service CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1845 of 2585

OPERATION

The relay is supplied fused B+ voltage, energized

by the PCM/TCM, and is used to supply power to the

solenoid pack when the transmission is in normal

operating mode. When the relay is ªoffº, no power is

supplied to the solenoid pack and the transmission is

in ªlimp-inº mode. After a controller reset (ignition

key turned to the ªrunº position or after cranking

engine), the PCM/TCM energizes the relay. Prior to

this, the PCM/TCM verifies that the contacts are

open by checking for no voltage at the switched bat-

tery terminals. After this is verified, the voltage at

the solenoid pack pressure switches is checked. After

the relay is energized, the PCM/TCM monitors the

terminals to verify that the voltage is greater than 3

volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

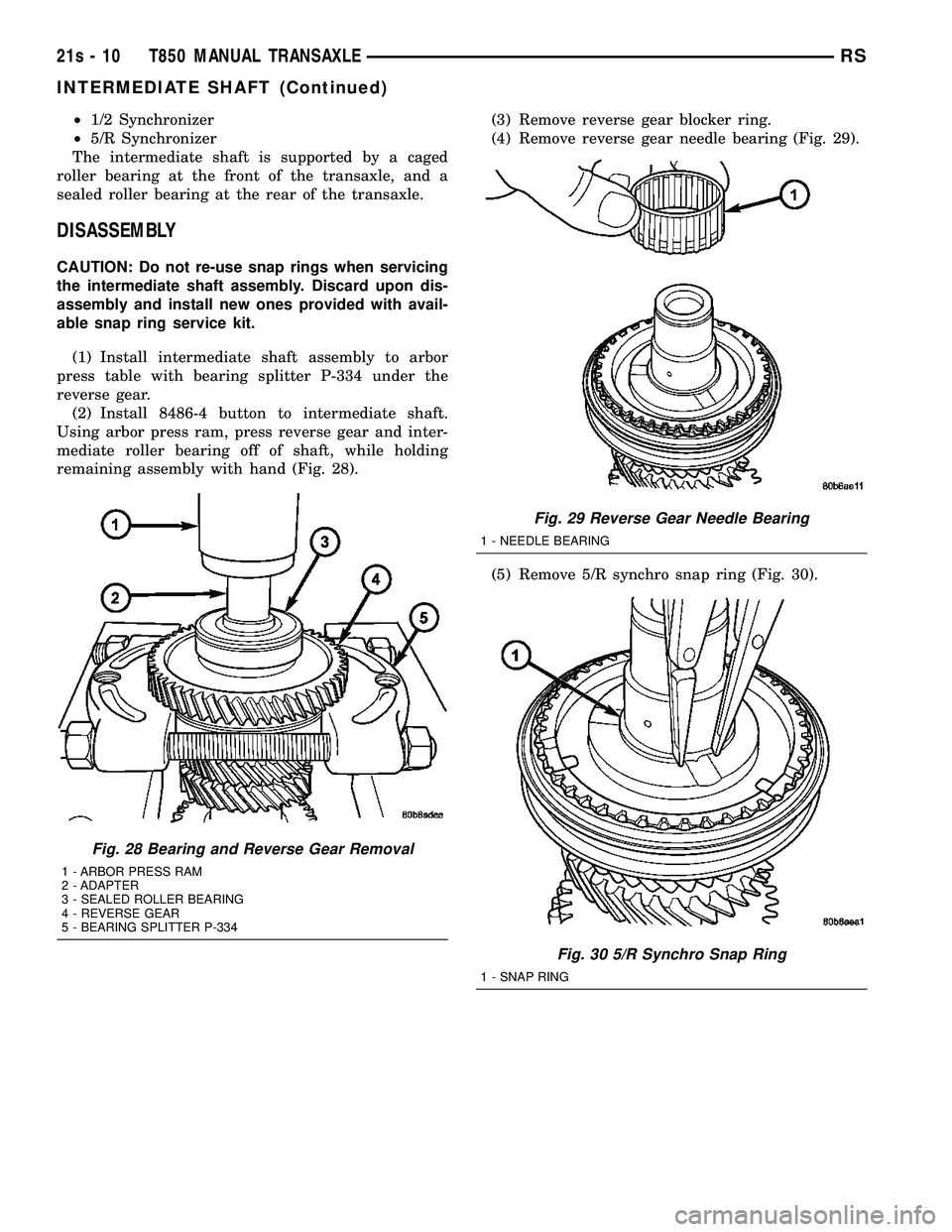

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle and

can only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 328).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 329).

OPERATION

The Transmission Range Sensor (TRS) (Fig. 328)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combination

of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM inter-

prets this information and determines the appropriate

transaxle gear position and shift schedule.

