ECO mode CHRYSLER VOYAGER 2004 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2401 of 2585

²FAN/MODE± The Fan and Mode knobs have

17 manual selectable positions. Manually changing

either of the rotary knobs for mode or fan speed set-

tings makes control of that blowe motor manual. If

only one is changed manually, the other remains

under automatic control. Pressing the HI-AUTO/LO-

AUTO rocker switch restores full automatic control.

²REAR CONTROL± When the Rear System

control knob is moved to the OFF position, there will

be a delay of approximately 1 second before the sys-

tem actually turns off. This delay is to prevent an

undesired blower dropout if the knob is moved

through OFF to the other selections.

²BLOWER DELAY TIMER± The word DELAY

is displayed at start-up to signify that the system is

waiting so that cold air will not be blowing. This tells

the operator that it is unnecessary to turn the sys-

tem off, raise the temperature setting or turn the fan

speed setting down to prevent cold air from blowing.

A countdown in minutes and seconds until the engine

is warm enough to begin delivering heat to the pas-

sengers alternates with the DELAY message at 25

second intervals. This countdown is based on actual

measurement of the rate of engine coolant tempera-

ture change. During the delay time, mix mode is

selected and the fan operates at a low speed to keep

the windshield fog free.

REAR CONTROL PANEL

Primary control of the rear compartment unit is in

the instrument panel center stack. The rear unit con-

trol knob there allows the driver to turn the rear

unit off, allow control by the intermediate seat occu-

pants by switching to the REAR position, or provide

fully automatic control based on the temperature set-

ting shown on the front control display.

²REAR CONTROL± Selecting automatic control

of the rear unit at the instrument panel, illuminates

a Locked Padlock in the rear control panel display.

Selecting REAR activates the rear control panel and

the Padlock then appears unlocked.

²FAN KNOB± The rear fan control has Off and

AUTO positions and a range of manual speed set-

tings that override the AUTO setting.

²MODE KNOB± The mode control allows inter-

mediate seat occupants to manually override the

automatic mode and select any balance of air flow

between overhead and floor outlets from full over-

head to full floor.

²SET TEMP± The rear set temp control will

operate identical to the front controls. If the front

control rear set temp button is pressed simulta-

neously with the rear control head, then the front

control head press events shall have priority, i.e. if

the front user presses Rear Set Temp down and therear user presses Set Temp up, then the rear set

temp will decrease.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C COOL DOWN

TEST

The heater-A/C control module can perform an A/C

cool down test, which is a test performed during the

manufacturing process to confirm that the air condi-

tioning system is performing satisfactorily. This test

can also provide a quick confirmation of air condi-

tioning system performance to the service technician.

If the test is completed satisfactorily, no further ser-

vice is required. If the test is failed, proceed to the

A/C Performance Test to confirm the A/C system is

operating properly, or use a DRBIIItscan tool to

diagnose the A/C system control and distribution sys-

tems. Refer to the appropriate diagnostic informa-

tion.

MANUAL TEMPERATURE CONTROL

The front blower speed and rear blower speed (if

equipped with rear HVAC) must be set to High and

the evaporator temperature sensor must be greater

than 13É C (55É F) or the test will fail immediately.

The test is activated by depressing the A/C and Rear

Wipe/Wash buttons simultaneously and holding them

depressed for no less than five seconds. The Rear

Wipe/Wash and A/C LEDs will blink on and off until

the test is complete. If the LEDs stop blinking before

two minutes, then the cool down test has been com-

pleted successfully. If the two minutes expire without

the expansion valve temperature reaching -6É C (20É

F) less than the outside air temperature, then the

cool down test has been failed and further A/C sys-

tem diagnosis is required. If the test is failed, the

LEDs will continue to blink until the vehicle has

been driven for greater than 1.6 km (8 miles).

AUTOMATIC TEMPERATURE CONTROL

The ambient air temperature in the room where

the vehicle will be tested must be a minimum of 21É

C (70ÉF) for this test. The test is activated by

depressing the A/C and PWR buttons simultaneously

and holding them depressed for no less than four sec-

onds. The snowflake icon and the DELAY text in the

ATC display will blink on and off alternately until

the test is complete. If the snowflake icon and the

DELAY text stop blinking before two minutes, then

the cool down test has been completed successfully. If

the two minutes expire without the evaporator tem-

perature reaching -6É C (20É F) less than the evapo-

rator initial temperature, then the cool down test has

been failed and further A/C system diagnosis is

24 - 6 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2413 of 2585

ented and routed so that they are not pinched

between the compressor front cover and the clutch

coil.

NOTE: A new snap ring must be used to secure the

clutch coil to the compressor. The bevel side of the

snap ring must face outward.

(2) Using snap ring pliers (Special Tool C-4574 or

equivalent), install the external snap ring that

secures the clutch coil to the front cover of the com-

pressor. The bevel side of the snap ring must face

outward and both snap ring eyelets must be oriented

to the right or the left of the clutch coil dowel pin

location on the compressor. Be certain that the snap

ring is fully and properly seated in the groove.

CAUTION: If the snap ring is not fully seated in the

groove it will vibrate out, resulting in a clutch fail-

ure and severe damage to the compressor front

cover.

(3) Install and securely tighten the screw that

secures the clutch coil pigtail wire connector bracket

and ground clip to the top of the compressor housing.

(4) Install the pulley onto the front cover of the

compressor. If necessary, tap the pulley gently with a

block of wood placed on the pulley friction surface

(Fig. 6).

