ECO mode CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 464 of 2585

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS

BATTERY

DESCRIPTION

There are three different batteries available on this

model. Vehicles equipped with a diesel engine utilize

a spiral wound plate designed battery with recombi-

nation technology. This is a maintenance-free battery

that is capable of delivering more power than a con-

ventional battery. This additional power is required

by a diesel engine during cold cranking. Vehicles

equipped with a gasoline engine utilize a conven-

tional battery. Refer to the following information for

detailed differences and descriptions of these batter-

ies.

SPIRAL PLATE BATTERY - DIESEL ENGINE

Spiral plate technology takes the elements of tradi-

tional batteries - lead and sulfuric acid - to the next

level. By tightly winding layers of spiral grids and

acid-permeated vitreous separators into cells, the

manufacturer has developed a battery with more

power and service life than conventional batteries the

same size. The spiral plate battery is completely, per-

manently sealed. Through gas recombination, hydro-

gen and oxygen within the battery are captured

during normal charging and reunited to form the

water within the electrolyte, eliminating the need to

add distilled water. Therefore, these batteries have non-removable battery vent caps (Fig. 4). Water

can-

not be added to this battery.

The acid inside a spiral plate battery is bound

within the vitreous separators, ending the threat of

acid leaks. This feature allows the battery to be

installed in any position anywhere in the vehicle. Spiral plate technology is the process by which the

plates holding the active material in the battery are

wound tightly in coils instead of hanging flat, like

conventional batteries. This design has a lower inter-

nal resistance and also increases the active material

surface area.

WARNING: NEVER EXCEED 14.4 VOLTS WHEN

CHARGING A SPIRAL PLATE BATTERY. PERSONAL

INJURY AND/OR BATTERY DAMAGE MAY RESULT.

Due to the maintanance-free design, distilled water

cannot be added to this battery. Therefore, if more

than 14.4 volts are used during the spiral plate bat-

tery charging process, water vapor can be exhausted

through the pressure-sensitive battery vents and lost

for good. This can permanently damage the spiral

plate battery. Never exceed 14.4 volts when charging

a spiral plate battery. Personal injury and/or battery

damage may result.

