torque CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2079 of 2585

(2) Install transaxle oil filter (Fig. 187). Inspect

the o-ring and replace if necessary.

(3) Ensure the transaxle oil pan and transaxle

case sealing surfaces are clean and dry. Install an

1/8º bead of Mopar tSilicone Rubber Adhesive Seal-

ant to the oil pan and install (Fig. 188). Torque oil

pan-to-transaxle case bolts (Fig. 189) to 19 N´m (165

in. lbs.). (4) Lower vehicle.

(5) Connect transmission range sensor connector.

(6) Install manual valve lever to manual shaft.

(7) Install gearshift cable to manual valve lever.

(8) Connect battery negative cable.

(9) Fill transaxle with Mopar

tATF +4 Transmis-

sion fluid. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 186 Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 187 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 188 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

Fig. 189 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

21s - 218 41TE AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

Page 2088 of 2585

(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires (excludes spare).

Pressure in the spare tire is not monitored.

There is a sensor (transmitter) in each of the vehi-

cle's four road wheels. The system alerts the driver

when tire pressure falls outside predetermined

thresholds (pressure too low or too high). A message

is then displayed on the Electronic Vehicle Informa-

tion Center (EVIC) located in the overhead console.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit tire pressure read-

ings to a receiver located in the overhead console.

These transmissions occur once every minute at

speeds over 20 mph (32 km/h). The Tire Pressure

Monitoring system remains active even if no tire

pressure related message is displayed in the EVIC.

If any road tire pressure has exceeded the low or

high pressure threshold (refer to chart below), the

TPM system will display a message in the EVIC and

sound a chime. This message will be displayed for

the rest of the ignition cycle, or until either the Low/

High Tire pressure condition has been corrected. If

the C/T, MENU, STEP or RESET button is pressed,

the message is replaced by the new message

requested; however, if the Low/High Tire condition

has not been corrected, the Low/High Tire pressure

message will again be displayed.

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

Page 2089 of 2585

If a road tire is replaced by the spare, the TPM

system will detect the swap and the message9SPARE

TIRE IN USE? Y/N9(along with a chime) will be dis-

played.

For further information, refer to the Owners Man-

ual or the Appropriate Diagnostic Information.

TPM THRESHOLD PRESSURES

High Pressure ON Threshold 48 PSI (331 kPa)

High Pressure OFF Threshold 43 PSI (296 kPa)

Placard Pressure (Cold) 36 PSI (248 kPa)

Low Pressure OFF Threshold 33 PSI (228 kPa)

Low Pressure ON Threshold 28 PSI (193 kPa)

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each

wheel (Fig. 19). Each sensor has an internal battery

that lasts up to 10 years. The battery is not service-

able. At the time of battery failure, the sensor must

be replaced. The serviceable components of the tire

pressure sensor are:

²Sensor-To-Wheel Grommet

²Valve Stem Cap

²Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

CAUTION: Do not try to install a tire pressure sen-

sor in a steel wheel or aftermarket wheel. Use only

in original style factory wheels.

OPERATION

Tire pressure sensors are battery operated. They

transmit tire pressure data once every minute at

speeds above 20 mph (32 km/h) or up to once every

hour when stationary (parked). For additional infor-

mation, refer to Appropriate Diagnostic Information.

CAUTION

CAUTION: The use of tire sealants is strictly prohib-

ited for vehicles equipped with the Tire Pressure

Monitoring system. Tire sealants can clog tire pres-

sure sensors.

CAUTION: Tire pressure sensor valve stem caps

and cores are specially designed for the sensors.

Due to risk of corrosion, do not use a standard

valve stem cap or core in a tire pressure sensor in

place of the original equipment style sensor cap

and core.

CAUTION: Do not attempt to install a tire pressure

sensor in a steel wheel or aftermarket wheel. Use

tire pressure sensors in original style factory

wheels only.

