maintenance DAEWOO LACETTI 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1888 of 2643

SECTION : 5C

CLUTCH

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS5C–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 5C–1. . . . . . . . . . .

SPECIAL TOOLS5C–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 5C–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS5C–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Operation 5C–2. . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR5C–4 . . . . . . . . . . . . . . . . . . . .

Clutch Components 5C–4. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR5C–6 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 5C–6. . . . . . . . . . . . . . . . . . . . .

Clutch Pedal 5C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clutch Pedal Adjustment 5C–7. . . . . . . . . . . . . . . . . . . .

Clutch Release Point Adjustment 5C–8. . . . . . . . . . . .

Air Bleeding 5C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Plate and Clutch Disc 5C–8. . . . . . . . . . . . . .

Clutch Master Cylinder Assembly 5C–10. . . . . . . . . . .

Concentric Slave Cylinder 5C–12. . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION5C–14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driving Members 5C–14. . . . . . . . . . . . . . . . . . . . . . . . .

Driven Members 5C–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Members 5C–14. . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Clutch Master Cylinder nuts2216–

Concentric Slave Cylinder Retaining Bolts7–62

Concentric Slave Cylinder–to–Clutch Oil Pipe Screw1511–

Pressure Plate–to–Flywheel Bolts1511–

Page 1893 of 2643

5C – 6ICLUTCH

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

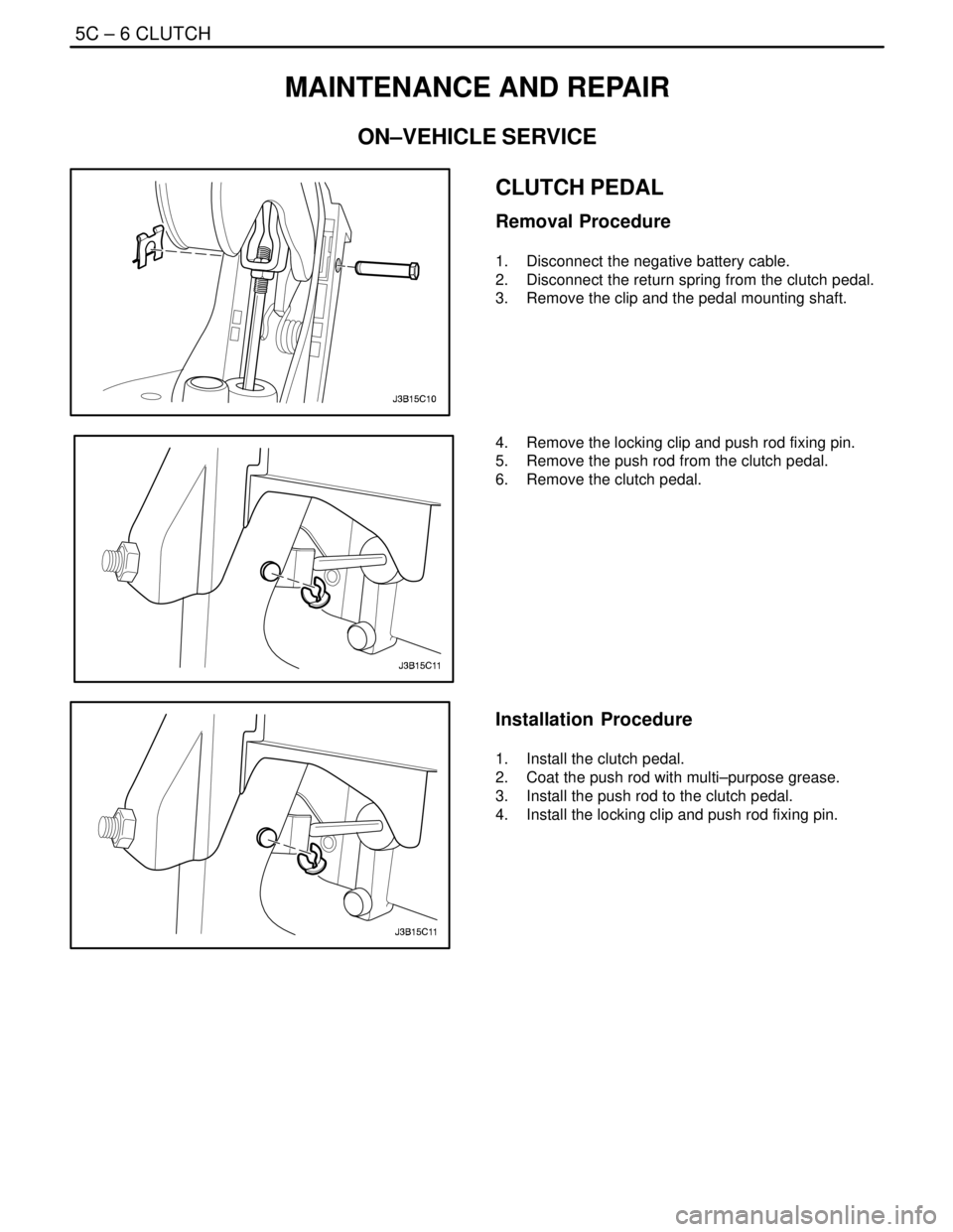

CLUTCH PEDAL

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the return spring from the clutch pedal.

3. Remove the clip and the pedal mounting shaft.

4. Remove the locking clip and push rod fixing pin.

5. Remove the push rod from the clutch pedal.

6. Remove the clutch pedal.

Installation Procedure

1. Install the clutch pedal.

2. Coat the push rod with multi–purpose grease.

3. Install the push rod to the clutch pedal.

4. Install the locking clip and push rod fixing pin.

Page 1902 of 2643

SECTION : 6A

POWER STEERING SYSTEM

TABLE OF CONTENTS

SPECIFICATIONS6A–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6A–1. . . . . . . . . . .

SPECIAL TOOLS6A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6A–1. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6A–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering System Pressure Test 6A–2. . . . . . . .

Power Steering System Leak Test 6A–2. . . . . . . . . . .

MAINTENANCE AND REPAIR6A–3 . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 6A–3. . . . . . . . . . . . . . . . . . . . .

