Citroen C4 PICASSO 2015 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2015, Model line: C4 PICASSO, Model: Citroen C4 PICASSO 2015 2.GPages: 420, PDF Size: 10.72 MB

Page 251 of 420

249

This kit is installed i n t he s torage b ox, u nder t he b

oot floor.

This

kit

consists

of

a

compressor

and

a

sealant

c

artridge.

It allows the temporary repair

of

a

tyre.

You

are

then

able

to

go

to

the

nearest

garage.

It

is

designed

to

repair

most

punctures

which

c

ould

affect

the

tyre,

located

on

the

tyre

tread

o

r

shoulder.

Its

compressor

can

be

used

to

check

and

a

djust

the

pressure

of

the

tyre.

Temporary pu

ncture r epair k it

Access to the kit

Depending on version, the kit is stowed under t

he front passenger's seat or in the storage

b

ox under the second row footwell.

7

Practical information

Page 252 of 420

250

List of tools

* Depending on equipment.

al

l of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

1

2 V compressor.

C

ontains a sealant cartridge for the

t

emporary repair of a tyre and can also be

u

sed for adjusting tyre pressures.

2.

C

hocks* to immobilise the wheels of the

v

ehicle.

3.

B

olt cover removal tool*.

F

or removing the wheel bolt finishers

(

covers) on alloy wheels.

4.

R

emovable towing eye.

S

ee the "Towing the vehicle" section.

Practical information

Page 253 of 420

251

A. "Sealant" or "Air" position selector.

B. on "

I" / off "O" s witch.

C.

D

eflation button.

D.

P

ressure gauge (in bar and psi).

E.

C

ompartment

h

ousing:

-

a

cable with adaptor for 12 V socket,

-

v

arious inflation adaptors for

a

ccessories, such as balls,

bicycle tyres...

Description of the kit

The speed limit sticker I must be affixed t o the vehicle's steering wheel to remind

y

ou that a wheel is in temporary use.

Do

not exceed a speed of 50 mph

(

80 km/h) when driving with a tyre

r

epaired using this type of kit.

F.

S

ealant

c

artridge.

G.

W

hite pipe with cap for repair.

H.

B

lack pipe for inflation.

I.

S

peed limit sticker.

The

tyre

inflation

pressures

are

given

on

this

lab

el.

The

vehicle's

electric

system

allows

the

c

onnection

of

a

compressor

for

long

e

nough

to

inflate

a

tyre

after

a

puncture

r

epair

or

for

inflating

a

small

inflatable

a

ccessory.

7

Practical information

Page 254 of 420

252

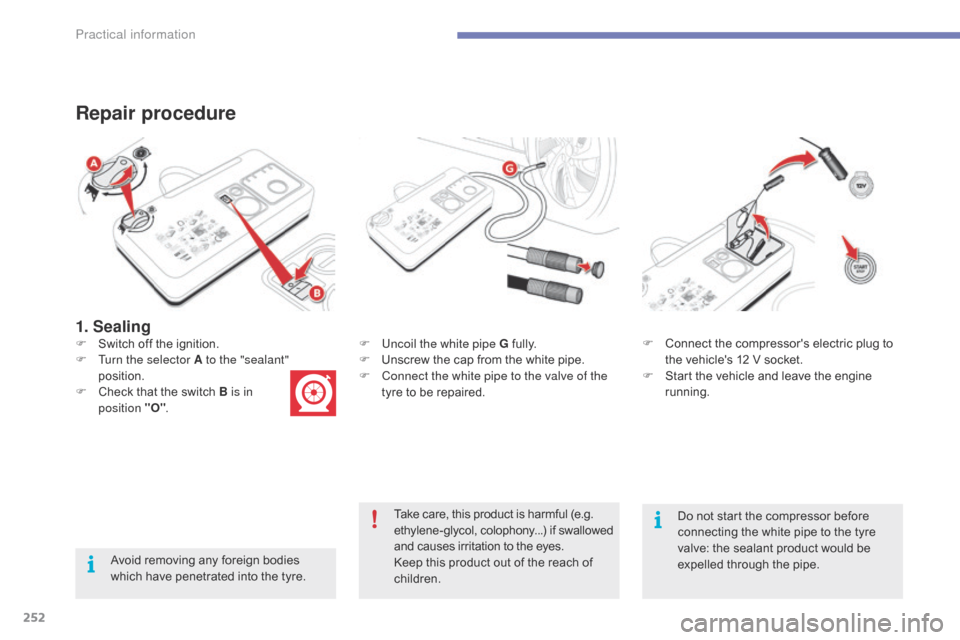

1. Sealing

Repair procedure

Avoid removing any foreign bodies which have penetrated into the tyre.F

U

ncoil the white pipe G

f

ully.