NOTE: TPM thresholds have been established for

the original tire size equipped on the vehicle. Use

original size tires only to maintain system accuracy.

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR

NOTE: Tire pressure may increase from 2 to 6 psi

(14 to 41 kPa) during normal driving conditions. Do

NOT reduce this normal pressure build up.

If a fault in the system is detected, always check

air pressure in the tires first with a known accurate

air gauge and correct the inflation pressure. If any

tire is low, inspectalltires.

If gauge-read pressure in the tires does not reflect

the reading on the EVIC, retrain the sensors, then

reevaluate (Refer to 22 - TIRES/WHEELS/TIRE

PRESSURE MONITORING/SENSOR - STANDARD

PROCEDURE). Refer to the appropriate diagnostic

information for complete diagnosis of the Tire Pres-

sure Monitoring System.

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN

WARNING: DEATH OR SERIOUS INJURY CAN

OCCUR IF MAGNETICALLY SENSITIVE DEVICES

ARE EXPOSED TO THE RELEARN MAGNET. MAG-

NETS CAN AFFECT PACEMAKERS.

22 - 10 TIRES/WHEELSRS

TIRE PRESSURE MONITORING (Continued)

Page 2091 of 2585

INSTALLATION

NOTE: Before reinstalling a tire pressure sensor,

replace sealing grommet at base of valve stem.

(1) Wipe area clean where sensor sealing grommet

contacts wheel. Make sure surface of wheel is not

damaged.

(2) Install sensor in wheel as shown (Fig. 19). Do

not attempt to mount sensor otherwise, damage may

occur.

(3) Using a thin wall socket, install special sensor

nut (Fig. 19). Tighten nut to 4 N´m (35 in. lbs.)

torque.

CAUTION: Over-torquing the sensor nut by as little

as 12 N´m (106 in. lbs.) may result in sensor sepa-

ration from the valve stem. Under this condition,

the sensor may still function, however, the condi-

tion should be corrected immediately.

(4) Mount tire on wheel following tire changer

manufacturers instructions, paying special attention

to the following to avoid damaging tire pressure sen-

sor:

(a) Rotating Wheel Tire Changers - Once the

wheel is mounted to the changer, position the sen-

sor valve stem approximately 210É from the head

of the changer in a clockwise direction before rotat-

ing the wheel (also in a clockwise direction) to

mount the tire (Fig. 20). Use this procedure on

both the upper and lower tire beads.

(b) Rotating Tool Tire Changers - Position the

wheel on the changer so that the sensor valve stem

is approximately 210É from the head of the changer

in a clockwise direction from the mounting end of

the tool (Fig. 21) Make sure the sensor is clear of

the lower bead breaker area to avoid damaging the

sensor when the breaker rises (Fig. 21). Rotate the

tool in a counterclockwise direction to mount the

tire. Use this procedure on both the upper and

lower tire beads.

(5) Install wheel and tire assembly on vehicle.

(Refer to 22 - TIRES/WHEELS - INSTALLATION)

(6) Retrain tire pressure sensors. (Refer to 22 -

TIRES/WHEELS/TIRE PRESSURE MONITORING/

SENSOR - STANDARD PROCEDURE)

Fig. 18 Start Mount/Dismount Tool Within 10

Degrees Of Valve Stem

Fig. 19 Sensor Mounting To Wheel

1 - TIRE PRESSURE SENSOR

2 - WHEEL

3 - NUT

22 - 12 TIRES/WHEELSRS

SENSOR - TPM (Continued)

Page 2096 of 2585

pressures may increase from 2 to 6 pounds per

square inch (psi) (14 to 41 kPa) during operation. Do

not reduce this normal pressure buildup.

