Citroen C4 PICASSO 2015 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2015, Model line: C4 PICASSO, Model: Citroen C4 PICASSO 2015 2.GPages: 420, PDF Size: 10.72 MB

Page 261 of 420

259

Changing a wheelProcedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

S

ome

of

the

tools are accessible from inside

t

he

boot.

The

wheel

chock 2 as well as the wheelbrace

extension

6

are stowed under the right hand

b

oot

sill

trim.

The wheelbrace 1

and the towing eye 7 are

stowed

under

the left hand boot sill.

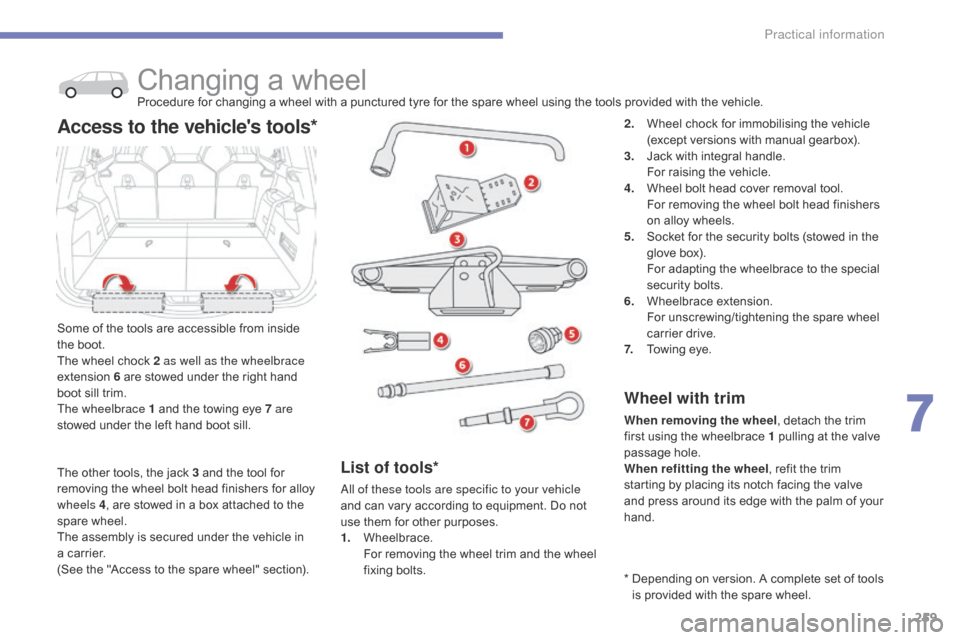

Access to the vehicle's tools*2. Wheel chock for immobilising the vehicle (

except versions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt head cover removal tool.

F

or removing the wheel bolt head finishers

o

n alloy wheels.

5.

S

ocket for the security bolts (stowed in the

g

love box).

F

or adapting the wheelbrace to the special

s

ecurity bolts.

6.

W

heelbrace

e

xtension.

F

or unscrewing/tightening the spare wheel

c

arrier drive.

7.

T

owing eye.

Wheel with trim

When removing the wheel , detach the trim f

irst using the wheelbrace 1 pulling at the valve

p

assage hole.

When refitting the wheel ,

refit the trim

s

tarting by placing its notch facing the valve

a

nd press around its edge with the palm of your

han

d.

List of tools*

all of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

W

heelbrace.

F

or removing the wheel trim and the wheel

f

ixing

bol

ts. *

D

epending on version. A complete set of tools

i

s provided with the spare wheel.

The

other

tools,

the

jack

3

and

the

tool

for

r

emoving

the

wheel

bolt

head

finishers

for

alloy

w

heels 4 ,

are

stowed

in

a

box

attached

to

the

spar

e

w

heel.

The

assembly

is

secured

under

the

vehicle

in

a

carrier.

(See

the

"Access

to

the

spare

wheel"

section).

