DAEWOO NUBIRA 2004 Service Repair Manual

NUBIRA 2004

DAEWOO

DAEWOO

https://www.carmanualsonline.info/img/54/56879/w960_56879-0.png

DAEWOO NUBIRA 2004 Service Repair Manual

Trending: key, battery replacement, tow bar, checking oil, fuel, clutch, automatic transmission fluid

Page 1731 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 141

DAEWOO V–121 BL4

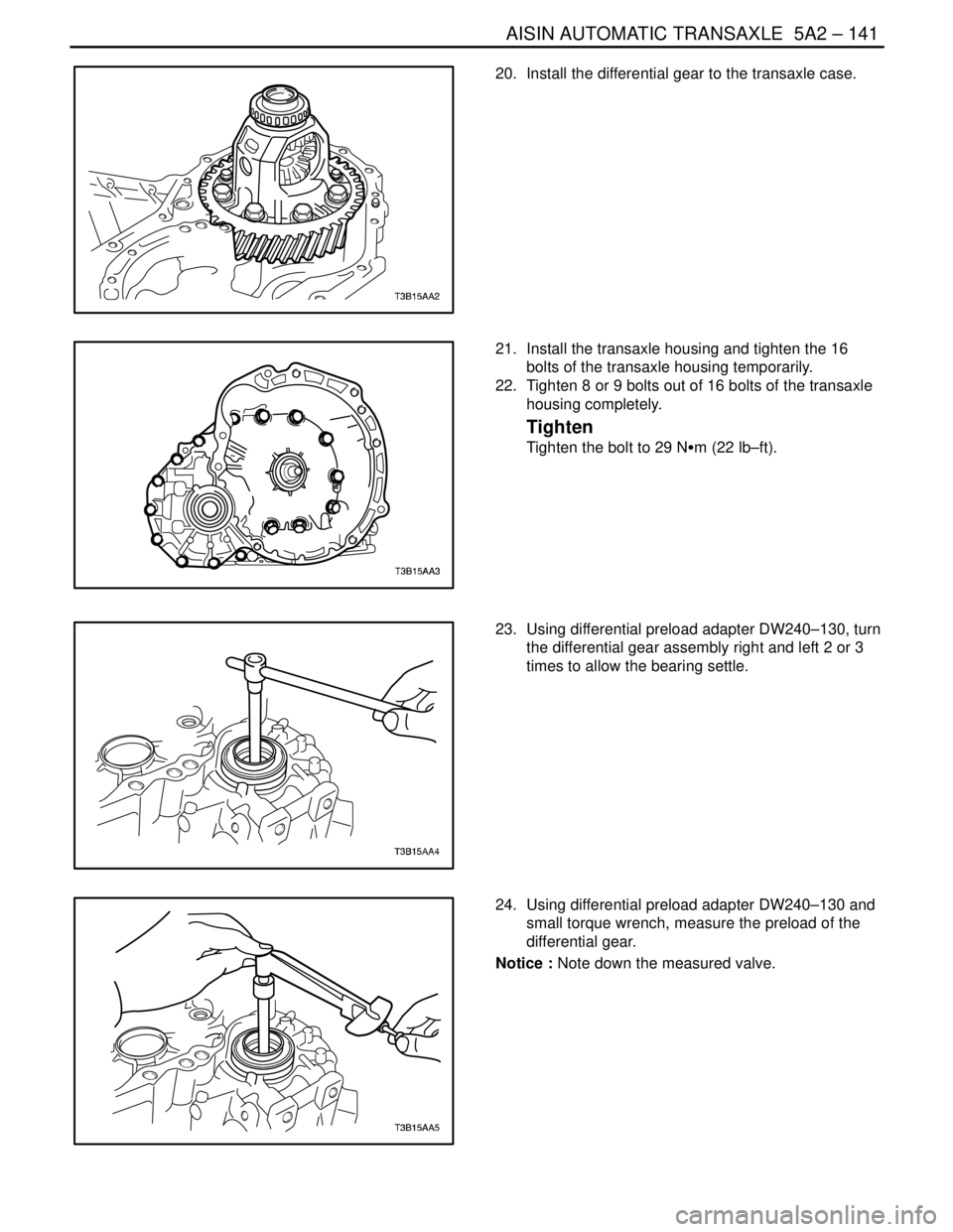

20. Install the differential gear to the transaxle case.

21. Install the transaxle housing and tighten the 16

bolts of the transaxle housing temporarily.

22. Tighten 8 or 9 bolts out of 16 bolts of the transaxle

housing completely.

Tighten

Tighten the bolt to 29 NSm (22 lb–ft).

23. Using differential preload adapter DW240–130, turn

the differential gear assembly right and left 2 or 3

times to allow the bearing settle.

24. Using differential preload adapter DW240–130 and

small torque wrench, measure the preload of the

differential gear.

Notice : Note down the measured valve.

Page 1732 of 2643

5A2 – 142IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

25. Remove the transaxle housing and install the

counter driven gear.

26. Install the transaxle housing and tighten the 16

bolts of the transaxle housing temporarily.

27. Tighten the bolts of the transaxle housing in the

same manner as in step 22.

Tighten

Tighten the bolts to 29 NSm (22 lb–in).

28. Using differential preload adapter DW240–130, turn

the differential gear assembly right and left 2 or 3

times to allow the bearing settle.

29. Using differential preload adapter DW240–130 and

a small torque wrench, measure the preload of the

differential gear. From this valve deduct the valve

measured in step 23. This is the preload of the

counter driven gear.

