torque CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1962 of 2585

(5) If the turning torque is within specifications,

remove tools. Setup is complete. (6) If turning torque is not within specifications

proceed with the following steps. (a) Remove differential bearing retainer from

the transaxle case. (b) Remove the bearing cup from the differential

bearing retainer using Tool 6062A. (c) Remove the existing shim from under the

cup. (d) Measure the existing shim.

(e) If the turning torque was too high when mea-

sured, install a 0.05 mm (0.002 inch) thinner shim.

If the turning torque is was too low, install a 0.05

mm (0.002 inch) thicker shim. Repeat until 5 to 18

inch-pounds turning torque is obtained. Oil Baffle

is not required to be installed when making shim

selection. (f) Install the proper shim under the bearing

cup. Make sure the oil baffle is installed properly in the bearing retainer, below the bearing shim

and cup.

(g) Install the differential bearing retainer using

Tool 5052 and C-4171. Seal the retainer to the

housing with MOPAR tAdhesive Sealant and

torque bolts to 28 N´m (250 in. lbs.).

(7) Using Tool L-4436A and an inch-pound torque

wrench, recheck the turning torque of the differential

(Fig. 186). The turning torque should be

between 5 and 18 inch-pounds. Shim thickness need be determined only if any of

the following parts are replaced: ² Transaxle case

² Differential carrier

² Differential bearing retainer

² Extension housing

² Differential bearing cups and cones

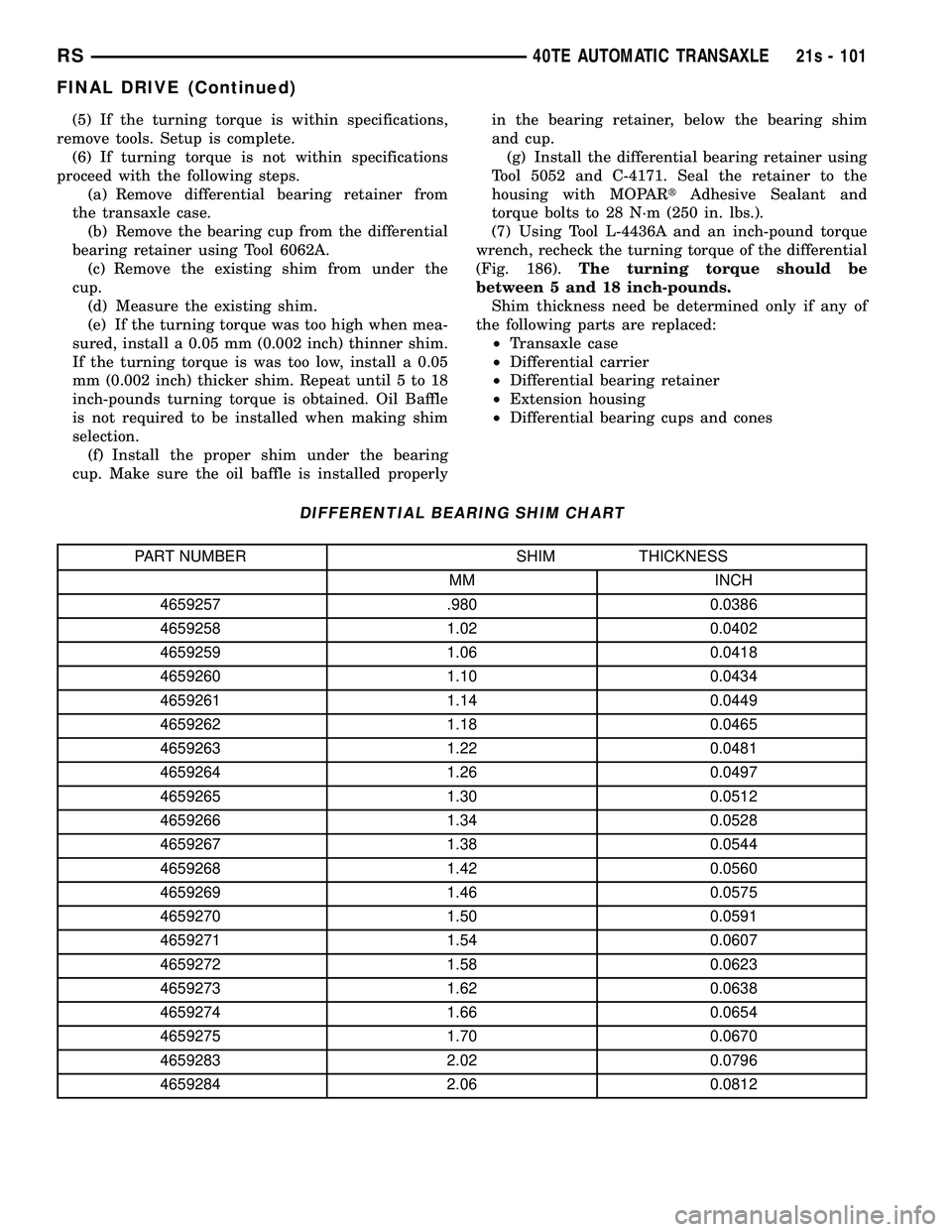

DIFFERENTIAL BEARING SHIM CHART

PART NUMBER SHIM THICKNESS

MM INCH

4659257 .980 0.0386

4659258 1.02 0.0402

4659259 1.06 0.0418

4659260 1.10 0.0434

4659261 1.14 0.0449

4659262 1.18 0.0465

4659263 1.22 0.0481

4659264 1.26 0.0497

4659265 1.30 0.0512

4659266 1.34 0.0528

4659267 1.38 0.0544

4659268 1.42 0.0560

4659269 1.46 0.0575

4659270 1.50 0.0591

4659271 1.54 0.0607

4659272 1.58 0.0623

4659273 1.62 0.0638

4659274 1.66 0.0654

4659275 1.70 0.0670

4659283 2.02 0.0796

4659284 2.06 0.0812

RS 40TE AUTOMATIC TRANSAXLE21s - 101

FINAL DRIVE (Continued)

Page 1963 of 2585