F

U

nscrew the cap from the white pipe.

F

C

onnect the white pipe to the valve of the

tyre to be repaired.

F

S

witch off the ignition.

F

T

urn the selector A to the "sealant"

position.

F

C

heck that the switch B is in

position "O" . F

C

onnect the compressor's electric plug to

t

he vehicle's 12 V socket.

F

S

tart the vehicle and leave the engine

r

unning.

Take care, this product is harmful (e.g.

e

thylene-glycol, colophony...) if swallowed

a

nd causes irritation to the eyes.

Keep this product out of the reach of

c

hildren.Do

not start the compressor before

c

onnecting the white pipe to the tyre v

alve: the sealant product would be e

xpelled through the pipe.

Practical information

Page 255 of 420

253

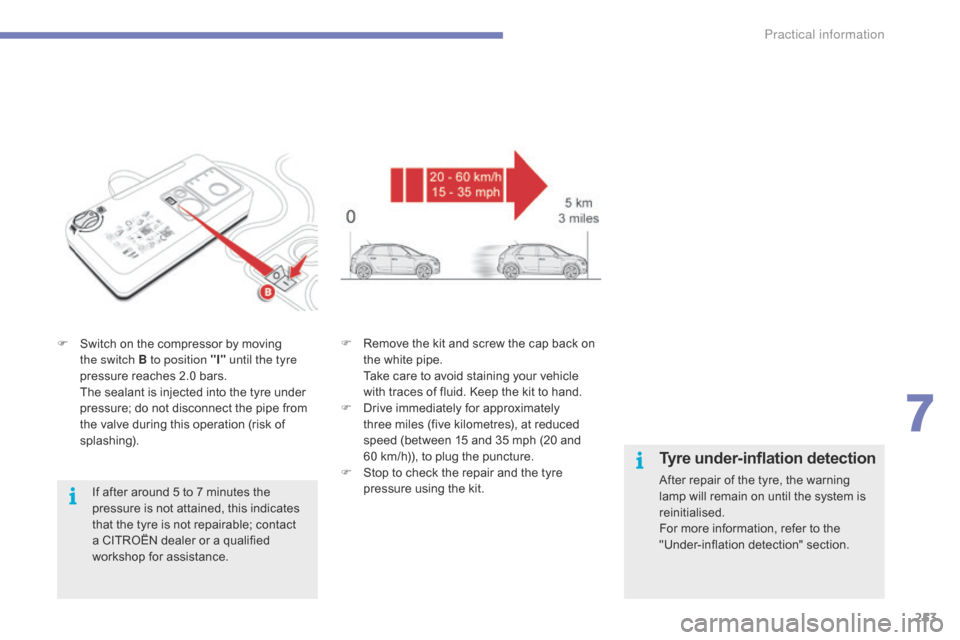

F Switch on the compressor by moving t

he switch B to position "I" until the tyre

pressure

reaches 2.0 bars.

T

he sealant is injected into the tyre under

p

ressure; do not disconnect the pipe from

t

he valve during this operation (risk of

sp

lashing).

If

after around 5 to 7 minutes the

p

ressure is not attained, this indicates

t

hat the tyre is not repairable; contact

a

CITROËN dealer or a qualified

w

orkshop for assistance. F

R emove the kit and screw the cap back on t

he white pipe.

T

ake care to avoid staining your vehicle

w

ith traces of fluid. Keep the kit to hand.

F

D

rive immediately for approximately

t

hree miles (five kilometres), at reduced

s

peed (between 15 and 35 mph (20 and

6

0 km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

p

ressure using the kit.

Tyre under-inflation detection

After repair of the tyre, the warning lamp will remain on until the system is

r

einitialised.

For

more information, refer to the

"

Under-inflation

d

etection"

s

ection.