S Preload:

New bearing: 0.33–0.76 NSm (3.21–6.77 lb–in)

Used bearing: 0.17–0.38 NSm (1.48–3.39 lb–in)

Page 1733 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 143

DAEWOO V–121 BL4

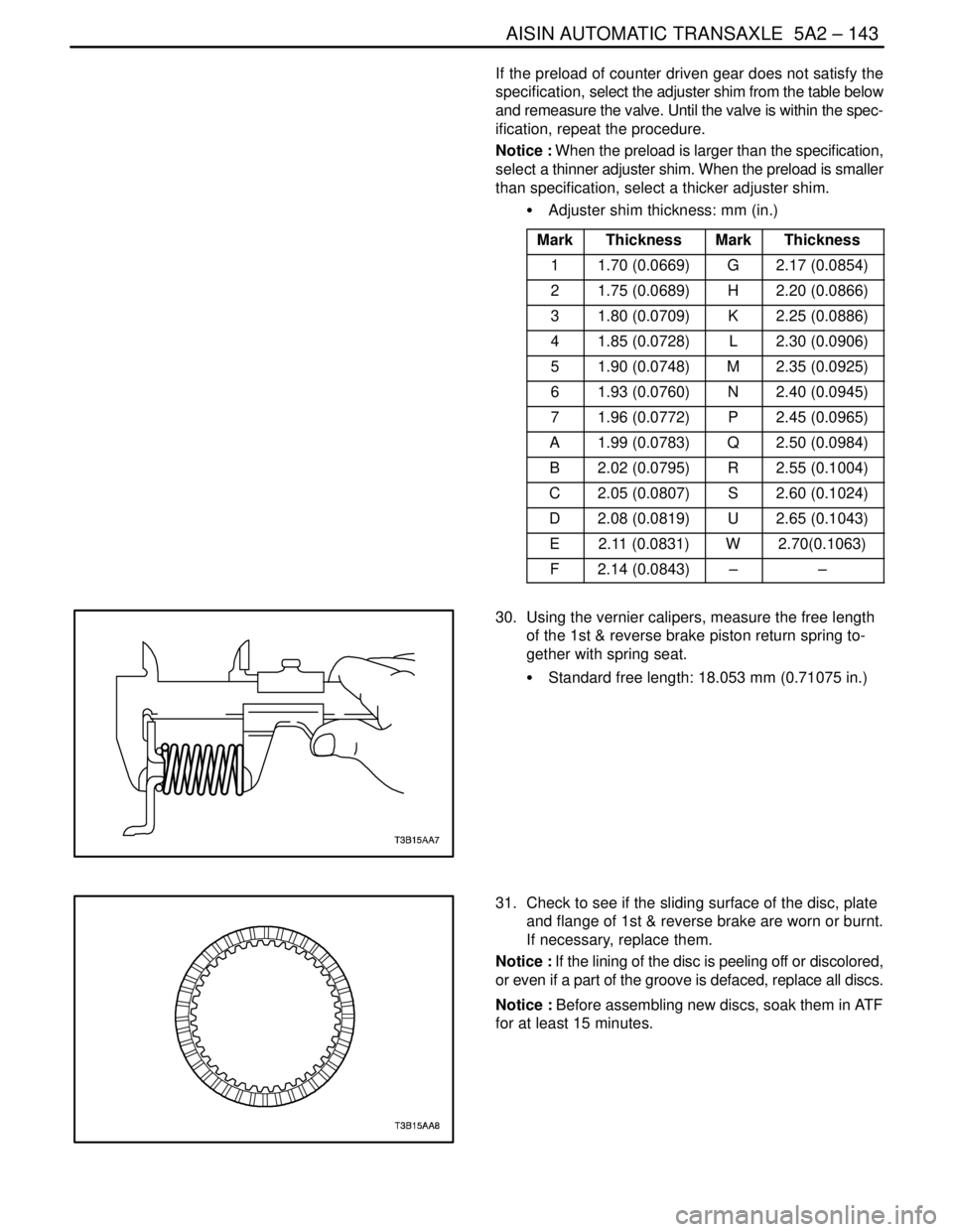

If the preload of counter driven gear does not satisfy the

specification, select the adjuster shim from the table below

and remeasure the valve. Until the valve is within the spec-

ification, repeat the procedure.

Notice : When the preload is larger than the specification,

select a thinner adjuster shim. When the preload is smaller

than specification, select a thicker adjuster shim.

S Adjuster shim thickness: mm (in.)

Mark

ThicknessMarkThickness

11.70 (0.0669)G2.17 (0.0854)

21.75 (0.0689)H2.20 (0.0866)

31.80 (0.0709)K2.25 (0.0886)

41.85 (0.0728)L2.30 (0.0906)

51.90 (0.0748)M2.35 (0.0925)

61.93 (0.0760)N2.40 (0.0945)

71.96 (0.0772)P2.45 (0.0965)

A1.99 (0.0783)Q2.50 (0.0984)

B2.02 (0.0795)R2.55 (0.1004)

C2.05 (0.0807)S2.60 (0.1024)

D2.08 (0.0819)U2.65 (0.1043)

E2.11 (0.0831)W2.70(0.1063)

