Solenoid DAEWOO LACETTI 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 256 of 2643

1F – 10IENGINE CONTROLS

DAEWOO V–121 BL4

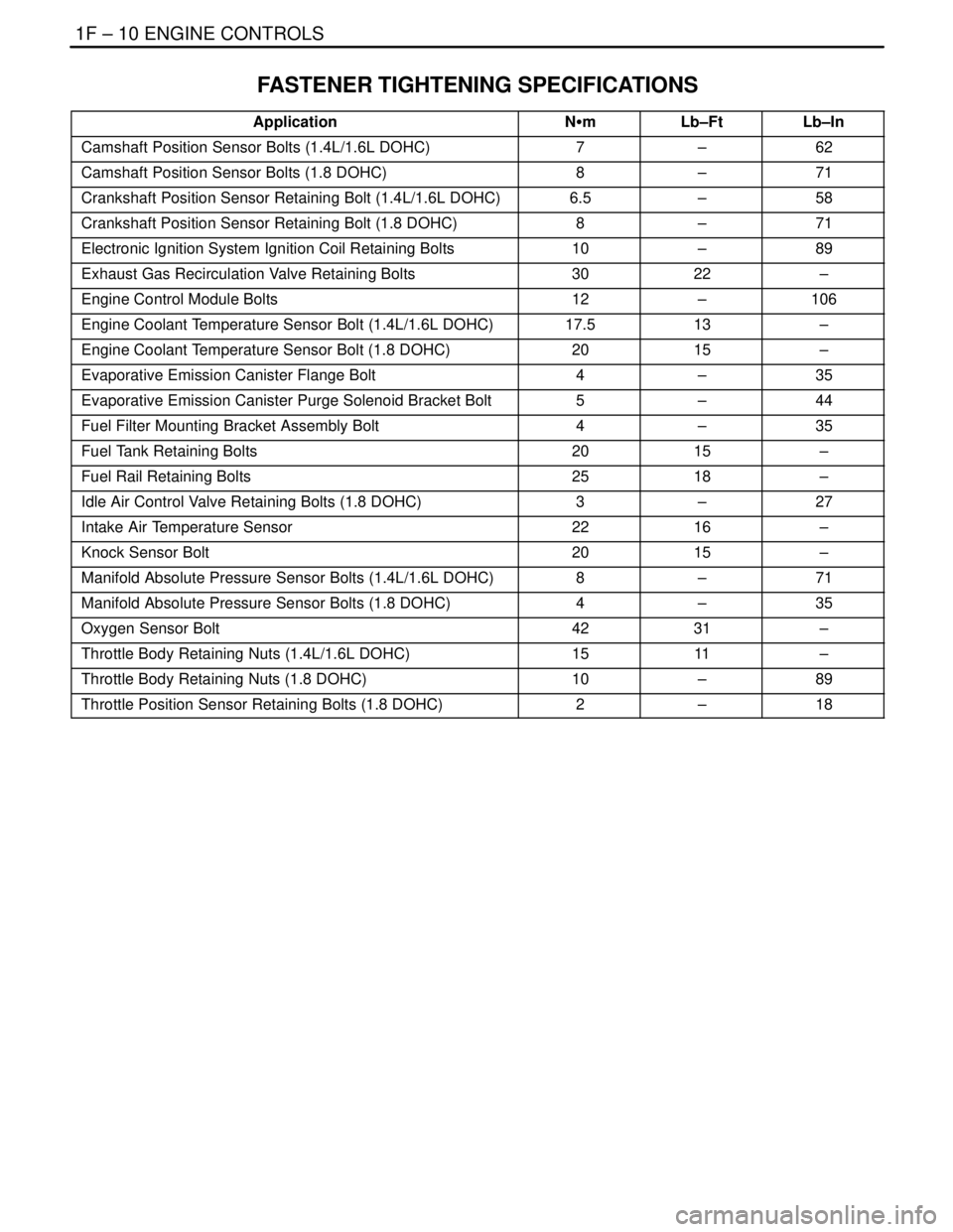

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Camshaft Position Sensor Bolts (1.4L/1.6L DOHC)7–62

