torque CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2104 of 2585

INSTALLATION

NOTE: Before reinstalling a tire pressure sensor,

replace sealing grommet at base of valve stem.(1) Wipe area clean where sensor sealing grommet

contacts wheel. Make sure surface of wheel is not

damaged. (2) Install sensor in wheel as shown (Fig. 2). Do

not attempt to mount sensor otherwise, damage may

occur. (3) Using a thin wall socket, install special sensor

nut (Fig. 2). Tighten nut to 4 N´m (35 in. lbs.) torque.

CAUTION: Over-torquing the sensor nut by as little

as 12 N´m (106 in. lbs.) may result in sensor sepa-

ration from the valve stem. Under this condition,

the sensor may still function, however, the condi-

tion should be corrected immediately.

(4) Mount tire on wheel following tire changer

manufacturers instructions, paying special attention

to the following to avoid damaging tire pressure sen-

sor: (a) Rotating Wheel Tire Changers - Once the

wheel is mounted to the changer, position the sen-

sor valve stem approximately 210É from the head

of the changer in a clockwise direction before rotat-

ing the wheel (also in a clockwise direction) to

mount the tire (Fig. 3). Use this procedure on both

the upper and lower tire beads. (b) Rotating Tool Tire Changers - Position the

wheel on the changer so that the sensor valve stem

is approximately 210É from the head of the changer

in a clockwise direction from the mounting end of

the tool (Fig. 4) Make sure the sensor is clear of

the lower bead breaker area to avoid damaging the

sensor when the breaker rises (Fig. 4). Rotate the

tool in a counterclockwise direction to mount the

tire. Use this procedure on both the upper and

lower tire beads.

Fig. 1 Start Mount/Dismount Tool Within 10 Degrees Of Valve Stem

Fig. 2 Sensor Mounting To Wheel

1 - TIRE PRESSURE SENSOR

2 - WHEEL

3 - NUT

Fig. 3 Mounting Tire Using Rotating Wheel Machine

1 - HEAD OF CHANGER LOCATED HERE

2 - VALVE STEM

RS TIRE PRESSURE MONITORING22s-3

SENSOR - TPM (Continued)

Page 2110 of 2585

pressures may increase from 2 to 6 pounds per

square inch (psi) (14 to 41 kPa) during operation. Do

not reduce this normal pressure buildup.Improper inflation can cause:

² Uneven wear patterns

² Reduced tread life

² Reduced fuel economy

² Unsatisfactory ride

² The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

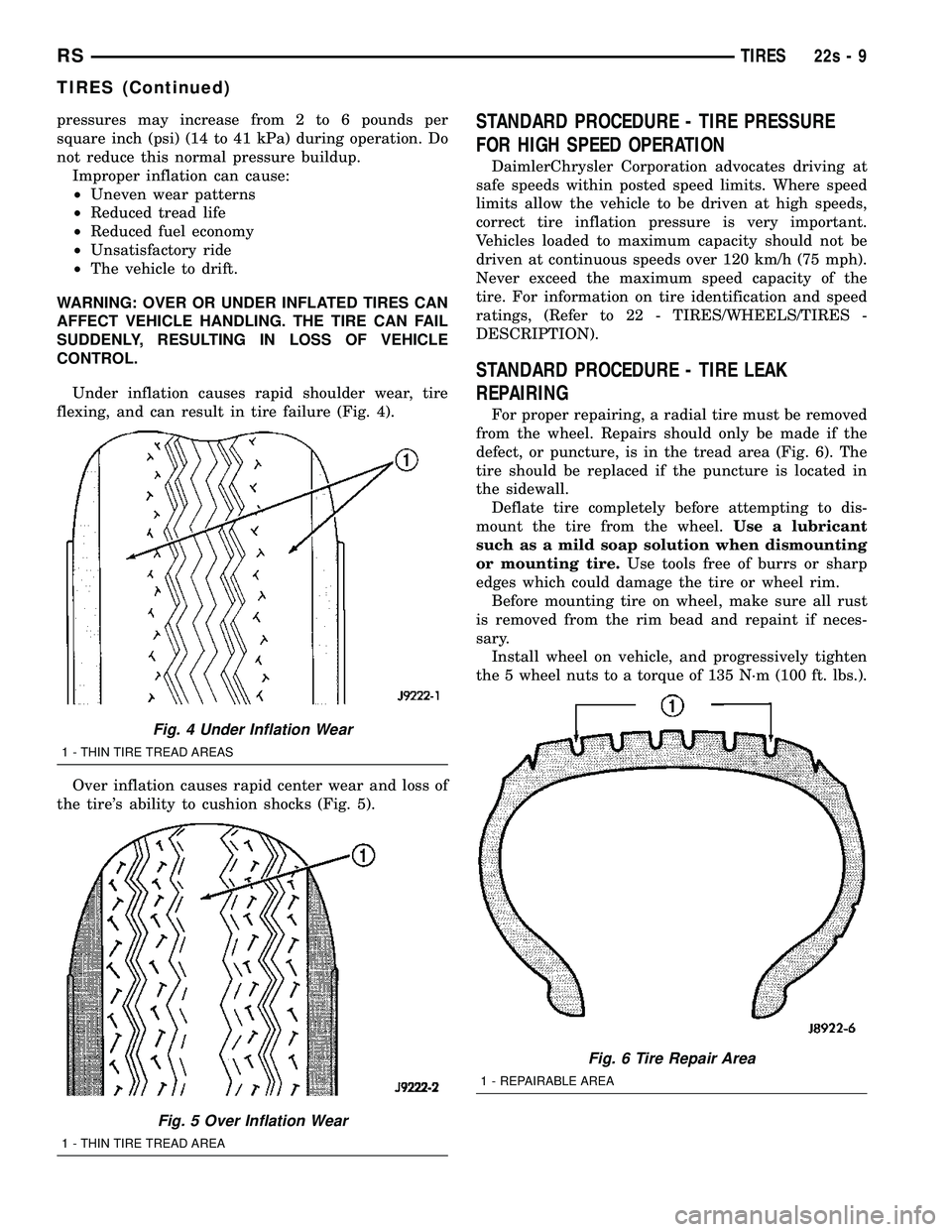

CONTROL. Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 4).