F2.14 (0.0843)––

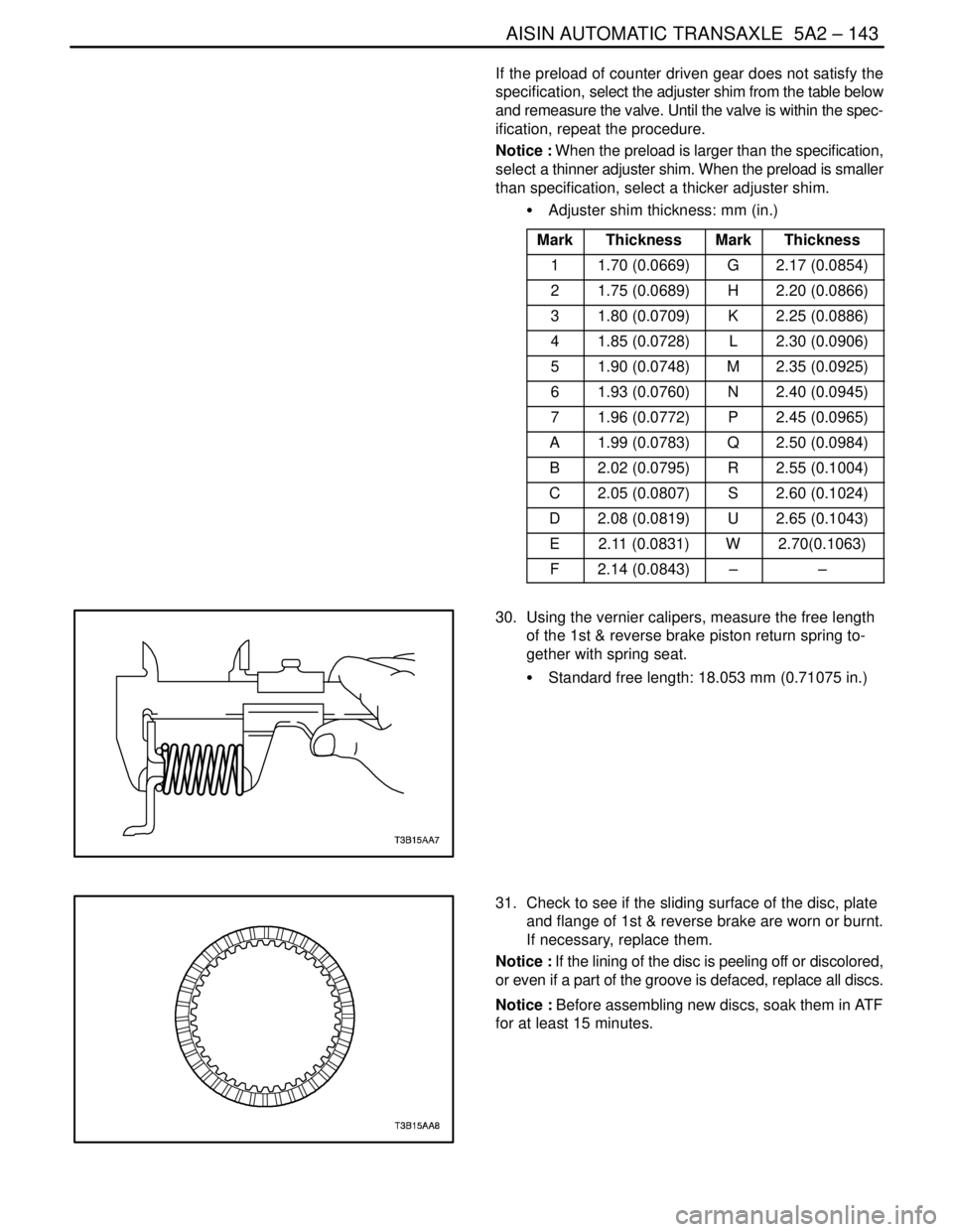

30. Using the vernier calipers, measure the free length

of the 1st & reverse brake piston return spring to-

gether with spring seat.

S Standard free length: 18.053 mm (0.71075 in.)

31. Check to see if the sliding surface of the disc, plate

and flange of 1st & reverse brake are worn or burnt.

If necessary, replace them.

Notice : If the lining of the disc is peeling off or discolored,

or even if a part of the groove is defaced, replace all discs.

Notice : Before assembling new discs, soak them in ATF

for at least 15 minutes.

