maintenance DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2106 of 2643

8B – 2ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

DTC 80 Driver Side Airbag Sensor Loop Is

Shorted To Power 8B–72. . . . . . . . . . . . . . . . . . . . . . .

DTC 81 Driver Side Airbag Sensor Loop Is

Shorted To Ground 8B–74. . . . . . . . . . . . . . . . . . . . . .

DTC 82 Driver Side Airbag Sensor Communication

Error 8B–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 83 Driver Side Airbag Sensor Failure 8B–78. . .

DTC 84 Passenger Side Airbag Sensor Loop Is

Shorted To Power 8B–80. . . . . . . . . . . . . . . . . . . . . . .

DTC 85 Passenger Side Airbag Sensor Loop Is

Shorted To Ground 8B–82. . . . . . . . . . . . . . . . . . . . . .

DTC 86 Passenger Side Airbag Sensor

Communication Error 8B–84. . . . . . . . . . . . . . . . . . . .

DTC 87 Passenger Side Airbag Sensor Failure 8B–86

MAINTENANCE AND REPAIR8B–88 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 8B–88. . . . . . . . . . . . . . . . . . . .

Disabling the Supplemental Inflatable

Restraints(SIR) 8B–88. . . . . . . . . . . . . . . . . . . . . . . . .

Enabling the Supplemental Inflatable

Restraints(SIR) 8B–88. . . . . . . . . . . . . . . . . . . . . . . . .

Handling, Installation and Diagnosis 8B–89. . . . . . . . .

Repairs and Inspections Required After an

Accident 8B–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accident With Deployment Components

Replacements 8B–90. . . . . . . . . . . . . . . . . . . . . . . . . . Accident Without Deployment Component

Inspection 8B–90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) 8B–90. . . . . .

Driver Airbag Module 8B–91. . . . . . . . . . . . . . . . . . . . . .

Clock Spring 8B–92. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Spring Alignment 8B–93. . . . . . . . . . . . . . . . . . . .

Passenger Airbag Module 8B–94. . . . . . . . . . . . . . . . . .

Side Airbag Sensor 8B–95. . . . . . . . . . . . . . . . . . . . . . .

Front Seat Belt Pretensioner 8B–95. . . . . . . . . . . . . . .

Airbag Module Deployment (Inside of Vehicle) 8B–95

Airbag Module Deployment (Outside of Vehicle) 8B–97

Deployed Airbag Module Disposal Procedure 8B–98.

SIR Wiring Repair 8B–99. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION8B–100 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Inflatable Restraints(SIR) 8B–100. . . .

Airbag Modules 8B–100. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Seat Belt Pretensioners 8B–101. . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) 8B–101. . . . .

Airbag Warning Lamp 8B–101. . . . . . . . . . . . . . . . . . . .

Clock Spring 8B–101. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Harness Connectors 8B–102. . . . . . . . . . . . . . .

Page 2192 of 2643

8B – 88ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

SERVICE PRECAUTION

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be excuted immediately without waiting for one–

minute time period to expire. Failure to tempo-

rarily disable the SIR during service can result in

unexpected deployment, personal injury and un-

necessary SIR repairs.

DISABLING THE SUPPLEMENTAL

INFLATABLE RESTRAINTS(SIR)

1. Turn the steering wheel to the straight–ahead posi-

tion.

2. Turn the ignition switch to LOCK and remove the

key.

3. Remove the airbag fuse F1 in the I/P fuse block

and wait more than one minute for SIR capacitor to

discharge.

ENABLING THE SUPPLEMENTAL

INFLATABLE RESTRAINTS(SIR)

1. Insert the airbag fuse F8 in the I/P fuse block.

2. Turn the ignition switch to ON and verify that the

airbag indicator flashes seven times and turns OFF.

If it does not operate as described, perform the”

SIR Diagnostic System Check” referring in this sec-

tion.

CAUTION : While turning the ignition switch,

staying well away from the inflator modules, or

personal injury can be occurred.

Page 2227 of 2643

SECTION : 9B

LIGHTING SYSTEMS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9B–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Bulb Usage Chart 9B–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9B–2. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9B–3 . . . . .

Backup Lamps Circuit 9B–3. . . . . . . . . . . . . . . . . . . . . .