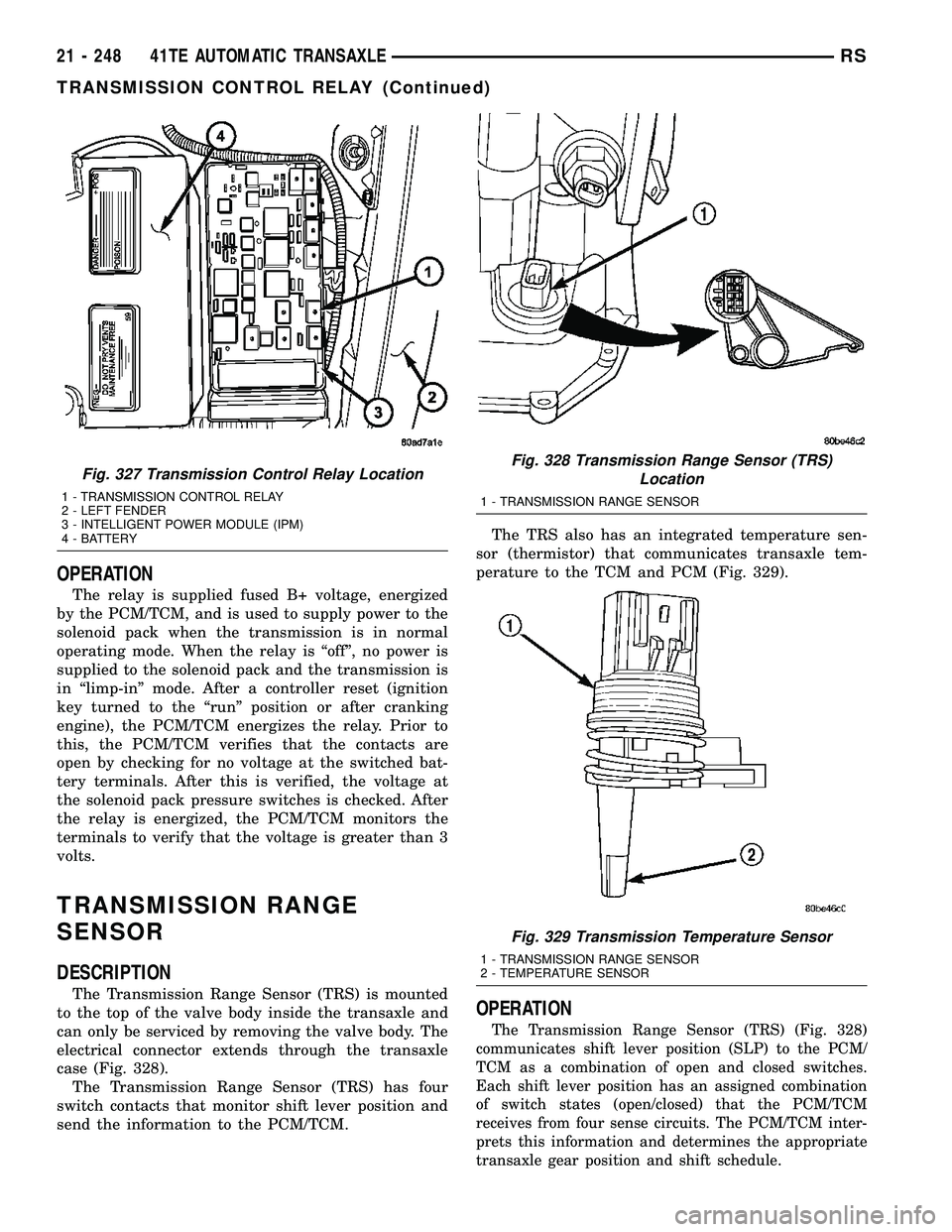

Fig. 327 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 328 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 329 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 248 41TE AUTOMATIC TRANSAXLERS

TRANSMISSION CONTROL RELAY (Continued)

Page 1871 of 2585

┬▓1/2 Synchronizer

┬▓ 5/R Synchronizer

The intermediate shaft is supported by a caged

roller bearing at the front of the transaxle, and a

sealed roller bearing at the rear of the transaxle.

DISASSEMBLY

CAUTION: Do not re-use snap rings when servicing

the intermediate shaft assembly. Discard upon dis-

assembly and install new ones provided with avail-

able snap ring service kit.

(1) Install intermediate shaft assembly to arbor

press table with bearing splitter P-334 under the

reverse gear. (2) Install 8486-4 button to intermediate shaft.

Using arbor press ram, press reverse gear and inter-

mediate roller bearing off of shaft, while holding

remaining assembly with hand (Fig. 28). (3) Remove reverse gear blocker ring.

(4) Remove reverse gear needle bearing (Fig. 29).

(5) Remove 5/R synchro snap ring (Fig. 30).

Fig. 28 Bearing and Reverse Gear Removal

1 - ARBOR PRESS RAM

2 - ADAPTER

3 - SEALED ROLLER BEARING

4 - REVERSE GEAR

5 - BEARING SPLITTER P-334

Fig. 29 Reverse Gear Needle Bearing

1 - NEEDLE BEARING

Fig. 30 5/R Synchro Snap Ring

1 - SNAP RING

21s - 10 T850 MANUAL TRANSAXLERS

INTERMEDIATE SHAFT (Continued)

Page 1878 of 2585

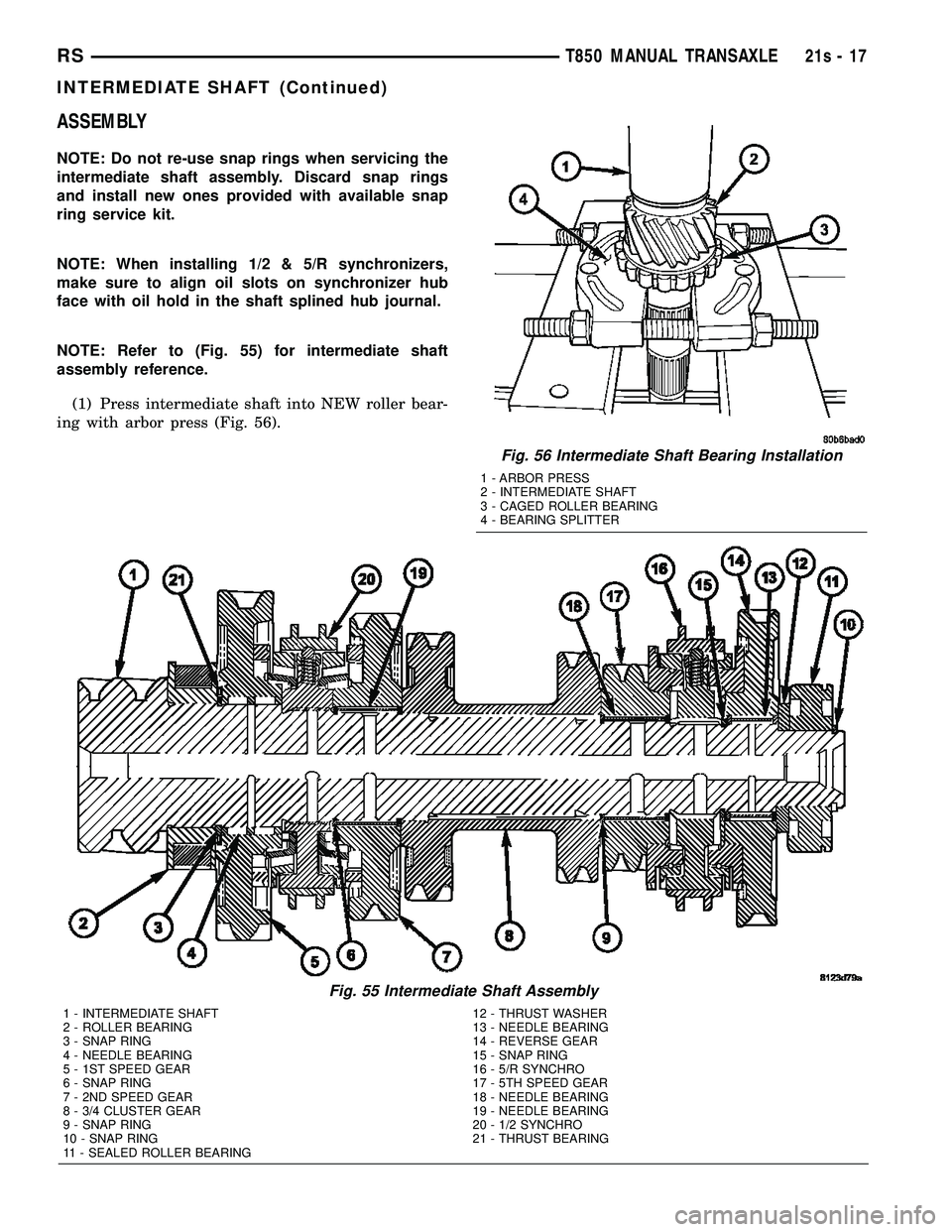

ASSEMBLY

NOTE: Do not re-use snap rings when servicing the

intermediate shaft assembly. Discard snap rings

and install new ones provided with available snap

ring service kit.

