torque CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1931 of 2585

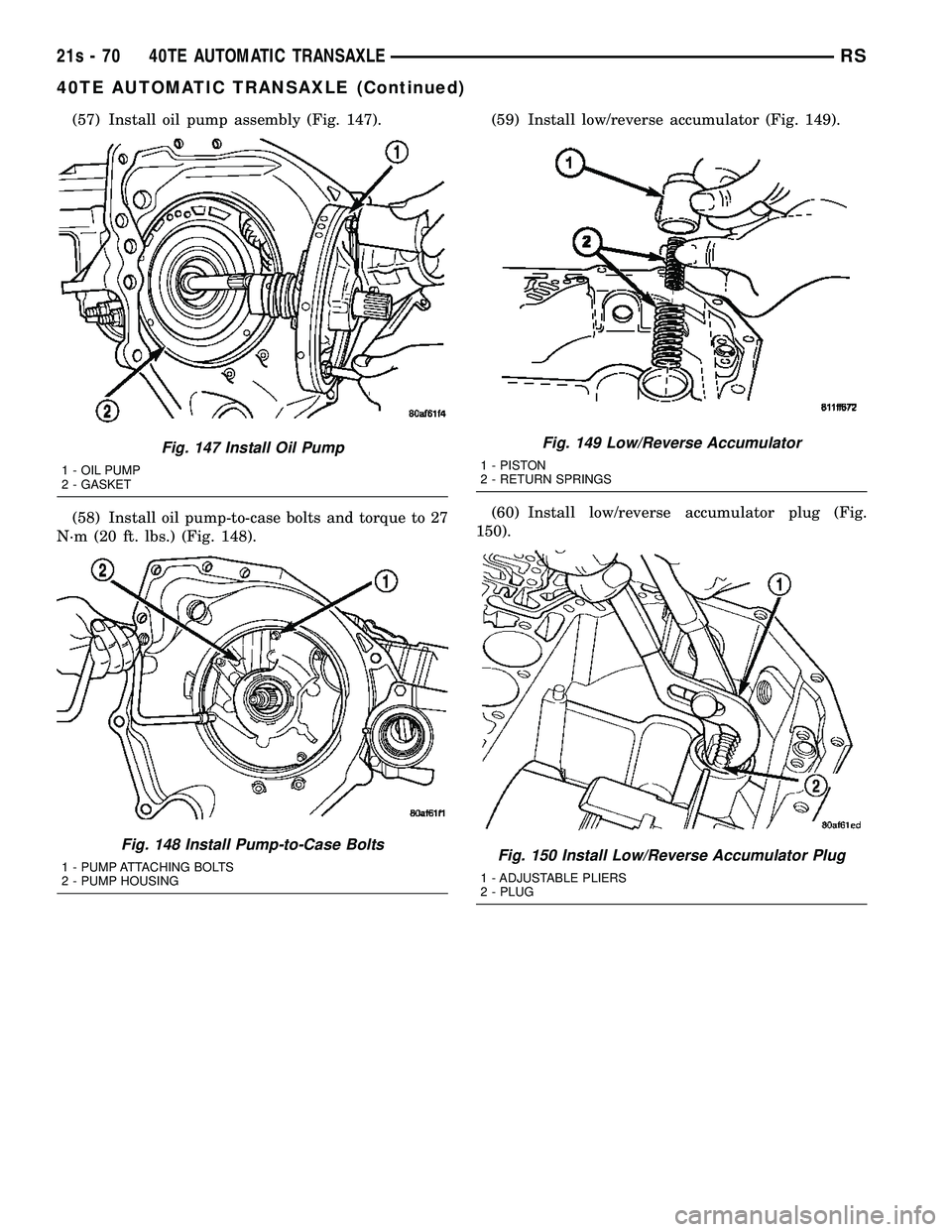

(57) Install oil pump assembly (Fig. 147).

(58) Install oil pump-to-case bolts and torque to 27

N´m (20 ft. lbs.) (Fig. 148). (59) Install low/reverse accumulator (Fig. 149).

(60) Install low/reverse accumulator plug (Fig.

150).

Fig. 147 Install Oil Pump

1 - OIL PUMP

2 - GASKET

Fig. 148 Install Pump-to-Case Bolts

1 - PUMP ATTACHING BOLTS

2 - PUMP HOUSING

Fig. 149 Low/Reverse Accumulator

1 - PISTON

2 - RETURN SPRINGS

Fig. 150 Install Low/Reverse Accumulator Plug

1 - ADJUSTABLE PLIERS

2 - PLUG

21s - 70 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1932 of 2585

(61) Install low/reverse accumulator snap ring

(Fig. 151).

NOTE: Depending on engine application, some

accumulators will have two springs, and others will

have one spring. The springs are color-coded for

application and year.