Instruments Circuit (W/O Dimmer Control :

General Only) 9B–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instruments Circuit (W/ Dimmer Control) 9B–5. . . . . .

Front And Rear Fog Lamps Circuit 9B–6. . . . . . . . . . .

Headlamps–On Reminder Chime Circuit 9B–7. . . . . .

Headlamps and Headlamp Leveling Circuit 9B–8. . . .

Daytime Running Lamps Circuit 9B–9. . . . . . . . . . . . .

Parking, Tail and License Lamps Circuit 9B–10. . . . . .

Stoplamps Circuit 9B–11. . . . . . . . . . . . . . . . . . . . . . . . .

Turn and Hazard Lamps Circuit 9B–12. . . . . . . . . . . . .

Interior Courtesy and Luggage Compartment Lamp

Circuit 9B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS9B–14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlamps–On Reminder Chime 9B–14. . . . . . . . . . .

Headlamps 9B–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlamp Leveling 9B–20. . . . . . . . . . . . . . . . . . . . . . .

Daytime Running Lamps 9B–22. . . . . . . . . . . . . . . . . . .

Parking Lamps and Taillamps 9B–23. . . . . . . . . . . . . .

Interior Courtesy and Luggage Compartment

Lamps 9B–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fog Lamps 9B–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9B–36 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9B–36. . . . . . . . . . . . . . . . . . . . Headlamps/Front Turn Signal Lamps 9B–36. . . . . . . .

Daytime Running Lamp Module 9B–37. . . . . . . . . . . . .

Parking Lamps 9B–37. . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Turn Signal Lamps 9B–38. . . . . . . . . . . . . . . . . . .

Front Fog Lamps 9B–38. . . . . . . . . . . . . . . . . . . . . . . . .

Notchback Rear Combination Lamps 9B–39. . . . . . . .

Hatchback Rear Combination Lamps 9B–40. . . . . . . .

Hatchback Extension Lamps 9B–40. . . . . . . . . . . . . . .

Notchback Center High–Mounted Stoplamp 9B–41. .

Hatchback Center High–Mounted Stoplamp 9B–41. .

License Plate Lamps 9B–42. . . . . . . . . . . . . . . . . . . . . .

Door Jamb Switch 9B–42. . . . . . . . . . . . . . . . . . . . . . . .

Center Room Lamp 9B–43. . . . . . . . . . . . . . . . . . . . . . .

Map Lamp 9B–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Luggage Compartment Lamp 9B–44. . . . . . . . . . . . . . .

Ashtray and Cigar Lighter Lamp 9B–44. . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9B–46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlamps–On Reminder Chime 9B–46. . . . . . . . . . .

Headlamps 9B–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Daytime Running Lamps 9B–46. . . . . . . . . . . . . . . . . . .

Parking and Turn Signal Lamps 9B–46. . . . . . . . . . . . .

Fog Lamps 9B–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Combination Lamps 9B–46. . . . . . . . . . . . . . . . . .

License Plate Lamp 9B–46. . . . . . . . . . . . . . . . . . . . . . .

Interior Courtesy Lamp 9B–46. . . . . . . . . . . . . . . . . . . .

Luggage Compartment Lamp 9B–46. . . . . . . . . . . . . . .

Backup Lamps 9B–47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2262 of 2643

