wheel CITROEN BERLINGO VAN 2019 Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2019, Model line: BERLINGO VAN, Model: CITROEN BERLINGO VAN 2019Pages: 324, PDF Size: 9.41 MB

Page 199 of 324

197

Practical information

7brake must be adjusted, even between two

services.

This system must be checked by a CITROËN

dealer or a qualified workshop.

Electric parking brake

This system does not require any routine servicing. However, in the event of a

problem, do not hesitate to have the system

checked by a CITROËN dealer or a qualified

workshop.

For more information on the Electric

parking brake, refer to the

corresponding section.

Wheels and tyres

The inflation pressure of all tyres, including the spare wheel, must be

checked on "cold” tyres.

The pressures indicated on the tyre pressure

label are valid for "cold" tyres. If you have driven

for more than 10 minutes or more than 6 miles

(10 kilometres) at over 31 mph (50

km/h), add

0.3 bar (30 kPa) to the values indicated on the

label.

Under-inflation increases energy

consumption. Non-compliant tyre

pressures cause tyres to wear prematurely

and have an adverse effect on the vehicle's

road holding - risk of accident! Driving with worn or damaged tyres reduces the

braking and road holding performance of the

vehicle. Regularly check the condition of the

tyres (tread and sidewalls) and rims as well as

the presence of the valve caps.

When the wear indicators no longer appear set

back from the tread, the depth of the grooves is

less than 1.6 mm; replace the tyres as soon as

possible.

Using different size wheels and tyres from those

specified can affect the lifetime of tyres, wheel

rotation, ground clearance, the speedometer

reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Always mark the direction of rotation on the tyres

that will be stored when fitting winter or summer

tyres. Store them in a cool, dry place and away

from direct exposure to the sun's rays.

Winter or 4-seasons tyres can be

identified by this symbol on their

sidewalls.

AdBlue® (BlueHDi)

To respect the environment and ensure compliance with the Euro 6 standard, without

adversely affecting the performance or fuel

consumption of its Diesel engines, CITROËN

has taken the decision to equip its vehicles with

a system that combines SCR (Selective Catalytic

Reduction) with a Diesel Particle Filter (DPF) for

the treatment of exhaust gases.

SCR system

Using a liquid called AdBlue® that contains

urea, a catalytic converter turns up to 85% of

the nitrogen oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

The AdBlue® is contained in a special

tank holding about 17 litres.

Its capacity allows a driving range of

approximately 3,000

miles (5,000 km) (which

may vary considerably depending on your

driving style and the vehicle). An alert system

is automatically triggered when the remaining

range reaches 1,500 miles (2,400

km), i.e. once

the reserve level has been reached.

Several alerts are triggered successively during

the remaining 1,500 miles (2,400

km) until the

tank is empty and the vehicle is immobilised.

For more information on the Warning

and indicator lamps and the associated

alerts, or the Indicators, please refer to the

corresponding sections.

Once the AdBlue® tank is empty, a device

required by law prevents the engine from

being restarted.

If the SCR system is faulty, the level of

emissions from the vehicle will no longer meet

Page 201 of 324

199

Practical information

7AdBlue, it is essential to wait around 5

minutes before switching on the ignition,

without opening the driver’s door,

unlocking the vehicle, inserting the key

into the ignition switch, or bringing the

key for the "Keyless Entry and Start"

system into the passenger compartment.

Switch on the ignition, then wait for 10

seconds before starting the engine.

►

Switch off the ignition and remove the key

from the switch to switch off the engine.

or

►

With Keyless Entry and Start, press the

"

START/STOP" button to switch off the engine.

► With the vehicle unlocked and the fuel filler

flap open, turn the blue cap of the AdBlue® tank

anti-clockwise and remove it.

►

With a container of

AdBlue

®: after checking

the expiry date, read the instructions on the

label carefully before pouring the contents of the

container into the vehicle's AdBlue tank.

►

With an

AdBlue® pump: insert the nozzle and

fill the tank until the nozzle automatically cuts

out.

