ECO mode CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 687 of 2585

OPERATION

The Mechanical Instrument Cluster (MIC) per-

forms a four second bulb check via PCI communica-

tion with the Sentry Key Remote Entry Module

(SKREEM). After the bulb check, the lamp is con-

trolled according to SKREEM messages. Then, the

SKREEM sends messages to the BCM to operate the

light based upon the results of the Sentry Key

Remote Entry System (SKREES) self tests. The light

may be actuated in two possible ways, flashing or on

solid. If the light comes on and stays on solid after a

power-up test, this indicates that the SKREEM has

detected a system malfunction. If the SKREEM

detects an invalid key when the ignition switch is

moved to the ON position, it sends a message on thePCI bus to the MIC, to flash the light. The SKREEM

can also send a message to flash the light and gen-

erate a single audible chime at the same time. These

two events occurring simultaneously indicate that

the SKIS has been placed into the9Customer Learn9

mode (Refer to 8 - ELECTRICAL/VEHICLE THEFT

SECURITY/TRANSPONDER KEY - STANDARD

PROCEDURE). If the light comes on and stays on

after the power-up test, diagnosis of the SKREES

should be performed using a DRBIIItscan tool and

the appropriate Body Diagnostic Procedures informa-

tion. The light is a Light Emitting Diode (LED) and

is not a serviceable component.

8Q - 8 VEHICLE THEFT SECURITYRS

VTSS/SKIS INDICATOR LAMP (Continued)

Page 689 of 2585

brushes inside the motor. The current flow is con-

trolled by the multi-function switch. The high speed/

low speed relays are located in the IPM. The speed

sensitive intermittent wiper is controlled by the Body

Control Module (BCM). The intermittent mode, with

the vehicle traveling greater than 10.4 mph, has a

range of 0.5 to 18 seconds. With the vehicle traveling

less than 10.4 mph, the time delay doubles to a

range of 1 to 36 seconds. The wiper arms will park at

the base of the windshield just above the cowl cover

after the wiper switch is turned OFF.

The windshield wiper motor and linkage is located

in an integral wiper unit at the rear of the engine

compartment. The wiper unit must be removed to

gain access to the wiper motor.

REAR WIPER/WASHER SYSTEM

When rear wiper operation is required, the BCM

will provide ignition ON voltage to the rear wiper

motor (Export and ATC equipped vehicles only).

When the wiper switch is turned OFF, the BCM pro-

vides circuit ground to operate the motor until the

wipe cycle is complete and the wiper arm returns to

the base of the rear window.

Switch only offers an intermittent rear wiper

mode. The wiper motor will cycle every 7 seconds.

The intermittent delay time is also adjusted based

upon vehicle speed. With the vehicle traveling

greater than 50 mph, the cycle changes to every 5

seconds.

When rear washer is requested by depressing and

holding down the switch, the BCM then provides a

ground for the rear washer motor. Until the switch is

released, the motor will be in a continuous wipe

mode, then return to an intermittent wipe mode.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT WIPER

SYSTEM

The windshield wiper system operates in several

modes:

²Low and high speed normal wipe

²Speed sensitive intermittent wipe

²Wipe after wash

²Park (switch OFF)

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. DTC's can

be retrieved using a DRB IIItscan tool. Refer to the

proper Body Diagnostic Procedures manual for DTC

descriptions and retrieval information.The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the Wiper System Diagnosis

table.

DIAGNOSIS AND TESTING - FRONT

WIPER/WASHER SWITCH

(1) Remove the multi-function switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - REMOVAL).

(2) Using an ohmmeter check resistance readings

between switch pins. Refer to the WIPER/WASHER

SWITCH RESISTANCE table.

WIPER/WASHER SWITCH RESISTANCE

SWITCH POSITION RESISTANCE BETWEEN

OFF 1 AND 2 = 23.9KV 5%

DELAY POSITION

1ST 1 AND 2 = 7.9KV 5%

2ND 1 AND 2 = 4.6KV 5%

3RD 1 AND 2 = 2.9KV 5%

4TH 1 AND 2 = 1.9KV 5%

5TH 1 AND 2 = 1.3KV 5%

LOW 1 AND 2 = 670V 5%

HIGH 1 AND2=240V 5%

WASH 1 AND 4 = 5.9KV 5%

DIAGNOSIS AND TESTING - FAILED PARK

SWITCH

If the wiper park switch has failed, the windshield

wipers will operate as follows:

²SWITCH OFF- Wipers stop in current location

regardless of the park signal.