9B – 36ILITHING SYSTEMS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

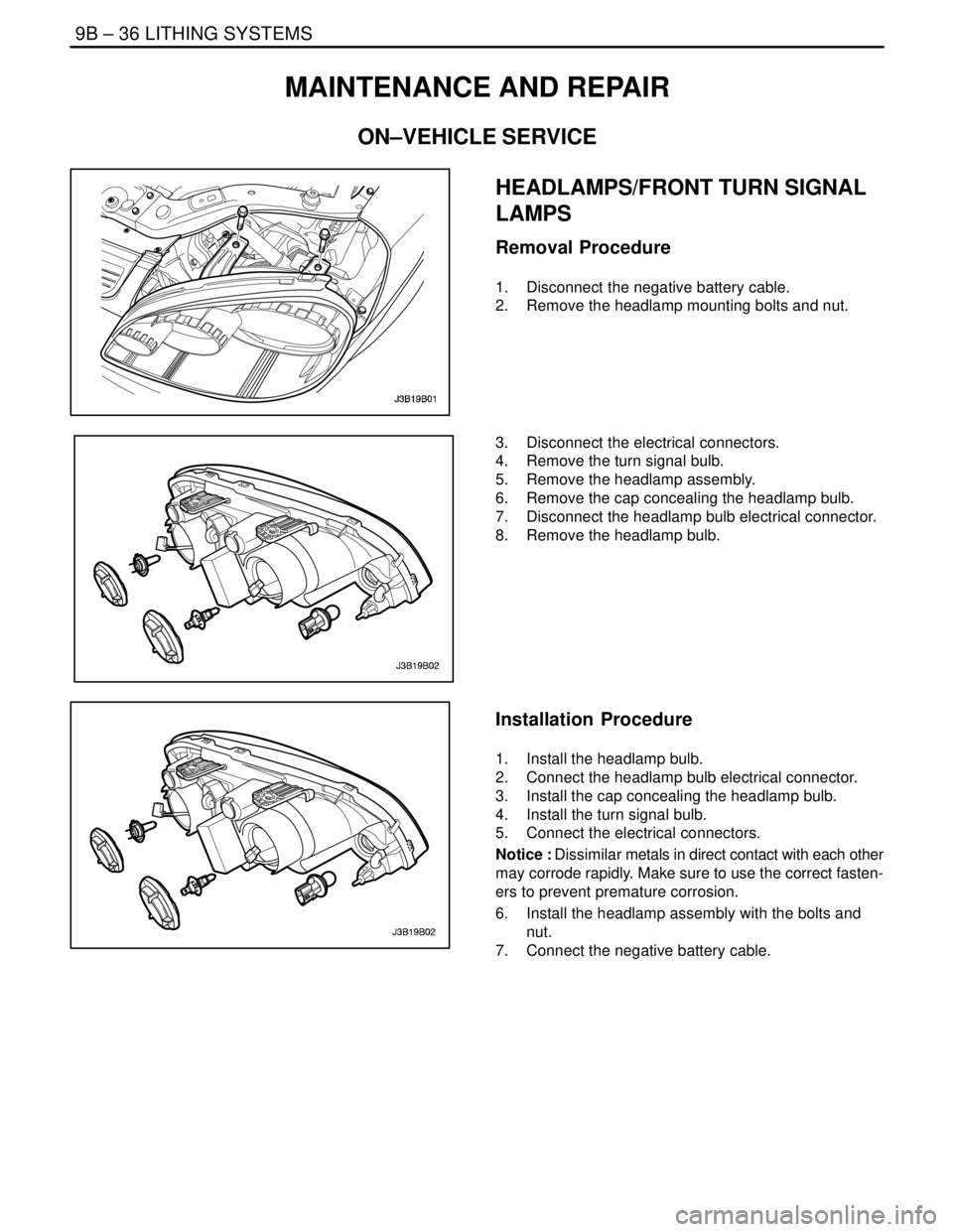

HEADLAMPS/FRONT TURN SIGNAL

LAMPS

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the headlamp mounting bolts and nut.

3. Disconnect the electrical connectors.

4. Remove the turn signal bulb.

5. Remove the headlamp assembly.

6. Remove the cap concealing the headlamp bulb.

7. Disconnect the headlamp bulb electrical connector.

8. Remove the headlamp bulb.

Installation Procedure

1. Install the headlamp bulb.

2. Connect the headlamp bulb electrical connector.

3. Install the cap concealing the headlamp bulb.

4. Install the turn signal bulb.

5. Connect the electrical connectors.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

6. Install the headlamp assembly with the bolts and

nut.

7. Connect the negative battery cable.

Page 2274 of 2643

SECTION : 9C

HORN(S)

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9C–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9C–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9C–2 . . . . .

Horn Wiring System 9C–2. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9C–3 . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 9C–3. . . . . . . . . . . . . . . . . . . . .