Page 1734 of 2643

5A2 – 144IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

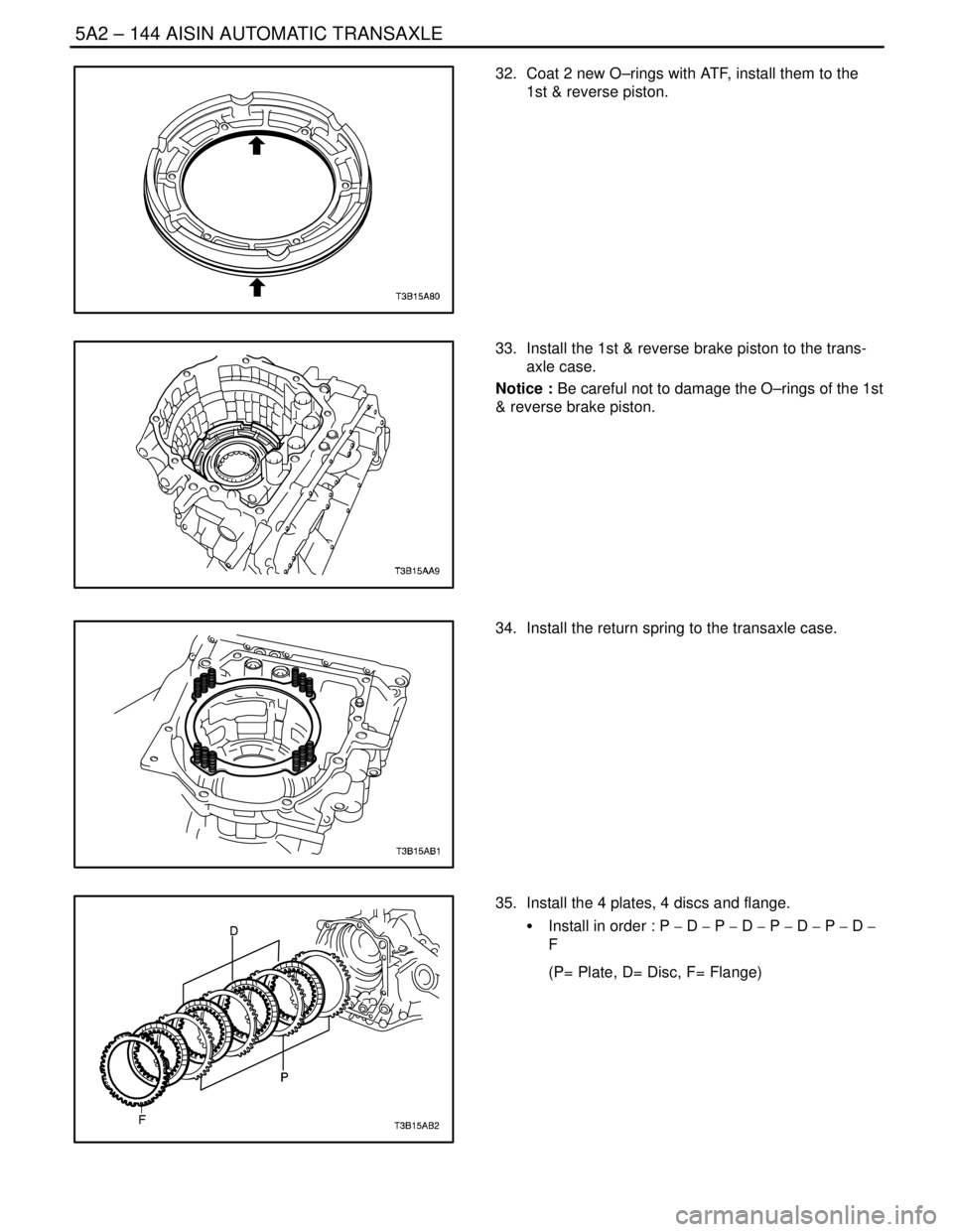

32. Coat 2 new O–rings with ATF, install them to the

1st & reverse piston.

33. Install the 1st & reverse brake piston to the trans-

axle case.

Notice : Be careful not to damage the O–rings of the 1st

& reverse brake piston.

34. Install the return spring to the transaxle case.

35. Install the 4 plates, 4 discs and flange.

S Install in order : P � D � P � D � P � D � P � D �

F

(P= Plate, D= Disc, F= Flange)

Page 1735 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 145

DAEWOO V–121 BL4

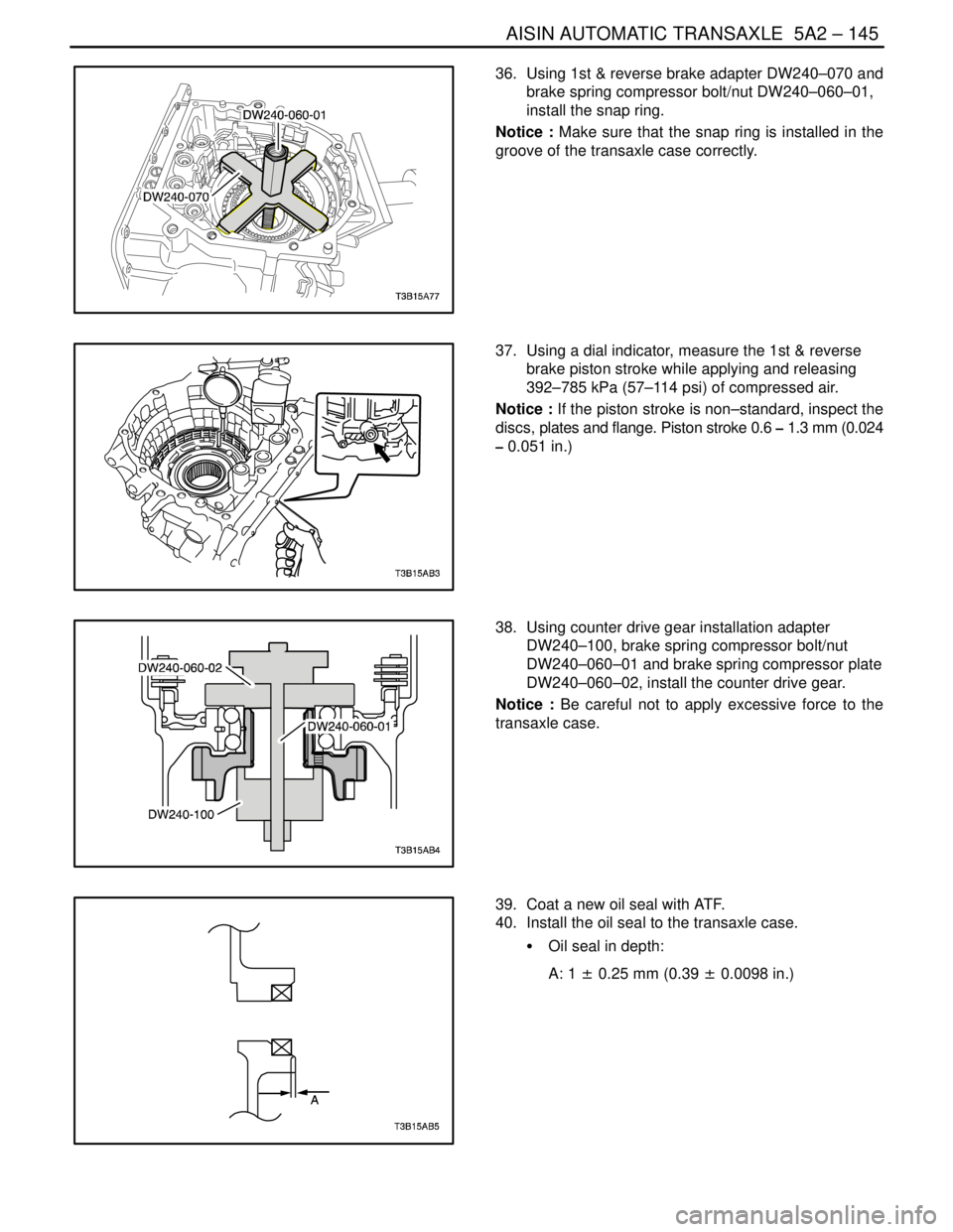

36. Using 1st & reverse brake adapter DW240–070 and

brake spring compressor bolt/nut DW240–060–01,

install the snap ring.