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

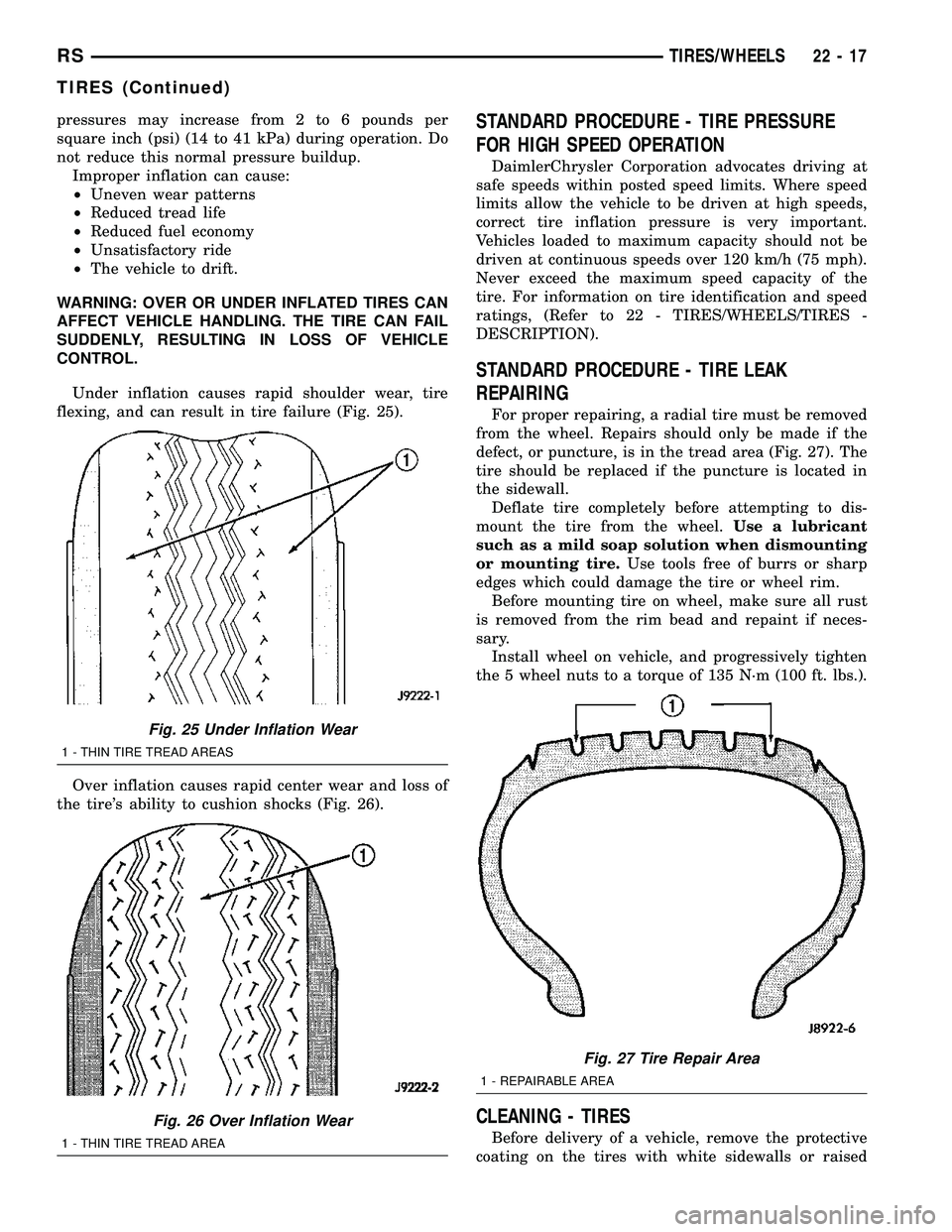

Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 25).

