ECO mode CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 627 of 2585

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. When the memory set

switch is depressed, a resistance value is sent to the

Body Control Module via hard wired connections.

When the memory system is in ªsetº mode a chime

will be generated by the body control module.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch.

DIAGNOSIS AND TESTING - MEMORY SWITCH

(1) Remove the memory set switch from the driv-

ers door panel (Refer to 8 - ELECTRICAL/POWER

SEATS/MEMORY SET SWITCH - REMOVAL).

(2) Using an ohmmeter, check the continuity of the

memory select switch MUX circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

3. If not OK, repair the open or shorted MUX circuit

as required.

(3) Using an ohmmeter, check the continuity of the

memory select switch return circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

4. If not OK, repair the open or shorted return circuit

as required.

(4) Using an ohmmeter, test the resistances of the

memory switch at the pins in the switch connector

receptacle in each switch position. See the Memory

Switch Test Table. If OK, refer toDiagnosis and

Testing Memory Systemin this section. If not OK,

replace the faulty memory set switch.

MEMORY SWITCH TEST TABLE

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEEN

PINSRESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24650 5%

(24.65 k)

MEMORY 1 1&2 6850 5%

(6.85 k)

MEMORY 2 1&2 2100 5%

(2.10 k)

SET 1&2 4490 5%

(4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel.

(5) Remove the memory switch.

INSTALLATION

(1) Position the memory switch and install and

tighten the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel. Tighten the screws to 2.2 N´m (20

in. lbs.).

(2) Reconnect the memory switch wire harness

connector to the memory switch.

(3) Install the trim panel switch bezel onto the

driver side front door.

(4) Reconnect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

Vehicles equipped with a passenger side power seat

utilize a four-way power seat switch. This four-way

power seat switch features two knobs ganged

together on the outboard seat cushion side shield.

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

8N - 56 POWER SEAT SYSTEMRS

MEMORY SET SWITCH (Continued)

Page 629 of 2585

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Install the switch knobs on the switch control

levers, if equipped.

(7) Reconnect the battery negative cable.

DRIVER POWER SEAT TRACK

DESCRIPTION

The eight-way driver side power seat option

includes a electrically operated power seat track

located under the driver side front seat. The front

power seat track on the driver side of the vehicle also

provides the mounting location for the Memory Seat/

Mirror Module (MSMM). The power seat circuit

breakers are mounted on the rear of the driver side

power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

pan to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.

The power seat track unit includes four reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the four power seat

track motors used on models equipped with the

optional memory system incorporates a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position. This

enables the memory system to function by referenc-

ing the motor positions programmed into the memory

seat/mirror module.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

The forth motor is the recliner adjustment motor,

which moves the seat back in the forward and rear-

ward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any componentin this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When the driver side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the driver side power seat switch to move

all three power seat track adjusters in each direction.

The power seat track adjusters should move in each

of the selected directions. If a power seat track

adjuster fails to operate in only one direction, move

the adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switchin this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer toWiring

Diagrams.

8N - 58 POWER SEAT SYSTEMRS

PASSENGER SEAT SWITCH (Continued)

Page 649 of 2585

REMOVAL

(1) Disconnect and isolate the battery negative

cable. (2) On models equipped with the eight-way power

seat, using a push pin remover or another suitable

wide flat-bladed tool, gently pry the power seat and

power recliner switch knobs off of the switch levers

(Fig. 4).

(3) Remove the screws that secure the outboard

seat cushion side shield to the seat cushion frame.

Refer to the Body section of the service manual for

the procedure. (4) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness connector. (5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle. (6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield. (7) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield. (2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.). (3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle. (4) Position the outboard seat cushion side shield

onto the seat cushion frame (5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.). (6) Install the switch knobs on the switch control

levers, if equipped. (7) Reconnect the battery negative cable.

MEMORY SET SWITCH

DESCRIPTION

Vehicles equipped with the memory system have a

memory switch mounted to the driver side front door

trim panel (Fig. 5). This switch is used to set and

recall all of the memory system settings for up to two

drivers. The memory switch is a resistor multiplexed

unit that is hard wired to the Body Control Module

(BCM). The BCM sends out the memory system set

and recall requests to the other electronic modules

over the Programmable Communications Interface

(PCI) data bus. The memory switch cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced. For

complete circuit diagrams, refer to Wiring Dia-

grams .