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 5).STANDARD PROCEDURE - TIRE PRESSURE

FOR HIGH SPEED OPERATION

DaimlerChrysler Corporation advocates driving at

safe speeds within posted speed limits. Where speed

limits allow the vehicle to be driven at high speeds,

correct tire inflation pressure is very important.

Vehicles loaded to maximum capacity should not be

driven at continuous speeds over 120 km/h (75 mph).

Never exceed the maximum speed capacity of the

tire. For information on tire identification and speed

ratings, (Refer to 22 - TIRES/WHEELS/TIRES -

DESCRIPTION).

STANDARD PROCEDURE - TIRE LEAK

REPAIRING

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 6). The

tire should be replaced if the puncture is located in

the sidewall. Deflate tire completely before attempting to dis-

mount the tire from the wheel. Use a lubricant

such as a mild soap solution when dismounting

or mounting tire. Use tools free of burrs or sharp

edges which could damage the tire or wheel rim. Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary. Install wheel on vehicle, and progressively tighten

the 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

Fig. 4 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

Fig. 5 Over Inflation Wear

1 - THIN TIRE TREAD AREA

Fig. 6 Tire Repair Area

1 - REPAIRABLE AREA

RS TIRES22s-9

TIRES (Continued)

Page 2112 of 2585

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 1

DIAGNOSIS AND TESTING - WIND NOISE . . . 2

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . 10

SPECIFICATIONS

TORQUE............................11

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......40

EXTERIOR.............................45

HOOD.................................60

INSTRUMENT PANEL.....................63

INTERIOR..............................73

PAINT.................................84

SEATS................................86

STATIONARY GLASS....................108