NOTE: When installing 1/2 & 5/R synchronizers,

make sure to align oil slots on synchronizer hub

face with oil hold in the shaft splined hub journal.

NOTE: Refer to (Fig. 55) for intermediate shaft

assembly reference.(1) Press intermediate shaft into NEW roller bear-

ing with arbor press (Fig. 56).

Fig. 55 Intermediate Shaft Assembly

1 - INTERMEDIATE SHAFT 12 - THRUST WASHER

2 - ROLLER BEARING 13 - NEEDLE BEARING

3 - SNAP RING 14 - REVERSE GEAR

4 - NEEDLE BEARING 15 - SNAP RING

5 - 1ST SPEED GEAR 16 - 5/R SYNCHRO

6 - SNAP RING 17 - 5TH SPEED GEAR

7 - 2ND SPEED GEAR 18 - NEEDLE BEARING

8 - 3/4 CLUSTER GEAR 19 - NEEDLE BEARING

9 - SNAP RING 20 - 1/2 SYNCHRO

10 - SNAP RING 21 - THRUST BEARING

11 - SEALED ROLLER BEARING

Fig. 56 Intermediate Shaft Bearing Installation

1 - ARBOR PRESS

2 - INTERMEDIATE SHAFT

3 - CAGED ROLLER BEARING

4 - BEARING SPLITTER

RS T850 MANUAL TRANSAXLE21s-17

INTERMEDIATE SHAFT (Continued)