Notice : Make sure that the snap ring is installed in the

groove of the transaxle case correctly.

37. Using a dial indicator, measure the 1st & reverse

brake piston stroke while applying and releasing

392–785 kPa (57–114 psi) of compressed air.

Notice : If the piston stroke is non–standard, inspect the

discs, plates and flange. Piston stroke 0.6 � 1.3 mm (0.024

� 0.051 in.)

38. Using counter drive gear installation adapter

DW240–100, brake spring compressor bolt/nut

DW240–060–01 and brake spring compressor plate

DW240–060–02, install the counter drive gear.

Notice : Be careful not to apply excessive force to the

transaxle case.

39. Coat a new oil seal with ATF.

40. Install the oil seal to the transaxle case.

S Oil seal in depth:

A: 1 ± 0.25 mm (0.39 ± 0.0098 in.)

Page 1736 of 2643

5A2 – 146IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

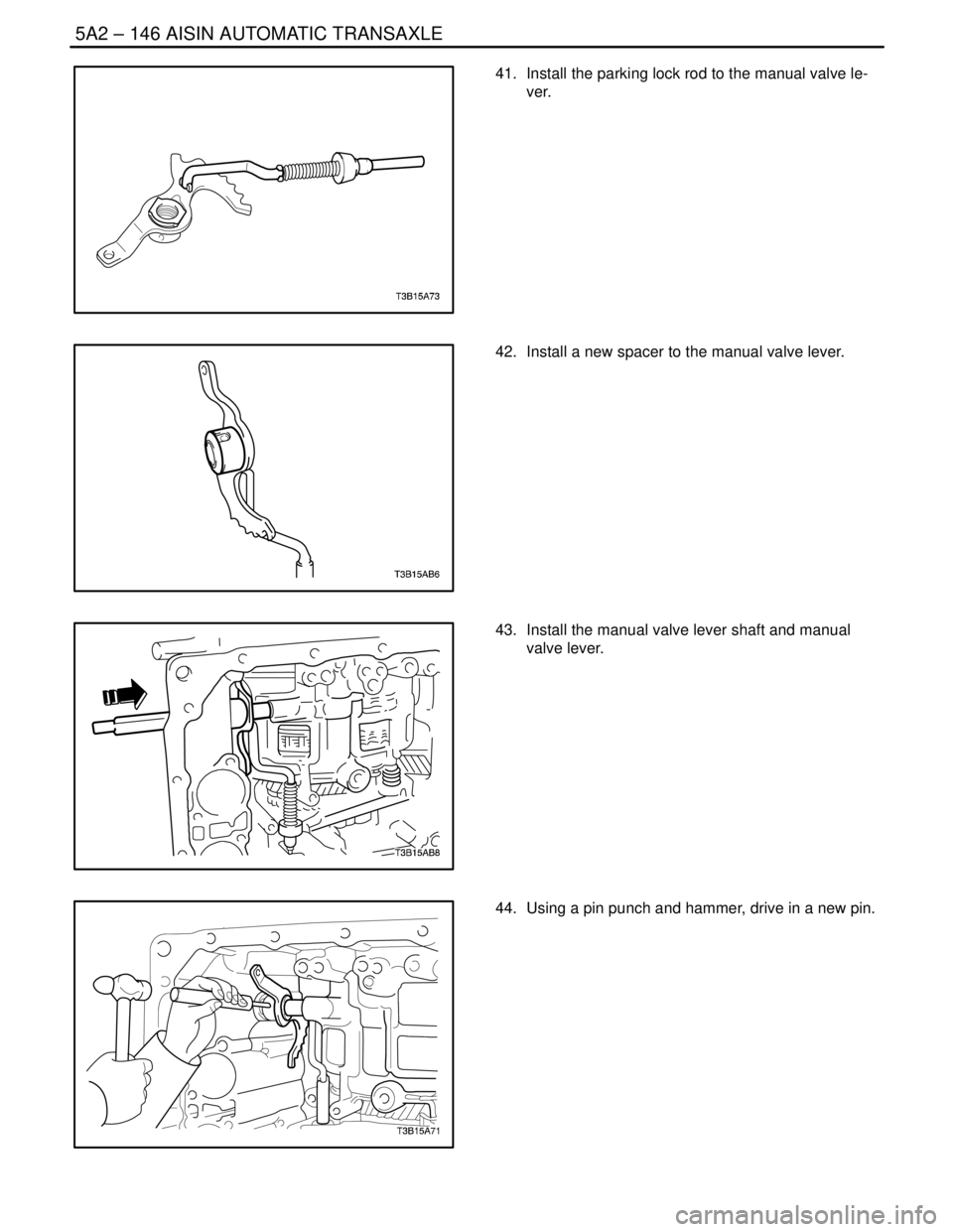

41. Install the parking lock rod to the manual valve le-

ver.

42. Install a new spacer to the manual valve lever.

43. Install the manual valve lever shaft and manual

valve lever.