PRELOAD ADJUSTMENT W/O SHIM(1) Remove the bearing cup from the differential

bearing retainer using Miller special Tool 6062A. (2) Remove existing shim from under bearing cup.

(3) Reinstall the bearing cup into the retainer

using Miller Special Tool 6061, and C-4171.

NOTE: Oil baffle is not required when making the

shim calculation.

(4) Install the bearing retainer into the case.

Torque bolts to 28 N ²m (250 in. lbs.).

(5) Position the transaxle assembly vertically on

the support stand and install Miller Special Tool

L-4436-A into the bearing retainer. (6) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated. (7) Attach a dial indicator to the case and zero the

dial. Place the tip on the end of Special Tool

L-4436-A. (8) Place a large screwdriver to each side of the

ring gear and lift. Check the dial indicator for the

amount of end play.

CAUTION: Do not damage the transaxle case and/or

differential retainer sealing surface.

(9) Using the end play measurement that was

determined, add 0.18mm (0.007 inch). This should

give you between 5 and 18 inch pounds of bearing

preload. Refer to the Differential Bearing Shim Chart

to determine which shim to use. (10) Remove the differential bearing retainer.

Remove the bearing cup. (11) Install the oil baffle. Install the proper shim

combination under the bearing cup. (12) Install the differential bearing retainer. Seal

the retainer to the housing with Mopar tSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N ²m

(250 in. lbs.). (13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 186). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a 0.05mm

(0.002 inch) thicker shim. If the turning torque is too

low, install a 0.05mm (0.002 inch) thinner shim.

Repeat until 5-18 inch-pounds of turning torque is

obtained.FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing. The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate. The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 187). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.

Fig. 187 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21s - 102 40TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1992 of 2585