Camshaft Position Sensor Bolts (1.8 DOHC)8–71

Crankshaft Position Sensor Retaining Bolt (1.4L/1.6L DOHC)6.5–58

Crankshaft Position Sensor Retaining Bolt (1.8 DOHC)8–71

Electronic Ignition System Ignition Coil Retaining Bolts10–89

Exhaust Gas Recirculation Valve Retaining Bolts3022–

Engine Control Module Bolts12–106

Engine Coolant Temperature Sensor Bolt (1.4L/1.6L DOHC)17.513–

Engine Coolant Temperature Sensor Bolt (1.8 DOHC)2015–

Evaporative Emission Canister Flange Bolt4–35

Evaporative Emission Canister Purge Solenoid Bracket Bolt5–44

Fuel Filter Mounting Bracket Assembly Bolt4–35

Fuel Tank Retaining Bolts2015–

Fuel Rail Retaining Bolts2518–

Idle Air Control Valve Retaining Bolts (1.8 DOHC)3–27

Intake Air Temperature Sensor2216–

Knock Sensor Bolt2015–

Manifold Absolute Pressure Sensor Bolts (1.4L/1.6L DOHC)8–71

Manifold Absolute Pressure Sensor Bolts (1.8 DOHC)4–35

Oxygen Sensor Bolt4231–

Throttle Body Retaining Nuts (1.4L/1.6L DOHC)1511–

Throttle Body Retaining Nuts (1.8 DOHC)10–89

Throttle Position Sensor Retaining Bolts (1.8 DOHC)2–18

Page 272 of 2643

1F – 26IENGINE CONTROLS

DAEWOO V–121 BL4

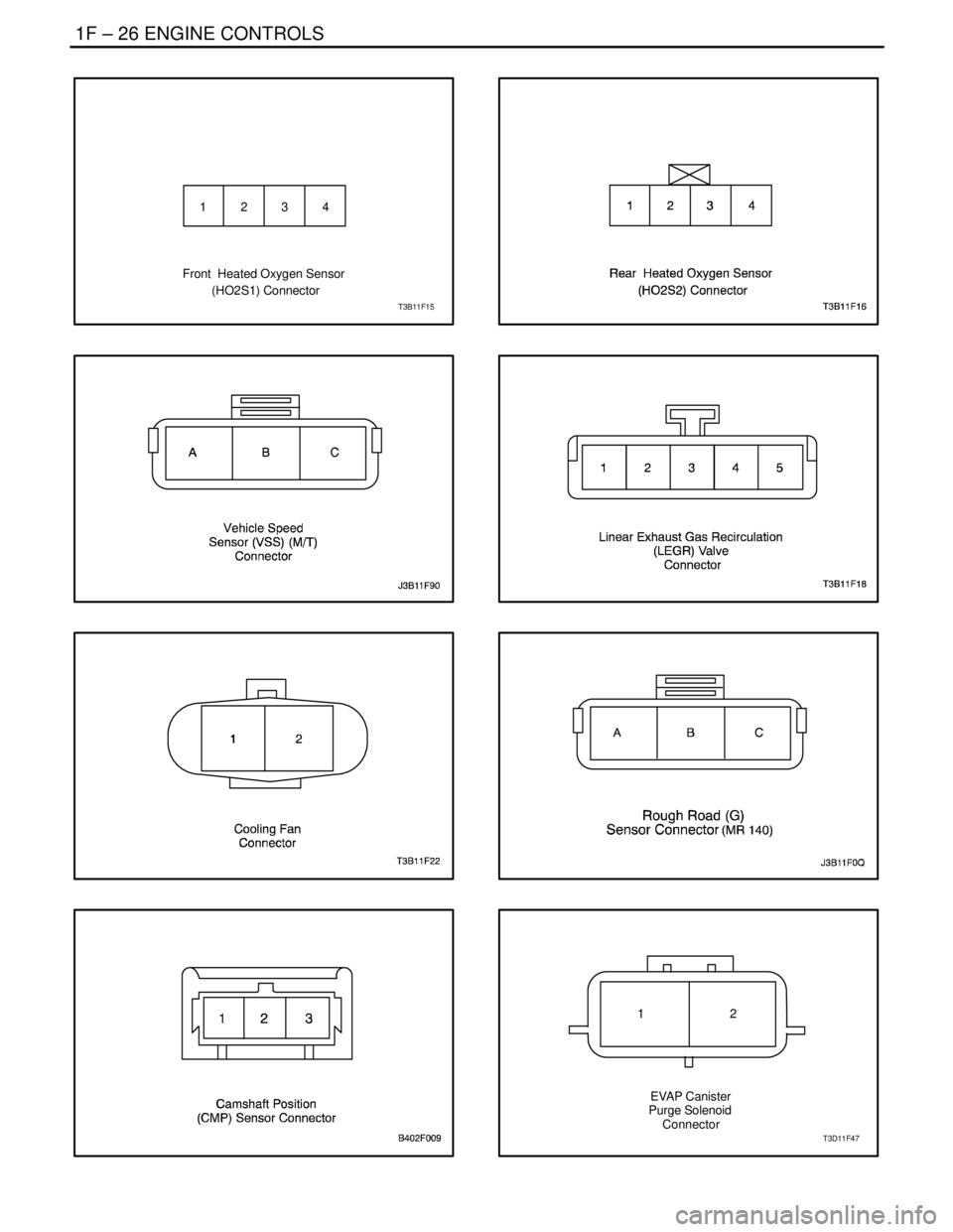

T3B11F15

Front Heated Oxygen Sensor

(HO2S1) Connector

234 1

T3D11F47

EVAP Canister

Purge Solenoid

Connector

12

Page 317 of 2643

ENGINE CONTROLS 1F – 71

DAEWOO V–121 BL4

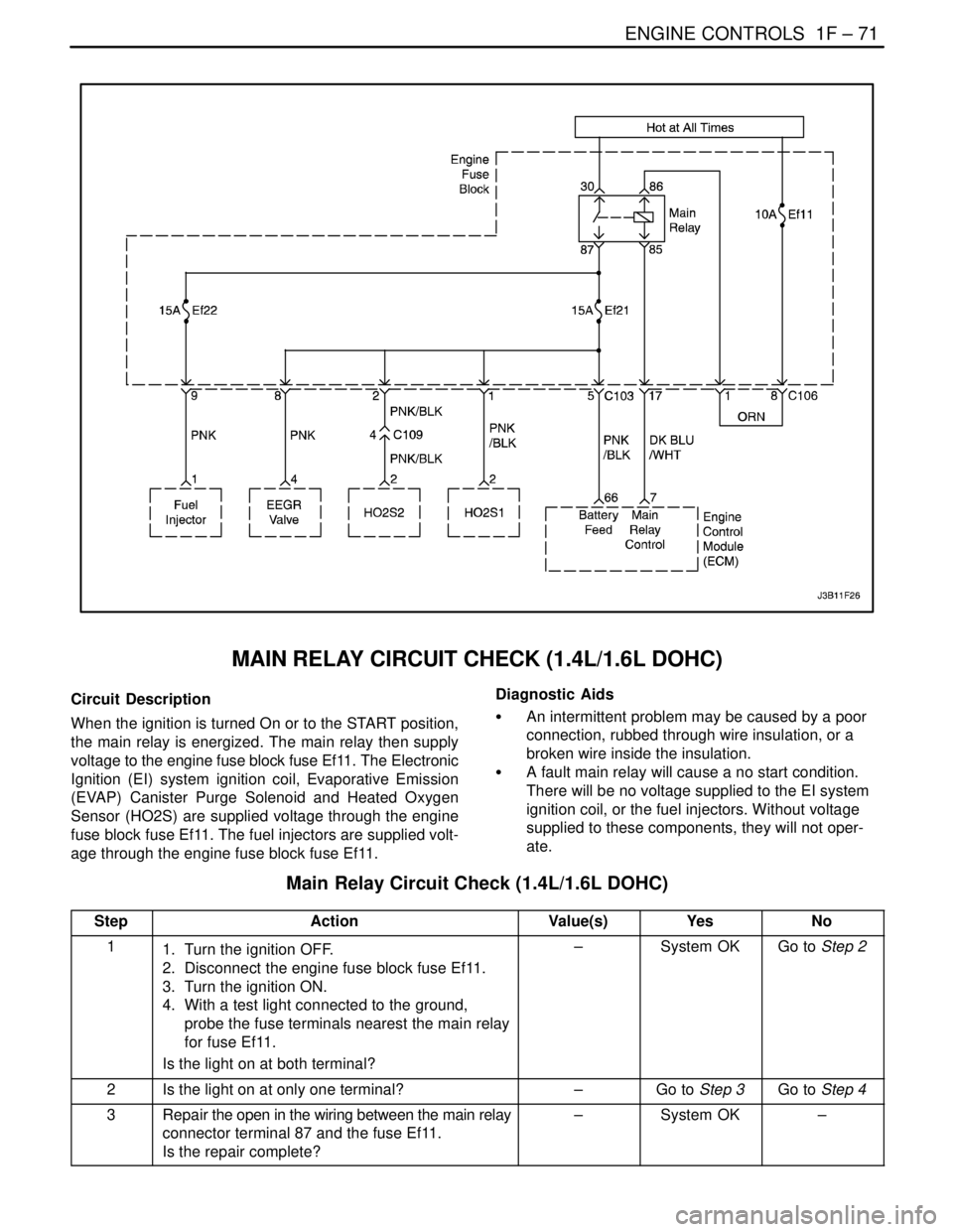

MAIN RELAY CIRCUIT CHECK (1.4L/1.6L DOHC)

Circuit Description

When the ignition is turned On or to the START position,

the main relay is energized. The main relay then supply

voltage to the engine fuse block fuse Ef11. The Electronic

Ignition (EI) system ignition coil, Evaporative Emission

(EVAP) Canister Purge Solenoid and Heated Oxygen

Sensor (HO2S) are supplied voltage through the engine

fuse block fuse Ef11. The fuel injectors are supplied volt-

age through the engine fuse block fuse Ef11.Diagnostic Aids

S An intermittent problem may be caused by a poor

connection, rubbed through wire insulation, or a

broken wire inside the insulation.