CAUTION: Do not mar the friction surfaces of the

pulley.NOTE: A new snap ring must be used to secure the

clutch pulley to the compressor. The bevel side of

the snap ring must face outward.

(5) Using snap ring pliers (Special Tool C-4574 or

equivalent), install the external snap ring (bevel side

facing outward) that secures the clutch pulley to the

front cover of the compressor. Be certain that the

snap ring is fully and properly seated in the groove.

(6) If the original clutch plate and clutch pulley

are to be reused, reinstall the original shim(s) on the

compressor shaft against the shoulder. If a new

clutch plate and/or clutch pulley are being used,

install a trial stack of shims 1.0 mm (0.040 in.) thick

on the compressor shaft against the shoulder.

(7) Install the clutch plate onto the compressor

shaft.

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is still correct. Spin the

pulley before performing a final check of the air

gap.

(8) With the clutch plate assembly tight against

the shim(s), measure the air gap between the clutch

plate and the pulley face with feeler gauges. The air

gap should be between 0.35 - 0.60 mm (0.014 - 0.024

in.). If the proper air gap is not obtained, add or sub-

tract shims as needed until the desired air gap is

obtained.

(9) Install the compressor shaft bolt. Tighten the

bolt to 17.5 N´m (155 in. lbs.).

(10) On models with the 2.4L and 2.5L engines,

loosely install the four bolts that secure the compres-

sor to the mounting bracket on the engine (2.4L), or

the cylinder block (2.5L). Tighten the bolts to 28 N´m

(21 ft. lbs.).

(11) On models with the 3.3L and 3.8L engines,

loosely install the two bolts and two nuts that secure

the compressor to the engine. Tighten each of the fas-

teners to 54 N´m (40 ft. lbs.) using the following

sequence:

²The upper nut at the front of the compressor.

²The lower nut at the front of the compressor.

²The upper bolt at the rear of the compressor.

²The lower bolt at the rear of the compressor.

(12) On models with the 3.3L and 3.8L engines,

engage the retainer on the engine wire harness com-

pressor clutch coil take out with the bracket on the

top of the compressor.

(13) Reconnect the engine wire harness connector

for the compressor clutch coil to the coil pigtail wire

connector on the top of the compressor.

(14) Reinstall the serpentine accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - 2.4L - INSTALLATION) or (Refer to 7 -

Fig. 6 Install Clutch Pulley

1 - PULLEY ASSEMBLY

2 - WOOD BLOCK

24 - 18 CONTROLS - FRONTRS

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2414 of 2585

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

3.3L/3.8L - INSTALLATION).

(15) Lower the vehicle.

(16) Reconnect the battery negative cable.