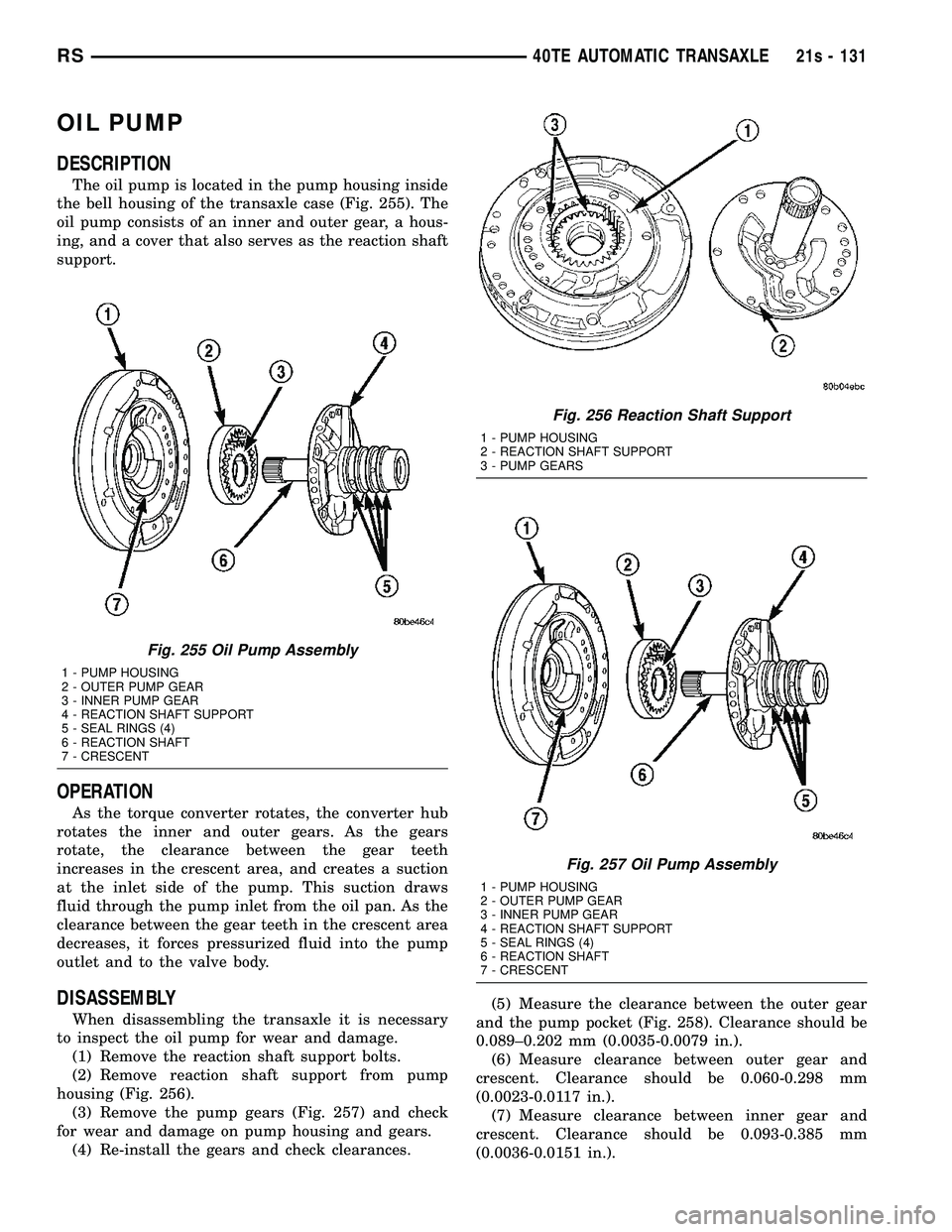

OIL PUMP

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transaxle case (Fig. 255). The

oil pump consists of an inner and outer gear, a hous-

ing, and a cover that also serves as the reaction shaft

support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

DISASSEMBLY

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage. (1) Remove the reaction shaft support bolts.

(2) Remove reaction shaft support from pump

housing (Fig. 256). (3) Remove the pump gears (Fig. 257) and check

for wear and damage on pump housing and gears. (4) Re-install the gears and check clearances. (5) Measure the clearance between the outer gear

and the pump pocket (Fig. 258). Clearance should be

0.089±0.202 mm (0.0035-0.0079 in.). (6) Measure clearance between outer gear and

crescent. Clearance should be 0.060-0.298 mm

(0.0023-0.0117 in.). (7) Measure clearance between inner gear and

crescent. Clearance should be 0.093-0.385 mm

(0.0036-0.0151 in.).