S A fault main relay will cause a no start condition.

There will be no voltage supplied to the EI system

ignition coil, or the fuel injectors. Without voltage

supplied to these components, they will not oper-

ate.

Main Relay Circuit Check (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Disconnect the engine fuse block fuse Ef11.

3. Turn the ignition ON.

4. With a test light connected to the ground,

probe the fuse terminals nearest the main relay

for fuse Ef11.

Is the light on at both terminal?–System OKGo to Step 2

2Is the light on at only one terminal?–Go to Step 3Go to Step 4

3Repair the open in the wiring between the main relay

connector terminal 87 and the fuse Ef11.

Is the repair complete?–System OK–

Page 319 of 2643

ENGINE CONTROLS 1F – 73

DAEWOO V–121 BL4

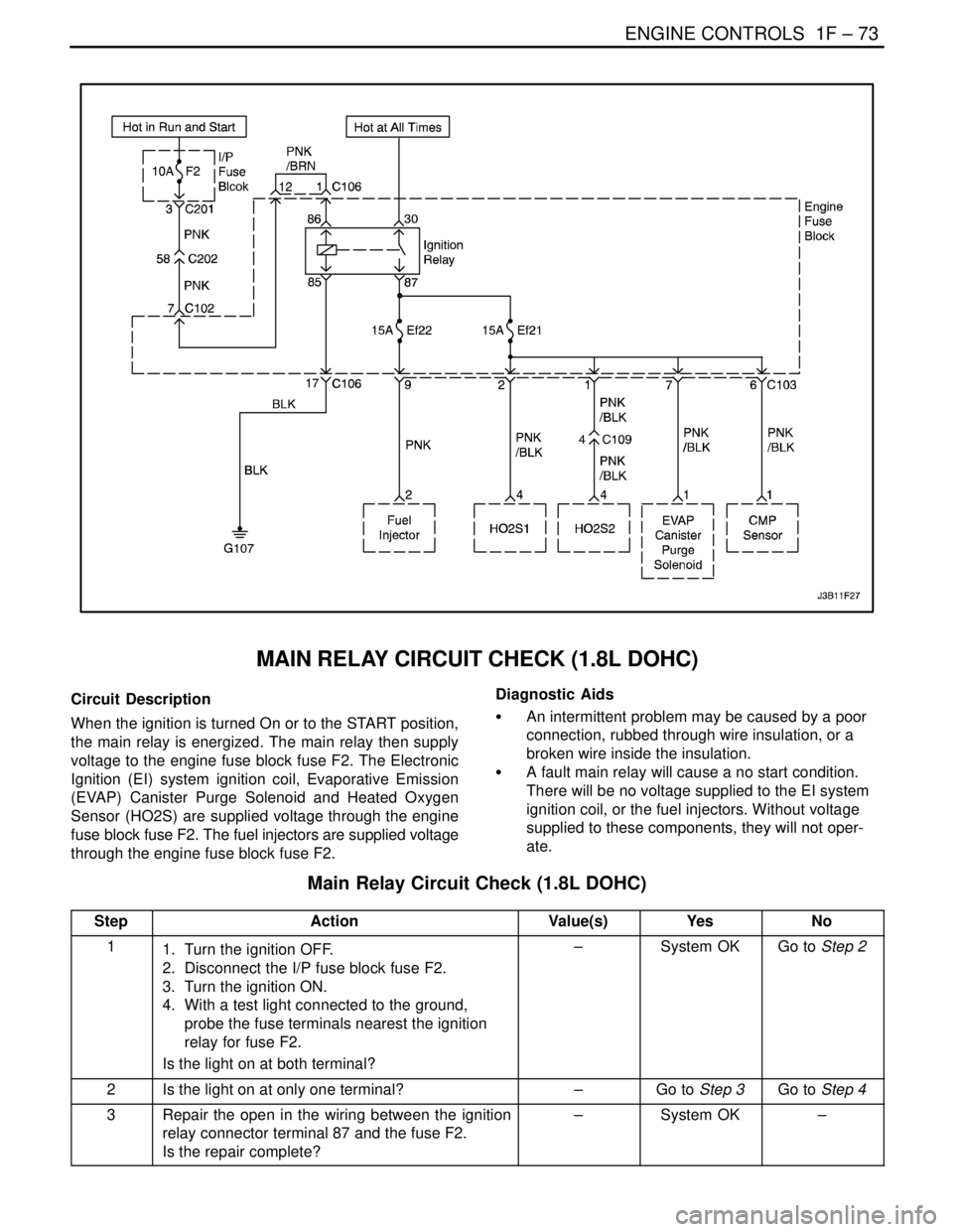

MAIN RELAY CIRCUIT CHECK (1.8L DOHC)

Circuit Description

When the ignition is turned On or to the START position,

the main relay is energized. The main relay then supply

voltage to the engine fuse block fuse F2. The Electronic

Ignition (EI) system ignition coil, Evaporative Emission

(EVAP) Canister Purge Solenoid and Heated Oxygen

Sensor (HO2S) are supplied voltage through the engine

fuse block fuse F2. The fuel injectors are supplied voltage

through the engine fuse block fuse F2.Diagnostic Aids

S An intermittent problem may be caused by a poor

connection, rubbed through wire insulation, or a

broken wire inside the insulation.

S A fault main relay will cause a no start condition.

There will be no voltage supplied to the EI system

ignition coil, or the fuel injectors. Without voltage

supplied to these components, they will not oper-

ate.

Main Relay Circuit Check (1.8L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Disconnect the I/P fuse block fuse F2.

3. Turn the ignition ON.

4. With a test light connected to the ground,

probe the fuse terminals nearest the ignition

relay for fuse F2.

Is the light on at both terminal?–System OKGo to Step 2

2Is the light on at only one terminal?–Go to Step 3Go to Step 4

3Repair the open in the wiring between the ignition

relay connector terminal 87 and the fuse F2.