7

Practical information

Page 256 of 420

254

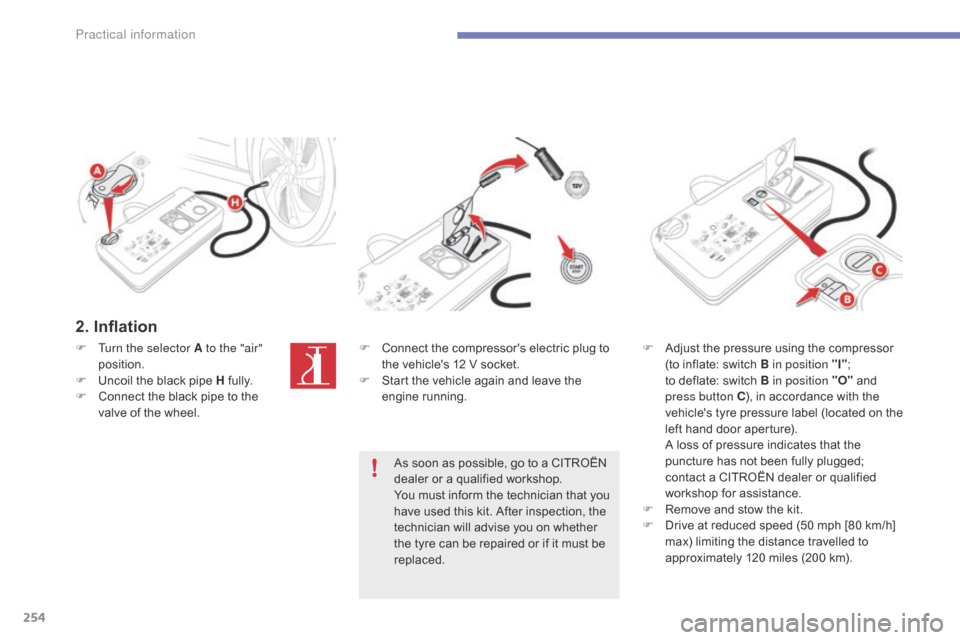

2. Inflation

F Turn the selector A to the "air" position.

F

U

ncoil the black pipe H

f

ully.

F

C

onnect the black pipe to the

v

alve of the wheel. F

C onnect the compressor's electric plug to t

he vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

e

ngine

r

unning.

As

soon as possible, go to a CITROËN

d

ealer or a qualified workshop.

You

must inform the technician that you

h

ave used this kit. After inspection, the

t

echnician will advise you on whether

t

he tyre can be repaired or if it must be

r

eplaced.F

A djust the pressure using the compressor (

to inflate: switch B in position "I";

t

o deflate: switch B in position "O"

and

p

ress button C),

in accordance with the

v

ehicle's

t

yre pressure label (located on the

l

eft hand door aperture).

A

loss of pressure indicates that the

p

uncture has not been fully plugged;

c

ontact a CITROËN dealer or qualified

w

orkshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph [80 km/h]

m

ax) limiting the distance travelled to

a

pproximately 120 miles (200 km).

Practical information

Page 257 of 420

255

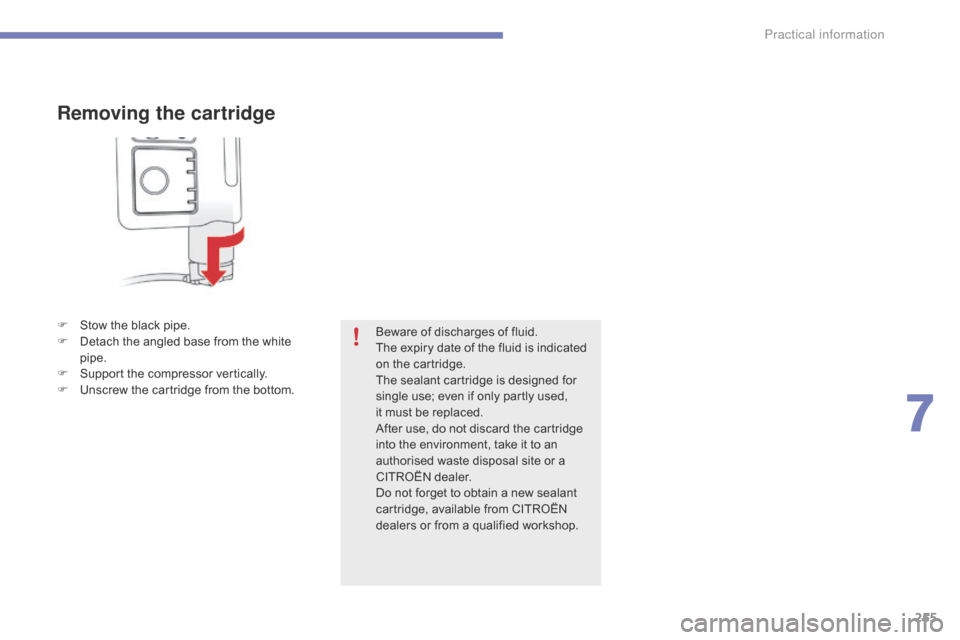

Removing the cartridge

F Stow the black pipe.

F D etach the angled base from the white

p

ipe.

F

S

upport the compressor vertically.