Page 1885 of 2585

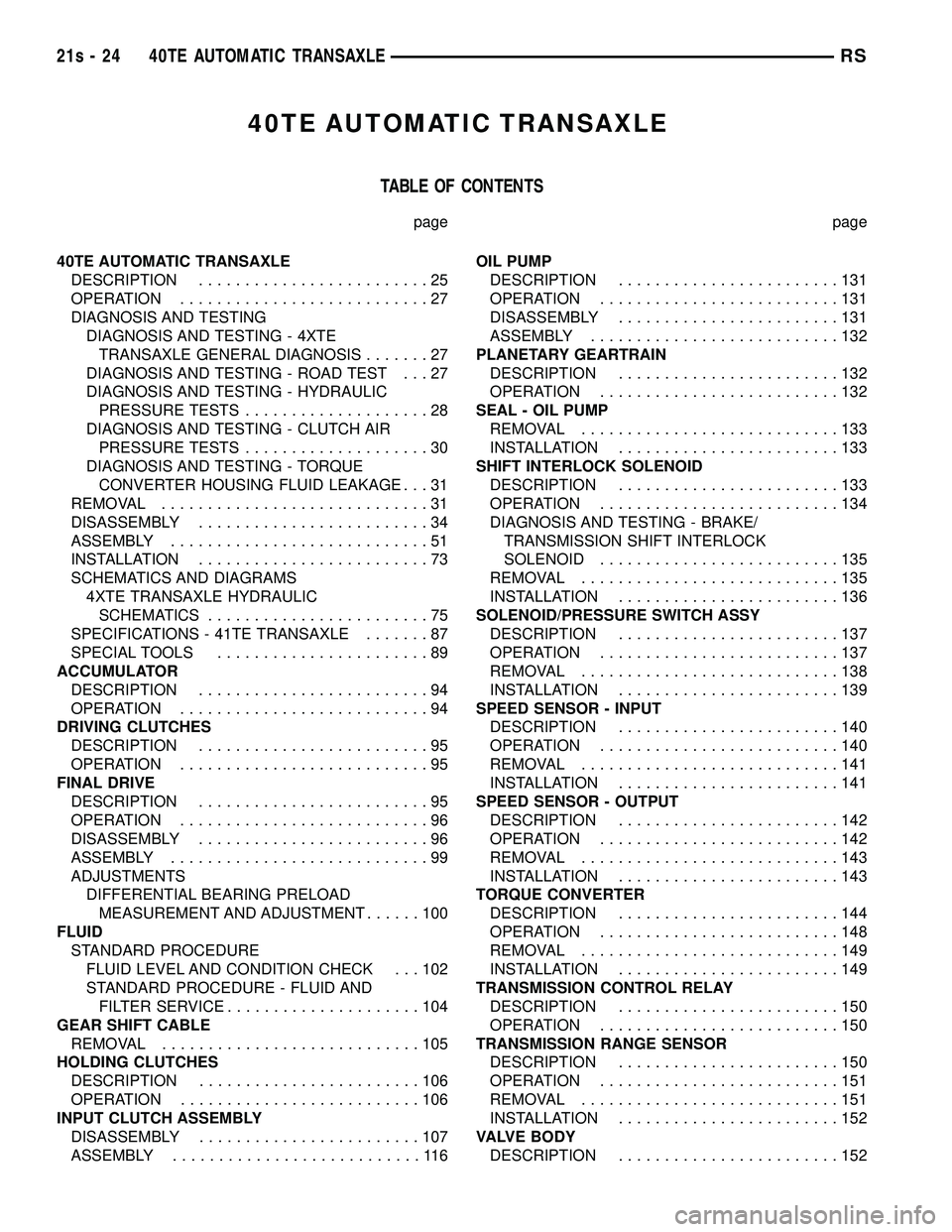

40TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

40TE AUTOMATIC TRANSAXLE DESCRIPTION .........................25

OPERATION ...........................27

DIAGNOSIS AND TESTING DIAGNOSIS AND TESTING - 4XTETRANSAXLE GENERAL DIAGNOSIS .......27

DIAGNOSIS AND TESTING - ROAD TEST . . . 27

DIAGNOSIS AND TESTING - HYDRAULIC PRESSURE TESTS ....................28

DIAGNOSIS AND TESTING - CLUTCH AIR PRESSURE TESTS ....................30

DIAGNOSIS AND TESTING - TORQUE CONVERTER HOUSING FLUID LEAKAGE . . . 31

REMOVAL .............................31

DISASSEMBLY .........................34

ASSEMBLY ............................51

INSTALLATION .........................73

SCHEMATICS AND DIAGRAMS 4XTE TRANSAXLE HYDRAULICSCHEMATICS ........................75

SPECIFICATIONS - 41TE TRANSAXLE .......87

SPECIAL TOOLS .......................89

ACCUMULATOR DESCRIPTION .........................94

OPERATION ...........................94

DRIVING CLUTCHES DESCRIPTION .........................95

OPERATION ...........................95

FINAL DRIVE DESCRIPTION .........................95

OPERATION ...........................96

DISASSEMBLY .........................96

ASSEMBLY ............................99

ADJUSTMENTS DIFFERENTIAL BEARING PRELOADMEASUREMENT AND ADJUSTMENT ......100

FLUID STANDARD PROCEDURE FLUID LEVEL AND CONDITION CHECK . . . 102

STANDARD PROCEDURE - FLUID ANDFILTER SERVICE .....................104

GEAR SHIFT CABLE REMOVAL ............................105

HOLDING CLUTCHES DESCRIPTION ........................106

OPERATION ..........................106

INPUT CLUTCH ASSEMBLY DISASSEMBLY ........................107

ASSEMBLY ...........................116 OIL PUMP

DESCRIPTION ........................131

OPERATION ..........................131

DISASSEMBLY ........................131

ASSEMBLY ...........................132

PLANETARY GEARTRAIN DESCRIPTION ........................132

OPERATION ..........................132

SEAL - OIL PUMP REMOVAL ............................133

INSTALLATION ........................133

SHIFT INTERLOCK SOLENOID DESCRIPTION ........................133

OPERATION ..........................134

DIAGNOSIS AND TESTING - BRAKE/ TRANSMISSION SHIFT INTERLOCK

SOLENOID ..........................135

REMOVAL ............................135

INSTALLATION ........................136

SOLENOID/PRESSURE SWITCH ASSY DESCRIPTION ........................137

OPERATION ..........................137

REMOVAL ............................138

INSTALLATION ........................139

SPEED SENSOR - INPUT DESCRIPTION ........................140

OPERATION ..........................140

REMOVAL ............................141

INSTALLATION ........................141

SPEED SENSOR - OUTPUT DESCRIPTION ........................142

OPERATION ..........................142

REMOVAL ............................143

INSTALLATION ........................143

TORQUE CONVERTER DESCRIPTION ........................144

OPERATION ..........................148

REMOVAL ............................149

INSTALLATION ........................149

TRANSMISSION CONTROL RELAY DESCRIPTION ........................150

OPERATION ..........................150

TRANSMISSION RANGE SENSOR DESCRIPTION ........................150

OPERATION ..........................151

REMOVAL ............................151

INSTALLATION ........................152

VALVE BODY DESCRIPTION ........................152

21s - 24 40TE AUTOMATIC TRANSAXLERS

Page 1893 of 2585

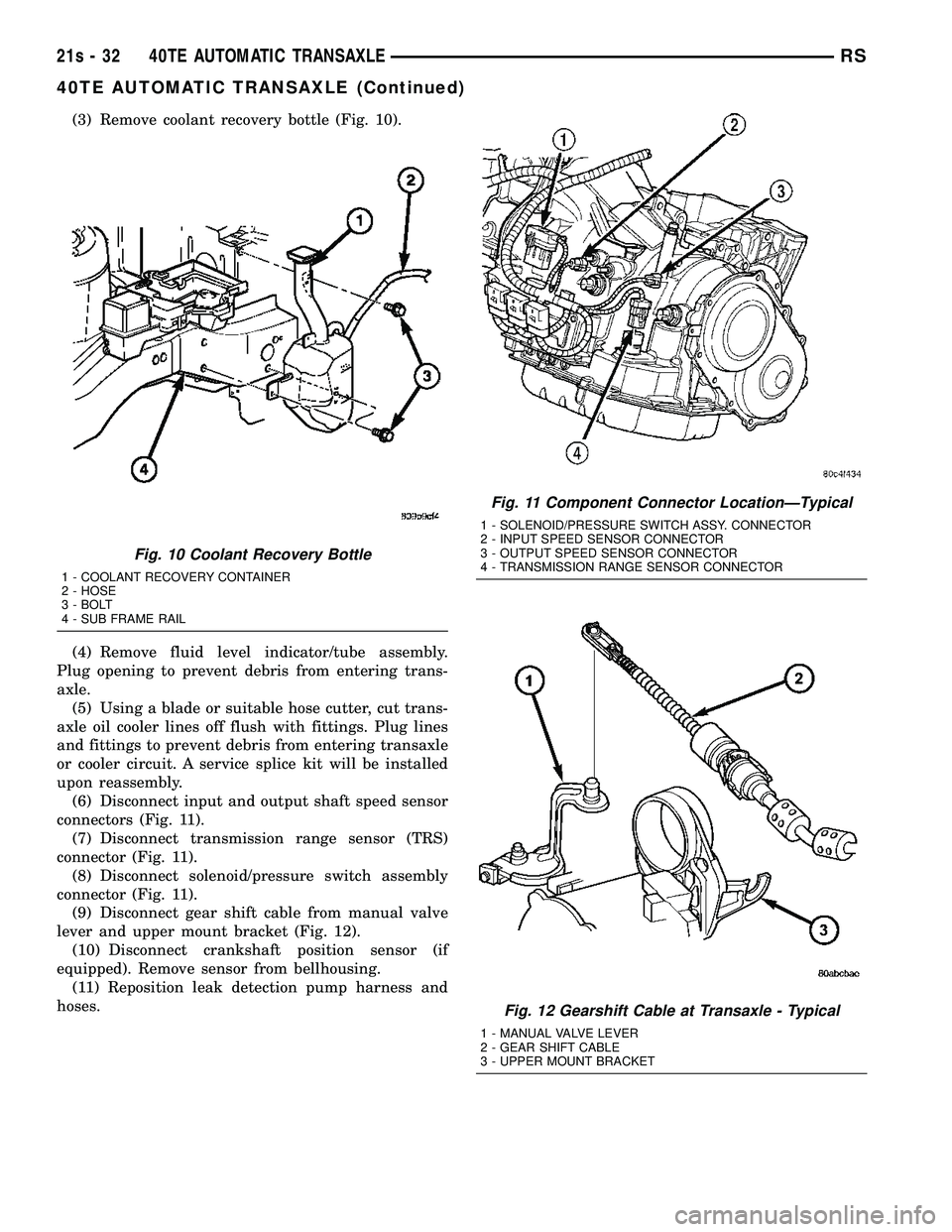

(3) Remove coolant recovery bottle (Fig. 10).