WEATHERSTRIP/SEALS..................113

SUNROOF.............................116

BODY STRUCTURE.....................124

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

RSBODY23-1

Page 2122 of 2585

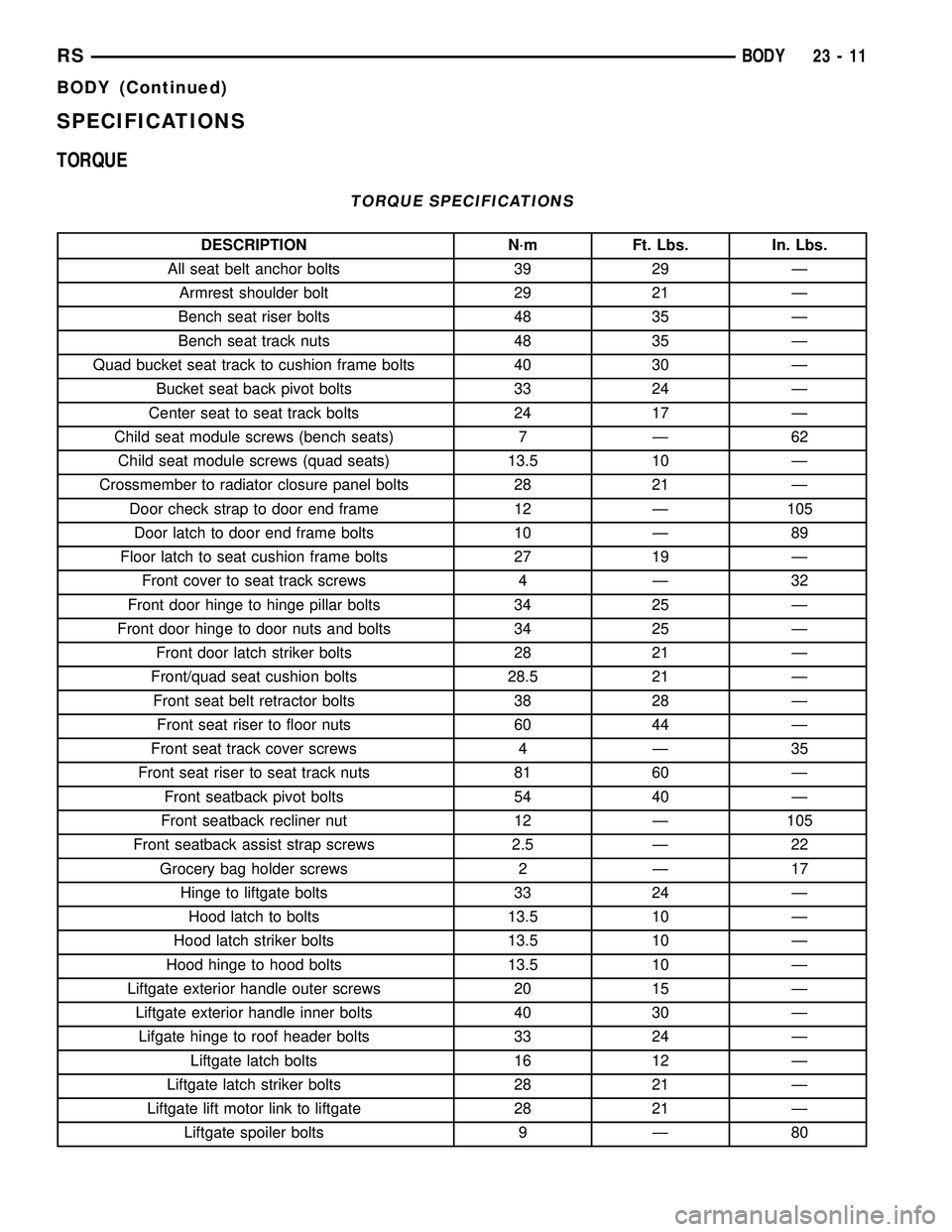

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

All seat belt anchor bolts 39 29 Ð

Armrest shoulder bolt 29 21 Ð

Bench seat riser bolts 48 35 Ð

Bench seat track nuts 48 35 Ð

Quad bucket seat track to cushion frame bolts 40 30 Ð

Bucket seat back pivot bolts 33 24 Ð

Center seat to seat track bolts 24 17 Ð

Child seat module screws (bench seats) 7 Ð 62

Child seat module screws (quad seats) 13.5 10 Ð

Crossmember to radiator closure panel bolts 28 21 Ð

Door check strap to door end frame 12 Ð 105

Door latch to door end frame bolts 10 Ð 89

Floor latch to seat cushion frame bolts 27 19 Ð

Front cover to seat track screws 4 Ð 32

Front door hinge to hinge pillar bolts 34 25 Ð

Front door hinge to door nuts and bolts 34 25 Ð

Front door latch striker bolts 28 21 Ð

Front/quad seat cushion bolts 28.5 21 Ð

Front seat belt retractor bolts 38 28 Ð

Front seat riser to floor nuts 60 44 Ð

Front seat track cover screws 4 Ð 35

Front seat riser to seat track nuts 81 60 Ð

Front seatback pivot bolts 54 40 Ð

Front seatback recliner nut 12 Ð 105

Front seatback assist strap screws 2.5 Ð 22

Grocery bag holder screws 2 Ð 17

Hinge to liftgate bolts 33 24 Ð

Hood latch to bolts 13.5 10 Ð

Hood latch striker bolts 13.5 10 Ð

Hood hinge to hood bolts 13.5 10 Ð

Liftgate exterior handle outer screws 20 15 Ð

Liftgate exterior handle inner bolts 40 30 Ð

Lifgate hinge to roof header bolts 33 24 Ð

Liftgate latch bolts 16 12 Ð

Liftgate latch striker bolts 28 21 Ð

Liftgate lift motor link to liftgate 28 21 Ð

Liftgate spoiler bolts 9 Ð 80

RSBODY23-11

BODY (Continued)

Page 2126 of 2585

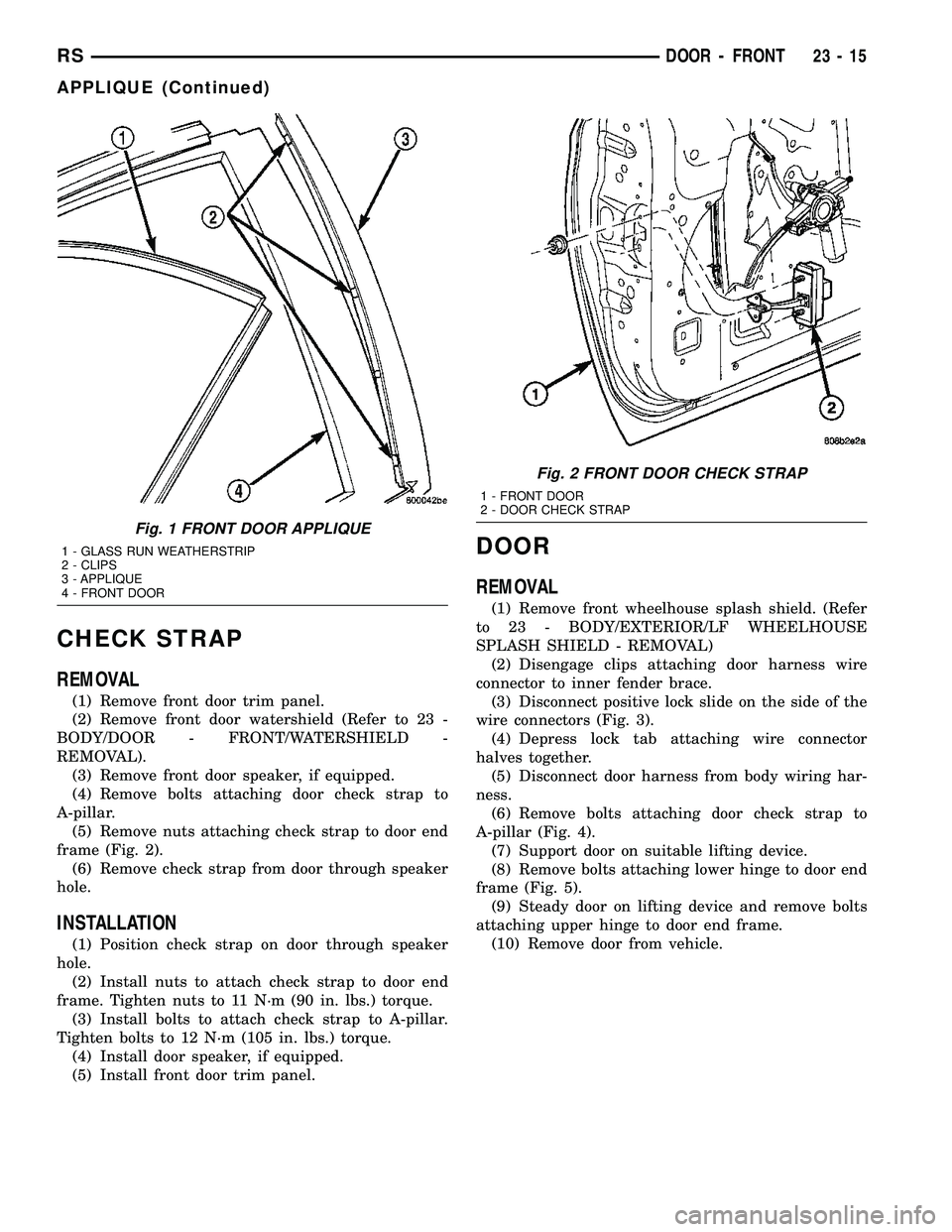

CHECK STRAP

REMOVAL

(1) Remove front door trim panel.

