ECO mode CHRYSLER VOYAGER 2005 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2240 of 2339

INSTALLATION

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

(1) Using spring tension clamp pliers, compress

and slide the clamp away from the end of the heater

return hose.

(2) Install each hose end by carefully twisting the

hose back and forth while gently pushing it onto the

tube.

(3) Using spring tension clamp pliers, compress

and slide the clamps onto each end of the heater

return hose.

(4) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

LIQUID LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).NOTE: The front A/C liquid line is serviced in two

sections. The front section connects between the

A/C condenser and the receiver/drier and includes

the high side service port. The rear section con-

nects between the receiver/drier and the expansion

valve and includes the fitting for the A/C pressure

transducer. On models equipped with the optional

rear heating-A/C system, the rear section of the

front A/C liquid line also includes a hose and tube

extension that connects the front liquid line to the

liquid line for the rear A/C system.

FRONT SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

RECOVERY).

(2) Disconnect and isolate the negative battery

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

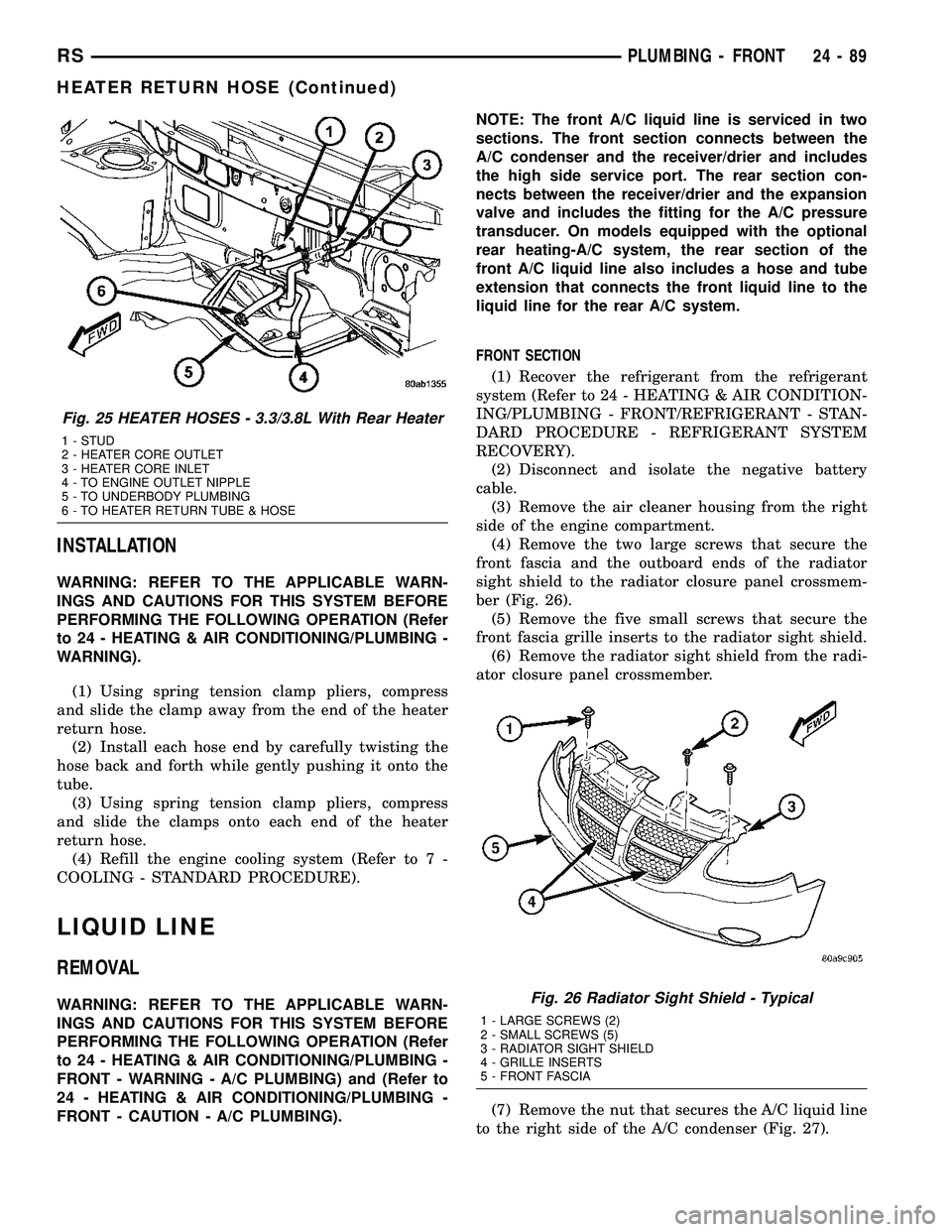

(4) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 26).

(5) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(6) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

(7) Remove the nut that secures the A/C liquid line

to the right side of the A/C condenser (Fig. 27).

Fig. 25 HEATER HOSES - 3.3/3.8L With Rear Heater

1 - STUD

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - TO ENGINE OUTLET NIPPLE

5 - TO UNDERBODY PLUMBING

6 - TO HEATER RETURN TUBE & HOSE

Fig. 26 Radiator Sight Shield - Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-89

HEATER RETURN HOSE (Continued)

Page 2241 of 2339

(8) Disconnect the A/C liquid line from the A/C

condenser and remove and discard the O-ring seal

and gasket.

(9) Install plugs in, or tape over the opened liquid

line fitting and the condenser outlet port.

(10) Disengage the retainer that secures the liquid

line routing clip to the top of the right frame rail

ahead of the front strut tower in the engine compart-

ment (Fig. 28).

(11) Remove the bolt that secures the front section

of the A/C liquid line to the receiver/drier.

(12) Disconnect the A/C liquid line from the receiv-