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C-heater control to the A/C

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

A/C COMPRESSOR CLUTCH

RELAY

DESCRIPTION

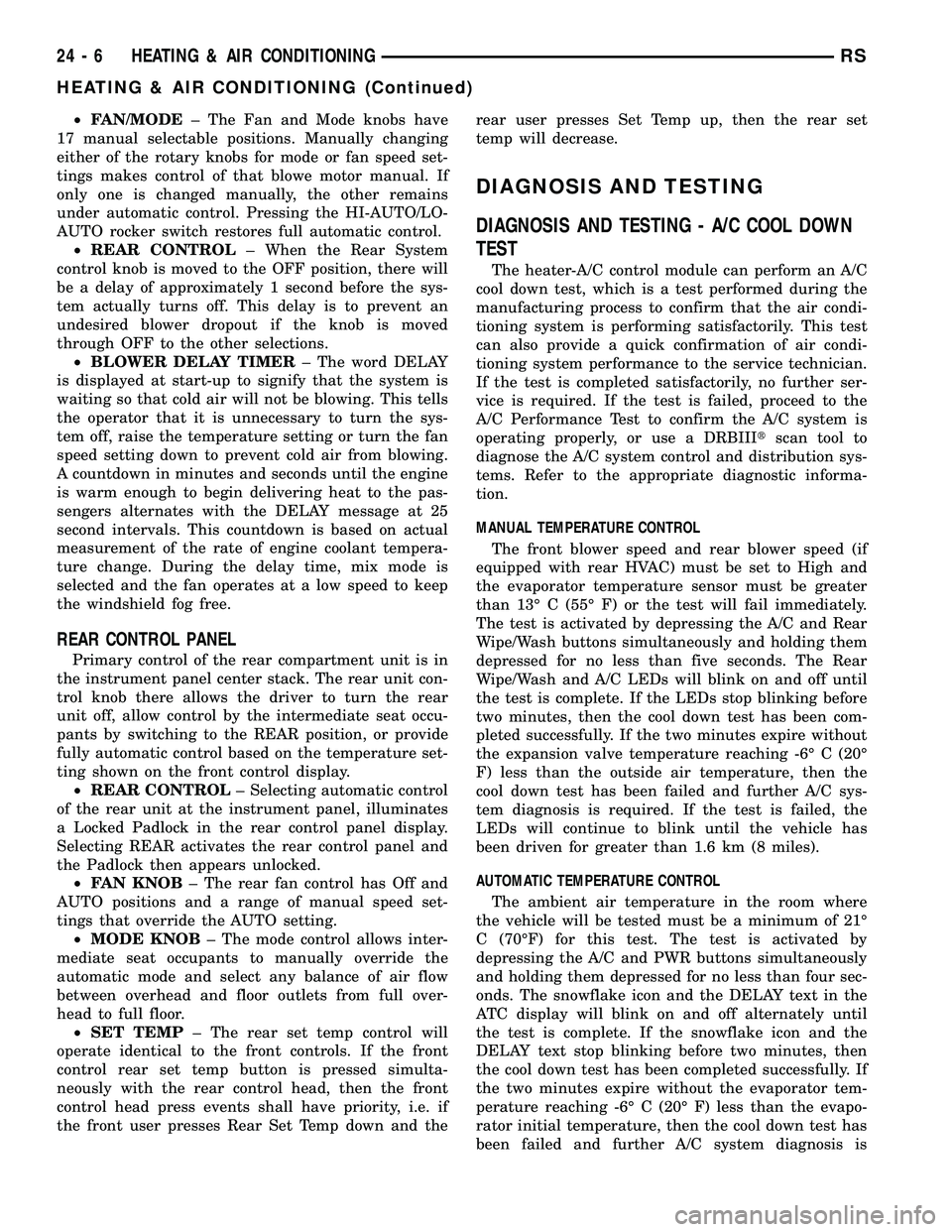

The compressor clutch relay (Fig. 7) is a Interna-

tional Standards Organization (ISO) micro-relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The ISO

micro-relay terminal functions are the same as a con-

ventional ISO relay. However, the ISO micro-relay

terminal pattern (or footprint) is different, the cur-

rent capacity is lower, and the physical dimensions

are smaller than those of the conventional ISO relay.

The A/C compressor clutch relay is located in the

Integrated Power Module (IPM) in the engine com-

partment. See the fuse and relay layout map molded

into the inner surface of the IPM cover for A/C com-

pressor clutch relay identification and location.The black, molded plastic case is the most visible

component of the A/C compressor clutch relay. Five

male spade-type terminals extend from the bottom of

the base to connect the relay to the vehicle electrical

system, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

OPERATION

The A/C compressor clutch relay is an electrome-

chanical switch that uses a low current input from

the powertrain control module (PCM) to control the

high current output to the compressor clutch electro-

magnetic coil. The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. The resistor or diode is con-

nected in parallel with the relay coil in the relay, and

helps to dissipate voltage spikes and electromagnetic

interference that can be generated as the electromag-

netic field of the relay coil collapses.

The compressor clutch relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the integrated power module (IPM). The

inputs and outputs of the A/C compressor clutch

relay include:

²The common feed terminal (30) receives a bat-

tery current input from a fuse in the IPM through a

fused B(+) circuit at all times.

²The coil ground terminal (85) receives a ground

input from the PCM through the compressor clutch

relay control circuit only when the PCM electroni-

cally pulls the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the PCM through a fused ignition

switch output (run-start) circuit only when the igni-

tion switch is in the On or Start positions.