In order not to overfill the AdBlue® tank:

–

Add between 10 and 13 litres using

AdBlue® containers.

–

Stop after the nozzle’ s first automatic cut-

out, if you are refilling at a service station.

The system only registers AdBlue

® top-ups of

5

litres or more.

If the AdBlue® tank is completely empty

– which is confirmed by the message

“Top up

AdBlue: Starting impossible ” – it is

essential to add at least 5 litres.

After refilling

► Refit the blue cap to the tank filler and turn it

clockwise, as far as it will go.

►

Close the fuel filler flap.

Do not dispose of AdBlue® bottles or

containers in the household waste.

Place them in a container reserved for this

purpose or take them back to where you

purchased them.

Free-wheeling

In certain situations, it is necessary to put the

vehicle into free-wheeling mode (e.g. towing, on

a rolling road, automatic car wash (Wash mode),

rail or sea transport).

The procedure varies according to the type of

gearbox and parking brake.

Do not leave the vehicle unattended

while coasting.

Keyless Entry and Start

You must not depress the brake pedal

while switching the ignition on again, then

switching it off. If you do, the engine will start,

requiring you to restart the procedure.

With a manual gearbox and

electric parking brake

/

To release them

► With the engine running and while depressing

the brake pedal, move the gear selector to the

neutral position.

►

While depressing the brake pedal, switch off

the engine.

►

Release the brake pedal, then switch on the

ignition.

►

While depressing the brake pedal, press the

control to release the parking brake.

►

Release the brake pedal, then switch off the

ignition.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine and apply the parking brake.

Page 202 of 324

200

Practical information

With an automatic gearbox

and electric parking brake

/

To release them

► With the engine running and while depressing

the brake pedal, set the gear selector to N

.

►

While depressing the brake pedal, switch off

the engine.

►

Release the brake pedal, then switch on the

ignition again.

►

While depressing the brake pedal, press the

control lever to release the parking brake.

►

Release the brake pedal, then switch off the

ignition.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine and select mode P .

With drive selector and

electric parking brake

/

Release procedure

► With the vehicle stationary and the engine

running, depress the brake pedal and select

mode

N.

Within 5

seconds:

► Depress and hold the brake pedal, then

observe this order: switch off the engine and

move the push selector forwards or backwards.

►

Release the brake pedal, then switch on the

ignition.

►

Place your foot on the brake and press the

electric parking brake control to release it.

►

Release the brake pedal, then switch off the

ignition.

A message is displayed on the instrument panel to confirm the unlocking

of the wheels for 15

minutes.

When the vehicle is free-wheeling, the

audio system cannot be updated (message

displayed on the instrument panel).

After 15 minutes or reverting to normal

operation

► While depressing the brake pedal, restart the

engine and select mode P .

Advice on care and maintenance

General recommendations

Observe the following recommendations to avoid

damaging the vehicle.

Exterior

Never use a high-pressure jet wash in

the engine compartment - risk of

damaging the electrical components!

Do not wash the vehicle in bright sunshine or

extremely cold conditions.

When washing the vehicle in an

automatic roller-brush car wash, be sure

to lock the doors and, depending on version,

move the electronic key away.

When using a pressure washer, keep the jet

nozzle at a minimum distance of 30 cm from

the vehicle (particularly when cleaning areas

containing chipped paint, sensors or seals).

Promptly clean up any stains containing

chemicals liable to damage the vehicle's

paintwork (including tree resin, bird

droppings, insect secretions, pollen and tar).

Depending on the environment, clean the

vehicle frequently to remove salty deposits

(in coastal areas), soot (in industrial areas)

and mud/salts (in wet or cold areas). These

substances can be highly corrosive.

Contact a CITROËN dealer or a qualified

workshop for advice on removing stubborn

stains requiring special products (such as tar

or insect removers).

Preferably, have paint touch-ups performed

by a CITROËN dealer or a qualified

workshop.

Page 204 of 324

202

In the event of a breakdown

Running out of fuel

(Diesel)

With Diesel engines, the fuel system must be

primed if you run out of fuel.