44. Using a pin punch and hammer, drive in a new pin.

Page 1737 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 147

DAEWOO V–121 BL4

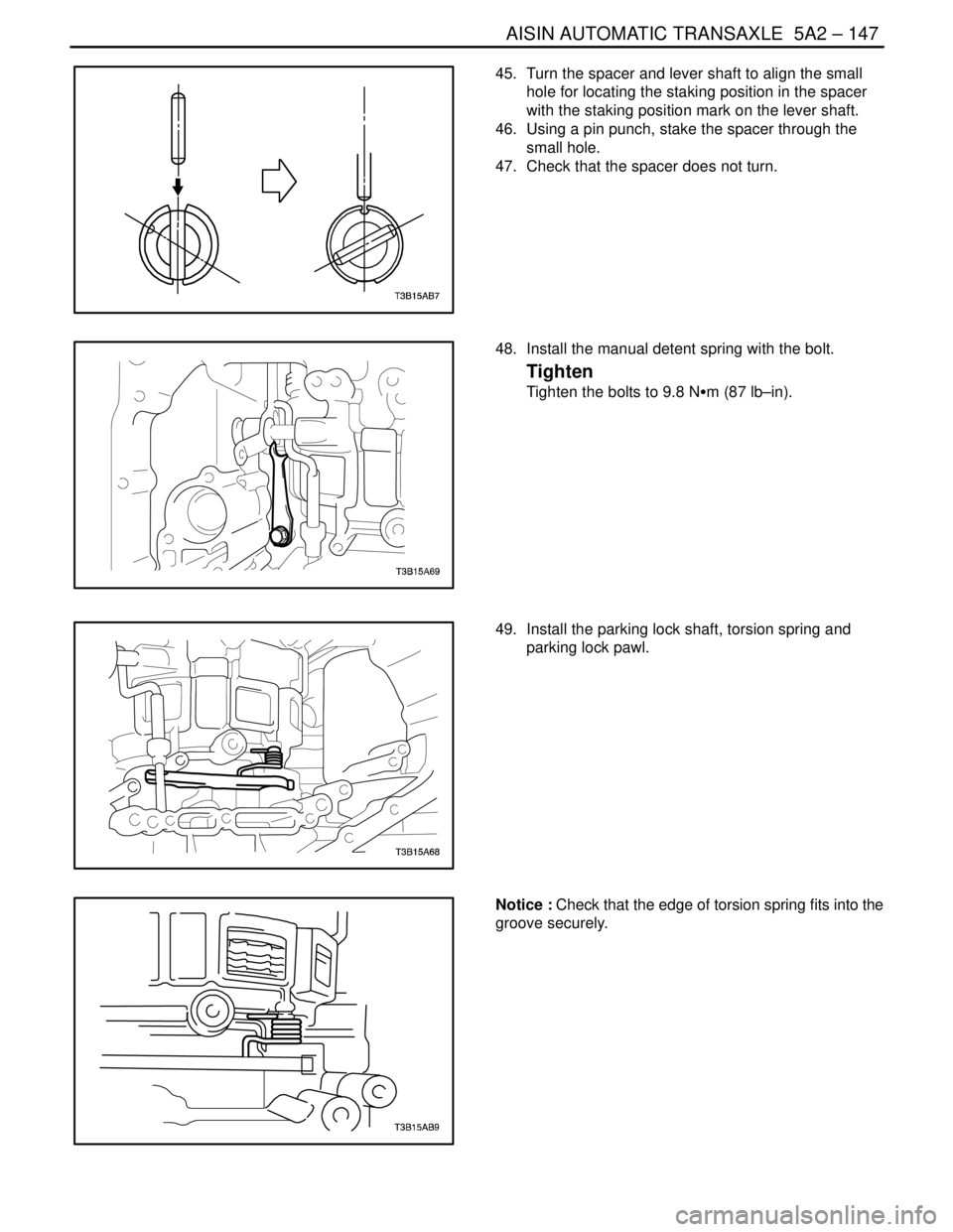

45. Turn the spacer and lever shaft to align the small

hole for locating the staking position in the spacer

with the staking position mark on the lever shaft.

46. Using a pin punch, stake the spacer through the

small hole.

47. Check that the spacer does not turn.

48. Install the manual detent spring with the bolt.

Tighten

Tighten the bolts to 9.8 NSm (87 lb–in).

49. Install the parking lock shaft, torsion spring and

parking lock pawl.

Notice : Check that the edge of torsion spring fits into the

groove securely.