Fig. 255 Oil Pump Assembly

1 - PUMP HOUSING

2 - OUTER PUMP GEAR

3 - INNER PUMP GEAR

4 - REACTION SHAFT SUPPORT

5 - SEAL RINGS (4)

6 - REACTION SHAFT

7 - CRESCENT

Fig. 256 Reaction Shaft Support

1 - PUMP HOUSING

2 - REACTION SHAFT SUPPORT

3 - PUMP GEARS

Fig. 257 Oil Pump Assembly

1 - PUMP HOUSING

2 - OUTER PUMP GEAR

3 - INNER PUMP GEAR

4 - REACTION SHAFT SUPPORT

5 - SEAL RINGS (4)

6 - REACTION SHAFT

7 - CRESCENT

RS 40TE AUTOMATIC TRANSAXLE21s - 131

Page 1993 of 2585

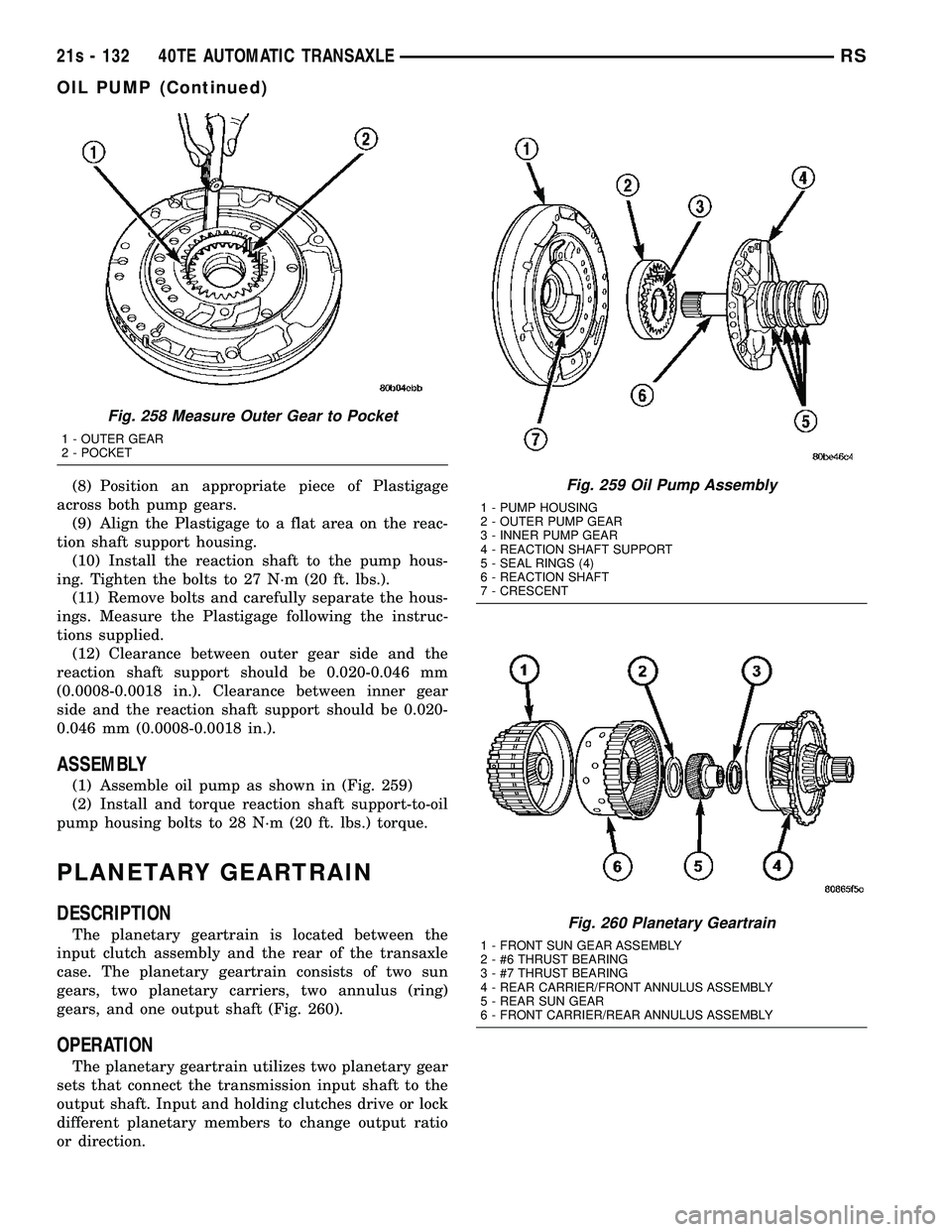

(8) Position an appropriate piece of Plastigage

across both pump gears. (9) Align the Plastigage to a flat area on the reac-

tion shaft support housing. (10) Install the reaction shaft to the pump hous-

ing. Tighten the bolts to 27 N´m (20 ft. lbs.). (11) Remove bolts and carefully separate the hous-