Fig. 7 A/C Compressor Clutch Relay

RSCONTROLS - FRONT24-19

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2418 of 2585

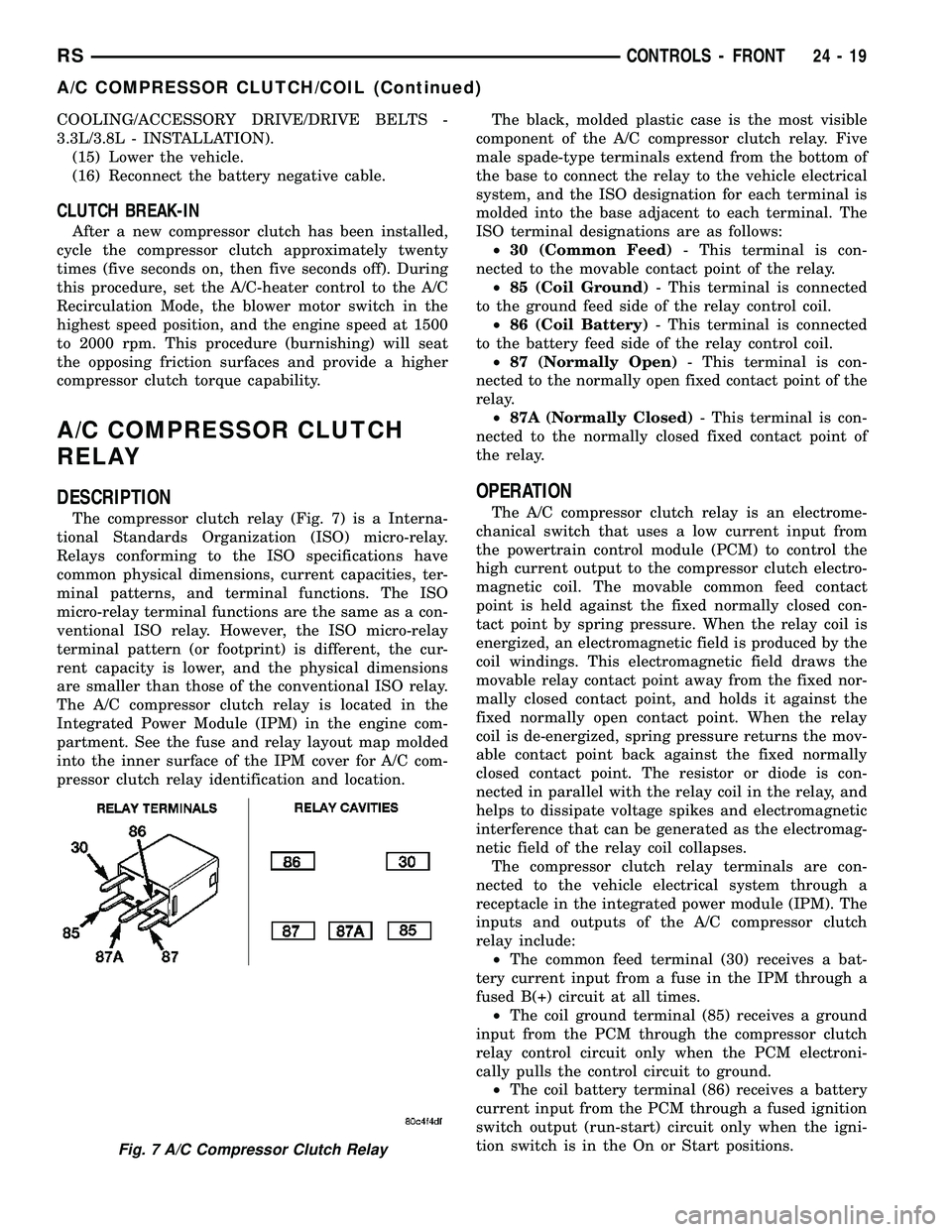

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a single

blend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver's side end of the

HVAC housing, close to the middle of the distribution

housing. In the dual zone system, the same blend

door actuator used for the single zone system

becomes the passenger blend door actuator, and is

mechanically connected to only the passenger side

blend air door. In the dual zone system, a second sep-

arate blend door actuator is also located on the

driver side end of the HVAC housing, close to the

middle of the distribution housing, and is mechani-

cally connected to only the driver's side blend air

door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the distri-

bution housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module.

OPERATION

Each blend door actuator is connected to the A/C-

heater control through the vehicle electrical system

by a dedicated two-wire lead and connector from the

HVAC wire harness. The blend door actuator can

move the blend-air door in two directions. When the

A/C-heater control pulls the voltage on one side of

the motor connection high and the other connection

low, the blend-air door will move in one direction.

When the A/C-heater control reverses the polarity of

the voltage to the motor, the blend-air door moves in

the opposite direction. When the A/C-heater control

makes the voltage to both connections high or both

connections low, the blend-air door stops and will not

move. The motor connections also provide a feedback

signal to the A/C-heater control. This feedback signal

allows the A/C-heater control to monitor the opera-

tion and relative positions of the blend door actuator

and the blend-air door. The A/C-heater control learnsthe blend door stop positions during the calibration

procedure and will store a diagnostic trouble code

(DTC) for any problems it detects in the blend door

actuator circuits.

The blend door actuator can be diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures for more information. The blend door actuators

cannot be adjusted or repaired and, if damaged or

faulty, they must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The single zone heating and air conditioning

system is equipped with a single blend door actua-

tor. The dual zone system has two blend door

actuators, one for the driver side blend air door and

one for the passenger side blend air door. The

same service procedures can be used for each of

these actuators.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the silencer from beneath the driver

side end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

(3) Disconnect the wire harness connector from the

blend door actuator(s) (Fig. 11).

(4) Remove the two screws that secure the blend

door actuator to the distribution housing.

(5) Remove the blend door actuator.

INSTALLATION

(1) Position the blend door actuator onto the distri-

bution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the blend air door linkage.

(2) Install the two screws that secure the blend

door actuator to the housing. Tighten the screws to 2

N´m (17 in. lbs.).