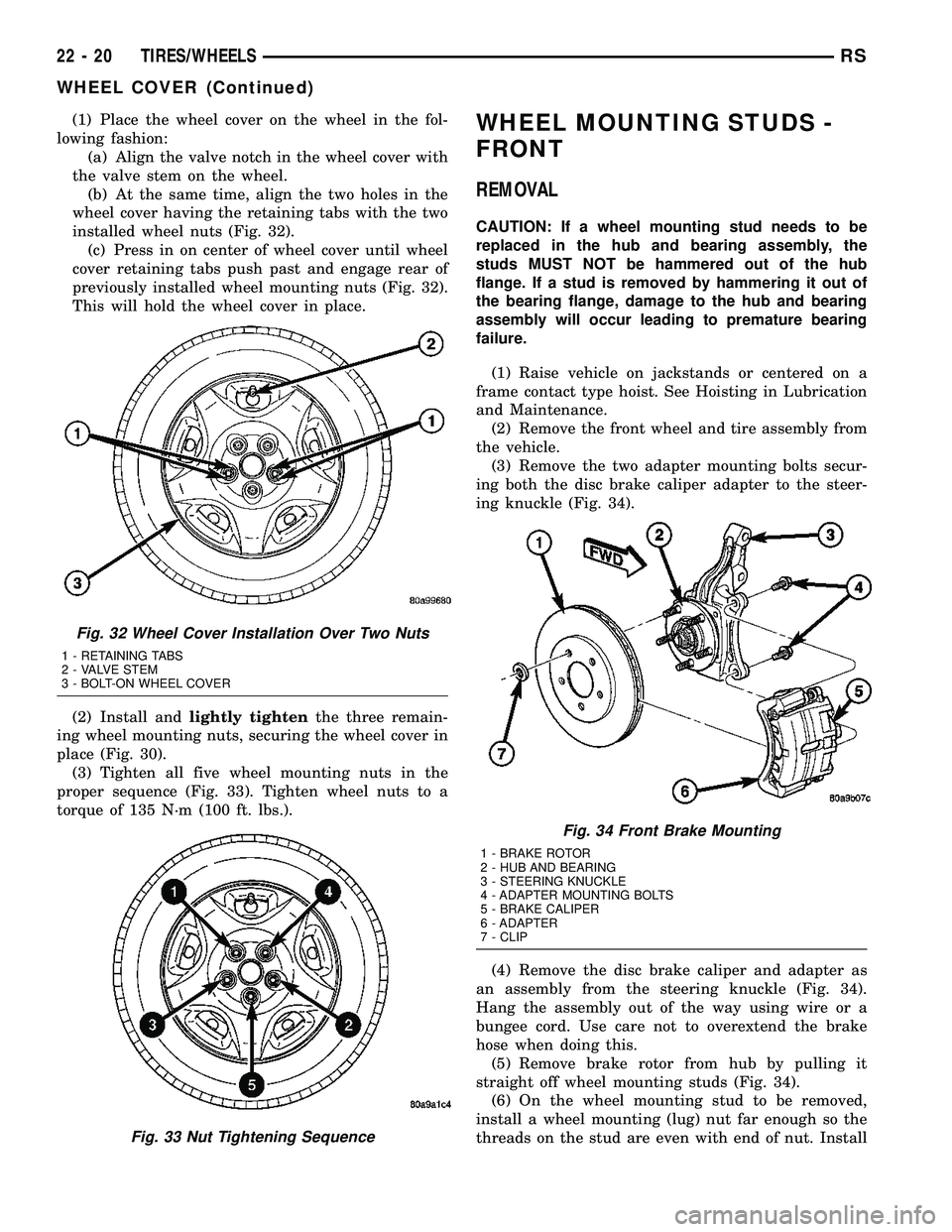

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 26).STANDARD PROCEDURE - TIRE PRESSURE

FOR HIGH SPEED OPERATION

DaimlerChrysler Corporation advocates driving at

safe speeds within posted speed limits. Where speed

limits allow the vehicle to be driven at high speeds,

correct tire inflation pressure is very important.

Vehicles loaded to maximum capacity should not be

driven at continuous speeds over 120 km/h (75 mph).