ings. Measure the Plastigage following the instruc-

tions supplied. (12) Clearance between outer gear side and the

reaction shaft support should be 0.020-0.046 mm

(0.0008-0.0018 in.). Clearance between inner gear

side and the reaction shaft support should be 0.020-

0.046 mm (0.0008-0.0018 in.).

ASSEMBLY

(1) Assemble oil pump as shown in (Fig. 259)

(2) Install and torque reaction shaft support-to-oil

pump housing bolts to 28 N´m (20 ft. lbs.) torque.

PLANETARY GEARTRAIN

DESCRIPTION

The planetary geartrain is located between the

input clutch assembly and the rear of the transaxle

case. The planetary geartrain consists of two sun

gears, two planetary carriers, two annulus (ring)

gears, and one output shaft (Fig. 260).

OPERATION

The planetary geartrain utilizes two planetary gear

sets that connect the transmission input shaft to the

output shaft. Input and holding clutches drive or lock

different planetary members to change output ratio

or direction.

Fig. 258 Measure Outer Gear to Pocket

1 - OUTER GEAR

2 - POCKET

Fig. 259 Oil Pump Assembly

1 - PUMP HOUSING

2 - OUTER PUMP GEAR

3 - INNER PUMP GEAR

4 - REACTION SHAFT SUPPORT

5 - SEAL RINGS (4)

6 - REACTION SHAFT

7 - CRESCENT

Fig. 260 Planetary Geartrain

1 - FRONT SUN GEAR ASSEMBLY

2 - #6 THRUST BEARING

3 - #7 THRUST BEARING

4 - REAR CARRIER/FRONT ANNULUS ASSEMBLY

5 - REAR SUN GEAR

6 - FRONT CARRIER/REAR ANNULUS ASSEMBLY

21s - 132 40TE AUTOMATIC TRANSAXLERS

OIL PUMP (Continued)