F

U

nscrew the cartridge from the bottom.Beware

of discharges of fluid.

The

expiry date of the fluid is indicated

o

n the cartridge.

The

sealant cartridge is designed for

s

ingle use; even if only partly used,

i

t must be replaced.

After

use, do not discard the cartridge

i

nto the environment, take it to an

a

uthorised waste disposal site or a

C

ITROËN dealer.

Do

not forget to obtain a new sealant

c

artridge, available from CITROËN

d

ealers or from a qualified workshop.

7

Practical information

Page 258 of 420

256

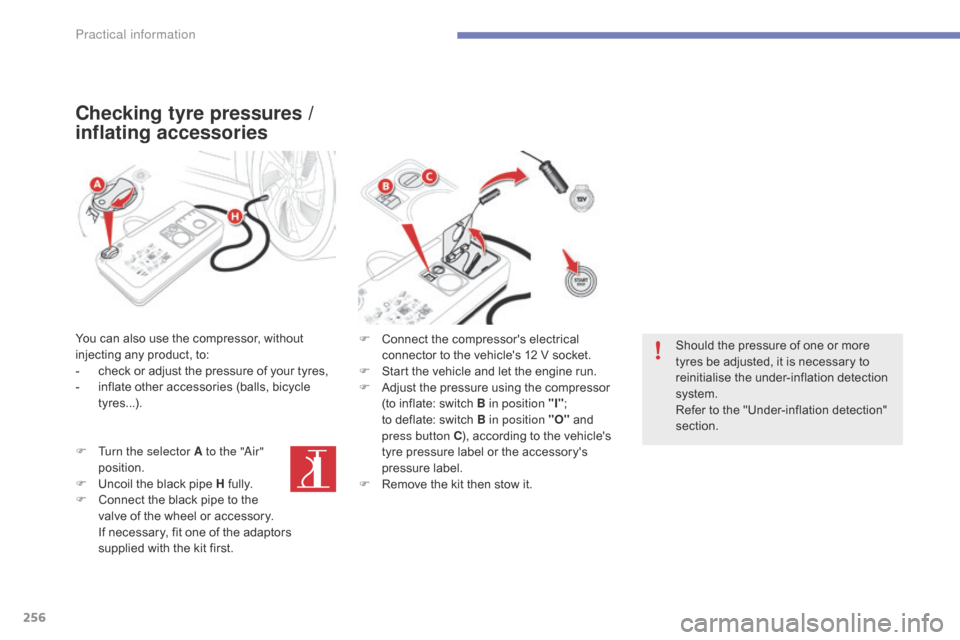

Checking tyre pressures /

inflating accessories

You can also use the compressor, without injecting any product, to:

-

c

heck or adjust the pressure of your tyres,

-

i

nflate other accessories (balls, bicycle

t

yres...).

F

T

urn the selector A to the "

ai

r"

position.

F

U

ncoil the black pipe H

f

ully.

F

C

onnect the black pipe to the

v

alve of the wheel or accessory.

I

f necessary, fit one of the adaptors

s

upplied with the kit first. F

C onnect the compressor's electrical

c

onnector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(

to inflate: switch B in position "I";

t

o deflate: switch B in position "O"

and

p

ress button C),

according to the vehicle's

t

yre pressure label or the accessory's

p

ressure label.

F

R

emove the kit then stow it.Should

the pressure of one or more

t

yres be adjusted, it is necessary to

r

einitialise the under-inflation detection

s

ystem.

Refer

to the "Under-inflation detection"

s

ection.