²INTERMITTENT MODE- Wipers operate con-

tinuously or at low speed for one or more extra

wipes.

²LOW SPEED- Wipers operate at low speed.

²HIGH SPEED- Wipers operate at high speed.

²WIPE AFTER WASH- Wipers operate at low

speed in any mode setting. Wipers operate only while

the wash button is depressed with switch in the OFF

mode and wipers stop in mid-cycle when button is

released.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the WIPER SYSTEM DIAGNO-

SIS table.

8R - 2 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

Page 698 of 2585

REAR WIPER MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear wiper arm. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/REAR WIPER ARM -

REMOVAL) in this section.

(3) Open liftgate.

(4) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(5) Disconnect wire connector from rear wiper

motor.

(6) Remove screws holding rear wiper motor to lift-

gate (Fig. 3).

(7) Remove wiper motor from liftgate.

INSTALLATION

(1) Position the wiper motor in the liftgate.

(2) Install the retaining screws.

(3) Connect the wire harness connector.

(4) Install the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

(5) Connect wire connector to rear wiper motor.

(6) Install the screws holding rear wiper motor to

liftgate (Fig. 3).

(7) Install the wiper motor to the liftgate (Fig. 3).

(8) Close the liftgate.

(9) Install the wiper arm. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/REAR WIPER ARM -

INSTALLATION) in this section.

(10) Connect the battery negative cable.

REAR WIPER/WASHER

SWITCH

DESCRIPTION

On Automatic Temperature Control (ATC) vehicles

only, the rear window wiper/washer switches are

located on the center bezel with the hazard and

heated seat switches (Fig. 4). They are not service-

able separately from the hazard and heated seat

switches. If defective, the entire switch assembly

must be replaced.

On Manual Temperature Control (MTC) vehicles

only, the rear window wiper/washer switch is located

on the HVAC control head (Fig. 5) attached to the

center bezel. They are not serviceable separately

from the control head. If found faulty, the entire

MTC head must be replaced.

OPERATION

When rear wiper operation is required, the BCM

will provide ignition ON voltage to the rear wiper

motor. When the wiper switch is turned OFF, the

BCM provides circuit ground to operate the motor

until the wipe cycle is complete and the wiper arm

returns to the base of the rear window.

The rear wiper/washer switch only offers an inter-

mittent rear wiper mode. The wiper motor will cycle

every 7 seconds. The intermittent delay time is also

adjusted based upon vehicle speed. With the vehicle

traveling greater than 50 mph, the cycle changes to

every 5 seconds.