Page 2000 of 2585

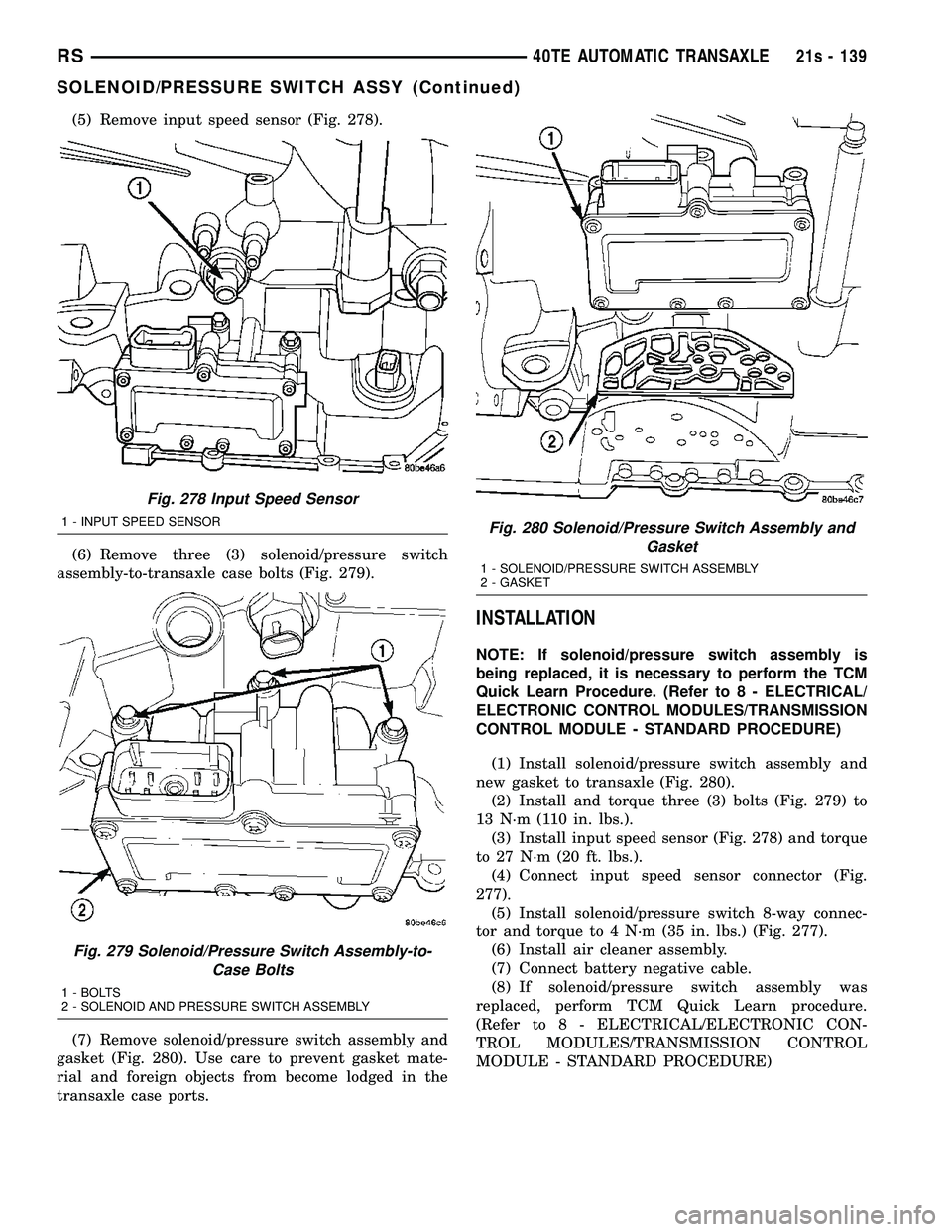

(5) Remove input speed sensor (Fig. 278).

(6) Remove three (3) solenoid/pressure switch

assembly-to-transaxle case bolts (Fig. 279).

(7) Remove solenoid/pressure switch assembly and

gasket (Fig. 280). Use care to prevent gasket mate-

rial and foreign objects from become lodged in the

transaxle case ports.

INSTALLATION

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the TCM

Quick Learn Procedure. (Refer t o 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Install solenoid/pressure switch assembly and

new gasket to transaxle (Fig. 280). (2) Install and torque three (3) bolts (Fig. 279) to

13 N´m (110 in. lbs.). (3) Install input speed sensor (Fig. 278) and torque

to 27 N´m (20 ft. lbs.). (4) Connect input speed sensor connector (Fig.

277). (5) Install solenoid/pressure switch 8-way connec-

tor and torque to 4 N´m (35 in. lbs.) (Fig. 277). (6) Install air cleaner assembly.

(7) Connect battery negative cable.

(8) If solenoid/pressure switch assembly was

replaced, perform TCM Quick Learn procedure.

(Refer t o 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

Fig. 278 Input Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 279 Solenoid/Pressure Switch Assembly-to- Case Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 280 Solenoid/Pressure Switch Assembly and Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