er/drier and remove and discard the O-ring seal.

(13) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier inlet port.

(14) Remove the front section of the A/C liquid line

from the engine compartment.

REAR SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the negative battery

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER -

REMOVAL).(6) If equipped, remove the nut that secures the

A/C ground strap to the weld stud on the top of the

right front strut tower (Fig. 28).

(7) If equipped, remove the A/C ground strap eye-

let terminal connector from the weld stud.

(8) Remove the bolt that secures the rear section

of the A/C liquid line to the receiver/drier.

(9) Disconnect the A/C liquid line from the receiv-

er/drier and remove and discard the O-ring seal.

(10) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(11) Remove the nut that secures the A/C suction

line and the A/C liquid line to the A/C expansion

valve.

(12) Disconnect the A/C suction line and the A/C

liquid line from the A/C expansion valve and remove

and discard the O-ring seals.

(13) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(14) On RHD models, remove the rear section of

the A/C liquid line from the retaining bracket located

at the top of the dash panel

Fig. 27 A/C Condenser Connections

1 - A/C CONDENSER

2 - A/C DISCHARGE LINE

3 - A/C LIQUID LINE

4 - NUT (2)Fig. 28 A/C Liquid Line - LHD Shown, RHD Typical

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - A/C EXPANSION VALVE

7 - A/C LIQUID LINE (REAR SECTION)

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - A/C LIQUID LINE (FRONT SECTION)

24 - 90 PLUMBING - FRONTRS

LIQUID LINE (Continued)

Page 2243 of 2339

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the A/C liquid line to the receiver/

drier.

(9) Install the bolt that secures the A/C liquid line

to the receiver/drier. Tighten the bolt to 11 N´m (97

in. lbs.).

(10) If equipped, reinstall the A/C ground strap

eyelet terminal connector onto the weld stud on the

top of the right front strut tower (if equipped).

(11) If equipped, install the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.)

(12) Install the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER - INSTAL-

LATION).

(13) Connect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Install the air cleaner housing into the right

side of the engine compartment.

(15) On RHD models, install the liquid line into

the retaining bracket located at the top of the dash

panel.