Bleeding the Power Steering System 6A–3. . . . . . . . .

Checking and Adding Fluid 6A–3. . . . . . . . . . . . . . . . . .

Fluid Reservoir 6A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hoses and Pipes 6A–4. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6A–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering System 6A–8. . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Power Steering Pump Pressure Line Fitting2821–

Return Line Clip Bolts8–71

Steering Gear Inlet and Outlet Pipe Fittings2821–

SPECIAL TOOLS

SPECIAL TOOLS TABLE

KM–354–B

Pressure Test

Gauge Kit

Page 1904 of 2643

POWER STEERING SYSTEM 6A – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

BLEEDING THE POWER STEERING

SYSTEM

If the power steering hydraulic system has been serviced,

an accurate fluid level reading cannot be obtained until the

air is bled from the system. Follow these steps to bleed the

air from the system.

1. Turn the wheels all the way to the left and add the

power steering fluid to the MIN mark on the fluid

level indicator.

Notice : When adding fluid or making a complete fluid

change, always use DEXRON®–II or III power steering

fluid. Failure to use the proper fluid will cause hose and

seal damage and fluid leaks.

2. Start the engine. With the engine running at fast

idle, recheck the fluid level. If necessary, add fluid

to bring the level up to the MIN mark.

3. Bleed the system by turning the wheels from side to

side without reaching the stop at either end. Keep

the fluid level at the MIN mark. The air must be

eliminated from the fluid before normal steering ac-

tion can be obtained.

4. Return the wheels to the center position. Continue

running the engine for 2 to 3 minutes.

5. Road test the car to be sure the steering functions

normally and is free from noise.

6. Recheck the fluid level as described in steps 1 and

2. Make sure the fluid level is at the MAX mark af-

ter the system has stabilized at its normal operating

temperature. Add fluid as needed.

CHECKING AND ADDING FLUID

Notice : When adding fluid or making a complete fluid

change, always use DEXRON®–II or III power steering

fluid. Failure to use the proper fluid will cause hose and

seal damage and fluid leaks.

1. The power steering fluid level is indicated either by

marks on a see–through fluid reservoir or by marks

on a fluid level indicator on the fluid reservoir cap.

2. If the fluid is warmed up to 66°C (150°F), the fluid

level should be between the MAX and MIN marks.

Add fluid as needed.

3. If the fluid is cool, 21°C (70°F), the fluid level

should be at the MIN mark. Add fluid as needed.

Page 1910 of 2643

SECTION : 6B

POWER STEERING PUMP

TABLE OF CONTENTS

SPECIFICATIONS6B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6B–1. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6B–1. . . . . . . . . . .