(2) Remove front door watershield (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL).

(3) Remove front door speaker, if equipped.

(4) Remove bolts attaching door check strap to

A-pillar.

(5) Remove nuts attaching check strap to door end

frame (Fig. 2).

(6) Remove check strap from door through speaker

hole.

INSTALLATION

(1) Position check strap on door through speaker

hole.

(2) Install nuts to attach check strap to door end

frame. Tighten nuts to 11 N´m (90 in. lbs.) torque.

(3) Install bolts to attach check strap to A-pillar.

Tighten bolts to 12 N´m (105 in. lbs.) torque.

(4) Install door speaker, if equipped.

(5) Install front door trim panel.

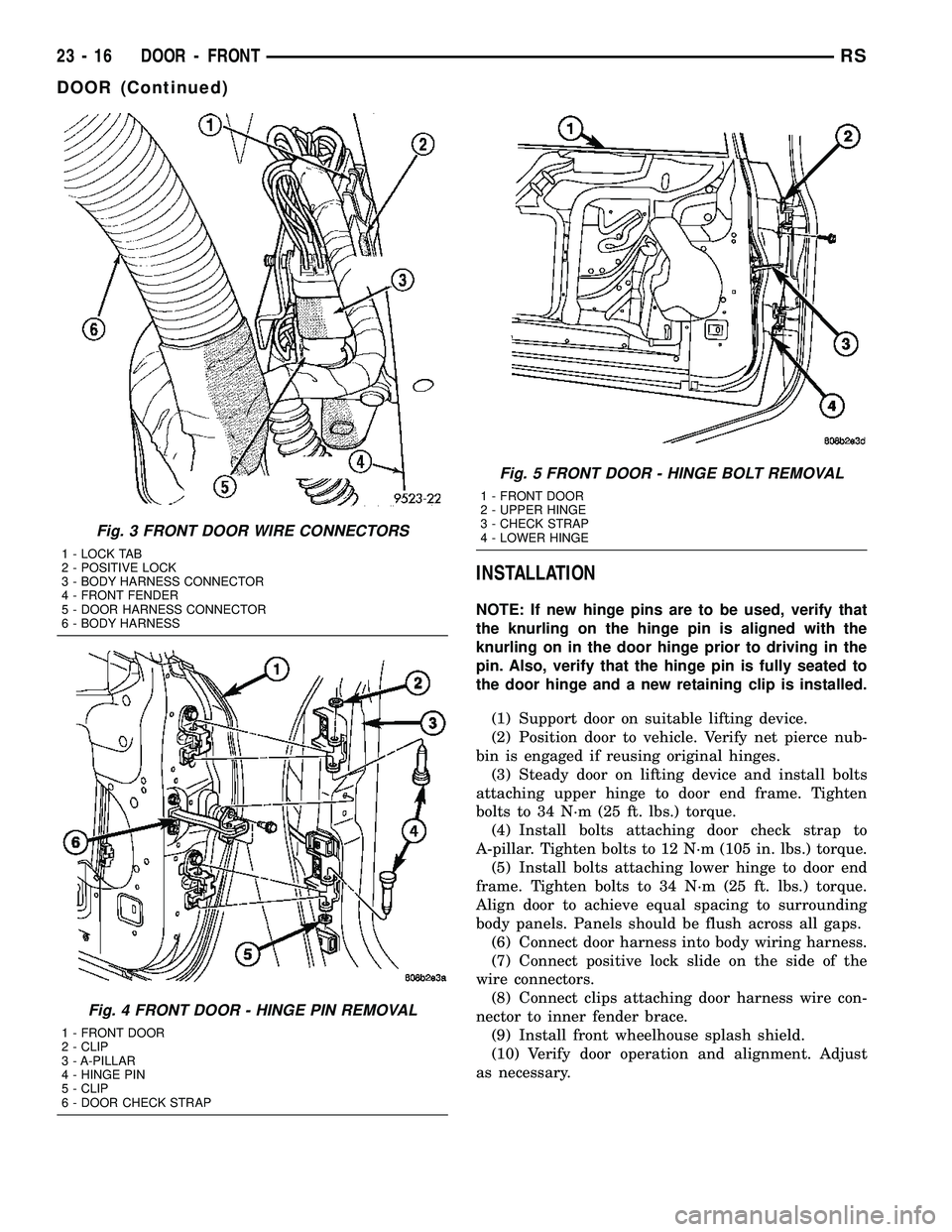

DOOR

REMOVAL

(1) Remove front wheelhouse splash shield. (Refer

to 23 - BODY/EXTERIOR/LF WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(2) Disengage clips attaching door harness wire

connector to inner fender brace.

(3) Disconnect positive lock slide on the side of the

wire connectors (Fig. 3).

(4) Depress lock tab attaching wire connector

halves together.

(5) Disconnect door harness from body wiring har-

ness.

(6) Remove bolts attaching door check strap to

A-pillar (Fig. 4).

(7) Support door on suitable lifting device.

(8) Remove bolts attaching lower hinge to door end

frame (Fig. 5).