Page 1738 of 2643

5A2 – 148IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

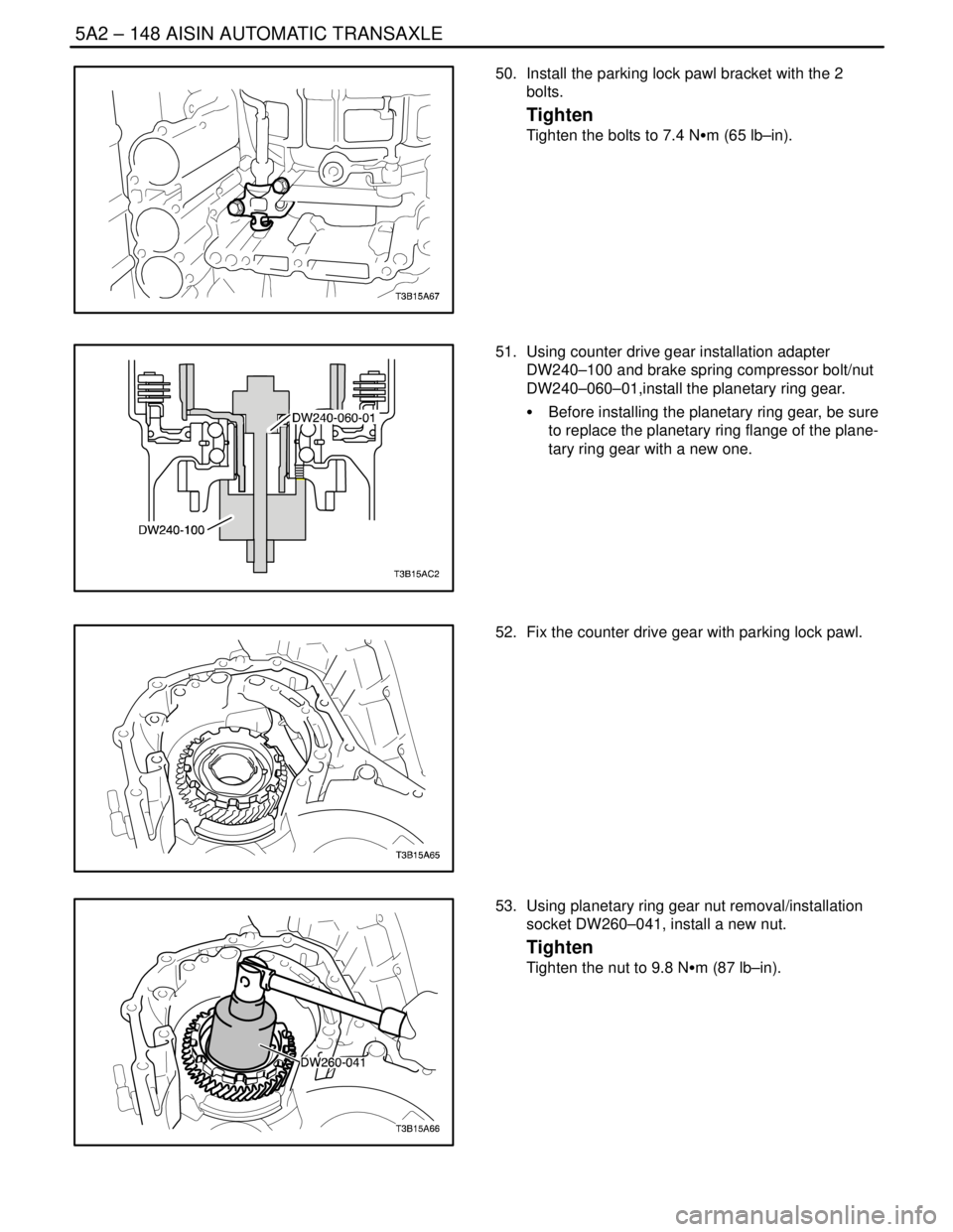

50. Install the parking lock pawl bracket with the 2

bolts.

Tighten

Tighten the bolts to 7.4 NSm (65 lb–in).

51. Using counter drive gear installation adapter

DW240–100 and brake spring compressor bolt/nut

DW240–060–01,install the planetary ring gear.

S Before installing the planetary ring gear, be sure

to replace the planetary ring flange of the plane-

tary ring gear with a new one.

52. Fix the counter drive gear with parking lock pawl.

53. Using planetary ring gear nut removal/installation

socket DW260–041, install a new nut.

Tighten

Tighten the nut to 9.8 NSm (87 lb–in).

Page 1739 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 149

DAEWOO V–121 BL4

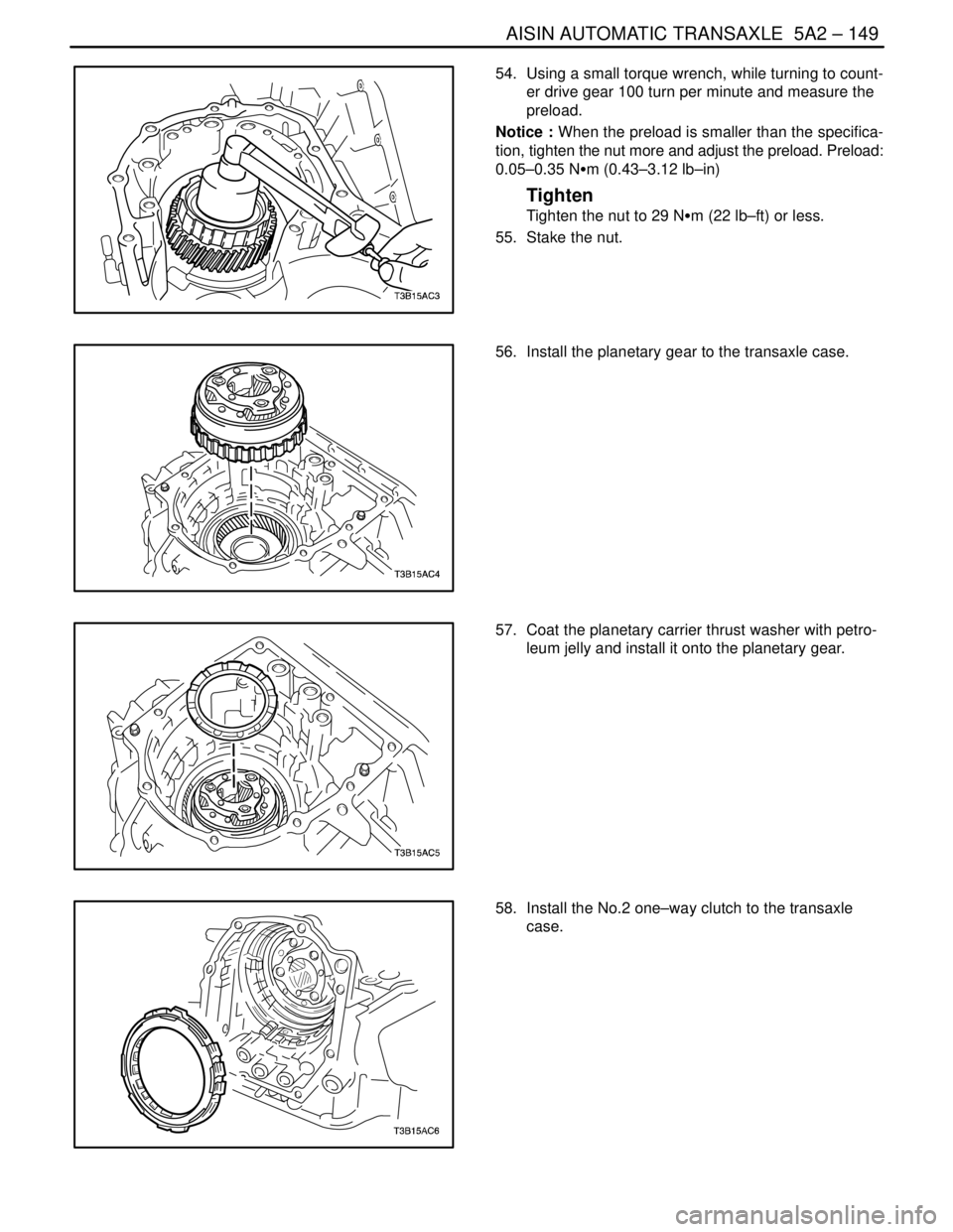

54. Using a small torque wrench, while turning to count-

er drive gear 100 turn per minute and measure the

preload.