DIAGNOSIS6B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pump Diagnosis 6B–2. . . . . . . . . . . . .

MAINTENANCE AND REPAIR6B–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6B–3. . . . . . . . . . . . . . . . . . . . . Serpentine Accessory Drive Belt 6B–3. . . . . . . . . . . . .

Pump Assembly 6B–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6B–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pump 6B–8. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

LubricantPower Steering Fluid DEXRON®–II or III

Pressure

– without EVO8330 kPa ~ 8820 kPa (1208 psi ~ 1279 psi)

– with EVO8500 kPa ~ 8960 kPa (1233 psi ~ 1299 psi)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Air Filter Housing Assembly Bolts6–53

High–Pressure Hose Fitting2821–

Power Steering Pump Bolts2518–

Right Side Power Steering Pump Bracket Bolts3526–

Page 1912 of 2643

POWER STEERING PUMP 6B – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

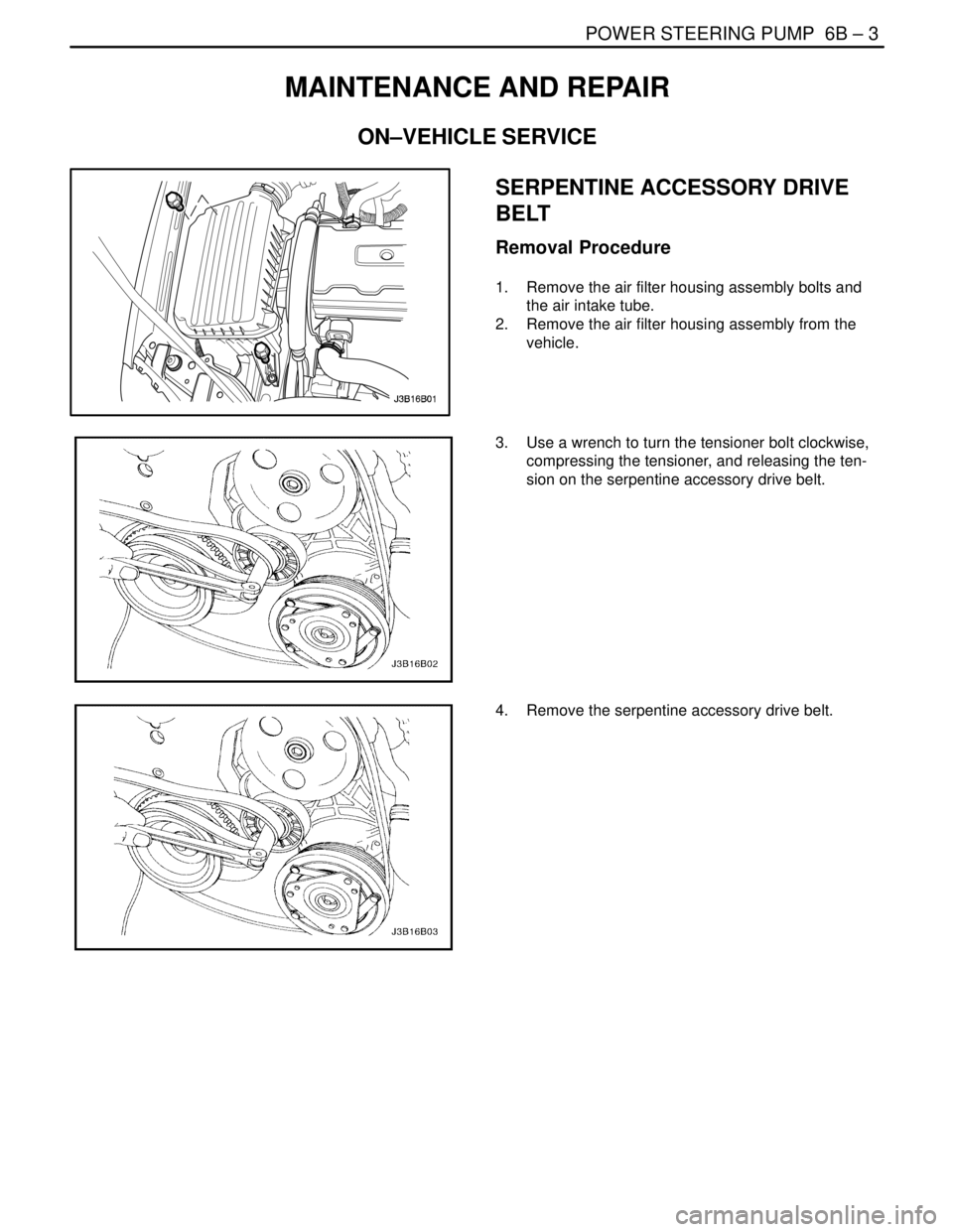

SERPENTINE ACCESSORY DRIVE

BELT

Removal Procedure

1. Remove the air filter housing assembly bolts and

the air intake tube.