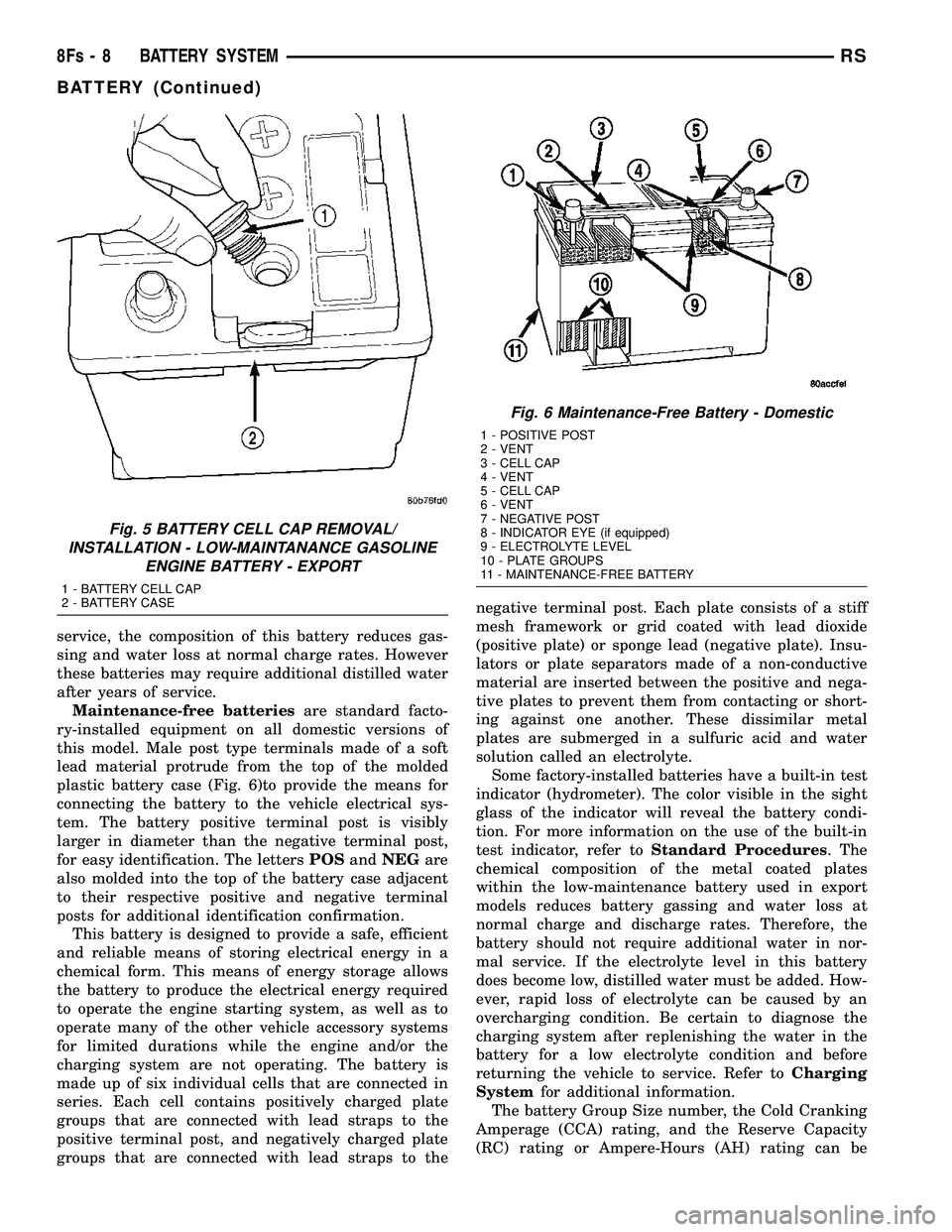

CONVENTIONAL BATTERY - GASOLINE ENGINE

Low-maintenance batteries are used on export

vehicles equipped with a gasoline engine, these bat-

teries have removable battery cell caps (Fig. 5).

Water canbe added to this battery. Under normal

Micro 420 Battery Tester

Fig. 4 MAINTENANCE-FREE DIESEL ENGINE

BATTERY

RS BATTERY SYSTEM8Fs-7

BATTERY SYSTEM (Continued)

Page 465 of 2585

service, the composition of this battery reduces gas-

sing and water loss at normal charge rates. However

these batteries may require additional distilled water

after years of service.Maintenance-free batteries are standard facto-

ry-installed equipment on all domestic versions of

this model. Male post type terminals made of a soft

lead material protrude from the top of the molded

plastic battery case (Fig. 6)to provide the means for

connecting the battery to the vehicle electrical sys-

tem. The battery positive terminal post is visibly

larger in diameter than the negative terminal post,

for easy identification. The letters POSandNEG are

also molded into the top of the battery case adjacent

to their respective positive and negative terminal

posts for additional identification confirmation. This battery is designed to provide a safe, efficient

and reliable means of storing electrical energy in a

chemical form. This means of energy storage allows

the battery to produce the electrical energy required

to operate the engine starting system, as well as to

operate many of the other vehicle accessory systems

for limited durations while the engine and/or the

charging system are not operating. The battery is

made up of six individual cells that are connected in

series. Each cell contains positively charged plate

groups that are connected with lead straps to the

positive terminal post, and negatively charged plate

groups that are connected with lead straps to the negative terminal post. Each plate consists of a stiff

mesh framework or grid coated with lead dioxide

(positive plate) or sponge lead (negative plate). Insu-

lators or plate separators made of a non-conductive

material are inserted between the positive and nega-

tive plates to prevent them from contacting or short-

ing against one another. These dissimilar metal

plates are submerged in a sulfuric acid and water

solution called an electrolyte.

Some factory-installed batteries have a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. For more information on the use of the built-in

test indicator, refer to Standard Procedures . The

chemical composition of the metal coated plates

within the low-maintenance battery used in export

models reduces battery gassing and water loss at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, distilled water must be added. How-

ever, rapid loss of electrolyte can be caused by an

overcharging condition. Be certain to diagnose the

charging system after replenishing the water in the

battery for a low electrolyte condition and before

returning the vehicle to service. Refer to Charging

System for additional information.

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

Fig. 5 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTANANCE GASOLINE ENGINE BATTERY - EXPORT

1 - BATTERY CELL CAP

2 - BATTERY CASE

Fig. 6 Maintenance-Free Battery - Domestic

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - VENT

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

8 - INDICATOR EYE (if equipped)

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - MAINTENANCE-FREE BATTERY

8Fs - 8 BATTERY SYSTEMRS

BATTERY (Continued)

Page 499 of 2585

(2) Position the rear window defogger relay into

the proper receptacle in the IPM.

(3) Align the rear window defogger relay terminals

with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the rear window defogger

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the battery negative cable.