Fig. 4 REMOVING SWITCH CONTROL KNOBS -

TYPICAL

Fig. 5 MEMORY SWITCH LOCATION

1 - MEMORY SWITCH

2 - SWITCH BEZEL

8Ns - 12 POWER SEAT SYSTEMRS

DRIVER SEAT SWITCH (Continued)

Page 650 of 2585

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. When the memory set

switch is depressed, a resistance value is sent to the

Body Control Module via hard wired connections.

When the memory system is in ªsetº mode a chime

will be generated by the body control module. See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch.

DIAGNOSIS AND TESTING - MEMORY SWITCH

(1) Remove the memory set switch from the driv-

ers door panel (Refer t o 8 - ELECTRICAL/POWER

SEATS/MEMORY SET SWITCH - REMOVAL). (2) Using an ohmmeter, check the continuity of the

memory select switch MUX circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

3. If not OK, repair the open or shorted MUX circuit

as required. (3) Using an ohmmeter, check the continuity of the

memory select switch return circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

4. If not OK, repair the open or shorted return circuit

as required. (4) Using an ohmmeter, test the resistances of the

memory switch at the pins in the switch connector

receptacle in each switch position. See the Memory

Switch Test Table. If OK, refer to Diagnosis and

Testing Memory System in this section. If not OK,

replace the faulty memory set switch.

MEMORY SWITCH TEST TABLE

MEMORY SWITCH

POSITION RESISTANCE

BETWEEN PINS RESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24650 5% (24.65 k)

MEMORY 1 1&2 6850 5% (6.85 k)

MEMORY 2 1&2 2100 5% (2.10 k)

SET 1&2 4490 5% (4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable. (2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-

bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel. (3) Disconnect the memory switch wire harness

connector from the memory switch. (4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel. (5) Remove the memory switch.

INSTALLATION

(1) Position the memory switch and install and

tighten the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel. Tighten the screws to 2.2 N´m (20

in. lbs.). (2) Reconnect the memory switch wire harness

connector to the memory switch. (3) Install the trim panel switch bezel onto the

driver side front door. (4) Reconnect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

Vehicles equipped with a passenger side power seat

utilize a four-way power seat switch. This four-way

power seat switch features two knobs ganged

together on the outboard seat cushion side shield. The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield. The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

RS POWER SEAT SYSTEM8Ns-13

MEMORY SET SWITCH (Continued)

Page 652 of 2585

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield. (2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.). (3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle. (4) Position the outboard seat cushion side shield

onto the seat cushion frame (5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.). (6) Install the switch knobs on the switch control

levers, if equipped. (7) Reconnect the battery negative cable.

DRIVER POWER SEAT TRACK

DESCRIPTION

The eight-way driver side power seat option

includes a electrically operated power seat track

located under the driver side front seat. The front

power seat track on the driver side of the vehicle also

provides the mounting location for the Memory Seat/

Mirror Module (MSMM). The power seat circuit

breakers are mounted on the rear of the driver side

power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

pan to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit. The power seat track unit includes four reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the four power seat

track motors used on models equipped with the

optional memory system incorporates a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position. This

enables the memory system to function by referenc-

ing the motor positions programmed into the memory

seat/mirror module. The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

The forth motor is the recliner adjustment motor,

which moves the seat back in the forward and rear-

ward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any component

in this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When the driver side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction. No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the driver side power seat switch to move

all three power seat track adjusters in each direction.

The power seat track adjusters should move in each

of the selected directions. If a power seat track

adjuster fails to operate in only one direction, move

the adjuster a short distance in the opposite direction

RS POWER SEAT SYSTEM8Ns-15

PASSENGER SEAT SWITCH (Continued)

Page 658 of 2585

(2) Turn the ignition key to the ON position. Exit

vehicle with the scan tool.

(3) After checking that no one is inside the vehicle,

connect the battery negative remote terminal.