Before starting to prime the system, it is

essential to put at least 5 litres of Diesel into the

fuel tank.

For more information on Refuelling and

on Misfuel prevention (Diesel), refer to

the corresponding section.

For non-BlueHDi versions, the fuel system

components are located in the engine

compartment; this may be under a removable

cover.

For more information on the Engine

compartment, in particular the location

of these components under the bonnet, refer

to the corresponding section.

With 1.6 BlueHDi (Euro 6.1)

► Switch on the ignition (without starting the

engine).

►

W

ait around 6 seconds and switch off the

ignition.

►

Repeat the operation 10

times.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

With 1.5 BlueHDi (Euro 6.2/6.3)

► Switch on the ignition (without starting the

engine).

►

W

ait around 1 minute and switch off the

ignition.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

Non-BlueHDi engines

► Open the bonnet and then, if necessary ,

unclip the cover to access the priming pump.

► Operate the priming pump repeatedly

until resistance is felt (resistance may be

felt at the first press).

►

Operate the starter motor to start the engine

(if the engine does not start at the first attempt,

wait around 15 seconds before trying again).

►

If the engine does not start after a few

attempts, operate the priming pump again, then

the starter motor

.

►

Put the cover back in place and clip it in, then

close the bonnet.

Tool kit

► For easier access, move the seat(s) forward.

Accessing the tools

Vehicle with electric motor

With temporary puncture repair kit

The tools are located in the passenger footwell. With spare wheel

The tools are located under the right-hand front

seat.

To access the tools:

–

With non-adjustable front seat, lift the seat

cushion by placing your hand between the

cushion and the backrest.

–

With adjustable front seat, move the seat

forward as far as possible.

The jack is located in the passenger footwell.

Vehicle with Petrol or Diesel engine

With temporary puncture repair kit

The kit is located under the right-hand front seat.

With spare wheel

The jack is located under the right-hand front

seat.

The tools are located under the left-hand front

seat.