RSCONTROLS - FRONT24-23

Page 2419 of 2585

(3) Connect the HVAC wire harness connector to

the blend door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

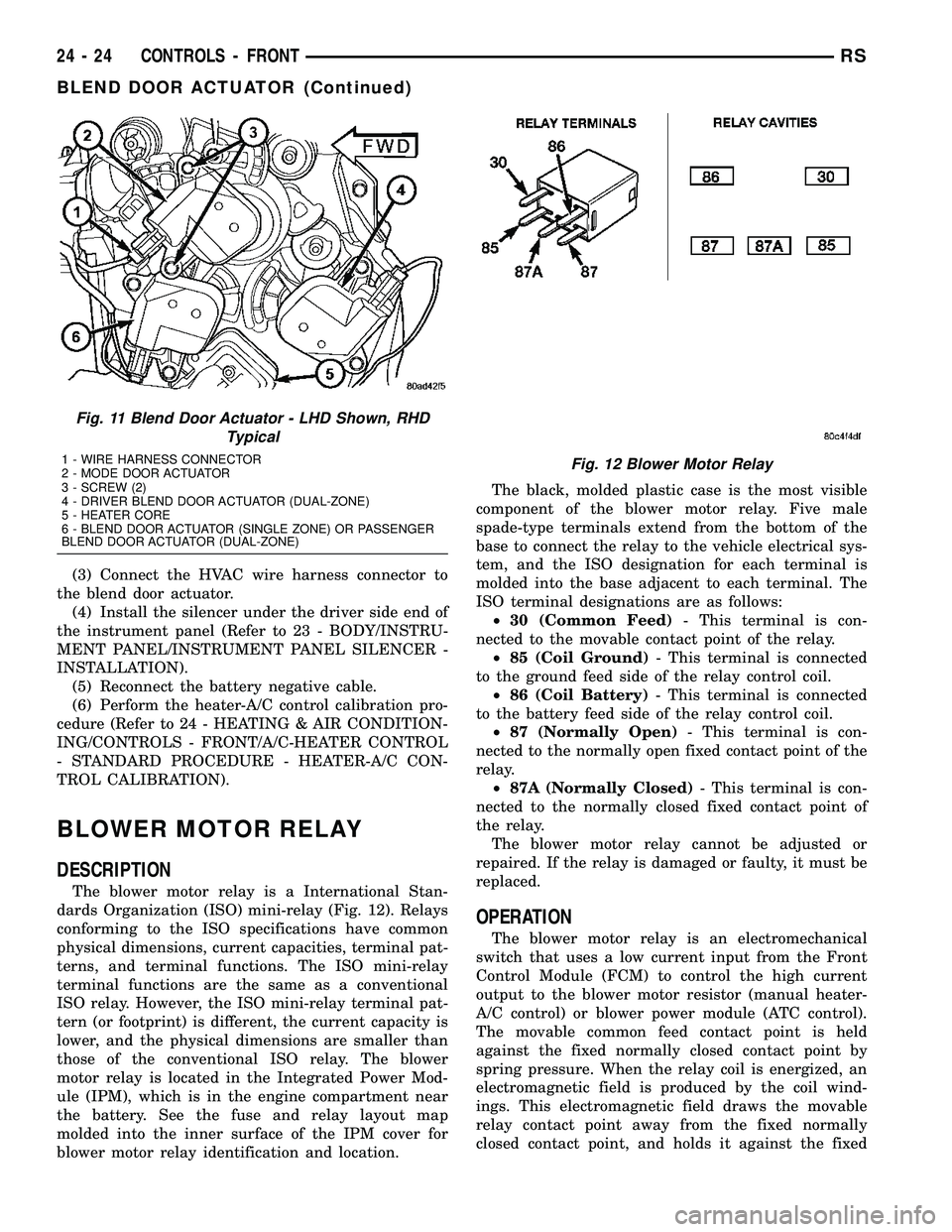

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO) mini-relay (Fig. 12). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Integrated Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

blower motor relay identification and location.The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The blower motor relay cannot be adjusted or

repaired. If the relay is damaged or faulty, it must be

replaced.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (ATC control).

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

Fig. 11 Blend Door Actuator - LHD Shown, RHD

Typical

1 - WIRE HARNESS CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)Fig. 12 Blower Motor Relay

24 - 24 CONTROLS - FRONTRS

BLEND DOOR ACTUATOR (Continued)

Page 2421 of 2585

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C system.

Models equipped with the optional Automatic Tem-

perature Control (ATC) system use a blower power

module, instead of the blower motor resistor block

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/POWER MODULE - DESCRIPTION).

The blower motor resistor block is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The resistor

block consists of a molded plastic mounting plate

with two integral connector receptacles. Concealed

behind the mounting plate are four coiled resistor

wires contained within a protective stamped steel

cage. The blower motor resistor block is accessed for

service by removing the glove box from the instru-

ment panel.

OPERATION

The blower motor resistor block is connected to the

vehicle electrical system through a dedicated take

out and connector of the instrument panel wire har-

ness. A second connector receptacle receives the pig-

tail wire connector from the blower motor. The

blower motor resistor has multiple resistor wires,

each of which will reduce the current flow through

the blower motor to change the blower motor speed.

The blower motor switch in the manual heater-A/C

system directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through all of the resistor wires. Each higher speed

selected with the blower motor switch applies the

blower motor ground path through fewer of the resis-

tor wires, increasing the blower motor speed.

The blower motor resistor cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR BLOCK

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor resistor block.

(4) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor, blower motor or blower motor

relay as required. If not OK, replace the faulty

blower motor resistor block.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE BLOWER MOTOR RESISTOR

BLOCK MAY GET VERY HOT DURING NORMAL

OPERATION. IF THE BLOWER MOTOR WAS

TURNED ON PRIOR TO SERVICING THE BLOWER

MOTOR RESISTOR BLOCK, WAIT FIVE MINUTES

TO ALLOW THE BLOWER MOTOR RESISTORS TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

24 - 26 CONTROLS - FRONTRS

Page 2422 of 2585

CAUTION: Do not operate the blower motor with the

blower motor resistor removed from the circuit.

Failure to take this precaution can result in vehicle

damage.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor resistor block (Fig. 14).

(4) Remove the two screws that secure the blower

motor resistor block to the HVAC housing.

(5) Remove the resistor block from the HVAC

housing.

INSTALLATION

(1) Position the blower motor resistor block into

the HVAC housing.

(2) Install the two screws that secure the blower

motor resistor block to the HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(3) Connect the two wire connectors to the resistor

block.

(4) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(5) Reconnect the battery negative cable.

EVAPORATOR TEMPERATURE

SENSOR

DESCRIPTION

NOTE: The following applies to RS models only. RG

models use an expansion valve mounted evapora-

tor temperature sensor for both manual and auto-

matic temperature control systems due to A/C-

heater control calibration requirements.

The evaporator temperature sensor used for the

manual temperature control (MTC) system is

installed on the top of the HVAC housing behind the

instrument panel and measures the air temperature

downstream of the evaporator (Fig. 15). The sensor is

an electrical thermistor in a plastic housing that is

inserted into the HVAC housing. Two terminals

within the molded plastic connector receptacle on the

sensor connect it to the vehicle electrical system

through a take out and connector of the HVAC wire

harness.