7

Practical information

Page 262 of 420

260

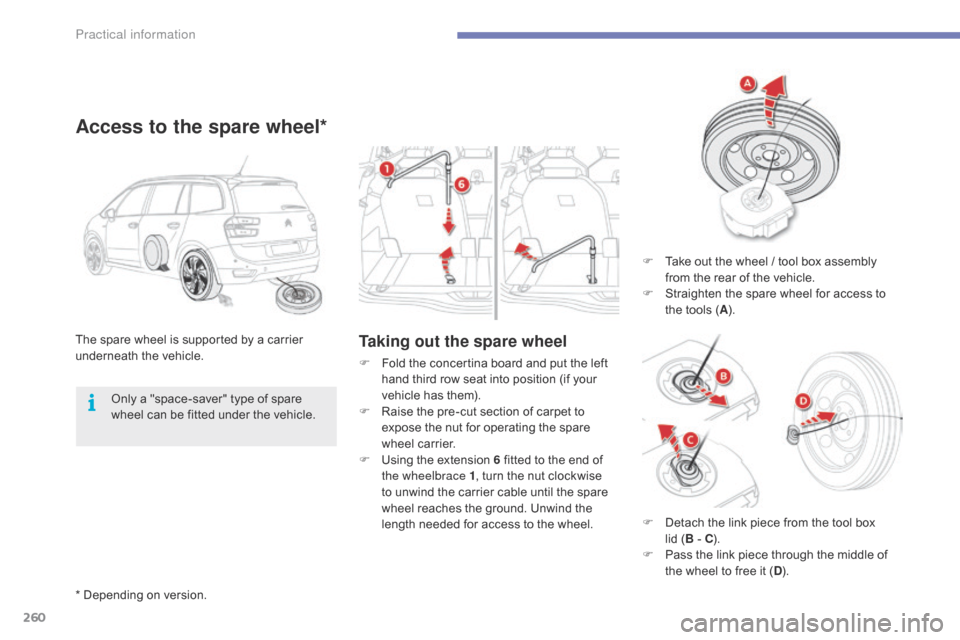

Taking out the spare wheelThe spare wheel is supported by a carrier underneath t he v ehicle.

Access to the spare wheel*

F Take out the wheel / tool box assembly f

rom the rear of the vehicle.

F

S

traighten the spare wheel for access to

t

he tools (A ).

F

F

old

the

concertina

board

and

put

the

left

h

and

third

row

seat

into

position

(if

your

v

ehicle

has

them).

F

R

aise

the

pre-cut

section

of

carpet

to

e

xpose

the

nut

for

operating

the

spare

w

heel

carrier.

F

U

sing

the

extension

6

fitted

to

the

end

of

t

he wheelbrace 1 ,

turn

the

nut

clockwise

t

o

unwind

the

carrier

cable

until

the

spare

w

heel

reaches

the

ground.

Unwind

the

l

ength

needed

for

access

to

the

wheel.

Only

a

"space-saver"

type

of

spare

w

heel

can

be

fitted

under

the

vehicle.

*

Depending

on

version. F

D

etach the link piece from the tool box

l

id (B - C ).

F

P

ass the link piece through the middle of

t

he wheel to free it (D ).

