CITROEN RELAY 2016 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2016, Model line: RELAY, Model: CITROEN RELAY 2016Pages: 308, PDF Size: 10.98 MB

Page 261 of 308

259

● Ensure that there is no person or obstacle nearby (below or

above) when unloading.

●

Never leave the tipper body raised when not in use.

●

Always discharge the load with the top part of the rear body si

de

secured.

●

Observe the maximum payload on the weights plate on the

vehicle.

●

Check regularly that the suspension is in good condition and

that the tyres are inflated to the recommended pressures.

●

Distribute the load uniformly in the tipper body

.

●

T

ransport similar products that discharge easily.

SAFEtY A d VI c E

Discharge onto a flat and hard surface: a sloping

or loose surface may cause a change in the centre

of gravity, with an adverse affect on the stability of

the vehicle.

●

Never drive, even slowly

, with the tipper body raised.

SPECIAL FEATURES

Tipper body

Page 262 of 308

260

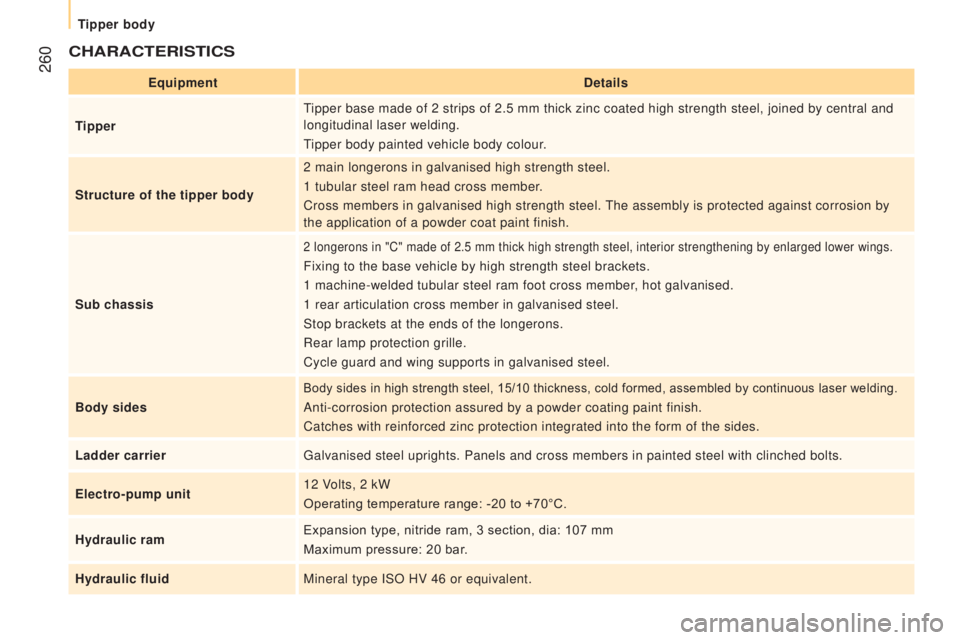

cHArActErIStIcS

Equipmentdetails

tipperT

ipper base made of 2 strips of 2.5 mm thick zinc coated high strength st\

eel, joined by central and

longitudinal laser welding.

Tipper body painted vehicle body colour.

Structure of the tipper body 2 main longerons in galvanised high strength steel.

1 tubular steel ram head cross member.

Cross members in galvanised high strength steel. The assembly is protected against corrosion by

the application of a powder coat paint finish.

Sub chassis

2 longerons in "C" made of 2.5 mm thick high strength steel, interior st\

rengthening by enlarged lower wings.

Fixing to the base vehicle by high strength steel brackets.

1 machine-welded tubular steel ram foot cross member, hot galvanised.

1 rear articulation cross member in galvanised steel.

Stop brackets at the ends of the longerons.

Rear lamp protection grille.

Cycle guard and wing supports in galvanised steel.

Body sides

Body sides in high strength steel, 15/10 thickness, cold formed, assembled by continuous laser welding.

Anti-corrosion protection assured by a powder coating paint finish.

Catches with reinforced zinc protection integrated into the form of the \

sides.

Ladder carrier Galvanised steel uprights. Panels and cross members in painted steel wit\

h clinched bolts.

Electro-pump unit 12 Volts, 2 kW

Operating temperature range: -20 to +70°C.

Hydraulic ram Expansion type, nitride ram, 3 section, dia: 107 mm

Maximum pressure: 20 bar.

Hydraulic fluid Mineral type ISO HV 46 or equivalent.

Tipper body

Page 263 of 308

261

tipper (in mm)

Load length 3 200

Overall length 3

248

Load width 2 000

Overall width 2 100

Height of body sides 350

Overall height 550

dIMEnSIOnS

This conversion is only available on the L2 single chassis-cab; refer to\

the table below for the characteristics of the tipper.