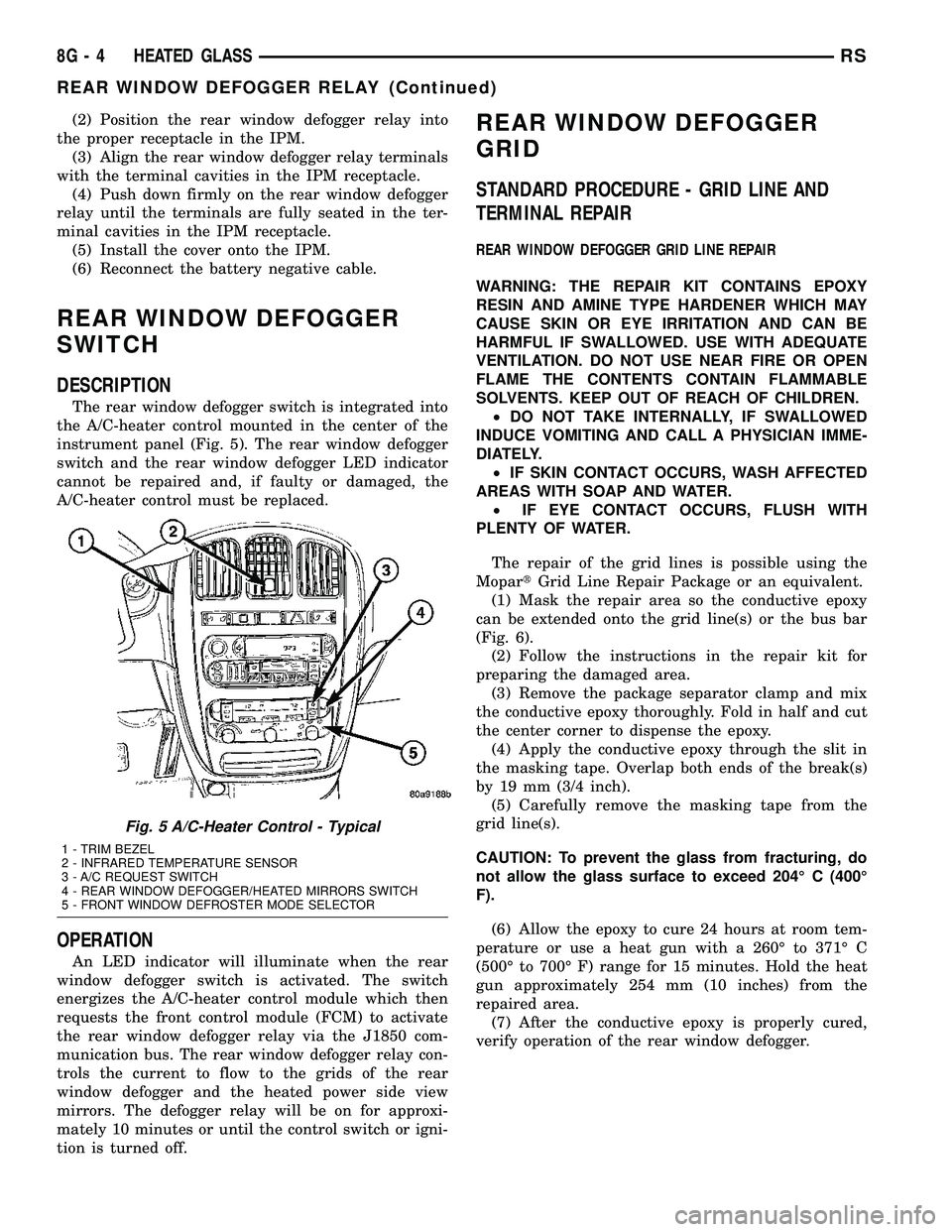

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The rear window defogger switch is integrated into

the A/C-heater control mounted in the center of the

instrument panel (Fig. 5). The rear window defogger

switch and the rear window defogger LED indicator

cannot be repaired and, if faulty or damaged, the

A/C-heater control must be replaced.

OPERATION

An LED indicator will illuminate when the rear

window defogger switch is activated. The switch

energizes the A/C-heater control module which then

requests the front control module (FCM) to activate

the rear window defogger relay via the J1850 com-

munication bus. The rear window defogger relay con-

trols the current to flow to the grids of the rear

window defogger and the heated power side view

mirrors. The defogger relay will be on for approxi-

mately 10 minutes or until the control switch or igni-

tion is turned off.

REAR WINDOW DEFOGGER

GRID

STANDARD PROCEDURE - GRID LINE AND

TERMINAL REPAIR

REAR WINDOW DEFOGGER GRID LINE REPAIR

WARNING: THE REPAIR KIT CONTAINS EPOXY

RESIN AND AMINE TYPE HARDENER WHICH MAY

CAUSE SKIN OR EYE IRRITATION AND CAN BE

HARMFUL IF SWALLOWED. USE WITH ADEQUATE

VENTILATION. DO NOT USE NEAR FIRE OR OPEN

FLAME THE CONTENTS CONTAIN FLAMMABLE

SOLVENTS. KEEP OUT OF REACH OF CHILDREN.

²DO NOT TAKE INTERNALLY, IF SWALLOWED

INDUCE VOMITING AND CALL A PHYSICIAN IMME-

DIATELY.

²IF SKIN CONTACT OCCURS, WASH AFFECTED

AREAS WITH SOAP AND WATER.

²IF EYE CONTACT OCCURS, FLUSH WITH

PLENTY OF WATER.

The repair of the grid lines is possible using the

MopartGrid Line Repair Package or an equivalent.

(1) Mask the repair area so the conductive epoxy

can be extended onto the grid line(s) or the bus bar

(Fig. 6).

(2) Follow the instructions in the repair kit for

preparing the damaged area.

(3) Remove the package separator clamp and mix

the conductive epoxy thoroughly. Fold in half and cut

the center corner to dispense the epoxy.

(4) Apply the conductive epoxy through the slit in

the masking tape. Overlap both ends of the break(s)

by 19 mm (3/4 inch).

(5) Carefully remove the masking tape from the

grid line(s).

CAUTION: To prevent the glass from fracturing, do

not allow the glass surface to exceed 204É C (400É

F).