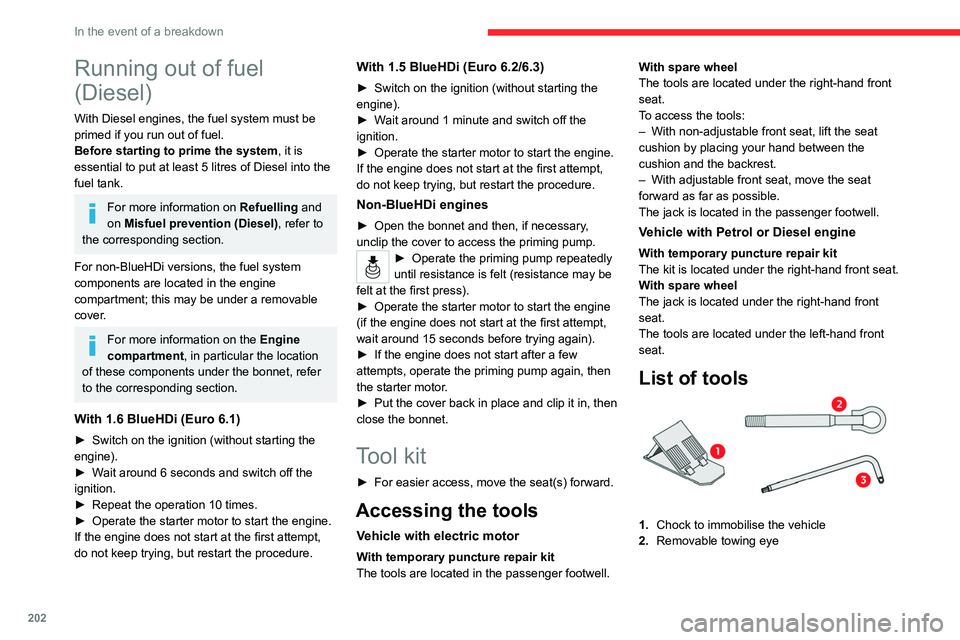

List of tools

1. Chock to immobilise the vehicle

2. Removable towing eye

Page 205 of 324

203

In the event of a breakdown

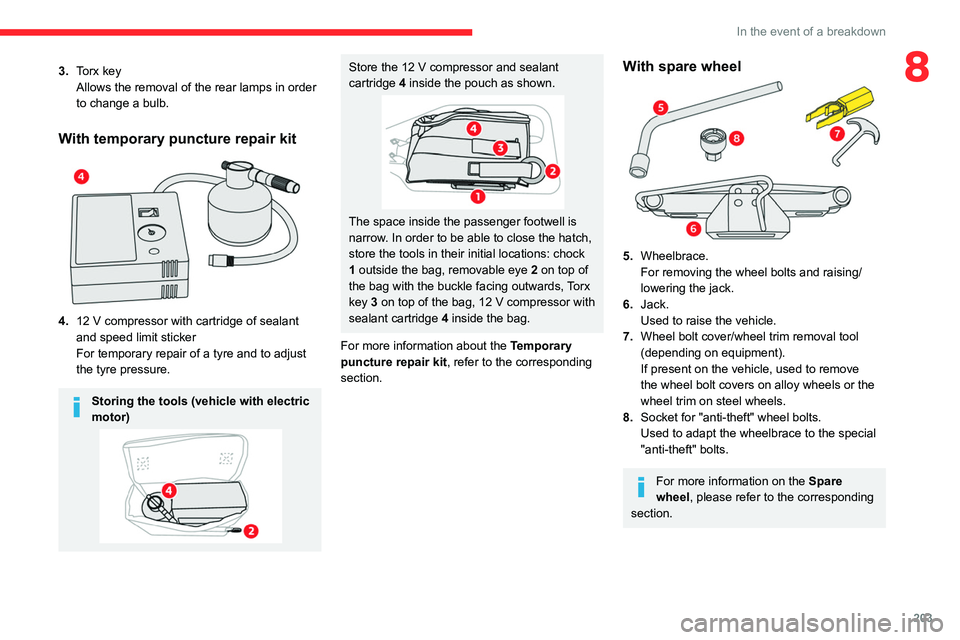

83.Torx key

Allows the removal of the rear lamps in order

to change a bulb.

With temporary puncture repair kit

4.12 V compressor with cartridge of sealant

and speed limit sticker

For temporary repair of a tyre and to adjust

the tyre pressure.

Storing the tools (vehicle with electric

motor)

Store the 12 V compressor and sealant

cartridge 4 inside the pouch as shown.

The space inside the passenger footwell is

narrow. In order to be able to close the hatch,

store the tools in their initial locations: chock

1 outside the bag, removable eye

2

on top of

the bag with the buckle facing outwards, Torx

key 3 on top of the bag, 12

V compressor with

sealant cartridge 4 inside the bag.

For more information about the Temporary

puncture repair kit, refer to the corresponding

section.

With spare wheel

5. Wheelbrace.

For removing the wheel bolts and raising/

lowering the jack.

6. Jack.

Used to raise the vehicle.

7. Wheel bolt cover/wheel trim removal tool

(depending on equipment).

If present on the vehicle, used to remove

the wheel bolt covers on alloy wheels or the

wheel trim on steel wheels.

8. Socket for "anti-theft" wheel bolts.

Used to adapt the wheelbrace to the special

"anti-theft" bolts.

For more information on the Spare

wheel, please refer to the corresponding

section.

Page 206 of 324

204

In the event of a breakdown

All of these tools are specific to your vehicle and may vary depending on

equipment.

Do not use them for any other purposes.

The jack must only be used to change a wheel with a damaged or punctured tyre.

The jack does not require any maintenance.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

EC.

Some parts of the jack such as the

screws and hinges could cause injury:

avoid touching them.

Carefully remove any traces of grease.

Temporary puncture repair kit

Scan the QR Code on page 3 to view

explanatory videos.