Fig. 3 REAR WINDOW WIPER MOTOR

1 - REAR WINDOW

2 - REAR WIPER MOTOR

3 - CHMSL

4 - WELL NUTS

Fig. 4 INSTRUMENT PANEL CENTER BEZEL

1 - TRIM BEZEL

2 - IN CAR TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

RSWIPERS/WASHERS8R-11

Page 711 of 2585

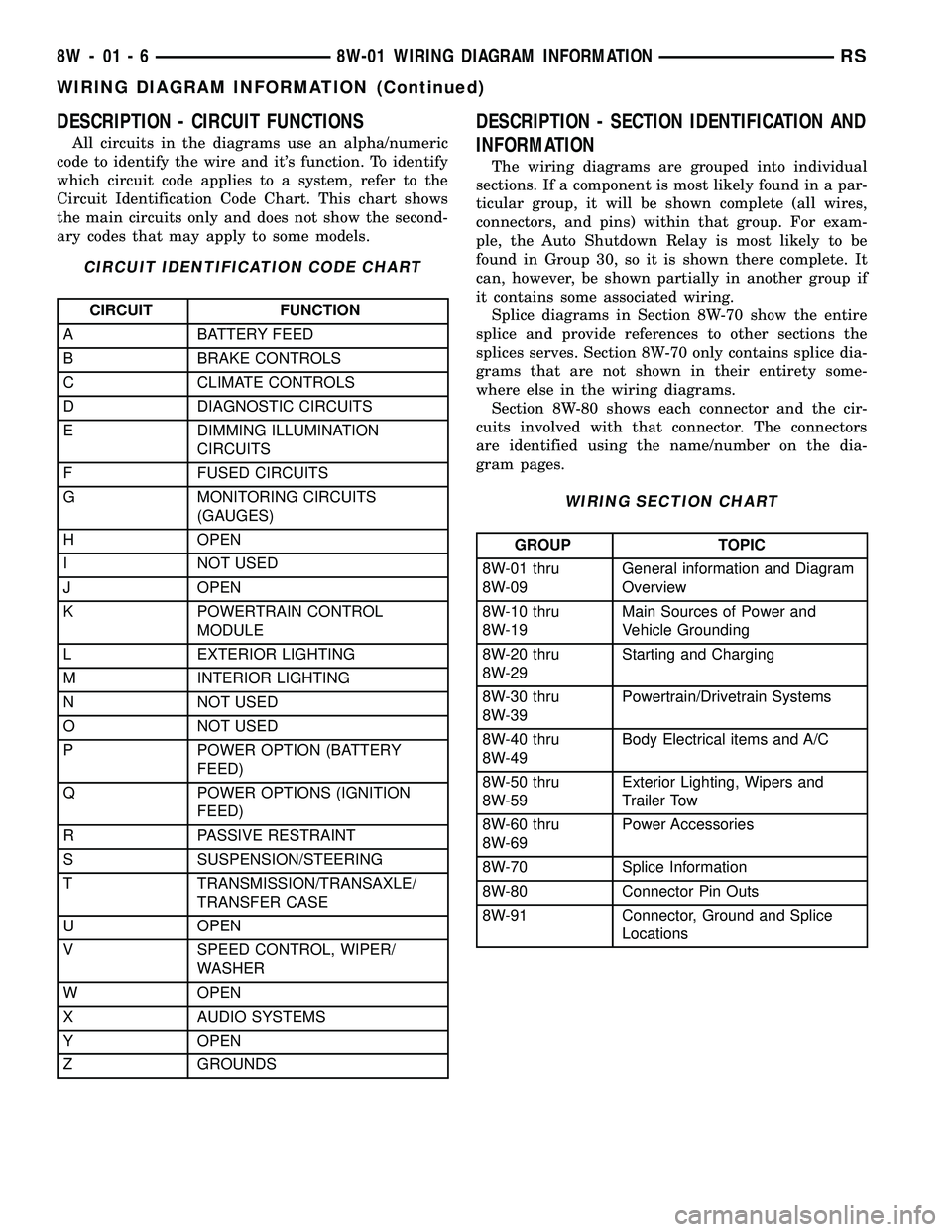

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONRS

WIRING DIAGRAM INFORMATION (Continued)

Page 1294 of 2585

INSTALLATION

(1) Snap the left side of the Integrated Power Mod-

ule (IPM) housing in its mounting bracket and con-

nect the various electrical connectors. Care must be

taken that the Connector Positive Assurance (CPA)

on the five-pin B+ connector is positively engaged to

prevent generating a Diagnostic Trouble Code (DTC).

NOTE: IPM electrical connectors are color coded to

ease location reference.

(2) Being certain no wires are stressed or pinched,

rotate the IPM clock-wise until secured in mounting

bracket. An audible click may be heard.

(3) Install the battery in the vehicle. Refer to the

Battery section for the procedure.

(4) Install the battery thermal guard in the vehi-

cle. Refer to the Battery section for the procedure.

(5)

Connect the negative and positive battery cables.

(6) Using a diagnostic scan tool, check for any

stored diagnostic trouble codes and correct, check

that all vehicle options are operational before return-

ing the vehicle to service.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) whenthe vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IPM has a molded plastic cover that can be

removed to provide service access to all of the fuses

and relays in the IPM. An integral latch and hinges

are molded into the IPM cover for easy removal. A

fuse layout map is integral to the underside of the

IPM cover to ensure proper fuse and relay identifica-

tion. The IOD fuse is a 20 ampere blade-type mini

fuse and, when removed, it is stored in a fuse cavity

adjacent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw identifies a normal condi-

tion where power is being drained from the battery with

the ignition switch in the Off position. The IOD fuse

feeds the memory and sleep mode functions for some of

the electronic modules in the vehicle as well as various

other accessories that require battery current when the

ignition switch is in the Off position, including the

clock. The only reason the IOD fuse is removed is to

reduce the normal IOD of the vehicle electrical system

during new vehicle transportation and pre-delivery stor-

age to reduce battery depletion, while still allowing

vehicle operation so that the vehicle can be loaded,

unloaded and moved as needed by both vehicle trans-

portation company and dealer personnel.

The IOD fuse is removed from the IPM fuse cavity

when the vehicle is shipped from the assembly plant.

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation. Once the

vehicle is prepared for delivery, the IOD function of

this fuse becomes transparent and the fuse that has

been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

Battery Systemfor additional service information.