(6) Allow the epoxy to cure 24 hours at room tem-

perature or use a heat gun with a 260É to 371É C

(500É to 700É F) range for 15 minutes. Hold the heat

gun approximately 254 mm (10 inches) from the

repaired area.

(7) After the conductive epoxy is properly cured,

verify operation of the rear window defogger.

Fig. 5 A/C-Heater Control - Typical

1 - TRIM BEZEL

2 - INFRARED TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8G - 4 HEATED GLASSRS

REAR WINDOW DEFOGGER RELAY (Continued)

Page 501 of 2585

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION..........................6OPERATION............................6

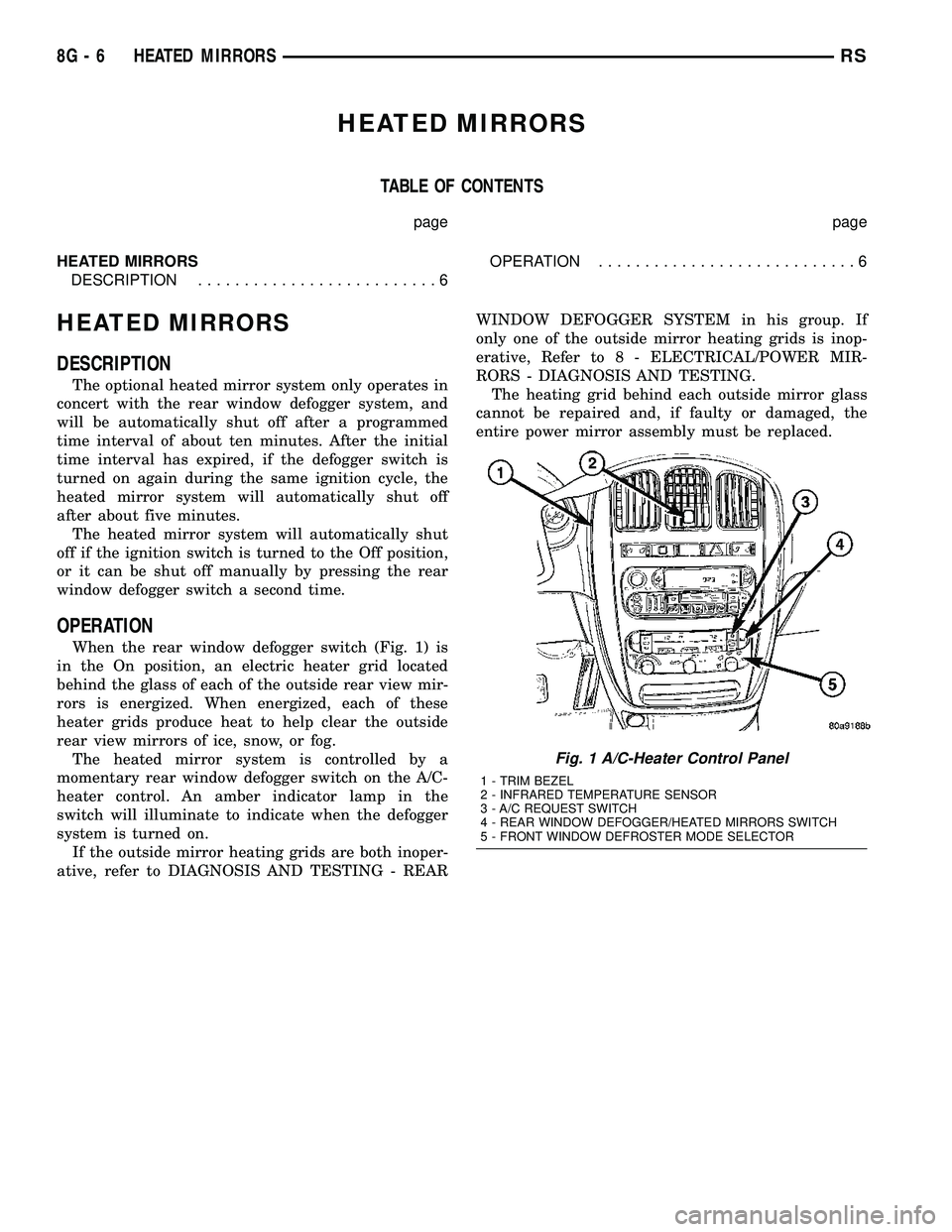

HEATED MIRRORS

DESCRIPTION

The optional heated mirror system only operates in

concert with the rear window defogger system, and

will be automatically shut off after a programmed

time interval of about ten minutes. After the initial

time interval has expired, if the defogger switch is

turned on again during the same ignition cycle, the

heated mirror system will automatically shut off

after about five minutes.

The heated mirror system will automatically shut

off if the ignition switch is turned to the Off position,

or it can be shut off manually by pressing the rear

window defogger switch a second time.

OPERATION

When the rear window defogger switch (Fig. 1) is

in the On position, an electric heater grid located

behind the glass of each of the outside rear view mir-

rors is energized. When energized, each of these

heater grids produce heat to help clear the outside

rear view mirrors of ice, snow, or fog.