(62) Install underdrive and overdrive accumulators

and springs (Fig. 152). (63) Install valve body to transaxle (Fig. 153).

Rotate manual valve shaft fully clockwise to ease

installation. Make sure park rod rollers are posi-

tioned within park guide bracket.

(64) Install and torque valve body-to-case bolts to

12 N´m (105 in. lbs.) (Fig. 154).

Fig. 151 Install Low/Reverse Accumulator Snap Ring

1 - SNAP RING

2 - PLUG

Fig. 152 Underdrive and Overdrive Accumulators

1 - OVERDRIVE PISTON AND SPRING

2 - UNDERDRIVE PISTON AND SPRING

Fig. 153 Valve Body Removal/Installation

1 - VALVE BODY

Fig. 154 Install Valve Body-to-Case Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

RS 40TE AUTOMATIC TRANSAXLE21s-71

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1933 of 2585

(65) Install oil filter and new o-ring (Fig. 155).

(66) Apply an 1/8º bead of MopartATF RTV (MS-

GF41) to oil pan and immediately install to case (Fig.

156).

(67) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.). (68) Install solenoid/pressure switch assembly and

gasket to case (Fig. 157). (69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 158).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

Fig. 155 Install Oil Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 156 Install Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41)

3 - OIL FILTER

Fig. 157 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 158 Attaching Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

21s - 72 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1934 of 2585

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is nec-

essary to perfrom the TCM Quick Learn procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.). (2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 159). (3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 159). (4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.) (7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

(11) Align and install rear mount bracket-to-case

bolts by hand (Fig. 160). Torque horizontal bolt to

102 N´m (75 ft. lbs.). (12) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

Fig. 160 Rear Mount Bracket - Typical

1 - BOLT - VERTICAL 102 N´m (75 ft. lbs.)

2 - BRACKET - REAR MOUNT 3 - BOLT - HORIZONTAL 102 N´m (75 ft. lbs.)