Horn(s) 9C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9C–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn(s) 9C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Horn Bolt2015–

Page 2276 of 2643

HORN(S) 9C – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

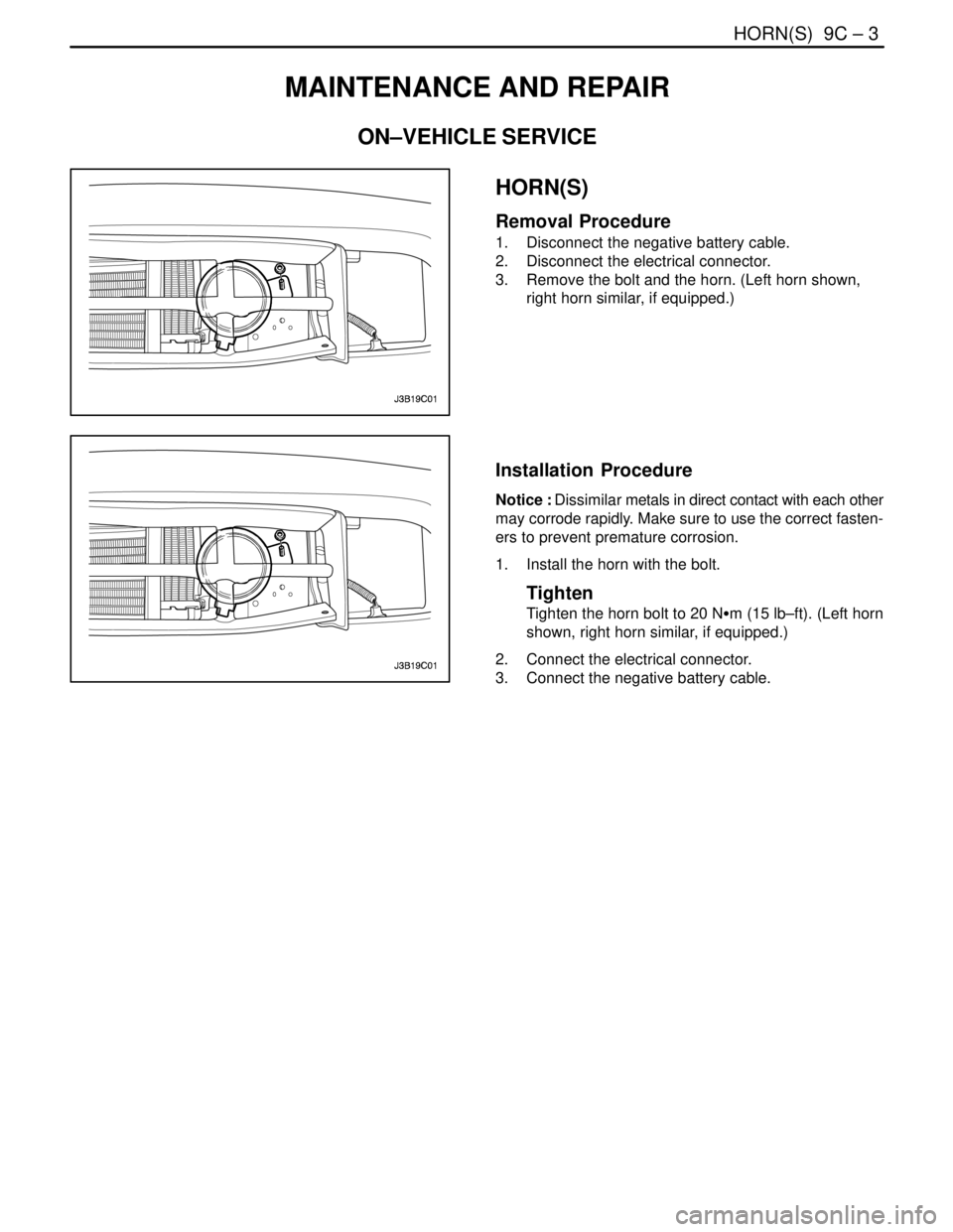

HORN(S)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector.

3. Remove the bolt and the horn. (Left horn shown,

right horn similar, if equipped.)

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the horn with the bolt.

Tighten

Tighten the horn bolt to 20 NSm (15 lb–ft). (Left horn

shown, right horn similar, if equipped.)

2. Connect the electrical connector.

3. Connect the negative battery cable.

Page 2278 of 2643

SECTION : 9D

WIPERS/WASHER SYSTEMS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9D–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9D–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9D–2 . . . . .