(9) Steady door on lifting device and remove bolts

attaching upper hinge to door end frame.

(10) Remove door from vehicle.

Fig. 1 FRONT DOOR APPLIQUE

1 - GLASS RUN WEATHERSTRIP

2 - CLIPS

3 - APPLIQUE

4 - FRONT DOOR

Fig. 2 FRONT DOOR CHECK STRAP

1 - FRONT DOOR

2 - DOOR CHECK STRAP

RSDOOR - FRONT23-15

APPLIQUE (Continued)

Page 2127 of 2585

INSTALLATION

NOTE: If new hinge pins are to be used, verify that

the knurling on the hinge pin is aligned with the

knurling on in the door hinge prior to driving in the

pin. Also, verify that the hinge pin is fully seated to

the door hinge and a new retaining clip is installed.

(1) Support door on suitable lifting device.

(2) Position door to vehicle. Verify net pierce nub-

bin is engaged if reusing original hinges.

(3) Steady door on lifting device and install bolts

attaching upper hinge to door end frame. Tighten

bolts to 34 N´m (25 ft. lbs.) torque.

(4) Install bolts attaching door check strap to

A-pillar. Tighten bolts to 12 N´m (105 in. lbs.) torque.

(5) Install bolts attaching lower hinge to door end

frame. Tighten bolts to 34 N´m (25 ft. lbs.) torque.

Align door to achieve equal spacing to surrounding

body panels. Panels should be flush across all gaps.

(6) Connect door harness into body wiring harness.

(7) Connect positive lock slide on the side of the

wire connectors.

(8) Connect clips attaching door harness wire con-

nector to inner fender brace.

(9) Install front wheelhouse splash shield.

(10) Verify door operation and alignment. Adjust

as necessary.

Fig. 3 FRONT DOOR WIRE CONNECTORS

1 - LOCK TAB

2 - POSITIVE LOCK

3 - BODY HARNESS CONNECTOR

4 - FRONT FENDER

5 - DOOR HARNESS CONNECTOR

6 - BODY HARNESS

Fig. 4 FRONT DOOR - HINGE PIN REMOVAL

1 - FRONT DOOR

2 - CLIP

3 - A-PILLAR

4 - HINGE PIN

5 - CLIP

6 - DOOR CHECK STRAP

Fig. 5 FRONT DOOR - HINGE BOLT REMOVAL

1 - FRONT DOOR

2 - UPPER HINGE

3 - CHECK STRAP

4 - LOWER HINGE

23 - 16 DOOR - FRONTRS

DOOR (Continued)

Page 2129 of 2585

(5) Remove bolts attaching hinge to pillar.

(6) Remove door hinge from vehicle.

INSTALLATION

CAUTION: When installing a new hinge, make sure

that the head of each hinge pin is fully seated into

the door hinge. Also, remove the plastic shipping

clip and replace it with the correct metal retaining

clip once the hinge pin is seated.

(1) Paint hinge prior to installation, if necessary.

(2) Position door hinge on vehicle.

(3) Install bolts attaching hinge to pillar. Tighten

bolts to 34 N´m (25 ft. lbs.).

(4) Install bolts attaching front door to door hinge.

Tighten bolts to 34 N´m (25 ft. lbs.).

(5) Align door to achieve equal spacing to sur-

rounding body panels. Panels should be flush across

all gaps.

(6) Verify door alignment and operation. Adjust as

necessary.

LATCH

REMOVAL

(1) Roll door glass up.

(2) Remove front door trim panel. (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL)

(3) Remove watershield as necessary to gain access

to the outside door handle.

(4) Through access hole at rear of inner door

panel, disconnect wire connector from power door

lock motor, if equipped.

(5) Disengage clips holding linkage to door latch

(Fig. 8).

(6) Remove linkages from door latch.

(7) Remove screws attaching door latch to door end

frame (Fig. 9).

(8) Remove door latch from door.

INSTALLATION

NOTE: The screws attaching the door latch to the

door end frame have nylon patches on the threads.

All screws must be replaced when the latch has

been removed.

(1) Insert inside handle latch link to door latch

and engage clip (Fig. 8).

(2) Place door latch in position on door end frame.

(3) Install screws attaching door latch to door end

frame. Tighten screws to 10 N´m (90 in. lbs.) torque

(Fig. 9).

(4) Insert other linkages to door latch and engage

clips.(5) Connect wire connector into power door lock

motor, if equipped.

(6) Insert a hex wrench through the elongated hole

located in the door shut face above the latch.

(7) Loosen allen head screw.

(8) Pull outward on the outside door handle and

release.

(9) Tighten allen head screw.

Fig. 8 LATCH ASSEMBLY

1 - OUTSIDE HANDLE TO LATCH LINK

2 - KEY CYLINDER TO LATCH LINK

3 - LATCH ASSEMBLY

4 - INSIDE HANDLE LINK AND SLEEVE

5 - LOCK KNOB LINK

Fig. 9 FRONT DOOR LATCH

1 - FRONT DOOR

2 - LATCH ASSEMBLY

3 - INSIDE HANDLE LINK

23 - 18 DOOR - FRONTRS

HINGE (Continued)

Page 2130 of 2585

(10) Verify door latch and power door lock opera-

tion.

(11) Install watershield and front door trim panel.

