maintenance DAEWOO LACETTI 2004 Service Owners Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2377 of 2643

SECTION : 9K

SQUEAKS AND RATTLES

TABLE OF CONTENTS

DIAGNOSIS9K–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Squeak and Rattle Diagnosis 9K–1. . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9K–3 . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 9K–3. . . . . . . . . . . . . . . . . . . . .

Squeak and Rattle Repair 9K–3. . . . . . . . . . . . . . . . . . .

DIAGNOSIS

SQUEAK AND RATTLE DIAGNOSIS

Rattle Coming From the Side Rail

ChecksAction

Check the brake lines.S Tap lightly on the brake lines and listen for a rattle.

S Install plastic tie straps to secure the brake lines

tightly together.

Rattle Under Vehicle at Higher RPM

ChecksAction

Check for heat shield contact with the underbody.S Raise the vehicle and perform a visual inspection.

S Bend the heat shield slightly to gain clearance from

the underbody.

Squeak From the Front of the Vehicle in Cold Weather

ChecksAction

Check the front stabilizer shaft insulators.S While the vehicle is cold, perform a test drive and

achieve full front suspension travel by driving through

a dip in the road.

S Remove the insulators and wrap teflon tape around

the stabilizer shaft. Reinstall the insulators over the

tape.

Thump From Rear of Vehicle on Bumps

ChecksAction

Check for a properly secured spare tire in the rear

compartment.S Open the rear compartment and perform a visual

inspection of the spare tire and the tools.

S Tightly secure the spare tire and all tools.

S Perform a road test to verify that the noise is elimi-

nated.

Page 2379 of 2643

SQUEAKS AND RATTLES 9K – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

SQUEAK AND RATTLE REPAIR

Squeaks and rattles are caused by the unwanted move-

ment between parts of a vehicle. There are three means

to prevent squeaks or rattles.

S Attach the parts securely so that there is no relative

motion during the operation of the vehicle.

S Separate the parts so that there is no contact dur-

ing operation.

S Insulate the parts so that no squeaks or rattles oc-

cur with the movement of the parts. Low uniform

friction surfaces can be used to eliminate ”stick–

slip” motion.

Page 2380 of 2643

SECTION : 9L

GLASS AND MIRRORS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9L–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9L–2. . . . . . . . . . . .

SPECIAL TOOLS9L–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 9L–2. . . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9L–3 . . . . . .

Defogger System 9L–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Control OSRV (Outside Rear View)

Mirror System 9L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS9L–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Rear Window Defogger Grid Line 9L–5. . . . . .

Outside Rearview Mirror Defoggers 9L–5. . . . . . . . . . .

Electric Control Outside Rearview Mirrors 9L–6. . . . . .

Folding Mirror Unit 9L–8. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9L–10 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9L–10. . . . . . . . . . . . . . . . . . . . .

Windshield 9L–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rear Window Glass 9L–11. . . . . . . . . . . . . . . . . . . . . . . .

Rear Window Defogger Grid Line Repair 9L–13. . . . . .

Rear Window Defogger Braided Lead Wire

Repair 9L–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Door Glass 9L–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door Glass 9L–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door Quarter Glass 9L–16. . . . . . . . . . . . . . . . . . .

Inside Rearview Mirror 9L–17. . . . . . . . . . . . . . . . . . . . .

Outside Rearview Mirrors 9L–18. . . . . . . . . . . . . . . . . . .

Folding Mirrors Unit 9L–18. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9L–19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stationary Glass 9L–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Control Heated Outside Rearview

Mirror 9L–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside Rearview Mirror 9L–19. . . . . . . . . . . . . . . . . . . . .

Folding Mirror Unit 9L–19. . . . . . . . . . . . . . . . . . . . . . . . .