(16) If the vehicle is equipped with the optional

rear heating-A/C system, go to Step 17. If the vehicle

does not have the optional rear heating-A/C system,

go to Step 23.

(17) Raise and support the vehicle.

(18) Remove the tape or plugs from the A/C liquid

line extension fitting and the underbody liquid line

fitting.

(19) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(20) Connect the A/C liquid line extension fitting

to the underbody liquid line fitting. Tighten the fit-

tings to 23 N´m (17 ft. lbs.).

(21) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heating-

A/C system.

(22) Lower the vehicle.

(23) Reconnect the negative battery cable.

(24) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(25) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).RECEIVER / DRIER

DESCRIPTION

The receiver/drier is mounted in a bracket secured

to the right front strut tower in the engine compart-

ment. The receiver/drier is connected between the

front and rear sections of the liquid line between the

condenser outlet and the evaporator inlet. The receiv-

er/drier cannot be repaired. If the receiver/drier is

faulty or damaged, or if the refrigerant system has

been contaminated or left open to the atmosphere for

an indeterminable period or if the A/C compressor

has failed, it must be replaced.

OPERATION

The receiver/drier performs a filtering action to

prevent foreign material in the refrigerant from con-

taminating the expansion valve. Desiccant inside the

receiver/drier canister absorbs any moisture which

may have entered and become trapped within the

refrigerant system. In addition, during periods of

high demand air conditioner operation, the receiver/

drier acts as a reservoir to store surplus refrigerant.

Refrigerant enters the receiver/drier as a high-pres-

sure, low temperature liquid.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Remove the air cleaner housing from the right

side of the engine compartment.

(3) Remove the bolt that secures the liquid line

front section fitting to the top of the receiver/drier

(Fig. 30).

(4) Disconnect the liquid line fitting from the

receiver/drier inlet port.

(5) Remove the O-ring seal from the liquid line fit-

ting and discard.

(6) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier inlet port.

24 - 92 PLUMBING - FRONTRS

LIQUID LINE (Continued)

Page 2247 of 2339

CAUTION: A valve core that is not fully seated in

the A/C service port can result in damage to the

valve during refrigerant system evacuation and

charge. Such damage may result in a loss of sys-

tem refrigerant while uncoupling the charge adapt-

ers.

(4) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(5) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

(6) Reinstall the protective cap onto the A/C ser-

vice port.

SUCTION LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: The front suction line includes the low side

service port on a section of tubing located near the

A/C compressor. On models equipped with the

optional rear A/C system, the front suction line also

includes a suction line hose and tube extension

that connects the front suction line to the suction

line for the rear A/C system.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the air cleaner top cover and snorkel

from the air cleaner housing located on the right side

of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the nut that secures the suction line

fitting to the top of the A/C compressor.

(6) Disconnect the suction line fitting from the

compressor suction port.(7) Remove the O-ring seal from the suction line

fitting and discard.

(8) Install plugs in, or tape over the opened suc-

tion line fitting and the compressor suction port.

(9) Remove the retainer that secures the suction

line routing clip to the receiver/drier mounting

bracket on the side of the right front strut tower in

the engine compartment (Fig. 31).

(10) Remove the nut that secures the suction line

and liquid line fittings to the expansion valve.

(11) Disconnect the suction line and liquid line fit-

tings from the expansion valve.

(12) Remove the seals from the suction line and

liquid line fittings and discard.

(13) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(14) Remove the suction line from the retaining

bracket located at the top of the dash panel.

(15) If the vehicle is equipped with the optional

rear air conditioner, go to Step 16. If the vehicle does

not have the optional rear air conditioner, go to Step

22.

(16) Raise and support the vehicle.

(17) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear

heater and air conditioner (Fig. 32).

Fig. 31 Suction Line - LHD Shown, RHD Typical

1 - A/C EXPANSION VALVE

2 - SUCTION LINE EXTENSION (REAR A/C ONLY)

3 - NUT

4 - RETAINING CLIP

5 - SUCTION LINE

24 - 96 PLUMBING - FRONTRS

SERVICE PORT VALVE CORE (Continued)

Page 2248 of 2339

(18) Disconnect the suction line extension fitting

from the underbody suction line fitting for the rear

air conditioner.