The heated mirror system is controlled by a

momentary rear window defogger switch on the A/C-

heater control. An amber indicator lamp in the

switch will illuminate to indicate when the defogger

system is turned on.

If the outside mirror heating grids are both inoper-

ative, refer to DIAGNOSIS AND TESTING - REARWINDOW DEFOGGER SYSTEM in his group. If

only one of the outside mirror heating grids is inop-

erative, Refer to 8 - ELECTRICAL/POWER MIR-

RORS - DIAGNOSIS AND TESTING.

The heating grid behind each outside mirror glass

cannot be repaired and, if faulty or damaged, the

entire power mirror assembly must be replaced.

Fig. 1 A/C-Heater Control Panel

1 - TRIM BEZEL

2 - INFRARED TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8G - 6 HEATED MIRRORSRS

Page 505 of 2585

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

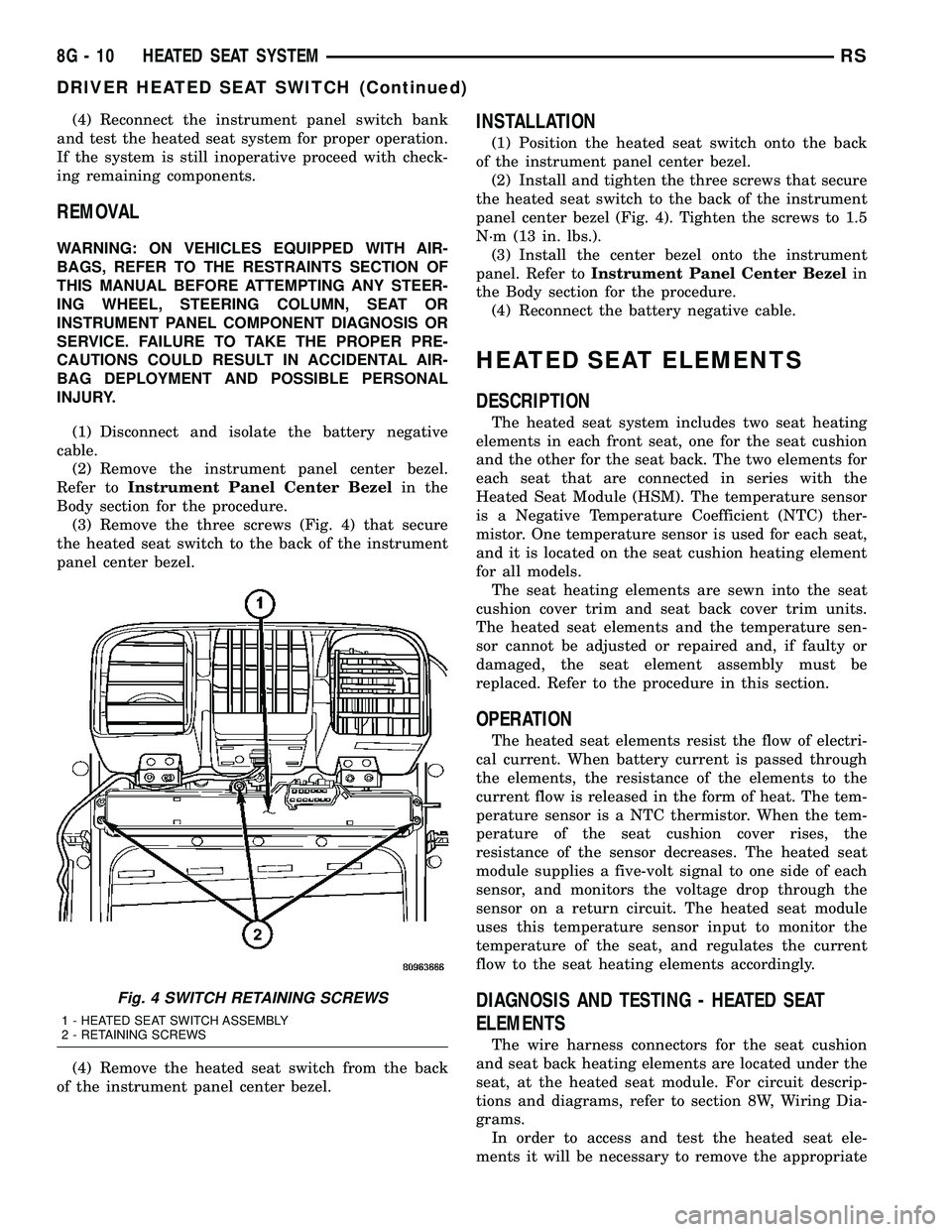

(3) Remove the three screws (Fig. 4) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel (Fig. 4). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

HEATED SEAT ELEMENTS

DESCRIPTION

The heated seat system includes two seat heating

elements in each front seat, one for the seat cushion

and the other for the seat back. The two elements for

each seat that are connected in series with the

Heated Seat Module (HSM). The temperature sensor

is a Negative Temperature Coefficient (NTC) ther-

mistor. One temperature sensor is used for each seat,

and it is located on the seat cushion heating element

for all models.