For information on the characteristics of the L2 chassis cab, refer to t\

he "Dimensions" section for the floor cab version.

SPECIAL FEATURES

Tipper body

Page 264 of 308

262

WEIGHtS And tOWE d LOA d S ( KG )

For more information, refer to your registration certificate.

In each country, it is imperative that the towed loads authorised by

local legislation are complied with. To find out your vehicle's towing

capacities and its gross train weight, consult a franchised dealer.

The maximum authorised speed is reduced when towing (comply

with the legislation in force in your country).

With load transfer, the braked trailer weight can be increased,

on condition that the equivalent of this load is removed from the

vehicle so that the GTW is not exceeded. Warning: towing with a

lightly loaded towing vehicle may have an adverse effect on its road

holding.

The GTW and towed load values indicated are valid up to a

maximum altitude of 1000 metres; the towed load mentioned must

be reduced by 10 % for each additional 1000 metres.

High ambient temperatures may result in a reduction in the

performance of the vehicle in order to protect the engine; when the

ambient temperature is higher than 37 °C, limit the towed weight.

The kerb weight is equal to the weight without load + driver (75

kg) +

fuel tank filled to 90%. Before towing a trailer, check

that:

-

the nose weight on the

towbar ball does not exceed

the value (S) indicated on

the trailer's weights plate,

-

the maximum trailer weight

is less than the value

indicated on the trailer's

weights plate and the Gross

Vehicle Weight (GVW)

does not exceed the value

indicated on the vehicle's

weights plate.

-

in the case of a self-

supporting trailer

, the Gross

Train Weight must not

exceed the value indicated

on the vehicle's weights

plate.

General points

Tipper body

Page 265 of 308

263

HYdrAuLIc SYStEM

these precautions are mandatory for any work on the hydraulic

system.

●

When carrying out maintenance work under the tipper body

,

place the tipper body in the safety position secured with its stay

(position indicated by a red arrow under the back of the tipper

body),

●

Never work under a tipper body that is not supported,

●

Switch of

f the power supply to the electro-hydraulic unit using

the circuit breaker,

●

V

ehicle stationary, engine off.

As a safety measure we strongly advise against doing anything

under the tipper body while it is being operated or while it is

being serviced.

SPECIAL FEATURES

Tipper body

Page 266 of 308

264

SErVIc I n G

r eservoir

Check and top up the fluid level regularly. Replace the fluid

annually. Replace the fluid if it contains water.

Check the condition of the hydraulic hose and the sealing of the

hydraulic system regularly.

Pump and motor

Requires no servicing, the ball bearings are lubricated for life and

the plain bearings by the pumped fluid.

Lubrication

The tipper body and ram pivots do not have grease nipples.

Lubricate regularly the hinges and retainers for the tipper body sides

as well as the catches for the rear tipper body side.

Sub-chassis and tipper body

For maximum life, we recommend that you clean your tipper body

by washing it down regularly with hose.

Touch-in the paint chips quickly to avoid the spread of rust.

After 8 months of use, check the tightening torque of the

fixings of the underbody to the chassis (following the

recommendations of the body converter).

cleaning the valve slider

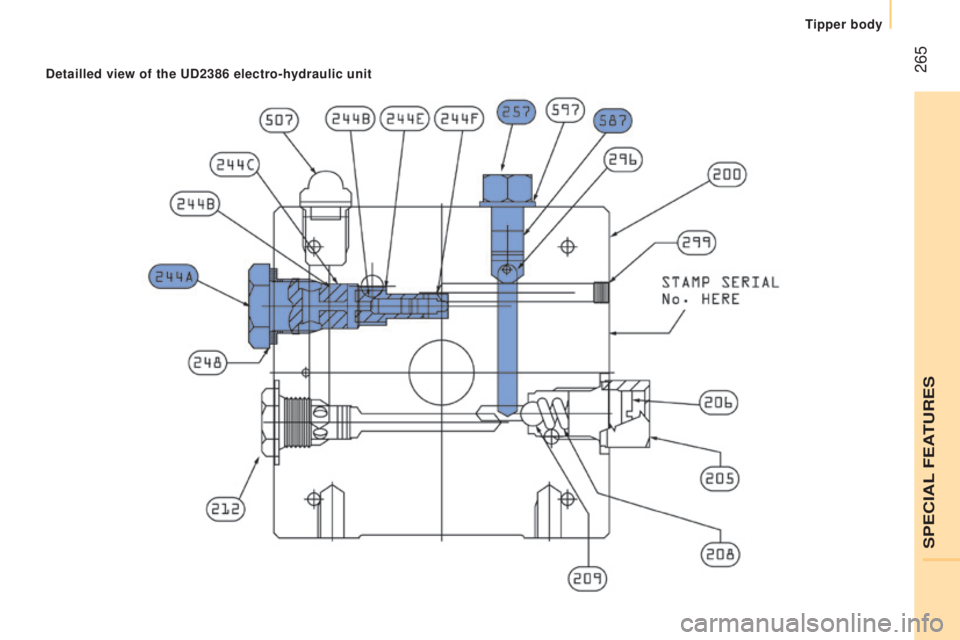

● Remove the plug 244A taking care to recover the ball.