(19) Remove the O-ring seal from the underbody

suction line fitting and discard.

(20) Install plugs in, or tape over the opened suc-

tion line fittings.

(21) Lower the vehicle.

(22) Remove the suction line from the engine com-

partment.

INSTALLATION

(1) Position the suction line into the engine com-

partment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install the nut that secures the suction line

and liquid line fittings to the expansion valve.

Tighten the nut to 23 N´m (17 ft. lbs.).

(6) Install the retainer that secures the suction

line routing clip to the receiver/drier mounting

bracket on the side of the right front strut tower in

the engine compartment.(7) Remove the tape or plugs from the compressor

suction port and the suction line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting.

(9) Install a new dual plan seal and reconnect the

suction line fitting to the compressor suction port.

(10) Install the nut that secures the suction line

fitting to the A/C compressor. Tighten the nut to 23

N´m (17 ft. lbs.).

(11) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(12) Install the air cleaner top cover and snorkel

onto the air cleaner housing located on the right side

of the engine compartment.

(13) On RHD models, install the suction line into

the retaining bracket located at the top of the dash

panel.

(14) If the vehicle is equipped with the optional

rear air conditioner, go to Step 15. If the vehicle does

not have the optional rear air conditioner, go to Step

21.

(15) Raise and support the vehicle.

(16) Remove the tape or plugs from the suction

line extension fitting and the underbody suction line

fitting.

(17) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody suction

line fitting.

(18) Reconnect the suction line extension fitting to

the underbody suction line fitting. Tighten the fit-

tings to 23 N´m (17 ft. lbs.).

(19) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heater

and air conditioner.

(20) Lower the vehicle.

(21) Reconnect the battery negative cable.

(22) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(23) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

Fig. 32 Underbody A/C Line Connections

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

RSPLUMBING - FRONT24-97

SUCTION LINE (Continued)

Page 2252 of 2339

DIAGNOSIS AND TESTING

REAR A/C EXPANSION VALVE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The expansion valve should only be tested

following testing of the compressor.

NOTE: Liquid CO

2is required to test the expansion

valve. This material is available from most welding

supply facilities. Liquid CO

2is also available from

companies which service and sell fire extinguish-

ers.

When testing the expansion valve, the work area

and the vehicle temperature must be 21É to 27É C

(70É to 85É F). To test the expansion valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set the heater-air conditioner controls so that

the compressor is operating, the temperature control

is in the highest temperature position, the mode door

is directing the output to the floor outlets, and the

blower is operating at the highest speed setting.

(4) Start the engine and allow it to idle at 1000

rpm. After the engine has reached normal operating

temperature, allow the passenger compartment to

heat up. This will create the need for maximum

refrigerant flow into the evaporator.

(5) If the refrigerant charge is sufficient, the dis-

charge (high pressure) gauge should read 965 to 1655

kPa (140 to 240 psi). The suction (low pressure)

gauge should read 140 kPa to 207 kPa (20 psi to 30

psi). If OK, go to Step 6. If not OK, replace the faulty

expansion valve.

WARNING: PROTECT THE SKIN AND EYES FROM

EXPOSURE TO LIQUID CO

2. PERSONAL INJURY

CAN RESULT.

(6)

If the suction (low pressure) gauge reads within

the specified range, freeze the expansion valve control

head for 30 seconds using liquid CO

2or another suit-

able super-cold material.Do not spray R-134a or

R-12 refrigerant on the expansion valve controlhead for this test.

The suction (low pressure) gauge

reading should drop by 10 psi. If OK, go to Step 7 If

not OK, replace the faulty expansion valve.

(7) Allow the expansion valve control head to thaw.

The suction (low pressure) gauge reading should sta-

bilize at 140 kPa to 240 kPa (20 psi to 30 psi). If not

OK, replace the faulty expansion valve.