Page 2389 of 2643

9L – 10IGLASS AND MIRRORS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

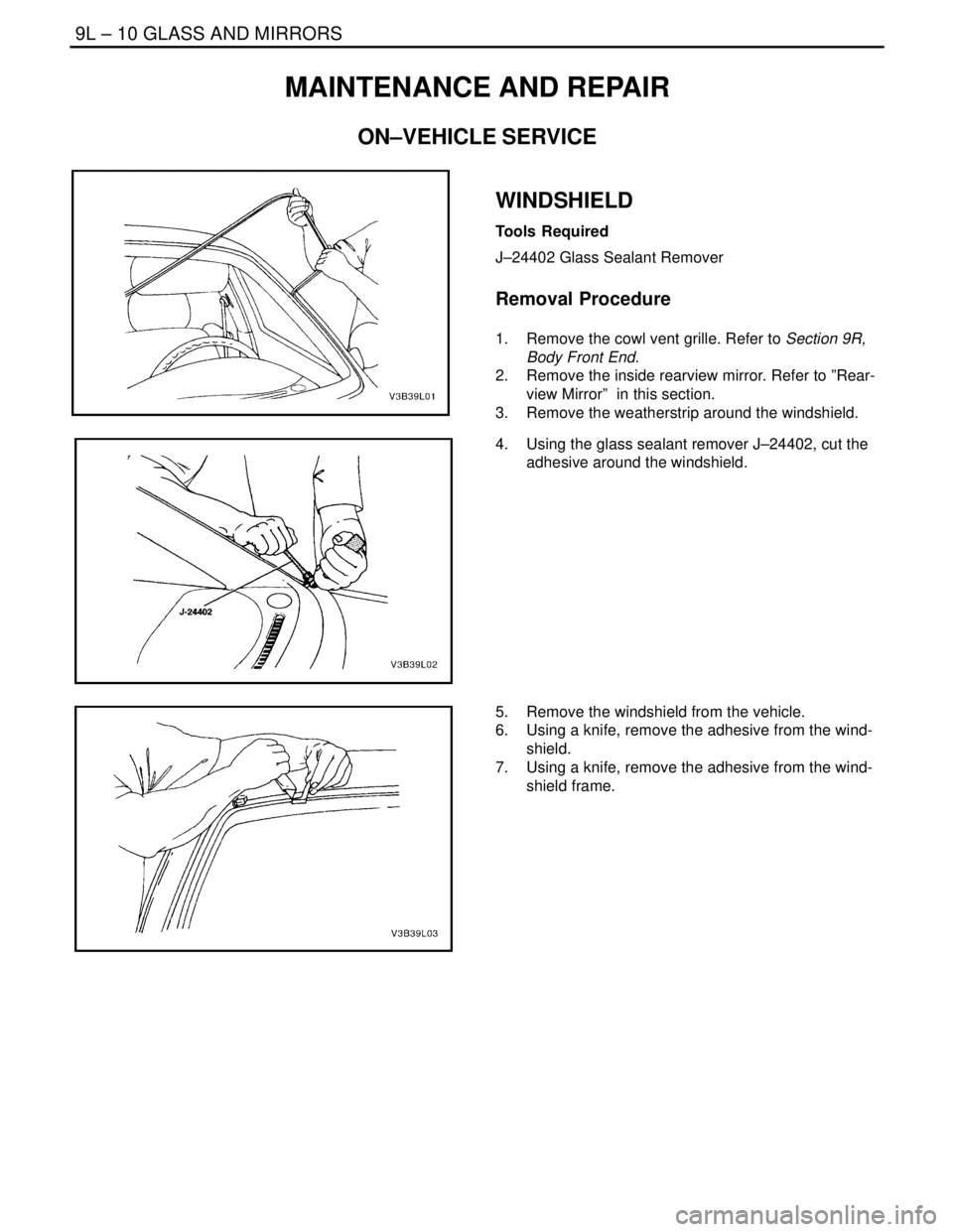

WINDSHIELD

Tools Required

J–24402 Glass Sealant Remover

Removal Procedure

1. Remove the cowl vent grille. Refer to Section 9R,

Body Front End.

2. Remove the inside rearview mirror. Refer to ”Rear-

view Mirror” in this section.

3. Remove the weatherstrip around the windshield.

4. Using the glass sealant remover J–24402, cut the

adhesive around the windshield.

5. Remove the windshield from the vehicle.

6. Using a knife, remove the adhesive from the wind-

shield.

7. Using a knife, remove the adhesive from the wind-

shield frame.

Page 2399 of 2643

SECTION : 9M

EXTERIOR TRIM

TABLE OF CONTENTS

SPECIFICATIONS9M–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9M–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9M–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9M–2. . . . . . . . . . . . . . . . . . . . .

B–Pillar Molding 9M–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Roof Molding 9M–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mud Guards 9M–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Rear Spoiler 9M–3. . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9M–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emblems and Lettering 9M–5. . . . . . . . . . . . . . . . . . . . .