Wipers and Washer System 9D–2. . . . . . . . . . . . . . . . .

Wipers and Washer System 9D–3. . . . . . . . . . . . . . . . .

Wipers and Washer System (HatchBack) 9D–4. . . . .

Wipers and Washer System (HatchBack) 9D–5. . . . .

DIAGNOSIS9D–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wipers 9D–6. . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Washer System 9D–10. . . . . . . . . . . . . . . .

Rear Window Wiper (Hatchback) 9D–11. . . . . . . . . . .

Rear Window Washer System (Hatchback) 9D–13. . .

MAINTENANCE AND REPAIR9D–14 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9D–14. . . . . . . . . . . . . . . . . . . .

Windshield Wiper Arm 9D–14. . . . . . . . . . . . . . . . . . . . . Windshield Wiper Motor 9D–14. . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade 9D–15. . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade Insert 9D–16. . . . . . . . . . . . . .

Windshield Washer Reservoir 9D–16. . . . . . . . . . . . . .

Windshield Washer Pump(s) 9D–17. . . . . . . . . . . . . . .

Windshield Washer Nozzles 9D–18. . . . . . . . . . . . . . . .

Windshield Washer Hoses 9D–18. . . . . . . . . . . . . . . . .

Rear Window Wiper Arm (HATCHBACK) 9D–19. . . .

Rear Window Wiper Motor (HATCHBACK) 9D–20. . .

Rear Window Washer Nozzle (HATCHBACK) 9D–20

GENERAL DESCRIPTION AND SYSTEM

OPERATION9D–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper System 9D–22. . . . . . . . . . . . . . . . . .

Windshield Washer System 9D–22. . . . . . . . . . . . . . . .

Rear Window Wiper/Washer System 9D–22. . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Front Wheel Well Splash Shield Bolts1.5–13