Fig. 159 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

RS

40TE AUTOMATIC TRANSAXLE21s-73

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1935 of 2585

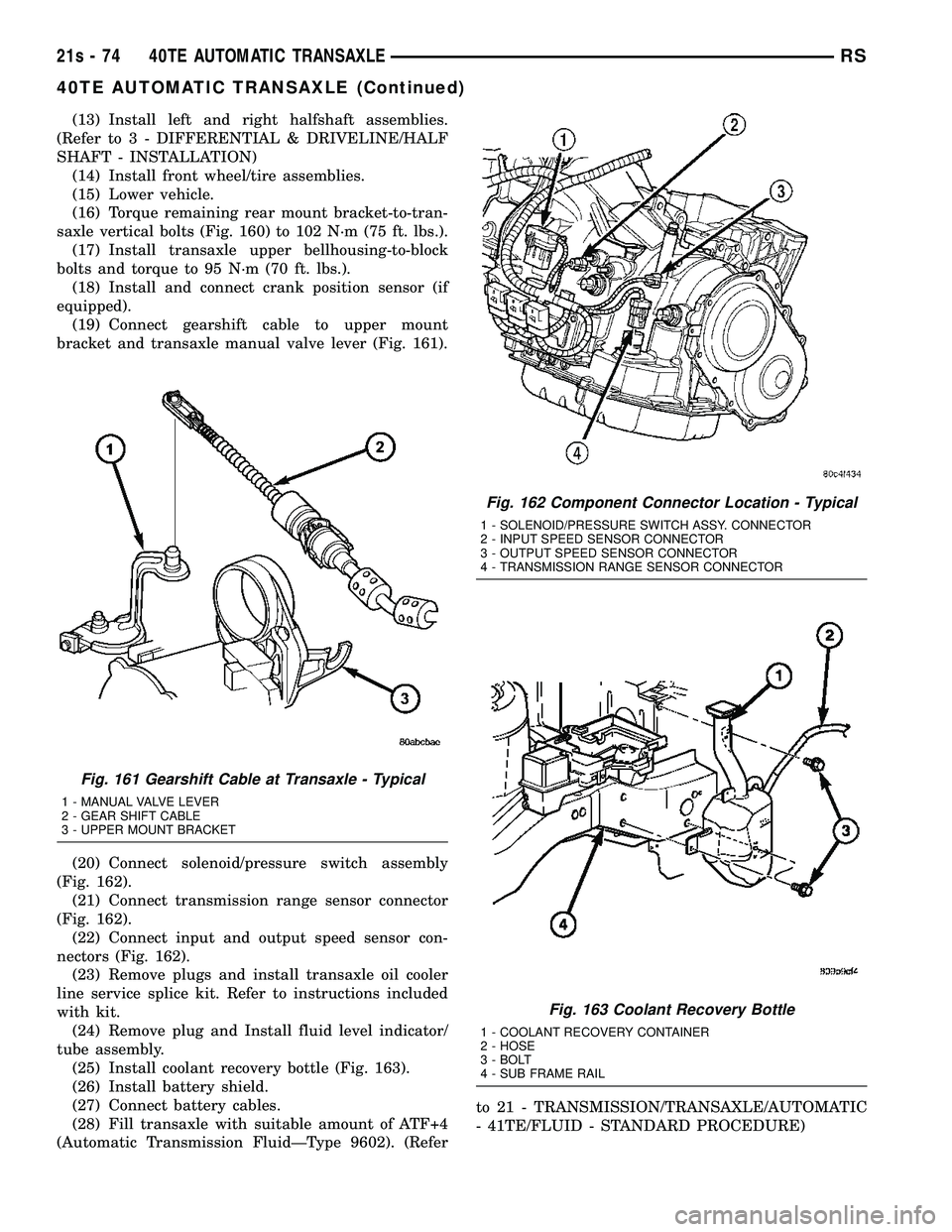

(13) Install left and right halfshaft assemblies.

(Refer t o 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION) (14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 160) to 102 N´m (75 ft. lbs.). (17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.). (18) Install and connect crank position sensor (if

equipped). (19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 161).

(20) Connect solenoid/pressure switch assembly

(Fig. 162). (21) Connect transmission range sensor connector

(Fig. 162). (22) Connect input and output speed sensor con-

nectors (Fig. 162). (23) Remove plugs and install transaxle oil cooler

line service splice kit. Refer to instructions included

with kit. (24) Remove plug and Install fluid level indicator/

tube assembly. (25) Install coolant recovery bottle (Fig. 163).

(26) Install battery shield.

(27) Connect battery cables.

(28) Fill transaxle with suitable amount of ATF+4

(Automatic Transmission FluidÐType 9602). (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/FLUID - STANDARD PROCEDURE)

Fig. 161 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 162 Component Connector Location - Typical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 163 Coolant Recovery Bottle