Never exceed the maximum speed capacity of the

tire. For information on tire identification and speed

ratings, (Refer to 22 - TIRES/WHEELS/TIRES -

DESCRIPTION).

STANDARD PROCEDURE - TIRE LEAK

REPAIRING

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 27). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before attempting to dis-

mount the tire from the wheel.Use a lubricant

such as a mild soap solution when dismounting

or mounting tire.Use tools free of burrs or sharp

edges which could damage the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and progressively tighten

the 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

CLEANING - TIRES

Before delivery of a vehicle, remove the protective

coating on the tires with white sidewalls or raised

Fig. 25 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

Fig. 26 Over Inflation Wear

1 - THIN TIRE TREAD AREA

Fig. 27 Tire Repair Area

1 - REPAIRABLE AREA

RSTIRES/WHEELS22-17

TIRES (Continued)

Page 2098 of 2585

Care must be taken in the selection of tire and

wheel cleaning chemicals and equipment to prevent

damage to the wheels. Any of the ªDO NOT USEº

items listed below WILL damage chrome plated and

painted aluminum wheels.

DO NOT USE:

²any abrasive metal cleaner

²any abrasive cleaning pad or brush

²any cleaner that contains an acid (this will

immediately react with and discolor the chromium

surface)

²chrome polish (unless it is buffed off immedi-

ately after application)

²oven cleaner

²a car wash that uses carbide-tipped wheel clean-

ing brushes

SPECIFICATIONS

WHEEL

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Wheel Mounting (Lug)

Nut Hex Size19 mm

Wheel Mounting Stud

SizeM12 x 1.5 mm

TORQUE SPECIFICATIONS

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

TPM Sensor Mounting Nut 4 Ð 35

Wheel Mounting (Lug ) Nut 135 100 Ð

WHEEL COVER

DESCRIPTION

This vehicle uses a bolt-on type wheel cover (Fig.

30).

This bolt-on wheel cover cannot be removed from

the wheel until three of the five wheel mounting nuts

shown are removed (Fig. 30). The bolt-on wheel cover

can then be removed with the remaining two wheel

nuts tightened in place.

REMOVAL

(1) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 30).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can resultin damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

INSTALLATION

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 31).

Fig. 30 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 31 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

RSTIRES/WHEELS22-19

WHEELS (Continued)