Washer Fluid Reservoir Bolts8–71

Wiper Arm Linkage Nut5–44

Wiper Arm Nut2216–

Wiper Motor Bolts8–71

Rear Wiper Arm Nut11–97

Page 2291 of 2643

9D – 14IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

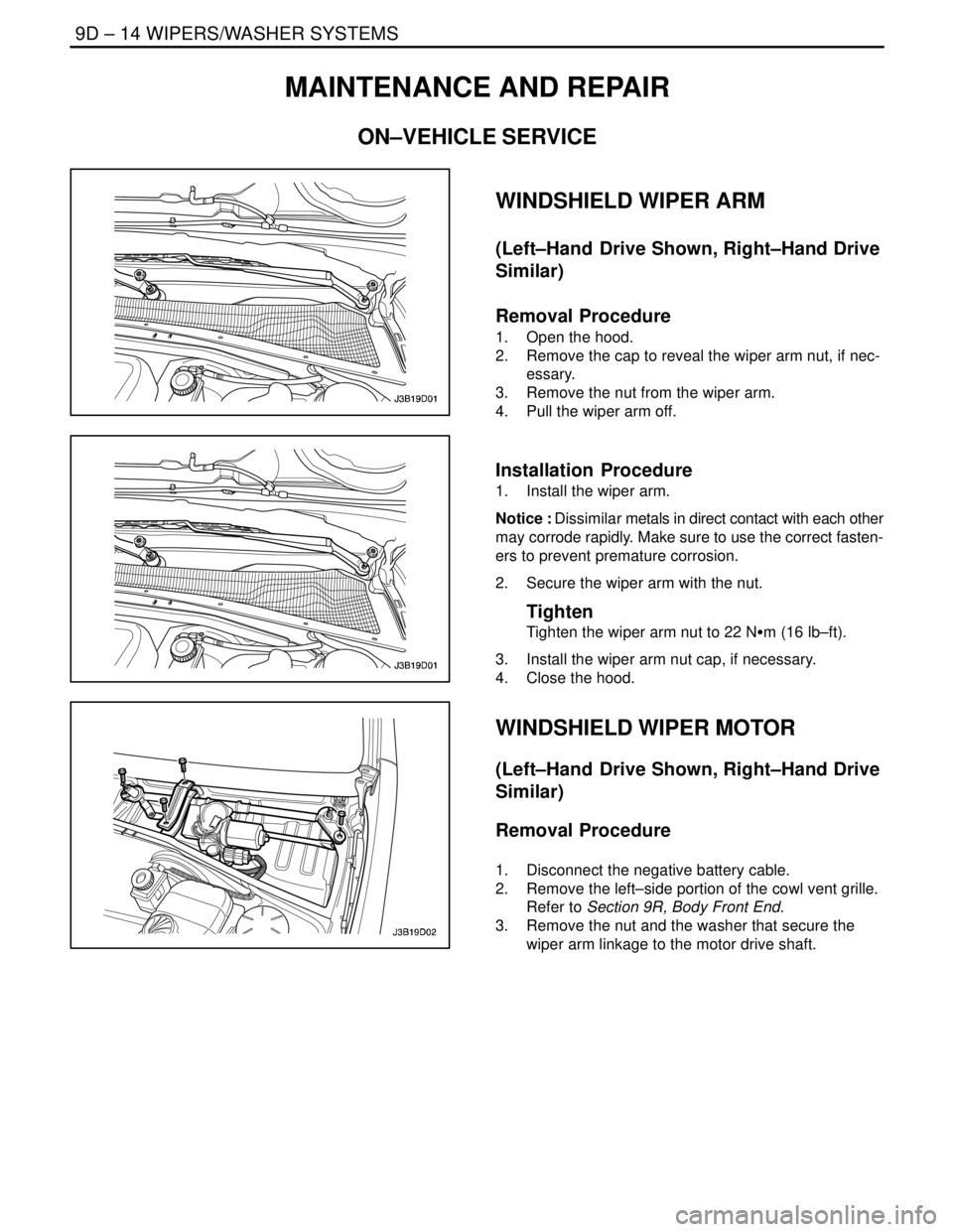

WINDSHIELD WIPER ARM

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Open the hood.

2. Remove the cap to reveal the wiper arm nut, if nec-

essary.

3. Remove the nut from the wiper arm.

4. Pull the wiper arm off.

Installation Procedure

1. Install the wiper arm.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Secure the wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 22 NSm (16 lb–ft).

3. Install the wiper arm nut cap, if necessary.

4. Close the hood.

WINDSHIELD WIPER MOTOR

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the left–side portion of the cowl vent grille.

Refer to Section 9R, Body Front End.

3. Remove the nut and the washer that secure the

wiper arm linkage to the motor drive shaft.

Page 2300 of 2643

SECTION : 9E

INSTRUMENTATION/DRIVER INFORMATION

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9E–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9E–2. . . . . . . . . . .

Instrument Cluster Indicator Lamps

Specifications 9E–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9E–3 . . . . .

Instrument Cluster Circuit (1 of 2) 9E–3. . . . . . . . . . . .

Instrument Cluster Circuit (2 of 2) 9E–4. . . . . . . . . . . .

Cigar Lighter And Extra Power Jack Circuit 9E–5. . . .

DIAGNOSIS9E–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigar Lighter 9E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Clock 9E–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Illumination 9E–9. . . . . . . . . . . . . . . .

Speedometer 9E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge 9E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Gauge 9E–11. . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–12. . . . . . . . .

Chime Module 9E–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chime Module 9E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9E–18 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9E–18. . . . . . . . . . . . . . . . . . . .

Center Molding 9E–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Trim Panel 9E–18. . . . . . . . . . . . . .

Garnish Molding 9E–19. . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray 9E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cigar Lighter 9E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glove Box 9E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notchback Deposit Box 9E–21. . . . . . . . . . . . . . . . . . . .

Notchback Digital Clock 9E–21. . . . . . . . . . . . . . . . . . .

Hatchback Digital Clock 9E–22. . . . . . . . . . . . . . . . . . .

Instrument Cluster 9E–23. . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Dimmer/Headlamp

Leveling Switch 9E–23. . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–24. . . . . . . . .

Instrument Panel 9E–24. . . . . . . . . . . . . . . . . . . . . . . . .

Chime Module 9E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9E–30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigar Lighter 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Vents 9E–30. . . . . . . . . . . . . . . . . . . .

Glove Box 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Clock 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster 9E–30. . . . . . . . . . . . . . . . . . . . . . . .