Mud Guards 9M–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

B–Pillar Molding Screws1.3–12

Mud Guard Bolts2–18

Page 2400 of 2643

9M – 2IEXTERIOR TRIM

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

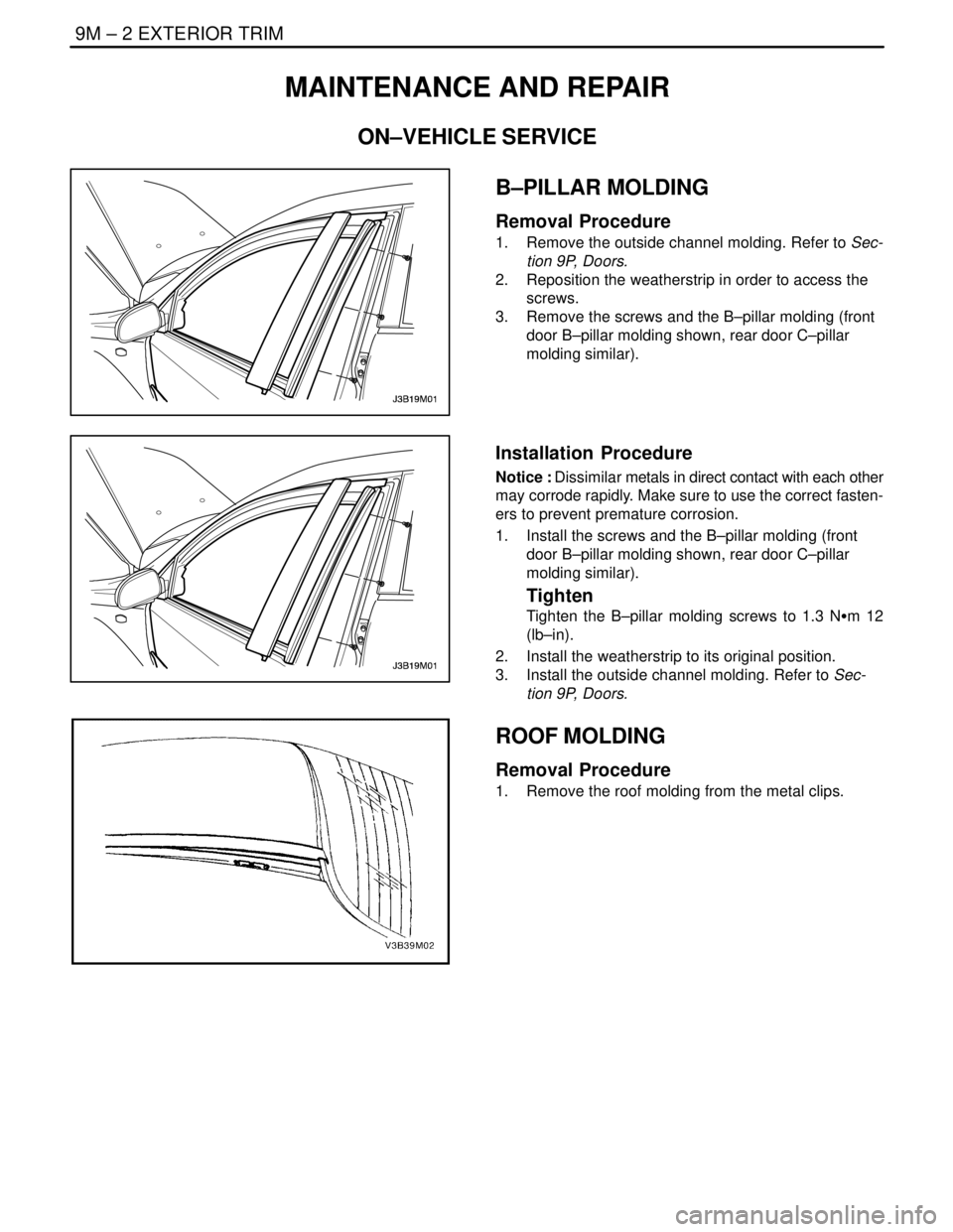

B–PILLAR MOLDING

Removal Procedure

1. Remove the outside channel molding. Refer to Sec-

tion 9P, Doors.

2. Reposition the weatherstrip in order to access the

screws.

3. Remove the screws and the B–pillar molding (front

door B–pillar molding shown, rear door C–pillar

molding similar).