Page 2099 of 2585

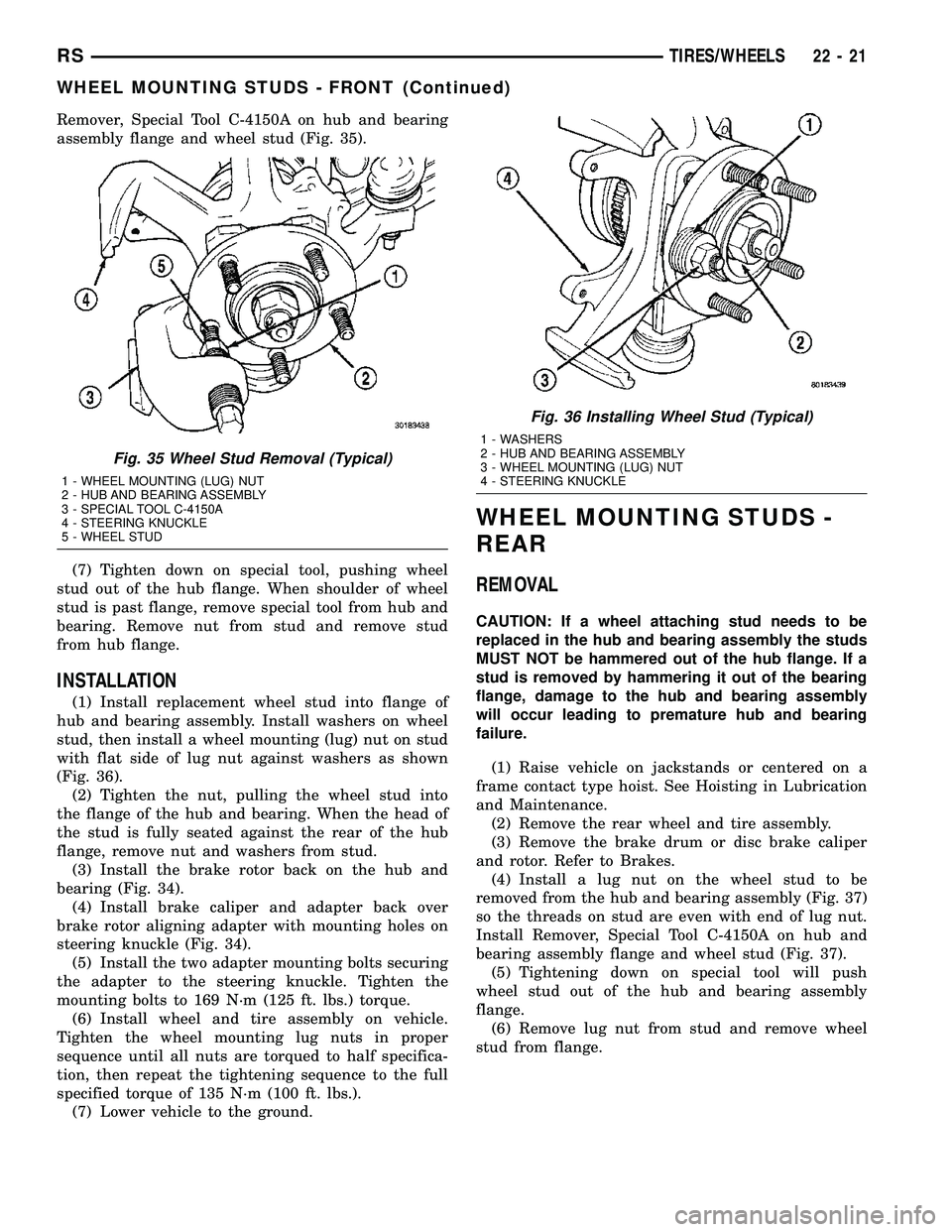

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 32).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 32).

This will hold the wheel cover in place.

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 30).