(8) When expansion valve testing is complete, test

the overall air conditioner performance (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE TEST).

Remove all test equipment before returning the vehi-

cle to service.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING), (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING), and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - HEATER PLUMBING).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Carefully remove the foam insulator wrap from

the rear expansion valve.

(3) Remove the rear evaporator line extension from

the expansion valve (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - REAR/EVAPORA-

TOR - REMOVAL - EVAPORATOR LINE EXTEN-

SION).

(4) Remove the two screws that secure the expan-

sion valve to the evaporator tube sealing plate.

(5) Remove the expansion valve from the evapora-

tor tubes.

(6) Remove the seals from the evaporator tube fit-

tings and discard.

(7) Install plugs in, or tape over the opened evap-

orator tube fittings and both expansion valve ports.

INSTALLATION

(1) Remove the tape or plugs from the rear A/C

evaporator tube fittings and both expansion valve

ports.

(2) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the rear evapora-

tor tube fittings.

(3) Position the expansion valve onto the evapora-

tor tubes.

(4) Install the two screws that secure the rear A/C

expansion valve to the evaporator tube sealing plate.

Tighten the screws to 11 N´m (97 in. lbs.).

RSPLUMBING - REAR24 - 101

A/C EXPANSION VALVE (Continued)

Page 2256 of 2339

INSTALLATION

(1) Install the front underbody heater inlet and

return hoses by carefully twisting the hoses back and

forth on the underbody tubes, while gently pushing

them onto the end of the tubes.

CAUTION:

DO NOT apply excessive pressure on heater tubes

or connections when removing heater hoses.

Excessive pressure may damage or deform the

tubes, causing an engine coolant leak.

(2) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose over the tubes. Release the clamp when

it is over the tube.

(3) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

LIQUID LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: On models equipped with the optional rear

A/C system, the rear section of the front air condi-

tioner liquid line also includes a liquid line hose

and tube extension that connects the front liquid

line to the underbody liquid line for the rear A/C

system.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER -

REMOVAL).(6) If equipped, remove the nut that secures the

A/C ground strap to the weld stud on the top of the

right front strut tower (Fig. 7).

(7) If equipped, remove the A/C ground strap eye-

let terminal connector from the weld stud.

(8) Remove the bolt that secures the liquid line

rear section fitting to the top of the receiver/drier.

(9) Disconnect the liquid line fitting from the

receiver/drier outlet port.

(10) Remove the O-ring seal from the liquid line

fitting and discard.

(11) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(12) Remove the nut that secures the suction line

and liquid line fittings to the expansion valve.

(13) Disconnect the suction line and liquid line fit-

tings from the expansion valve.

(14) Remove the seals from the suction line and

liquid line fittings and discard.

(15) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(16) Raise and support the vehicle.

Fig. 7 Liquid Line

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - A/C EXPANSION VALVE

7 - A/C LIQUID LINE (REAR SECTION)

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - A/C LIQUID LINE (FRONT SECTION)

RSPLUMBING - REAR24 - 105

HEATER HOSES (Continued)

Page 2257 of 2339

(17) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear heat-

er-A/C system (Fig. 8).

(18) Disconnect the front liquid line extension fit-

ting from the underbody liquid line fitting for the

rear air conditioner.

(19) Remove the O-ring seal from the underbody

liquid line fitting and discard.

(20) Install plugs in, or tape over the opened liquid

line fittings.

(21) Lower the vehicle.

(22) Remove the liquid line from the engine com-

partment.

INSTALLATION

(1) Position the rear section of the front liquid line

into the engine compartment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install the nut that secures the suction line

and liquid line fittings to the expansion valve.

Tighten the nut to 23 N´m (17 ft. lbs.).

(6) Remove the tape or plugs from the liquid line

rear section fitting for the receiver/drier and the

receiver/drier outlet port.(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the liquid line fitting to the receiver/

drier outlet port on the top of the receiver/drier.