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the screws and the B–pillar molding (front

door B–pillar molding shown, rear door C–pillar

molding similar).

Tighten

Tighten the B–pillar molding screws to 1.3 NSm 12

(lb–in).

2. Install the weatherstrip to its original position.

3. Install the outside channel molding. Refer to Sec-

tion 9P, Doors.

ROOF MOLDING

Removal Procedure

1. Remove the roof molding from the metal clips.

Page 2404 of 2643

SECTION : 9N

FRAME AND UNDERBODY

TABLE OF CONTENTS

SPECIFICATIONS9N–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9N–1. . . . . . . . . . .

Notchback Underbody Dimensions 9N–2. . . . . . . . . . .

Hatchback Underbody Dimensions 9N–4. . . . . . . . . . .

MAINTENANCE AND REPAIR9N–6 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9N–6. . . . . . . . . . . . . . . . . . . . . Alignment Checking 9N–6. . . . . . . . . . . . . . . . . . . . . . . .

Floor Pan Insulators 9N–6. . . . . . . . . . . . . . . . . . . . . . . .

Engine Under Covers 9N–7. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9N–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Body Construction 9N–8. . . . . . . . . . . . . . . . .

Engine Under Covers 9N–8. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Engine Under Cover Bolts3.5–31

Page 2409 of 2643

9N – 6IFRAME AND UNDERBODY

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

ALIGNMENT CHECKING

An accurate method of determining the alignment of the

underbody uses a measuring tram gauge. The tram gauge

set used to perform the recommended measuring checks

must include a vertical pointer able to reach 457 mm (18

inches).

Two types of measurements can be made with a tram

gauge: direct point–to–point measurements and mea-

surements calculated on a horizontal plane (datum line)

parallel to the underbody. Point–to–point measurements

are generally taken on steering and suspension engine

compartment parts and simply require the vertical pointers

to be set equally.

For horizontal plane measurements, the vertical pointers

must be set as specified for each point to be measured.

Dimensions–to–gauge holes are measured to the center

of the holes and flush to the adjacent surface metal unless

otherwise specified. It is recommended that the diagonal

dimensions to the cross–body be checked on both sides

in order to verify the dimensional accuracy of the vehicle

underbody.

FLOOR PAN INSULATORS

The floor pan insulators have been designed for the higher

floor pan temperatures that result from the use of the cata-

lytic converter in the exhaust system. Therefore, when

servicing a vehicle, it is essential that any insulators that

may have been disturbed or removed be reinstalled in the

original sequence and location. Also, if an insulator needs

to be replaced, use only the insulation specified for that

location on the floor pan.

When servicing or replacing interior insulators, observe

the following instructions.

S Install the insulators in the original position and se-

quence. Butt the pieces together in order to avoid

gapping or overlapping.

S If it is necessary to replace an insulator, use only

the specified insulation.

S Use the original part to determine the amount of

replacement material required and as a template for

cutting and fitting the new piece to the floor pan.

S When installing the insulator, do not enlarge any

cutouts or holes that are used for the attachment of

interior parts such as the instrument panel or the

floor console.

S Route the cross–body harness for interior parts

over the floor pan insulators. Clip it in the original

location.

S Do not apply spray–on deadeners or trim adhesives

to the top of the floor pan at the area directly over

the catalytic converter or the muffler.

Page 2412 of 2643

SECTION : 9O

BUMPERS AND FASCIAS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9O–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9O–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9O–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9O–2. . . . . . . . . . . . . . . . . . . . .

Front Bumper Fascia 9O–2. . . . . . . . . . . . . . . . . . . . . . .

Front Bumper Energy Absorber 9O–3. . . . . . . . . . . . . . Front Bumper Impact Bar 9O–4. . . . . . . . . . . . . . . . . . .

Notchback Rear Bumper Fascia 9O–4. . . . . . . . . . . . .

Hatchback Rear Bumper Fascia 9O–6. . . . . . . . . . . . .