Practical information

Page 263 of 420

261

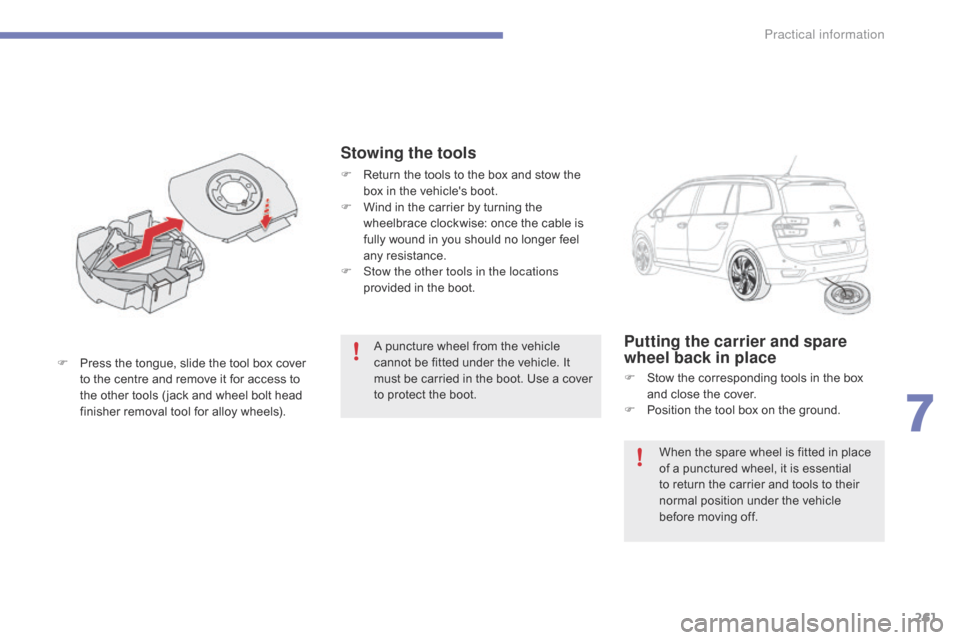

A puncture wheel from the vehicle cannot be fitted under the vehicle. It

m

ust

b

e

c

arried

i

n

t

he

b

oot.

U

se

a

c

over

t

o protect the boot.

F

P

ress

the

tongue,

slide

the

tool

box

cover

t

o

the

centre

and

remove

it

for

access

to

t

he

other

tools

( jack

and

wheel

bolt

head

f

inisher

removal

tool

for

alloy

wheels).Putting the carrier and spare

wheel back in place

F Stow the corresponding tools in the box a

nd close the cover.

F

P

osition the tool box on the ground.

Stowing the tools

F Return the tools to the box and stow the b

ox in the vehicle's boot.

F

W

ind in the carrier by turning the

w

heelbrace clockwise: once the cable is

f

ully wound in you should no longer feel

an

y

r

esistance.

F

S

tow the other tools in the locations

provided

in the boot.

When

the spare wheel is fitted in place

o

f a punctured wheel, it is essential

t

o return the carrier and tools to their

n

ormal position under the vehicle

b

efore moving off.

7

Practical information

Page 264 of 420

262

F Insert the link piece in the aperture in the t

ool box (B

- C). F

I

nsert the centre guide into the middle of

t

he wheel.

F

P

lace the wheel / tool box assembly under

t

he rear of the vehicle.

F

C

entre and position the spare wheel on the

t

ool box (D ). F

R

aise the wheel / tool box assembly

u

nderneath the vehicle by turning the

c

arrier drive nut anticlockwise using the

w

heelbrace and the extension.

F

T

ighten fully. When the cable is fully wound

i

n, rotation of the nut no longer presents

an

y

r

esistance.

F

C

heck that the wheel is horizontally flat a

gainst the floor.

F

S

traighten the wheel.

F

P

ass the link piece through the middle of

t

he wheel (

A ).

Practical information

Page 265 of 420

263

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be level,

s

table and not slippery.

Apply

the parking brake unless it has

b

een programmed to automatic mode,

s

witch off the ignition and engage first

g

ear* to block the wheels.

Check

that the braking warning lamp

a

nd the P warning lamp in the parking

b

rake control lever come on.

For

greater safety, place the chock 2

against

the wheel opposite to the one

b

eing

c

hanged.

The

occupants must get out of the

v

ehicle and wait where they are safe.

Never

go underneath a vehicle raised

u

sing a jack; use an axle stand.

List of operations

F Remove the finisher from from each o

f bolts using the tool 4 (depending on

e

quipment).

F

F

it the security socket 5 on the

wheelbrace

1 to slacken the security bolt

(

if fitted).

F

S

lacken the other bolts (no more than a

1

/4 turn) using the wheelbrace 1

o

n l y.

*

Position R

for

an

electronic

gearbox

or

P for

an

automatic

gearbox. Do

not use:

-

t

he jack for any purpose other than

l

ifting the vehicle,

-

a

ny other jack than the one

s

upplied by the manufacturer.