Is the repair complete?–System OK–

Page 358 of 2643

1F – 112IENGINE CONTROLS

DAEWOO V–121 BL4

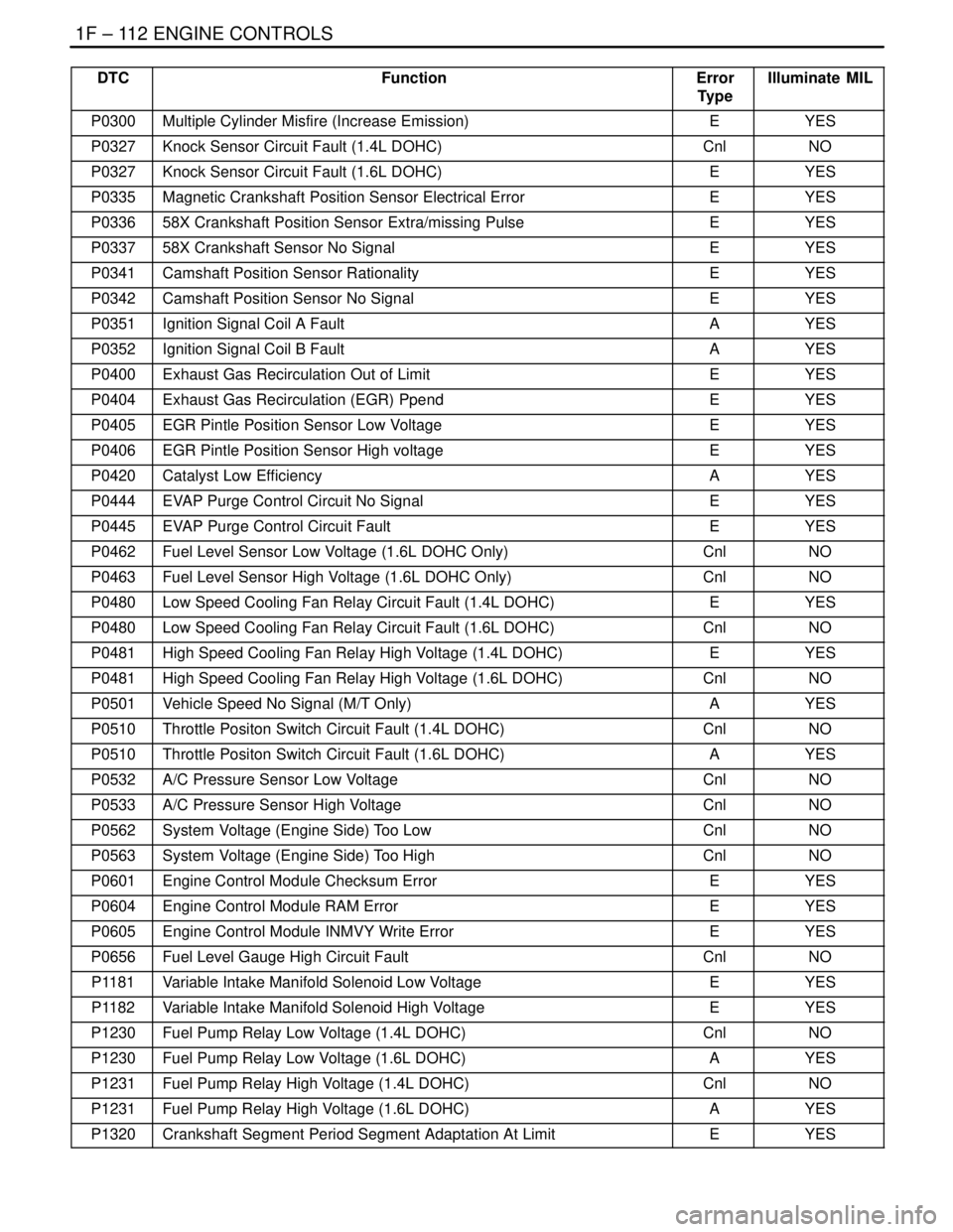

DTCIlluminate MIL Error

Type Function

P0300Multiple Cylinder Misfire (Increase Emission)EYES

P0327Knock Sensor Circuit Fault (1.4L DOHC)CnlNO

P0327Knock Sensor Circuit Fault (1.6L DOHC)EYES

P0335Magnetic Crankshaft Position Sensor Electrical ErrorEYES

P033658X Crankshaft Position Sensor Extra/missing PulseEYES

P033758X Crankshaft Sensor No SignalEYES

P0341Camshaft Position Sensor RationalityEYES

P0342Camshaft Position Sensor No SignalEYES

P0351Ignition Signal Coil A FaultAYES

P0352Ignition Signal Coil B FaultAYES

P0400Exhaust Gas Recirculation Out of LimitEYES

P0404Exhaust Gas Recirculation (EGR) PpendEYES

P0405EGR Pintle Position Sensor Low VoltageEYES

P0406EGR Pintle Position Sensor High voltageEYES

P0420Catalyst Low EfficiencyAYES

P0444EVAP Purge Control Circuit No SignalEYES

P0445EVAP Purge Control Circuit FaultEYES

P0462Fuel Level Sensor Low Voltage (1.6L DOHC Only)CnlNO

P0463Fuel Level Sensor High Voltage (1.6L DOHC Only)CnlNO

P0480Low Speed Cooling Fan Relay Circuit Fault (1.4L DOHC)EYES

P0480Low Speed Cooling Fan Relay Circuit Fault (1.6L DOHC)CnlNO

P0481High Speed Cooling Fan Relay High Voltage (1.4L DOHC)EYES

P0481High Speed Cooling Fan Relay High Voltage (1.6L DOHC)CnlNO

P0501Vehicle Speed No Signal (M/T Only)AYES

P0510Throttle Positon Switch Circuit Fault (1.4L DOHC)CnlNO

P0510Throttle Positon Switch Circuit Fault (1.6L DOHC)AYES

P0532A/C Pressure Sensor Low VoltageCnlNO

P0533A/C Pressure Sensor High VoltageCnlNO

P0562System Voltage (Engine Side) Too LowCnlNO

P0563System Voltage (Engine Side) Too HighCnlNO

P0601Engine Control Module Checksum ErrorEYES

P0604Engine Control Module RAM ErrorEYES

P0605Engine Control Module INMVY Write ErrorEYES

P0656Fuel Level Gauge High Circuit FaultCnlNO

P1181Variable Intake Manifold Solenoid Low VoltageEYES

P1182Variable Intake Manifold Solenoid High VoltageEYES

P1230Fuel Pump Relay Low Voltage (1.4L DOHC)CnlNO