The evaporator temperature sensor used for the

automatic temperature control (ATC) system is

installed on the top of the expansion valve in the

right rear corner of the engine compartment and

measures the temperature of the evaporator coils

(Fig. 16). The sensor has a small probe that is

Fig. 14 Blower Motor Resistor Block - Typical

1 - BLOWER MOTOR RESISTOR

2 - INSTRUMENT PANEL WIRE HARNESS

3 - SCREW (2)

4 - GLOVE BOX OPENING REINFORCEMENT

5 - BLOWER MOTOR PIGTAIL WIRE HARNESS

6 - HVAC HOUSING

Fig. 15 Evaporator Temperature Sensor - MTC

System

1 - EVAPORATOR TEMPERATURE SENSOR

2 - HVAC HOUSING

3 - A/C EVAPORATOR

RSCONTROLS - FRONT24-27

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2426 of 2585

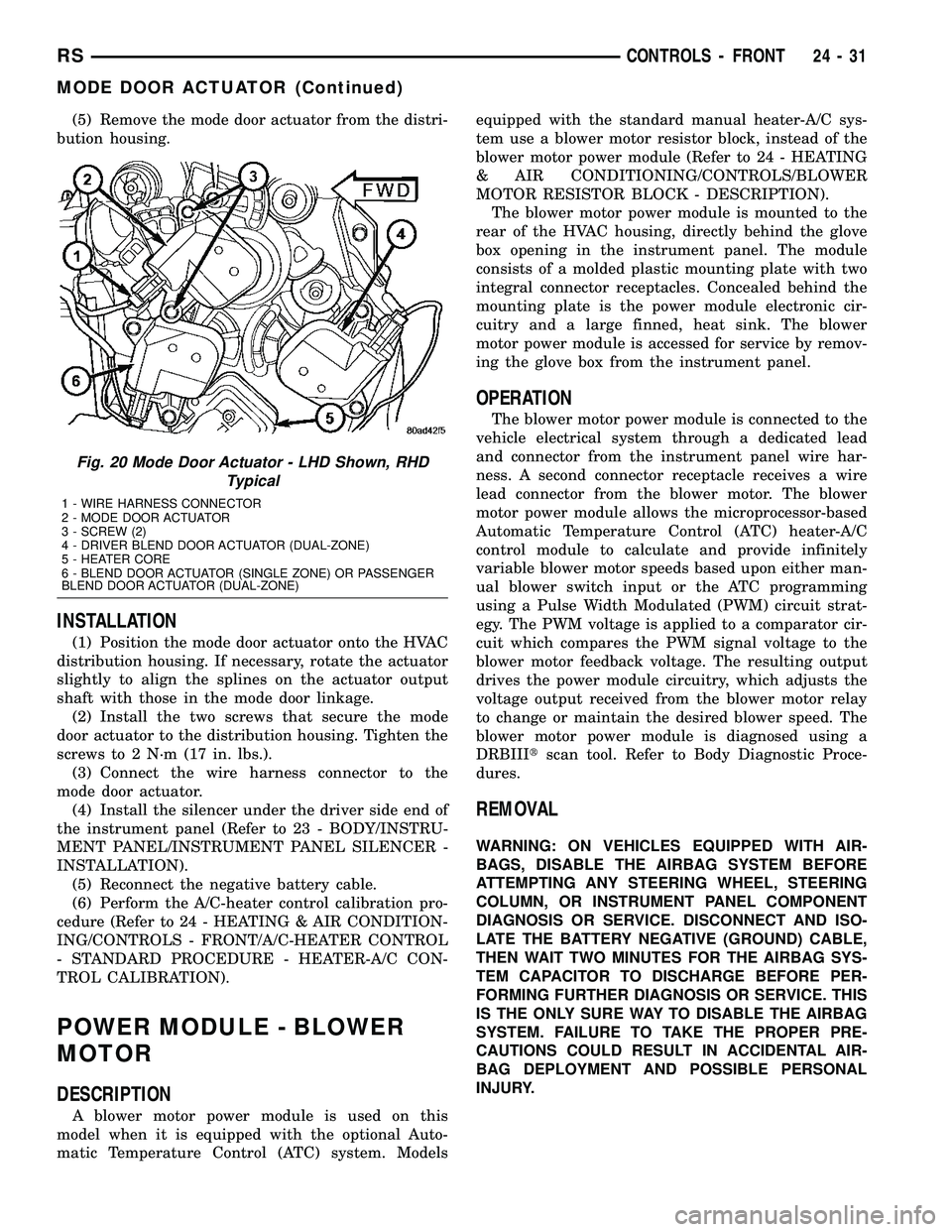

(5) Remove the mode door actuator from the distri-

bution housing.

INSTALLATION

(1) Position the mode door actuator onto the HVAC

distribution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install the two screws that secure the mode

door actuator to the distribution housing. Tighten the

screws to 2 N´m (17 in. lbs.).

(3) Connect the wire harness connector to the

mode door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the negative battery cable.

(6) Perform the A/C-heater control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

POWER MODULE - BLOWER

MOTOR

DESCRIPTION

A blower motor power module is used on this

model when it is equipped with the optional Auto-

matic Temperature Control (ATC) system. Modelsequipped with the standard manual heater-A/C sys-

tem use a blower motor resistor block, instead of the

blower motor power module (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - DESCRIPTION).

The blower motor power module is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The module

consists of a molded plastic mounting plate with two

integral connector receptacles. Concealed behind the

mounting plate is the power module electronic cir-

cuitry and a large finned, heat sink. The blower

motor power module is accessed for service by remov-

ing the glove box from the instrument panel.