RS 40TE AUTOMATIC TRANSAXLE21s - 139

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 2001 of 2585

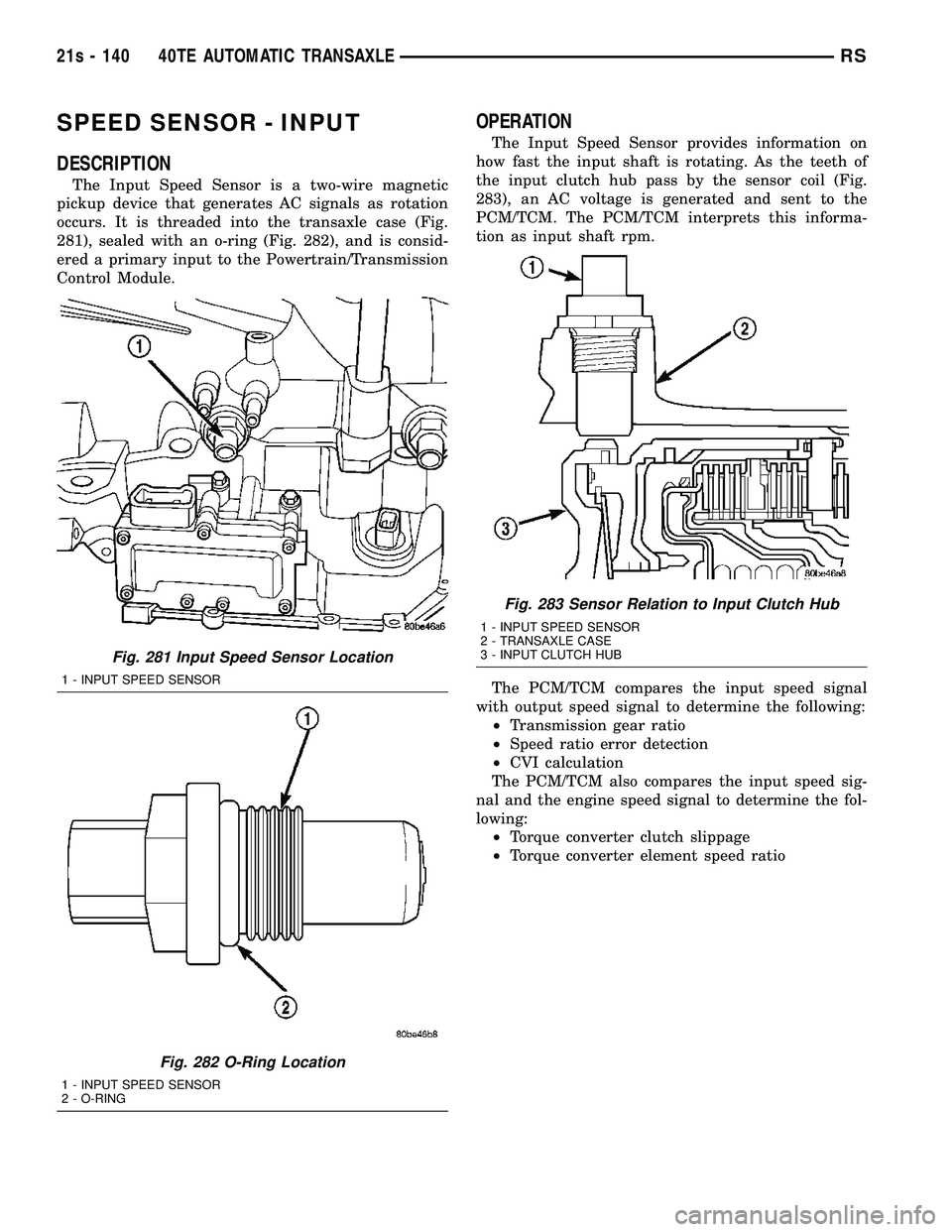

SPEED SENSOR - INPUT

DESCRIPTION

The Input Speed Sensor is a two-wire magnetic

pickup device that generates AC signals as rotation

occurs. It is threaded into the transaxle case (Fig.

281), sealed with an o-ring (Fig. 282), and is consid-

ered a primary input to the Powertrain/Transmission

Control Module.

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

283), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following: ² Transmission gear ratio

² Speed ratio error detection

² CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing: ² Torque converter clutch slippage

² Torque converter element speed ratio

Fig. 281 Input Speed Sensor Location

1 - INPUT SPEED SENSOR

Fig. 282 O-Ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

Fig. 283 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

21s - 140 40TE AUTOMATIC TRANSAXLERS

Page 2005 of 2585

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 293) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump. The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

Fig. 293 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21s - 144 40TE AUTOMATIC TRANSAXLERS

Page 2006 of 2585

IMPELLER

The impeller (Fig. 294) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving member of the system.