P1230Fuel Pump Relay Low Voltage (1.6L DOHC)AYES

P1231Fuel Pump Relay High Voltage (1.4L DOHC)CnlNO

P1231Fuel Pump Relay High Voltage (1.6L DOHC)AYES

P1320Crankshaft Segment Period Segment Adaptation At LimitEYES

Page 478 of 2643

1F – 232IENGINE CONTROLS

DAEWOO V–121 BL4

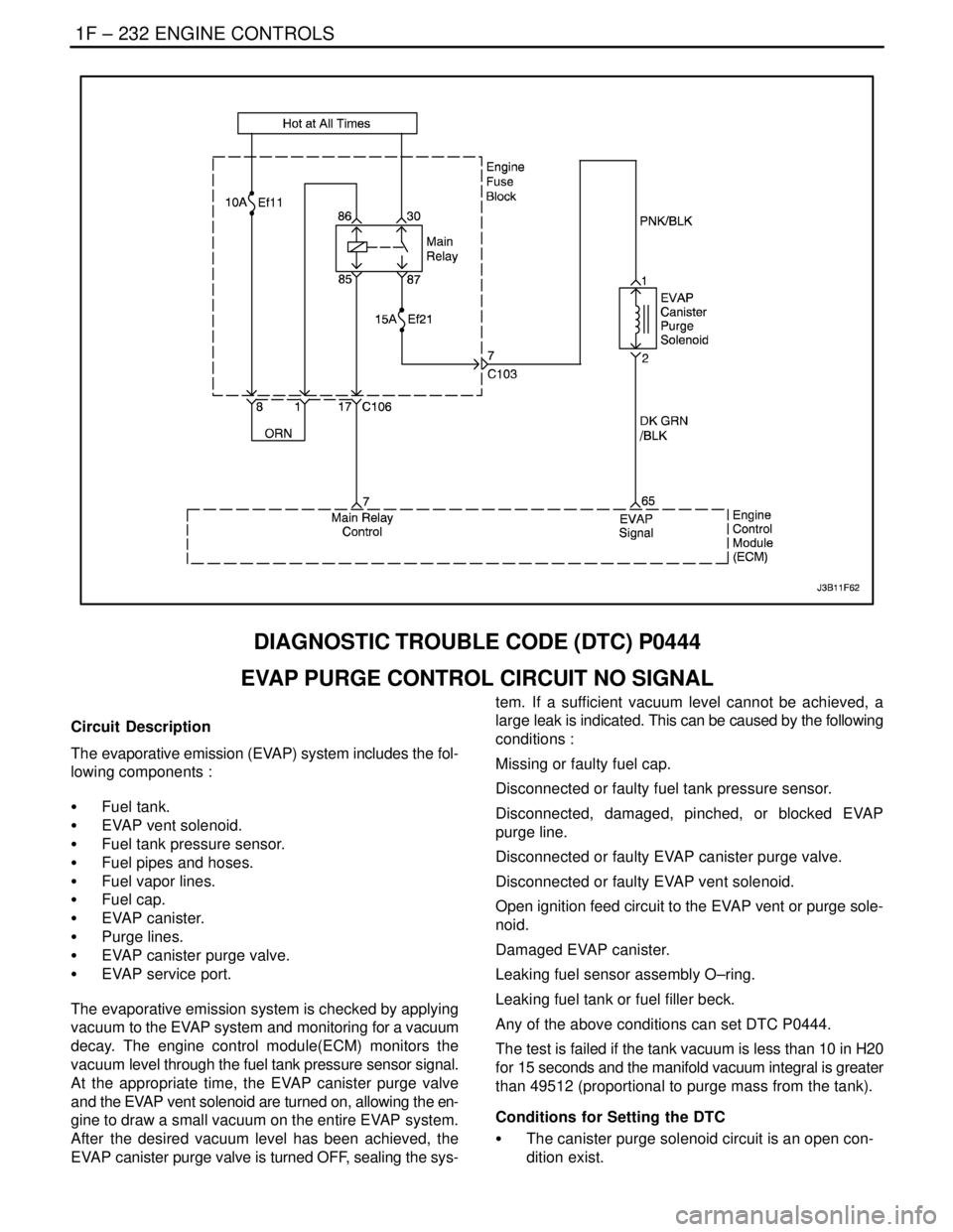

DIAGNOSTIC TROUBLE CODE (DTC) P0444

EVAP PURGE CONTROL CIRCUIT NO SIGNAL

Circuit Description

The evaporative emission (EVAP) system includes the fol-

lowing components :

S Fuel tank.

S EVAP vent solenoid.

S Fuel tank pressure sensor.

S Fuel pipes and hoses.

S Fuel vapor lines.

S Fuel cap.

S EVAP canister.

S Purge lines.

S EVAP canister purge valve.

S EVAP service port.

The evaporative emission system is checked by applying

vacuum to the EVAP system and monitoring for a vacuum

decay. The engine control module(ECM) monitors the

vacuum level through the fuel tank pressure sensor signal.

At the appropriate time, the EVAP canister purge valve

and the EVAP vent solenoid are turned on, allowing the en-

gine to draw a small vacuum on the entire EVAP system.

After the desired vacuum level has been achieved, the

EVAP canister purge valve is turned OFF, sealing the sys-tem. If a sufficient vacuum level cannot be achieved, a

large leak is indicated. This can be caused by the following

conditions :

Missing or faulty fuel cap.

Disconnected or faulty fuel tank pressure sensor.

Disconnected, damaged, pinched, or blocked EVAP

purge line.

Disconnected or faulty EVAP canister purge valve.

Disconnected or faulty EVAP vent solenoid.

Open ignition feed circuit to the EVAP vent or purge sole-

noid.

Damaged EVAP canister.

Leaking fuel sensor assembly O–ring.

Leaking fuel tank or fuel filler beck.

Any of the above conditions can set DTC P0444.

The test is failed if the tank vacuum is less than 10 in H20

for 15 seconds and the manifold vacuum integral is greater

than 49512 (proportional to purge mass from the tank).

Conditions for Setting the DTC

S The canister purge solenoid circuit is an open con-

dition exist.