The seat heating elements are sewn into the seat

cushion cover trim and seat back cover trim units.

The heated seat elements and the temperature sen-

sor cannot be adjusted or repaired and, if faulty or

damaged, the seat element assembly must be

replaced. Refer to the procedure in this section.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the resistance of the elements to the

current flow is released in the form of heat. The tem-

perature sensor is a NTC thermistor. When the tem-

perature of the seat cushion cover rises, the

resistance of the sensor decreases. The heated seat

module supplies a five-volt signal to one side of each

sensor, and monitors the voltage drop through the

sensor on a return circuit. The heated seat module

uses this temperature sensor input to monitor the

temperature of the seat, and regulates the current

flow to the seat heating elements accordingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS

The wire harness connectors for the seat cushion

and seat back heating elements are located under the

seat, at the heated seat module. For circuit descrip-

tions and diagrams, refer to section 8W, Wiring Dia-

grams.

In order to access and test the heated seat ele-

ments it will be necessary to remove the appropriate

Fig. 4 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 10 HEATED SEAT SYSTEMRS

DRIVER HEATED SEAT SWITCH (Continued)

Page 537 of 2585

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

LAMP SYSTEMS

Lighting circuits are protected by fuses. Lighting

circuits require an overload protected power and high

side drivers source, ON/OFF device, lamps and body

grounds to operate properly. Plastic lamps require a

wire in the harness to supply body ground to the

lamp socket. Replace sockets and bulbs that are cor-

roded.

Some of the interior and exterior lighting functions

are governed by the Body Control Module (BCM).

The headlamp, dome, and the door ajar switches pro-

vide signals to the BCM. The BCM in turn sends a

Programmable Communication Interface (PCI) bus

message to the Front Control Module (FCM) to

enable the necessary drivers to set the required illu-

mination configuration.

Wire connectors can make intermittent contact or

become corroded. Before coupling wire connectors,

inspect the terminals inside the connector. Male ter-

minals should not be bent or disengaged from the

insulator. Female terminals should not be sprung

open or disengaged from the insulator. Bent and

sprung terminals can be repaired using needle nose

pliers and pick tool. Corroded terminals appear

chalky or green. Corroded terminals should be

replaced to avoid recurrence of the problem symp-

toms.

Begin electrical system failure diagnosis by testing

related fuses in the fuse block and intelligent power

module. Verify that bulbs are in good condition and

test continuity of the circuit ground. Refer to the

appropriate wiring information.

AUTOMATIC HEADLAMP SYSTEM

The Automatic Headlamp system turns the instru-

mentation and exterior illumination lamps ON when

the ambient light levels are Night and the engine

RPM is 450 or above, and OFF when light levels are

Day.

DAYTIME RUNNING LAMPS

Operating the high-beam headlamps at reduced

power provides daytime running lamps, which are

required on all new Canadian vehicles. Daytime run-

ning lamps are functional when 450 rpm's are

reached.

HEADLAMPS ON WITH WINDSHIELD WIPERS

For vehicles equipped with the Automatic Head-

lamp System, the instrumentation and exterior illu-

mination lamps will be turned ON when the

headlamp switch is in the AUTO position, RPM >450 and the windshield wipers have been in the

intermittent, low or high mode of operation for more

than ten seconds. When the windshield wipers are

turned OFF the Body Control Module will determine

if the instrumentation and exterior illumination

lamps should remain ON base upon the current

ambient light level.

HEADLAMP SYSTEM

The configuration of the headlamp system of head-

lamps, park lamps and fog lamps is determined by

the BCM. The BCM determines the lighting configu-

ration as a result of the inputs from the ignition

switch, headlamp switch and multi-function switch. A

PCI bus is transmitted from the BCM to the FCM to

enable the necessary drivers to set the illumination

configuration. Four wires are connected between the

headlamp switch and the BCM. The first wire con-

tains information regarding the position of the head-

lamp switch (Off, Automatic Headlamps, Automatic

Headlamp switch fog, Park with Fog, Head, or Head

with Fog Lamps). The second wire contains informa-

tion regarding the position of the dimmer switch

(Dome Lamp, Daytime Brightness, Dimming Level or

Off). The third wire is a dedicated signal return

(ground) wire. The fourth wire provides power to the

front fog lamp indicator.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is controlled by

the Body Control Module (BCM) via a PCI bus mes-

sage transmitted by the BCM to the FCM to turn off

the headlamps.

OPERATION

AUTOMATIC HEADLAMP SYSTEM

Automatic headlamps are controlled by the Body

Control Module (BCM). With the headlamp switch in

the AUTO position, the BCM will control the head-

lamp, parking, side marker, tail and instrumentation

lamps based on ambient light levels. Ambient light

levels are monitored by the BCM using the Day/

Night signal and Electrochromatic Mirror (ECM)

present from the Compass Mini Trip (CMTC) located

on the front windshield in front of the rear view mir-

ror ECM. Ambient light readings are averaged to

limit cycling the lamps ON and OFF when passing

through areas with varying light levels. The auto-

matic headlamps will only function when the engine

is running with RPM > 450. When the headlamp

switch is in the AUTO position (Automatic mode), the

Headlamp Time Delay system will function when the

ignition switch is placed in any position other than

run/start.