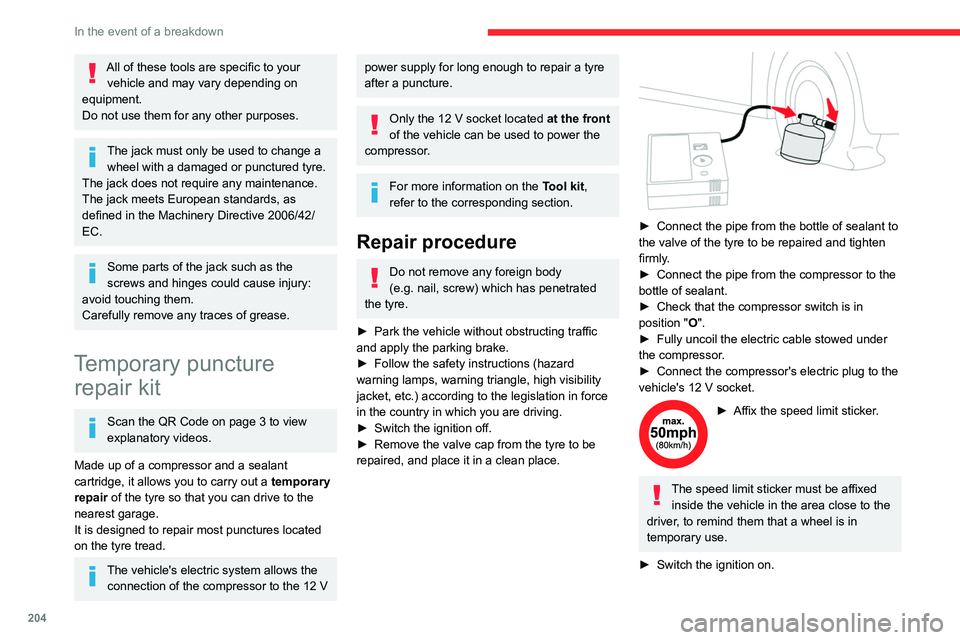

Made up of a compressor and a sealant

cartridge,

it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located

on the tyre tread.

The vehicle's electric system allows the connection of the compressor to the 12 V

power supply for long enough to repair a tyre

after a puncture.

Only the 12 V socket located at the front

of the vehicle can be used to power the

compressor.

For more information on the Tool kit,

refer to the corresponding section.

Repair procedure

Do not remove any foreign body

(e.g. nail, screw) which has penetrated

the tyre.

►

Park the vehicle without obstructing traffic

and apply the parking brake.

►

Follow the safety instructions (hazard

warning lamps, warning triangle, high visibility

jacket, etc.) according to the legislation in force

in the country in which you are driving.

►

Switch the ignition off.

►

Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Connect the pipe from the bottle of sealant to

the valve of the tyre to be repaired and tighten

firmly

.

►

Connect the pipe from the compressor to the

bottle of sealant.

►

Check that the compressor switch is in

position

"O".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

► Affix the speed limit sticker .

The speed limit sticker must be affixed

inside the vehicle in the area close to the

driver, to remind them that a wheel is in

temporary use.

►

Switch the ignition on.