Page 479 of 2643

ENGINE CONTROLS 1F – 233

DAEWOO V–121 BL4

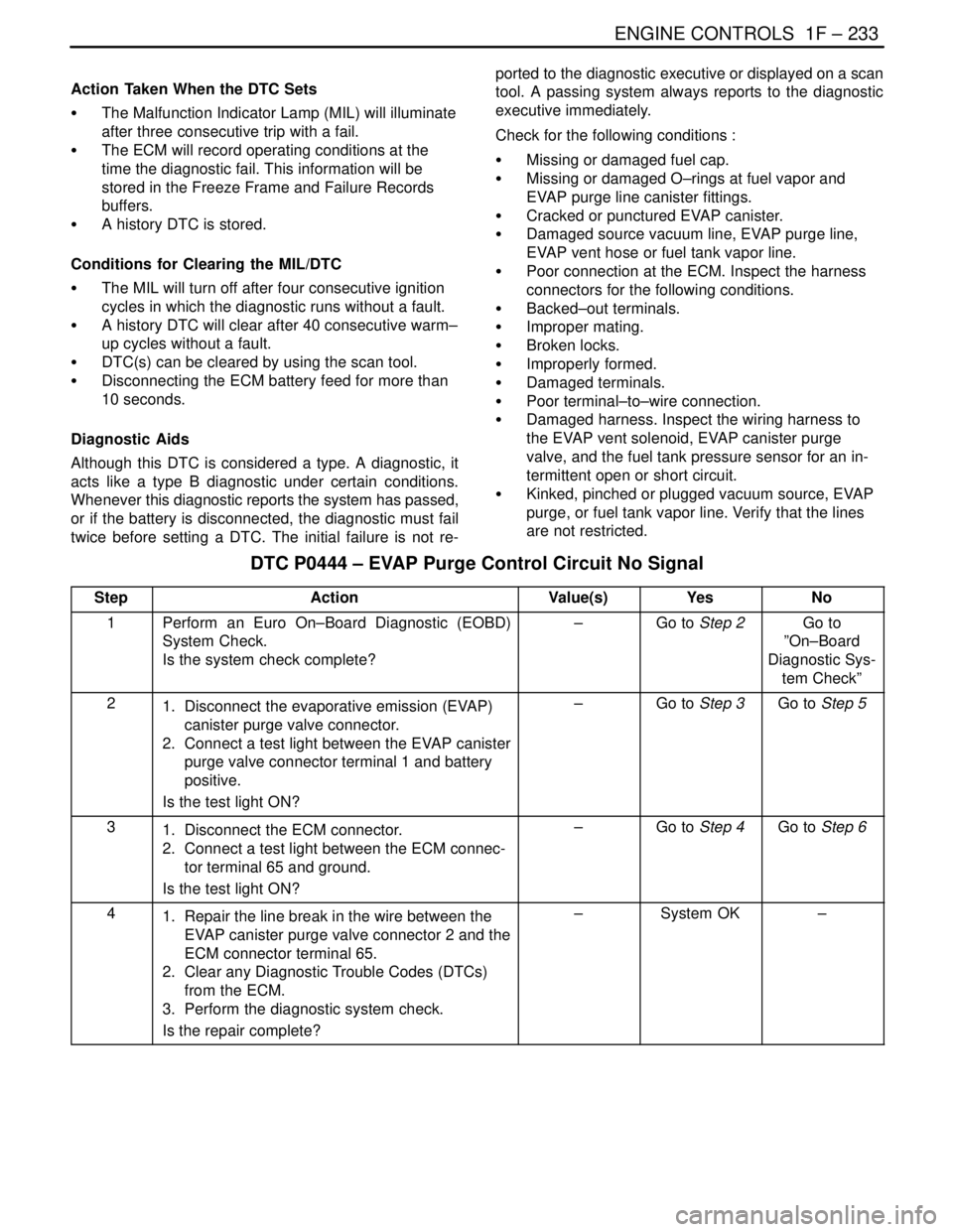

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Although this DTC is considered a type. A diagnostic, it

acts like a type B diagnostic under certain conditions.

Whenever this diagnostic reports the system has passed,

or if the battery is disconnected, the diagnostic must fail

twice before setting a DTC. The initial failure is not re-ported to the diagnostic executive or displayed on a scan

tool. A passing system always reports to the diagnostic

executive immediately.

Check for the following conditions :

S Missing or damaged fuel cap.

S Missing or damaged O–rings at fuel vapor and

EVAP purge line canister fittings.

S Cracked or punctured EVAP canister.

S Damaged source vacuum line, EVAP purge line,

EVAP vent hose or fuel tank vapor line.

S Poor connection at the ECM. Inspect the harness

connectors for the following conditions.

S Backed–out terminals.

S Improper mating.

S Broken locks.

S Improperly formed.

S Damaged terminals.

S Poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness to

the EVAP vent solenoid, EVAP canister purge

valve, and the fuel tank pressure sensor for an in-

termittent open or short circuit.

S Kinked, pinched or plugged vacuum source, EVAP

purge, or fuel tank vapor line. Verify that the lines

are not restricted.

DTC P0444 – EVAP Purge Control Circuit No Signal

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Disconnect the evaporative emission (EVAP)

canister purge valve connector.

2. Connect a test light between the EVAP canister

purge valve connector terminal 1 and battery

positive.

Is the test light ON?–Go to Step 3Go to Step 5

31. Disconnect the ECM connector.

2. Connect a test light between the ECM connec-

tor terminal 65 and ground.

Is the test light ON?–Go to Step 4Go to Step 6

41. Repair the line break in the wire between the

EVAP canister purge valve connector 2 and the

ECM connector terminal 65.

2. Clear any Diagnostic Trouble Codes (DTCs)

from the ECM.