Notice : When the preload is smaller than the specifica-

tion, tighten the nut more and adjust the preload. Preload:

0.05–0.35 NSm (0.43–3.12 lb–in)

Tighten

Tighten the nut to 29 NSm (22 lb–ft) or less.

55. Stake the nut.

56. Install the planetary gear to the transaxle case.

57. Coat the planetary carrier thrust washer with petro-

leum jelly and install it onto the planetary gear.

58. Install the No.2 one–way clutch to the transaxle

case.

Page 1740 of 2643

5A2 – 150IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

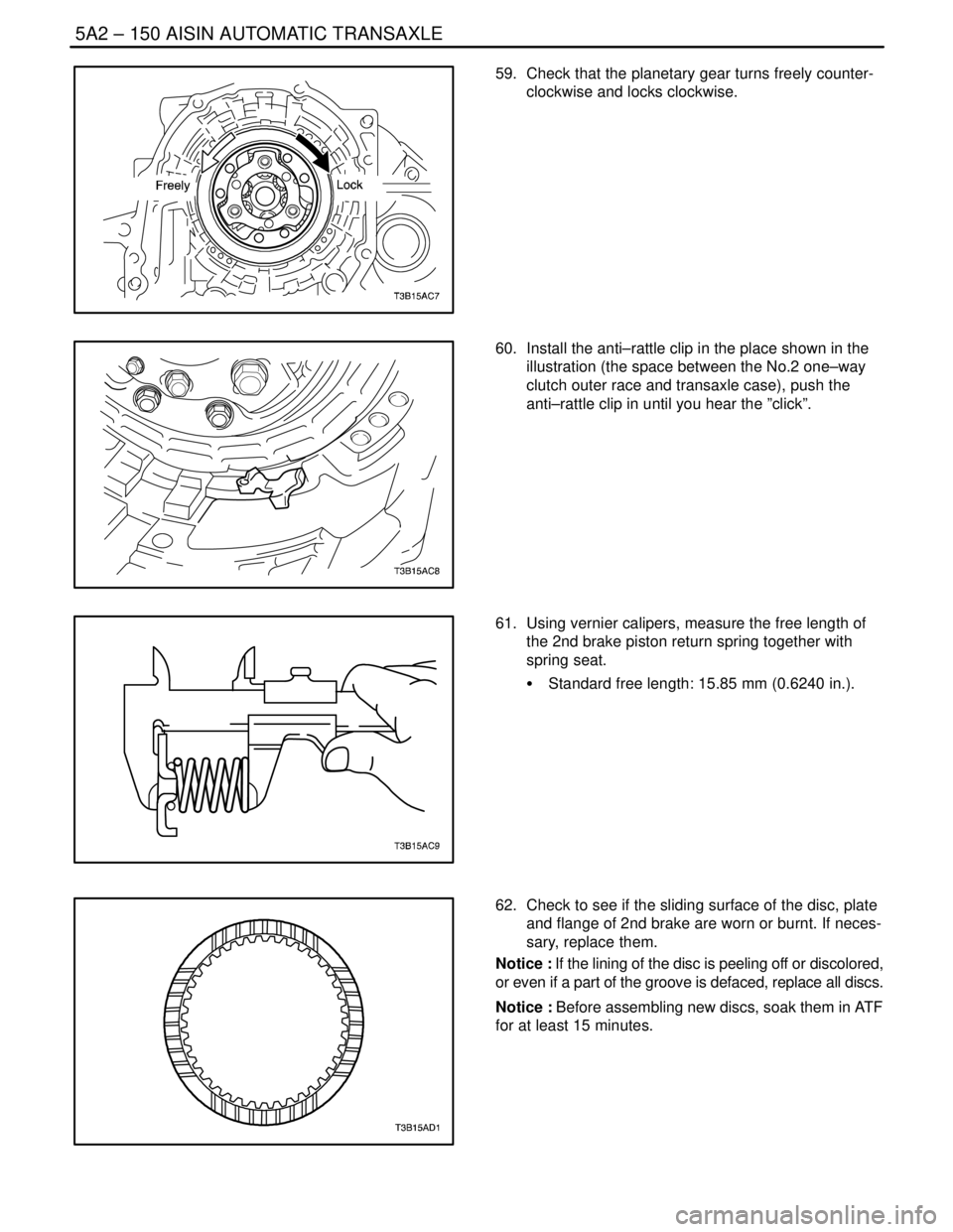

59. Check that the planetary gear turns freely counter-

clockwise and locks clockwise.

60. Install the anti–rattle clip in the place shown in the

illustration (the space between the No.2 one–way

clutch outer race and transaxle case), push the

anti–rattle clip in until you hear the ”click”.

61. Using vernier calipers, measure the free length of

the 2nd brake piston return spring together with

spring seat.

S Standard free length: 15.85 mm (0.6240 in.).

62. Check to see if the sliding surface of the disc, plate

and flange of 2nd brake are worn or burnt. If neces-

sary, replace them.

Notice : If the lining of the disc is peeling off or discolored,

or even if a part of the groove is defaced, replace all discs.

Notice : Before assembling new discs, soak them in ATF

for at least 15 minutes.

Trending: engine oil, service indicator, high idle speed, jacking, glove box, overheating, adding oil