Speedometer/Odometer/Trip Odometer 9E–30. . . . . .

Fuel Gauge 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Gauge 9E–30. . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–30. . . . . . . . .

Chime Module 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2317 of 2643

9E – 18IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

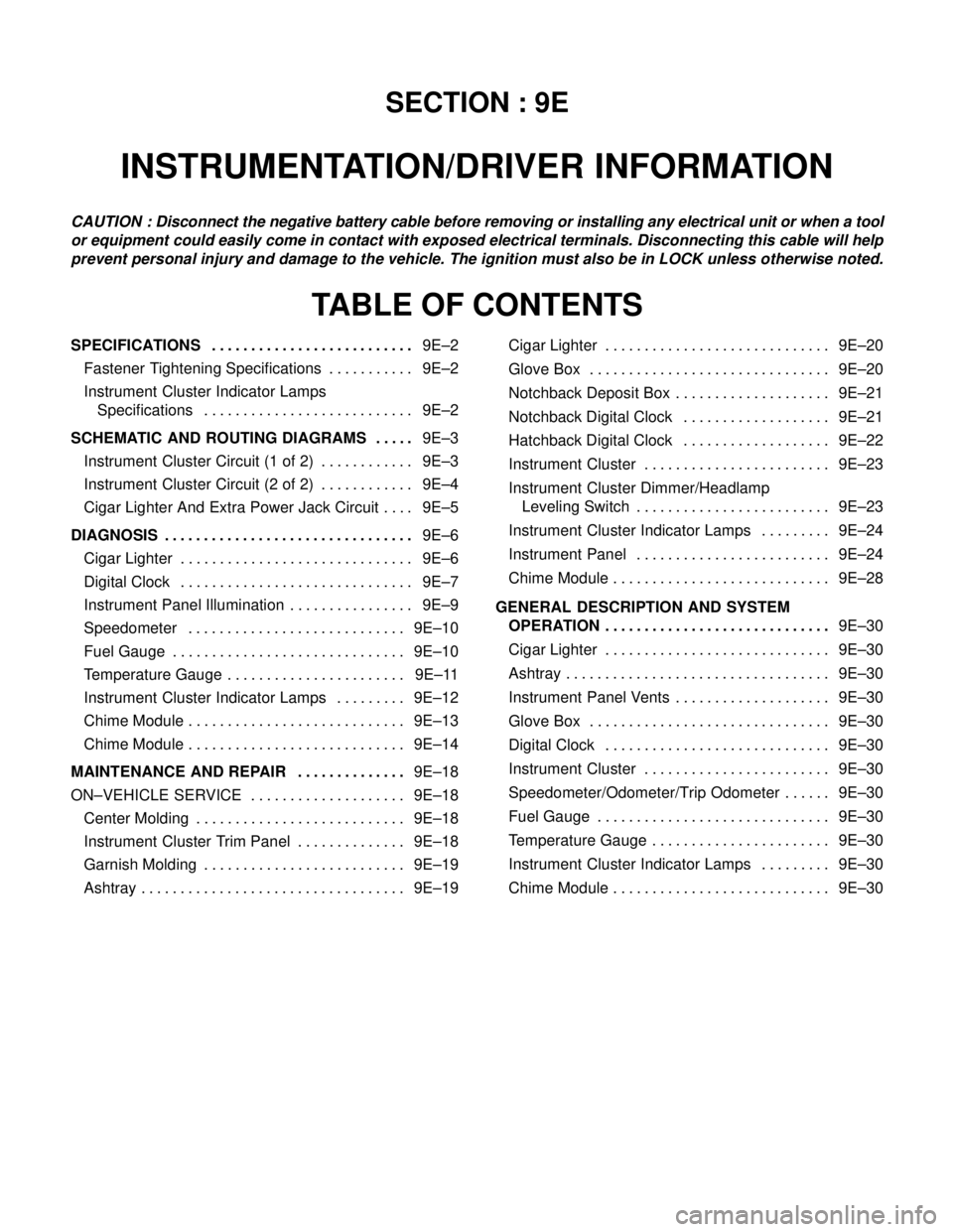

CENTER MODLING

Removal Procedure

1. Disconnect the mode control cable from the mode

door.