3. Perform the diagnostic system check.

Is the repair complete?–System OK–

Page 481 of 2643

ENGINE CONTROLS 1F – 235

DAEWOO V–121 BL4

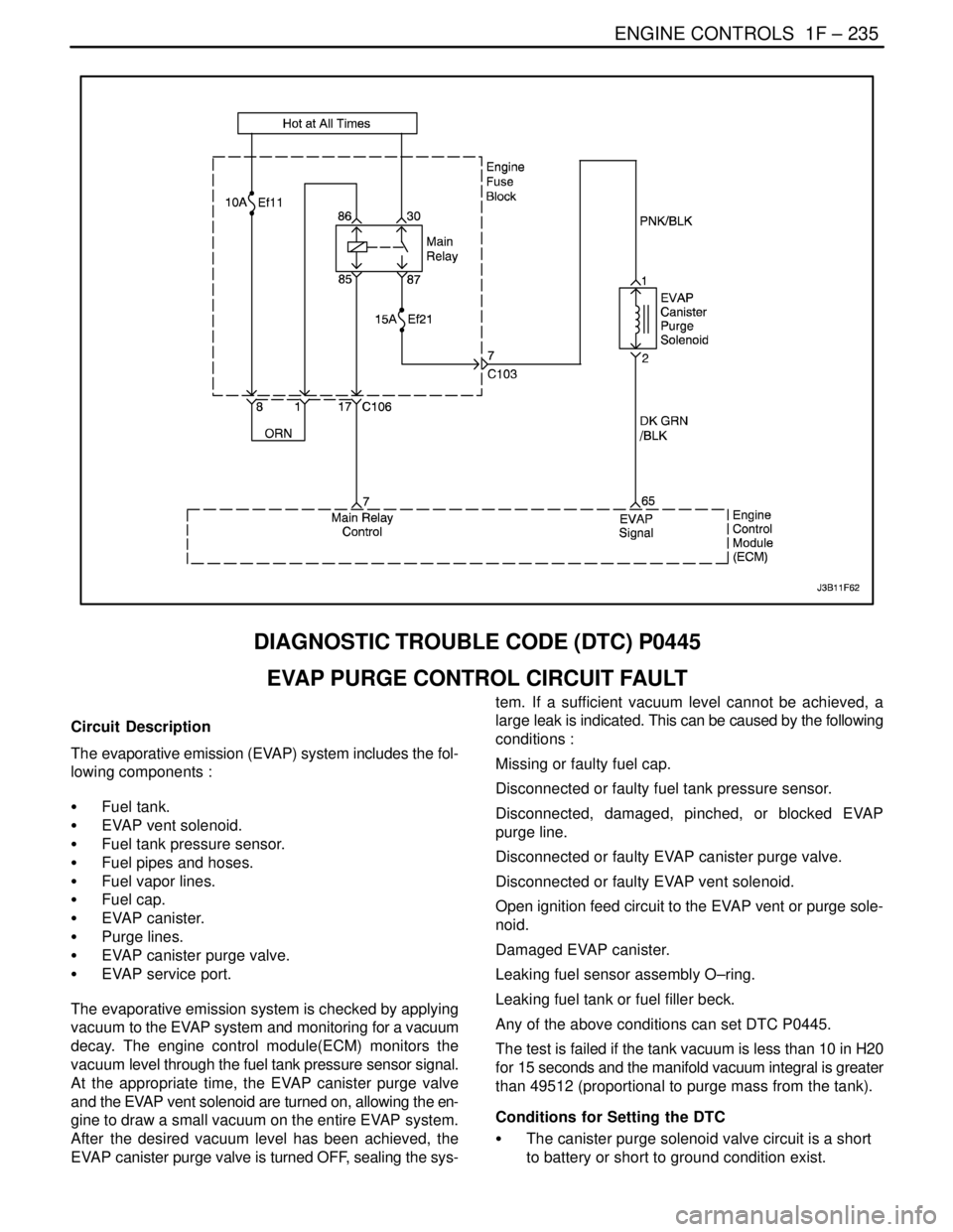

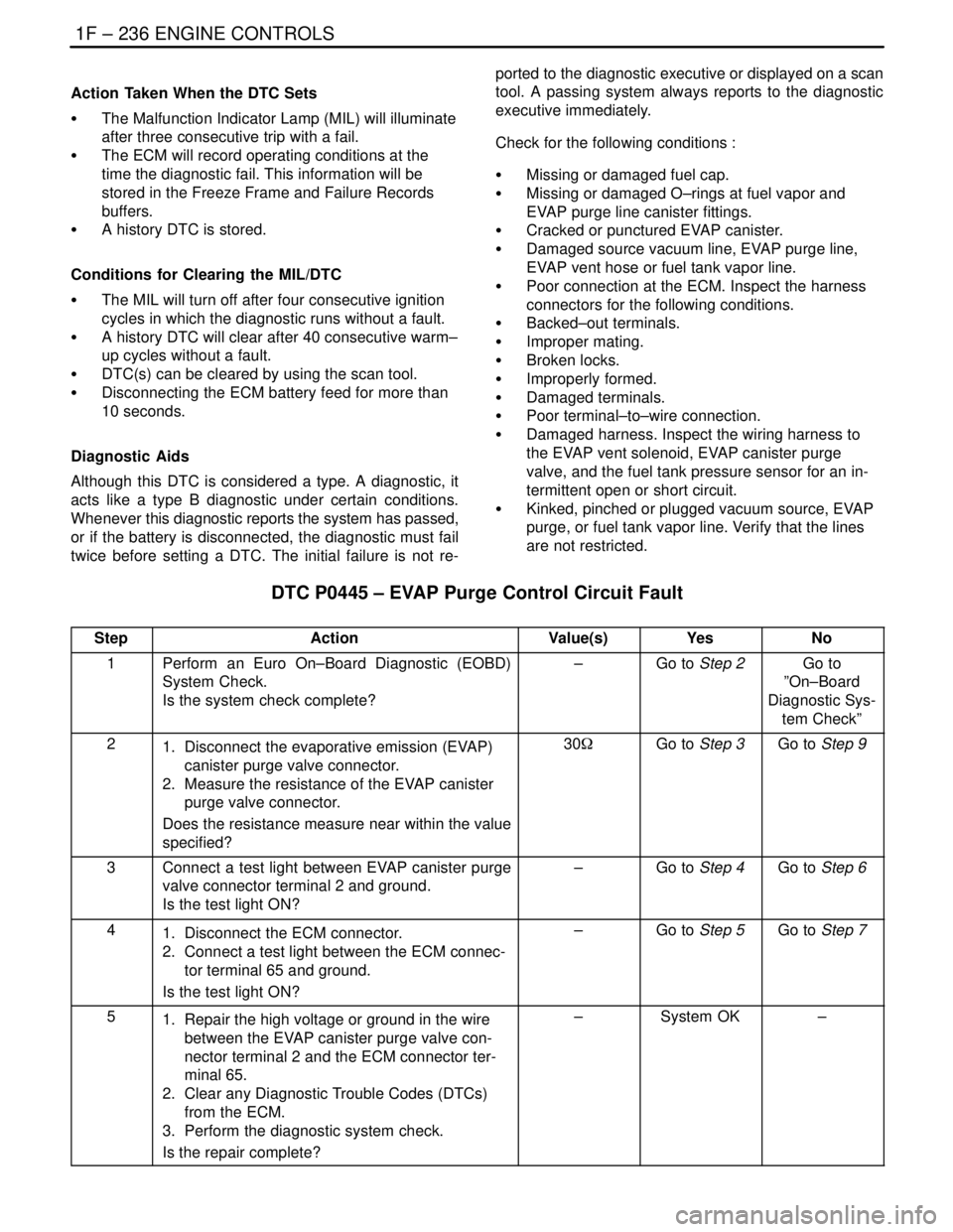

DIAGNOSTIC TROUBLE CODE (DTC) P0445

EVAP PURGE CONTROL CIRCUIT FAULT

Circuit Description

The evaporative emission (EVAP) system includes the fol-

lowing components :

S Fuel tank.

S EVAP vent solenoid.

S Fuel tank pressure sensor.

S Fuel pipes and hoses.

S Fuel vapor lines.

S Fuel cap.

S EVAP canister.

S Purge lines.

S EVAP canister purge valve.

S EVAP service port.

The evaporative emission system is checked by applying

vacuum to the EVAP system and monitoring for a vacuum

decay. The engine control module(ECM) monitors the

vacuum level through the fuel tank pressure sensor signal.

At the appropriate time, the EVAP canister purge valve

and the EVAP vent solenoid are turned on, allowing the en-

gine to draw a small vacuum on the entire EVAP system.

After the desired vacuum level has been achieved, the

EVAP canister purge valve is turned OFF, sealing the sys-tem. If a sufficient vacuum level cannot be achieved, a

large leak is indicated. This can be caused by the following

conditions :

Missing or faulty fuel cap.

Disconnected or faulty fuel tank pressure sensor.

Disconnected, damaged, pinched, or blocked EVAP

purge line.

Disconnected or faulty EVAP canister purge valve.

Disconnected or faulty EVAP vent solenoid.

Open ignition feed circuit to the EVAP vent or purge sole-

noid.

Damaged EVAP canister.

Leaking fuel sensor assembly O–ring.

Leaking fuel tank or fuel filler beck.

Any of the above conditions can set DTC P0445.

The test is failed if the tank vacuum is less than 10 in H20

for 15 seconds and the manifold vacuum integral is greater

than 49512 (proportional to purge mass from the tank).