7

Practical information

Page 266 of 420

264

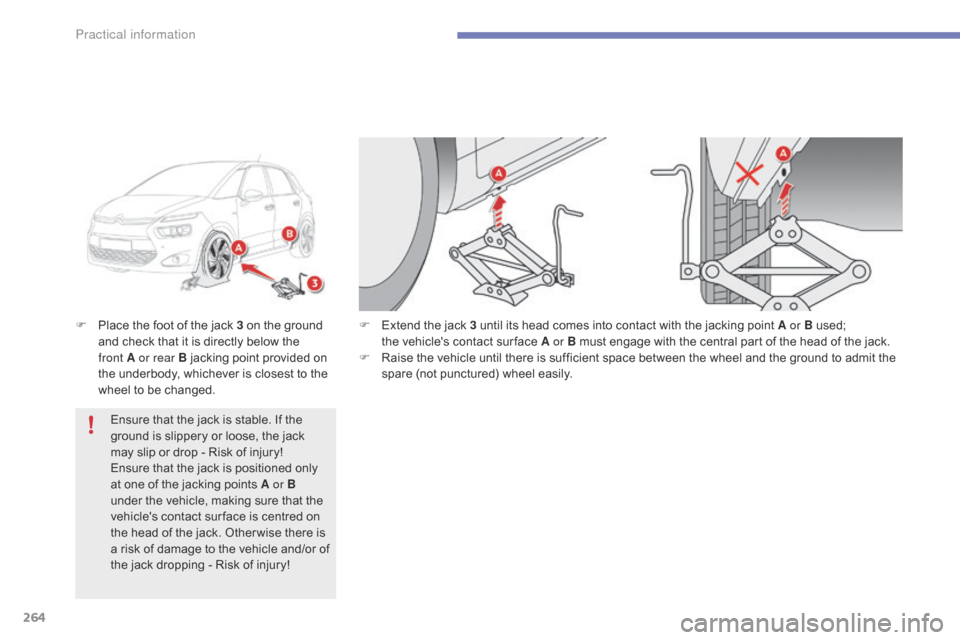

F Place the foot of the jack 3 on the ground a

nd check that it is directly below the

f

ront A or rear B jacking point provided on

t

he underbody, whichever is closest to the

w

heel to be changed. F

E xtend the jack 3 until its head comes into contact with the jacking point A or B used; t

he vehicle's contact sur face A or B must engage with the central part of the head of the jack.

F

R

aise the vehicle until there is sufficient space between the wheel and the ground to admit the

s

pare (not punctured) wheel easily.

Ensure

that the jack is stable. If the

g

round is slippery or loose, the jack

m

ay slip or drop - Risk of injury!

Ensure

that the jack is positioned only

a

t one of the jacking points A or B

under

the vehicle, making sure that the

v

ehicle's contact sur face is centred on

t

he head of the jack. Other wise there is

a

risk of damage to the vehicle and/or of

t

he jack dropping - Risk of injury!

Practical information

Page 267 of 420

265

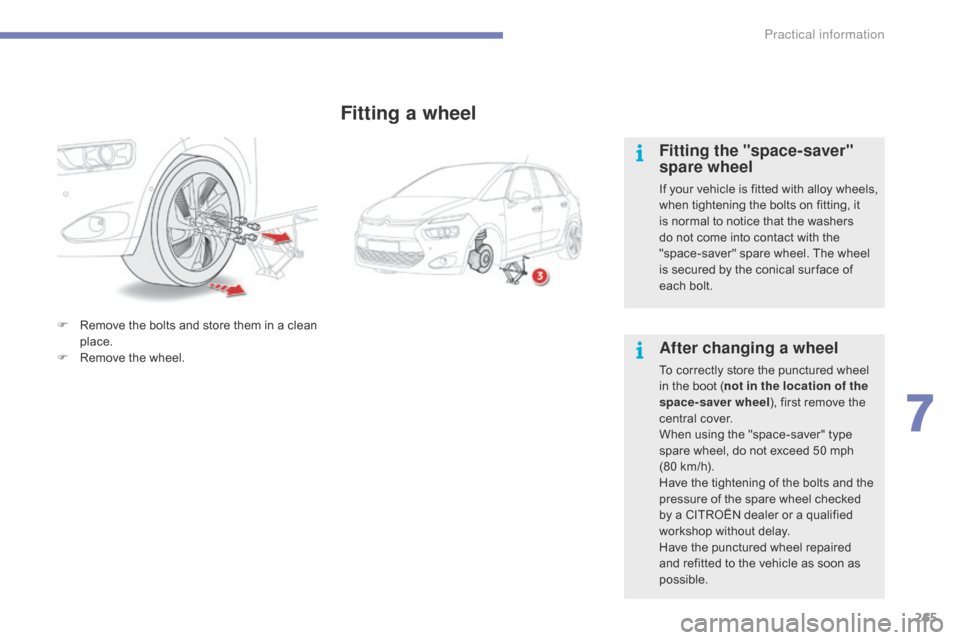

F Remove the bolts and store them in a clean p

lace.