OPERATION

The blower motor power module is connected to the

vehicle electrical system through a dedicated lead

and connector from the instrument panel wire har-

ness. A second connector receptacle receives a wire

lead connector from the blower motor. The blower

motor power module allows the microprocessor-based

Automatic Temperature Control (ATC) heater-A/C

control module to calculate and provide infinitely

variable blower motor speeds based upon either man-

ual blower switch input or the ATC programming

using a Pulse Width Modulated (PWM) circuit strat-

egy. The PWM voltage is applied to a comparator cir-

cuit which compares the PWM signal voltage to the

blower motor feedback voltage. The resulting output

drives the power module circuitry, which adjusts the

voltage output received from the blower motor relay

to change or maintain the desired blower speed. The

blower motor power module is diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 20 Mode Door Actuator - LHD Shown, RHD

Typical

1 - WIRE HARNESS CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)

RSCONTROLS - FRONT24-31

MODE DOOR ACTUATOR (Continued)

Page 2427 of 2585

WARNING: THE HEAT SINK FOR THE BLOWER

MOTOR POWER MODULE MAY GET VERY HOT

DURING NORMAL OPERATION. IF THE BLOWER

MOTOR WAS TURNED ON PRIOR TO SERVICING

THE BLOWER MOTOR POWER MODULE, WAIT

FIVE MINUTES TO ALLOW THE HEAT SINK TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

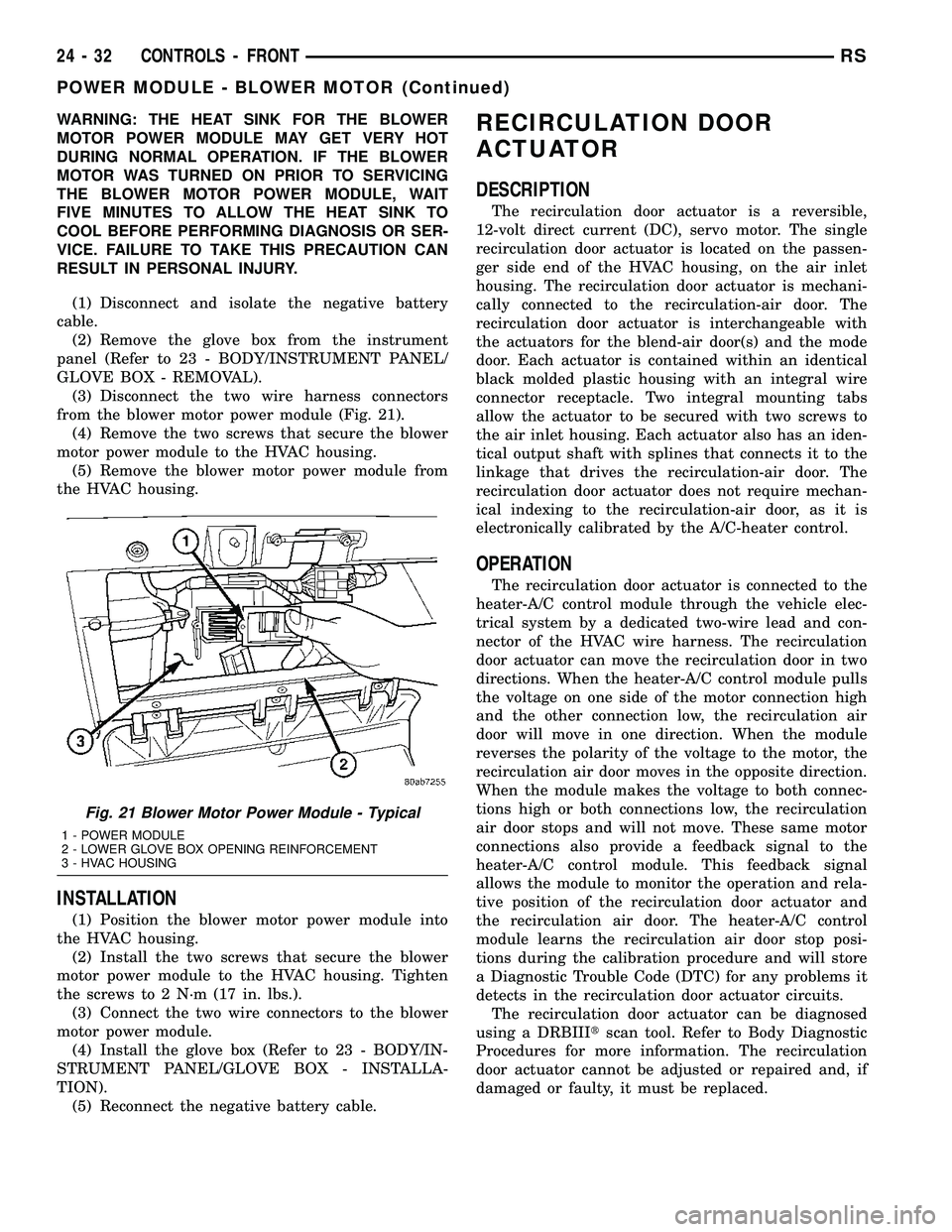

from the blower motor power module (Fig. 21).

(4) Remove the two screws that secure the blower

motor power module to the HVAC housing.

(5) Remove the blower motor power module from

the HVAC housing.

INSTALLATION

(1) Position the blower motor power module into

the HVAC housing.

(2) Install the two screws that secure the blower

motor power module to the HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(3) Connect the two wire connectors to the blower

motor power module.

(4) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(5) Reconnect the negative battery cable.