Page 208 of 324

206

In the event of a breakdown

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

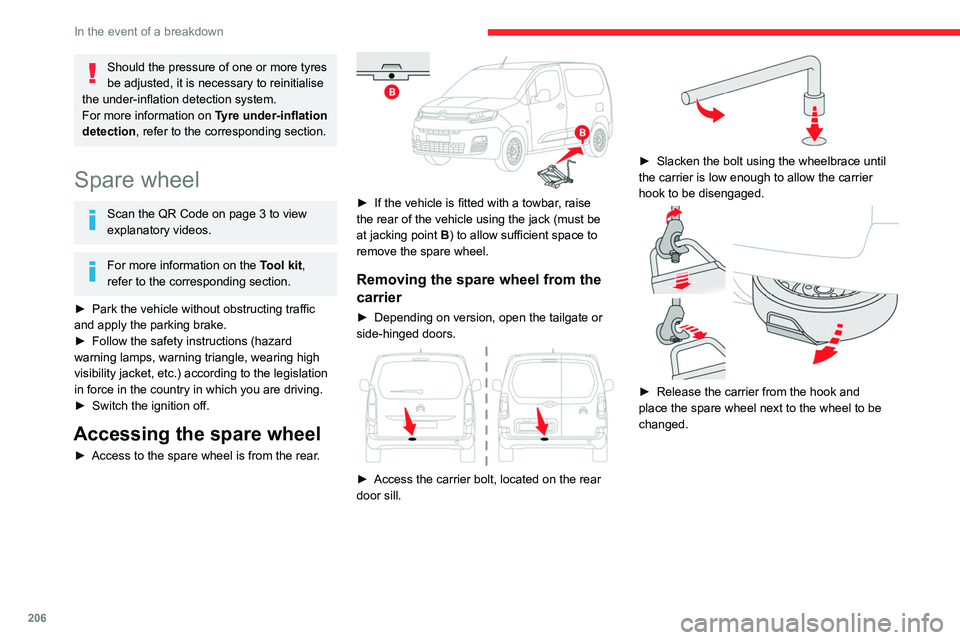

Spare wheel

Scan the QR Code on page 3 to view

explanatory videos.

For more information on the Tool kit,

refer to the corresponding section.

►

Park the vehicle without obstructing traffic

and apply the parking brake.

►

Follow the safety instructions (hazard

warning lamps, warning triangle, wearing high

visibility jacket, etc.) according to the legislation

in force in the country in which you are driving.

►

Switch the ignition off.

Accessing the spare wheel

► Access to the spare wheel is from the rear .

► If the vehicle is fitted with a towbar, raise

the rear of the vehicle using the jack (must be

at jacking point B) to allow sufficient space to

remove the spare wheel.

Removing the spare wheel from the

carrier

► Depending on version, open the tailgate or

side-hinged doors.

► Access the carrier bolt, located on the rear

door sill.

► Slacken the bolt using the wheelbrace until

the carrier is low enough to allow the carrier

hook to be disengaged.

► Release the carrier from the hook and

place the spare wheel next to the wheel to be

changed.

Page 209 of 324

207

In the event of a breakdown

8Putting the spare wheel back in the

carrier

► Position the wheel facing the carrier.

► Progressively return the wheel to the carrier

by pushing alternately at left and right until it is

clear of the hook fixing area.

►

Engage the carrier on the hook, then tighten

the bolt using the wheelbrace handle until the

bolt is tight.

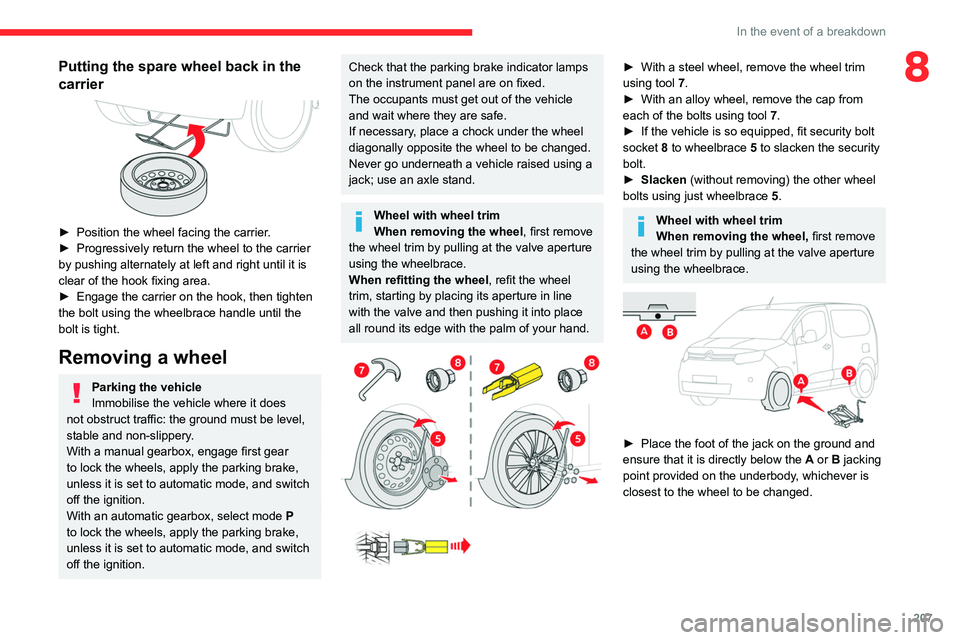

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With a manual gearbox, engage first gear