Conditions for Setting the DTC

S The canister purge solenoid valve circuit is a short

to battery or short to ground condition exist.

Page 482 of 2643

1F – 236IENGINE CONTROLS

DAEWOO V–121 BL4

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Although this DTC is considered a type. A diagnostic, it

acts like a type B diagnostic under certain conditions.

Whenever this diagnostic reports the system has passed,

or if the battery is disconnected, the diagnostic must fail

twice before setting a DTC. The initial failure is not re-ported to the diagnostic executive or displayed on a scan

tool. A passing system always reports to the diagnostic

executive immediately.

Check for the following conditions :

S Missing or damaged fuel cap.

S Missing or damaged O–rings at fuel vapor and

EVAP purge line canister fittings.

S Cracked or punctured EVAP canister.

S Damaged source vacuum line, EVAP purge line,

EVAP vent hose or fuel tank vapor line.

S Poor connection at the ECM. Inspect the harness

connectors for the following conditions.

S Backed–out terminals.

S Improper mating.

S Broken locks.

S Improperly formed.

S Damaged terminals.

S Poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness to

the EVAP vent solenoid, EVAP canister purge

valve, and the fuel tank pressure sensor for an in-

termittent open or short circuit.

S Kinked, pinched or plugged vacuum source, EVAP

purge, or fuel tank vapor line. Verify that the lines

are not restricted.

DTC P0445 – EVAP Purge Control Circuit Fault

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Disconnect the evaporative emission (EVAP)

canister purge valve connector.

2. Measure the resistance of the EVAP canister

purge valve connector.

Does the resistance measure near within the value

specified?30WGo to Step 3Go to Step 9

3Connect a test light between EVAP canister purge

valve connector terminal 2 and ground.

Is the test light ON?–Go to Step 4Go to Step 6

41. Disconnect the ECM connector.

2. Connect a test light between the ECM connec-

tor terminal 65 and ground.

Is the test light ON?–Go to Step 5Go to Step 7

51. Repair the high voltage or ground in the wire

between the EVAP canister purge valve con-

nector terminal 2 and the ECM connector ter-

minal 65.

2. Clear any Diagnostic Trouble Codes (DTCs)

from the ECM.

3. Perform the diagnostic system check.

Is the repair complete?–System OK–

Page 525 of 2643

ENGINE CONTROLS 1F – 279

DAEWOO V–121 BL4

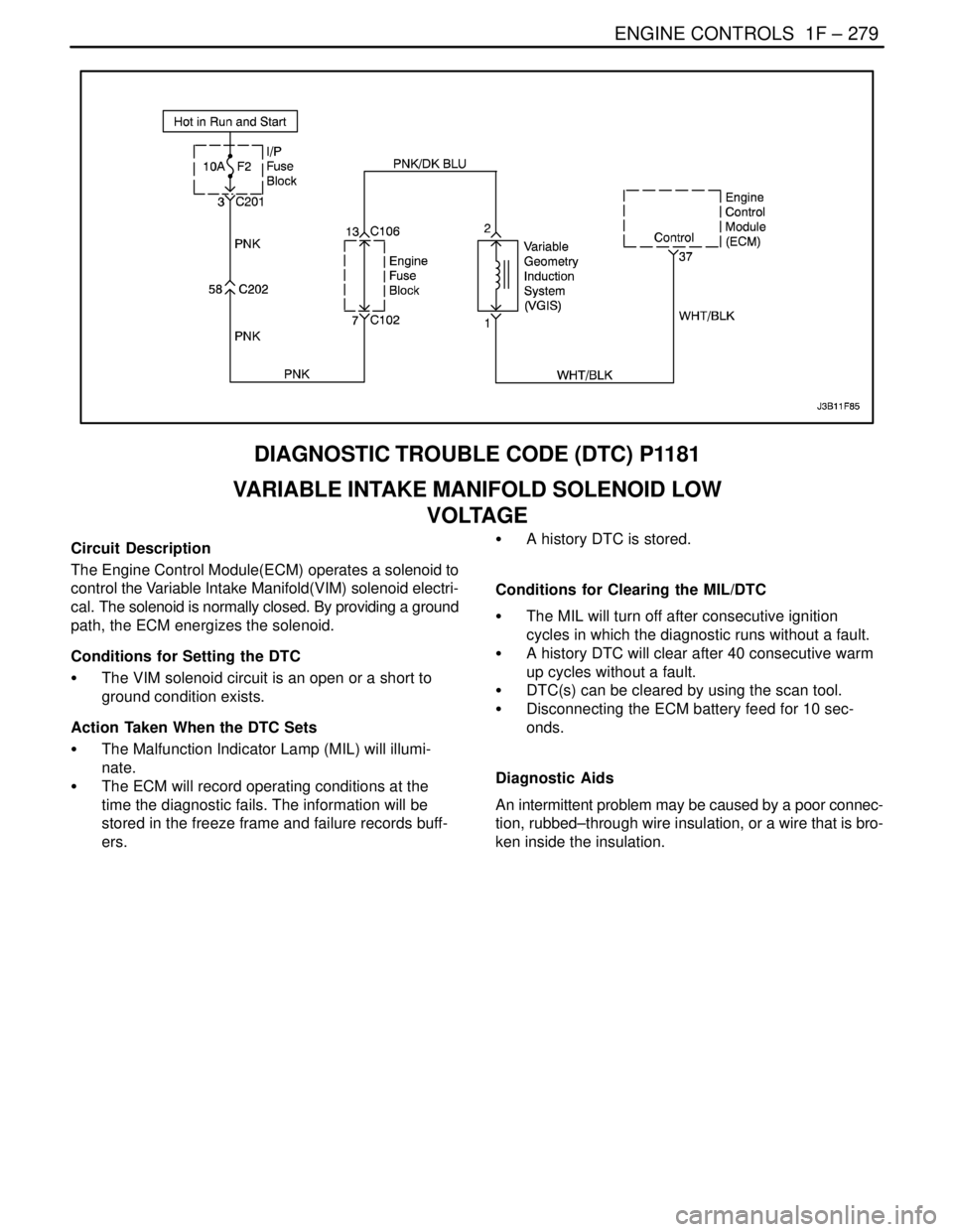

DIAGNOSTIC TROUBLE CODE (DTC) P1181

VARIABLE INTAKE MANIFOLD SOLENOID LOW

VOLTAGE

Circuit Description

The Engine Control Module(ECM) operates a solenoid to

control the Variable Intake Manifold(VIM) solenoid electri-

cal. The solenoid is normally closed. By providing a ground

path, the ECM energizes the solenoid.

Conditions for Setting the DTC

S The VIM solenoid circuit is an open or a short to

ground condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. The information will be

stored in the freeze frame and failure records buff-

ers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed–through wire insulation, or a wire that is bro-

ken inside the insulation.