8L - 2 LAMPS/LIGHTING - EXTERIORRS

Page 538 of 2585

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the FCM. Daytime running lamps are

functional when 450 rpm's are reached.

HEADLAMP SYSTEM

The headlamp system will default to headlamps

ON position when ignition switch is ON and when an

open or short circuit failure occurs on the headlamp

switch input or PCI data bus communication between

the BCM and the FCM fails. The system will return

to normal operation when the open or short is

repaired. A fault will be reported by the BCM when a

failure occurs on the dimmer or headlamp switch

input.

If the exterior lamps are ON and the headlamp

switch is in any position other than OFF or AUTO

and with the ignition switch OFF (LOCK) after 3

minutes the BCM sends a message via PCI bus to

the FCM informing the FCM to turn off the head-

lamps, park lamps and fog lamps. This feature pre-

vents the vehicle battery from being discharged when

the vehicle lights have been left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The BCM will allow

the headlamps to remain ON for 90 seconds (config-

urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then both the headlamps and park lamps

(including panel dimming) will be ON). Refer to the

Owner's Manual for more information.

If the headlamp switch is in the Auto Headlamp

Position, the headlamps are ON due to the night sig-

nal from the CMTC and the ignition switch is in any

position other than run/start, the BCM shall enter a

90 second (configurable) Auto Headlamps time delay

mode. If the key is in the ignition during the head-

lamp time delay mode, then both the headlamps and

park lamps (including panel dimming) will be ON. If

the key is not in the ignition, then only the head-

lamps will be ON. The BCM will allow the head-

lamps to remain ON for 90 seconds before they

automatically turn OFF. Refer to the Owner's Man-

ual for more information.

OPTICAL HORN/HIGH BEAMS

When the multi-function switch is pulled to the

first detent (optical horn) signal, the headlamps are

ON, key-in the ignition the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers to illuminate all four filaments (Low

and High beams). When the multi-function switch is

pulled to the second detent (high beam) signal and

the headlamps are ON, the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers. The High Beams are illuminated and

the Low Beams and Fog Lamps (if ON) are extin-

guished. If the headlamps were in the high beam

configuration when power was removed from the

headlamps, the headlamps will be configured as low

beam the next time they are activated.

NOTE: For RG - Export vehicles, the low beams and

front fog lamps will remain ON when high beams

are activated.

WARNING

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY OR DEATH CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

CAUTION: Do not use bulbs other than those listed

in the Bulb Application Table. Damage to lamp can

result. Do not touch halogen bulbs with fingers or

other oily surfaces. Bulb life will be reduced.

SPECIFICATIONS

EXTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

BACK-UP 3057

CHMSL 921

FRONT SIDE MARKER/PARK/

TURN3157A

RSLAMPS/LIGHTING - EXTERIOR8L-3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 560 of 2585

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT.........3

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT.......................3

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................3

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................4

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................5

REMOVAL - OVERHEAD CONSOLE..........6

INSTALLATION..........................6

SPECIAL TOOLS

OVERHEAD CONSOLE..................6

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................6

OPERATION............................7

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER.........7

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING.......................7

REMOVAL.............................9INSTALLATION..........................9

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER.................10

REMOVAL.............................10

INSTALLATION.........................10

UNIVERSAL TRANSMITTER

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER.......................10

STANDARD PROCEDURE

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES.................11

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES.................11

REMOVAL.............................11

AMBIENT TEMP SENSOR

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............12

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT........12

REMOVAL.............................12

INSTALLATION.........................12

OVERHEAD CONSOLE

DESCRIPTION

Three overhead consoles are available on RS/RG

models. These are the Electronic Vehicle Information

Center (EVIC), Compass Mini-Trip Computer

(CMTC) or a Compass Temperature Computer (CT).

All consoles are equipped with two reading/courtesy

lamps and if the vehicle is equipped with a power

liftgate or power sliding door(s) the overhead console

will also include command switches for these fea-

tures. The overhead console is mounted with one

screw and two snap clips to a molded plastic retainer

bracket located above the headliner.

DESCRIPTION - COMPASS

All the available overhead consoles on this model

include Compass information. While in the compass/temperature mode, the compass will display the

direction in which the vehicle is pointed using the

eight major compass headings (Examples: north is N,

northeast is NE). The self-calibrating compass unit

requires no adjusting in normal use. The only cali-

bration that may prove necessary is to drive the vehi-

cle in three complete circles at 5 to 8 kilometers-per-

hour (3 to 5 miles-per-hour), on level ground, in not

less than forty-eight seconds. This will reorient the

compass unit to its vehicle.

The compass unit also will compensate for magne-

tism the body of the vehicle may acquire during nor-

mal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral pro-

cession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Mag-

netic bit drivers used on the fasteners that hold the

overhead console assembly to the roof header can

RSMESSAGE SYSTEMS8M-1

Page 561 of 2585

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this section may be

required to restore proper compass operation.