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

With an automatic gearbox, select mode

P

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Check that the parking brake indicator lamps

on the instrument panel are on fixed.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

When refitting the wheel , refit the wheel

trim, starting by placing its aperture in line

with the valve and then pushing it into place

all round its edge with the palm of your hand.

► With a steel wheel, remove the wheel trim

using tool 7

.

►

With an alloy wheel, remove the cap from

each of the bolts using tool 7

.

►

If the vehicle is so equipped, fit security bolt

socket

8 to wheelbrace 5 to slacken the security

bolt.

►

Slacken

(without removing) the other wheel

bolts using just wheelbrace 5.

Wheel with wheel trim

When removing the wheel, first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

► Place the foot of the jack on the ground and

ensure that it is directly below the A

or B jacking

point provided on the underbody, whichever is

closest to the wheel to be changed.

Page 210 of 324

208

In the event of a breakdown

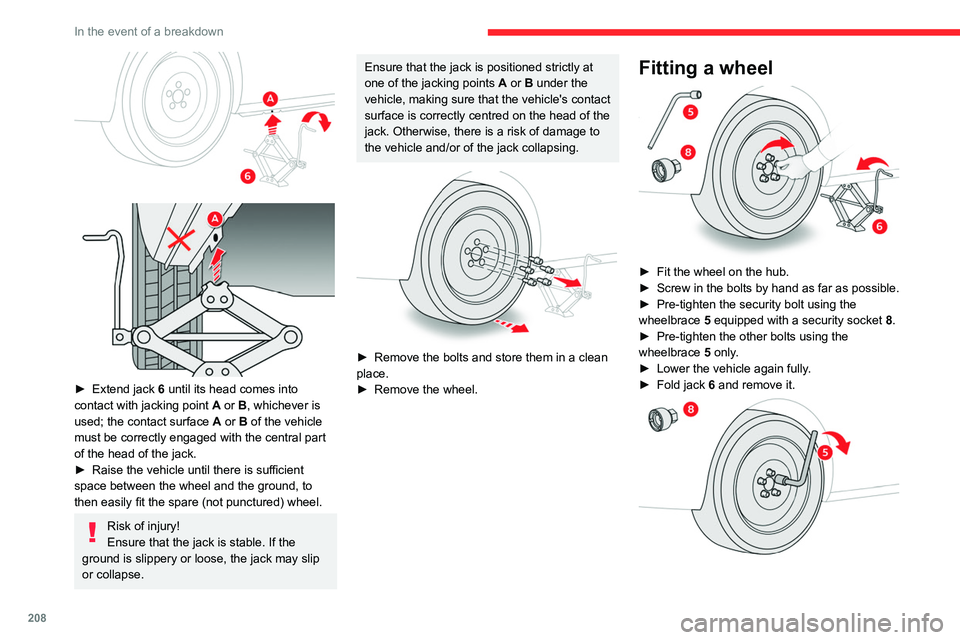

► Extend jack 6 until its head comes into

contact with jacking point A or B, whichever is

used; the contact surface A or B of the vehicle

must be correctly engaged with the central part

of the head of the jack.

►

Raise the vehicle until there is sufficient

space between the wheel and the ground, to

then easily fit the spare (not punctured) wheel.

Risk of injury!

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may slip

or collapse.

Ensure that the jack is positioned strictly at

one of the jacking points A or B under the

vehicle, making sure that the vehicle's contact

surface is correctly centred on the head of the

jack. Otherwise, there is a risk of damage to

the vehicle and/or of the jack collapsing.

