CYLINDER HEAD OFF . . . 109

INSTALLATION - CYLINDER HEAD ON....109

ROCKER ARMS

DESCRIPTION

DESCRIPTION - ROCKER ARMS.........110

DESCRIPTION - PUSHRODS............110

OPERATION

OPERATION - ROCKER ARMS..........110

OPERATION - PUSHRODS.............110

REMOVAL - ROCKER ARMS AND SHAFT....110

DISASSEMBLY - ROCKER ARMS AND

SHAFT.............................110

ASSEMBLY - ROCKER ARMS AND SHAFT . . . 111

INSTALLATION - ROCKER ARMS AND

SHAFT.............................111

VALVE STEM SEALS

DESCRIPTION........................112

REMOVAL............................113

INSTALLATION........................113

ENGINE BLOCK

DESCRIPTION........................113

STANDARD PROCEDURE - CYLINDER BORE

HONING............................113

9 - 74 ENGINE 3.3/3.8LRS

ProCarManuals.com

Page 1276 of 2399

CLEANING...........................113

INSPECTION..........................113

CAMSHAFT & BEARINGS (IN BLOCK)

DESCRIPTION........................114

OPERATION..........................114

REMOVAL............................114

INSPECTION..........................115

INSTALLATION........................115

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - MEASURING

CONNECTING ROD BEARING

CLEARANCE........................115

CRANKSHAFT

DESCRIPTION

DESCRIPTION - 3.3L..................116

DESCRIPTION - 3.8L..................117

OPERATION..........................117

STANDARD PROCEDURE - MEASURING

CRANKSHAFT END PLAY..............117

REMOVAL............................117

INSPECTION..........................118

INSTALLATION........................118

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - MAIN BEARING

FITTING............................119

REMOVAL - CRANKSHAFT MAIN

BEARINGS..........................121

INSTALLATION - CRANKSHAFT MAIN

BEARINGS..........................121

CRANKSHAFT OIL SEAL - FRONT

REMOVAL............................122

INSTALLATION........................123

CRANKSHAFT OIL SEAL - REAR

REMOVAL............................123

INSTALLATION........................123

CRANKSHAFT REAR OIL SEAL RETAINER

REMOVAL............................124

INSTALLATION........................124

FLEX PLATE

REMOVAL............................124

INSTALLATION........................124

HYDRAULIC LIFTERS (CAM IN BLOCK)

DESCRIPTION........................125

DIAGNOSIS AND TESTING - HYDRAULIC

LIFTERS...........................125

REMOVAL............................126

INSTALLATION........................126

PISTON & CONNECTING ROD

DESCRIPTION........................126

OPERATION..........................126

STANDARD PROCEDURE

STANDARD PROCEDURE - FITTING

CONNECTING RODS..................127

STANDARD PROCEDURE - FITTING

PISTONS...........................127

REMOVAL............................127

INSTALLATION........................128PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................130

REMOVAL............................131

INSTALLATION........................131

VIBRATION DAMPER

REMOVAL............................132

INSTALLATION........................132

ENGINE MOUNTING

DESCRIPTION........................133

FRONT MOUNT

REMOVAL............................133

INSTALLATION........................133

LEFT MOUNT

REMOVAL............................134

INSTALLATION........................134

REAR MOUNT

REMOVAL............................135

INSTALLATION........................136

RIGHT MOUNT

REMOVAL............................137

INSTALLATION........................137

LUBRICATION

DESCRIPTION........................137

OPERATION..........................137

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE.........................137