(4) Read and record theACTIVEDiagnostic Trou-

ble Code (DTC) data.

(5) Read and record anySTOREDDTC's.

(6) Refer to the proper Body Diagnostic Procedures

manual if any DTC's are found in Step 4 and Step 5.

(7) If the airbag warning lamp either fails to light,

or goes ON and stays ON, there is a system malfunc-

tion. To test the airbag warning lamp (bulb) opera-

tion in the cluster, refer to Electrical, Instrument

Cluster, Diagnosis and Testing - Instrument Cluster.

Refer to the proper Body Diagnostic Procedures man-

ual for any other system problems.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

AIRBAGS

DEPLOYED AIRBAG

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a by-product of

airbag deployment. Sodium hydroxide powder can

irritate the skin, eyes, nose and throat. Wear safety

glasses, rubber gloves, and long sleeved clothing

when cleaning any of the powder residue from the

vehicle.

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you

experience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

UNDEPLOYED AIRBAG

The airbags must be stored in its original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag module. When carrying or han-

dling an undeployed airbag module, the trim side of

the airbag should be pointing away from the body to

minimize possibility of injury if accidental deploy-

ment occurs. Do not place undeployed airbag face

down on a solid surface, the airbag will propel into

the air if accidental deployment occurs.

STANDARD PROCEDURE - SERVICE AFTER AN

AIRBAG DEPLOYMENT

DRIVER AIRBAG

After a Driver Airbag has been deployed due to a

collision, the followingMUSTbe replaced:

²Driver Airbag²Clock Spring Assembly

²Steering Wheel

²Complete Steering Column Assembly w/Lower

Steering Column Coupler

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

PASSENGER AIRBAG

After a Passenger Airbag has been deployed due to

a collision. the followingMUSTbe replaced:

²Passenger Airbag

²Instrument Panel and Pad Assembly

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

SEAT AIRBAG

After a Seat Airbag has been deployed due to a col-

lision. the followingMUSTbe replaced:

²Complete Seat Back Assembly

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

SEAT BELTS AND TENSIONERS

After a frontal impact where an airbag has been

deployed due to a collision. the followingMUSTbe

replaced:

²Front Seat Belt Buckle (driver and passenger)

with integral Tensioners.

All other seat belts should be closely inspected for

cuts, tears, fraying, or damage in any way following

any frontal impact or airbag deployment. The other

seat belts are to be replaced when visible damage is

incurred. Inspect the Lower Anchors and Tether for

CHildren (LATCH) child restraint anchors for dam-

age after an impact event and replace as needed.

CLEAN UP PROCEDURE

Roll or fold the airbag towards its mounting point

(i.e. instrument panel, steering wheel, or seat back).

Then tape the ripped cover over the deployed airbag

if applicable.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well (Fig.

1). If the heater or air conditioner was in RECIRC

mode at time of airbag deployment, operate blower

motor on low speed and vacuum powder residue

expelled from the heater and A/C outlets. Multiple

RSRESTRAINTS8O-3

RESTRAINTS (Continued)

Page 659 of 2585

vacuum cleaning may be necessary to decontaminate

the interior of the vehicle.