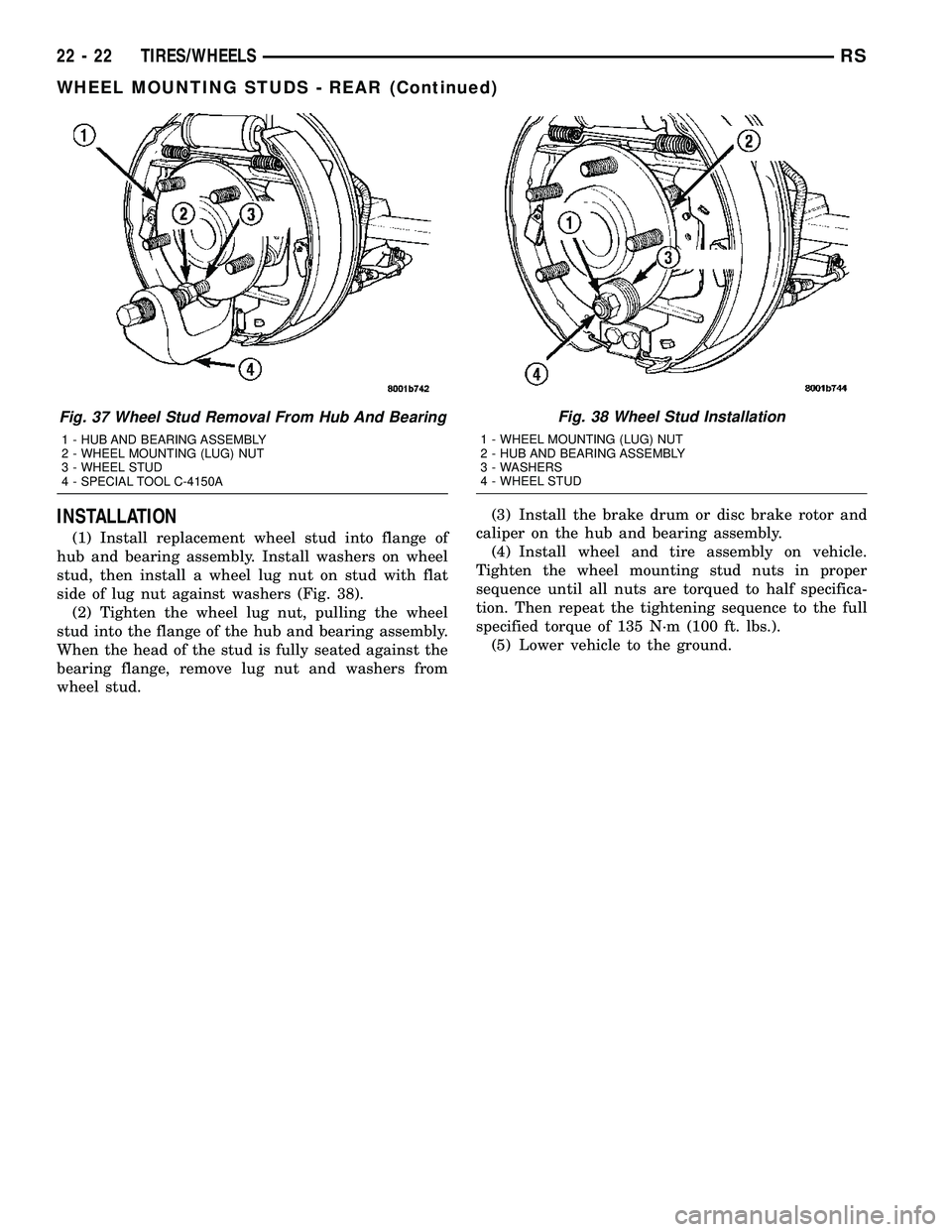

(3) Tighten all five wheel mounting nuts in the

proper sequence (Fig. 33). Tighten wheel nuts to a

torque of 135 N´m (100 ft. lbs.).WHEEL MOUNTING STUDS -

FRONT

REMOVAL

CAUTION: If a wheel mounting stud needs to be

replaced in the hub and bearing assembly, the

studs MUST NOT be hammered out of the hub

flange. If a stud is removed by hammering it out of

the bearing flange, damage to the hub and bearing

assembly will occur leading to premature bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the front wheel and tire assembly from

the vehicle.

(3) Remove the two adapter mounting bolts secur-

ing both the disc brake caliper adapter to the steer-

ing knuckle (Fig. 34).

(4) Remove the disc brake caliper and adapter as

an assembly from the steering knuckle (Fig. 34).

Hang the assembly out of the way using wire or a

bungee cord. Use care not to overextend the brake

hose when doing this.

(5) Remove brake rotor from hub by pulling it

straight off wheel mounting studs (Fig. 34).

(6) On the wheel mounting stud to be removed,

install a wheel mounting (lug) nut far enough so the

threads on the stud are even with end of nut. Install

Fig. 32 Wheel Cover Installation Over Two Nuts

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 33 Nut Tightening Sequence

Fig. 34 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

22 - 20 TIRES/WHEELSRS

WHEEL COVER (Continued)

Page 2100 of 2585

Remover, Special Tool C-4150A on hub and bearing

assembly flange and wheel stud (Fig. 35).

(7) Tighten down on special tool, pushing wheel

stud out of the hub flange. When shoulder of wheel

stud is past flange, remove special tool from hub and

bearing. Remove nut from stud and remove stud

from hub flange.