Fig. 3 DISCONNECTING IPM

1 - INTEGRATED POWER MODULE FUSE & RELAY CENTER

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1525 of 2585

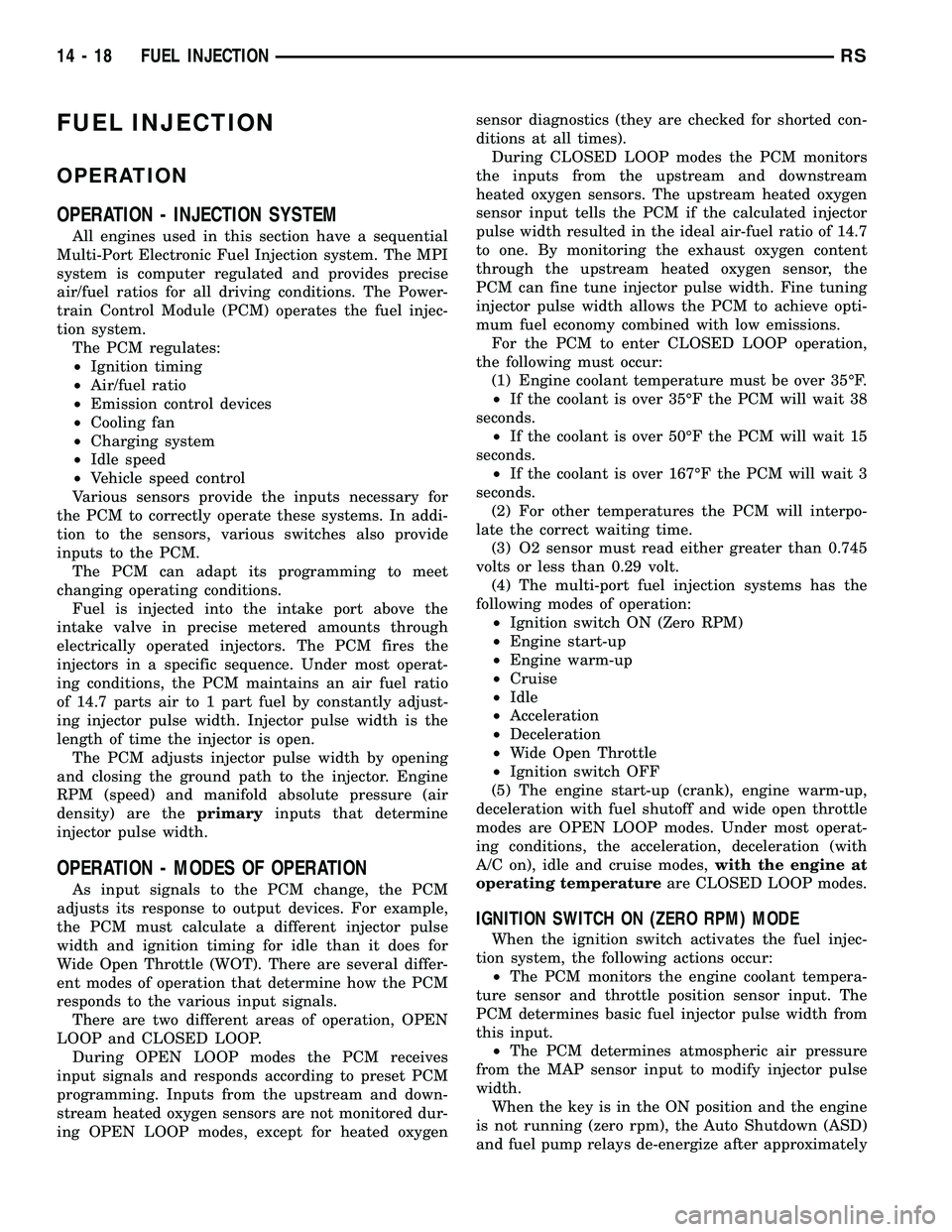

FUEL INJECTION

OPERATION

OPERATION - INJECTION SYSTEM

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

The PCM can adapt its programming to meet

changing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are theprimaryinputs that determine

injector pulse width.

OPERATION - MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygensensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35ÉF the PCM will wait 38

seconds.

²If the coolant is over 50ÉF the PCM will wait 15

seconds.