CHILD RESTRAINT ANCHOR

DESCRIPTION

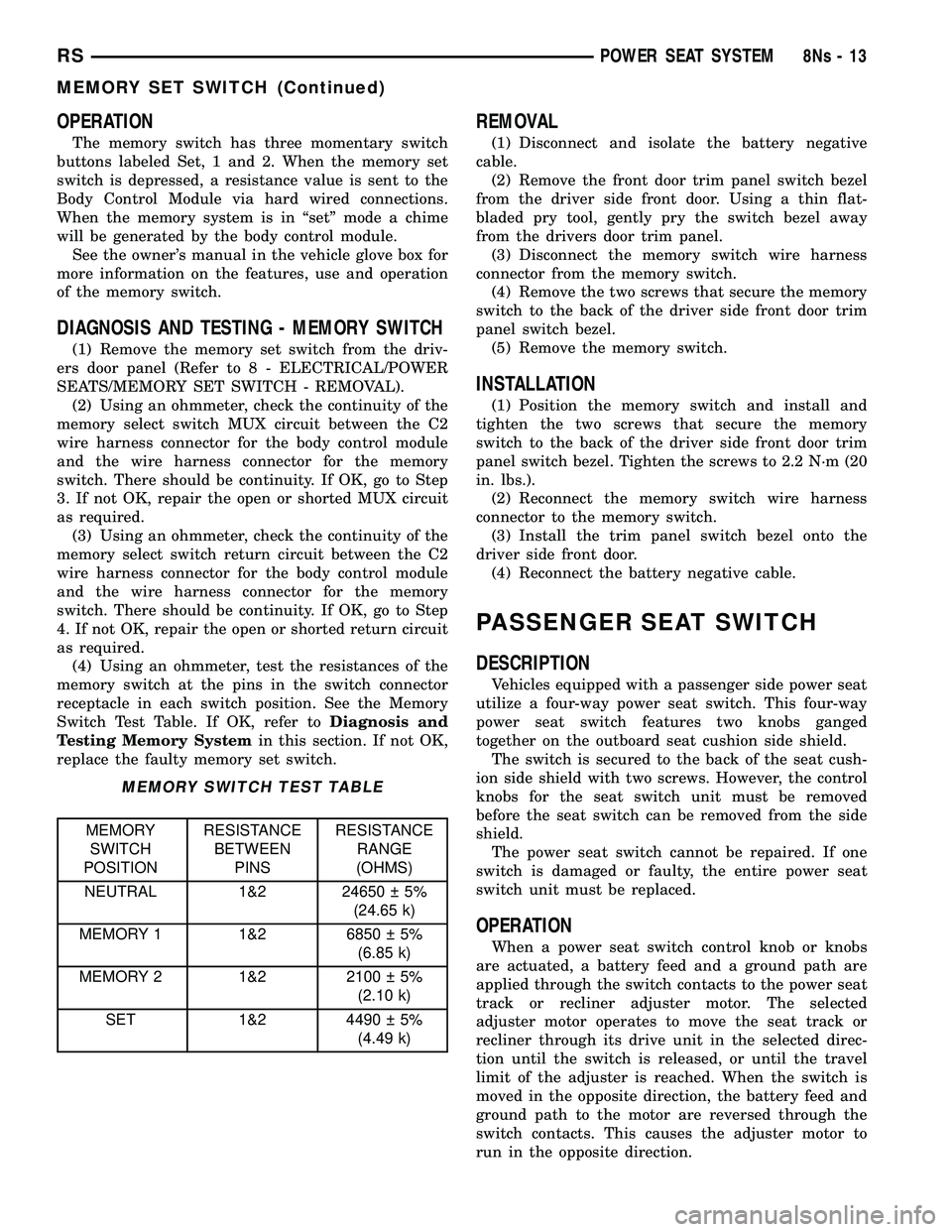

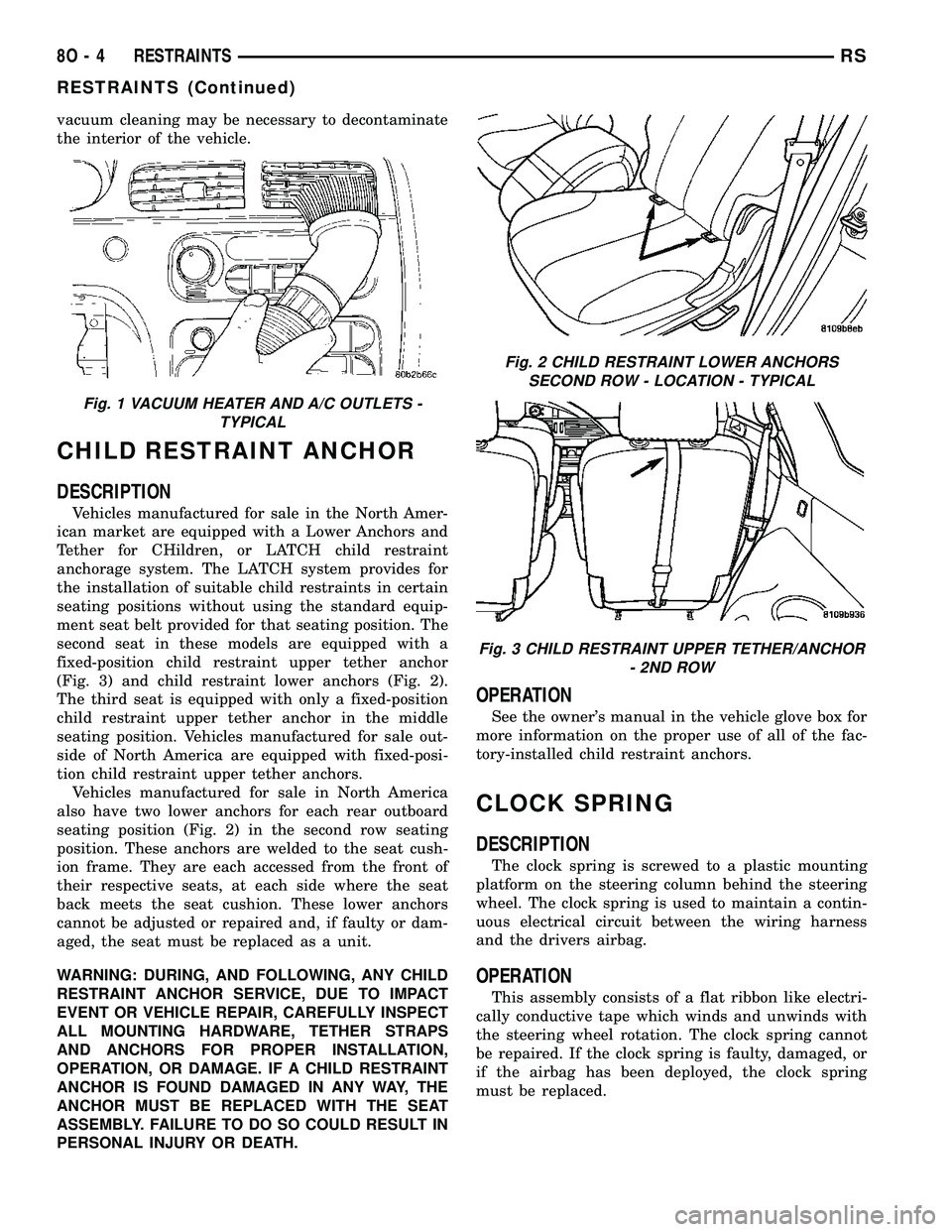

Vehicles manufactured for sale in the North Amer-

ican market are equipped with a Lower Anchors and

Tether for CHildren, or LATCH child restraint

anchorage system. The LATCH system provides for

the installation of suitable child restraints in certain

seating positions without using the standard equip-

ment seat belt provided for that seating position. The

second seat in these models are equipped with a

fixed-position child restraint upper tether anchor

(Fig. 3) and child restraint lower anchors (Fig. 2).

The third seat is equipped with only a fixed-position

child restraint upper tether anchor in the middle

seating position. Vehicles manufactured for sale out-

side of North America are equipped with fixed-posi-

tion child restraint upper tether anchors.

Vehicles manufactured for sale in North America

also have two lower anchors for each rear outboard

seating position (Fig. 2) in the second row seating

position. These anchors are welded to the seat cush-

ion frame. They are each accessed from the front of

their respective seats, at each side where the seat

back meets the seat cushion. These lower anchors

cannot be adjusted or repaired and, if faulty or dam-

aged, the seat must be replaced as a unit.

WARNING: DURING, AND FOLLOWING, ANY CHILD

RESTRAINT ANCHOR SERVICE, DUE TO IMPACT

EVENT OR VEHICLE REPAIR, CAREFULLY INSPECT

ALL MOUNTING HARDWARE, TETHER STRAPS

AND ANCHORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. IF A CHILD RESTRAINT

ANCHOR IS FOUND DAMAGED IN ANY WAY, THE

ANCHOR MUST BE REPLACED WITH THE SEAT

ASSEMBLY. FAILURE TO DO SO COULD RESULT IN

PERSONAL INJURY OR DEATH.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the proper use of all of the fac-

tory-installed child restraint anchors.