LATCH STRIKER

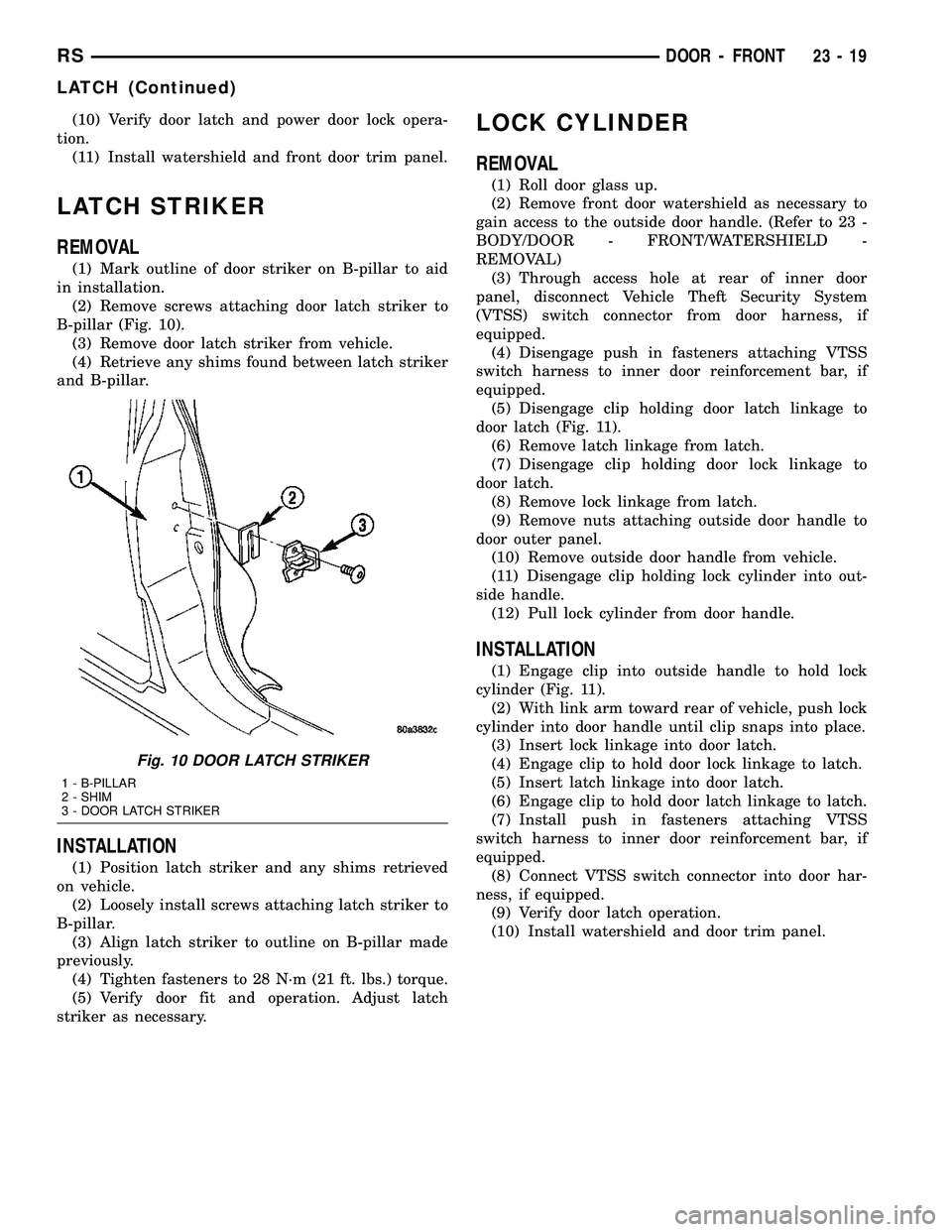

REMOVAL

(1) Mark outline of door striker on B-pillar to aid

in installation.

(2) Remove screws attaching door latch striker to

B-pillar (Fig. 10).

(3) Remove door latch striker from vehicle.

(4) Retrieve any shims found between latch striker

and B-pillar.

INSTALLATION

(1) Position latch striker and any shims retrieved

on vehicle.

(2) Loosely install screws attaching latch striker to

B-pillar.

(3) Align latch striker to outline on B-pillar made

previously.

(4) Tighten fasteners to 28 N´m (21 ft. lbs.) torque.

(5) Verify door fit and operation. Adjust latch

striker as necessary.

LOCK CYLINDER

REMOVAL

(1) Roll door glass up.

(2) Remove front door watershield as necessary to

gain access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts attaching outside door handle to

door outer panel.

(10) Remove outside door handle from vehicle.

(11) Disengage clip holding lock cylinder into out-

side handle.

(12) Pull lock cylinder from door handle.

INSTALLATION

(1) Engage clip into outside handle to hold lock

cylinder (Fig. 11).

(2) With link arm toward rear of vehicle, push lock

cylinder into door handle until clip snaps into place.

(3) Insert lock linkage into door latch.

(4) Engage clip to hold door lock linkage to latch.

(5) Insert latch linkage into door latch.

(6) Engage clip to hold door latch linkage to latch.

(7) Install push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(8) Connect VTSS switch connector into door har-

ness, if equipped.

(9) Verify door latch operation.

(10) Install watershield and door trim panel.

Fig. 10 DOOR LATCH STRIKER

1 - B-PILLAR

2 - SHIM

3 - DOOR LATCH STRIKER

RSDOOR - FRONT23-19

LATCH (Continued)

Page 2136 of 2585

NOTE: Center hinge has an adjustable bolt for

up/down alignment. (Refer to 23 - BODY/DOORS -

SLIDING/SLIDING DOOR - ADJUSTMENTS)

(1) Place center hinge in position on vehicle.

(2) Roll center hinge forward in roller channel.

(3) Place center hinge in position on sliding door

and align marks.

(4) Install bolts attaching center hinge to sliding

door.

(5) Verify sliding door alignment and operation.