Fig. 294 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION 5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

RS 40TE AUTOMATIC TRANSAXLE21s - 145

TORQUE CONVERTER (Continued)

Page 2007 of 2585

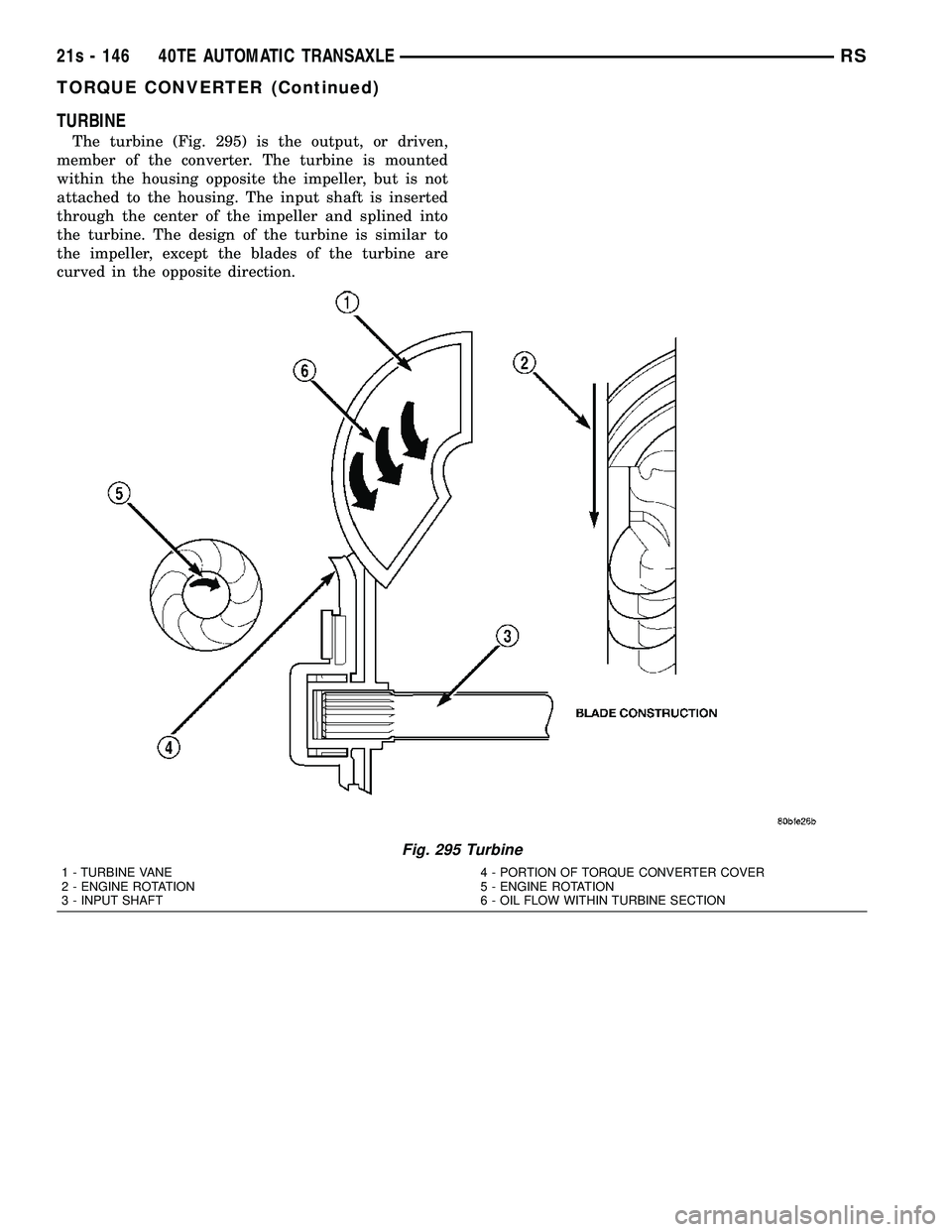

TURBINE

The turbine (Fig. 295) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

Fig. 295 Turbine

1 - TURBINE VANE

2 - ENGINE ROTATION

3 - INPUT SHAFT 4 - PORTION OF TORQUE CONVERTER COVER

5 - ENGINE ROTATION

6 - OIL FLOW WITHIN TURBINE SECTION

21s - 146 40TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

Page 2008 of 2585

STATOR

The stator assembly (Fig. 296) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 297).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 298) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock±free power transfer, it

is natural for all fluid couplings to slip. If the impel-

ler and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 296 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 297 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 298 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

RS 40TE AUTOMATIC TRANSAXLE21s - 147

TORQUE CONVERTER (Continued)