Practical information

Page 259 of 420

257

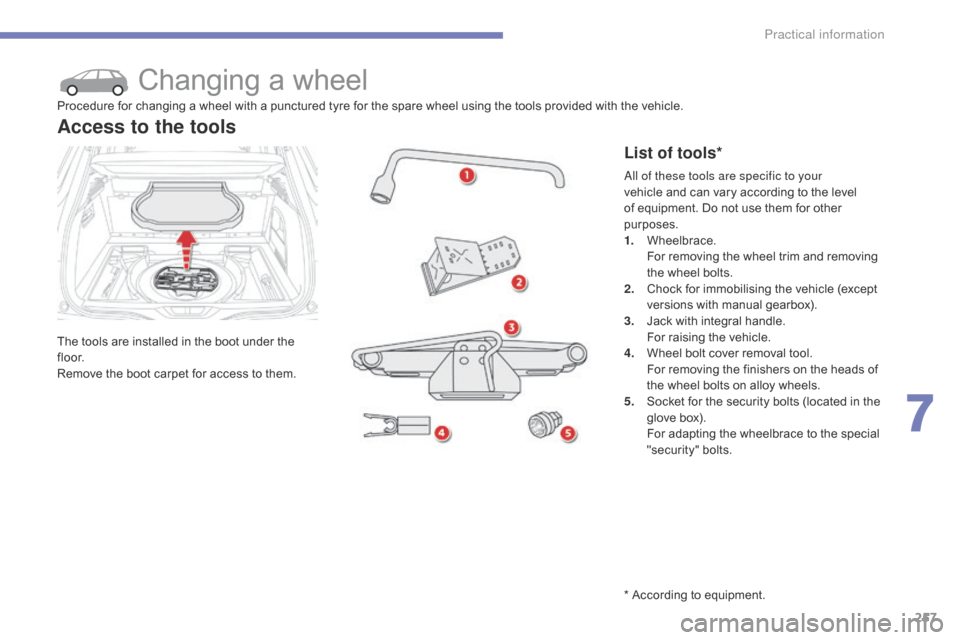

Changing a wheel

The tools are installed in the boot under the fl o o r.

Remove

the boot carpet for access to them.

Access to the tools

List of tools*

Procedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

al

l of these tools are specific to your

vehicle

and can vary according to the level

o

f equipment. Do not use them for other

p

urposes.

1.

W

heelbrace.

F

or removing the wheel trim and removing

t

he wheel bolts.

2.

C

hock for immobilising the vehicle (except

v

ersions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover removal tool.

F

or removing the finishers on the heads of

t

he wheel bolts on alloy wheels.

5.

S

ocket for the security bolts (located in the

g

love box).

F

or adapting the wheelbrace to the special

"s

ecurity"

b

olts.

*

According to equipment.

7

Practical information

Page 260 of 420

258

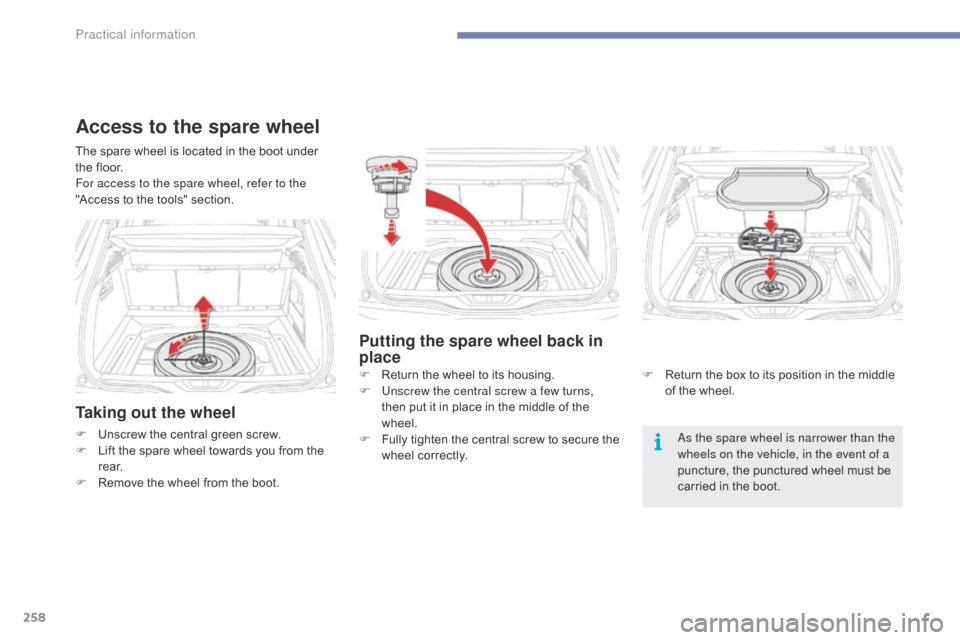

Taking out the wheel

F Unscrew the central green screw.

F L ift the spare wheel towards you from the

r

e a r.

F

R

emove the wheel from the boot.as t he spare wheel is narrower than the

wheels on the vehicle, in the event of a

puncture,

the punctured wheel must be

c

arried in the boot.

The

spare wheel is located in the boot under

t

he floor.

For access to the spare wheel, refer to the

"Access to the tools" section.

Access to the spare wheel

Putting the spare wheel back in

place

F Return

the wheel to its housing.

F U nscrew the central screw a few turns,

then

put it in place in the middle of the

w

heel.

F

F

ully

t

ighten

t

he

c

entral

s

crew

t

o

s

ecure

t

he

w

heel correctly. F

R eturn the box to its position in the middle o

f the wheel.

Practical information