1 - COOLANT RECOVERY CONTAINER

2 - HOSE

3 - BOLT

4 - SUB FRAME RAIL

21s - 74 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1948 of 2585

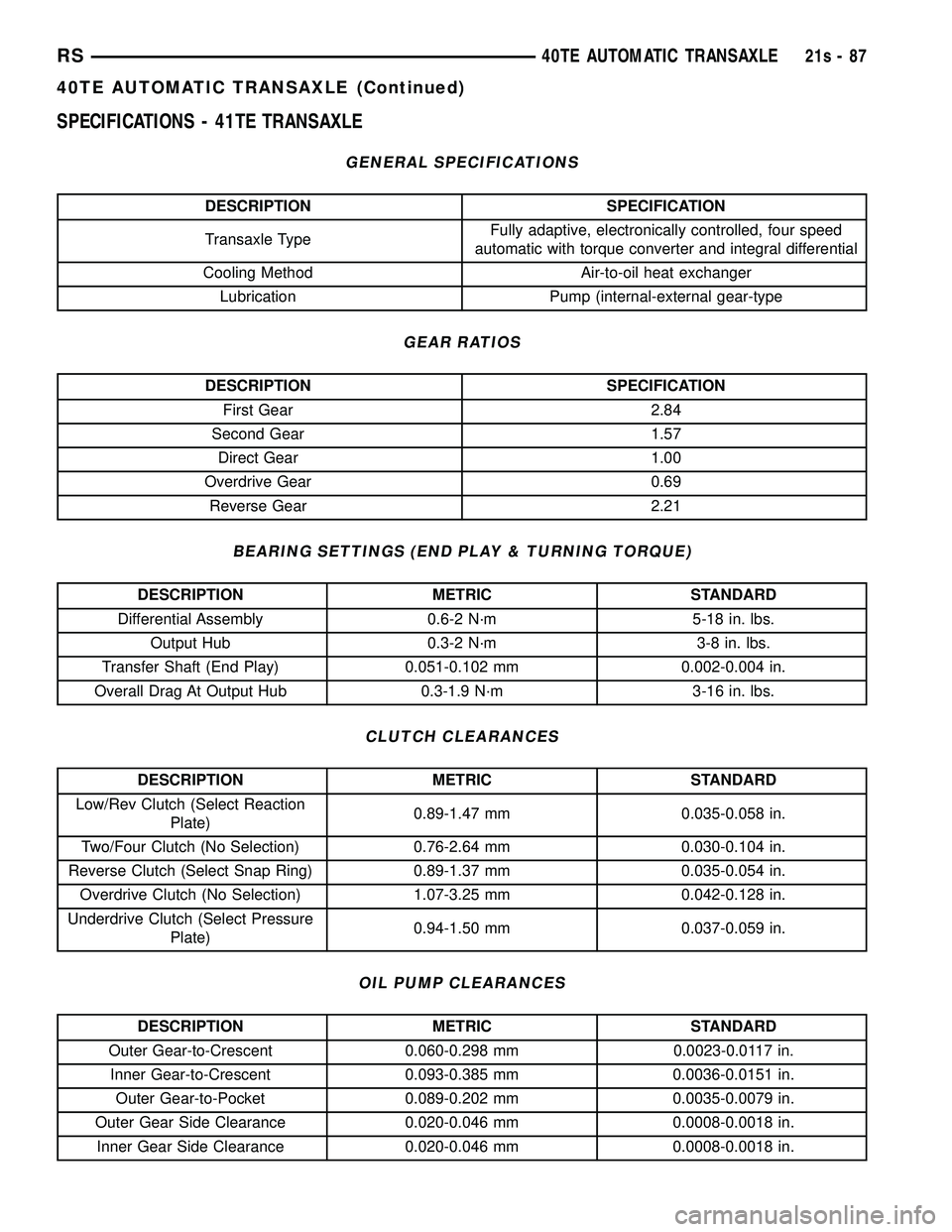

SPECIFICATIONS - 41TE TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle Type Fully adaptive, electronically controlled, four speed

automatic with torque converter and integral differential

Cooling Method Air-to-oil heat exchanger Lubrication Pump (internal-external gear-type

GEAR RATIOS

DESCRIPTION SPECIFICATION First Gear 2.84

Second Gear 1.57 Direct Gear 1.00

Overdrive Gear 0.69 Reverse Gear 2.21

BEARING SETTINGS (END PLAY & TURNING TORQUE)

DESCRIPTION METRIC STANDARD

Differential Assembly 0.6-2 N´m 5-18 in. lbs. Output Hub 0.3-2 N´m 3-8 in. lbs.

Transfer Shaft (End Play) 0.051-0.102 mm 0.002-0.004 in.

Overall Drag At Output Hub 0.3-1.9 N´m 3-16 in. lbs.

CLUTCH CLEARANCES

DESCRIPTION METRIC STANDARD

Low/Rev Clutch (Select Reaction Plate) 0.89-1.47 mm 0.035-0.058 in.

Two/Four Clutch (No Selection) 0.76-2.64 mm 0.030-0.104 in.

Reverse Clutch (Select Snap Ring) 0.89-1.37 mm 0.035-0.054 in. Overdrive Clutch (No Selection) 1.07-3.25 mm 0.042-0.128 in.

Underdrive Clutch (Select Pressure Plate) 0.94-1.50 mm 0.037-0.059 in.

OIL PUMP CLEARANCES

DESCRIPTION METRIC STANDARD

Outer Gear-to-Crescent 0.060-0.298 mm 0.0023-0.0117 in. Inner Gear-to-Crescent 0.093-0.385 mm 0.0036-0.0151 in. Outer Gear-to-Pocket 0.089-0.202 mm 0.0035-0.0079 in.

Outer Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in. Inner Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