2. Remove the air filter housing assembly from the

vehicle.

3. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the ten-

sion on the serpentine accessory drive belt.

4. Remove the serpentine accessory drive belt.

Page 1918 of 2643

SECTION : 6C

POWER STEERING GEAR

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6C–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6C–1. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6C–2. . . . . . . . . . .

SPECIAL TOOLS6C–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6C–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6C–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rack and Pinion Steering Gear 6C–3. . . . . . . .

Power Rack and Pinion Steering Gear Bench

Testing 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering System 6C–6. . . . . .

Speed Sensitive Power Steering System Operating

With Full Assist At All Times 6C–7. . . . . . . . . . . . . . .

Speed Sensitive Power Steering System Operating

with Decreased Assist At All Times 6C–9. . . . . . . . .

MAINTENANCE AND REPAIR6C–11 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6C–11. . . . . . . . . . . . . . . . . . . .

Rack and Pinion Assembly 6C–11. . . . . . . . . . . . . . . . . Outer Tie Rod 6C–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dust Boot 6C–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Straight–Ahead Check 6C–16. . . . . . . . . . . . . . . . . . . .

Intermediate Shaft and Dash Seal 6C–17. . . . . . . . . .

Hydraulic Cylinder Lines 6C–20. . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering Control

Module 6C–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6C–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack and Pinion 6C–22. . . . . . . . . . . . . . . . . . . . . . . . . .

Stub Shaft Seals and Upper and Lower

Bearing 6C–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Bearing 6C–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Bearing Preload Adjustment 6C–30. . . . . . . . . . .

Valve and Pinion 6C–30. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6C–33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rack and Pinion 6C–33. . . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering System 6C–33. . . . .

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Capacity1.1 Liter (1.16 qt)