(4) Remove fluid level indicator/tube assembly.

Plug opening to prevent debris from entering trans-

axle. (5) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug lines

and fittings to prevent debris from entering transaxle

or cooler circuit. A service splice kit will be installed

upon reassembly. (6) Disconnect input and output shaft speed sensor

connectors (Fig. 11). (7) Disconnect transmission range sensor (TRS)

connector (Fig. 11). (8) Disconnect solenoid/pressure switch assembly

connector (Fig. 11). (9) Disconnect gear shift cable from manual valve

lever and upper mount bracket (Fig. 12). (10) Disconnect crankshaft position sensor (if

equipped). Remove sensor from bellhousing. (11) Reposition leak detection pump harness and

hoses.

Fig. 10 Coolant Recovery Bottle

1 - COOLANT RECOVERY CONTAINER

2 - HOSE

3 - BOLT

4 - SUB FRAME RAIL

Fig. 11 Component Connector LocationÐTypical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 12 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

21s - 32 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1901 of 2585

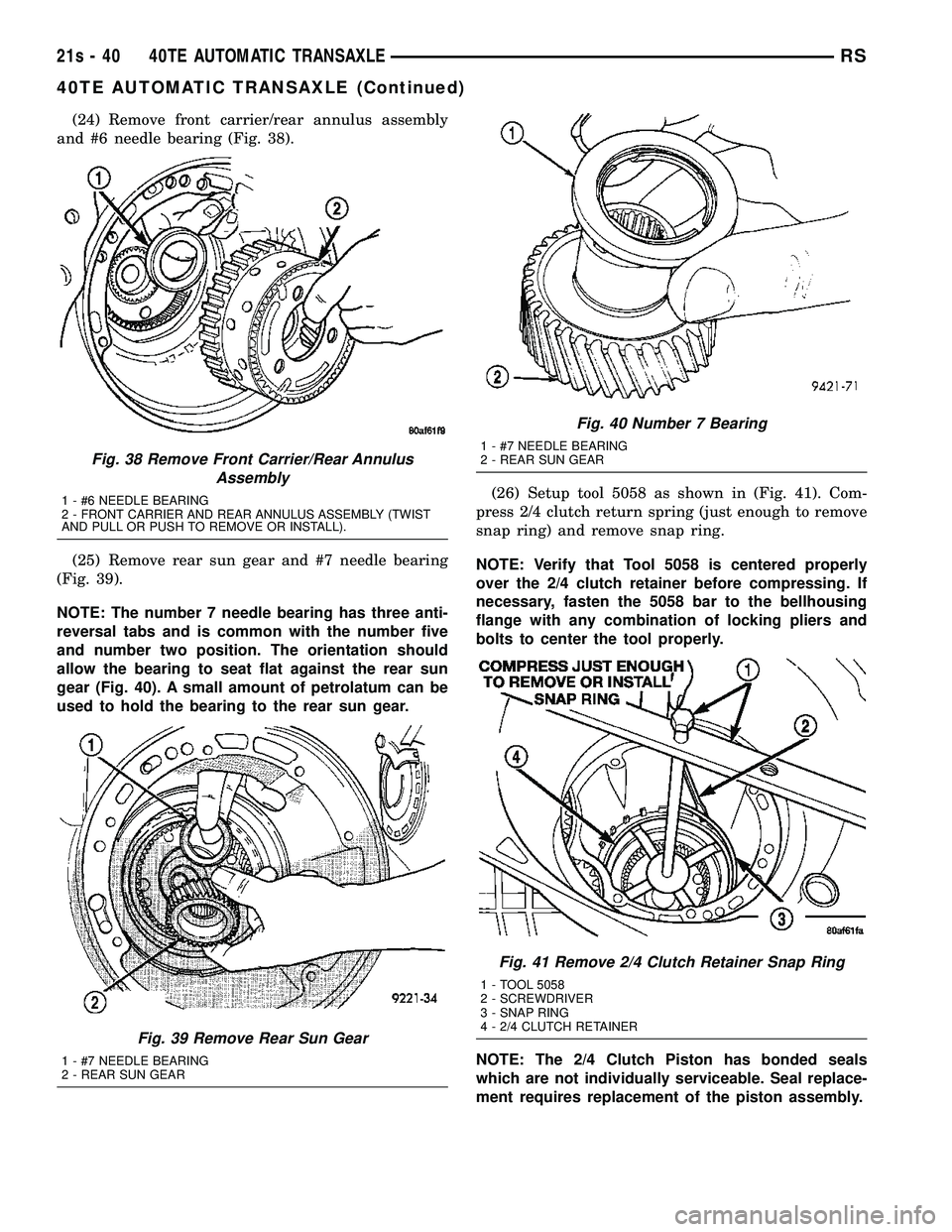

(24) Remove front carrier/rear annulus assembly

and #6 needle bearing (Fig. 38).

(25) Remove rear sun gear and #7 needle bearing

(Fig. 39).

NOTE: The number 7 needle bearing has three anti-

reversal tabs and is common with the number five

and number two position. The orientation should

allow the bearing to seat flat against the rear sun

gear (Fig. 40). A small amount of petrolatum can be

used to hold the bearing to the rear sun gear. (26) Setup tool 5058 as shown in (Fig. 41). Com-

press 2/4 clutch return spring (just enough to remove

snap ring) and remove snap ring.

NOTE: Verify that Tool 5058 is centered properly

over the 2/4 clutch retainer before compressing. If

necessary, fasten the 5058 bar to the bellhousing

flange with any combination of locking pliers and

bolts to center the tool properly.

NOTE: The 2/4 Clutch Piston has bonded seals

which are not individually serviceable. Seal replace-

ment requires replacement of the piston assembly.