RS 40TE AUTOMATIC TRANSAXLE21s-87

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1949 of 2585

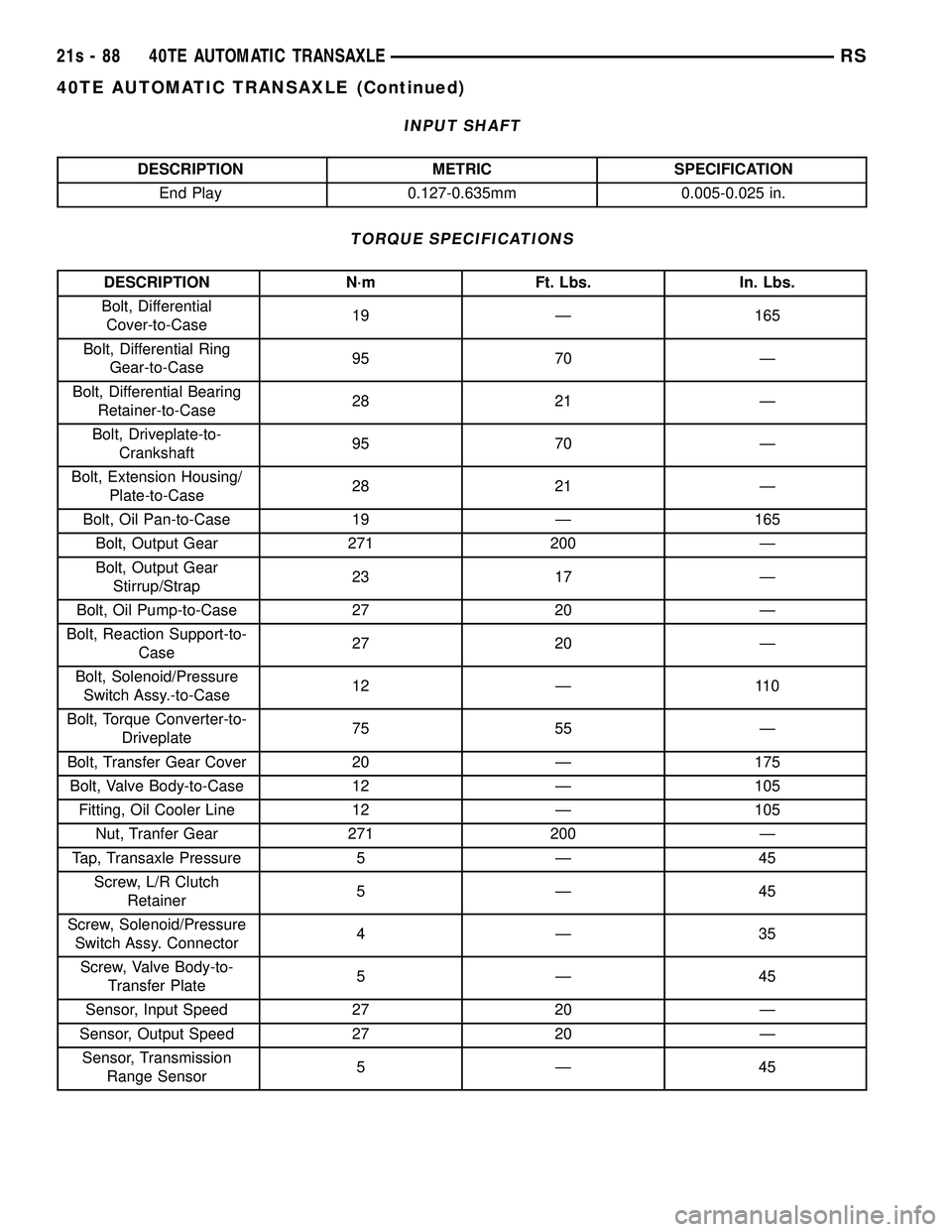

INPUT SHAFT

DESCRIPTION METRIC SPECIFICATIONEnd Play 0.127-0.635mm 0.005-0.025 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential Cover-to-Case 19 Ð 165

Bolt, Differential Ring Gear-to-Case 95 70 Ð

Bolt, Differential Bearing Retainer-to-Case 28 21 Ð

Bolt, Driveplate-to- Crankshaft 95 70 Ð

Bolt, Extension Housing/ Plate-to-Case 28 21 Ð

Bolt, Oil Pan-to-Case 19 Ð 165 Bolt, Output Gear 271 200 Ð

Bolt, Output Gear Stirrup/Strap 23 17 Ð

Bolt, Oil Pump-to-Case 27 20 Ð

Bolt, Reaction Support-to- Case 27 20 Ð

Bolt, Solenoid/Pressure Switch Assy.-to-Case 12 Ð 110

Bolt, Torque Converter-to- Driveplate 75 55 Ð

Bolt, Transfer Gear Cover 20 Ð 175 Bolt, Valve Body-to-Case 12 Ð 105 Fitting, Oil Cooler Line 12 Ð 105 Nut, Tranfer Gear 271 200 Ð

Tap, Transaxle Pressure 5 Ð 45 Screw, L/R Clutch Retainer 5Ð45

Screw, Solenoid/Pressure Switch Assy. Connector 4Ð35

Screw, Valve Body-to- Transfer Plate 5Ð45

Sensor, Input Speed 27 20 Ð

Sensor, Output Speed 27 20 Ð Sensor, Transmission Range Sensor 5Ð45

21s - 88 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1957 of 2585

OPERATION

The differential assembly is driven by the transfer

shaft by way of the differential ring gear. The ring

gear drives the differential case, and the case drives

the driveshafts through the differential gears. The

differential pinion and side gears are supported in

the case by thrust washers and a pinion shaft. Dif-

ferential pinion and side gears make it possible for

front tires to rotate at different speeds while corner-

ing.

DISASSEMBLY

NOTE: The differential is serviced as an assembly.

The only parts that are serviceable within the differ-

ential are the differential bearing cups and cones. If

any other part fails within the differential, you must

replace the differential assembly along with the

transfer shaft.