DESCRIPTION - TEMPERATURE

All the available overhead consoles on this model

include Temperature information. The temperature

displays the outside ambient temperature in whole

degrees. The temperature display can be toggled

from Fahrenheit to Celsius by selecting the desired

U.S./Metric option from the customer programmable

features. The displayed temperature is not an instant

reading of conditions, but an average temperature. It

may take the temperature display several minutes to

respond to a major temperature change, such as driv-

ing out of a heated garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the electronic control modules (CT, CMTC, EVIC)

memory. When the ignition switch is turned to the

On position again, the electronic module will display

the memory temperature for one minute; then update

the display to the current average temperature read-

ing within five minutes.

The temperature function is supported by an ambi-

ent temperature sensor. The sensor is mounted out-

side the passenger compartment near the front and

center of the vehicle, and is hard wired to the Front

Control Module (FCM). The FCM sends temperature

status messages to the module over the J1850 PCI

data bus circuit.

Following are general descriptions of the major

components used in the overhead console. Refer to

Wiring Diagrams for complete circuit schematics.

OPERATION

Refer to the vehicle Owner's Manual for specific

operation of each overhead console and its systems.

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE

If the problem with the overhead console is an

inaccurate or scrambled display, refer toSelf-Diag-

nostic Testbelow. If the problem with the overhead

console is incorrect Vacuum Fluorescent Display

(VFD) dimming levels, use a DRB IIItscan tool and

the proper Diagnostic Procedures manual to test for

the correct dimming message inputs being received

from the Body Control Module (BCM) or Front Con-

trol Module (FCM) over the J1850 Programmable

Communications Interface (PCI) data bus circuit. If

the problem is a no-display condition, use the follow-

ing procedures. For complete circuit diagrams, refer

toOverhead Consolein the Wiring Diagrams sec-

tion of the service manual.(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

fused B(+) fuse in the integrated power module as

required.

(3) Check the fused ignition switch output (run/

start) fuse in the integrated power module. If OK, go

to Step 4. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the integrated power mod-

ule. If OK, go to Step 5. If not OK, repair the open

fused ignition switch output (run/start) circuit to the

ignition switch as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavity of the roof wire

harness connector for the electronics module and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the electronics mod-

ule. If OK, go to Step 7. If not OK, repair the open

fused B(+) circuit to the fused B(+) fuse in the inte-

grated power module as required.

(7)

Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the electronics module. If OK, refer

toSelf-Diagnostic Test

later this group for further

diagnosis of the electronics module and the J1850

PCI data bus circuit. If not OK, repair the open fused

ignition switch output (run/start) circuit to the fuse

in the integrated power module as required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

electronics module is operating properly, and that all

the J1850 PCI data bus messages are being received

for initial operation. Initiate the self-diagnostic test

as follows:

(1) With the ignition switch in the Off position, on

Electronic Vehicle Information Center (EVIC) and

Compass Mini-Trip Computer (CMTC) equipped vehi-

cles simultaneously depress and hold theSTEP and

the RESET buttons. On Compass Temperature

Module (CT) equipped vehicles depress theC/T and

the US/M push buttons.

8M - 2 MESSAGE SYSTEMSRS

OVERHEAD CONSOLE (Continued)

Page 566 of 2585

sive, the use of a DRBIIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the EVIC module and the J1850

PCI data bus circuit.

The EVIC module cannot be repaired, and is avail-

able for service only as a unit. This unit includes the

plastic module and display lens. If any of these com-

ponents is faulty or damaged, the complete EVIC

module must be replaced.

OPERATION

The EVIC has access to both non-switched and

ignition switched sources of battery current so that

some of its features remain operational at any time,

while others may only operate with the ignition

switch in the On position. When the ignition switch

is turned to the On position, the EVIC module VFD

will return to the last function being displayed before

the ignition was turned to the Off position.

The compass/thermometer display is the normal

EVIC display. With the ignition switch in the On

position, momentarily depressing and releasing the

C/T (compass/thermometer) push button switch will

cause the EVIC to return to the compass/thermome-

ter/trip computer display mode from any other mode.

While in the compass/thermometer/trip computer dis-

play mode, momentarily depressing and releasing the

Step push button will step through the available trip

computer display options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Standard Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from the Body Control Module (BCM) on

the J1850 Data Bus circuit. The EVIC will display

dashes (- -) for any of the screens it did not receive

the bus messages. The label corresponding to the

missing information will be lit. If no EVIC data is

displayed, check the J1850 Data Bus circuit commu-

nications and the BCM. If the brightness level is

improper check the J1850 Data Bus circuit.

The DRB IIItis recommended for checking the

J1850 Data Bus circuit and the BCM. Perform the

EVIC self diagnosis before replacing the EVIC mod-

ule.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehi-

cle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter the

EVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

(2) Depress and release the Menu push button.

The first item in the programmable features menu

list will appear in the EVIC display.

(3) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(4) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(5) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(6) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

RSMESSAGE SYSTEMS8M-7

ELECTRONIC VEHICLE INFO CENTER (Continued)