► Remove the bolts and store them in a clean

place.

►

Remove the wheel.

Fitting a wheel

► Fit the wheel on the hub.

► Screw in the bolts by hand as far as possible.

►

Pre-tighten the security bolt using the

wheelbrace

5

equipped with a security socket

8

.

►

Pre-tighten the other bolts using the

wheelbrace

5

only.

►

Lower the vehicle again fully

.

►

Fold jack

6 and remove it.

Page 211 of 324

209

In the event of a breakdown

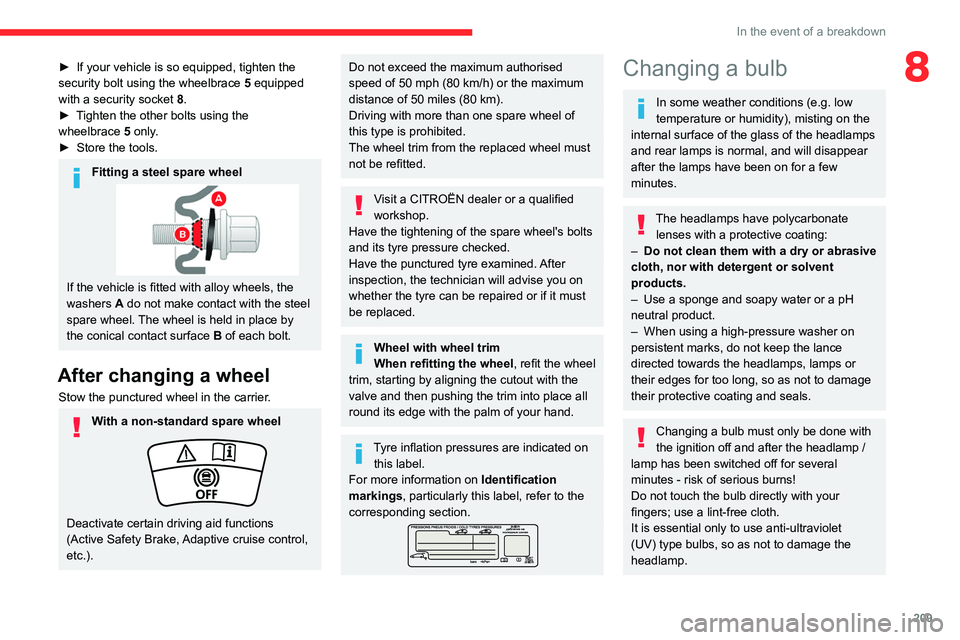

8► If your vehicle is so equipped, tighten the

security bolt using the wheelbrace 5 equipped

with a security socket

8.

►

T

ighten the other bolts using the

wheelbrace

5

only.

►

Store the tools.

Fitting a steel spare wheel

If the vehicle is fitted with alloy wheels, the

washers A do not make contact with the steel

spare wheel. The wheel is held in place by

the conical contact surface B of each bolt.

After changing a wheel

Stow the punctured wheel in the carrier.

With a non-standard spare wheel

Deactivate certain driving aid functions

(Active Safety Brake, Adaptive cruise control,

etc.).

Do not exceed the maximum authorised

speed of 50 mph (80

km/h) or the maximum

distance of 50 miles (80 km).

Driving with more than one spare wheel of

this type is prohibited.

The wheel trim from the replaced wheel must

not be refitted.

Visit a CITROËN dealer or a qualified

workshop.

Have the tightening of the spare wheel's bolts

and its tyre pressure checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Wheel with wheel trim

When refitting the wheel, refit the wheel

trim, starting by aligning the cutout with the

valve and then pushing the trim into place all

round its edge with the palm of your hand.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

The headlamps have polycarbonate lenses with a protective coating:

–

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

–

Use a sponge and soapy water or a pH

neutral product.

–

When using a high-pressure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Changing a bulb must only be done with

the ignition off and after the headlamp /

lamp has been switched off for several

minutes - risk of serious burns!

Do not touch the bulb directly with your

fingers; use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.