The transfer shaft should be removed for differen-

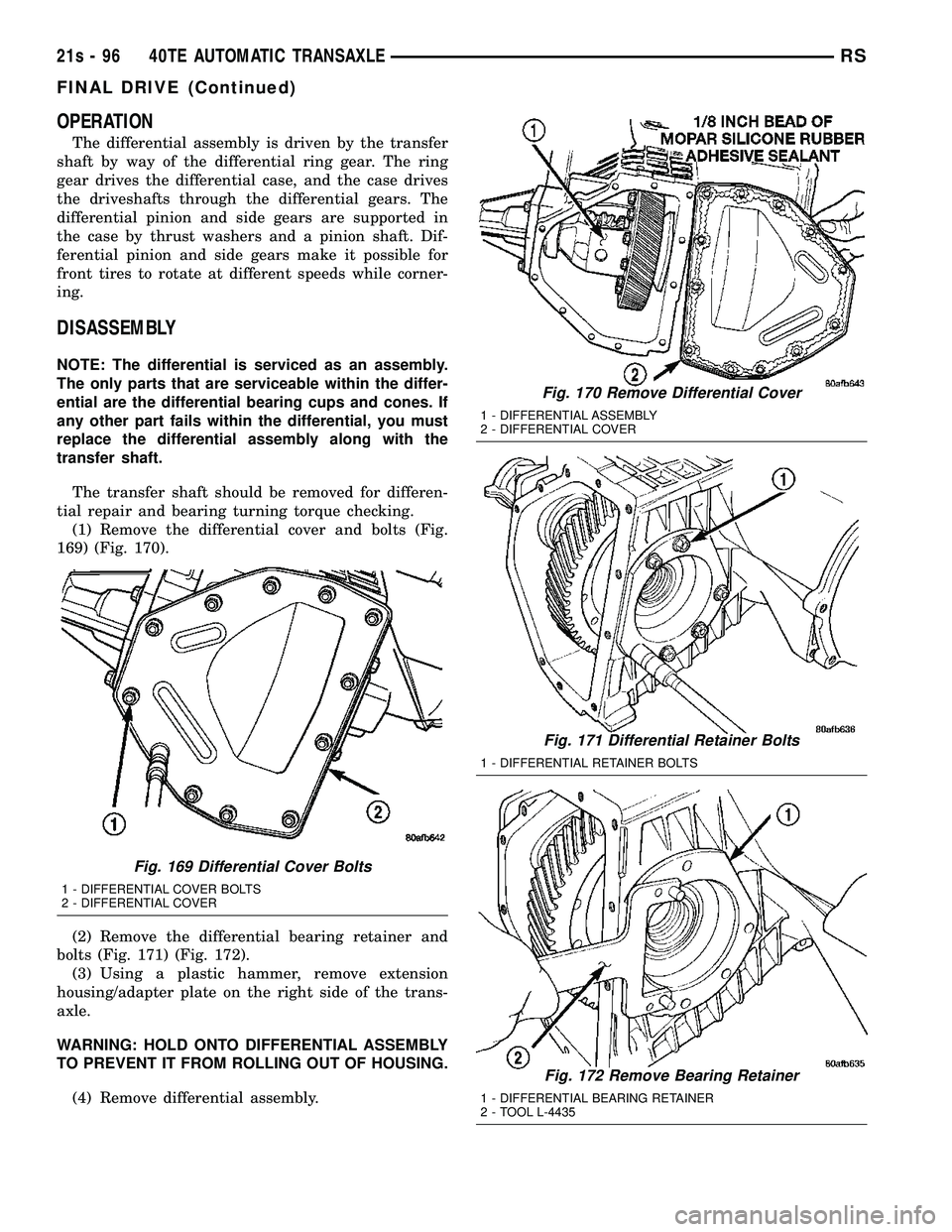

tial repair and bearing turning torque checking. (1) Remove the differential cover and bolts (Fig.

169) (Fig. 170).

(2) Remove the differential bearing retainer and

bolts (Fig. 171) (Fig. 172). (3) Using a plastic hammer, remove extension

housing/adapter plate on the right side of the trans-

axle.

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

(4) Remove differential assembly.

Fig. 169 Differential Cover Bolts

1 - DIFFERENTIAL COVER BOLTS

2 - DIFFERENTIAL COVER

Fig. 170 Remove Differential Cover

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL COVER

Fig. 171 Differential Retainer Bolts

1 - DIFFERENTIAL RETAINER BOLTS

Fig. 172 Remove Bearing Retainer

1 - DIFFERENTIAL BEARING RETAINER

2 - TOOL L-4435

21s - 96 40TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1960 of 2585

ASSEMBLY

NOTE: The differential is serviced as an assembly.

The only parts that are serviceable within the differ-

ential are the differential bearing cups and cones. If

any other part fails within the differential, you must

replace the differential assembly along with the

transfer shaft.

NOTE: Use MoparTATF RTV (MS-GF41), or equiva-

lent, on retainer and extension housing/adapter

plate to seal to case.