LubricantPower Steering Fluid DEXRON®–II or III

Page 1928 of 2643

POWER STEERING GEAR 6C – 11

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

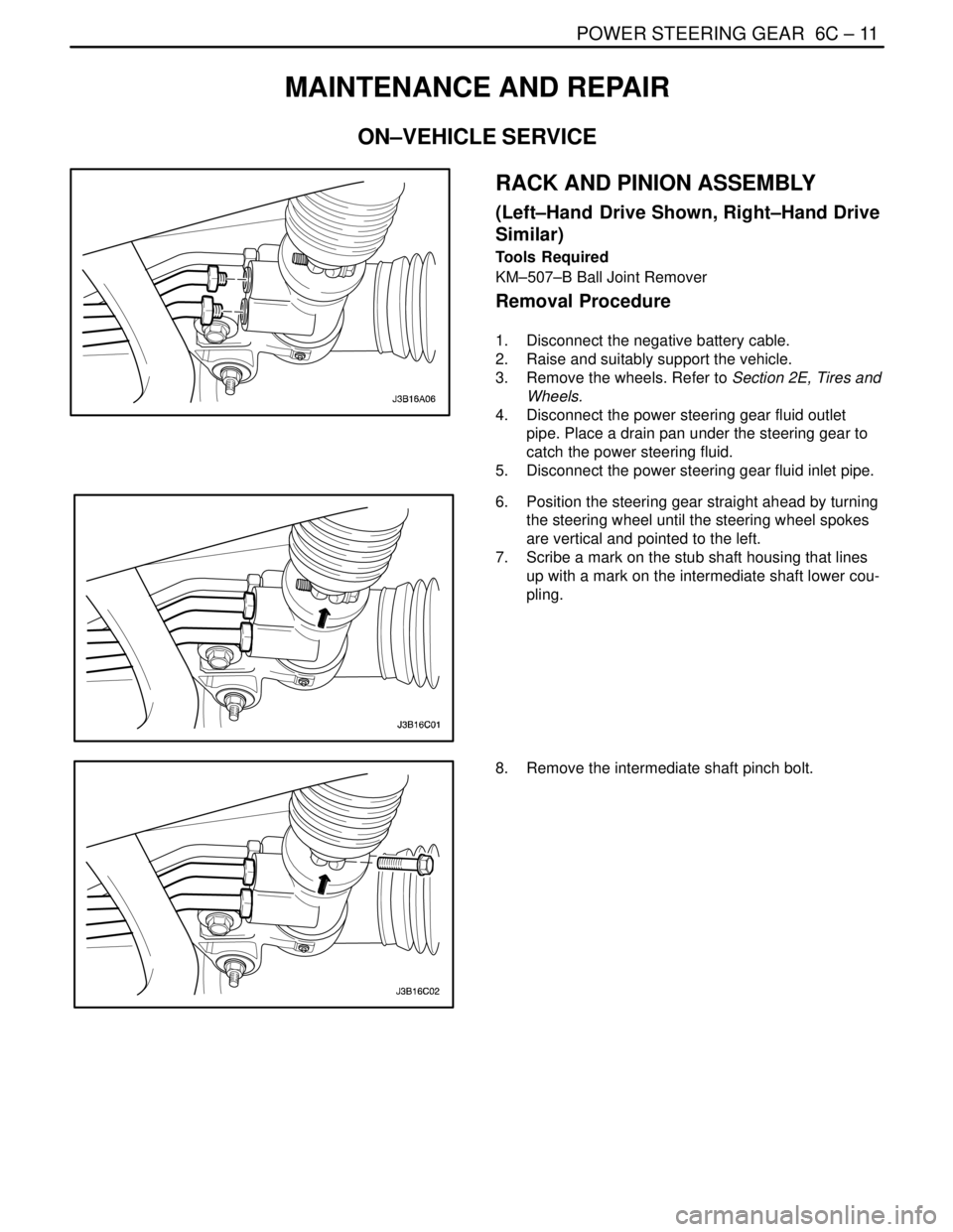

RACK AND PINION ASSEMBLY

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Disconnect the negative battery cable.

2. Raise and suitably support the vehicle.

3. Remove the wheels. Refer to Section 2E, Tires and

Wheels.

4. Disconnect the power steering gear fluid outlet

pipe. Place a drain pan under the steering gear to

catch the power steering fluid.

5. Disconnect the power steering gear fluid inlet pipe.

6. Position the steering gear straight ahead by turning

the steering wheel until the steering wheel spokes

are vertical and pointed to the left.

7. Scribe a mark on the stub shaft housing that lines

up with a mark on the intermediate shaft lower cou-

pling.

8. Remove the intermediate shaft pinch bolt.

Page 1955 of 2643

SECTION : 6E

STEERING WHEEL AND COLUMN

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6E–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6E–1. . . . . . . . . . .

SPECIAL TOOLS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6E–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Column Diagnosis 6E–2. . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR6E–8 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6E–8. . . . . . . . . . . . . . . . . . . . .

Headlamp/Turn Signal Switch and Lever 6E–8. . . . . .

Wiper Switch and Lever 6E–9. . . . . . . . . . . . . . . . . . . . Steering Wheel Rotation Sensor 6E–10. . . . . . . . . . . .

Steering Wheel Without SIR 6E–11. . . . . . . . . . . . . . . .

Steering Wheel With SIR 6E–13. . . . . . . . . . . . . . . . . .

Ignition Lock Cylinder and Switch 6E–13. . . . . . . . . . .

Steering Column 6E–15. . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tilt Steering Column 6E–19. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6E–20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel and Column 6E–20. . . . . . . . . . . . . . . .

Ignition Key Reminder 6E–20. . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Ignition Switch Housing Shear Bolts11–97