Fig. 38 Remove Front Carrier/Rear Annulus Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 39 Remove Rear Sun Gear

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 40 Number 7 Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 41 Remove 2/4 Clutch Retainer Snap Ring

1 - TOOL 5058

2 - SCREWDRIVER

3 - SNAP RING

4 - 2/4 CLUTCH RETAINER

21s - 40 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1910 of 2585

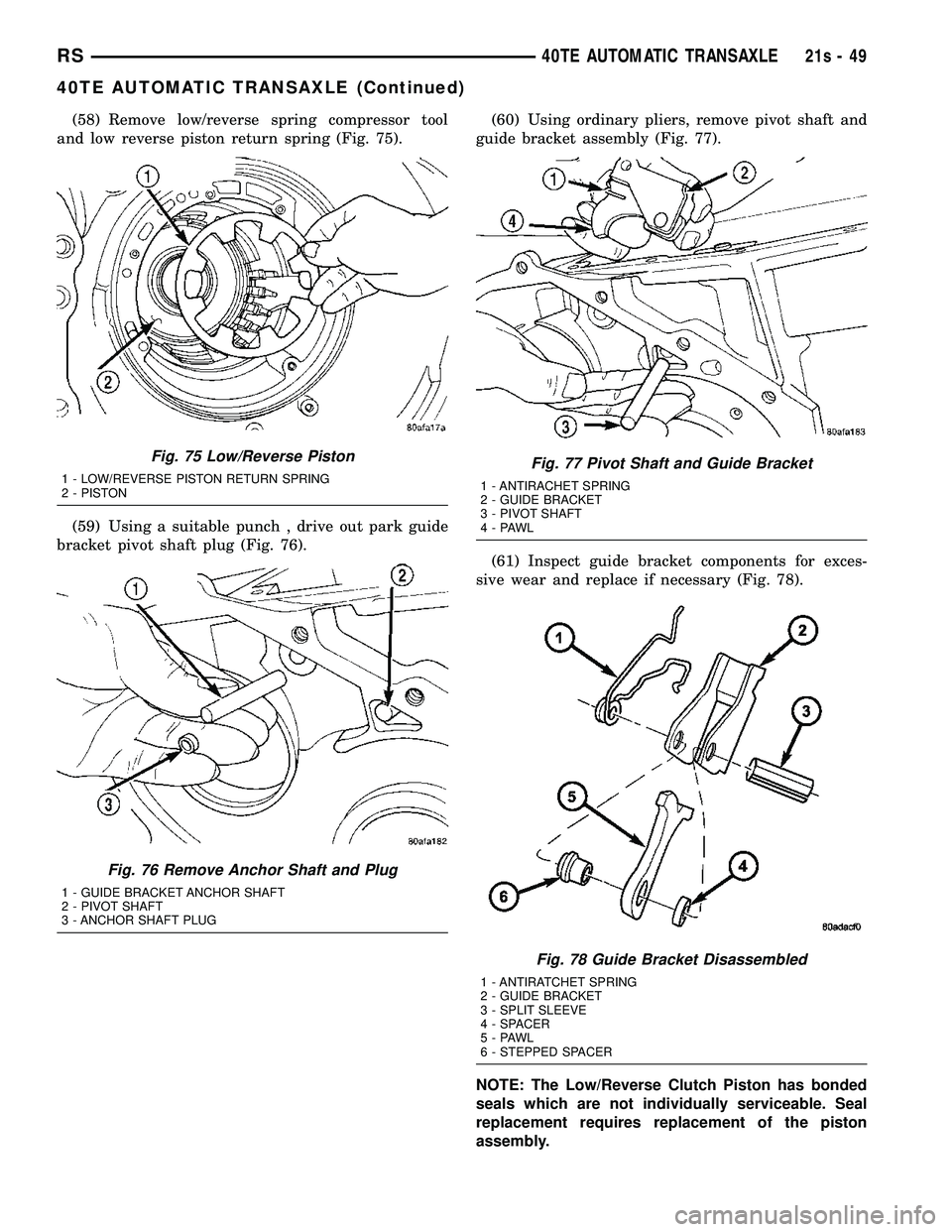

(58) Remove low/reverse spring compressor tool

and low reverse piston return spring (Fig. 75).

(59) Using a suitable punch , drive out park guide

bracket pivot shaft plug (Fig. 76). (60) Using ordinary pliers, remove pivot shaft and

guide bracket assembly (Fig. 77).

(61) Inspect guide bracket components for exces-

sive wear and replace if necessary (Fig. 78).

NOTE: The Low/Reverse Clutch Piston has bonded

seals which are not individually serviceable. Seal

replacement requires replacement of the piston

assembly.