²If the coolant is over 167ÉF the PCM will wait 3

seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.29 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

14 - 18 FUEL INJECTIONRS

Page 1526 of 2585

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

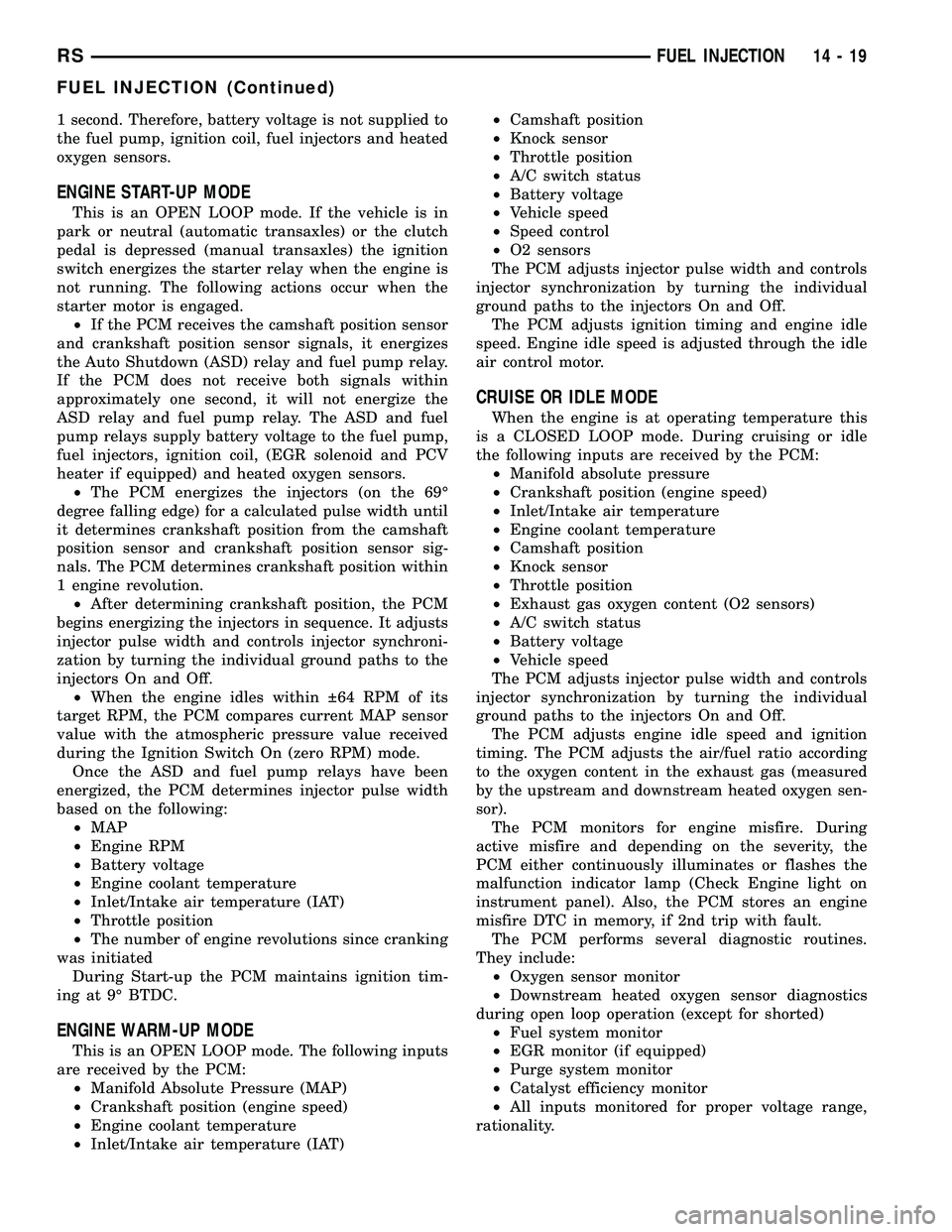

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay when the engine is

not running. The following actions occur when the

starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, (EGR solenoid and PCV

heater if equipped) and heated oxygen sensors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within 64 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²MAP

²Engine RPM

²Battery voltage

²Engine coolant temperature

²Inlet/Intake air temperature (IAT)

²Throttle position

²The number of engine revolutions since cranking

was initiated

During Start-up the PCM maintains ignition tim-

ing at 9É BTDC.