2. Remove the center molding.

3. Disconnect the electrical connector.

Installation Procedure

1. Connect the mode control cable from the mode

door.

2. Connect the electrical connector.

3. Install the center molding.

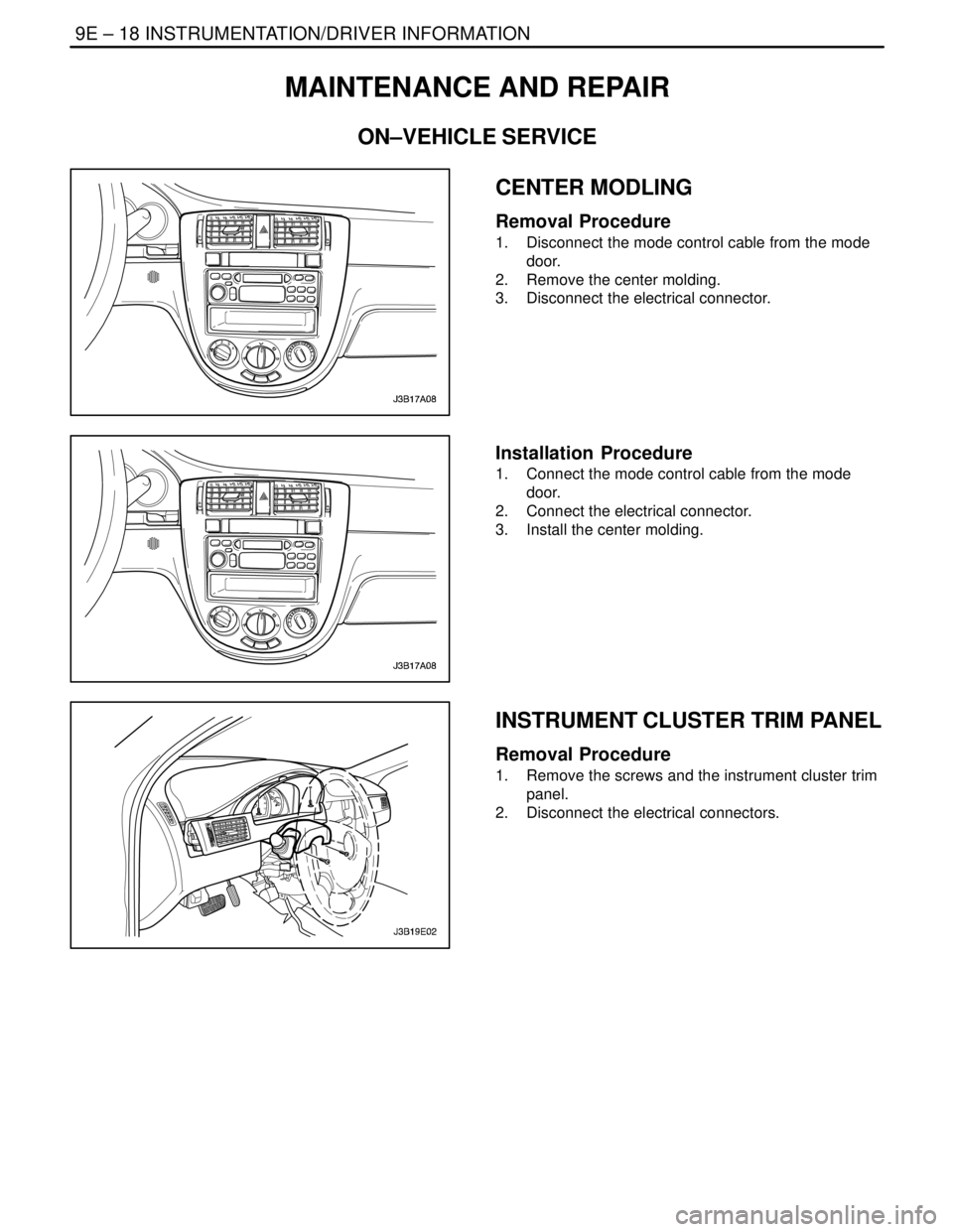

INSTRUMENT CLUSTER TRIM PANEL

Removal Procedure

1. Remove the screws and the instrument cluster trim

panel.

2. Disconnect the electrical connectors.