F

R

emove the wheel.

Fitting a wheel

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels, when tightening the bolts on fitting, it

i

s normal to notice that the washers

d

o not come into contact with the

"

space-saver" spare wheel. The wheel

i

s secured by the conical sur face of

e

ach bolt.

After changing a wheel

To correctly store the punctured wheel in the boot (not in the location of the

space-saver wheel ),

first remove the

c

entral cover.

When

using the "space-saver" type

s

pare wheel, do not exceed 50 mph

(

80 km/h).

Have

the tightening of the bolts and the

p

ressure of the spare wheel checked

b

y a CITROËN dealer or a qualified

w

orkshop without delay.

Have

the punctured wheel repaired

a

nd refitted to the vehicle as soon as

p

ossible.

7

Practical information

Page 268 of 420

266

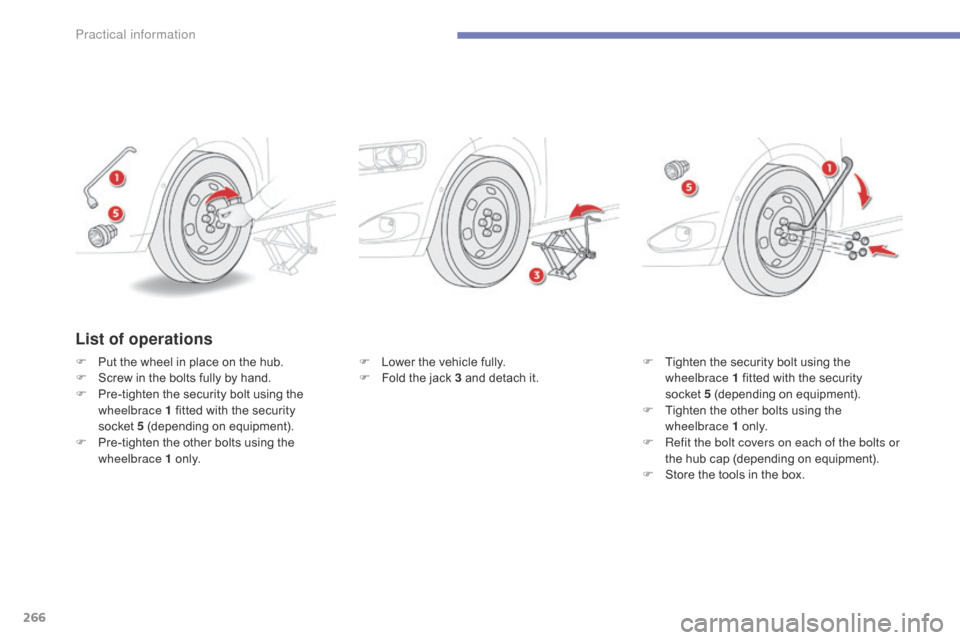

F Lower the vehicle fully.

F F old the jack 3 and detach it.F

T ighten the security bolt using the w

heelbrace 1 fitted with the security

s

ocket 5

(depending on equipment).

F

T

ighten the other bolts using the

w

heelbrace 1

o

n l y.

F

R

efit the bolt covers on each of the bolts or

the

hub cap (depending on equipment).

F

S

tore the tools in the box.

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts fully by hand.

F

P

re-tighten the security bolt using the

w

heelbrace 1 fitted with the security

s

ocket 5

(depending on equipment).

F

P

re-tighten the other bolts using the

w

heelbrace 1

o

n l y.