Rear Bumper Impact Bar 9O–7. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9O–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bumpers 9O–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Fender–to–Fascia Bolts10–89

Fender–to–Fascia Screws2–18

Front Impact Bar Bolts3929–

Lower Fascia Screws2–18

Luggage Compartment Fascia Bolts10–89

Luggage Compartment Fascia Screws2–18

Rear Wheel Well Fascia Bolts2–18

Page 2413 of 2643

9O – 2IBUMPERS AND FASCIAS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

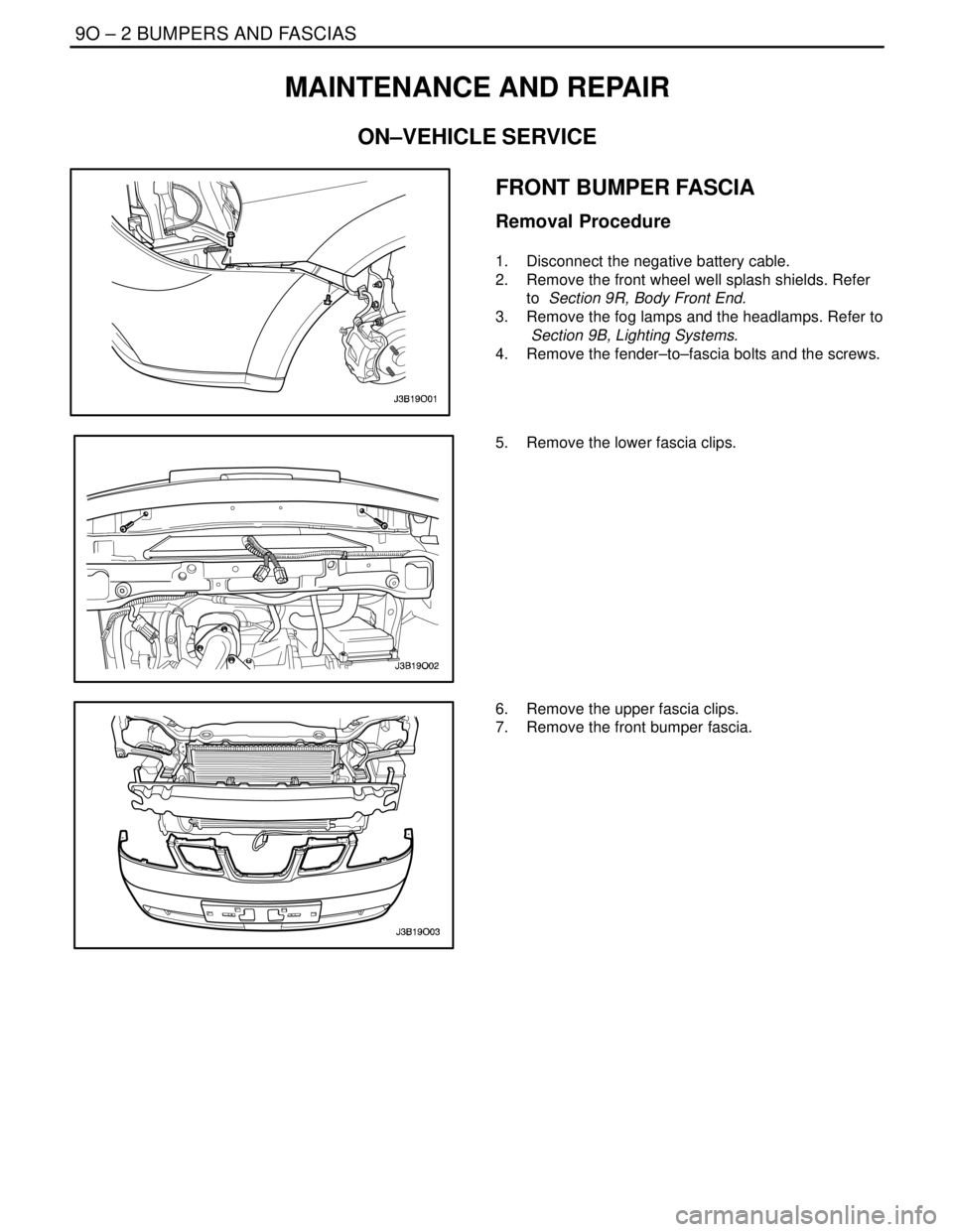

FRONT BUMPER FASCIA

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front wheel well splash shields. Refer

to Section 9R, Body Front End.

3. Remove the fog lamps and the headlamps. Refer to

Section 9B, Lighting Systems.

4. Remove the fender–to–fascia bolts and the screws.

5. Remove the lower fascia clips.

6. Remove the upper fascia clips.

7. Remove the front bumper fascia.