Fig. 75 Low/Reverse Piston

1 - LOW/REVERSE PISTON RETURN SPRING

2 - PISTON

Fig. 76 Remove Anchor Shaft and Plug

1 - GUIDE BRACKET ANCHOR SHAFT

2 - PIVOT SHAFT

3 - ANCHOR SHAFT PLUG

Fig. 77 Pivot Shaft and Guide Bracket

1 - ANTIRACHET SPRING

2 - GUIDE BRACKET

3 - PIVOT SHAFT

4-PAWL

Fig. 78 Guide Bracket Disassembled

1 - ANTIRATCHET SPRING

2 - GUIDE BRACKET

3 - SPLIT SLEEVE

4 - SPACER

5-PAWL

6 - STEPPED SPACER

RS 40TE AUTOMATIC TRANSAXLE21s-49

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1913 of 2585

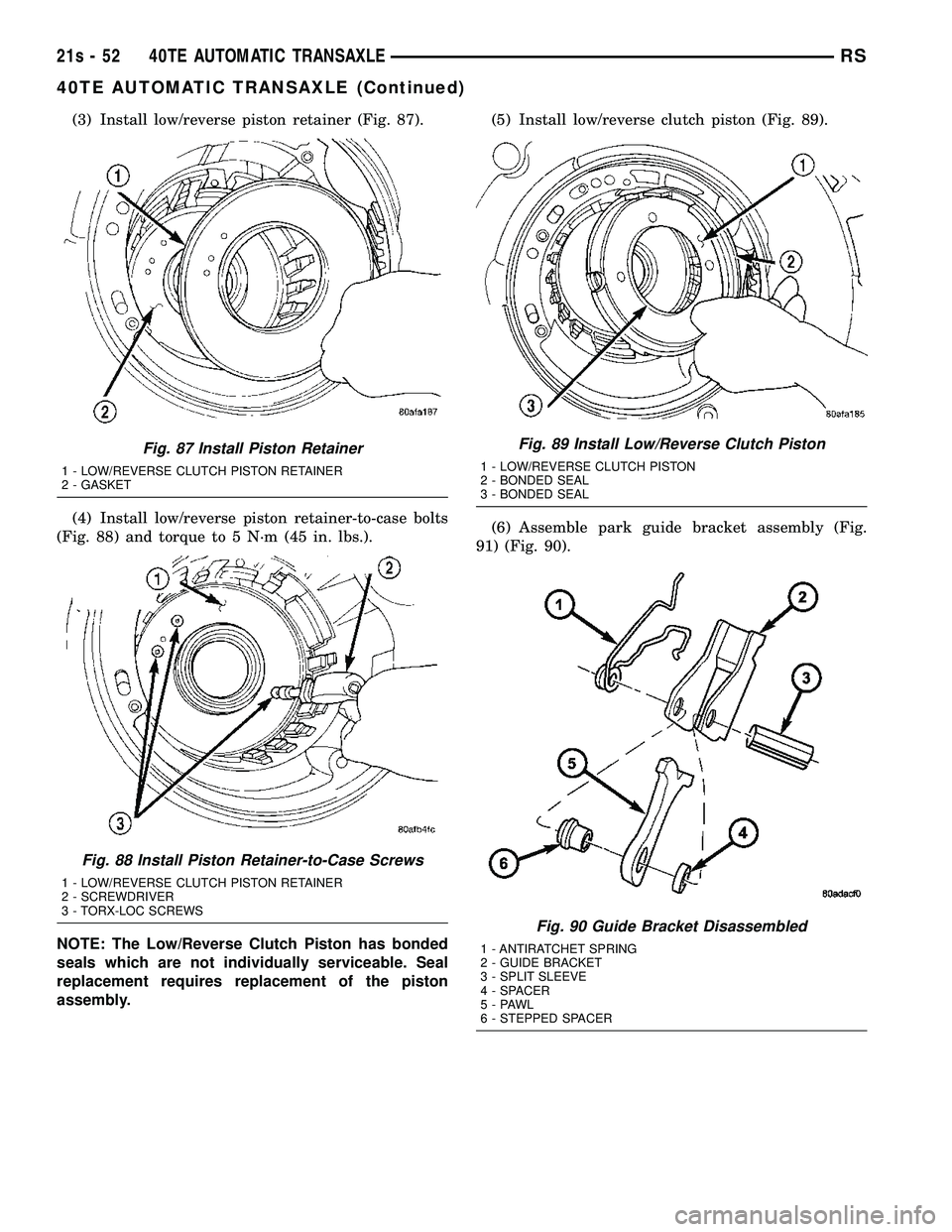

(3) Install low/reverse piston retainer (Fig. 87).

(4) Install low/reverse piston retainer-to-case bolts

(Fig. 88) and torque to 5 N┬┤m (45 in. lbs.).

NOTE: The Low/Reverse Clutch Piston has bonded

seals which are not individually serviceable. Seal

replacement requires replacement of the piston

assembly. (5) Install low/reverse clutch piston (Fig. 89).

(6) Assemble park guide bracket assembly (Fig.

91) (Fig. 90).

Fig. 87 Install Piston Retainer

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - GASKET

Fig. 88 Install Piston Retainer-to-Case Screws

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - SCREWDRIVER

3 - TORX-LOC SCREWS

Fig. 89 Install Low/Reverse Clutch Piston

1 - LOW/REVERSE CLUTCH PISTON

2 - BONDED SEAL

3 - BONDED SEAL

Fig. 90 Guide Bracket Disassembled

1 - ANTIRATCHET SPRING

2 - GUIDE BRACKET

3 - SPLIT SLEEVE

4 - SPACER

5-PAWL

6 - STEPPED SPACER

21s - 52 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1927 of 2585

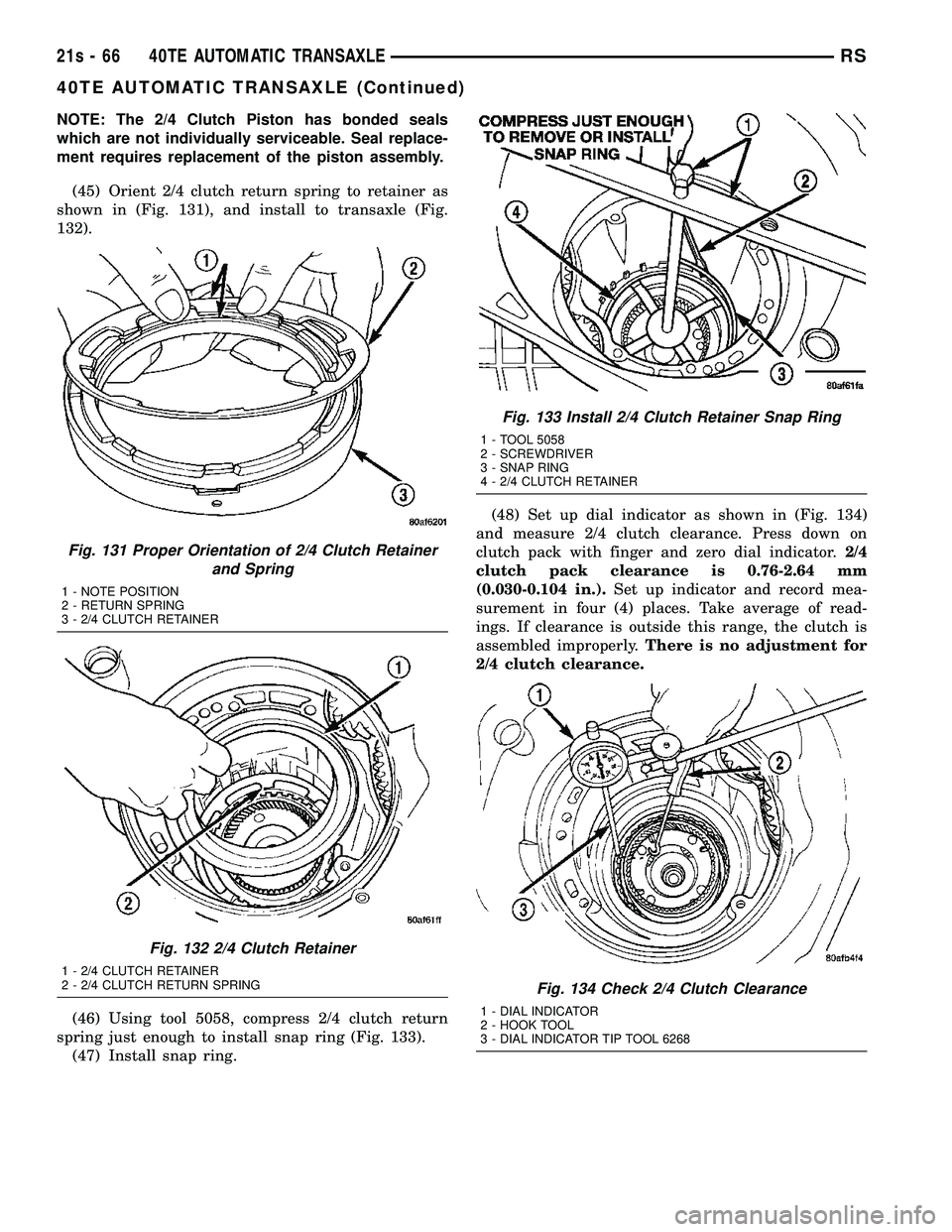

NOTE: The 2/4 Clutch Piston has bonded seals

which are not individually serviceable. Seal replace-

ment requires replacement of the piston assembly.(45) Orient 2/4 clutch return spring to retainer as

shown in (Fig. 131), and install to transaxle (Fig.