Practical information

Page 269 of 420

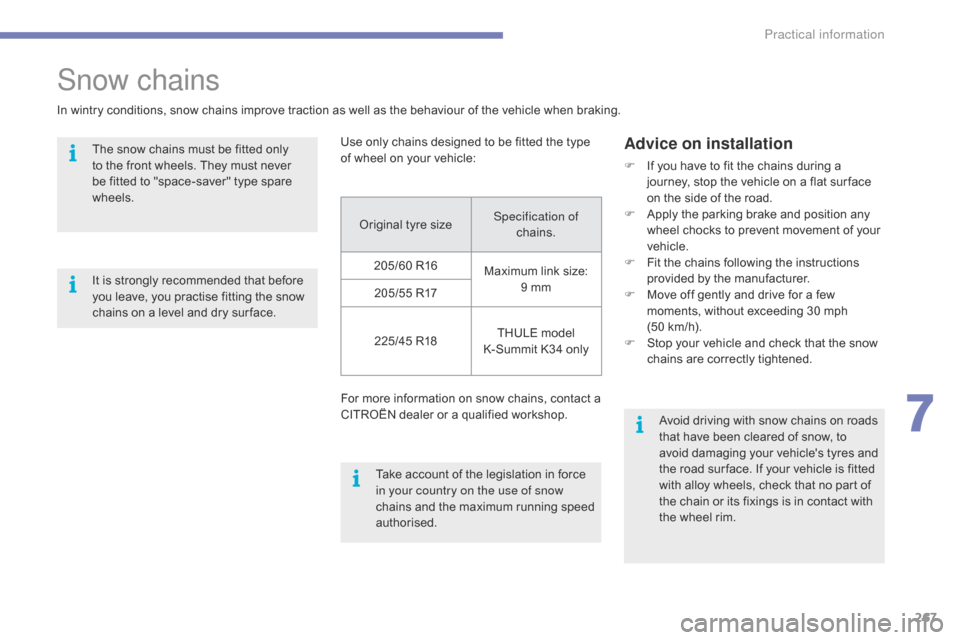

267

Original tyre sizeSpec ification of

chains.

205/60

R16 Maximum

link size:

9

mm

205/55

R17

225/45

R18 THULE

model

K-Summit

K34 only

For

more information on snow chains, contact a

C

ITROËN dealer or a qualified workshop.

Use

only chains designed to be fitted the type

o

f

wheel on your vehicle:

Snow chains

In wintry conditions, snow chains improve traction as well as the behaviour of the vehicle when braking.

T he snow chains must be fitted only

t

o the front wheels. They must never

b

e fitted to "space-saver" type spare

w

heels.

Advice on installation

F If you have to fit the chains during a j

ourney, stop the vehicle on a flat sur face

o

n the side of the road.

F

A

pply the parking brake and position any

w

heel chocks to prevent movement of your

v

ehicle.

F

F

it the chains following the instructions

p

rovided by the manufacturer.

F

M

ove off gently and drive for a few

m

oments, without exceeding 30 mph

(

50 km/h).

F

S

top your vehicle and check that the snow

c

hains are correctly tightened.

Take

account

of

the

legislation

in

force

i

n your country on the use of snow

chains

and

the

maximum

running

speed

a

uthorised. Avoid

driving with snow chains on roads

t

hat have been cleared of snow, to

a

void damaging your vehicle's tyres and

t

he road sur face. If your vehicle is fitted

w

ith alloy wheels, check that no part of

t

he chain or its fixings is in contact with

t

he wheel rim.

It

is

strongly

recommended

that

before

y

ou

leave,

you

practise

fitting

the

snow

c

hains

on

a

level

and

dry

sur face.

7

Practical information

Page 270 of 420

268

Changing a bulb

For H7 type bulbs with lugs... take care to observe their correct installation

so

as to ensure the best lighting

p

erformance.

Risk of electrocution

Xenon bulbs (D5S-25W) must be replaced by a CITROËN dealer or a

q

ualified

w

orkshop.

Front lamps

Model with xenon headlamps

1. Directional dipped beam headlamps

(D5S-25W).

2.

M

ain beam headlamps (H7-55W).

3.

D

aytime running lamps / sidelamps

(

6 light emitting diodes - LEDs).

4.

D

irection

i

ndicators

(

6 light emittng diodes - LEDs).

5.

F

ront foglamps (H11-55W).

Model with halogen headlamps

1. Dipped beam headlamps (H7-55W).

2. M ain beam headlamps (H7-55W).

3.

D

aytime

r

unning

lam

ps/sidelamps

(

4 light emitting diodes - LEDs).

4.

D

irection indicators (PW Y24W).

5.

F

oglamps

(

H11-55W). In

some weather conditions (e.g. low

t

emperature or humidity), the presence

o

f misting on the internal sur face of the

g

lass of the headlamps and rear lamps

i

s normal; it disappears after the lamps

h

ave been on for a few minutes.

Light emitting diodes-LEDs

For replacement, contact a CITROËN dealer or q

ualified w orkshop.

Practical information