ENGINE WARM-UP MODE

This is an OPEN LOOP mode. The following inputs

are received by the PCM:

²Manifold Absolute Pressure (MAP)

²Crankshaft position (engine speed)

²Engine coolant temperature

²Inlet/Intake air temperature (IAT)²Camshaft position

²Knock sensor

²Throttle position

²A/C switch status

²Battery voltage

²Vehicle speed

²Speed control

²O2 sensors

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising or idle

the following inputs are received by the PCM:

²Manifold absolute pressure

²Crankshaft position (engine speed)

²Inlet/Intake air temperature

²Engine coolant temperature

²Camshaft position

²Knock sensor

²Throttle position

²Exhaust gas oxygen content (O2 sensors)

²A/C switch status

²Battery voltage

²Vehicle speed

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas (measured

by the upstream and downstream heated oxygen sen-

sor).

The PCM monitors for engine misfire. During

active misfire and depending on the severity, the

PCM either continuously illuminates or flashes the

malfunction indicator lamp (Check Engine light on

instrument panel). Also, the PCM stores an engine

misfire DTC in memory, if 2nd trip with fault.

The PCM performs several diagnostic routines.

They include:

²Oxygen sensor monitor

²Downstream heated oxygen sensor diagnostics

during open loop operation (except for shorted)

²Fuel system monitor

²EGR monitor (if equipped)

²Purge system monitor

²Catalyst efficiency monitor

²All inputs monitored for proper voltage range,

rationality.

RSFUEL INJECTION14-19

FUEL INJECTION (Continued)

Page 1527 of 2585

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory, after 2

trips.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C status

²Battery voltage

²Battery temperature or Calculated Battery Tem-

perature

²Engine coolant temperature

²Engine run time

²Inlet/Intake air temperature

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

²Wide Open Throttle-open loop

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C status

²Battery voltage

²Inlet/Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position sensor

²IAC motor (solenoid) control changes in response

to MAP sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration (Open Loop). In response, the

PCM may momentarily turn off the injectors. This

helps improve fuel economy, emissions and engine

braking.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are used by

the PCM:

²Inlet/Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system and disables

EGR (if equipped).

The PCM adjusts injector pulse width to supply a

predetermined amount of additional fuel, based on

MAP and RPM.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

FUEL CORRECTION or ADAPTIVE MEMORIES

DESCRIPTION

In Open Loop, the PCM changes pulse width with-

out feedback from the O2 Sensors. Once the engine

warms up to approximately 30 to 35É F, the PCM

goes into closed loopShort Term Correctionand

utilizes feedback from the O2 Sensors. Closed loop

Long Term Adaptive Memoryis maintained above

170É to 190É F unless the PCM senses wide open

throttle. At that time the PCM returns to Open Loop

operation.

OPERATION

Short Term

The first fuel correction program that begins func-

tioning is the short term fuel correction. This system

corrects fuel delivery in direct proportion to the read-

ings from the Upstream O2 Sensor.

The PCM monitors the air/fuel ratio by using the

input voltage from the O2 Sensor. When the voltage

reaches its preset high or low limit, the PCM begins

to add or remove fuel until the sensor reaches its

switch point. The short term corrections then begin.

The PCM makes a series of quick changes in the

injector pulse-width until the O2 Sensor reaches its

14 - 20 FUEL INJECTIONRS

FUEL INJECTION (Continued)

Page 1672 of 2585

(10)2.4L Gas equipped models goto Step 15.

2.5L TD models:Remove battery thermal shield

(Fig. 138).

(11) Remove battery hold down nut, clamp, and

battery (Fig. 139).(12) Remove battery tray (Fig. 140). Disconnect

battery temperature sensor.

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 141).

Fig. 138 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 139 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 140 Battery Tray

1 - BATTERY TRAY

Fig. 141 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

RST850 MANUAL TRANSAXLE21-75

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 1673 of 2585

(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 142).

(16) Remove crossover cable retainer clip and dis-

engage cable from mount bracket (Fig. 142).

(17) Raise vehicle on hoist.

(18) Remove crossover cable from engine compart-

ment, then remove cable from passenger compart-

ment through opening in floor pan.

INSTALLATION

(1) From underneath vehicle, install gearshift

crossover cable into passenger compartment through

floor pan hole. Install remainder of cable into posi-

tion in engine compartment.

(2) Lower vehicle.

(3) Install crossover cable to mount bracket and

secure with retainer clip (Fig. 143).

(4) Install cable to transaxle crossover lever (Fig.

143).

(5)2.4L Gas models goto Step 10. 2.5L TD

Models:Install coolant recovery bottle bracket (Fig.

144).

Fig. 142 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 143 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 144 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

21 - 76 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - CROSSOVER (Continued)