CLOCK SPRING

DESCRIPTION

The clock spring is screwed to a plastic mounting

platform on the steering column behind the steering

wheel. The clock spring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the drivers airbag.

OPERATION

This assembly consists of a flat ribbon like electri-

cally conductive tape which winds and unwinds with

the steering wheel rotation. The clock spring cannot

be repaired. If the clock spring is faulty, damaged, or

if the airbag has been deployed, the clock spring

must be replaced.

Fig. 1 VACUUM HEATER AND A/C OUTLETS -

TYPICAL

Fig. 2 CHILD RESTRAINT LOWER ANCHORS

SECOND ROW - LOCATION - TYPICAL

Fig. 3 CHILD RESTRAINT UPPER TETHER/ANCHOR

- 2ND ROW

8O - 4 RESTRAINTSRS

RESTRAINTS (Continued)

Page 675 of 2585

NOTE: Turning the system off by depressing the

OFF switch or turning off the ignition switch will

erase the set speed stored in the PCM.

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral

²A rapid increase rpm (indicates that the clutch

has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The speed signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is greater than 20 mph over

the set speed.

²Autostick shifts into 1st or 2nd gear (autostick,

if equipped)

Once the speed control has been disengaged,

depressing the RESUME switch when speed is

greater than 20 mph allows the vehicle to resume

control to the target speed that was stored in the

PCM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the ACCEL

switch. The new target speed is stored in the PCM

when the ACCEL switch is released. The PCM also

has a9tap-up9feature in which target speed

increases by 2 mph for each momentary switch acti-

vation of the ACCEL switch. The PCM also provides

a means to decelerate to a new lower target speed

without disengaging speed control. Depress and hold

the COAST switch until the desired speed is reached,

then release the switch.

The PCM also has a ªTap Downº feature in which

target speed decreases at 1 mph for each momentary

switch activation of the coast switch.

OPERATION - INTERACTIVE SPEED CONTROL

(4 Speed EATX Only)

Interactive means that communication between the

PCM and the TCM is taking place, this communica-

tion is internal to the PCM on NGC vehicles. Inter-

active speed control avoids unnecessary shifting for

smoother, quieter operation and when downshifts are

required, makes the shifts smoother.

CLIMBING A GRADE

DESCRIPTION

When climbing a grade the interactive speed con-

trol tries to maintain the set speed by increasing the

throttle opening, while inhibiting/delaying down-

shifts.

OPERATION

If opening the throttle alone cannot maintain the

set speed and the vehicle speed drops more than

three mph below the set speed, the transmission will

downshift to third gear. If the vehicle continues to

lose speed, by more than 6 mph, the transmission

will downshift again to maintain the set speed. After

the vehicle encounters a less-steep grade, or has

crested the grade (reduced the load on the power-

train) and can maintain the set speed at a reduced

throttle position, the transmission will upshift, as

appropriate, until the set speed can be maintained in

Overdrive.

GRADE HUNTING

DESCRIPTION

All vehicles equipped with a four speed automatic

transmission have a grade hunting feature for the

2nd to 3rd gear upshift and the 3rd to Overdrive

upshift.

OPERATION

The TCM (on SBEC vehicles) (PCM on NGC vehi-

cles) identifies the powertrain loading conditions and

selects the proper gear to maintain the current vehi-

cle speed. Under moderate loading conditions the

transaxle will stay in 3rd gear until the top of the

grade is reached or the powertrain loading is

reduced.

If powertrain loading is severe, the transaxle may

shift into 2nd gear and remain there until power-

train loading is reduced, then a 2nd to 3rd gear

upshift will be scheduled. Grade hunting features

always operate regardless of whether or not the

interactive speed control is engaged.If the interac-

tive speed control is not engaged and power-

train loading is not reduced, the driver may

have to completely lift off of the throttle before

an upshift will occur. If the driver does lift off the

throttle to induce an upshift under these conditions,

vehicle speed will reduce and the Overdrive to 3rd

and 3rd to 2nd gear downshifts will reoccur when the

throttle is reapplied. If grade hunting is repeatedly

induced by the driver, transaxle damage may result.