●

Using a wide screwdriver

, remove the bore / piston bolt

assembly.

●

Check that the piston slides smoothly and remove any

impurities. Pass a magnet over if there is any swarf present.

●

Refit the assembly and ensure that the piston slides smoothly

.

Retain the ball with some grease on the plug for reassembly.

●

Bleed the hydraulic system.

Bleed the electro-hydraulic unit

● Remove the hexagonal plug 257.

●

Slacken by a half turn the bolt

587 located inside, using a

hexagonal 6 mm spanner.

●

Operate the electro-hydraulic unit for a few moments by

pressing the raise button.

●

The tipper body does not rise, or very slowly

. When fluid flows

from the orifice, the system is bled.

●

Retighten bolt

587 and refit the plug 257, check that the tipper

body lowers correctly.

Tipper body

Page 267 of 308

265detailled view of the ud2386 electro-hydraulic unit

SPECIAL FEATURES

Tipper body

Page 268 of 308

266

dIAGnOSIS

SymptomElectricalHydraulic Verification / c heck

The hydraulic unit does

not operate. X

Power supply harness and relay.

X Control harness (control unit).

X Circuit breaker.

Unit very noisy, body

rises slowly. X

Pick-up strainer blocked or squashed at the bottom of the reservoir.

New unit very noisy,

body rises quickly. X

Pump alignment, change the unit.

The ram goes down on

its own. X

Return valve squashed or jammed.

The ram does not go

down. X

Yes, check the valve slider and bleed.

Refer to the "Servicing" section.

X No, check the return valve winding and electrical connections.

X No, replace the electrovalve.

X No, check the alignment of the ram.

Tipper body

Page 269 of 308

267

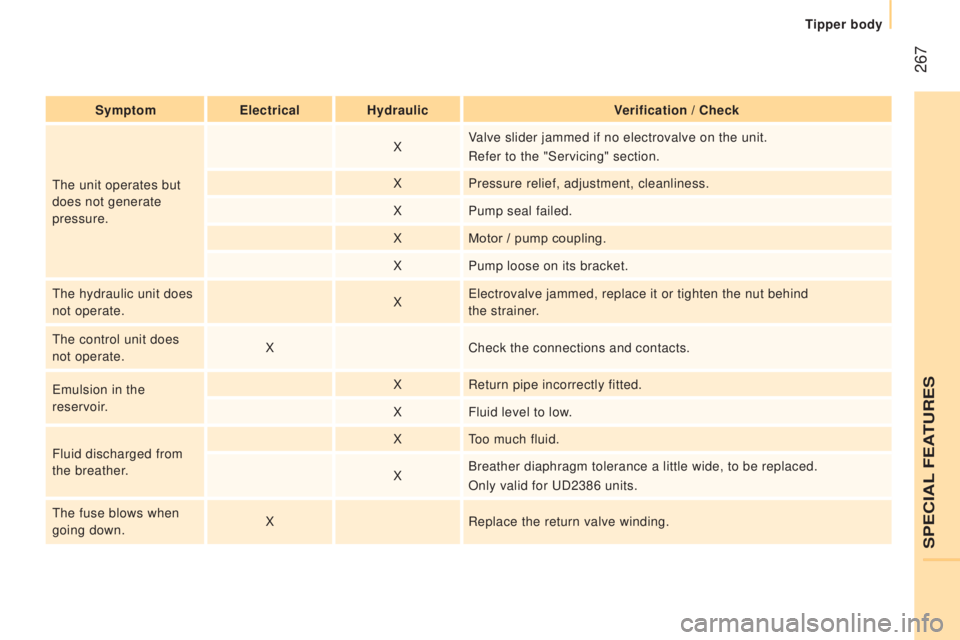

SymptomElectricalHydraulic Verification / c heck

The unit operates but

does not generate

pressure. X

Valve slider jammed if no electrovalve on the unit.

Refer to the "Servicing" section.

X Pressure relief, adjustment, cleanliness.

X Pump seal failed.

X Motor / pump coupling.

X Pump loose on its bracket.

The hydraulic unit does

not operate. XElectrovalve jammed, replace it or tighten the nut behind

the strainer.

The control unit does

not operate. X

Check the connections and contacts.

Emulsion in the

reservoir. X

Return pipe incorrectly fitted.

X Fluid level to low.

Fluid discharged from

the breather. X

Too much fluid.

X Breather diaphragm tolerance a little wide, to be replaced.

Only valid for UD2386 units.

The fuse blows when

going down. X

Replace the return valve winding.

SPECIAL FEATURES

Tipper body

Page 270 of 308