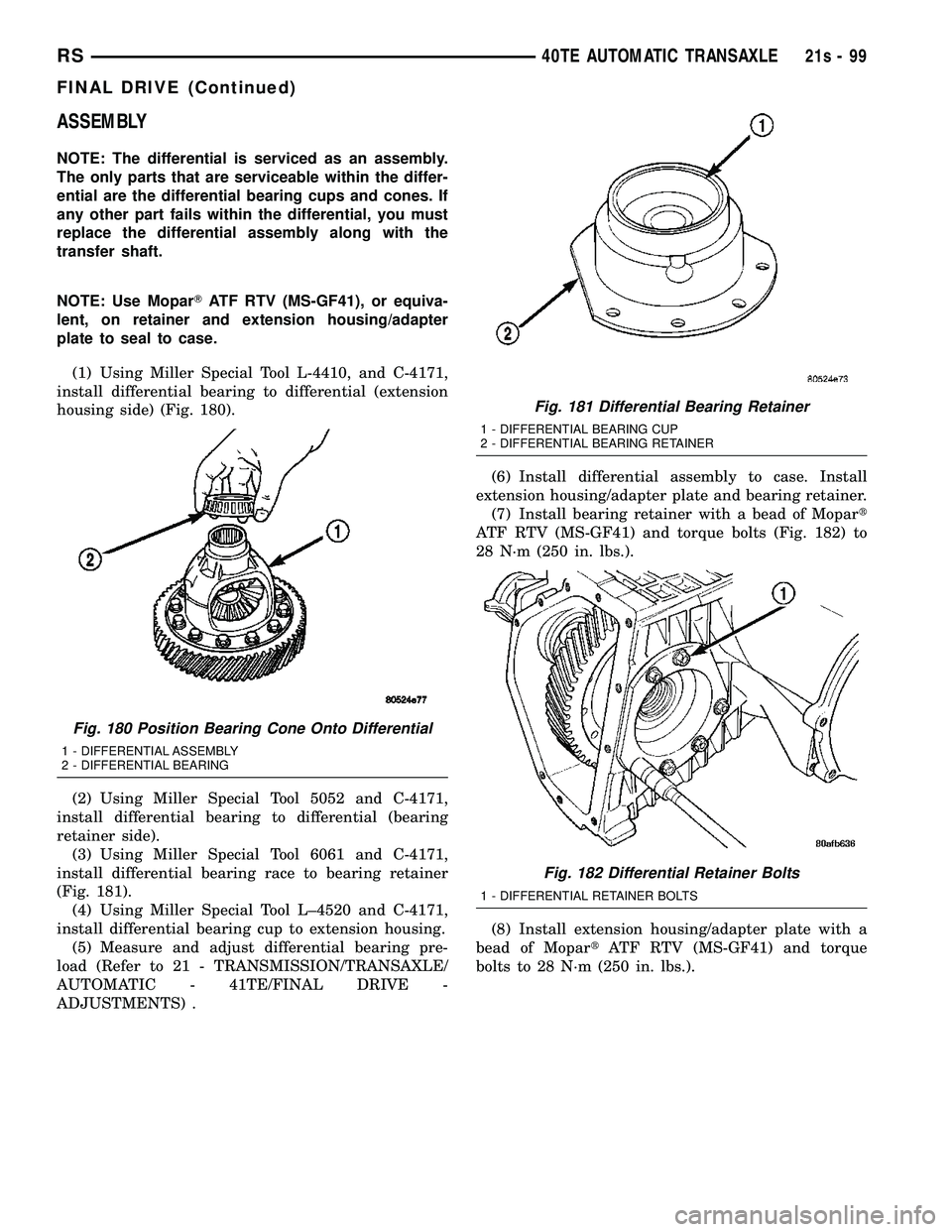

(1) Using Miller Special Tool L-4410, and C-4171,

install differential bearing to differential (extension

housing side) (Fig. 180).

(2) Using Miller Special Tool 5052 and C-4171,

install differential bearing to differential (bearing

retainer side). (3) Using Miller Special Tool 6061 and C-4171,

install differential bearing race to bearing retainer

(Fig. 181). (4) Using Miller Special Tool L±4520 and C-4171,

install differential bearing cup to extension housing. (5) Measure and adjust differential bearing pre-

load (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FINAL DRIVE -

ADJUSTMENTS) . (6) Install differential assembly to case. Install

extension housing/adapter plate and bearing retainer. (7) Install bearing retainer with a bead of Mopar t

ATF RTV (MS-GF41) and torque bolts (Fig. 182) to

28 N´m (250 in. lbs.).

(8) Install extension housing/adapter plate with a

bead of Mopar tATF RTV (MS-GF41) and torque

bolts to 28 N´m (250 in. lbs.).