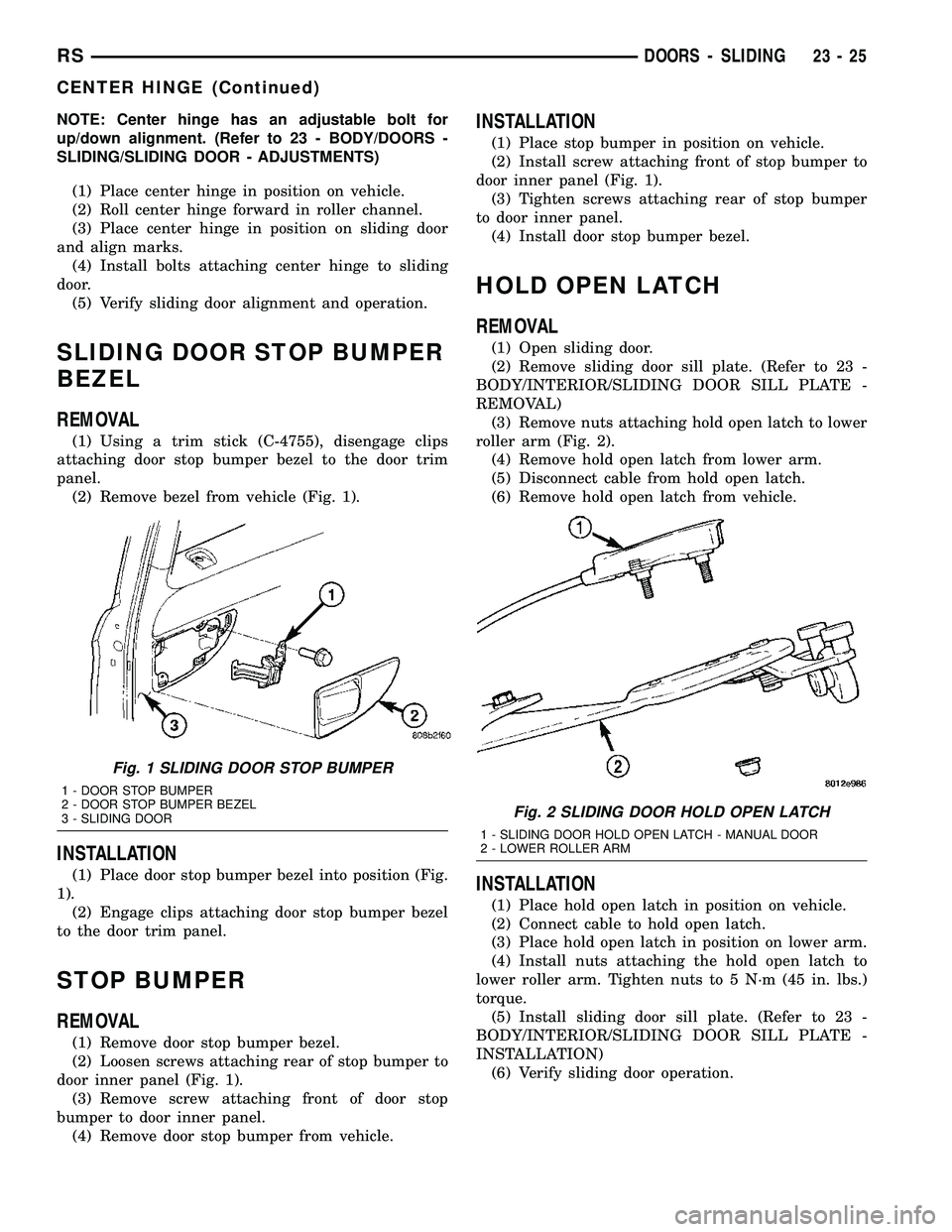

SLIDING DOOR STOP BUMPER

BEZEL

REMOVAL

(1) Using a trim stick (C-4755), disengage clips

attaching door stop bumper bezel to the door trim

panel.

(2) Remove bezel from vehicle (Fig. 1).

INSTALLATION

(1) Place door stop bumper bezel into position (Fig.

1).

(2) Engage clips attaching door stop bumper bezel

to the door trim panel.

STOP BUMPER

REMOVAL

(1) Remove door stop bumper bezel.

(2) Loosen screws attaching rear of stop bumper to

door inner panel (Fig. 1).

(3) Remove screw attaching front of door stop

bumper to door inner panel.

(4) Remove door stop bumper from vehicle.

INSTALLATION

(1) Place stop bumper in position on vehicle.

(2) Install screw attaching front of stop bumper to

door inner panel (Fig. 1).

(3) Tighten screws attaching rear of stop bumper

to door inner panel.

(4) Install door stop bumper bezel.

HOLD OPEN LATCH

REMOVAL

(1) Open sliding door.

(2) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(3) Remove nuts attaching hold open latch to lower

roller arm (Fig. 2).

(4) Remove hold open latch from lower arm.

(5) Disconnect cable from hold open latch.

(6) Remove hold open latch from vehicle.

INSTALLATION

(1) Place hold open latch in position on vehicle.

(2) Connect cable to hold open latch.

(3) Place hold open latch in position on lower arm.

(4) Install nuts attaching the hold open latch to

lower roller arm. Tighten nuts to 5 N´m (45 in. lbs.)

torque.

(5) Install sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(6) Verify sliding door operation.