OIL

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE OIL

AND FILTER CHANGE.................138

STANDARD PROCEDURE - ENGINE OIL

LEVEL CHECK.......................139

OIL COOLER & LINES

DESCRIPTION........................140

OPERATION..........................140

REMOVAL............................140

INSTALLATION........................140

OIL FILTER

REMOVAL............................140

INSTALLATION........................140

OIL FILTER ADAPTER

REMOVAL............................141

INSTALLATION........................141

OIL PAN

REMOVAL............................141

CLEANING...........................141

INSPECTION.........................142

INSTALLATION........................142

OIL PRESSURE RELIEF VALVE

REMOVAL............................142

INSTALLATION........................143

OIL PRESSURE SWITCH

DESCRIPTION........................143

OPERATION..........................143

REMOVAL............................143

INSTALLATION........................143

RSENGINE 3.3/3.8L9-75

ProCarManuals.com

Page 1277 of 2399

OIL PUMP

DESCRIPTION........................143

REMOVAL............................143

DISASSEMBLY........................144

CLEANING...........................144

INSPECTION.........................144

ASSEMBLY...........................146

INSTALLATION........................146

INTAKE MANIFOLD

DESCRIPTION........................146

OPERATION..........................146

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS....................146

INTAKE MANIFOLD - UPPER

STANDARD PROCEDURE

STANDARD PROCEDURE - MANIFOLD

STRIPPED THREAD REPAIR............146

STANDARD PROCEDURE - INTAKE

MANIFOLD VACUUM PORT REPAIR......147

REMOVAL - UPPER INTAKE MANIFOLD.....147

CLEANING...........................148

INSPECTION.........................149

INSTALLATION - UPPER INTAKE

MANIFOLD..........................149

INTAKE MANIFOLD - LOWER

REMOVAL - LOWER INTAKE MANIFOLD....150

CLEANING...........................150

INSPECTION.........................150

INSTALLATION - LOWER INTAKE MANIFOLD . 150

EXHAUST MANIFOLD

DESCRIPTION........................152OPERATION..........................152

EXHAUST MANIFOLD - RIGHT

REMOVAL............................152

CLEANING...........................152

INSPECTION.........................153

INSTALLATION........................153

EXHAUST MANIFOLD - LEFT

REMOVAL............................154

CLEANING...........................154

INSPECTION.........................154

INSTALLATION........................154

VALVE TIMING

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE TIMING

VERIFICATION.......................155

STANDARD PROCEDURE - MEASURING

TIMING CHAIN WEAR.................155

TIMING CHAIN COVER

REMOVAL............................155

INSTALLATION........................156

TIMING CHAIN AND SPROCKETS

REMOVAL

REMOVAL - TIMING CHAIN AND

CAMSHAFT SPROCKET...............159

REMOVAL - CRANKSHAFT SPROCKET . . . 159

INSTALLATION

INSTALLATION - CRANKSHAFT

SPROCKET.........................159

INSTALLATION - TIMING CHAIN AND

CAMSHAFT SPROCKET...............159

ENGINE 3.3/3.8L

DESCRIPTION

The 3.3 Liter (201 cu. in.) and 3.8 Liter (231 cu.

in.) engines are 60É V-6 engines with cast iron cylin-

der blocks and aluminum cylinder heads (Fig. 1). The

engine uses a single, block mounted camshaft with

pushrods to actuate the valves. These engines do not

have provisions for a free wheeling valve train.The firing order is 1±2±3±4±5±6. The cylinders are

numbered from the front of the engine to the rear.

The front cylinder bank is numbered 2, 4, and 6. The

rear cylinder bank is numbered 1, 3, and 5.

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 2).

9 - 76 ENGINE 3.3/3.8LRS

ProCarManuals.com

Page 1278 of 2399

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Hydraulic Lash Adjuster Noise Diagnosis

²Engine Oil Leak Inspection

Fig. 1 3.3/3.8L V-6 Engines

Fig. 2 Engine Identification

RSENGINE 3.3/3.8L9-77

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1279 of 2399

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery. 1. Test battery. Charge or replace

as necessary. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM -

DIAGNOSIS AND TESTING)

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Faulty starter. 3. Test starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Faulty coil(s) or control unit. 4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Incorrect spark plug gap. 5. Set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- SPECIFICATIONS)

6. Contamination in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Incorrect engine timing. 8. Check for a skipped timing

belt/chain.

ENGINE STALLS OR IDLES

ROUGH1. Idle speed too low. 1. Test minimum air flow. (Refer to

Appropriate Diagnostic Information)

2. Incorrect fuel mixture. 2. (Refer to Appropriate Diagnostic

Information)

3. Intake manifold leakage. 3. Inspect intake manifold, manifold

gasket, and vacuum hoses.

4. Faulty ignition coil(s). 4. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

9 - 78 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1280 of 2399

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped plugs. 1. Clean plugs and set gap.

2. Contamination in fuel system. 2. Clean system and replace fuel

filter.

3. Faulty fuel pump. 3. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

4. Incorrect valve timing. 4. Correct valve timing.

5. Leaking cylinder head gasket. 5. Replace cylinder head gasket.

6. Low compression. 6. Test compression of each

cylinder.

7. Burned, warped, or pitted valves. 7. Replace valves.

8. Plugged or restricted exhaust

system.8. Perform exhaust restriction test.

(Refer to 11 - EXHAUST SYSTEM -

DIAGNOSIS AND TESTING) Install

new parts, as necessary.

9. Faulty ignition coil(s). 9. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

ENGINE MISSES ON

ACCELERATION1. Dirty or incorrectly gapped spark

plugs.1. Clean spark plugs and set gap.

2. Contamination in Fuel System. 2. Clean fuel system and replace

fuel filter.

3. Burned, warped, or pitted valves. 3. Replace valves.

4. Faulty ignition coil(s). 4. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

ENGINE MISSES AT HIGH SPEED 1. Dirty or incorrect spark plug gap. 1. Clean spark plugs and set gap.

2. Faulty ignition coil(s). 2. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

3. Dirty fuel injector(s). 3. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

4. Contamination in fuel system. 4. Clean system and replace fuel

filter.

RSENGINE 3.3/3.8L9-79

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com