Fig. 180 Position Bearing Cone Onto Differential

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL BEARING

Fig. 181 Differential Bearing Retainer

1 - DIFFERENTIAL BEARING CUP

2 - DIFFERENTIAL BEARING RETAINER

Fig. 182 Differential Retainer Bolts

1 - DIFFERENTIAL RETAINER BOLTS

RS 40TE AUTOMATIC TRANSAXLE21s-99

FINAL DRIVE (Continued)

Page 1961 of 2585

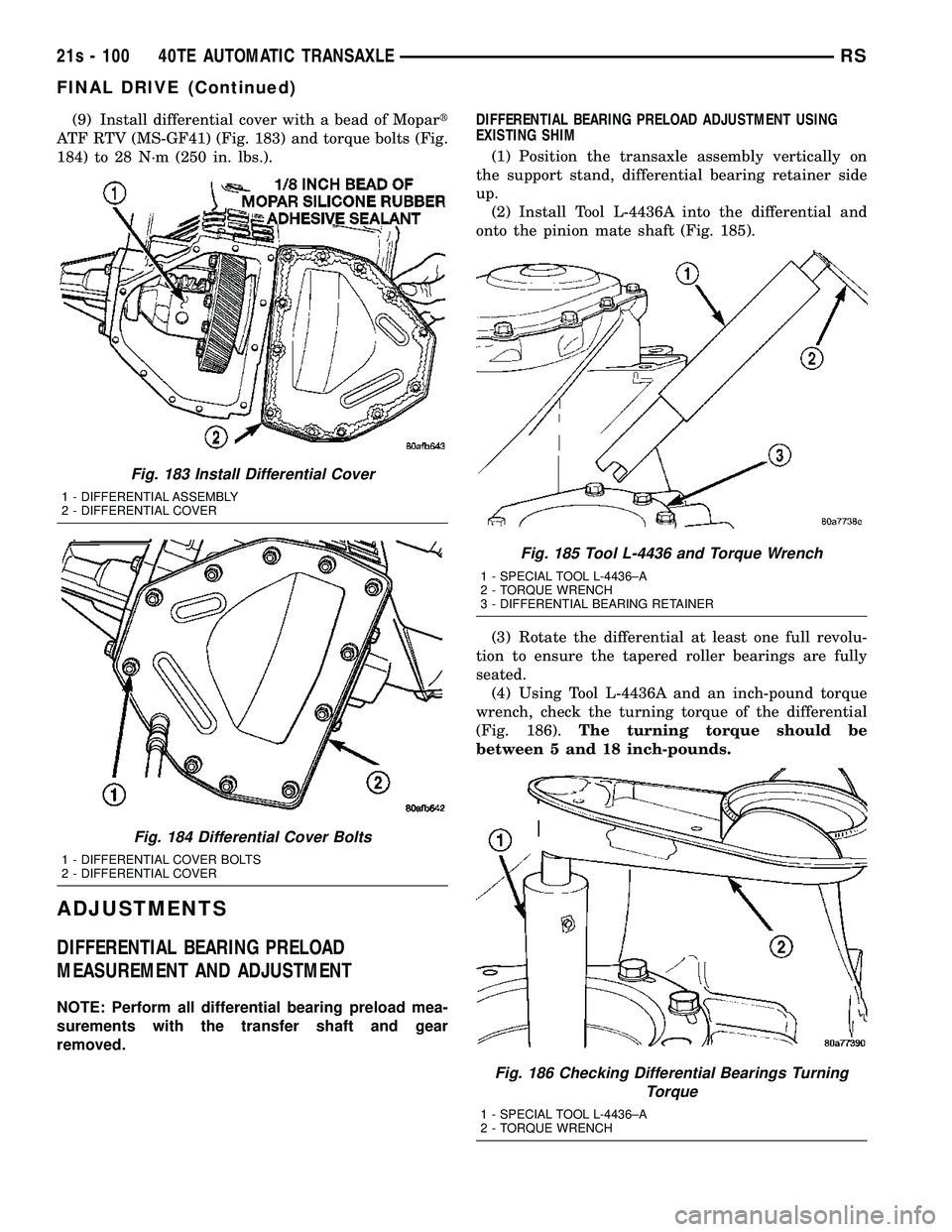

(9) Install differential cover with a bead of Mopart

ATF RTV (MS-GF41) (Fig. 183) and torque bolts (Fig.

184) to 28 N´m (250 in. lbs.).

ADJUSTMENTS

DIFFERENTIAL BEARING PRELOAD

MEASUREMENT AND ADJUSTMENT

NOTE: Perform all differential bearing preload mea-

surements with the transfer shaft and gear

removed. DIFFERENTIAL BEARING PRELOAD ADJUSTMENT USING

EXISTING SHIM

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up. (2) Install Tool L-4436A into the differential and

onto the pinion mate shaft (Fig. 185).

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated. (4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential

(Fig. 186). The turning torque should be

between 5 and 18 inch-pounds.

Fig. 183 Install Differential Cover

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL COVER

Fig. 184 Differential Cover Bolts

1 - DIFFERENTIAL COVER BOLTS

2 - DIFFERENTIAL COVER

Fig. 185 Tool L-4436 and Torque Wrench

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

3 - DIFFERENTIAL BEARING RETAINER

Fig. 186 Checking Differential Bearings Turning Torque

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

21s - 100 40TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)