8P - 2 SPEED CONTROLRS

SPEED CONTROL (Continued)

Page 685 of 2585

(6) Rotate the SKREEM upwards and then to the

side away from the steering column to slide the

SKREEM antenna ring from around the ignition

switch lock cylinder housing.

(7) Remove the SKREEM from the vehicle.

INSTALLATION

(1) Slip the Sentry Key Remote Entry Module

(SKREEM) antenna ring around the ignition switch

lock cylinder housing. Rotate the SKREEM down-

wards and then towards the steering column.

(2) Install the one screws securing the SKREEM to

the steering column.

(3) Connect the steering column wire harness to

the SKREEM.

(4) Install the steering column upper and lower

shrouds (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - INSTALLATION) and (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(5) Install the Steering Column Opening Cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

(6) Connect the battery negative cable.

TRANSPONDER KEY

DESCRIPTION

The Sentry Key Remote Entry System (SKREES)

uses a transponder chip that is integral to each igni-

tion key to communicate with the Sentry Key Remote

Entry Module (SKREEM). Ignition keys are supplied

with the vehicle when it is shipped from the factory.

The transponder chip is undermolded within the

head of the key.

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the Sentry Key Remote

Entry Module (SKREEM) has a unique9Secret Key9

code programmed into it by the manufacturer as

well. When a Sentry Key is programmed into the

memory of the SKREEM, the SKREEM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKREEM. Once the Sentry Key learns the

9Secret Key9code of the SKREEM, it is also perma-

nently programmed into the transponder's memory.

Therefore, blank keys for the Sentry Key Remote

Entry System (SKREES) must be programmed by

the SKREEM in addition to being cut to match the

mechanical coding of the ignition lock cylinder. Refer

to Electrical, Vehicle Theft Security, TransponderKey, Standard Procedure - Transponder Program-

ming.

The Sentry Key's transponder is within the range

of the SKREEM's transceiver antenna ring when it is

inserted into the ignition lock cylinder. When the

ignition switch is turned to the ON position, the

SKREEM communicates with the Sentry Key via a

radio frequency (RF) signal. The SKREEM deter-

mines if a valid key is present based on the informa-

tion it receives from the Sentry Key. If a valid key is

detected, that fact is communicated to the PCM via

the PCI bus and the vehicle is allowed to continue

running. If an invalid key is received by the PCM or

no status at all is communicated, the vehicle will

stall after two (2) seconds of running. The indicator

light will be flashing at this point. The Sentry Key's

transponder can not be repaired. If it is faulty or

damaged, it must be replaced.

Common communication problems:

²Two transponder keys too close together.

²Speed Pass too close to transponder key.

Solid indicator that there is a system failure.

²Loss of PCM communication.

²Failed antenna circuit.

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING

USING A DRBIIITSCAN TOOL

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Remote

Entry System (SKREES) when it is shipped from the

factory. The Sentry Key Remote Entry Module

(SKREEM) can be programmed to recognize up to a

total of eight Sentry Keys. When programming a

blank Sentry Key transponder, the key must first be

cut to match the ignition lock cylinder of the vehicle

for which it will be used. The vehicle's four digit PIN

code will be required to complete this task since you

will need it to enter the Secured Access Mode in the

SKREEM. The following steps must be completed

using a DRBIIItscan tool:

(1) Insert the blank key into the ignition and turn

it to the RUN position.

(2) Using a DRBIIItscan tool, select9Theft

Alarm,99SKREEM,99Miscellaneous,9and then9Pro-

gram New Key.9

(3) Enter the four digit PIN code using the

DRBIIItscan tool. When programming is completed,

the SKREEM will exit Secured Access Mode and the

DRBIIItscan tool will display the results of your

attempt to program the key. One of five distinct

results may be displayed. All five are listed below:

²(Programming Successful(is displayed if the

Sentry Key programming is successful.