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt direct current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the HVAC housing, on the air inlet

housing. The recirculation door actuator is mechani-

cally connected to the recirculation-air door. The

recirculation door actuator is interchangeable with

the actuators for the blend-air door(s) and the mode

door. Each actuator is contained within an identical

black molded plastic housing with an integral wire

connector receptacle. Two integral mounting tabs

allow the actuator to be secured with two screws to

the air inlet housing. Each actuator also has an iden-

tical output shaft with splines that connects it to the

linkage that drives the recirculation-air door. The

recirculation door actuator does not require mechan-

ical indexing to the recirculation-air door, as it is

electronically calibrated by the A/C-heater control.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire lead and con-

nector of the HVAC wire harness. The recirculation

door actuator can move the recirculation door in two

directions. When the heater-A/C control module pulls

the voltage on one side of the motor connection high

and the other connection low, the recirculation air

door will move in one direction. When the module

reverses the polarity of the voltage to the motor, the

recirculation air door moves in the opposite direction.

When the module makes the voltage to both connec-

tions high or both connections low, the recirculation

air door stops and will not move. These same motor

connections also provide a feedback signal to the

heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive position of the recirculation door actuator and

the recirculation air door. The heater-A/C control

module learns the recirculation air door stop posi-

tions during the calibration procedure and will store

a Diagnostic Trouble Code (DTC) for any problems it

detects in the recirculation door actuator circuits.

The recirculation door actuator can be diagnosed

using a DRBIIItscan tool. Refer to Body Diagnostic

Procedures for more information. The recirculation

door actuator cannot be adjusted or repaired and, if

damaged or faulty, it must be replaced.

Fig. 21 Blower Motor Power Module - Typical

1 - POWER MODULE

2 - LOWER GLOVE BOX OPENING REINFORCEMENT

3 - HVAC HOUSING

24 - 32 CONTROLS - FRONTRS

POWER MODULE - BLOWER MOTOR (Continued)

Page 2430 of 2585

(6) If required, remove the three screws that

secure the rear A/C-heater control to the bezel and

remove the control from the bezel (Fig. 2).

INSTALLATION

(1) If removed, position the rear A/C-heater control

onto the bezel.

(2) If removed, install the three screws that secure

the rear A/C-heater control to the bezel. Tighten the

screws to 2 N´m (17 in. lbs.).

(3) Position the rear A/C-heater control near the

headliner.

(4) Connect the wire harness connector to the rear

A/C-heater control.

(5) Insert the locator tabs on the back of the rear

A/C-heater control bezel over the forward edge of the

headliner opening.

(6) Slide the rear A/C-heater control bezel forward

far enough to align the snap clips on the bezel with

the receptacles on the headliner.

(7) Using hand pressure, press the top edge of the

rear A/C-heater control bezel upward until the two

snap clips are fully seated in their receptacles.

(8) Reconnect the battery negative cable.

(9) Using the DRB-IIItreset the Rear Tempera-

ture Selector calibration values.

(10) Verify that the Actuator Calibration of the

Front Control has passed. If an Actuator Calibration

has not passed correct any errors before proceeding

further.

(11) Rotate the Rear Temperature Selector counter

clockwise to the Cold Position, allow the Selector to

remain in the Cold Position for 5 seconds.(12) Rotate the Rear Temperature Selector Clock-

wise to the Hot Position, allow the Selector to remain

in the Cold Position for 5 seconds.

(13) Calibration is now complete.

BLEND DOOR ACTUATOR

DESCRIPTION

The rear blend door actuator is a reversible,

12-volt Direct Current (DC), servo motor. The single

blend door actuator is located on the outboard side of

the rear HVAC housing, below the mode door actua-

tor. The blend door actuator is mechanically con-

nected to the blend air door.

The rear blend door actuator is interchangeable

with the actuator for the mode door. Each actuator is

contained within an identical black molded plastic

housing with an integral wire connector receptacle.

Two integral mounting tabs allow the actuator to be

secured with two screws to the rear HVAC housing.

Each actuator also has an identical output shaft with

splines that connects it to the pivot or linkage of the

proper door. The rear blend door actuator does not

require mechanical indexing to the blend air door

pivot, as it is electronically calibrated by the front

heater-A/C control module.

OPERATION

The rear blend door actuator is connected to the

front heater-A/C control module through the vehicle

electrical system by a dedicated two-wire take out

and connector of the rear HVAC wire harness. The

blend door actuator can move the blend air door in

two directions. When the front heater-A/C control

module pulls the voltage on one side of the motor

connection high and the other connection low, the

blend air door will move in one direction. When the

module reverses the polarity of the voltage to the

motor, the blend air door moves in the opposite direc-

tion. When the module makes the voltage to both

connections high or both connections low, the blend

air door stops and will not move. These same motor

connections also provide a feedback signal to the

front heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive positions of the blend door actuator and the

blend air door. The front heater-A/C control module

learns the blend air door stop positions during the

calibration procedure and will store a Diagnostic

Trouble Code (DTC) for any problems it detects in

the blend door actuator circuits.

The rear blend door actuator can be diagnosed

using a DRBIIItscan tool. Refer to Body Diagnostic

Procedures for more information. The rear blend door

Fig. 2 Heater-A/C Control Bezel

1 - BEZEL

2 - SNAP CLIP (2)

3 - HEATER-A/C CONTROL

4 - SCREW (3)

5 - LOCATOR TAB (2)

RSCONTROLS - REAR24-35

A/C-HEATER CONTROL (Continued)