Fig. 1 SLIDING DOOR STOP BUMPER

1 - DOOR STOP BUMPER

2 - DOOR STOP BUMPER BEZEL

3 - SLIDING DOOR

Fig. 2 SLIDING DOOR HOLD OPEN LATCH

1 - SLIDING DOOR HOLD OPEN LATCH - MANUAL DOOR

2 - LOWER ROLLER ARM

RSDOORS - SLIDING23-25

CENTER HINGE (Continued)

Page 2140 of 2585

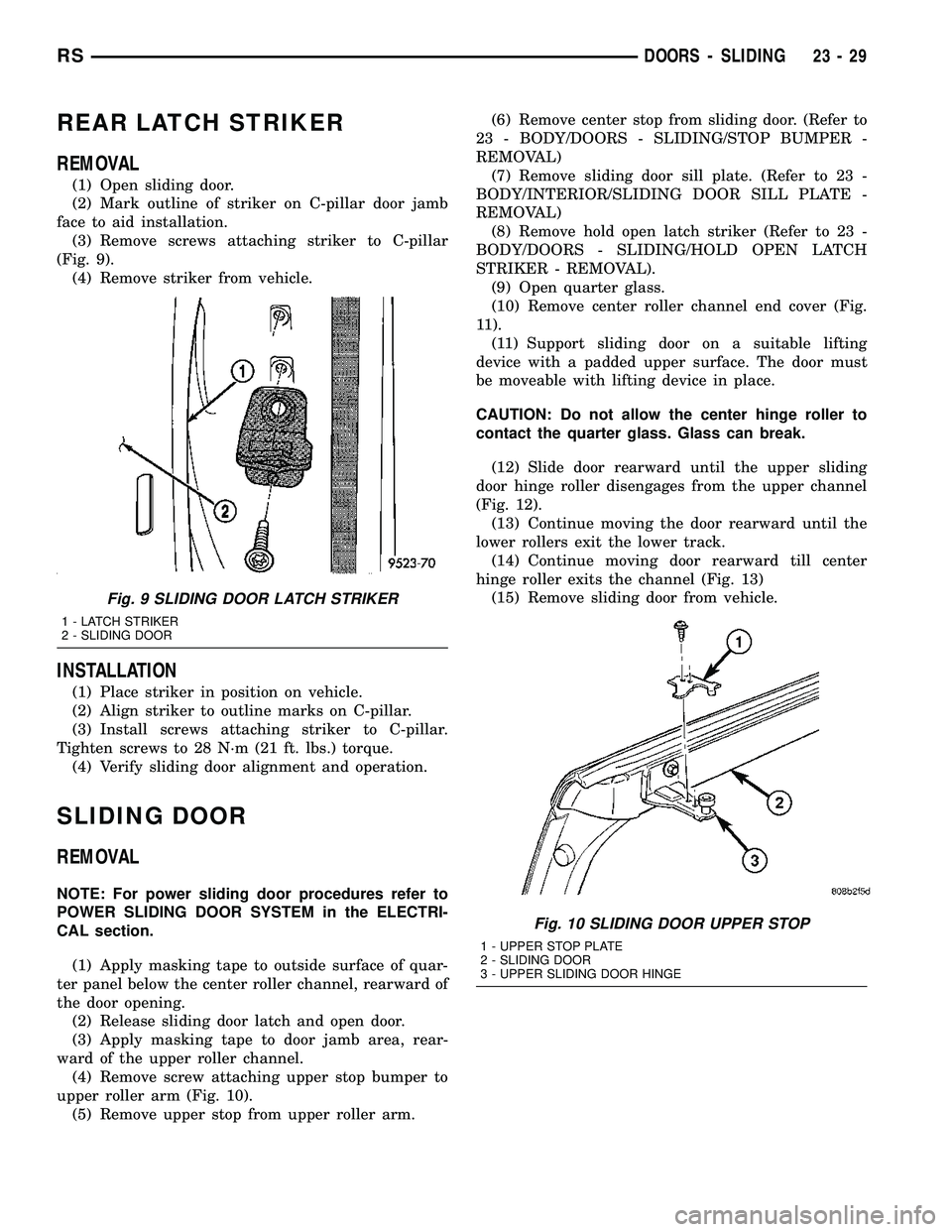

REAR LATCH STRIKER

REMOVAL

(1) Open sliding door.

(2) Mark outline of striker on C-pillar door jamb

face to aid installation.

(3) Remove screws attaching striker to C-pillar

(Fig. 9).

(4) Remove striker from vehicle.

INSTALLATION

(1) Place striker in position on vehicle.

(2) Align striker to outline marks on C-pillar.

(3) Install screws attaching striker to C-pillar.

Tighten screws to 28 N´m (21 ft. lbs.) torque.

(4) Verify sliding door alignment and operation.

SLIDING DOOR

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Apply masking tape to outside surface of quar-

ter panel below the center roller channel, rearward of

the door opening.

(2) Release sliding door latch and open door.

(3) Apply masking tape to door jamb area, rear-

ward of the upper roller channel.

(4) Remove screw attaching upper stop bumper to

upper roller arm (Fig. 10).

(5) Remove upper stop from upper roller arm.(6) Remove center stop from sliding door. (Refer to

23 - BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(7) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(8) Remove hold open latch striker (Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - REMOVAL).

(9) Open quarter glass.

(10) Remove center roller channel end cover (Fig.

11).

(11) Support sliding door on a suitable lifting

device with a padded upper surface. The door must

be moveable with lifting device in place.

CAUTION: Do not allow the center hinge roller to

contact the quarter glass. Glass can break.

(12) Slide door rearward until the upper sliding

door hinge roller disengages from the upper channel

(Fig. 12).

(13) Continue moving the door rearward until the

lower rollers exit the lower track.

(14) Continue moving door rearward till center

hinge roller exits the channel (Fig. 13)

(15) Remove sliding door from vehicle.

Fig. 9 SLIDING DOOR LATCH STRIKER

1 - LATCH STRIKER

2 - SLIDING DOOR

Fig. 10 SLIDING DOOR UPPER STOP

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

RSDOORS - SLIDING23-29