8Q - 6 VEHICLE THEFT SECURITYRS

SENTRY KEY REMOTE ENTRY MODULE (Continued)

Page 686 of 2585

²(Learned Key in Ignition(is displayed if the

key in the ignition has already been programmed

into that vehicle's SKREEM.

²(Eight Keys Already Learned (At The Maxi-

mum) Programming Not Done(is displayed if

eight keys have already been programmed into the

SKREEM. In this case, if a new key needs to be

added due to a lost or defective key, the9Erase All

Keys9command (which requires entering the Secured

Access Mode) has to be performed. Following the

9Erase All Keys9command, all keys that will be used

to operate the vehicleMUSTbe reprogrammed to

the SKREEM.

²(Programming Not Attempted(is displayed

after an9Erase All Keys9function is executed.

²(Programming Key Failed(is displayed if fur-

ther diagnosis is required.

To learn additional keys, turn the ignition OFF,

remove the learned key, insert the next new blank

key, and repeat the steps from the beginning.

ªCUSTOMER LEARNº MODE

This feature is only available on domestic vehicles

or those which have a U.S. country code designator.

This procedure requires access to at least two valid

Sentry Keys. If two valid Sentry Keys are not avail-

able, Sentry Key programming will require the use of

a DRBIIItscan tool.

The steps required to program Sentry Keys with

two valid Sentry Keys follows:

(1) Obtain the blank Sentry Key(s) that need to be

programmed. Cut the keys to match the ignition lock

cylinder mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

ON position.

(3) After the ignition switch has been in the ON

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

the OFF position. Replace the first valid Sentry Key

in the ignition lock cylinder with the second valid

Sentry Key and turn the ignition switch back to the

ON position. The second valid Sentry Key must be

inserted within 15 seconds of removing the first valid

Sentry key.

(4) About ten seconds after the completion of Step

3, the indicator light will start to flash and a single

audible chime tone will sound to indicate that the

system has entered the9Customer Learn9program-

ming mode.

(5) Within sixty seconds of entering the9Customer

Learn9programming mode, turn the ignition switch

to the OFF position, replace the valid Sentry Key

with a blank Sentry Key transponder, and turn the

ignition switch back to the ON position.(6) About ten seconds after the completion of Step

5, a single audible chime tone will sound and the

indicator light will stop flashing and stay on solid for

three seconds and then turn off to indicate that the

blank Sentry Key has been successfully programmed.

The SKREES will immediately exit the9Customer

Learn9programming mode and the vehicle may be

started using the newly programmed Sentry Key.

NOTE: The Remote Keyless Entry (RKE) Transmitter

will also be programmed during this procedure.

These steps must be completed in their entirety for

each additional Sentry Key to be programmed. If any

of the above steps are not completed in the given

sequence, or within the allotted time, the SKREES

will exit the9Customer Learn9programming mode

and the programming will be unsuccessful. The

SKREES will also automatically exit the9Customer

Learn9programming mode if:

²It sees a non-blank Sentry Key when it should

see a blank.

²If it has already programmed four (4) valid Sen-

try Keys.

²If the ignition switch is turned to the OFF posi-

tion for more than about fifty (50) seconds.

NOTE: If you attempt to start the vehicle while in

ªCustomer Learnº mode (LED flashing), the vehicle

will behave as though an invalid key is being used

(i.e. the engine will stall after two (2) seconds of

running). No faults will be logged.

NOTE: Once a Sentry Key has been programmed to

a particular vehicle, it cannot be used on any other

vehicle.

VTSS/SKIS INDICATOR LAMP

DESCRIPTION

The Sentry Key Remote Entry System (SKREES)

uses an indicator light to convey information on the

status of the system to the customer. This light is

shared with the Vehicle Theft Security System

(VTSS). The light is located in the Mechanical

Instrument Cluster (MIC). The VTSS status is con-

trolled by the Body Control Module (BCM), via Pro-

grammable Communication Interface (PCI) data bus

communication with the MIC, based upon messages

it receives from the Sentry Key Remote Entry Mod-

ule (SKREEM) on the PCI data bus.

RSVEHICLE THEFT SECURITY8Q-7

TRANSPONDER KEY (Continued)