132).

(46) Using tool 5058, compress 2/4 clutch return

spring just enough to install snap ring (Fig. 133). (47) Install snap ring. (48) Set up dial indicator as shown in (Fig. 134)

and measure 2/4 clutch clearance. Press down on

clutch pack with finger and zero dial indicator. 2/4

clutch pack clearance is 0.76-2.64 mm

(0.030-0.104 in.). Set up indicator and record mea-

surement in four (4) places. Take average of read-

ings. If clearance is outside this range, the clutch is

assembled improperly. There is no adjustment for

2/4 clutch clearance.

Fig. 131 Proper Orientation of 2/4 Clutch Retainer and Spring

1 - NOTE POSITION

2 - RETURN SPRING

3 - 2/4 CLUTCH RETAINER

Fig. 132 2/4 Clutch Retainer

1 - 2/4 CLUTCH RETAINER

2 - 2/4 CLUTCH RETURN SPRING

Fig. 133 Install 2/4 Clutch Retainer Snap Ring

1 - TOOL 5058

2 - SCREWDRIVER

3 - SNAP RING

4 - 2/4 CLUTCH RETAINER

Fig. 134 Check 2/4 Clutch Clearance

1 - DIAL INDICATOR

2 - HOOK TOOL

3 - DIAL INDICATOR TIP TOOL 6268

21s - 66 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1935 of 2585

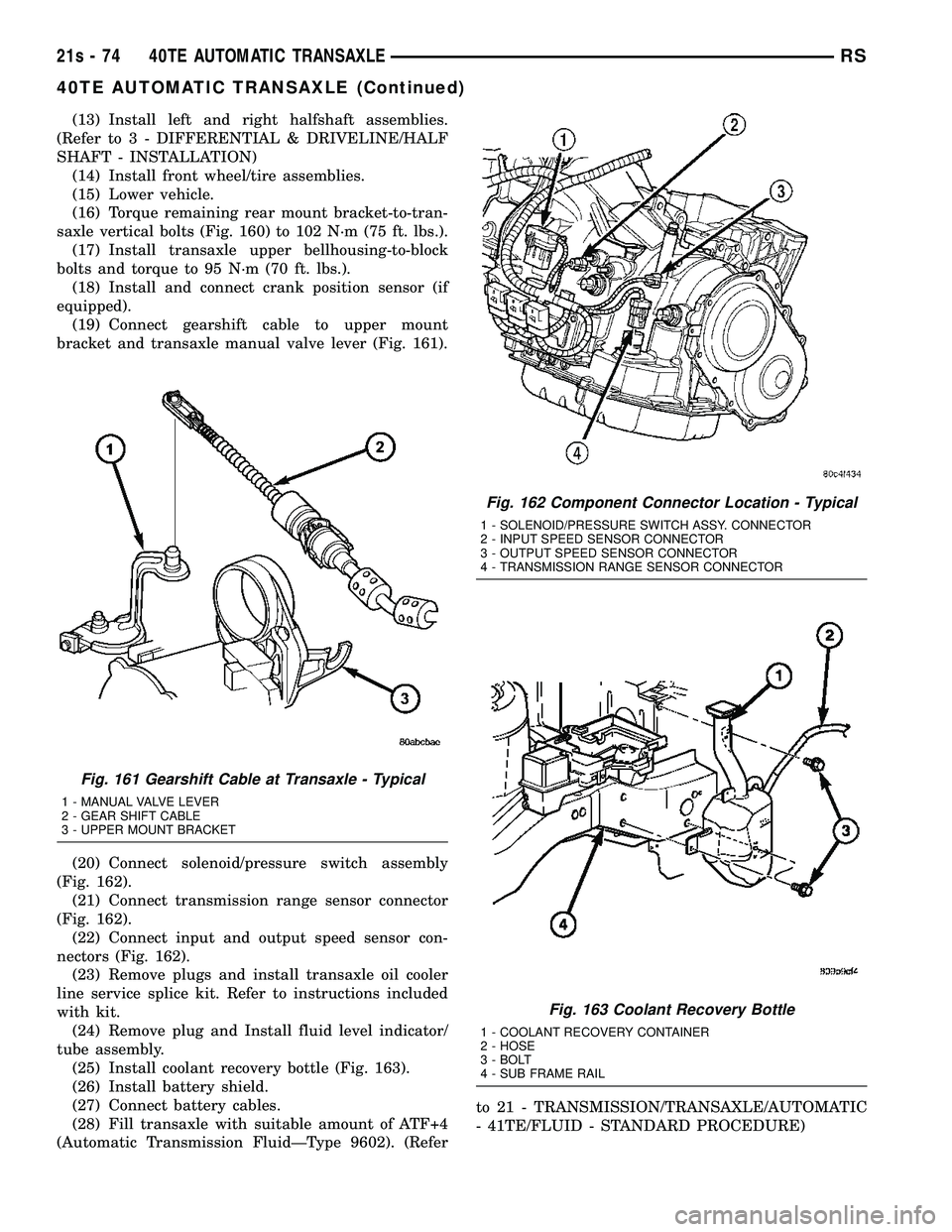

(13) Install left and right halfshaft assemblies.

(Refer t o 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION) (14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 160) to 102 N┬┤m (75 ft. lbs.). (17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N┬┤m (70 ft. lbs.). (18) Install and connect crank position sensor (if

equipped). (19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 161).

(20) Connect solenoid/pressure switch assembly

(Fig. 162). (21) Connect transmission range sensor connector

(Fig. 162). (22) Connect input and output speed sensor con-

nectors (Fig. 162). (23) Remove plugs and install transaxle oil cooler

line service splice kit. Refer to instructions included

with kit. (24) Remove plug and Install fluid level indicator/

tube assembly. (25) Install coolant recovery bottle (Fig. 163).

(26) Install battery shield.

(27) Connect battery cables.

(28) Fill transaxle with suitable amount of ATF+4

(Automatic Transmission FluidÐType 9602). (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/FLUID - STANDARD PROCEDURE)

Fig. 161 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 162 Component Connector Location - Typical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 163 Coolant Recovery Bottle

1 - COOLANT RECOVERY CONTAINER

2 - HOSE

3 - BOLT

4 - SUB FRAME RAIL

21s - 74 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)