(9) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(10) If equipped, reinstall the A/C ground strap

eyelet terminal connector onto the weld stud on the

top of the right front strut tower (if equipped).

(11) If equipped, install the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.)

(12) Install the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS/

A/C PRESSURE TRANSDUCER - INSTALLATION).

(13) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Raise and support the vehicle.

(16) Remove the tape or plugs from the liquid line

rear section extension fitting and the underbody liq-

uid line fitting.

(17) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(18) Reconnect the liquid line rear section exten-

sion fitting to the underbody liquid line fitting.

Tighten the fittings to 23 N´m (17 ft. lbs.).

(19) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heater-

A/C system.

(20) Lower the vehicle.

(21) Reconnect the battery negative cable.

(22) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(23) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

SUCTION LINE

REMOVAL

On models equipped with the optional rear A/C

system, the front air conditioner suction line also

includes a suction line hose and tube extension that

connects the front suction line to the underbody suc-

tion line for the rear A/C system.

Fig. 8 Underbody A/C Line Front Connections ±

Typical

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

24 - 106 PLUMBING - REARRS

LIQUID LINE (Continued)

Page 2259 of 2339

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install the nut that secures the suction line

and liquid line fittings to the front expansion valve.

Tighten the nut to 23 N´m (17 ft. lbs.).

(6) Engage the retainer that secures the suction

line routing clip to the receiver/drier mounting

bracket on the side of the right front strut tower in

the engine compartment.

(7) Remove the tape or plugs from the compressor

suction port and the suction line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting.

(9) Reconnect the suction line fitting to the com-

pressor suction port.

(10) Install the nut that secures the suction line

fitting to the A/C compressor. Tighten the nut to 23

N´m (17 ft. lbs.).

(11) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(12) Reinstall the air cleaner top cover and snorkel

onto the air cleaner housing located on the right side

of the engine compartment.

(13) Reconnect the battery negative cable.

(14) Raise and support the vehicle.

(15) Remove the tape or plugs from the suction

line extension fitting and the underbody suction line

fitting.

(16) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody suction

line fitting.(17) Reconnect the suction line extension fitting to

the underbody suction line fitting. Tighten the fitting

to 23 N´m (17 ft. lbs.).

(18) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heater

and air conditioner.

(19) Lower the vehicle.

(20) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(21) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

UNDERBODY LINES

DESCRIPTION

The underbody heater-A/C plumbing is used only

on models with the optional rear heater-A/C system

(Fig. 11). The underbody suction line, liquid line, and

heater tubes can each be serviced separately.

OPERATION

The rear heater and A/C lines are all serviced as

individual components. When disconnecting any lines

or connections, make sure that the area around the

line or connection is clean of any dirt or residue that

may enter and contaminate the rear heating-A/C sys-

tem (Fig. 12) and (Fig. 13).

Fig. 11 Rear Heater and A/C Lines ± Typical

1 - REAR HEATER TUBE CONNECTIONS2 - REAR A/C LINE CONNECTIONS

24 - 108 PLUMBING - REARRS

SUCTION LINE (Continued)

Page 2279 of 2339

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor, fuel system, or mis-

fire diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables. The misfire will however,

increase the oxygen content in the exhaust, deceiving

the PCM in to thinking the fuel system is too lean.

Also see misfire detection. There are DTC's that can

detect misfire and Ionization shorts in the secondary

ignition circuit, refer to the Powertrain Diagnostic

manual for more information

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression. Low compression lowers O2

content in the exhaust. Leading to fuel system, oxy-

gen sensor, or misfire detection fault.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR (if

equipped) or Fuel system or O2S fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCMto store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times,

including when diagnostics are performed.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the a scan tool.

The following is a list of the system monitors:

²EGR Monitor (if equipped)

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor (if

equipped)

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperatures of 300É to 350ÉC (572É to 662ÉF),

the sensor generates a voltage that is inversely pro-

portional to the amount of oxygen in the exhaust.

25 - 6 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)