INSTALLATION

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel mounting (lug) nut on stud

with flat side of lug nut against washers as shown

(Fig. 36).

(2) Tighten the nut, pulling the wheel stud into

the flange of the hub and bearing. When the head of

the stud is fully seated against the rear of the hub

flange, remove nut and washers from stud.

(3) Install the brake rotor back on the hub and

bearing (Fig. 34).

(4) Install brake caliper and adapter back over

brake rotor aligning adapter with mounting holes on

steering knuckle (Fig. 34).

(5) Install the two adapter mounting bolts securing

the adapter to the steering knuckle. Tighten the

mounting bolts to 169 N´m (125 ft. lbs.) torque.

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting lug nuts in proper

sequence until all nuts are torqued to half specifica-

tion, then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(7) Lower vehicle to the ground.

WHEEL MOUNTING STUDS -

REAR

REMOVAL

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

MUST NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature hub and bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the rear wheel and tire assembly.

(3) Remove the brake drum or disc brake caliper

and rotor. Refer to Brakes.

(4) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly (Fig. 37)

so the threads on stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 37).

(5) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange.

(6) Remove lug nut from stud and remove wheel

stud from flange.

Fig. 35 Wheel Stud Removal (Typical)

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - SPECIAL TOOL C-4150A

4 - STEERING KNUCKLE

5 - WHEEL STUD

Fig. 36 Installing Wheel Stud (Typical)

1 - WASHERS

2 - HUB AND BEARING ASSEMBLY

3 - WHEEL MOUNTING (LUG) NUT

4 - STEERING KNUCKLE

RSTIRES/WHEELS22-21

WHEEL MOUNTING STUDS - FRONT (Continued)

Page 2101 of 2585

INSTALLATION

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 38).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.(3) Install the brake drum or disc brake rotor and

caliper on the hub and bearing assembly.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(5) Lower vehicle to the ground.

Fig. 37 Wheel Stud Removal From Hub And Bearing

1 - HUB AND BEARING ASSEMBLY

2 - WHEEL MOUNTING (LUG) NUT

3 - WHEEL STUD

4 - SPECIAL TOOL C-4150A

Fig. 38 Wheel Stud Installation

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - WASHERS

4 - WHEEL STUD

22 - 22 TIRES/WHEELSRS

WHEEL MOUNTING STUDS - REAR (Continued)

Page 2102 of 2585

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRE PRESSURE MONITORING............... 1TIRES................................... 5

TIRE PRESSURE MONITORING

TABLE OF CONTENTS

page page

TIRE PRESSURE MONITORING DESCRIPTION ..........................1

OPERATION ............................1

SENSOR - TPM DESCRIPTION ..........................1

OPERATION ............................2

CAUTION ..............................2 DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR .............................2

STANDARD PROCEDURE - TIRE PRESSURE SENSOR RETRAIN .....................2

REMOVAL .............................2

INSTALLATION ..........................3

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires. Pressure in the

spare tire is not monitored. There is a sensor (transmitter) in each of the vehi-

cle's four road wheels that is built in to the valve

stem. The system alerts the driver when tire pres-

sure falls outside predetermined thresholds (pressure

too low or too high). A message is then displayed on

the Compass Mini Trip Computer (CMTC). For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit an RF frequency

indicating their individual pressure to a receiver

located in the Sentry Key Remote Entry Module

(SKREEM). These transmissions occur approximately

once every minute at speeds over 13 mph (20 km/h).

The Tire Pressure Monitoring system remains active

even if no tire pressure related message is displayed.

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each

wheel (Fig. 2). Each sensor has an internal battery

that lasts up to 10 years. The battery is not service-

able. At the time of battery failure, the sensor must

be replaced. The serviceable components of the tire

pressure sensor are: ² Sensor-To-Wheel Grommet

² Valve Stem Cap

² Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

RS TIRES/WHEELS22s-1