Ignition Switch Retaining Screw2.5–22

Steering Column Jacket Assembly Front Bracket Bolts2216–

Steering Column Jacket Assembly Rear Bracket Nuts2216–

Steering Shaft Universal Joint Pinch Bolt2518–

Steering Wheel Horn Cap Screws4.5–40

Steering Wheel Nut3828–

Steering Wheel Rotation Sensor Retaining Screw2–18

Support Housing Screws1612–

Turn Signal Switch Housing Screws3–27

Upper and Lower Steering Column Cover Panel Screws2.5–22

Page 1962 of 2643

6E – 8ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

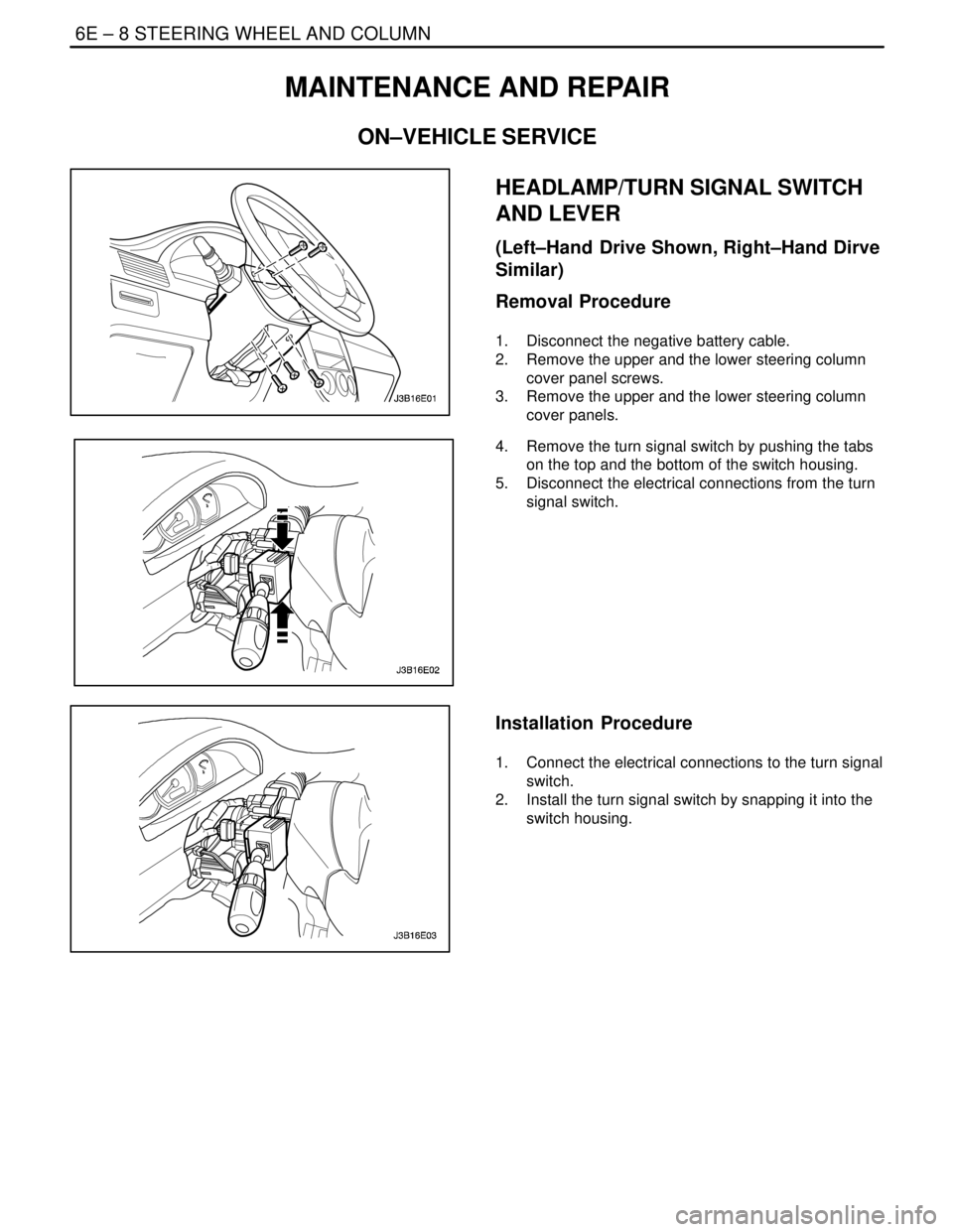

HEADLAMP/TURN SIGNAL SWITCH

AND LEVER

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower steering column

cover panel screws.

3. Remove the upper and the lower steering column

cover panels.

4. Remove the turn signal switch by pushing the tabs

on the top and the bottom of the switch housing.

5. Disconnect the electrical connections from the turn

signal switch.

Installation Procedure

1. Connect the electrical connections to the turn signal

switch.

2. Install the turn signal switch by snapping it into the

switch housing.